Patents

Literature

73results about "Acetylene gas generator details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

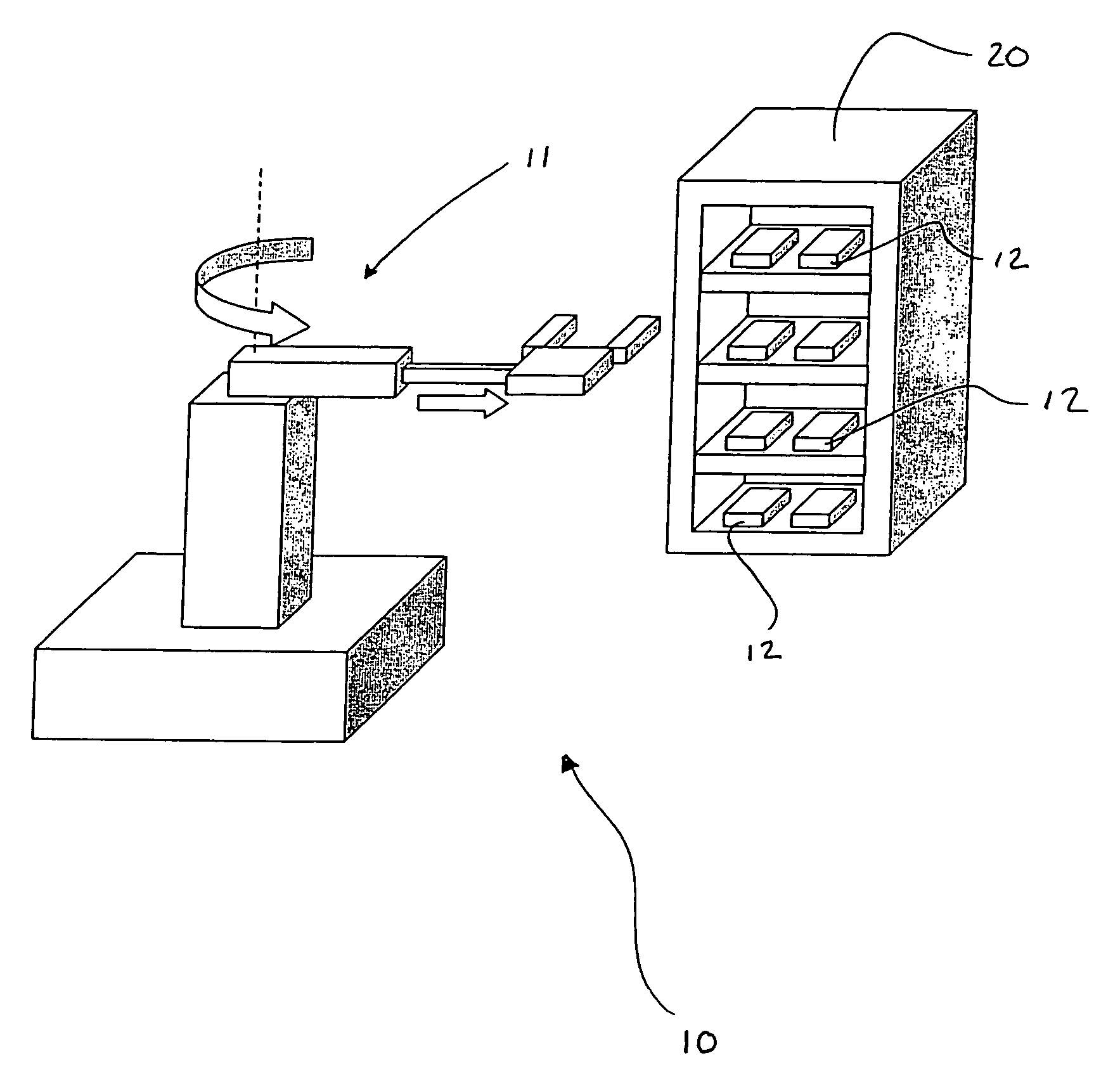

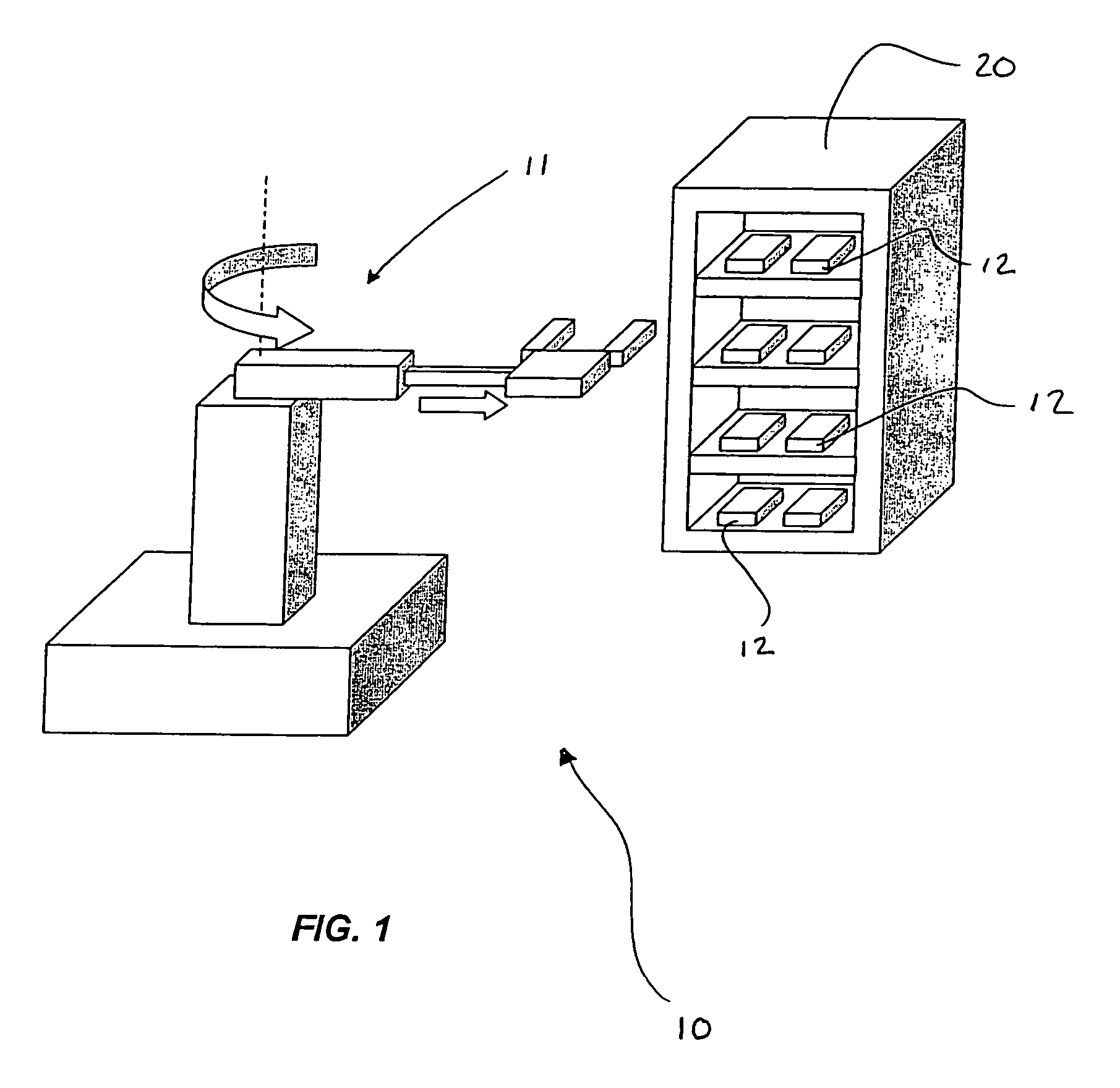

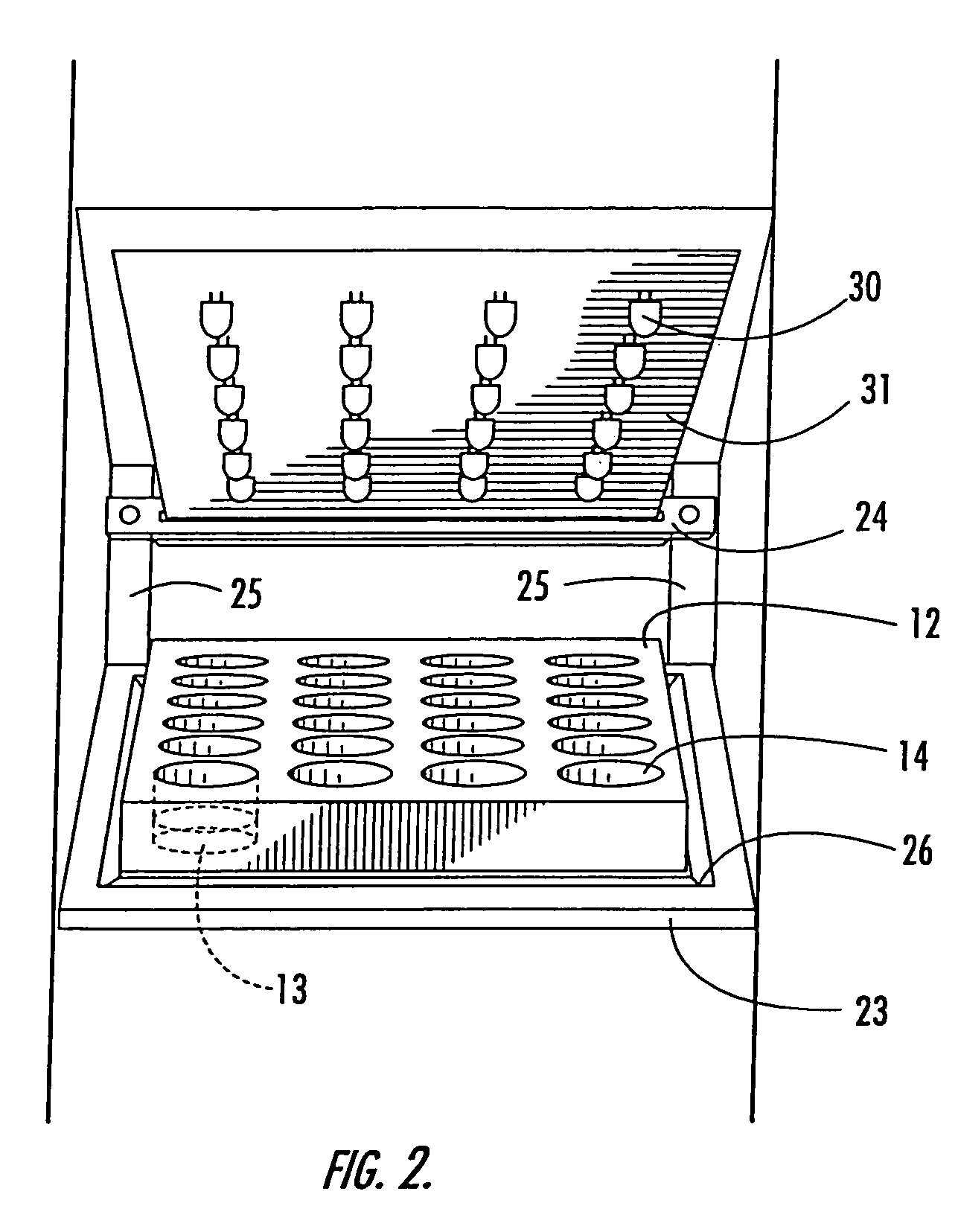

LED array for illuminating cell well plates and automated rack system for handling the same

InactiveUS7160717B2Improve storage efficiencyReduce amountBioreactor/fermenter combinationsBiological substance pretreatmentsCells/wellPlant tissue

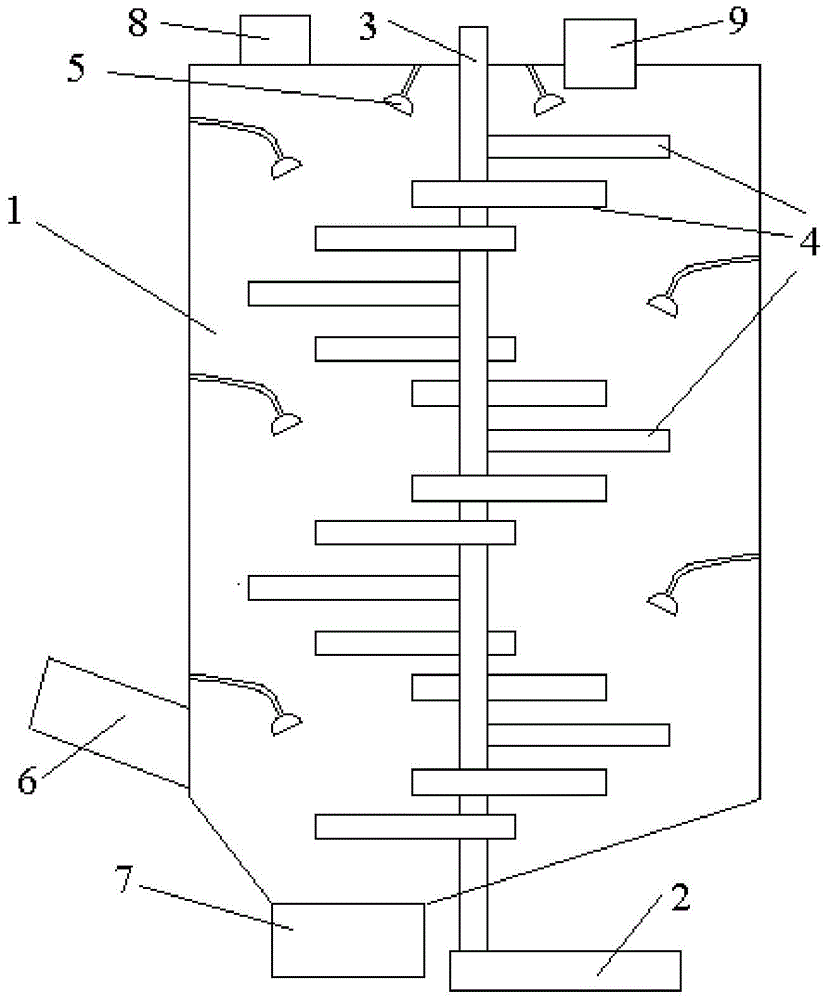

An assembly for promoting the growth of plant tissues that includes a plurality of plates each defining an array of wells wherein each of the wells contains a tissue sample. Support for the plates is provided by a rack having a plurality of vertically stacked shelves that may include one or more register depressions that urge the plates into predetermined positions. Light for the tissue samples is provided by a plurality of light-emitting diode arrays each mounted on a circuit board. Each circuit board is supported by a respective card edge connector of the rack so that the light-emitting diodes are in proximity to the plates supported on one of the shelves therebelow. Preferably, the light-emitting diode array corresponds to the well array supported in the registered position on the shelf therebelow so that each light-emitting diode is centered above a respective one of the wells.

