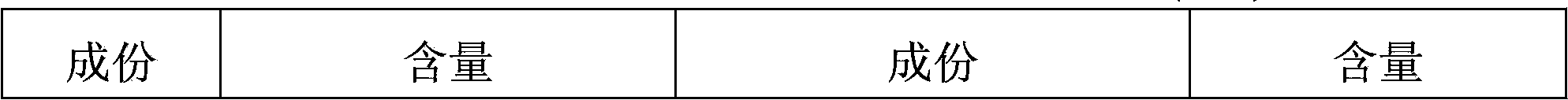

Patents

Literature

245 results about "Hydrogen phosphide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphine (PH3), also called hydrogen phosphide, a colourless, flammable, extremely toxic gas with a disagreeable garliclike odour. Phosphine is formed by the action of a strong base or hot water on white phosphorus or by the reaction of water with calcium phosphide (Ca3P2).

Preparation method of indium phosphide quantum dots

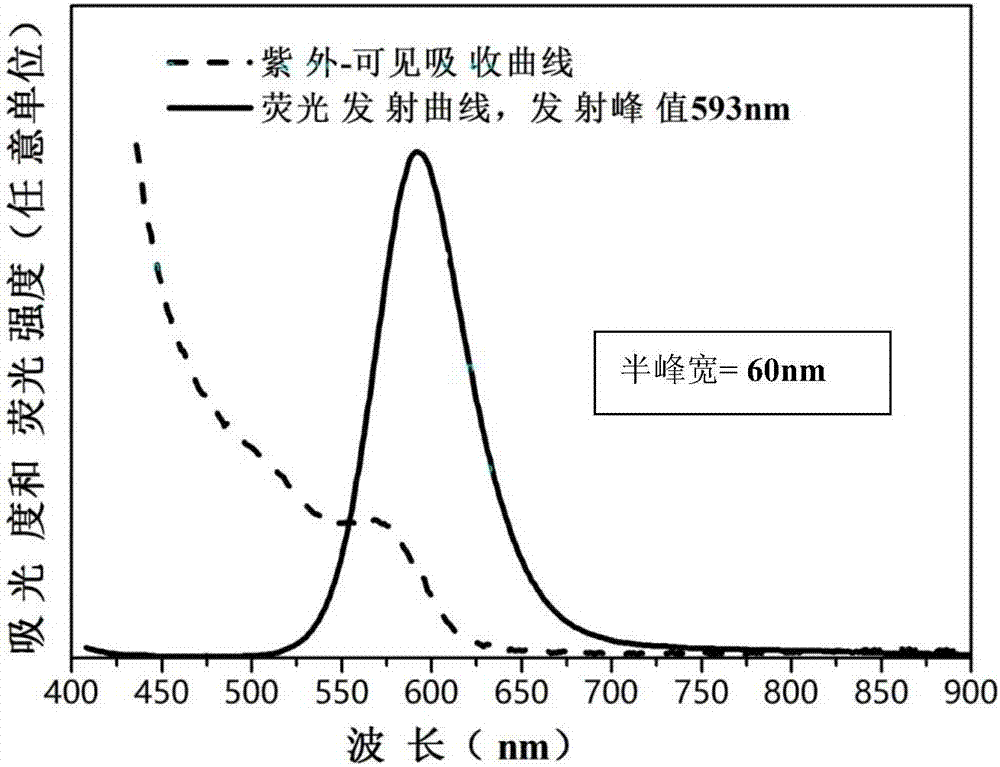

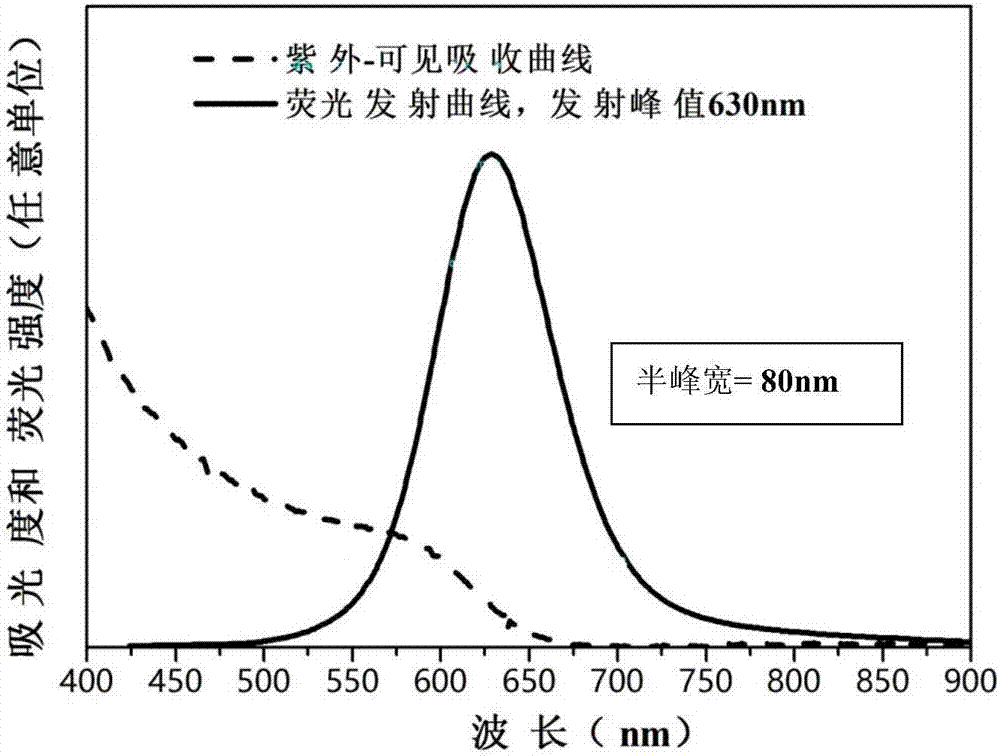

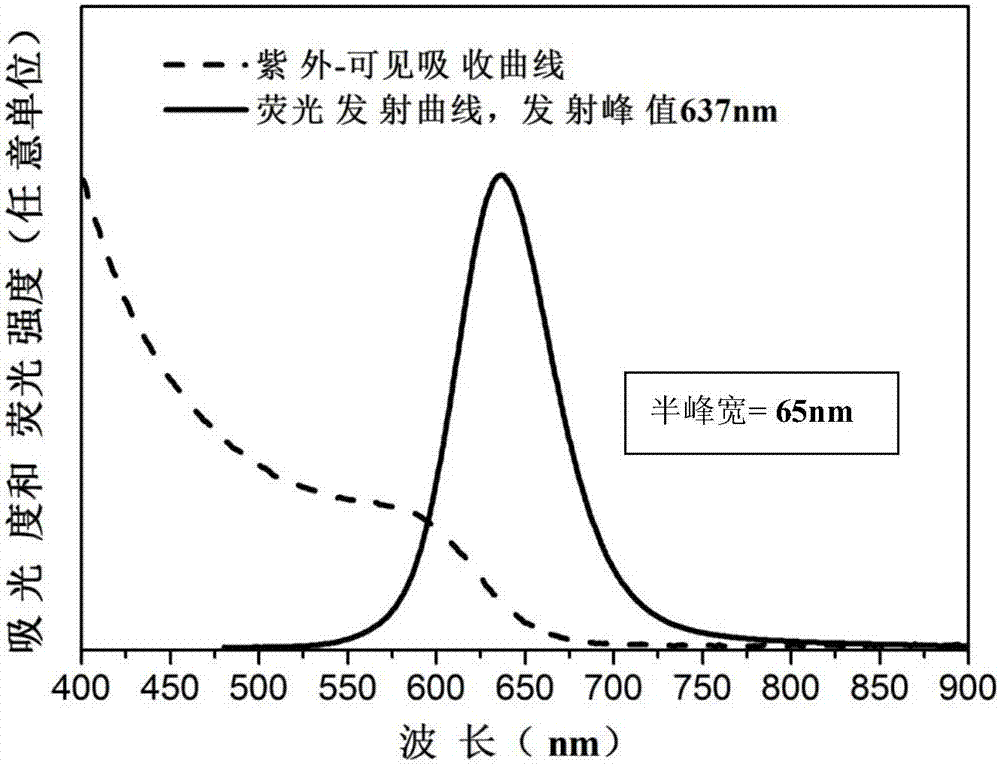

InactiveCN107098324AUniform size distributionGood optical performanceLuminescent compositionsPhosphidesIndiumSurface oxidation

The invention provides a preparation method of indium phosphide quantum dots. The preparation method comprises the following steps: firstly mixing an indium precursor, an acid ligand and a non-coordinating solvent and preparing a uniform indium precursor solution; then adding hydrogen phosphide at a temperature of 100-130 DEG C, raising the temperature to a second temperature and keeping for a period of time; finally regulating the solution to a third temperature and adding a precursor substance required by a synthetic shell to obtain the shell-coated indium phosphide quantum dots. The indium phosphide quantum dots with nuclear shell structures are synthesized by adopting the method of low-temperature nucleating, raised temperature-curing and high-temperature shell-coating; the nucleation and growth processes of indium phosphide nano crystalline nucleuses can be controlled at a low temperature, so that the synthesized quantum dots are uniform in size distribution; meanwhile, the risk of surface oxidation of the indium phosphide nano crystalline nucleuses can also be effectively avoided at a low temperature, so that the optical performance of the indium phosphide quantum dots are improved to a certain degree.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

A mechanically regulated, green and environmentally friendly storage method for sheet tobacco

InactiveCN102282982AEasy to buildBuild scienceTobacco preparationAgriculture tools and machinesHydrogen phosphideDeoxidization

The invention relates to a mechanical control and environmental-protection method for storing tobacco flakes, which is characterized by comprising the following steps: 1. constructing a tobacco leaf pile sealing space which is sealed in six surfaces and is capable of mechanically controlling a storage environment; 2. carrying out one-time thorough gas fumigation control: adopting any one or the combination of more than one of the following four methods to realize the fumigation control on insect and mildew damage to tobacco leaf piles: (1) hydrogen phosphide conventional fumigation control, (2) carbon dioxide gas fumigation control, (3) nitrogen-filled modified fumigation control and (4) iron powder deoxidant-applied deoxidization fumigation control; 3. carrying out emission or filter purification on fumigation gas after the fumigation control is finished; and 4. carrying out manual and mechanical control to discharge accumulated heat and damp in a plastic sealing tent. The method hasthe characteristics of low cost, mechanical control and environmental protection.

