Calcium carbide lifting hopper

A calcium carbide and hanging bucket technology, which is applied in the petroleum industry, load suspension components, acetylene generators, etc., can solve the problems of low precision, time-consuming, unstable control, etc., and achieve the effect of soft and fast docking in the docking process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

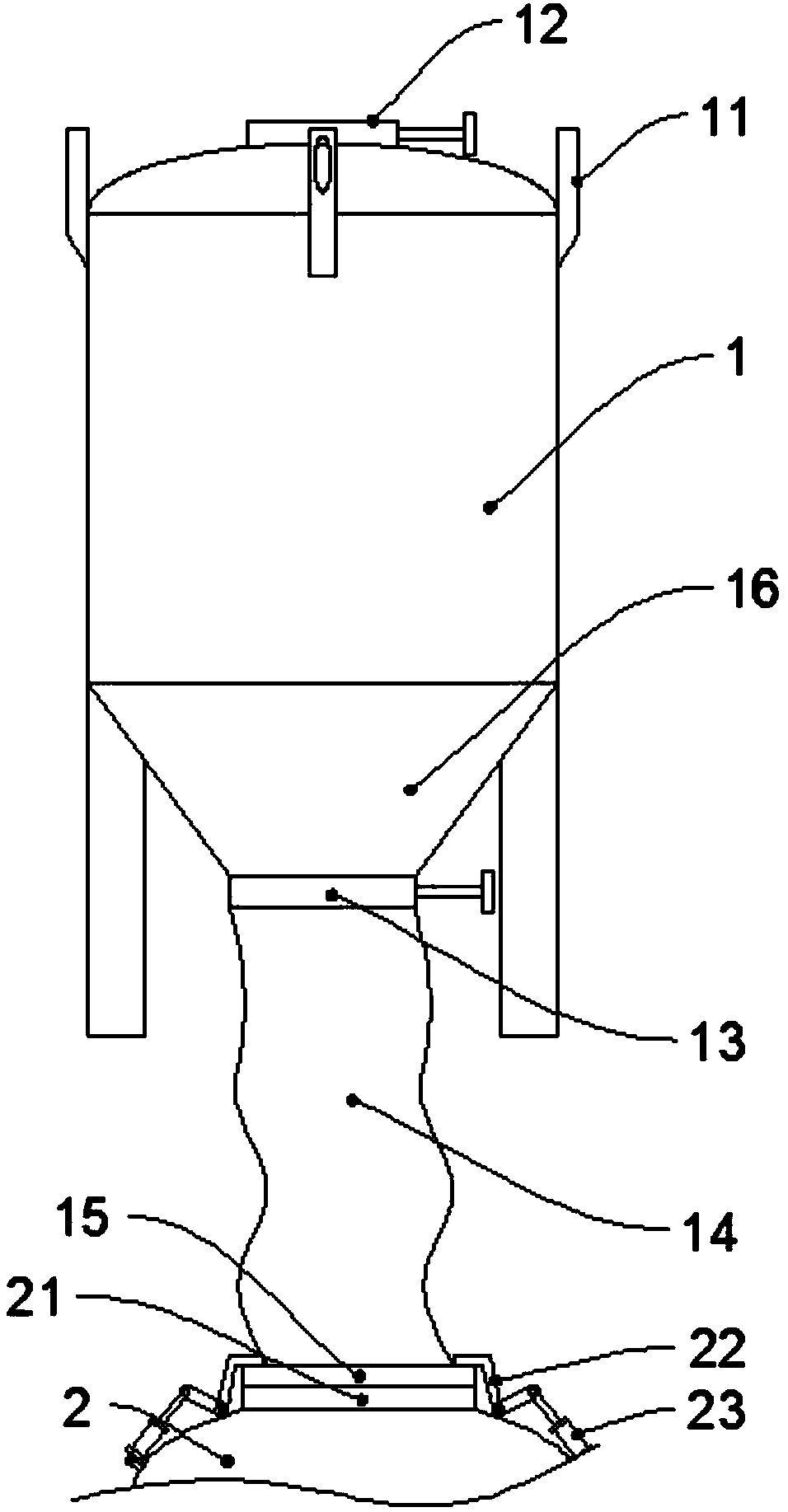

[0012] Such as figure 1 The shown calcium carbide bucket includes a cylindrical bucket body 1, the lower part of the bucket body 1 is a funnel-shaped blanking part 16, the upper part of the bucket body 1 is provided with a feeding port 12, and the bottom of the blanking part 16 is provided with a butterfly valve. The blanking port 13, the upper part of the bucket body 1 is closely attached to the outer wall surface and at least three sets of lifting parts 11 are arranged; the lower part of the blanking port 13 is fixedly connected to the high-strength cloth tube 14, and the end of the high-strength cloth tube 14 is fixedly connected to the first annular permanent Magnet 15; said a kind of calcium carbide bucket also includes ancillary fittings fixed on the calcium carbide hopper 2 inlet, including the second annular permanent magnet 21 fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com