Owner:BIOLEX THERAPEUTICS INC

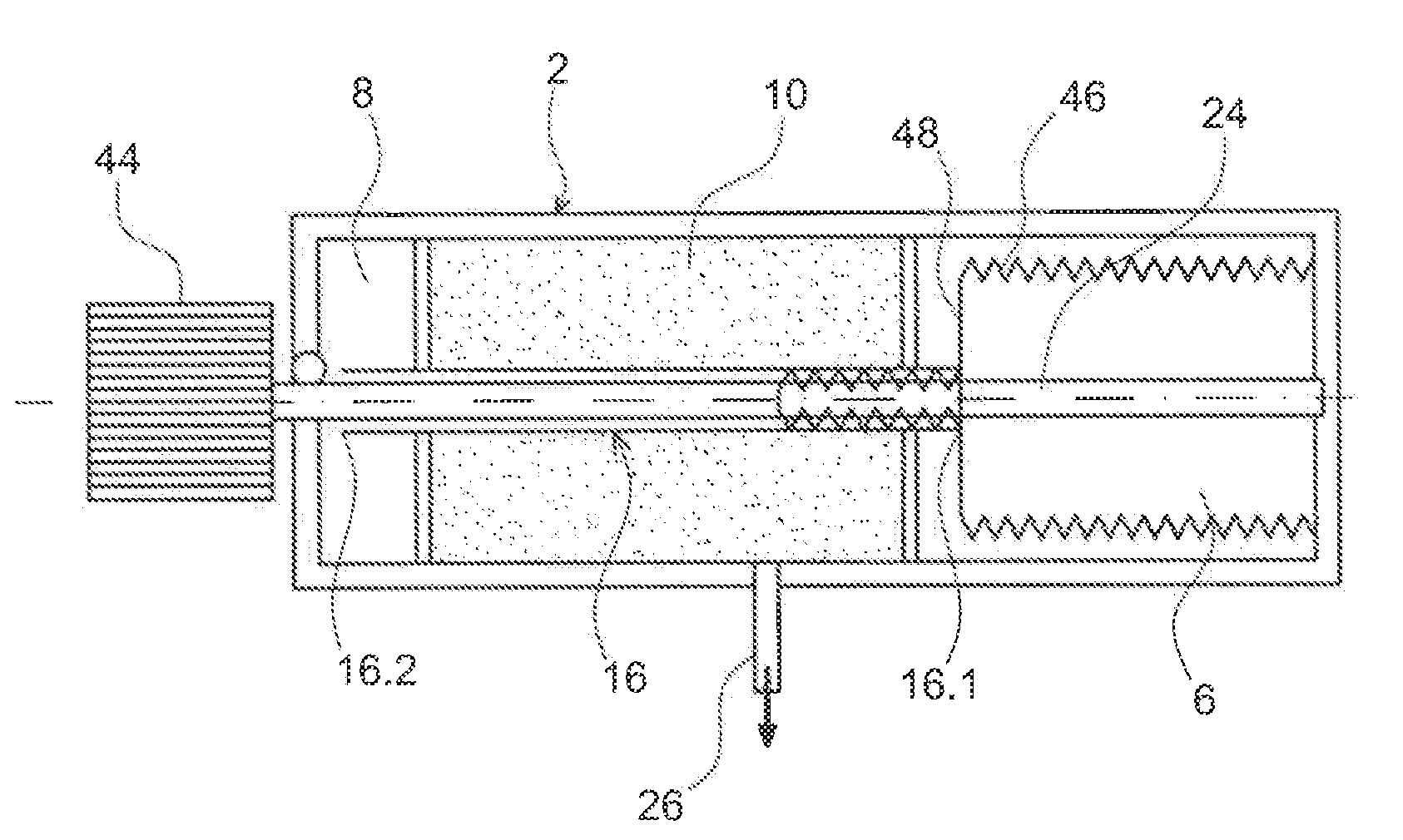

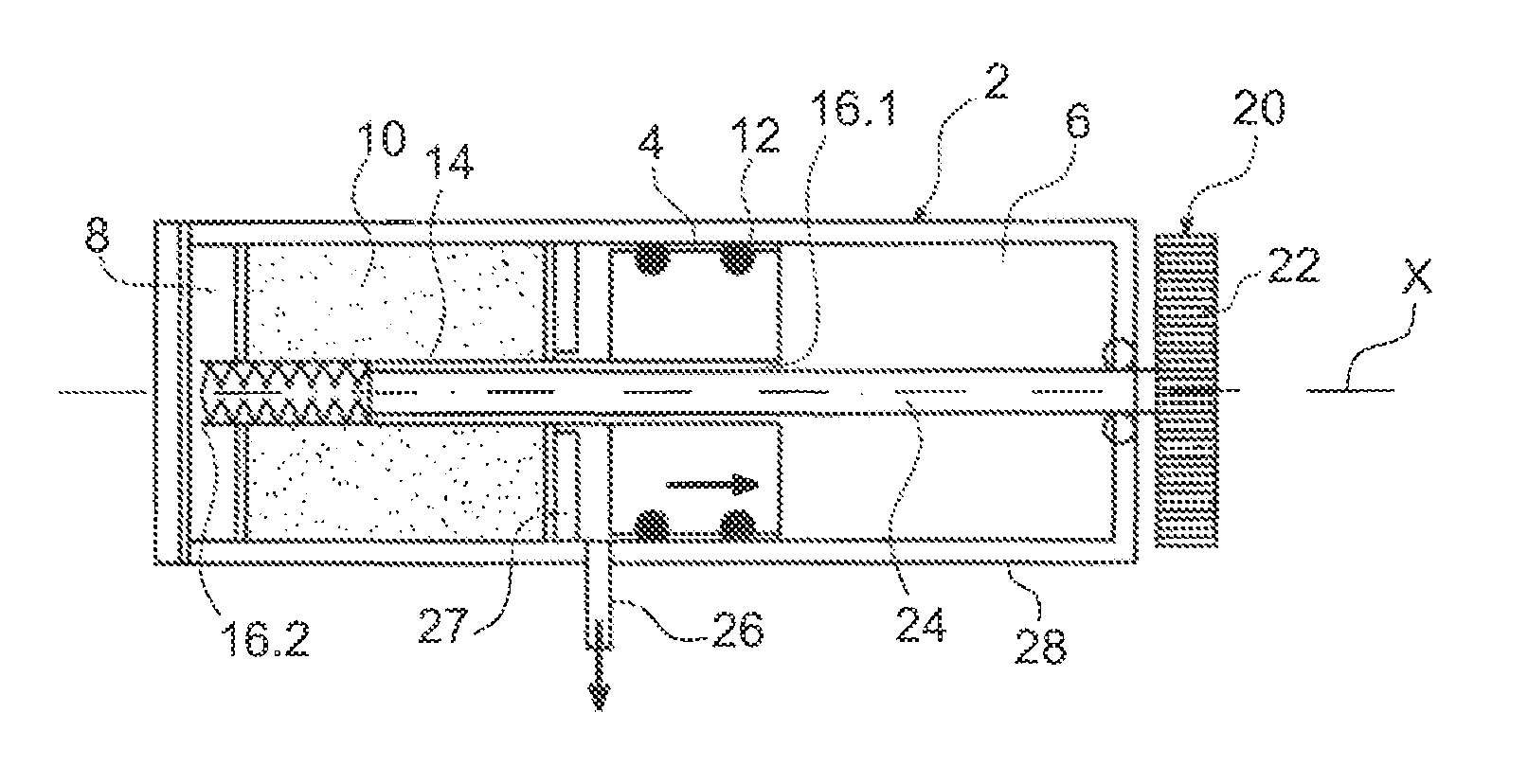

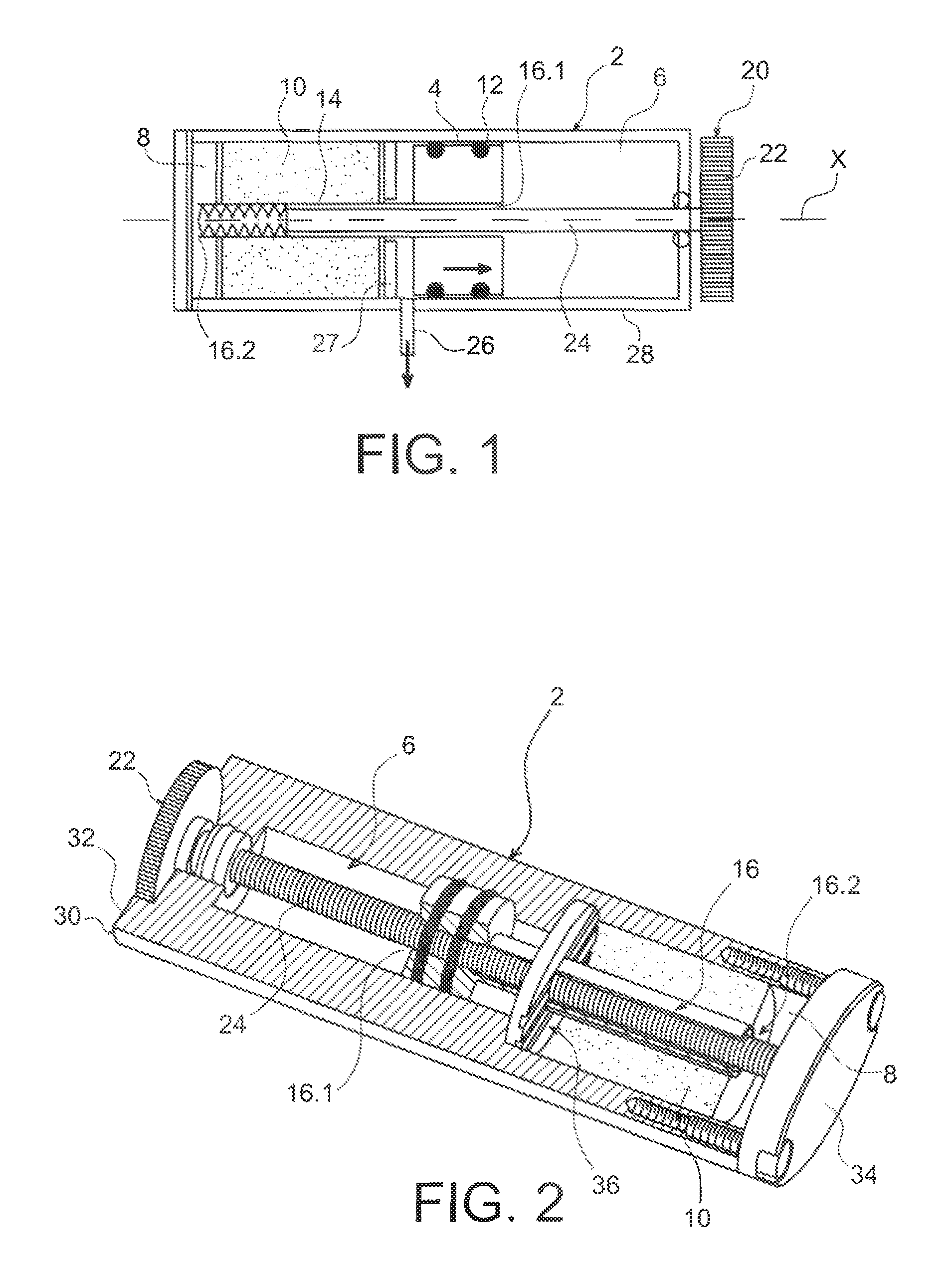

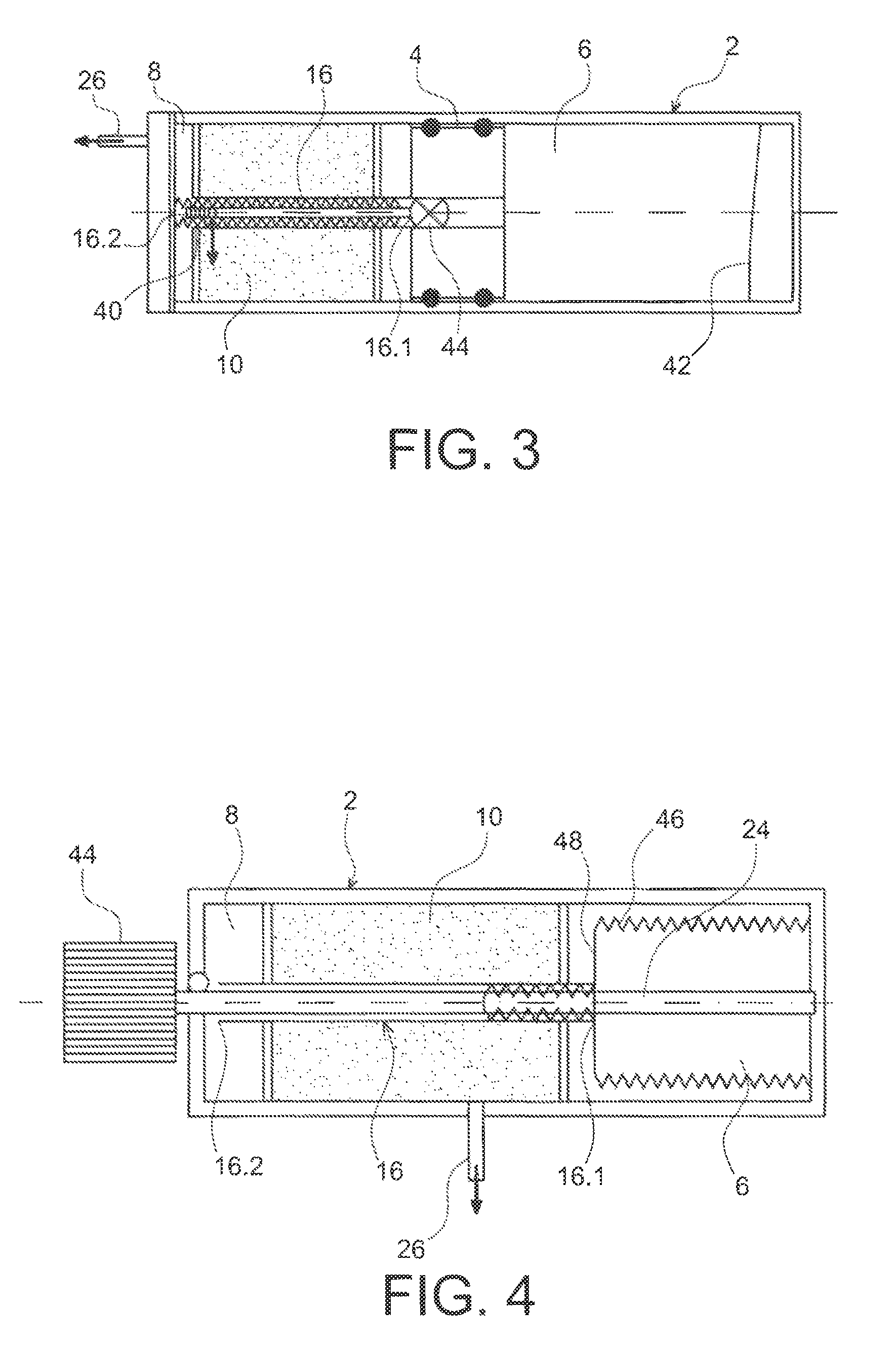

Portable gas generating device and electrical fuel cell power supply comprising such a device

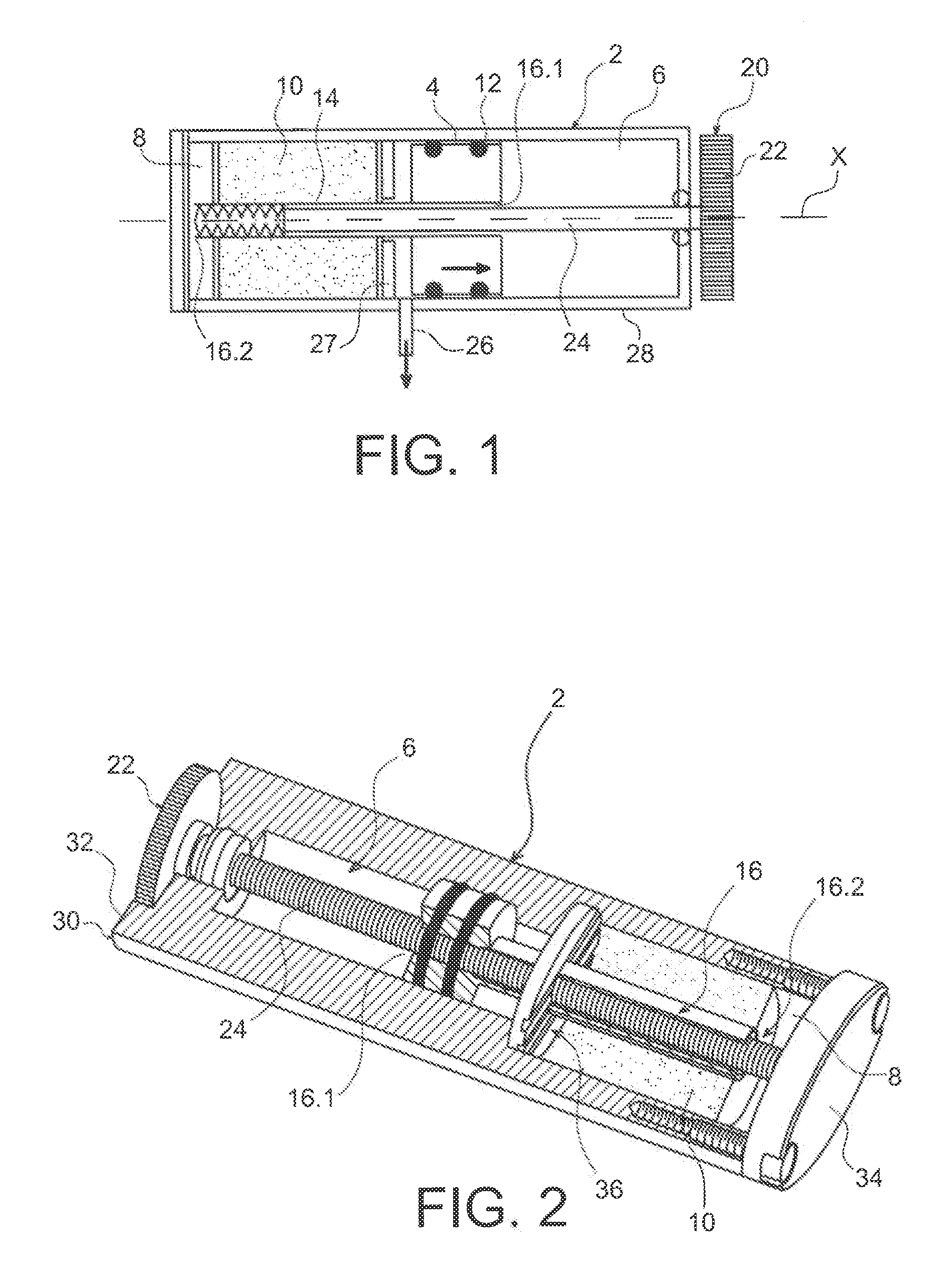

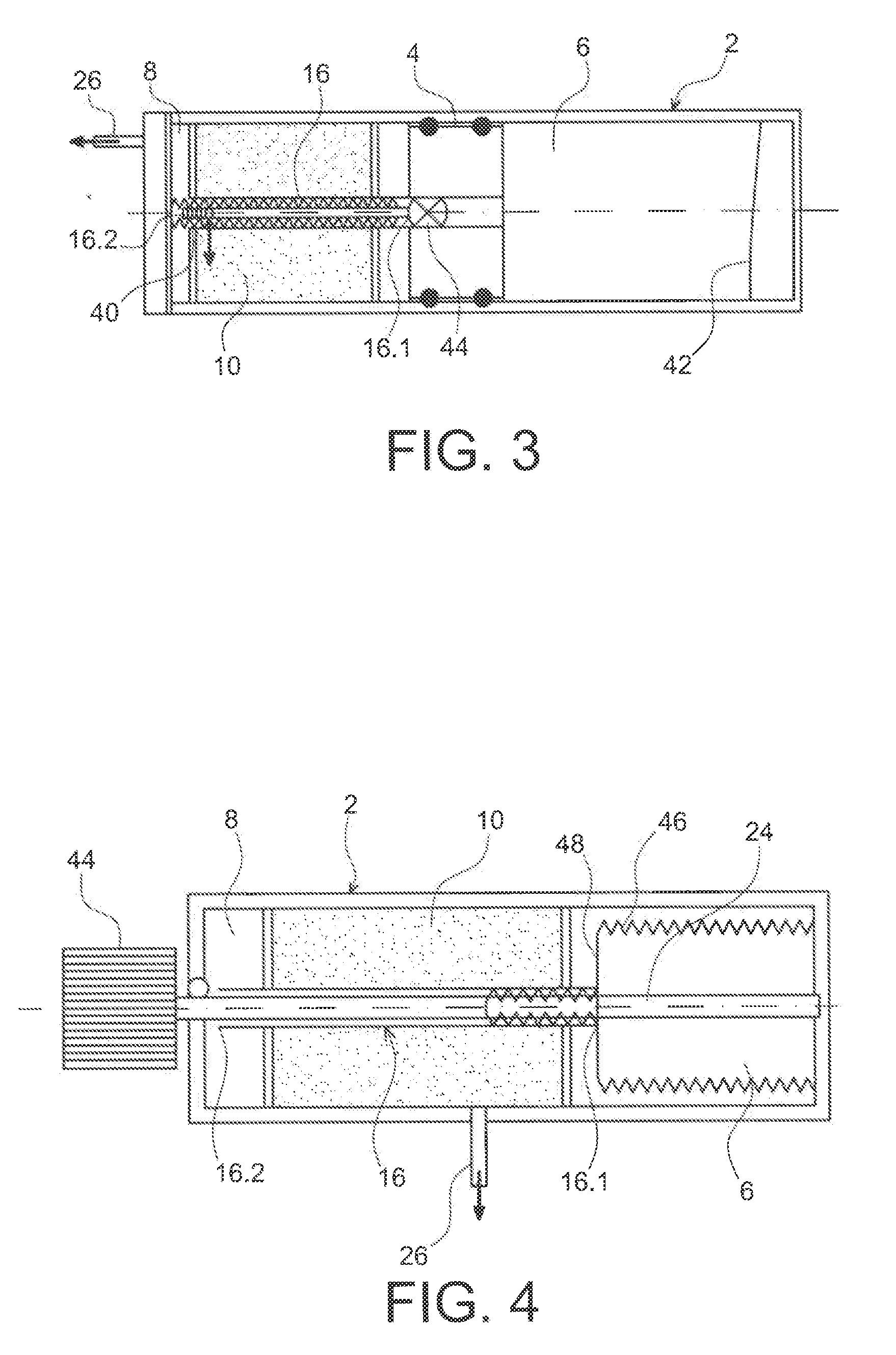

ActiveUS20090017347A1Keep for a long timeConstant volumeGenerators with non-automatic water feedAcetylene gas generator detailsFuel cellsEngineering