Owner:李翊玮

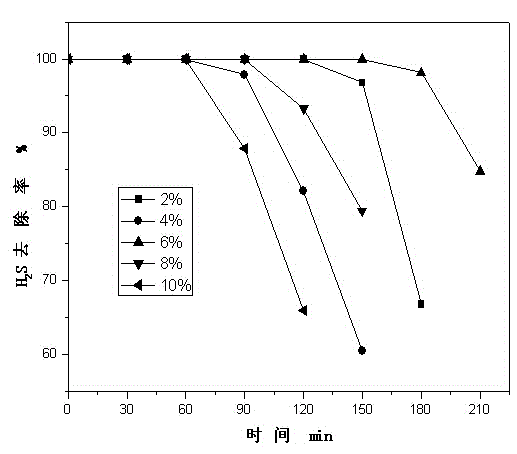

Preparation method of adsorbent for purifying hydrogen sulfide, hydrogen phosphide and arsenic hydride simultaneously

ActiveCN105233806ALarge specific surface areaGood hydrothermal stabilityOther chemical processesDispersed particle separationDesorptionSorbent

The invention relates to a preparation method of an adsorbent for purifying hydrogen sulfide, hydrogen phosphide and arsenic hydride simultaneously, and belongs to the technical field of adsorbent preparation. The method comprises the steps that P123 or F127 is dissolved in a dilute acid solution and stirred till being dissolved, a certain number of pore-enlarging agents are added, stirring and even mixing are carried out, ethyl orthosilicate is added, the mixture is poured into a reaction kettle after being stirred for 1-6 h, powder obtained after crystallization is washed with distilled water till the color of test paper is not changed, the dry powder obtained after drying is placed into a roaster to be roasted, temperature is naturally decreased to indoor temperature, an adsorbent carrier is obtained, the obtained carrier is dissolved in water, a certain amount of metal salt is added, filtering, drying and roasting are carried out, and then the large-aperture adsorbent is obtained. The preparation method is easy to implement, the metal salt impregnant is low in cost and easy to obtain, the desorption effect is good even at low temperature, and a wide development prospect is provided for simultaneous desulfurization, dephosphorization and dearsenization through a dry method.

