Method for producing methane

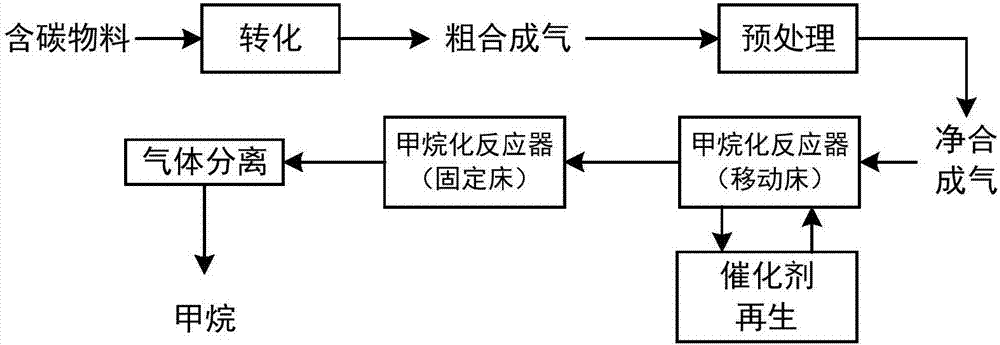

A methane and bed methane technology, applied in the field of indirect conversion of carbonaceous materials, can solve the problems of long catalyst development cycle and increase the difficulty of catalysts, achieve the effect of online regeneration and recycling, improve development efficiency, and reduce the severity of pretreatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

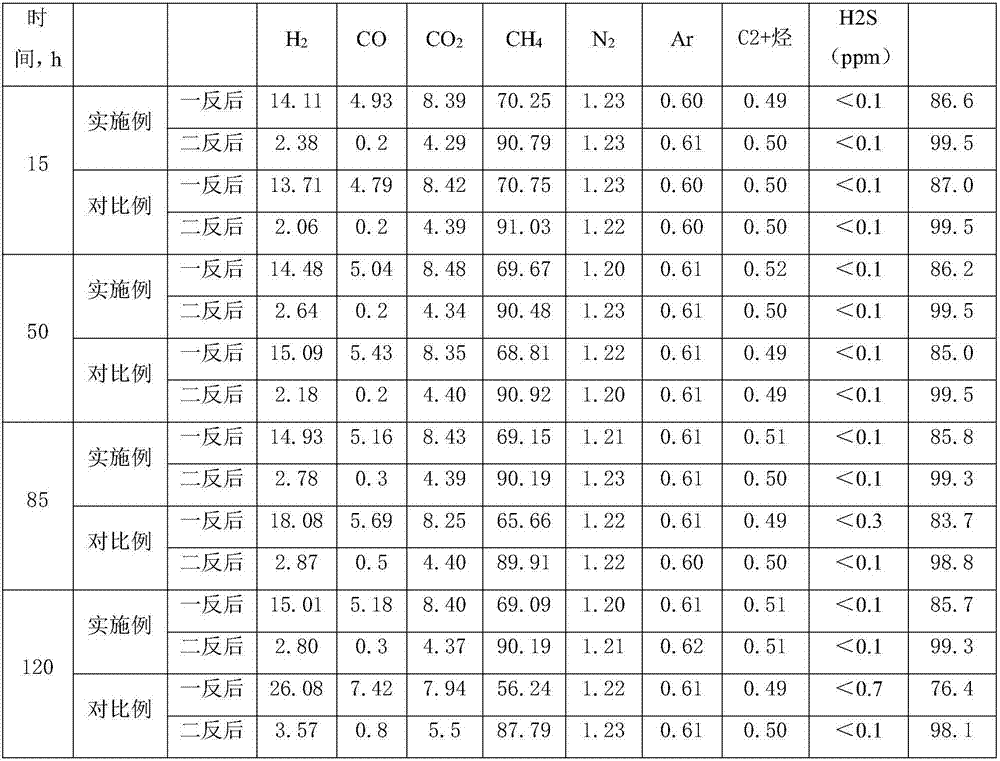

Examples

Embodiment 1

[0037] Lignite fragments with a particle size of 5-50mm (see Table 1 for chemical composition) are gasified into crude synthesis gas with oxygen / water vapor as gasification agent, and the obtained crude synthesis gas is sequentially cooled, detarred, water-gas shifted, After crude desulfurization, the net syngas (composition see Table 2) is obtained, in which (CO+H 2 ) content is 74.59% by volume, H 2 / CO molar ratio is 3.07, H 2 The S content was 4.4 ppm.

[0038] Table 1

[0039] project

lignite

Elemental analysis (weight %)

C

74.97

H

5.14

O

17.03

N

1.14

S

1.07

other trace elements

0.65

[0040] Table 2

[0041] main component

(mol%)

H 2

56.21

CO

18.38

CO 2

2.20

CH 4

20.87

N 2

1.14

Ar

0.57

C2+ hydrocarbons

0.63

h 2 S

4.4ppm

[0042] The net synthesis gas is used as the methanation raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com