Device for generating gas by placing a liquid reactant in contact with a solid element, comprising a liquid reactant tank (6) and a reaction chamber (8) intended to contain the solid element, wherein the tank (6) and the reaction chamber (8) are separated in a sealed manner by a mobile wall (4), with an outlet port (26) for collecting the gas generated in the reaction chamber and means (14) for injecting the liquid reactant onto the solid element, which injection means (14) pass through the mobile wall (4) and are capable of moving into the solid element.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

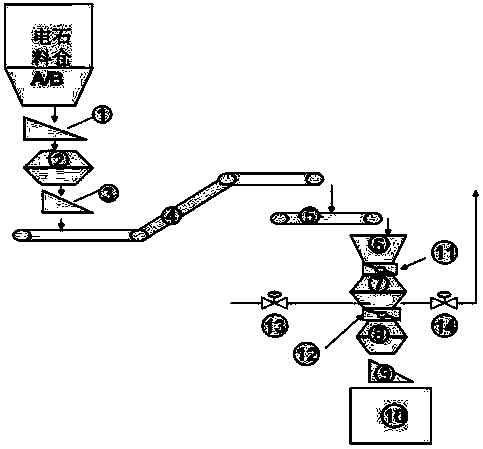

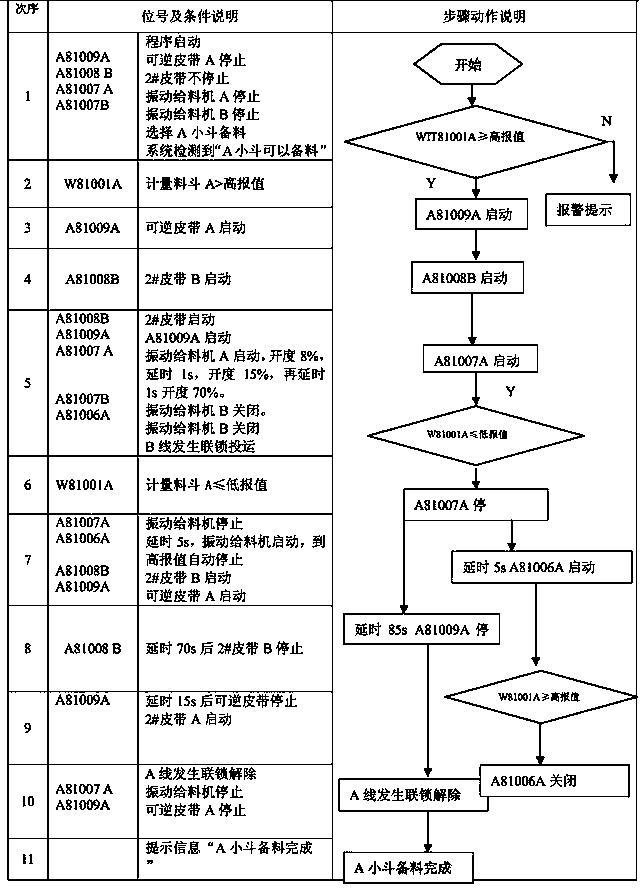

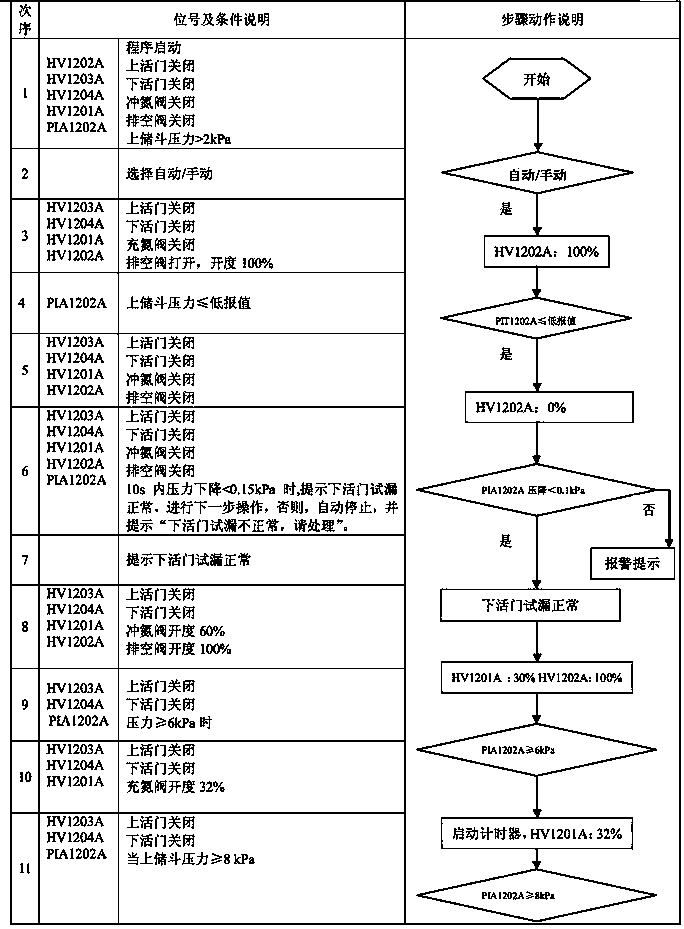

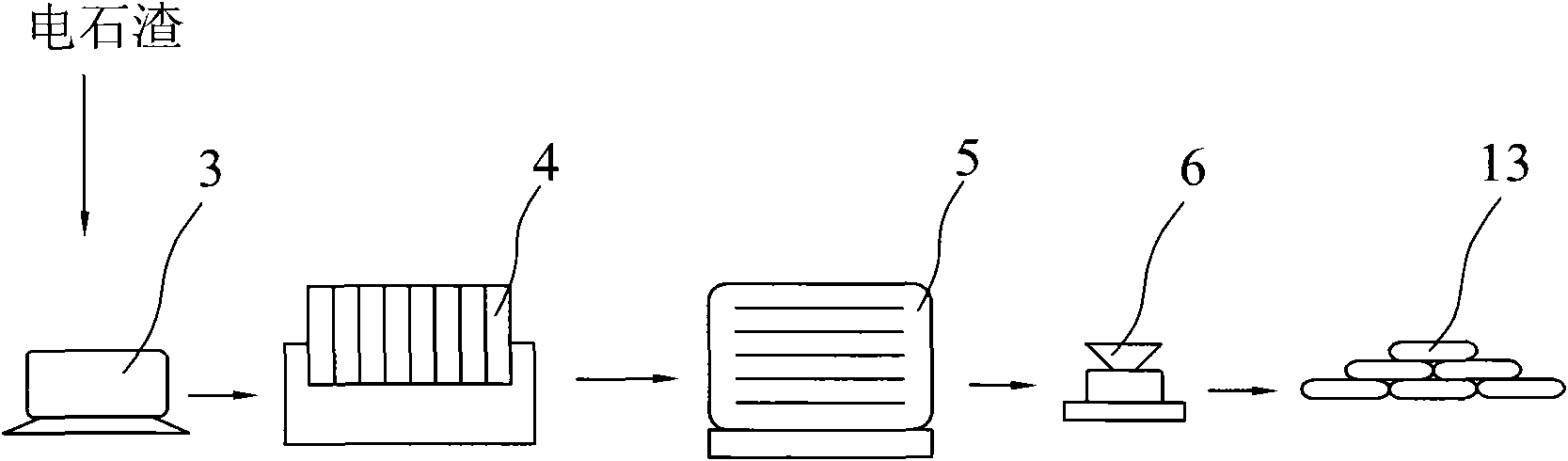

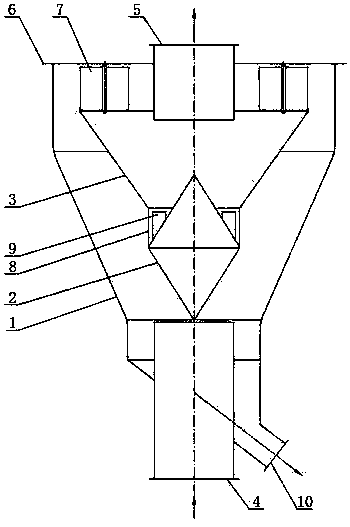

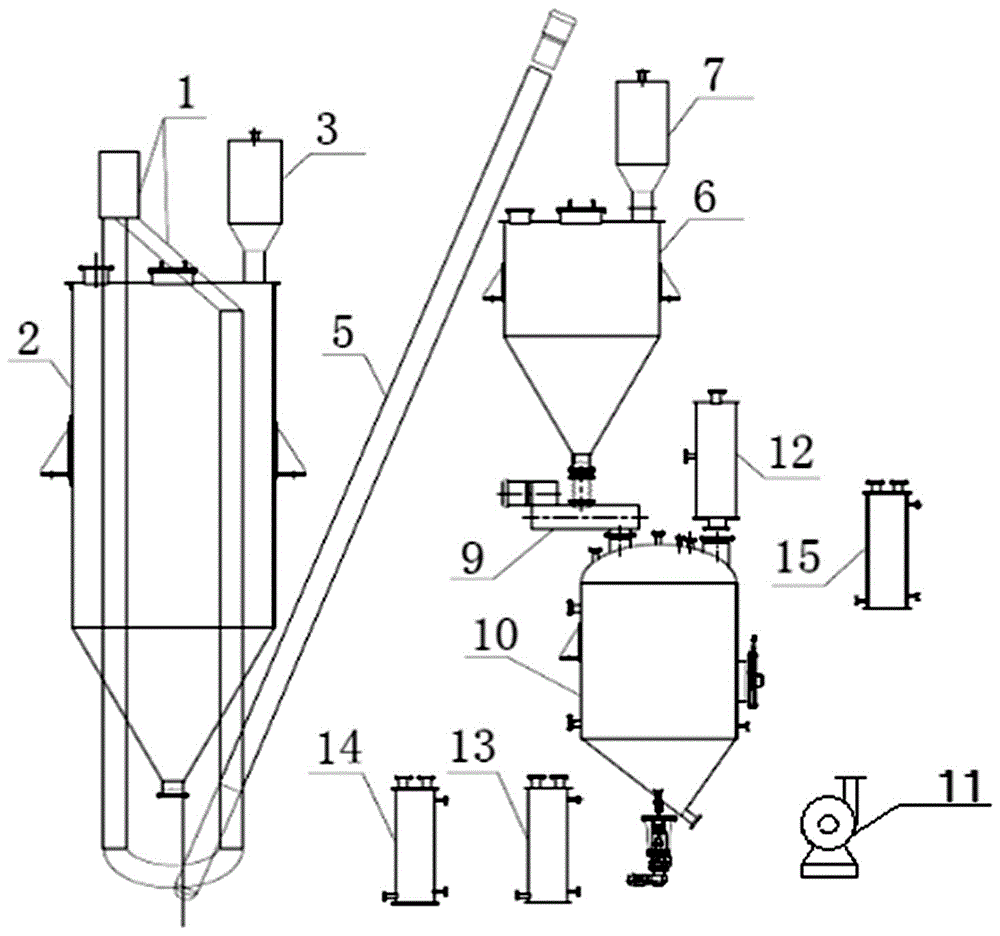

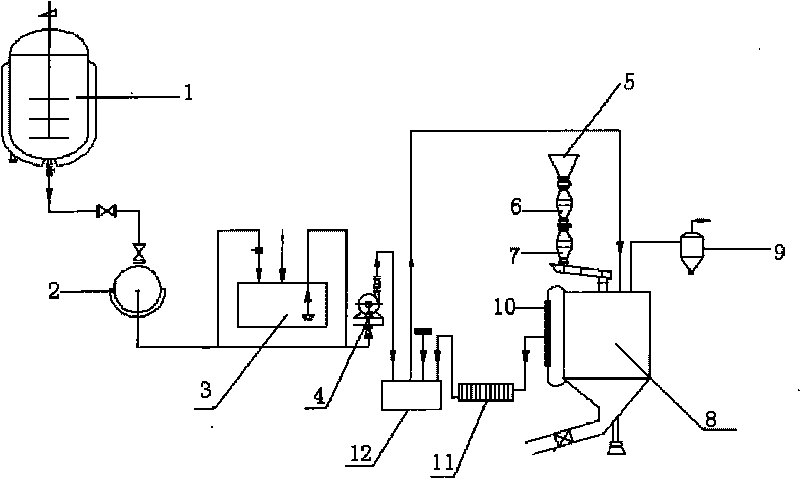

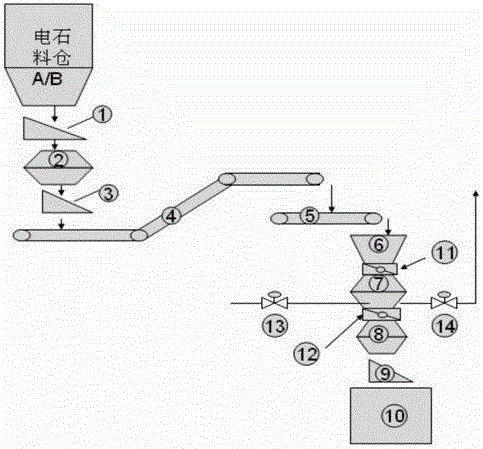

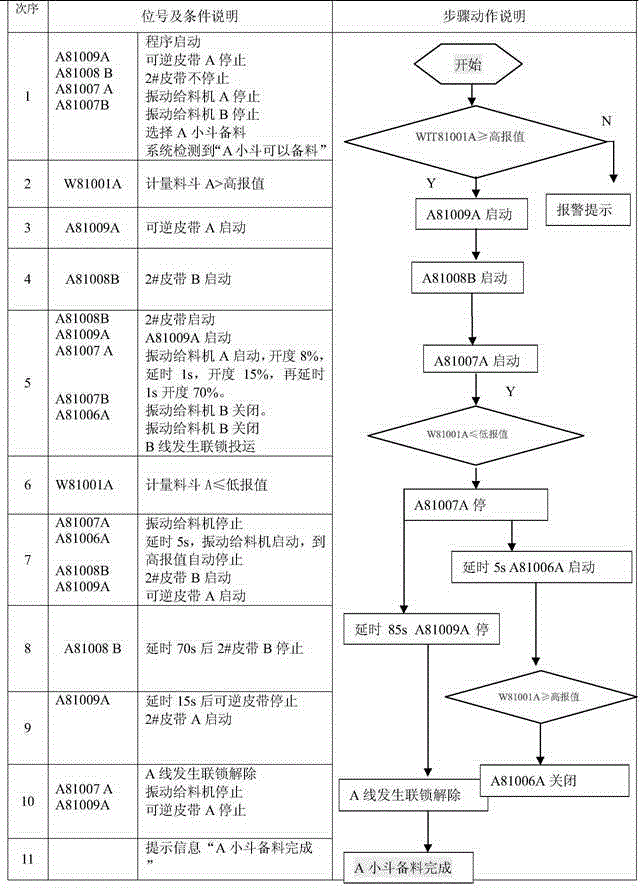

Calcium carbide preparing and feeding automatic control system of acetylene generator

InactiveCN103642528AAvoid displacement overpressureIncrease the level of automationAcetylene gas generator detailsTotal factory controlMaterials preparationAutomatic control

The invention discloses a calcium carbide preparing and feeding automatic control system of an acetylene generator. The automatic control system comprises a generator material preparation control module, a generator feeding control module, a first vibrating feeding machine (1), a metering hopper (2), a second vibrating feeding machine (3), a belt conveyer (4), a reversible belt conveyer (5), a generator small feeding storage hopper (6), a generator upper feeding storage hopper (7), a generator lower feeding storage hopper (8), a vibrating feeder (9) and a generator (10). Various interlocks are set during automatic operation, so that heavy material preparation, heavy material adding, replacement overpressure and overtime are avoided, all devices are interlocked when one device goes wrong, the automation level of an acetylene workshop is greatly improved, and the fault rate of a feeding device and the labor intensity of staff in operation are reduced.

Owner:甘肃银光聚银化工有限公司

Portable gas generating device and electrical fuel cell power supply comprising such a device

InactiveUS7976786B2Keep for a long timeConstant volumeGenerators with non-automatic water feedReactant parameters controlFuel cellsProduct gas

A device for generating gas by placing a liquid reactant in contact with a solid element, including: a liquid reactant tank, a reaction chamber configured to contain the solid element, an injector configured to inject the liquid reactant onto the solid element, and an outlet port configured to collect the gas generated in the reaction chamber, wherein the tank and the reaction chamber are separated in a sealed manner by a mobile wall, the mobile wall including an outlet port for collecting the gas generated in the reaction chamber, and wherein the injector passes through the mobile wall and configured to move into the solid element.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for using carbide slag for material circulation system in carbide industry

InactiveCN101805003AReduce manufacturing costAcetylene gas generator detailsSolid waste disposalSlagPolyvinyl chloride

The invention discloses a method for using carbide slag for a material circulation system in carbide industry. When the carbides are synthesized in carbide industry, and calcium oxides need to be calcined in a calcium oxide-consuming shop (1) in a carbide-calcining shop; and when acetylene is produced in polyvinyl chloride industry, the carbides need to be hydrolyzed to produce carbide slag, the carbide slag is calcined into calcium oxides in a calcium oxide-producing shop (2), and sequentially, the calcium oxides are returned to the carbide shop for synthesizing carbide by calcination. By using the organic circulation system for discharging waste in carbide industry, the method reduces the production cost of the carbide, and avoids the discharge of the carbide slag, thereby basically solving the problem of carbide slag waste in carbide industry, and making great contribution to environmental protection.