Owner:KUNMING UNIV OF SCI & TECH

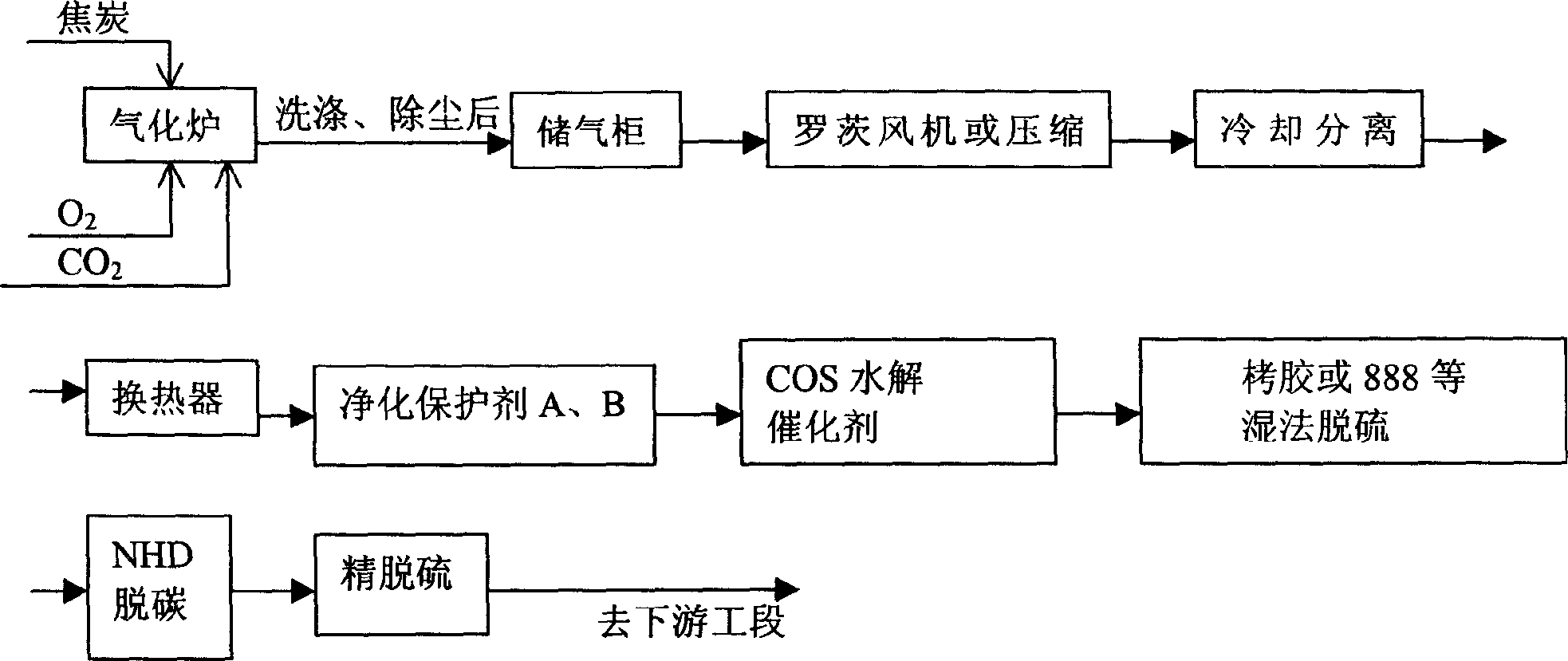

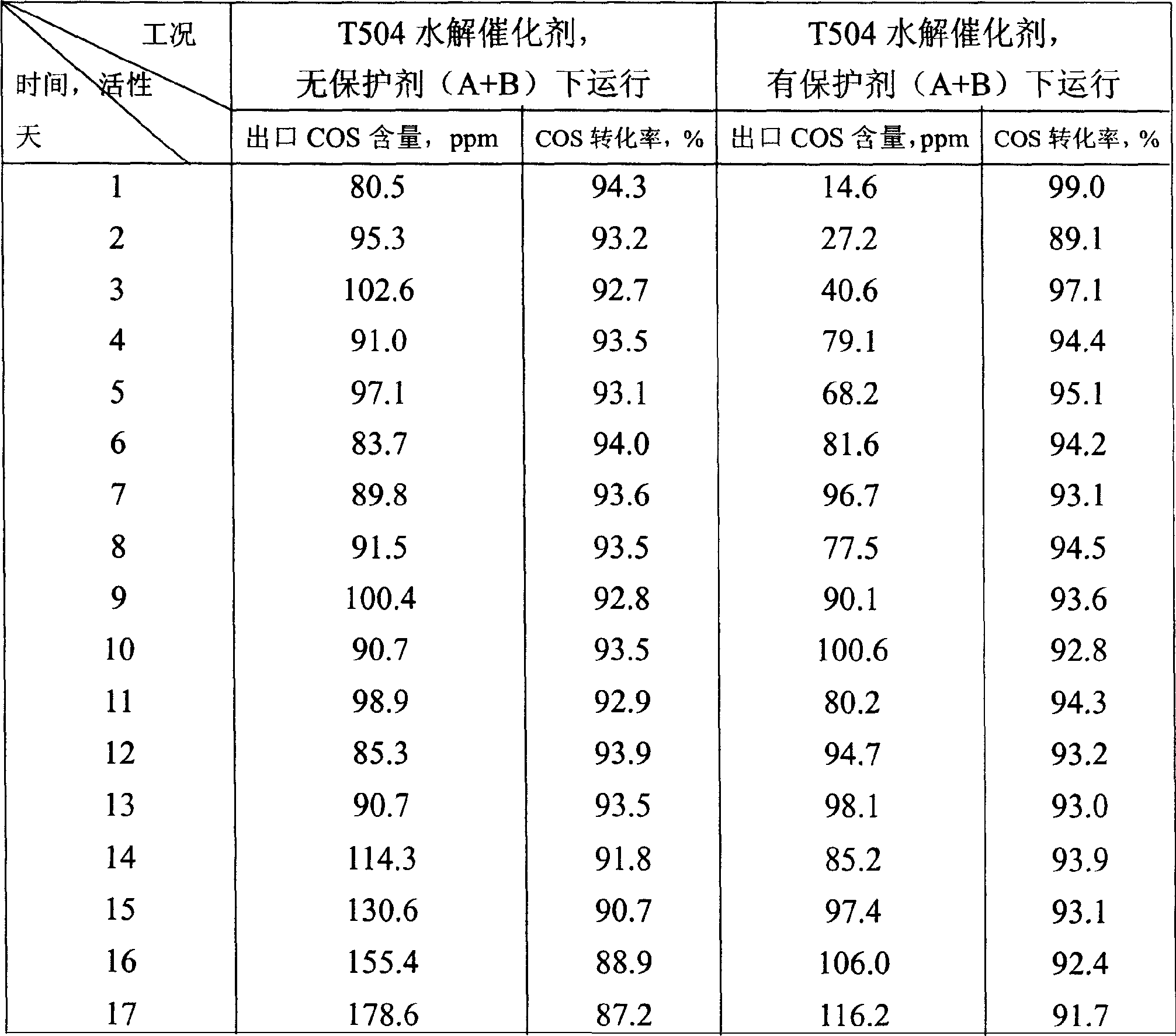

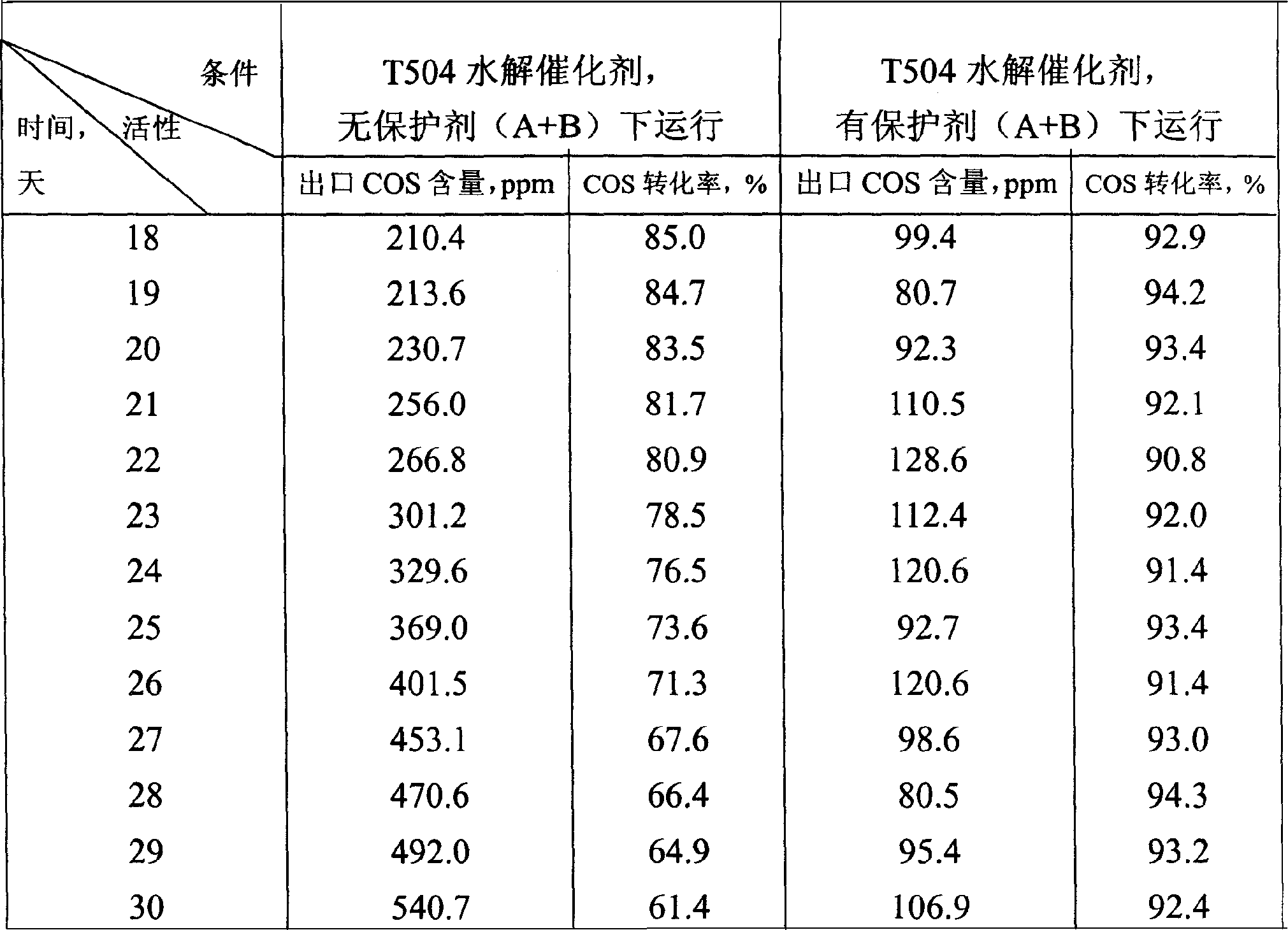

Process for preparing high purity carbon monoxide gas by desulfurization of organic sulfur at low and normal temperature

ActiveCN1844326AAchieve recyclingImprove and protect the ecological environmentCombustible gas purificationPoly(ethylene glycol) dimethyl etherDesorption

The invention relates to a technology for removing organic sulfur at a low or normal temperature to prepare high-purity carbonic oxide gas. The method consists of gasifying the coke with carbon monoxide or carbon dioxide to prepare the raw gases including 10 % -99 % CO, 0.1 %-90 % CO2, 0.001 %-2 % O2, 50-9000ppm COS, 10-10000ppm H2S, through gas storage holder, after pressurization and pyrogenation, entering purification tower filled with puripreservatives of A and B to remove hazardous materials including nitrogen oxide, hydrogen arsenide, hydrogen phosphide, hydrogen chloride, hydrogen nitrile, oxides of sulfur and sulfureted hydrogen, entering tower for removing organic sulfur filled with sulfur carbonyl hydrolyst, hydrolyzing 85%-95% of sulfur carbonyl for conversion into sulfureted hydrogen, at 20-150 DEG C, with a pressure of 0.1-10 MP, in which the refined raw gases can be used by productions of fine chemical industry including downstream acetate, dimethyl formamide,dimethyl ether, toluene diisocyanate or methyl diphenylene diisocyanate. The technology converts 85 %-95 % of sulfur carbonyl into sulfureted hydrogen, can adopt routine wet desulfurization to replace polyethylene glycol dimethyl ether desulfuration,can carry out cycle utilization of carbon dioxide and sulfur carbonyl of decarburized desorption gases of polyethylene glycol dimethyl ether, and can carry out zero discharge of poison material of sulfur carbonyl, which is good for environmental conservation.