Owner:王嘉兴

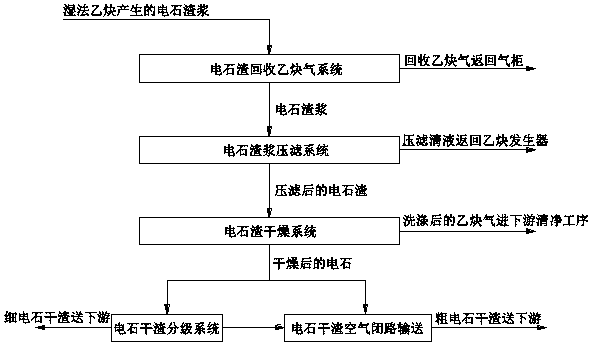

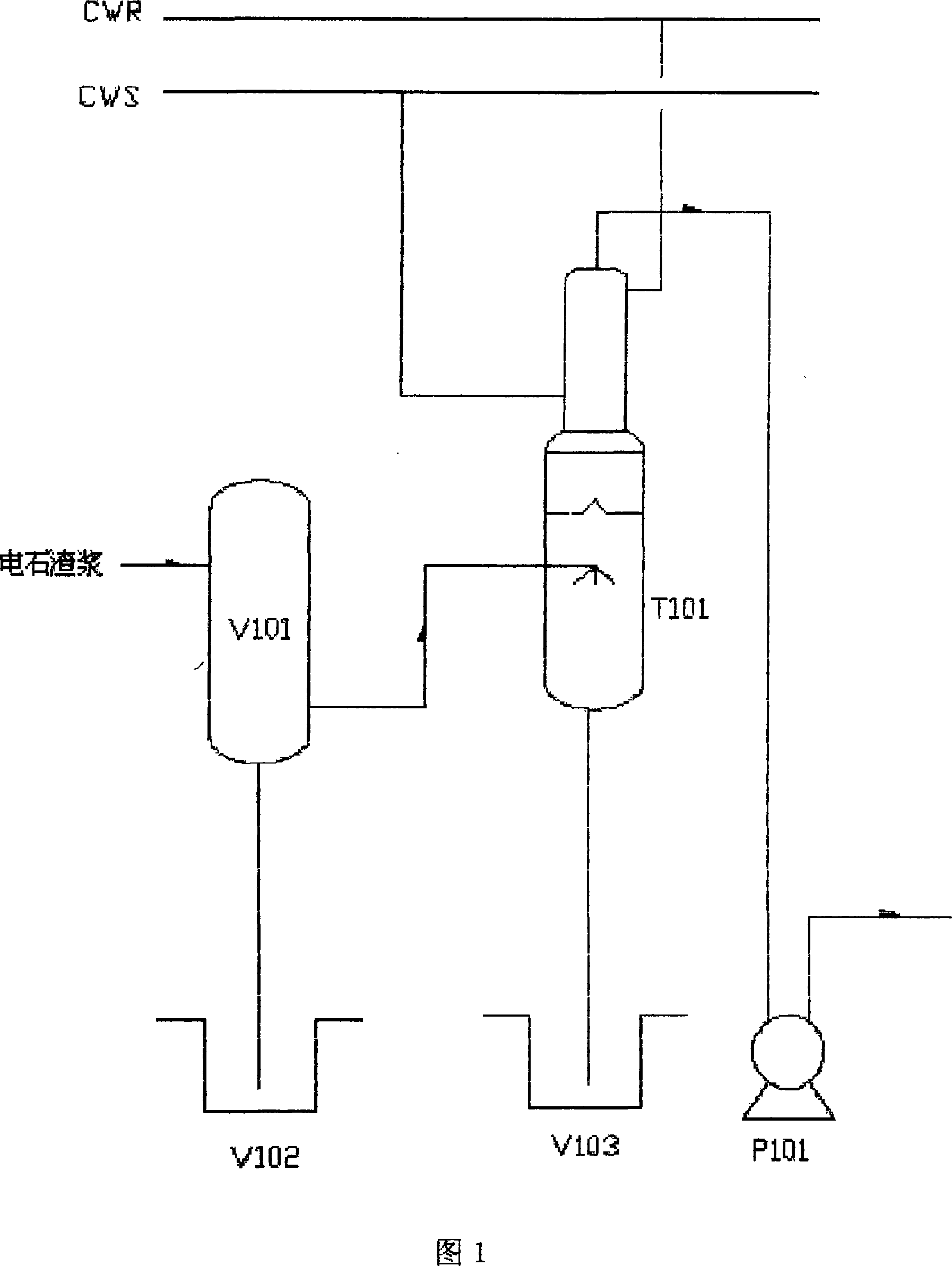

Treatment technology for carbide slag in wet-process acetylene production

The invention discloses a treatment technology for carbide slag in wet-process acetylene production, comprising the following steps: a) recovery of acetylene gas in carbide slag slurry: conducting preliminary sedimentation separation on the carbide slag slurry, injecting the carbide slag slurry into a degassing tower through a slag slurry pump, and pumping gas from the top of the degassing tower by a vacuum pump to maintain a certain vacuum degree; b) press filtration and drying of carbide slag slurry: conducting press filtration on the carbide slag slurry after acetylene gas recovery by a filter press system, conducting pre-drying by a dryer, sending pre-dried carbide slag to a drying tower, fully mixing the pre-dried carbide slag with a high-temperature dry airflow sent by a blower in the tower under the action of an induced draft fan, and discharging particles along with an airflow from the top of the tower during rising of a swirling flow; and c) classification of carbide slag: sending the dried carbide slag to a solid powder classifier for separation of coarse and fine carbide slag. The technology of the invention mainly aims at the problem that the processing cost of carbideslag in wet-process acetylene production is high, and adopts a comprehensive treatment and utilization technology of carbide slag to realize recovery of acetylene gas and comprehensive utilization ofthe carbide slag.

Owner:CHINA CHENGDA ENG

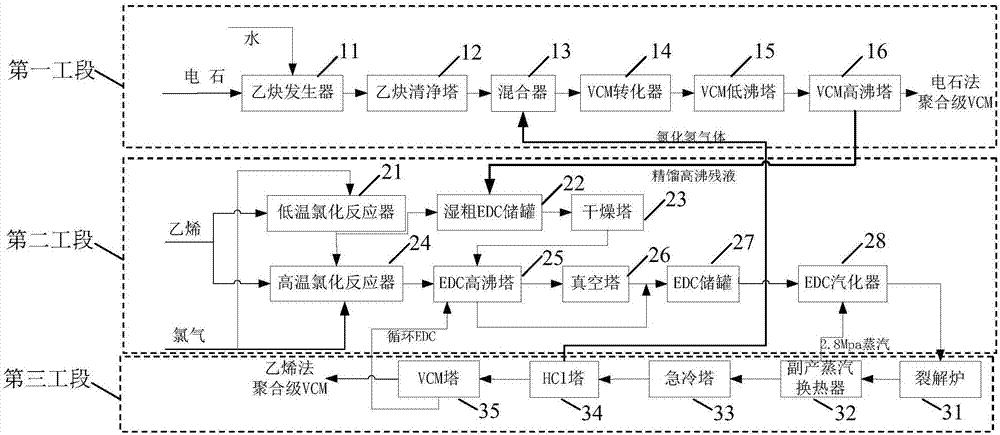

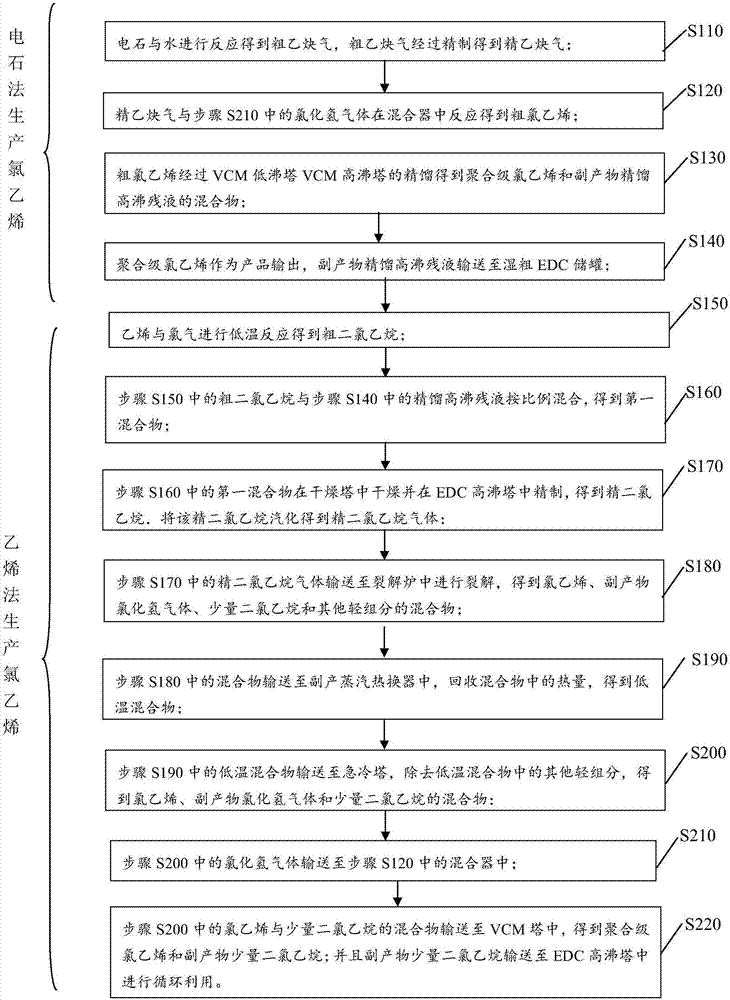

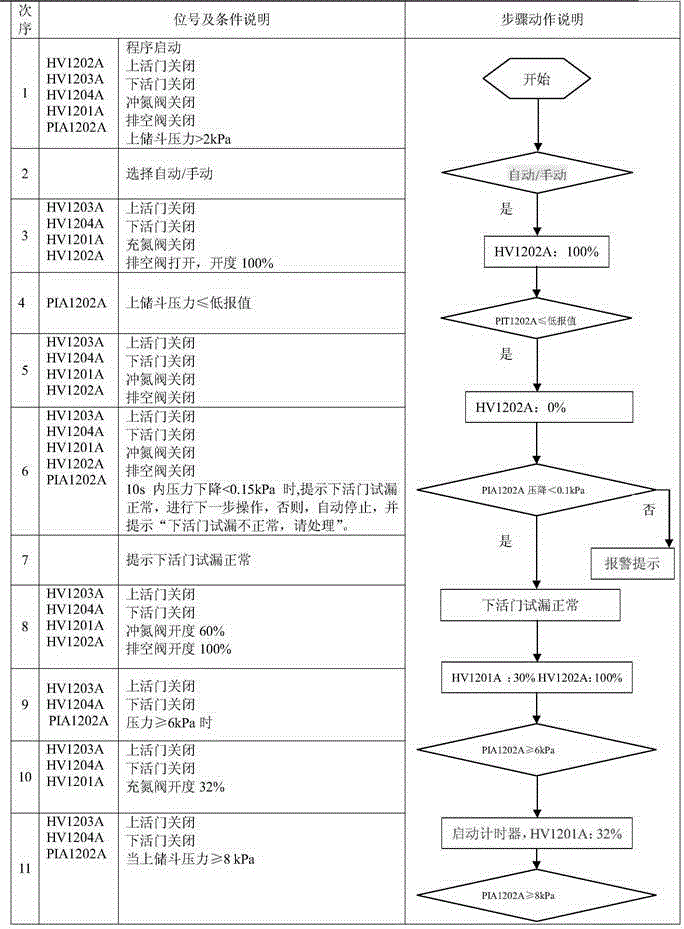

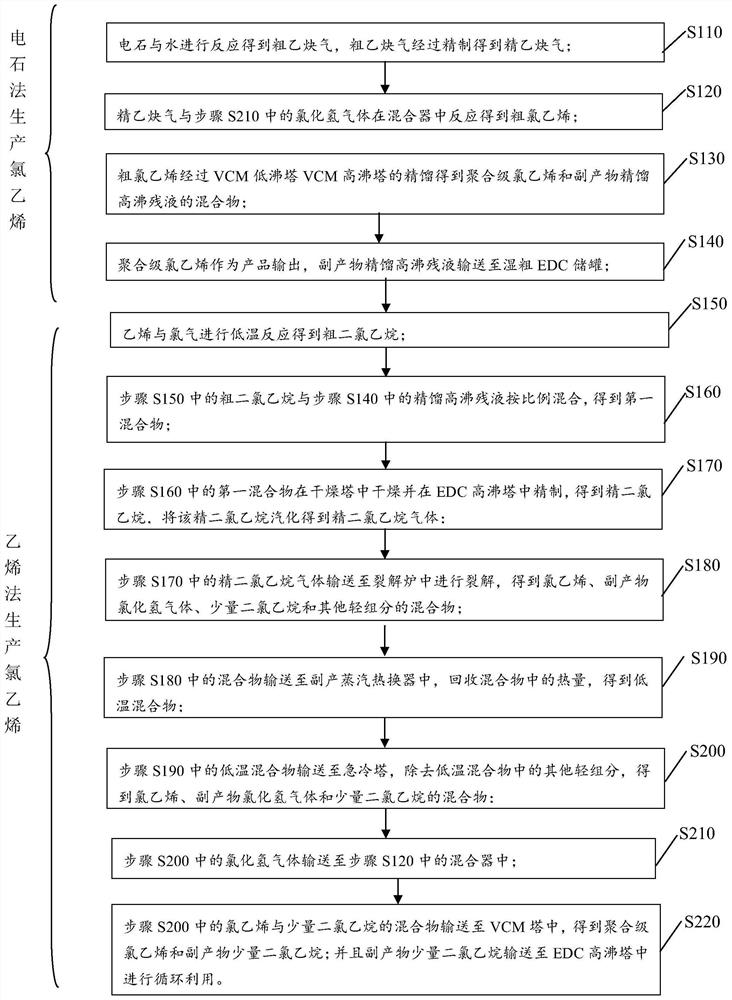

System and method for treating high boiling residuary solution in chloroethylene produced by adopting calcium carbide method

ActiveCN107311835ASolve the pollution of the environmentSolve processingPreparation by hydrogen halide split-offAcetylene gas generator detailsProcess engineeringEthyl Chloride

The invention discloses a system and method for treating a high boiling residuary solution in chloroethylene produced by adopting a calcium carbide method. The treatment system comprises a first working section including an acetylene generator (11), an acetylene purifying tower (12), a mixing device (13), a chloroethylene converter (14), a chloroethylene low-boiling tower (15) and a chloroethylene high-boiling tower (16) which are connected in sequence, a second working section including a low-temperature chlorination reactor (21), a wet coarse dichloroethane storage tank (22), a drying tower (23), a high-temperature chlorination reactor (24), a dichloroethane high-boiling tower (25), a vacuum tower (26), a dichloroethane storage tank (27) and a dichloroethane vaporizer (28), a third working section including a cracking furnace (31), a by-product steam heat exchanger (32), a quench tower (33), a hydrogen chloride tower (34) and a chloroethylene tower (35) which are connected in sequence, wherein the low-temperature chlorination reactor (21), the wet coarse dichloroethane storage tank (22) and the drying tower (23) are connected in sequence, the high-temperature chlorination reactor (24), the dichloroethane high-boiling tower (25), the vacuum tower (26), the dichloroethane storage tank (27) and the dichloroethane vaporizer (28) are connected in sequence, and the chloroethylene high-boiling tower (16) is connected with the wet coarse dichloroethane storage tank (22).

Owner:QINGHAI SALT LAKE IND

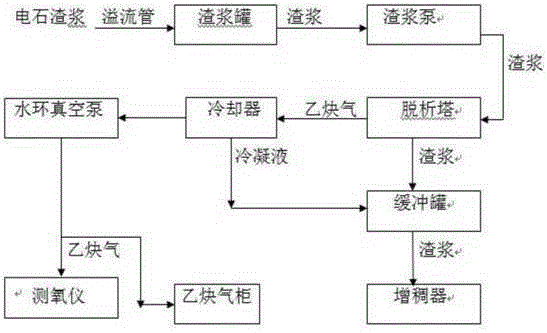

Method for recycling acetylene from slag slurry

InactiveCN105219435AReduce manufacturing costProcess operation is stableAcetylene gas generator detailsDesorptionSlag

A method for recycling acetylene from slag slurry comprises the steps that a vacuum desorption method is adopted to recycle acetylene gas, generator overflow is sent to a slag slurry tank through an airtight pipeline and then sent to a desorption tower through a slag slurry pump, and low pressure boiling desorption is conducted on carbide-slag slurry in the desorption tower; after the desorped acetylene gas is sent to a cooler to be cooled, the acetylene gas is sent to a steam-water separator through a water ring vacuum pump, a part of the acetylene gas enters an acetylene heat exchanger and enters an oxygen meter after being cooled, and if the measured oxygen content is higher than 1.8%, the acetylene gas opens an emptying valve and is emptied through a fire barrier; if the measured oxygen content is lower than 1.8%, the acetylene gas is sent to an acetylene header pipe to enter a gas cabinet through an acetylene buffer tank and a flow meter. Desorbed slag slurry enters a slag slurry buffer tank from the bottom of the desorption tower and is pumped to a thickener through a slag slurry buffer pump. According to the method for recycling the acetylene from the slag slurry, running of the technology is stable, and the benefit is obvious. Meanwhile, a generator overflow pipeline is airtight, and the problem that an original overflow well is openair and not safe is solved.