Owner:HAISO TECH +1

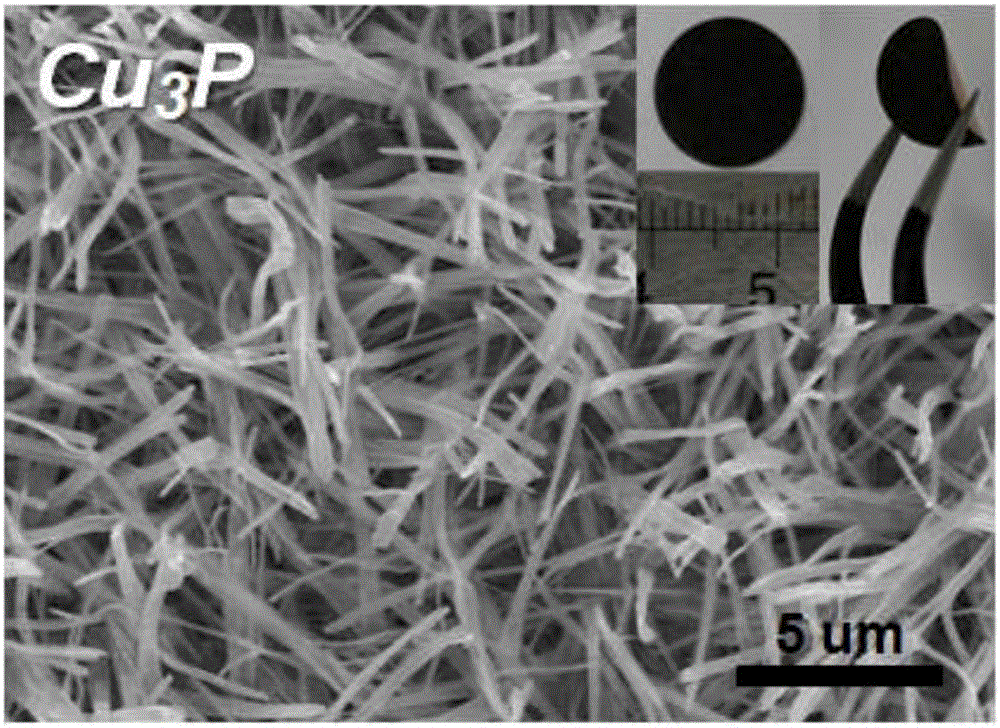

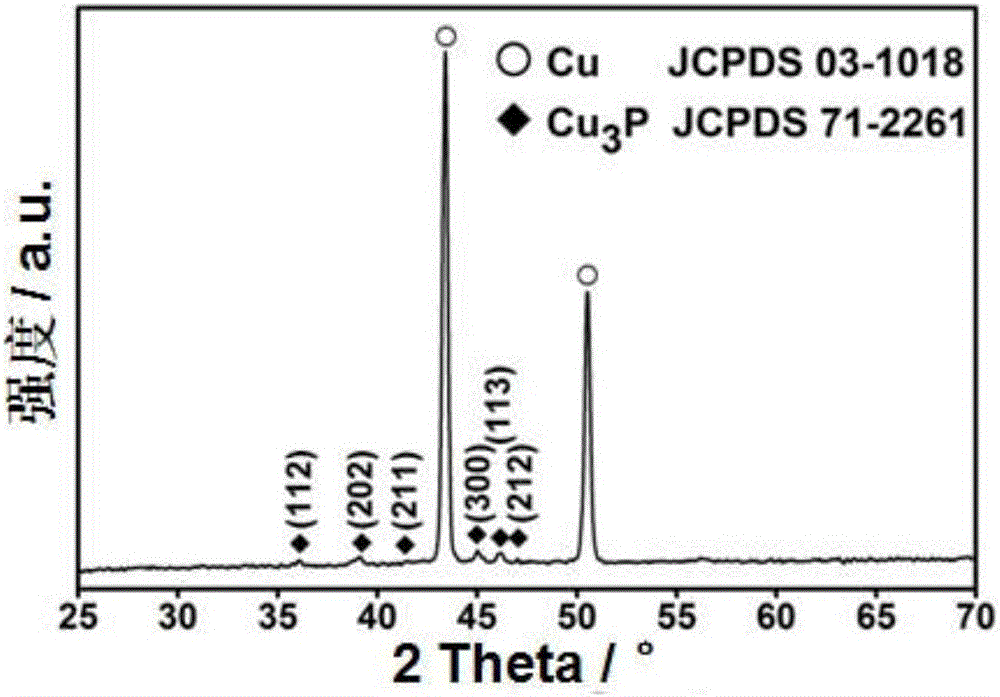

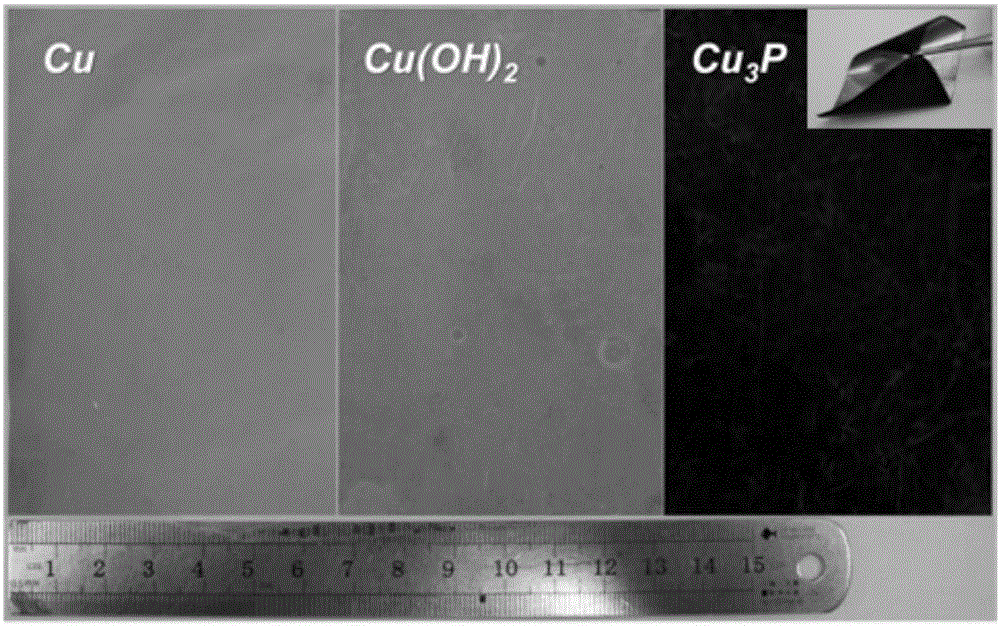

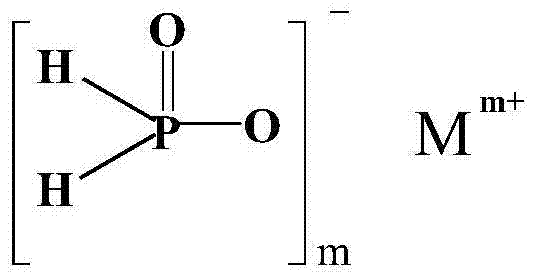

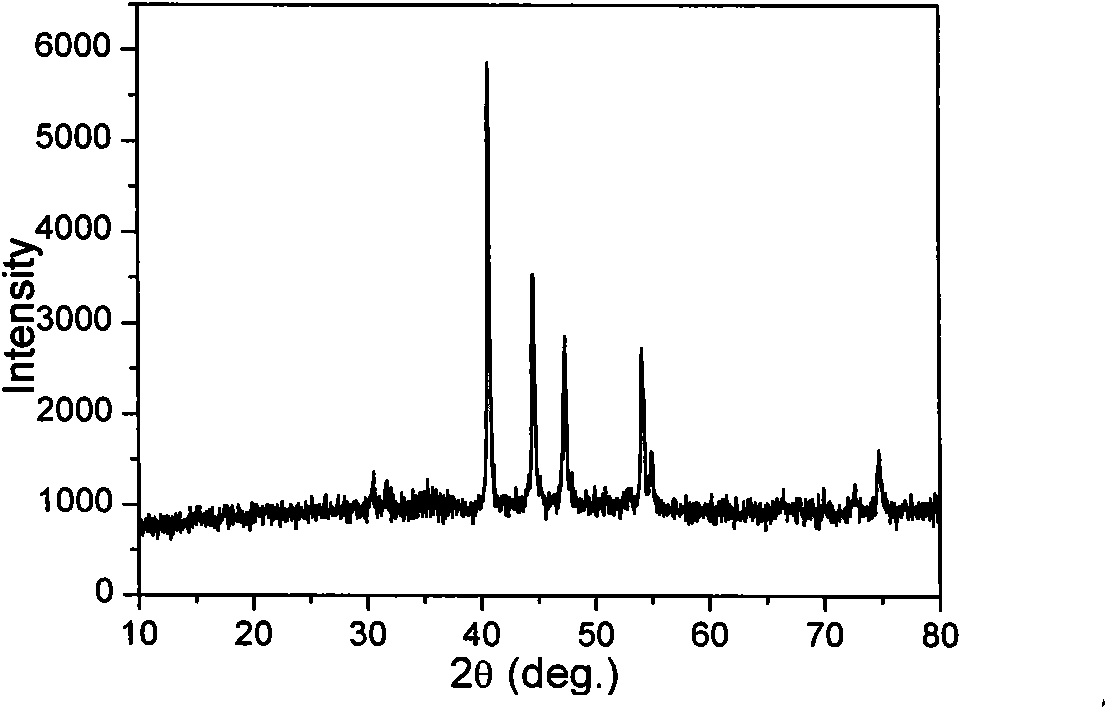

Preparation method of Cu3P nanowire negative electrode, Cu3P nanowire negative electrode prepared by method and application of Cu3P nanowire negative electrode

ActiveCN105845932ALow costThe process steps are simpleCell electrodesSecondary cellsNanowireElectrical battery

The invention relates to a preparation method of a Cu3P nanowire negative electrode, the Cu3P nanowire negative electrode prepared by the method and an application of the Cu3P nanowire negative electrode. The method comprises the following steps: (a) immersing one surface of a copper foil into a mixed water solution of persulfate and hydroxide for reaction, and forming a copper hydroxide nanowire in one side surface of the copper foil; and (b) putting excessive hypophosphite into the middle part of a tube furnace, putting the copper foil formed with the copper hydroxide nanowire in one side surface into the downstream part, discharging air in the tube furnace by an inert gas, then heating the air and reacting a generated hydrogen phosphide gas and the copper foil formed with the copper hydroxide nanowire in one side surface under a low-temperature condition to obtain a Cu3P nanowire negative electrode material in in-situ, unilateral and massive growth on the basis of a copper foil base. The material can be directly used as the negative electrode material for sodium-ion half-batteries and all-batteries. The processing steps are simple; the cost is relatively low; and enlarged production and large-scale promotion are facilitated.

Owner:SUZHOU UNIV

Coupling type sewage de-phosphorization purification regeneration treatment technique

ActiveCN102775019AEasy to recycleWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsSorbentUltraviolet

The invention discloses a coupling type sewage de-phosphorization purification regeneration treatment technique. Urban sewage is used as a treated object, the regeneration treatment method comprises the following steps of: a), preliminary precipitation, b), conversion of phosphor in the sewage to hydrogen phosphide in order to remove phosphor; c), conversion of hydrogen phosphide; and d), recovering of purified water; and in this way, the urban sewage is recovered and reused, all the mud after the sewage treatment is recovered, organic pollutants and nitrogen are removed. With the adoption of the technique, the defects of large mud treatment difficulty and large occupied area in the mud exhaust de-phosphorization of the existing normal biochemical treatment process and membrane bioreactor process are overcome; and meanwhile, new coagulant, adsorbent and flocculent are used in order to recover and regenerate water better, the sterilization is performed by nitrogen-ultrasonic-ultraviolet combination, hydrogen phosphide is converted into phosphatic fertilizer, in this way, the blank of effective conversion and utilization of hydrogen phosphide at home and abroad is filled.

Owner:SOUTH CHINA UNIV OF TECH

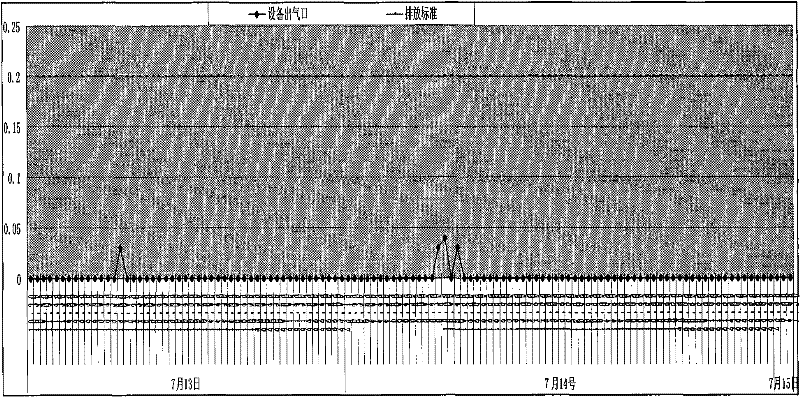

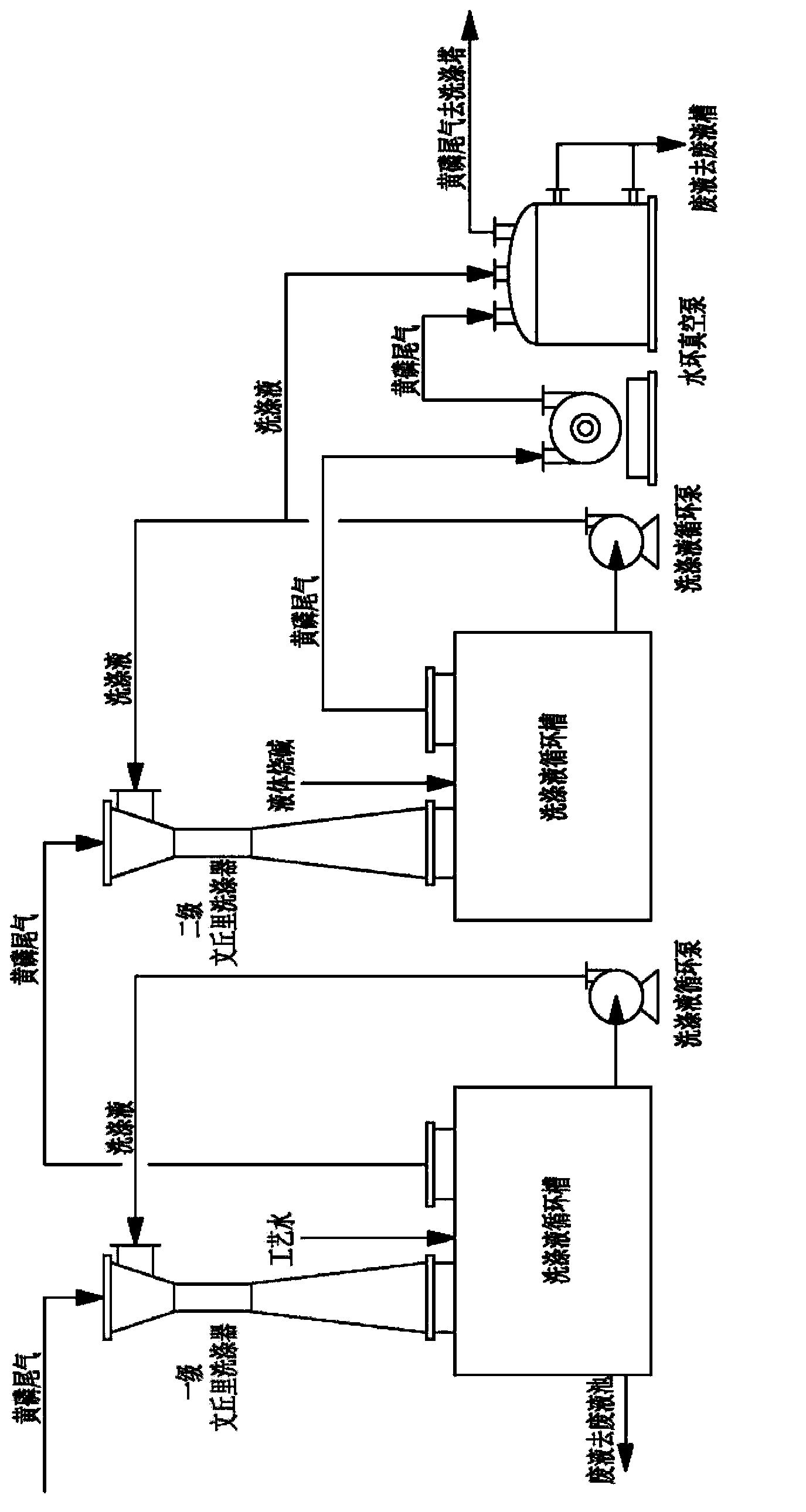

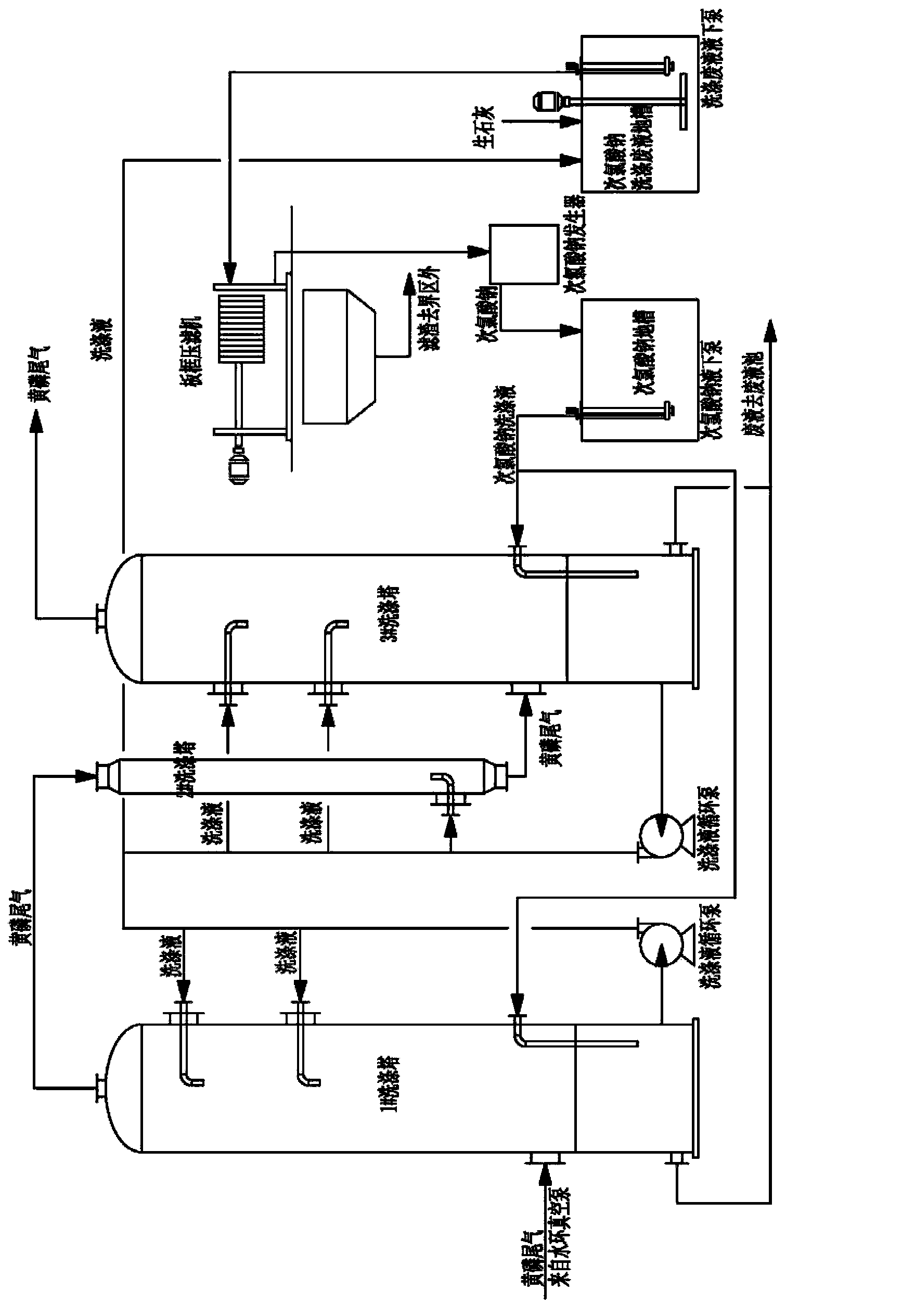

Deep purification method for oxidizing and alkali-washing yellow phosphorus tail gas

The invention discloses a deep purification method for oxidizing and alkali-washing yellow phosphorus tail gas. The method comprises the following steps: washing yellow phosphorus tail gas generated from a yellow phosphorus industry for removing dust; alkali-washing the washed tail gas by using an NaOH solution; oxidizing and alkali-washing the tail gas subjected to alkali-washing by adopting a sodium hypochlorite solution, so as to obtain purified yellow phosphorus tail gas; enabling a washing waste liquor generated after oxidizing and alkali-washing to react with CaO, filtering away precipitates, enabling the obtained filtrate to enter a sodium hypochlorite generator to generate a sodium hypochlorite solution, returning the sodium hypochlorite solution to the oxidizing and alkali-washing step for reuse. According to the method, sodium hypochlorite can be recycled, so that the use amount of the sodium hypochlorite can be greatly reduced, and the corrosion on equipment can be lightened. The content of phosphorus and hydrogen phosphide in discharged tail gas washed by adopting the method is not larger than 100 mg / m<3>, and the water content of discharged tail gas is not larger than 20 g / m<3>, so that the requirement that the content of sulfur and phosphorus impurities in a fuel is required to be lower than 100 mg / m<3>, can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

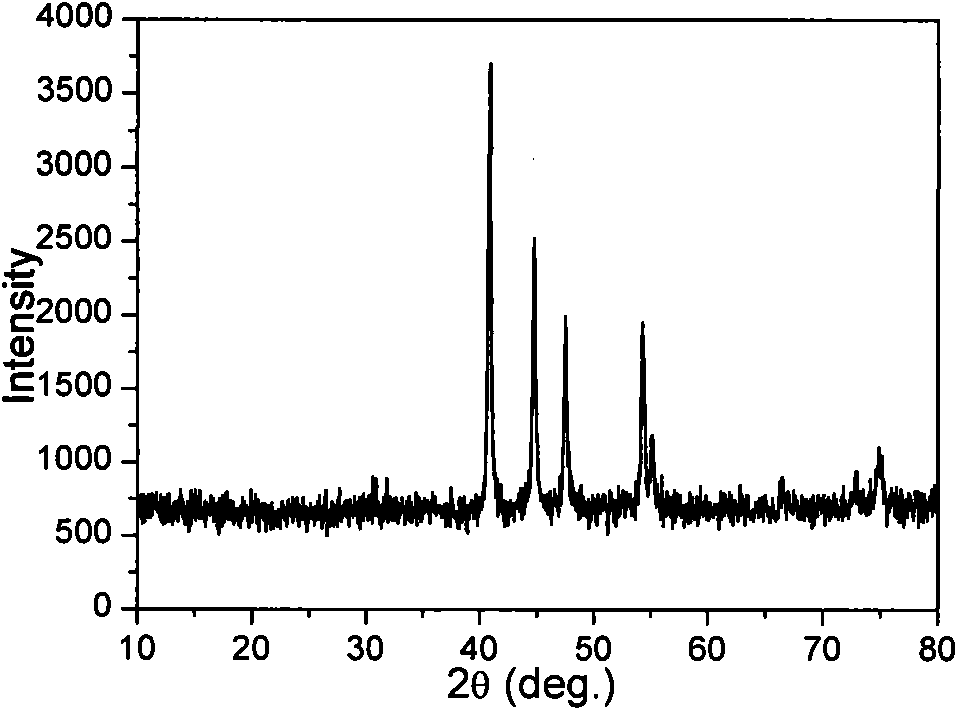

Method for preparing Ni2P by reducing nickel oxide precursor through thermal treatment at low temperature

InactiveCN101671009ALow preparation temperatureShorten the production cycleMolecular sieve catalystsCatalyst activation/preparationNitrateSodium Hypophosphite Monohydrate

The invention provides a novel method for preparing nickel phosphide (Ni2P) by utilizing phosphine produced by thermal decomposition of sodium hypophosphite to reduce nickel oxide precursor. In the method, nickel nitrate is adopted as a nickel source and then roasted to obtain nickel oxide, and the obtained nickel oxide is dipped into sodium hypophosphite solution to obtain the nickel oxide precursor, and simple low temperature thermal treatment of the nickel oxide precursor is carried out so as to synthesize supported and unsupported Ni2P. The invention has the characteristics of simple process, low Ni2P preparation temperature, short production period, without the complex steps of temperature programming, and the like as well as just simple thermal treatment at normal temperature. Raw materials used in the method are low in price and safety, and devices used in the method are low in cost. The catalyst can be widely used for hydrogenation treatment of oils due to higher hydrodesulfurization and hydrodenitrogenation activities.

Owner:NANKAI UNIV

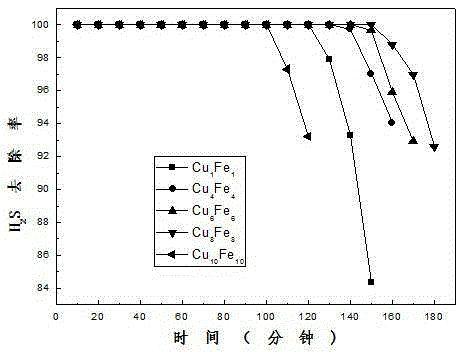

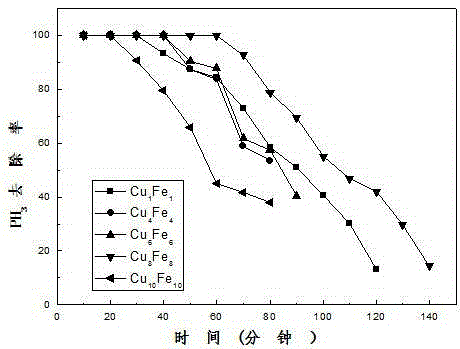

Combined desulfuration dephosphorization method

ActiveCN104117274AHigh desulfurization and dephosphorization efficiencyRealize resourcesDispersed particle separationChemical industryHydrogen phosphide

The invention relates to a combined desulfuration dephosphorization method. The method comprises: firstly preparing an iron-based ionic liquid and a Fe-M based ionic liquid (M=Cu, Mn, Zn or Pd), then introducing a gas mixture of hydrogen sulfide and hydrogen phosphide into the iron-based ionic liquid for desulfuration, then introducing the gas mixture of hydrogen sulfide and hydrogen phosphide into the Fe-M based ionic liquid for dephosphorization, so as to realize combined removal of hydrogen sulfide and hydrogen phosphide in the system and obtain a purified gas, and regenerating the iron-based ionic liquid and the Fe-M based ionic liquid and realizing cycle use. The method is a green efficient technology for removing hydrogen sulfide and hydrogen phosphide, and is applicable to purify industrial raw gas, chemical industry production process gas, industry production tail gas and other systems containing hydrogen sulfide and hydrogen phosphide. The method also has the characteristics of relatively high removal efficiency, no secondary pollution, regenerable and recyclable removing agent, low cost and the like.