Owner:TIANJIN DAGU CHEM CO LTD

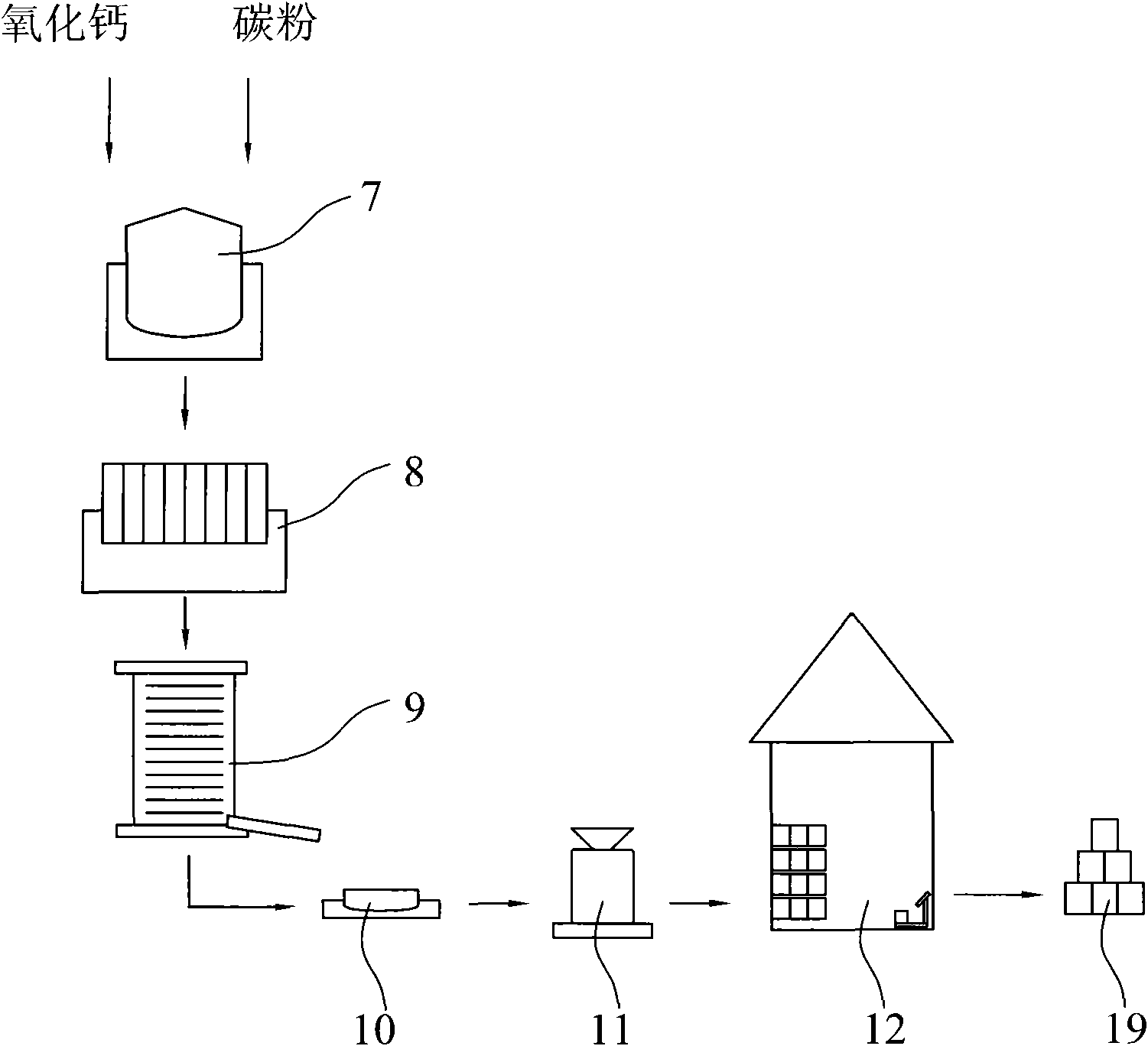

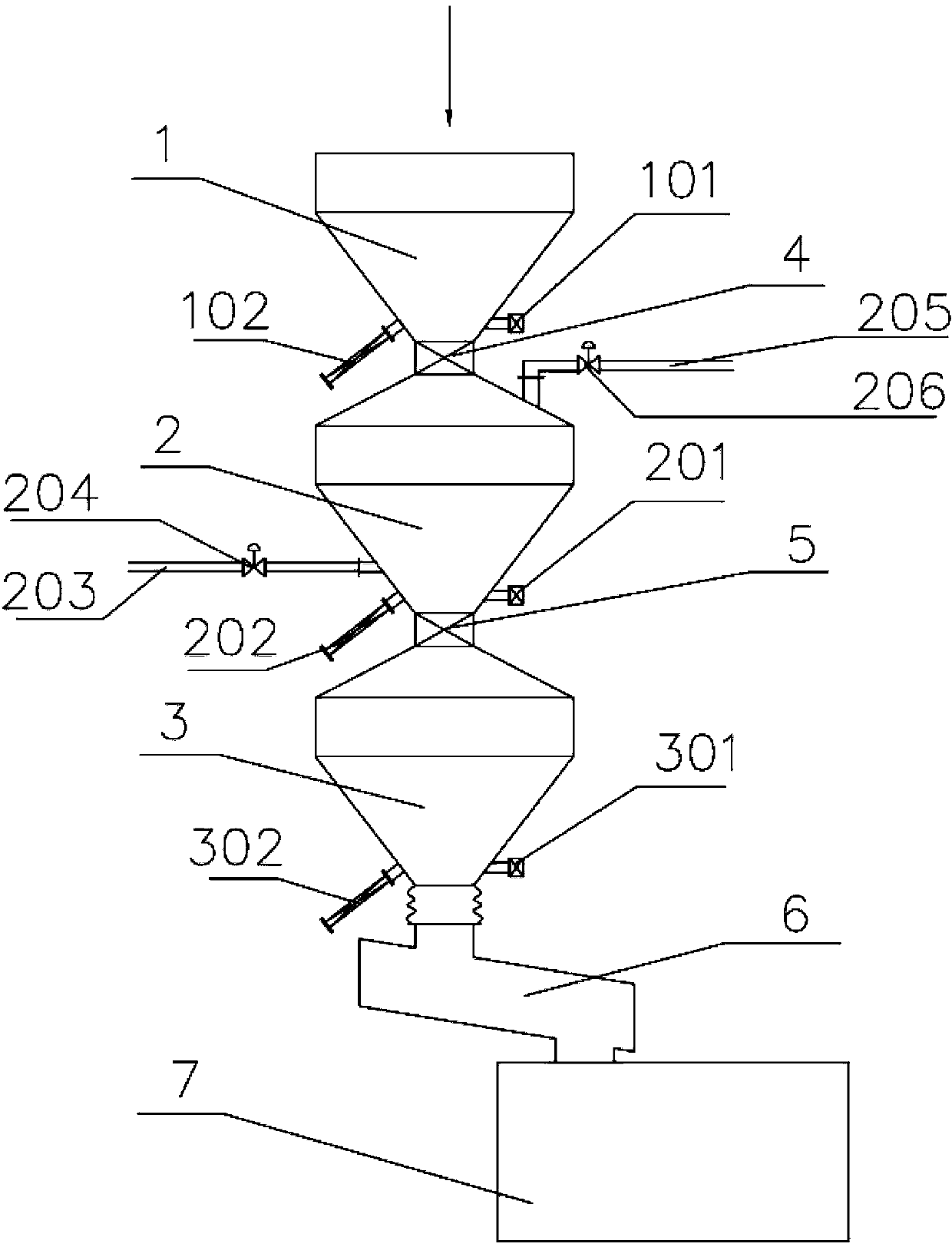

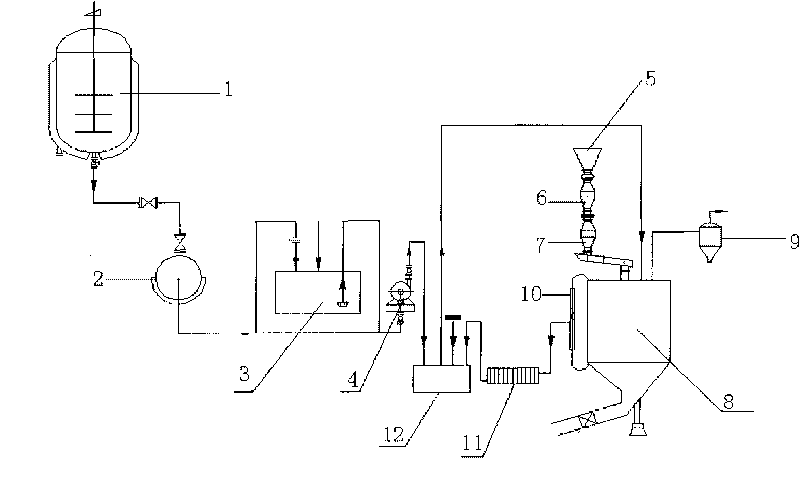

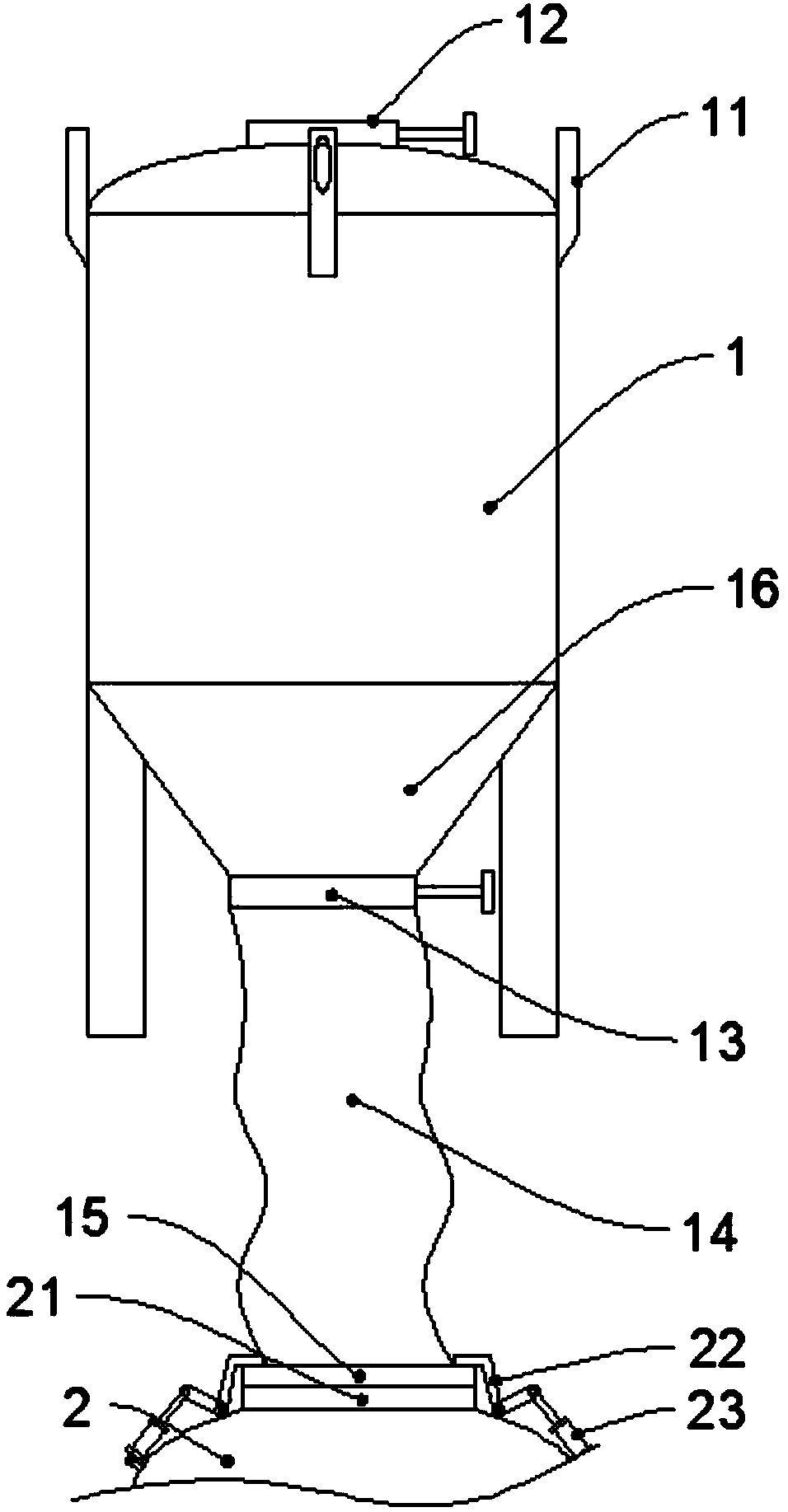

Feeding device and system for acetylene generator and operating method of feeding device

ActiveCN103387850AImprove securityEasy to operateAcetylene gas generator detailsExternal calciumAutomatic control

The invention relates to the technical field of acetylene preparation and particularly relates to a feeding device and system for an acetylene generator and an operating method of the feeding device. The feeding device for the acetylene generator comprises a charging hopper, an upper feeding hopper, a lower feeding hopper, an upper feeding valve, a lower feeding valve and a vibratory feeder, wherein a charging opening of the charging hopper is used for adding an external calcium carbide material, a discharging opening of the charging hopper is communicated with a charging opening of the upper feeding hopper through the upper feeding valve, a discharging opening of the upper feeding hopper is communicated with a charging opening of the lower feeding hopper through the lower feeding valve, a discharging opening of the lower feeding hopper is communicated with a charging opening of the vibratory feeder, and a discharging opening of the vibratory feeder is communicated with a charging opening of the acetylene generator and is used for adding the calcium carbide material in the vibratory feeder into the acetylene generator. The invention further relates the operating method of the feeding device. The device has the advantages that the sealing performance is good, the leakage is hardly caused, and potential safety hazards are eliminated; in addition, the degree of detection and protection is high, so that an automatic control system is formed favorably.

Owner:内蒙古君正化工有限责任公司

Technological method for producing acetylene by efficient calcium carbide process

ActiveCN107129830AImprove conversion rateHigh densityAcetylene gas generator detailsSolubilityInternal temperature

The invention provides a technological method for producing acetylene by an efficient calcium carbide process, which comprises the following steps: grinding calcium carbide, and then degressively adding into a vacuum reactor, wherein the internal temperature of the vacuum reactor is 45-55 DEG C and the vacuum reactor contains a mixture of a saturated salt solution and an alkaline water solution; controlling the temperature of the whole reaction system to be not higher than 70 DEG C; and introducing acetylene gas subjected to preliminary purification into an acidic water solution and concentrated sulfuric acid sequentially for carrying out secondary purification, so as to obtain highly pure acetylene gas. Compared with the prior art, the technological method provided by the invention has the following advantages: a generated pasty calcium hydroxide solid quickly settles so as to prevent the surface of powdered calcium carbide from being wrapped and affecting the continuous operation of the reaction; the gas production reaction is carried out under relatively mild conditions, and a baffle does not need to be arranged in the reactor; the solubility of non-polar acetylene gas in the solution is reduced, the solubility of polar gas, such as hydrogen sulfide, hydrogen phosphide and hydrogen arsenide, in the solution is increased, and the gas production rate and the acetylene gas purity are increased; and the reaction process and the preliminary purification process are carried out in one reactor, thereby saving the field.

Owner:HWASU

System and method for preparing light aromatic hydrocarbon by pulverized coal with heavy aromatic hydrocarbon recycling function

PendingCN107216896ASolve the problem of production constraintsSolve problems that are difficult to apply to industryAcetylene gas generator detailsCalcium carbideAromatic hydrocarbonPetroleum

The invention discloses a system for preparing aromatics from pulverized coal with the function of reusing heavy aromatics, which is characterized in that it includes a fast pyrolysis device, a purification and separation device, a mixing tank, a mixing tank, a filter, a pressure ball device, Calcium carbide furnace, acetylene generator, acetylene to aromatics reactor and separation system. The invention also discloses a method for preparing light aromatics from pulverized coal. Using the above system and method, aromatics are produced from coal, which solves the problem of limited aromatics production due to limited petroleum resources, and realizes the cleanliness of low-rank coal. Efficient utilization, the acetylene-to-aromatics unit couples thermal reaction and catalytic reaction, which increases the yield of light aromatics. At the same time, the by-produced heavy aromatics can be used as a diluent for rapid pyrolysis of coal tar to remove a large amount of dust contained in it, which is beneficial to coal. Deep processing of tar.

Owner:BEIJING HUAFU ENG

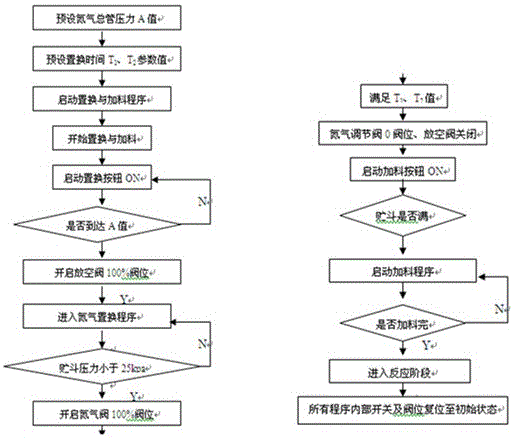

Acetylene production process operation displacement and charging control method

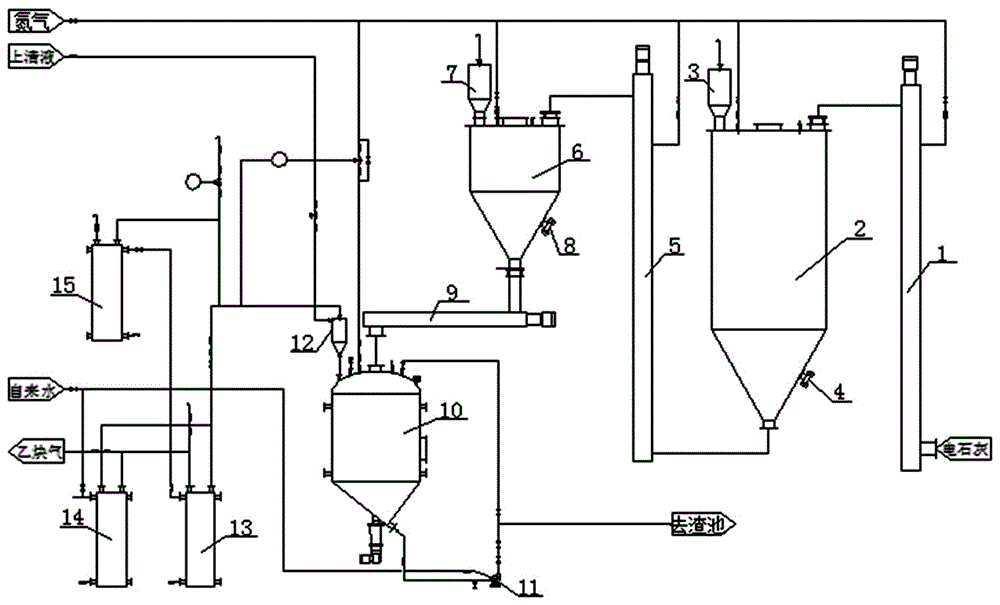

InactiveCN106125690AReduce labor intensityRealize automatic controlAcetylene gas generator detailsGenerators with carbide submersionAutomatic controlNitrogen

The invention discloses an acetylene production process operation control method and particularly relates to a displacement and charging operation process DCS control method. An emptying-displacement-charging-reaction process of an acetylene generator is controlled through a DCS, a displacement and charging process is changed into an automatic control mode, a nitrogen filling pressure A value is preset, an automatic replacement time T1 value is set, a time relay is newly added, the time T2 is set, operation starts to reach the A value, a replacement button starts to enter a replacement stage, the replacement time satisfies the T1 and the T2, a next program step is automatically carried out, if the nitrogen filling pressure is determined by the DCS to be smaller than the A value, the replacement time is T1+2 minutes and the T2+2 minutes, the T1+2 minutes and the T2+2 minutes are both satisfied, a next step is automatically carried out, the program is over, all internal switches and valve positions are reset to initial states, a reaction stage is finally entered, and ideal control standards can be realized through the previous operations. The method is further advantaged in that operation is convenient and rapid, influence of artificial factors can be solved, and automatic control and precision for the key acetylene production process are realized.