Owner:BEIJING UNIV OF CHEM TECH

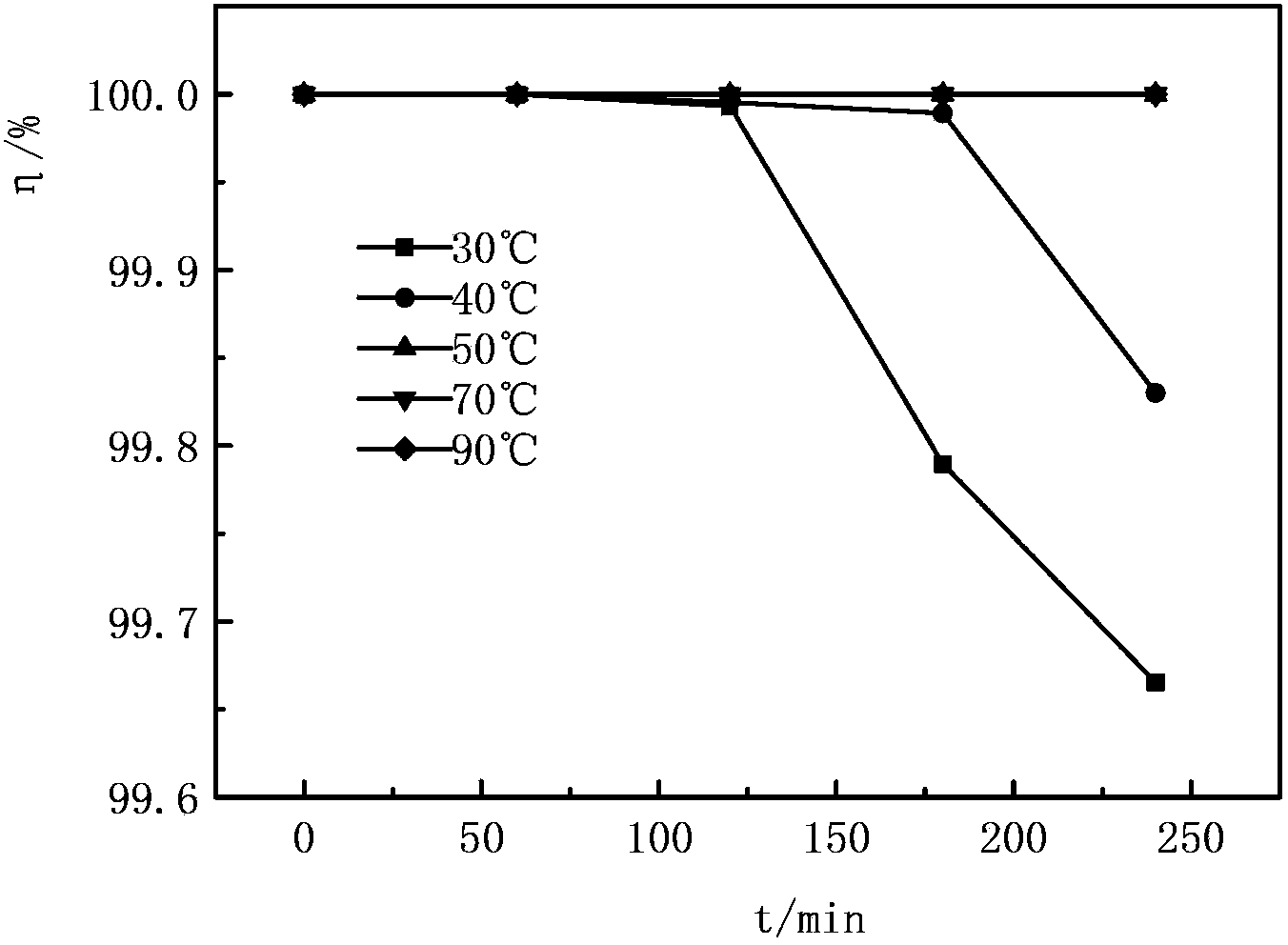

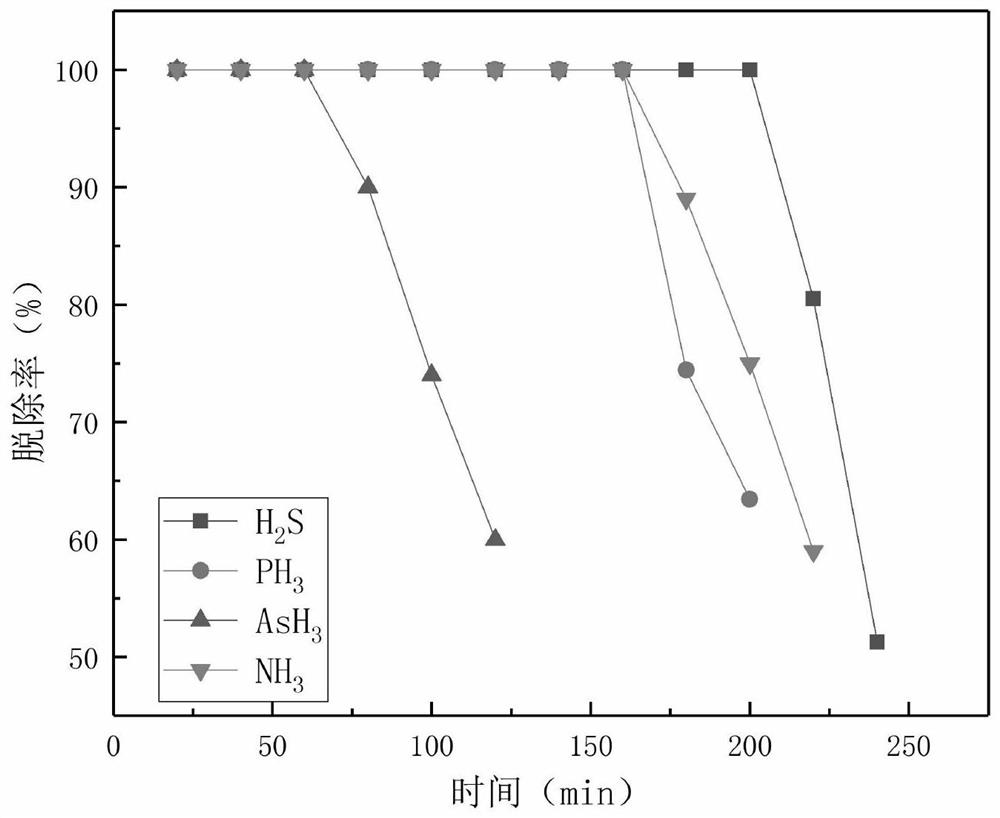

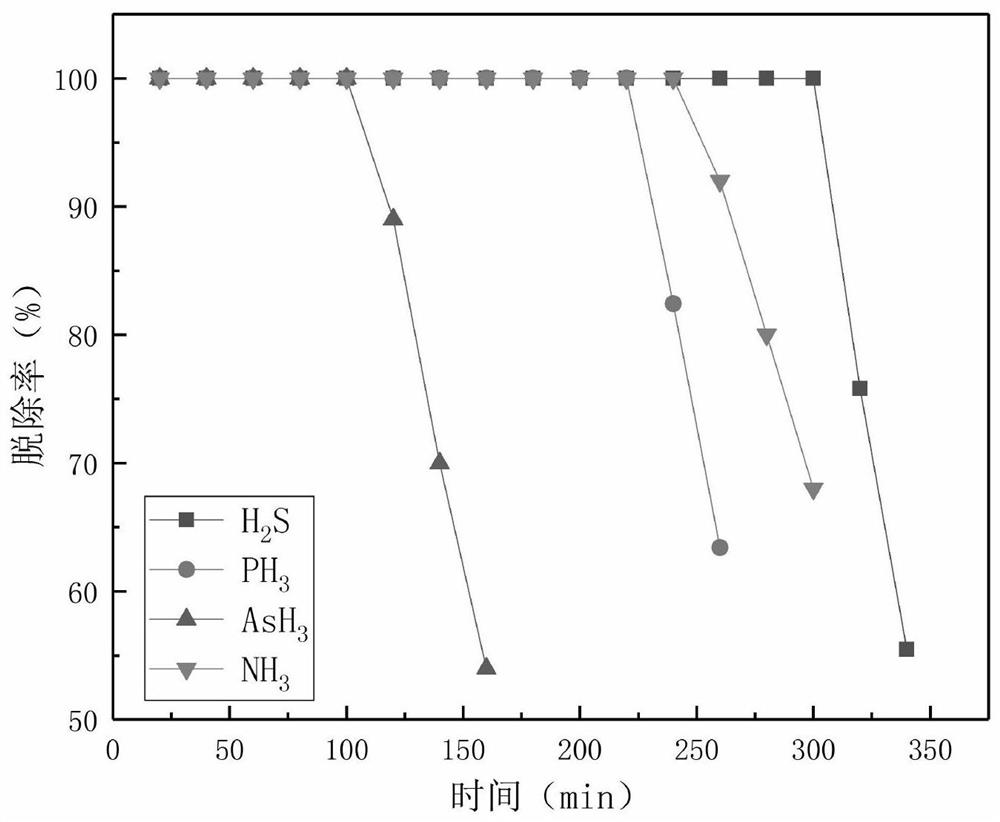

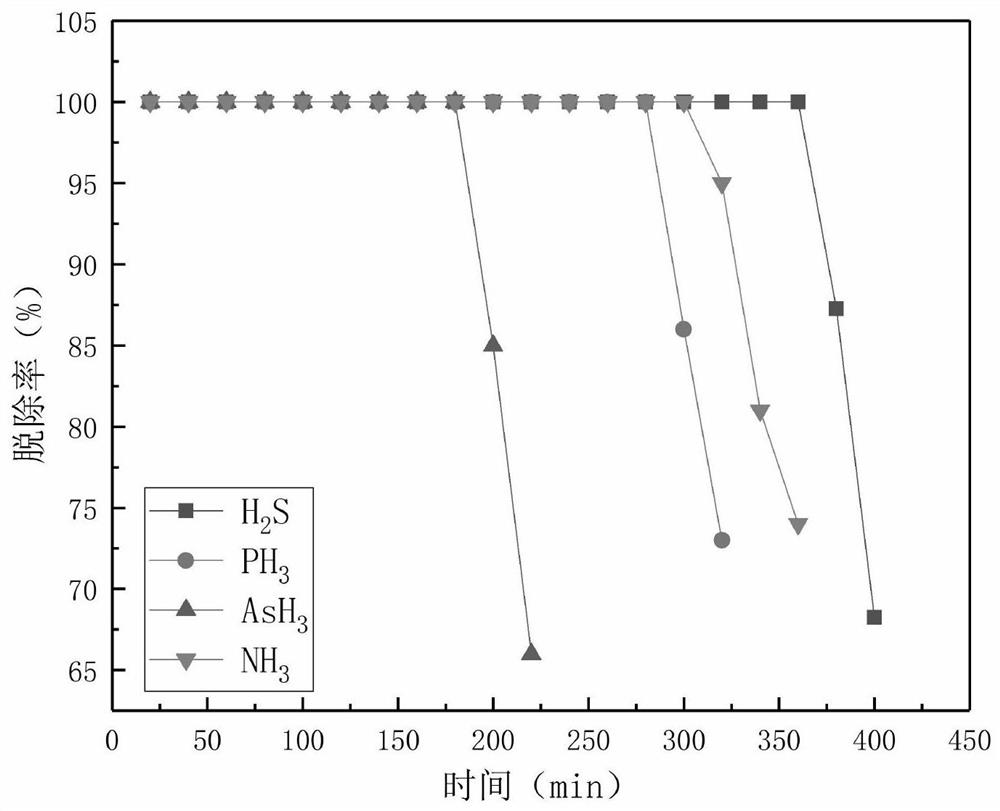

Preparation method and application of activated carbon fiber-based adsorbent for removing hydrogen sulfide, hydrogen phosphide, arsenic hydride and ammonia gas

ActiveCN112371087AImprove removal efficiencyImprove anti-pollution performanceGas treatmentOther chemical processesFiberActivated carbon

The invention provides a preparation method and application of an activated carbon fiber-based adsorbent for removing hydrogen sulfide, hydrogen phosphide, arsenic hydride and ammonia gas, and belongsto the technical field of air pollution prevention and control. The method comprises the following steps: firstly, carrying out remote argon plasma treatment on the activated carbon fiber, and then carrying out ultrasonic impregnation by using a hydrogen peroxide solution, so that the number of oxygen-containing functional groups such as phenolic hydroxyl, lactone and carboxyl on the surface of the activated carbon fiber is remarkably increased; modified activated carbon fibers and a copper nitrate solution are mixed and subjected to rotary evaporation, copper salt is loaded on the surfaces of the activated carbon fibers, the copper salt is converted into copper oxide after being roasted in a microwave muffle furnace, the copper oxide can serve as an active component for removing hydrogensulfide, hydrogen phosphide, arsenic hydride and ammonia gas, and therefore the removal efficiency of harmful gas is improved; the roasted activated carbon fiber is subjected to remote oxygen plasmatreatment, so that oxygen-containing functional groups on the surface of the activated carbon fiber can be enhanced, the anti-pollution performance of the activated carbon fiber-based adsorbent is improved, and the service life of the activated carbon fiber-based adsorbent is prolonged.