Owner:石河子天域新实化工有限公司 +1

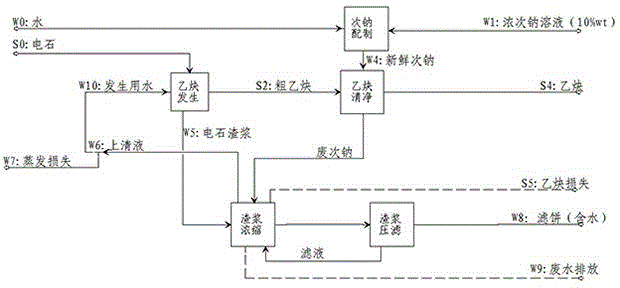

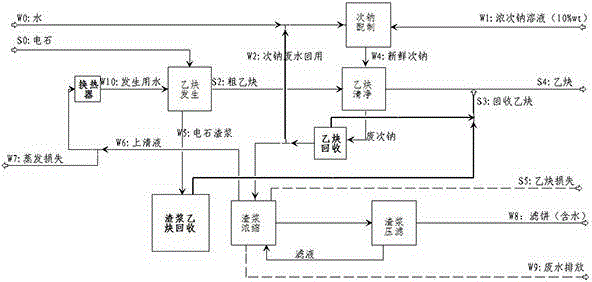

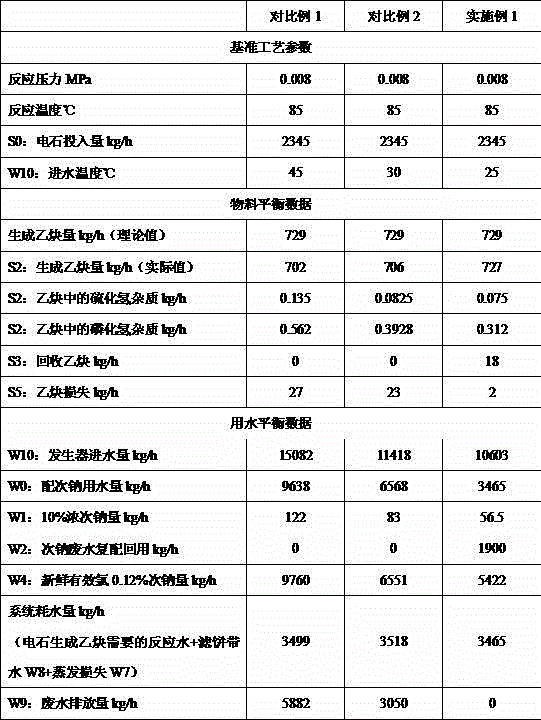

Waste water zero-discharge acetylene production technology

The invention relates to a wet method production technology for preparing acetylene from calcium carbide. Crude acetylene from a generator needs a large volume of sodium hypochlorite solution for cleaning, After the generated waste sodium hypochlorite solution goes through a first desorption tower and acetylene is recovered, part of the solution is used for compounding of a sodium hypochlorite solution, and part of the solution goes through a transition tank and goes into a concentration tank for reuse. Through adjusting of the compounding proportion, all the waste water generated in the technology can be reused without discharge. After a diluted calcium carbide slag slurry overflowed from the generator goes through a second desorption tower and acetylene is recovered, the diluted calcium carbide slag slurry goes into the concentration tank for concentration; the supernatant in the concentration tank is cooled in water cooling tower, a heat exchanger is added in front of an acetylene generator, circulating water cooling is carried out, stable water input temperature and water inflow of the acetylene generator are ensured, and the stability and the controllability of technology production are raised. The provided technology raises the acetylene yield, ensures water balance, achieves waste water zero discharge and has good economic and environmental protection benefits compared with traditional technologies.

Owner:QINGDAO UNIV OF SCI & TECH +2

System for producing acetylene gas by using recycled calcium carbide dust

InactiveCN105969424AIncrease profitReduce pollutionAcetylene gas generator detailsChemical reactionPollution

The invention relates to the technical field of treatment on calcium carbide broken dust and particularly relates to a system for producing acetylene gas by using recycled calcium carbide dust. The specific process is characterized by recycling calcium carbide dust on the ground, lifting the calcium carbide dust to a dust storage bin via a primary feeder for collecting, feeding the calcium carbide dust into a feeding hopper via a secondary feeder, adding the calcium carbide dust into an acetylene generator at the bottom of the feeding hopper, enabling the calcium carbide dust to carry out chemical reaction with supernate in the acetylene generator to generate acetylene gas, filtering the generated acetylene gas via a washer and a water seal, then feeding the acetylene gas into an acetylene gas conveying pipeline, metering the acetylene gas via a flow gauge, then safely feeding the acetylene gas into an acetylene process gas cabinet, and returning the acetylene gas to production. Through the system for producing acetylene gas by using recycled calcium carbide dust, the utilization rate of the calcium carbide is increased; the pollution of the calcium carbide dust to the environment is reduced; the potential safety hazard is eliminated.

Owner:中盐吉兰泰盐化集团有限公司 +1

Technique for extracting residual acetylene gas in acetylene generator (wet method) carbide slag slurry

InactiveCN101235319AReduce pollutionImprove business efficiencyAcetylene gas generator detailsProcess equipmentSlag

The invention relates to a process equipment technique for extracting supersaturated acetylene gas from carbide slag slurry of a wet-method acetylene generator. The technique comprises feeding carbide slag slurry about 80 DEG C into a desorption tower under the state of negative pressure, doffing out acetylene gas which is adsorbed in carbide slag and water through utilizing vapor, damaging a coating layer of micro grain calcium carbide which is not broken up to be further hydrolyzed. Acetylene gas which is doffed is recycled after being processed.

Owner:常泽民

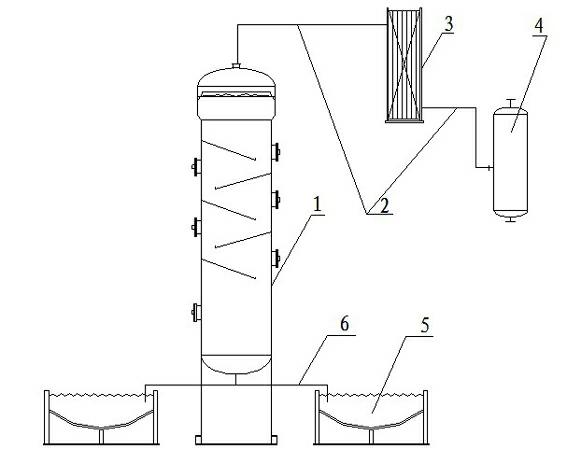

Slurry acetylene recycling device

InactiveCN102660327AAchieving Sealing RequirementsAvoid the phenomenon of clogging the raw liquid and sealing the tankAcetylene gas generator detailsPolyvinyl chlorideEconomic benefits

The invention relates to a wet type acetylene generating device in a polyvinyl chloride production process, and in particular relates to a slurry acetylene recycling device. The slurry acetylene recycling device comprises a stripping tower, an acetylene cooling device, a steam water separator and a concentrating tank, wherein the upper part of the stripping tower is connected with the acetylene cooling device by virtue of a pipeline, the lower part of the acetylene cooling device is connected with the steam water separator by virtue of the pipeline, and the outlet of a slurry discharging pipe at the bottom of the stripping tower is directly connected with the concentrating tank and is submerged under liquid level of the concentrating tank. According to the slurry acetylene recycling device disclosed by the invention, a liquid seal tank in the original device is eliminated, the slurry discharging pipe of the stripping tower is directly inserted under the liquid level of the concentrating tank, and liquid seal is guaranteed, thus sealing requirement of the stripping tower is realized, and a phenomenon that slurry blocks the original liquid seal tank is avoided; and the slurry acetylene recycling device disclosed by the invention has the characteristics of being obvious in economic benefit, easy and simple in operation and excellent in safety performance.

Owner:TANGSHAN SANYOU CHLOR ALKALI

Butadiene preparing method

InactiveCN107827695ALow costAchieve diversificationHydrogenAcetylene gas generator detailsDehydrogenationPetrochemical

The invention provides a butadiene preparing method and relates to the technical field of organic chemistry. Butadiene is prepared based on combination of preparation of acetylene from calcium carbideand liquefied petroleum gas dehydrogenation. Firstly, acetylene is prepared from calcium carbide as the raw material; then vinyl acetylene is prepared from acetylene as the raw material; hydrogen isgenerated from liquefied petroleum gas as a hydrogen source through a dehydrogenation reaction; the generated hydrogen is separated out and introduced into vinyl acetylene for a mixed reaction, and butadiene is generated, so that hydrogen generated from the liquefied petroleum gas is consumed away; meanwhile, butadiene generated in the dehydrogenized liquefied petroleum gas is separated out by a dimethylformamide extracting solvent. The butadiene preparing method is low in cost and high in reaction efficiency, the existing route for preparing butadiene on the basis of extraction of ethylene cracking byproduct C4 and dehydrogenation of C4 alkane or alkene currently is broken, a novel route is provided for industrial production of butadiene, and a key technology is provided for fusion of traditional acetylene chemical engineering (coal chemical engineering) and petrochemical engineering.

Owner:李瑞雪 +1

PMIDA wastewater treatment method

InactiveCN101746910AAchieve recyclingMeeting water needsAcetylene gas generator detailsMultistage water/sewage treatmentProduction lineGeneration process

The invention discloses a PMIDA wastewater treatment method, wherein PMIDA wastewater washing, drying, press filtration, catalyst pretreatment, wet acetylene reaction and treatment of carbide slurry produced after the reaction are comprised. The method treats and sends the PMIDA wastewater produced in the condensation section reaction in a glyphosate production process to an acetylene section of a resin production line, takes the wastewater as wet acetylene production water, and simultaneously, adjusts an acetylene generation process, thereby realizing the recycling of water resource and the zero emission of the PMIDA wastewater, reducing the environment protection pressure, and meeting the national policies of energy saving and emission reduction.

Owner:安徽锦邦化工股份有限公司

Coal gasification with additional production of useful materials

InactiveCN102361961AImprove economic efficiencyEfficient use ofAcetylene gas generator detailsGasification processes detailsCarbideBoron carbide

The present invention relates to a process for the gasification of carbon-containing compounds, characterized in that compounds are added which form carbides under the process conditions. These carbides can be used for the synthesis of useful materials such as for example acetylene.

Owner:LP AMINA

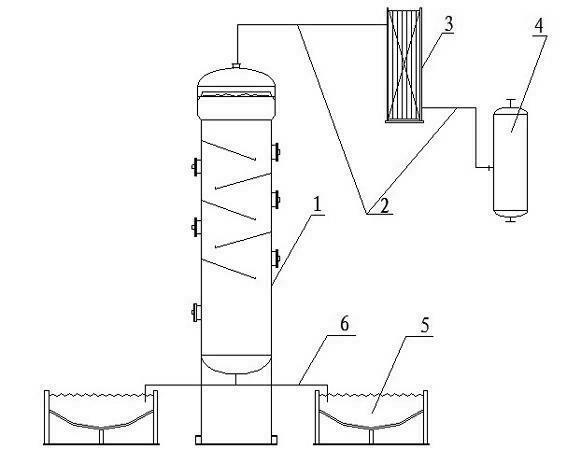

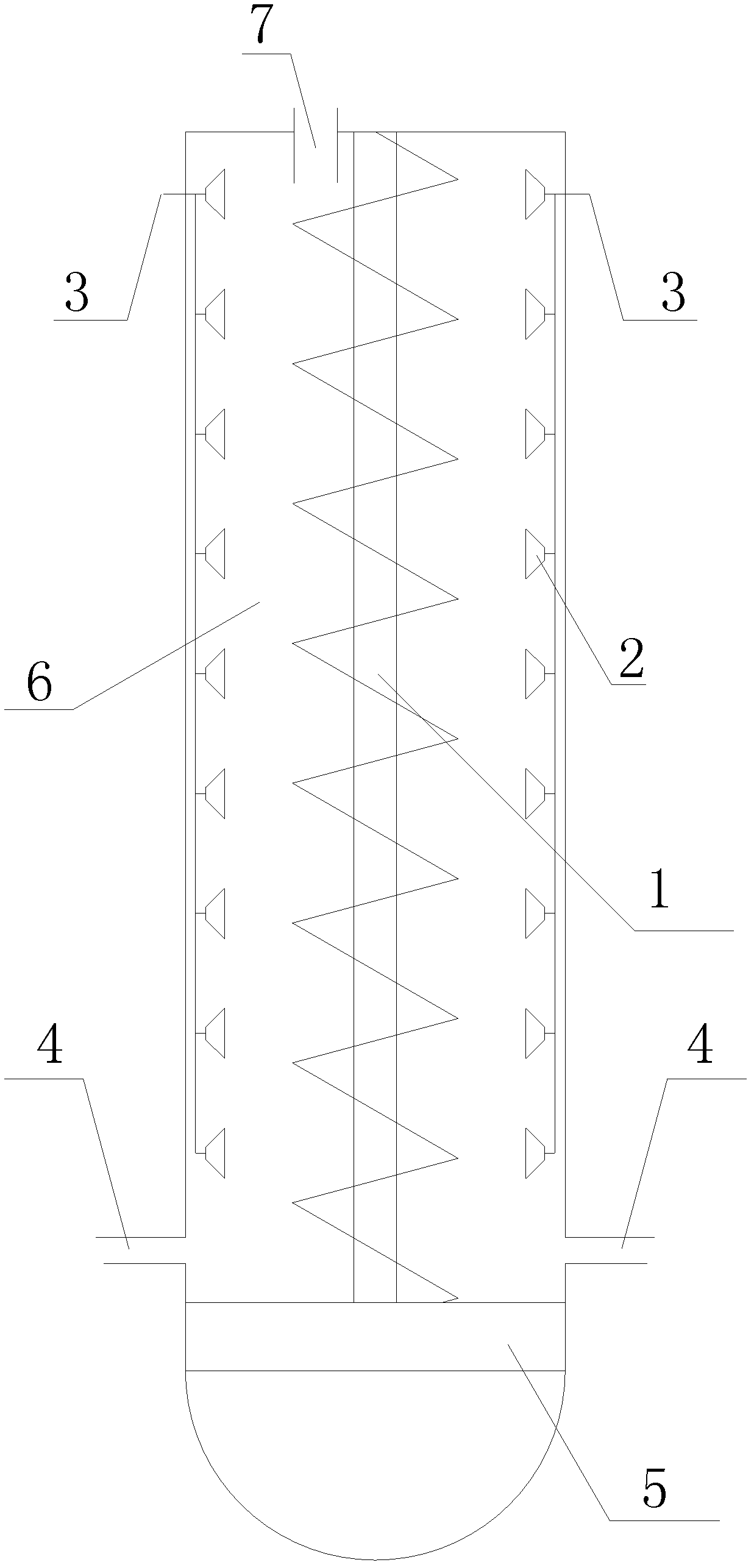

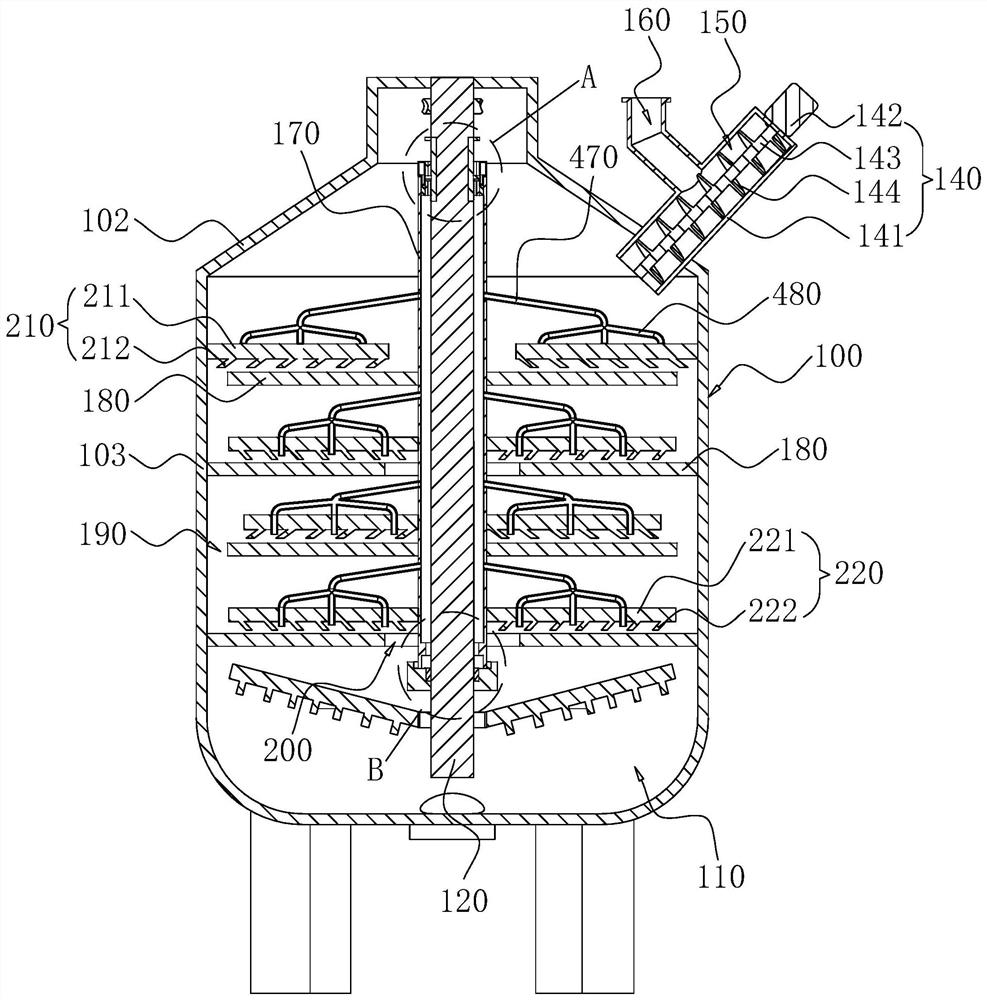

Acetylene generator

The invention relates to an acetylene generator. The acetylene generator comprises a cylinder body, the cylinder body has a circular cylindrical shape, the axis of the cylinder body is provided with a center column, the center column is cylindrical in shape, the outer wall of the center column is provided with a plurality of fan-shaped conveyor belts vertical to the axial direction of the center column, the fan-shaped conveyor belts are spirally arranged on the outer wall of the center column, the output end of the above fan-shaped conveyor belt in every two adjacent fan-shaped conveyor belts corresponds to a position above the input end of the lower fan-shaped conveyor belt, a residue discharge opening is arranged under the output end of the bottom fan-shaped conveyor belt, the inner lateral part of the cylinder body is provided with water mist spraying nozzles, and the water mist spraying nozzles align at the fan-shaped conveyor belts. The fan-shaped conveyor belts are spirally arranged along the central line in the cylinder body, calcium carbide powder continuously falls to the below conveyor belts from the top conveyor belt to generate flying calcium carbide powder, water mist spraying is carried out from positions above the conveyor belts and the lateral sides of the conveyor belts, and reacted calcium carbide powder and water mist are discharged from the bottom residue discharge opening, so no wastewater is generated, and environmental protection is realized.

Owner:宁波市北仑欧绿乙炔制造有限公司

Fast-reaction acetylene generator

The invention relates to a fast-reaction acetylene generator. The main body of the generator is in a vertical cylindrical shape. A vertical stirring shaft is arranged inside the main body of the generator. A plurality of water distributors are distributed on the inner wall of the main body of the generator. The water distributors are communicated with water inlets. An air hole is formed in the top portion of the main body of the generator. Calcium carbide feed inlets are arranged in the lateral walls of the bottom portion of the main body of the generator. The calcium carbide feed inlets are located above a rolling shaft. The rolling shaft is horizontally arranged inside the main body of the generator. Compared with the prior art, due to the fact that a stirring device is arranged in the generator and stirring vanes on the stirring device are capable of dispersing inlet water on the lateral walls, the water is enabled to be completely reacted with calcium carbide on the bottom of the generator, water and materials are saved, and the rolling shaft on the bottom of the main body of the generator can enable the calcium carbide to fully contact and react with the water.