Owner:KUNMING UNIV OF SCI & TECH

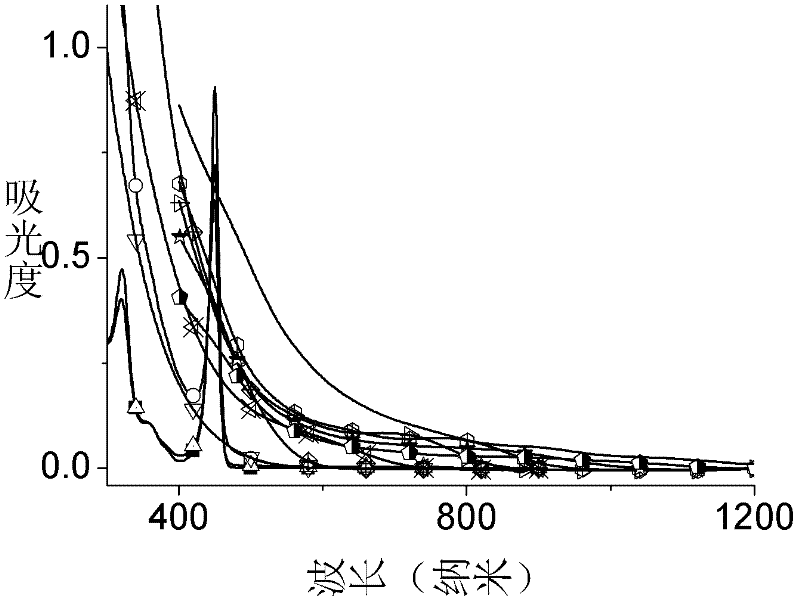

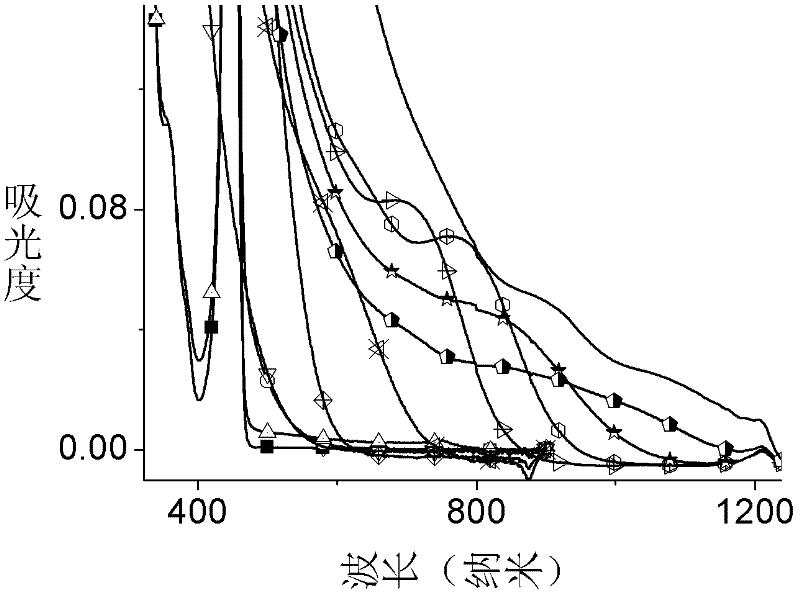

A kind of preparation method of low-cost cadmium phosphide quantum dot material

InactiveCN102268253AThe synthesis method is simpleContinuous operationLuminescent compositionsSynthesis methodsReaction temperature

The invention discloses a preparation method of a low-cost cadmium phosphide quantum dot material. The preparation method comprises the following steps: based on a cheap cadmium compound such as cadmium oxide, cadmium acetate or cadmium cetylacetonate and the like as a raw material, dissolving the cadmium compound and long-chain fatty acid in octadecylene at a high temperature so as to prepare a long-chain fatty acid salt of cadmium; or dissolving cadmium cetylacetonate in organic amine, and then carrying out a gas-liquid reaction based on hydrogen phosphide as a phosphorus source so as to prepare the high-quality cadmium phosphide quantum dot luminescent material. According to the invention, a cheap and continuously operable synthesis method is provided for the cadmium phosphide quantum dot material, and a solid foundation is provided for industrialized production of the cadmium phosphide quantum dot material; and through controlling factors such as reaction temperature, time and the like, the luminescence of the cadmium phosphide quantum dot material can be achieved in a wide region ranging from visible light (460nm) to infrared light (1500nm).

Owner:HEFEI UNIV OF TECH

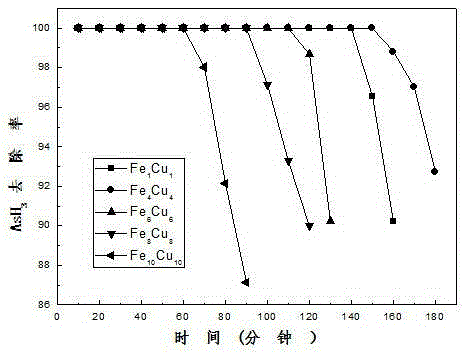

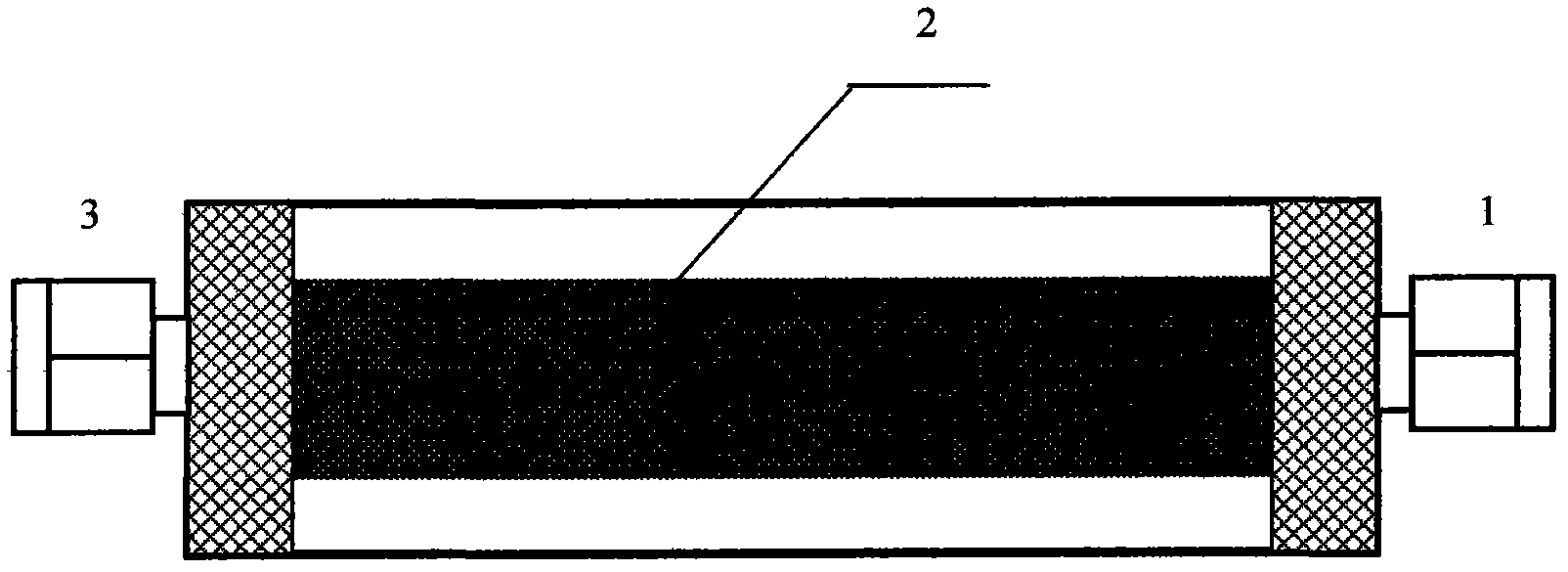

Purifier for adsorbing arsenic hydride and hydrogen phosphide in olefin tail gas and preparation method thereof

ActiveCN102806065AReduce contentSimple ingredientsOther chemical processesDispersed particle separationSimple componentAtmospheric pollution

The invention relates to a normal-temperature purifier for adsorbing arsenic hydride and hydrogen phosphide in an olefin tail gas, belonging to the atmospheric pollution purification field. The purifier comprises following components in percentages by mass: 0.5-5% of potassium permanganate, 1-10% of soluble copper salt, 1-10% of soluble zinc salt and 75-97.5% of active carbon; the active carbon is a carrier; the potassium permanganate, and the soluble copper salt and the soluble zinc salt are active components. The preparation method of the purifier comprises following steps: (1), preparing a mixed water solution of the potassium permanganate, the soluble copper salt and the soluble zinc salt; (2), loading the potassium permanganate, the soluble copper salt and the soluble zinc salt on the active carbon carrier by a dipping method to obtain a carrier loaded with active metals; and (3), drying the carrier loaded with active metals in a drying medium to obtain the finished product purifier. The purifier disclosed by the invention has the advantages of simple component, low cost and low usage cost; after the purification, the content of arsenic hydride and hydrogen phosphide is less than 10ppb (volume percentage).