Owner:XIAN JIAOTONG UNIV JINGSHENG SCI & TECH DEV

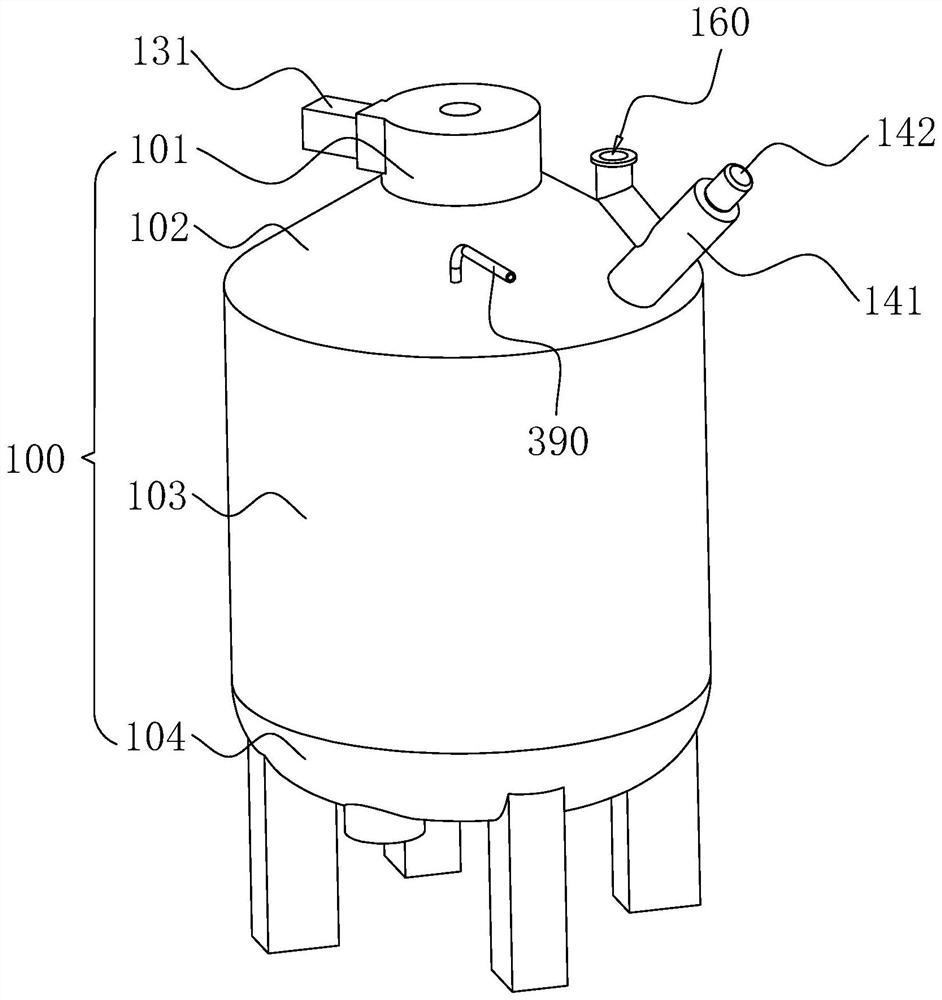

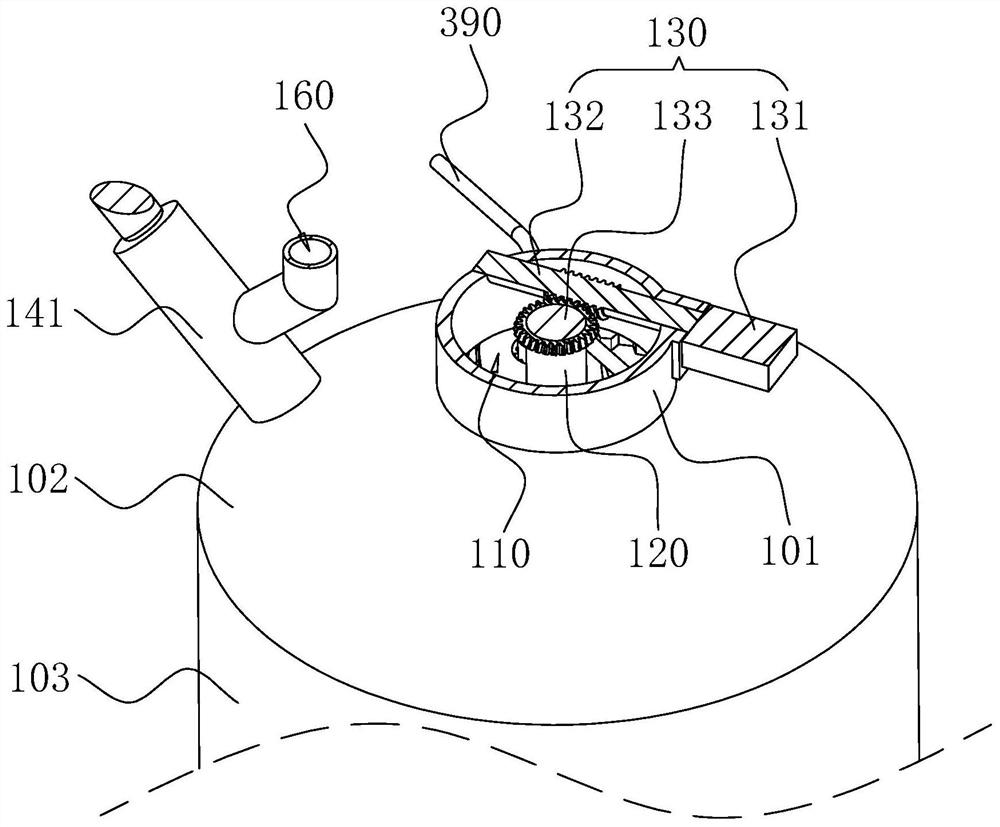

Acetylene production process

ActiveCN113214868ASpray evenlyRealize transportationAcetylene gas generator detailsPhysical chemistryWater spray

The invention relates to an acetylene production process, and relates to the technical field of acetylene production equipment. The acetylene production process comprises the following process steps: S1, raw material treatment; S2, charging; S3, reaction; S4, cooling and impurity removal; and S5, drying and collecting. The acetylene generator comprises a generator body and a spraying device installed in the generator body, a reaction cavity is formed in the generator body, a stirring shaft is rotationally installed on the generator body, a material disc is installed on the stirring shaft in the axial direction, a connecting pipe is arranged on the stirring shaft, and an installation assembly is arranged between the connecting pipe and the stirring shaft. The spraying device comprises a water inlet assembly, a sealing assembly and water spraying assemblies, and the water spraying assemblies are located above the material trays respectively. Through the arrangement of the installation assembly and the spraying device, water can be uniformly sprayed to each material tray, so that calcium carbide raw materials on each layer of material tray can be in full contact with the water and react with the water, the reaction degree between the calcium carbide raw materials and the water is improved, and the yield of acetylene products is further improved.

Owner:宁波市北仑欧绿乙炔制造有限公司

Method for preparing acetylene by utilization of calcium carbide powder

InactiveCN105694973AHigh puritySimple processAcetylene gas generator detailsGenerators with carbide submersionHydrogenHydrogen phosphide

The invention relates to a method for preparing acetylene by the utilization of calcium carbide powder. the method comprises the following steps: (1) pouring calcium carbide powder into an acetylene generator, and reacting between the calcium carbide powder and water at 76-78 DEG C to generate crude acetylene and calcium carbide residue; (2) cooling the crude acetylene, letting the cooled crude acetylene enter a concentrated sulfuric acid cleaning tower to remove hydrogen sulfide, hydrogen phosphide and arsenide hydrogen, neutralizing with alkali lye by entering a neutralizing tower, and removing acid gas in the crude acetylene; drying with calcium chloride by entering a dryer, removing part of moisture in acetylene, and carrying out oil-water separation by sending into an oil-water separator; and finally removing oil and moisture so as to obtain pure acetylene. The method has simple process, is easy to operate and is low-cost. Purity of acetylene can reach 99.99%. Thus, the problem of low purity of acetylene is solved. The method of the invention has a good application prospect.

Owner:宁波市北仑欧绿乙炔制造有限公司

Method for preparing barium carbide and producing acetylene

ActiveCN114057194AProcess reaction conditions are mildSimple processAcetylene gas generator detailsCarbon monoxidePhysical chemistryCarbide

The invention discloses a method for preparing barium carbide and producing acetylene. The method includes steps of: mixing a carbon raw material and a barium raw material in proportion to prepare a powdery material; placing the treated mixed material in a high-temperature furnace and heating the material to 1300-1650 DEG C in a non-oxygen atmosphere to react for 0.5-4 hours to obtain a barium carbide product, the mass percentage content of barium carbide in the product being not lower than 60%; and further feeding the prepared barium carbide into an acetylene generator to react with water to obtain acetylene gas. According to the method, barium carbide is adopted to replace calcium carbide to prepare acetylene, barium carbide with high content can be prepared under milder conditions, and acetylene can be directly generated through gas generation with water without complex procedures such as liquid-phase carbide cooling, demolding and crushing in the later period. Compared with a calcium carbide acetylene process, the barium carbide acetylene process is mild in reaction condition and simple in process, energy consumption and emission can be reduced, and the purposes of energy conservation, consumption reduction and environment-friendly acetylene production are achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

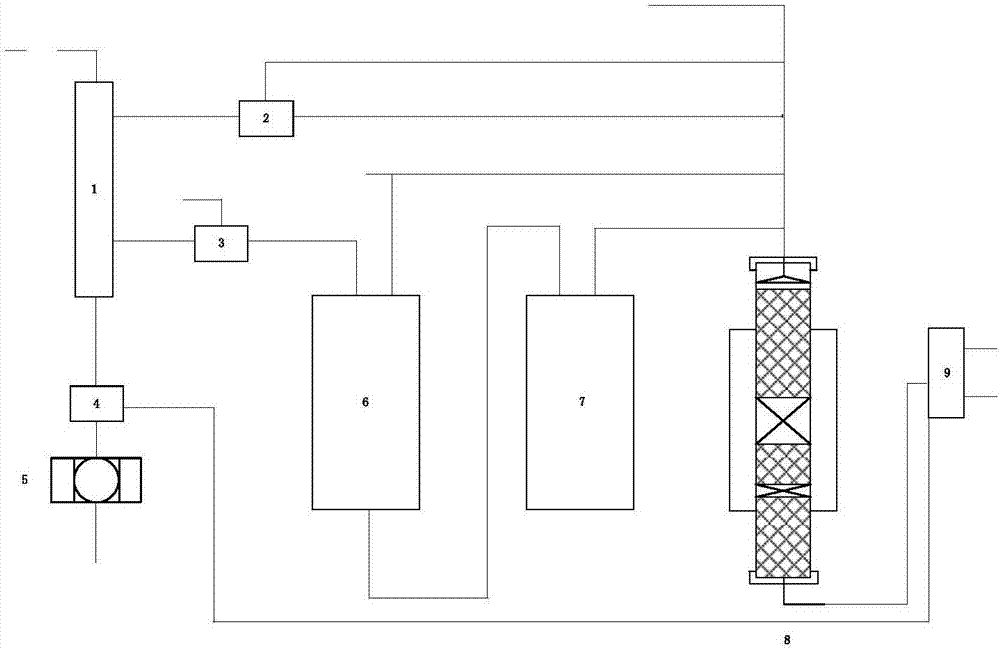

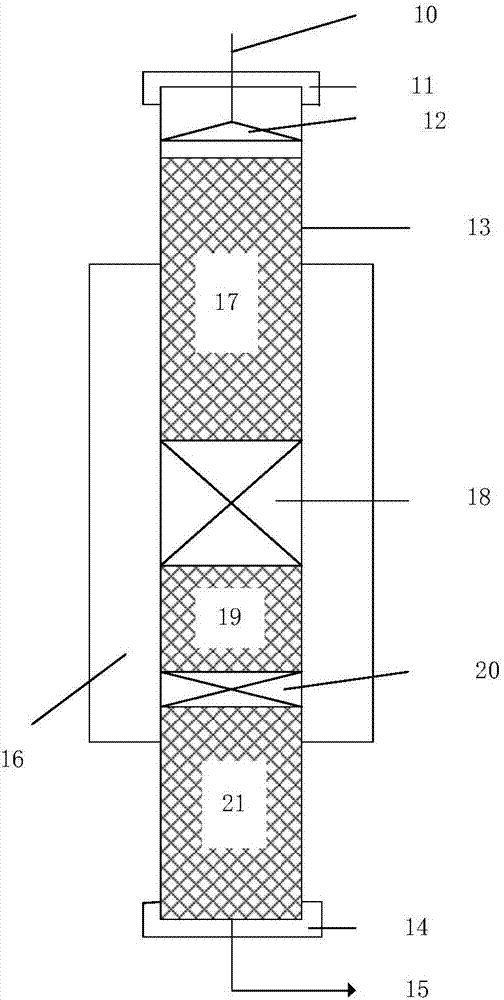

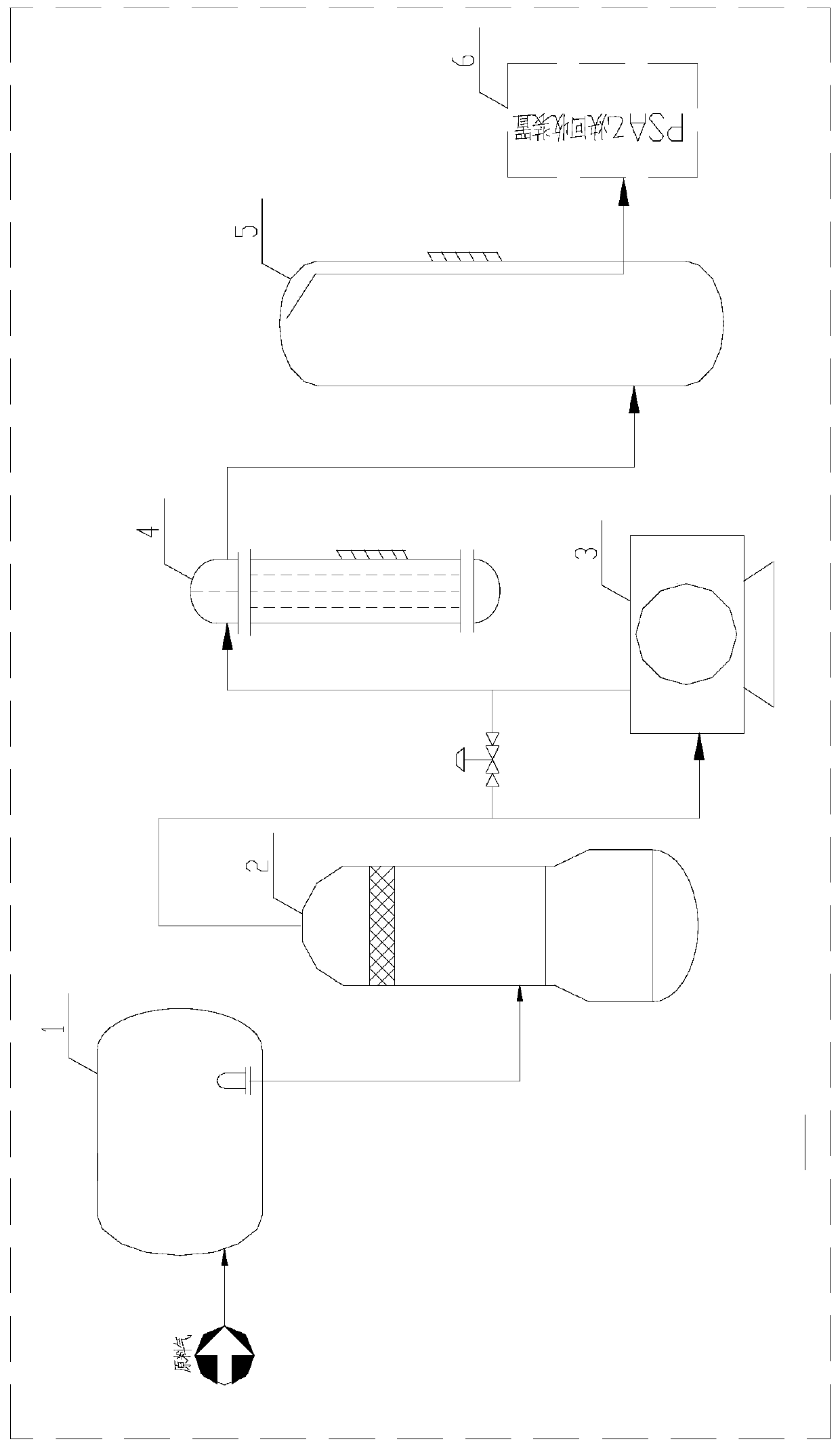

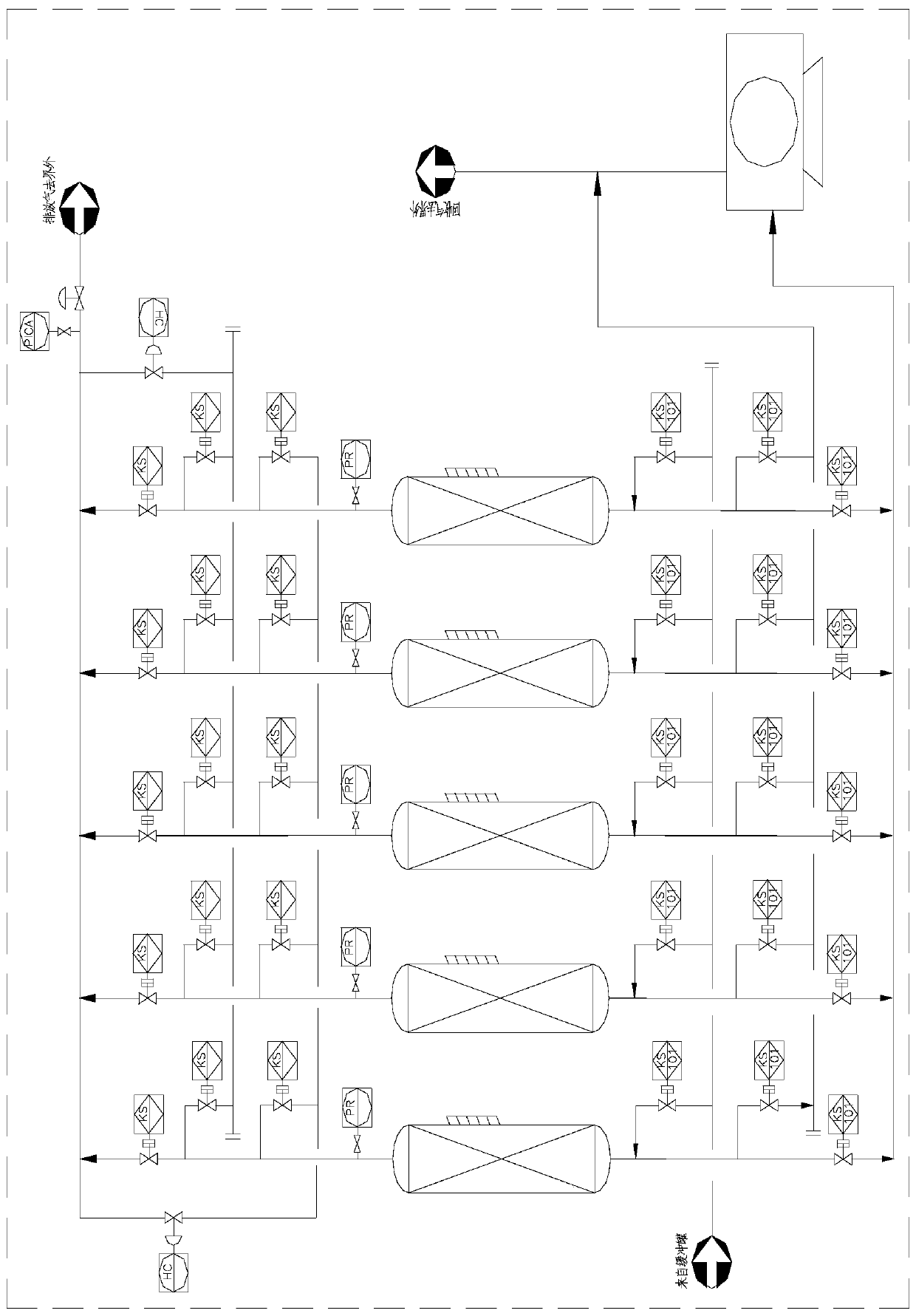

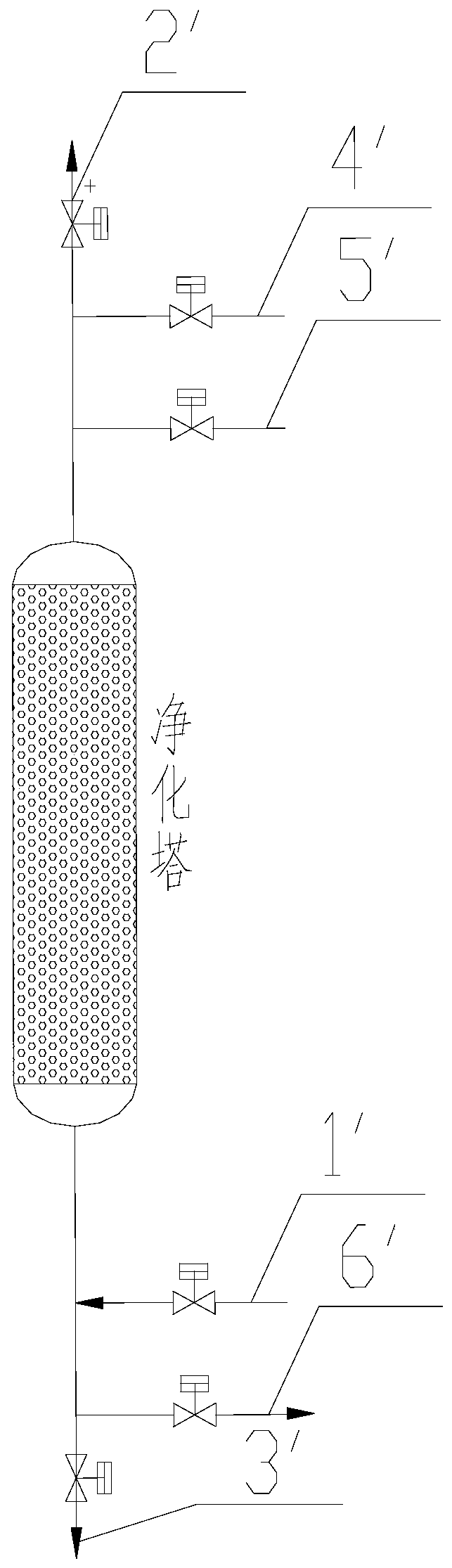

Method and device for recovering acetylene from displacement exhaust gas of acetylene generator

InactiveCN110548366AReduce manufacturing costHigh degree of automationHuman health protectionMethane captureDesorptionEngineering

The invention belongs to the technical field of chemical gas treatment, and specifically relates to a method and device for recovering acetylene from displacement exhaust gas of an acetylene generator. The method comprises the following steps: introducing the displacement exhaust gas of the acetylene generator into a gas storage device for buffering and dust falling, then removing dust through a dust remover, performing pressurization through a compressor, buffering the pressurized exhaust gas in a raw gas buffering tank, introducing the pre-treated exhaust gas into a purification tower for recover acetylene gas in the pre-treated exhaust gas, and performing pumping desorption on the acetylene gas from the bottom of the purification tower through a vacuum pump for recycling after treatmentthrough the purification tower. The recovery rate of the effective component acetylene in the displacement exhaust gas of the acetylene generator in a PVC plant can reach 99.9%, and the content of non-methane total hydrocarbons in the exhaust gas is 20 mg / m<3> or below; and the device and process are safe and reliable, the operation cost is low, and the device and process can be widely applied tothe PVC industry, so that the purposes of low-cost recovery of acetylene and reduction of environmental pollution are achieved.

Owner:四川开元科技有限责任公司

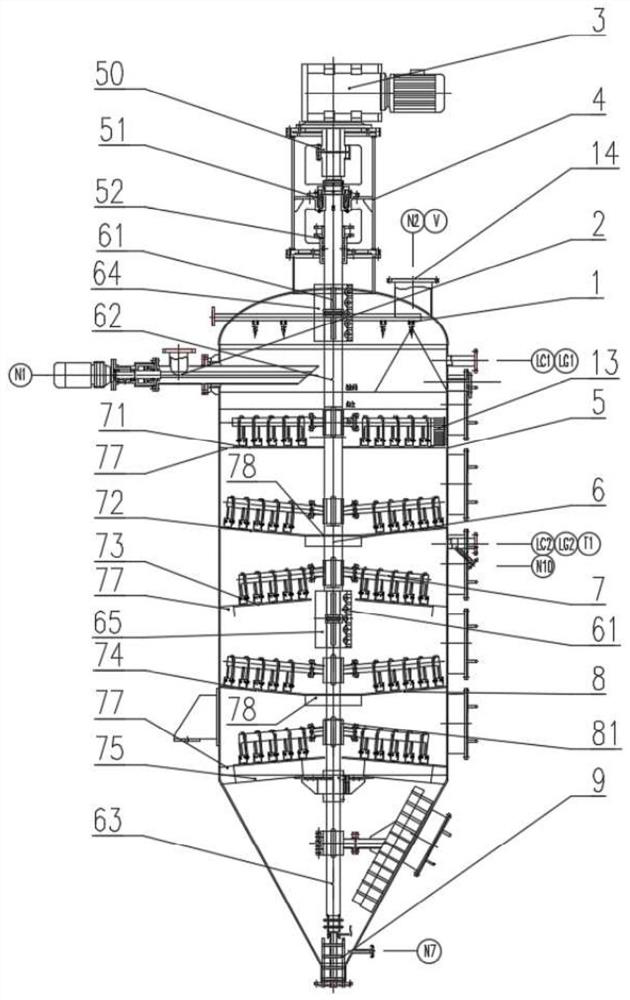

Acetylene generator

PendingCN111808637ASimple structureSmooth feedingAcetylene gas generator detailsDrive shaftEngineering

The invention provides an acetylene generator, and relates to the field of acetylene generation equipment. The acetylene generator comprises a generator cylinder body and is mainly composed of the generator cylinder, a connecting rack, a stirring driving device, a driving shaft, a first material guide disc, a second material guide disc, a third material guide disc, a fourth material guide disc anda fifth material guide disc, the first material guide disc, the second material guide disc, the third material guide disc, the fourth material guide disc and the fifth material guide disc are orderlyconnected to the generator cylinder body from top to bottom, the generator cylinder is vertically arranged, a sealing feeder is arranged on one side of the generator cylinder, a flaring feeding modeis adopted, and a nozzle device is arranged at the top of the generator cylinder and located above the first material guide disc. The acetylene generator has the advantages of being simple in structure, capable of achieving continuous feeding, small in water consumption, high in acetylene yield and the like, meanwhile, the six layers of guide arms are arranged, so that raw materials react sufficiently, and the utilization rate of the raw materials is high.

Owner:北京瑞思达化工设备有限公司

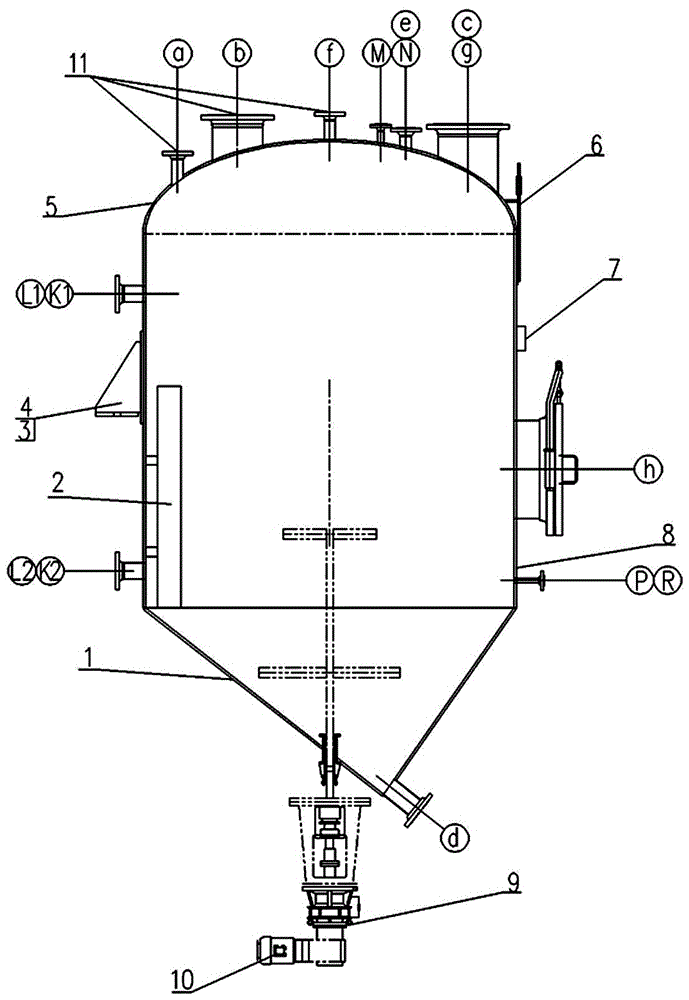

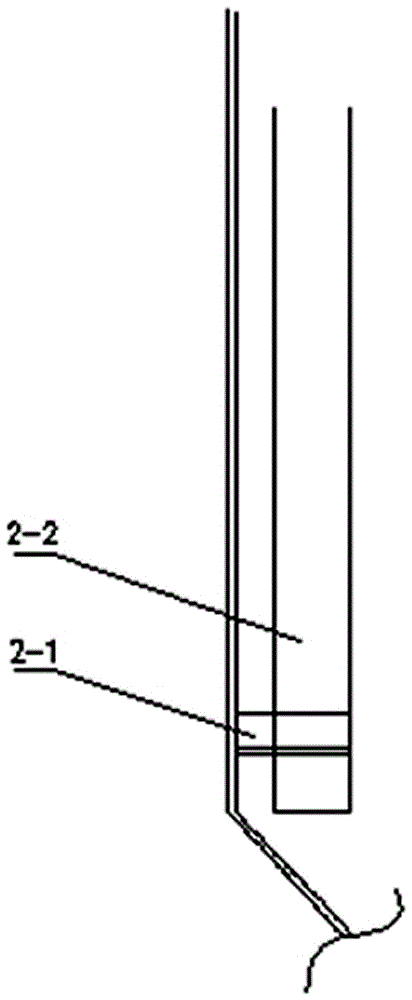

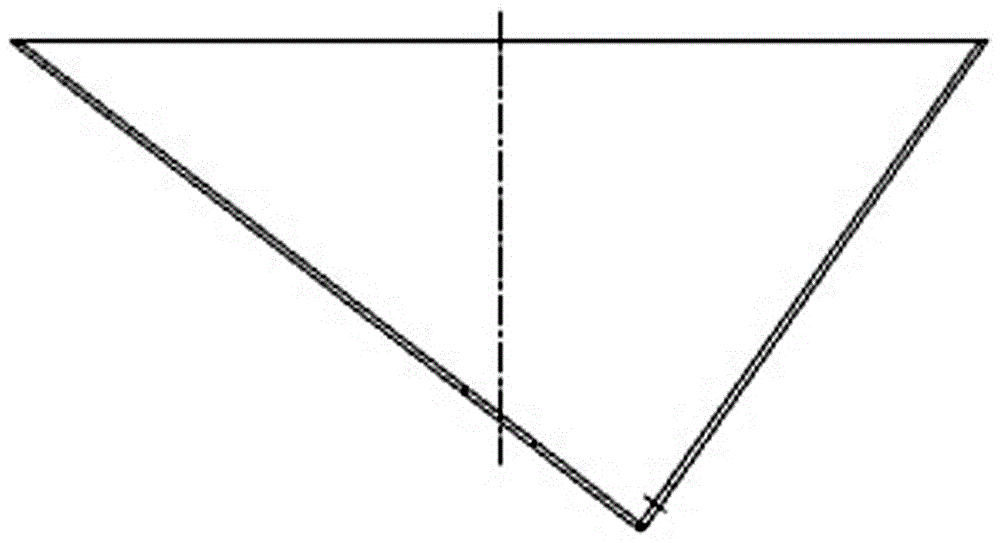

Acetylene gas generator taking calcium carbide dust as raw material

ActiveCN105885943AImprove protectionReduce pollutionAcetylene gas generator detailsGenerators with carbide submersionSlag (welding)Engineering

The invention relates to the technical field of crushing and dust treatment of calcium carbide and in particular relates to an acetylene gas generator taking calcium carbide dust as a raw material. The acetylene gas generator is formed through welding and connecting a barrel body, an upper end socket and a lower tapered shell, wherein the barrel body is internally provided with a stirring device and a baffle; the upper end socket is provided with a slag slurry circulating pipe connector, a calcium carbide dust inlet, an acetylene gas outlet, a nitrogen gas inlet, an exhausting hole, an explosion-proof hole, a teletransmission pressure gauge hole, a field pressure gauge hole, a pipe-connection short pipe and a flange; a lug type support and a support base plate are fixed on the outer wall of the barrel body and a manhole is further formed in the outer wall of the barrel body; a field liquid level meter hole, a field liquid level meter hole, a teletransmission liquid level meter hole, another teletransmission liquid level meter hole, a teletransmission thermometer hole and a field thermometer hole are further formed in the outer wall of the barrel body; the section of the lower tapered shell is an oblique triangle; a stirring shaft of the stirring device stretches into the barrel body through a central hole in a long oblique edge at the bottom of the lower tapered shell; a slag slurry outlet is formed in a short oblique edge of the lower tapered shell. By adopting the acetylene gas generator, environment protection is facilitated. The utilization rate of a chemical raw material, namely the calcium carbide, is effectively improved.

Owner:中盐吉兰泰氯碱化工有限公司 +3

Calcium carbide preparing and feeding automatic control method of acetylene generator

InactiveCN103642528BAvoid displacement overpressureIncrease the level of automationAcetylene gas generator detailsTotal factory controlMaterials preparationAutomatic control

Owner:甘肃银光聚银化工有限公司

A treatment system and treatment method for rectification high boiling raffinate in the production of vinyl chloride by calcium carbide method

ActiveCN107311835BSolve the pollution of the environmentRealize resource reusePreparation by hydrogen halide split-offAcetylene gas generator detailsWater chlorinationPhysical chemistry

The invention discloses a system and method for treating a high boiling residuary solution in chloroethylene produced by adopting a calcium carbide method. The treatment system comprises a first working section including an acetylene generator (11), an acetylene purifying tower (12), a mixing device (13), a chloroethylene converter (14), a chloroethylene low-boiling tower (15) and a chloroethylene high-boiling tower (16) which are connected in sequence, a second working section including a low-temperature chlorination reactor (21), a wet coarse dichloroethane storage tank (22), a drying tower (23), a high-temperature chlorination reactor (24), a dichloroethane high-boiling tower (25), a vacuum tower (26), a dichloroethane storage tank (27) and a dichloroethane vaporizer (28), a third working section including a cracking furnace (31), a by-product steam heat exchanger (32), a quench tower (33), a hydrogen chloride tower (34) and a chloroethylene tower (35) which are connected in sequence, wherein the low-temperature chlorination reactor (21), the wet coarse dichloroethane storage tank (22) and the drying tower (23) are connected in sequence, the high-temperature chlorination reactor (24), the dichloroethane high-boiling tower (25), the vacuum tower (26), the dichloroethane storage tank (27) and the dichloroethane vaporizer (28) are connected in sequence, and the chloroethylene high-boiling tower (16) is connected with the wet coarse dichloroethane storage tank (22).

Owner:QINGHAI SALT LAKE IND

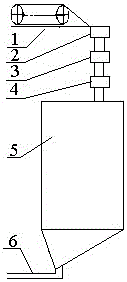

Calcium carbide lifting hopper

InactiveCN108439176AQuick dockingThe docking process is gentleAcetylene gas generator detailsLoad-engaging elementsButterfly valveMaterials science

The invention provides a calcium carbide lifting hopper, and belongs to the technical field of acetylene preparation equipment. In order to solve the problem that in the prior art, the abutting jointbetween a lifting hopper and a calcium carbide feeding hopper is difficult, the calcium carbide lifting hopper is provided. On the basis of the following scheme, the calcium carbide lifting hopper comprises a cylindrical hopper body. A funnel-shaped material falling portion is arranged on the lower portion of the hopper body, a feeding inlet is formed in the upper portion of the hopper body, a material falling opening with a butterfly valve is formed in the bottom of the material falling portion, and at least three lifting portions are arranged on the upper portion of the hopper body and closely attached to the outer wall face. A high-strength cloth cylinder is fixedly connected with the lower portion of the material falling opening, and a first annular permanent magnet is fixedly connected with the tail end of the high-strength cloth cylinder. The calcium carbide lifting hopper further comprises auxiliary parts, wherein the auxiliary parts are fixedly arranged in a feeding inlet of the calcium carbide feeding hopper. The auxiliary parts comprise a second annular permanent magnet and pneumatic fasteners, wherein the second annular permanent magnet is fixedly arranged in the feedinginlet of the calcium carbide feeding hopper, and the pneumatic fasteners are used for fastening the first annular permanent magnet and the second annular permanent magnet. The pneumatic fasteners areconnected with air cylinders, the air cylinders are fixedly arranged on the periphery of the feeding inlet of the calcium carbide feeding hopper, and therefore the problem is solved.

Owner:CHIZHOU SENDA LIGHT IND PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com