Owner:CHINA PETROLEUM & CHEM CORP +1

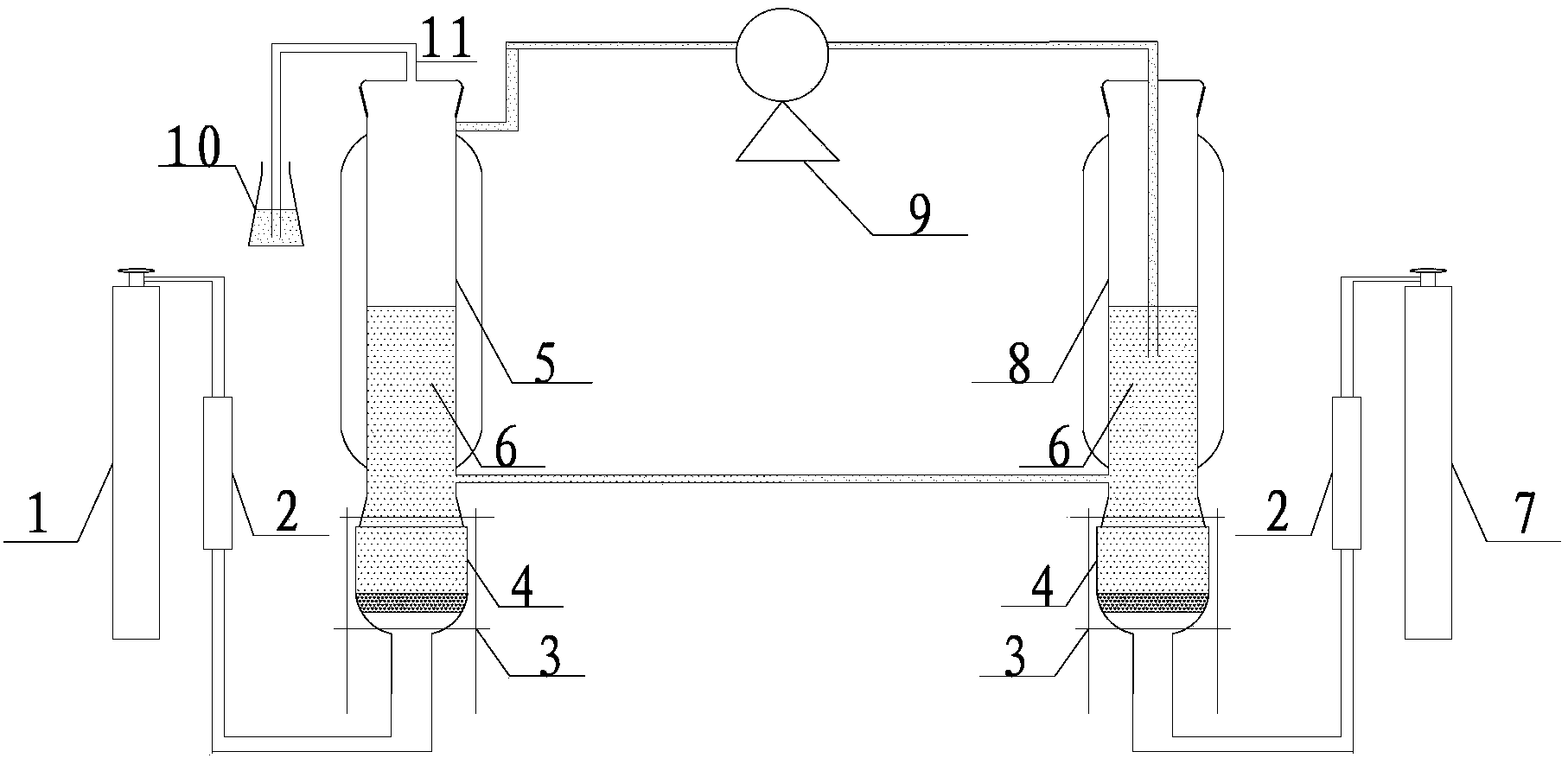

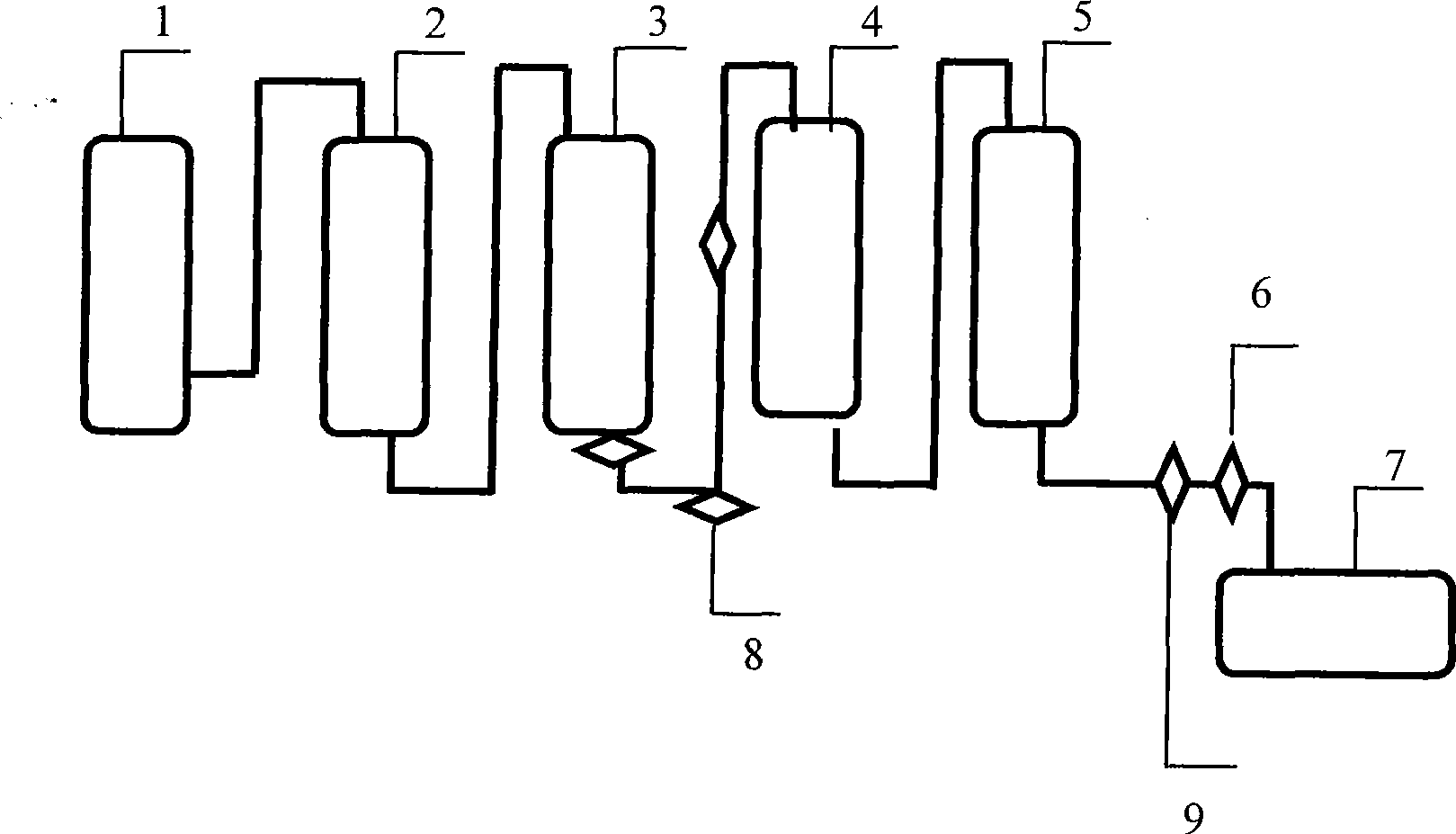

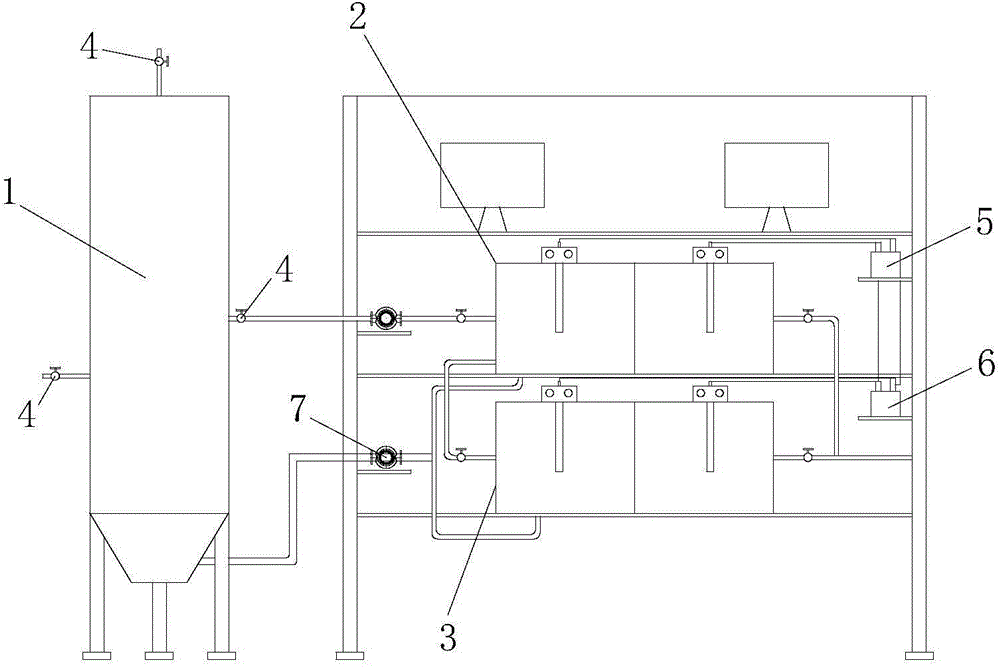

Preparation technique and device for ultra-pure hydrogen phosphide

ActiveCN101244810AReduce contentEfficient removalPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDistillationReverse osmosis

The invention provides a continuous production process for ultra-pure hydrogen peroxide, comprising the following steps: mixing the industrial hydrogen peroxide material with the modified active carbon; then classifying filter by microfiltration membrane and ultrafiltration membrane in sequence; the filtrate is pumped into the distillation column formed by a plurality of columns connected in series; adding metal ion complexing agent into the primary column; performing reverse osmosis on the semi-finished products out of the column before filtering by nanofiltration membrane to get ultra-pure hydrogen peroxide products. The device comprises the following parts: a raw material chute, an active carbon pre-mixer, a microfiltration and ultrafiltration filter, a distillation column formed by a plurality of columns connected in series, a reverse osmosis device, a nanofilter, a finished product receiver, a pump and a shaft; wherein, the raw material chute outlet is connected with the active carbon pre-mixer inlet; the microfiltration and ultrafiltration filter outlet is connected with the pump, the outlet of which is connected with the inlet of the distillation column formed by a plurality of columns connected in series; the outlet of the distillation column formed by a plurality of columns connected in series is connected with the inlet of the reverse osmosis device, the outlet of which is connected with the shaft; the outlet of the shaft is connected with the inlet of the nanofilter, the outlet of which is connected with the finished product receiver.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

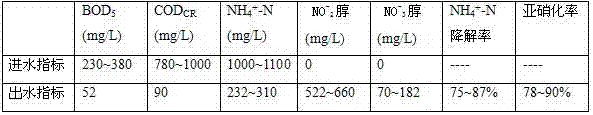

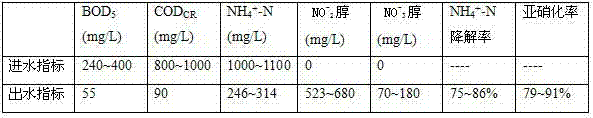

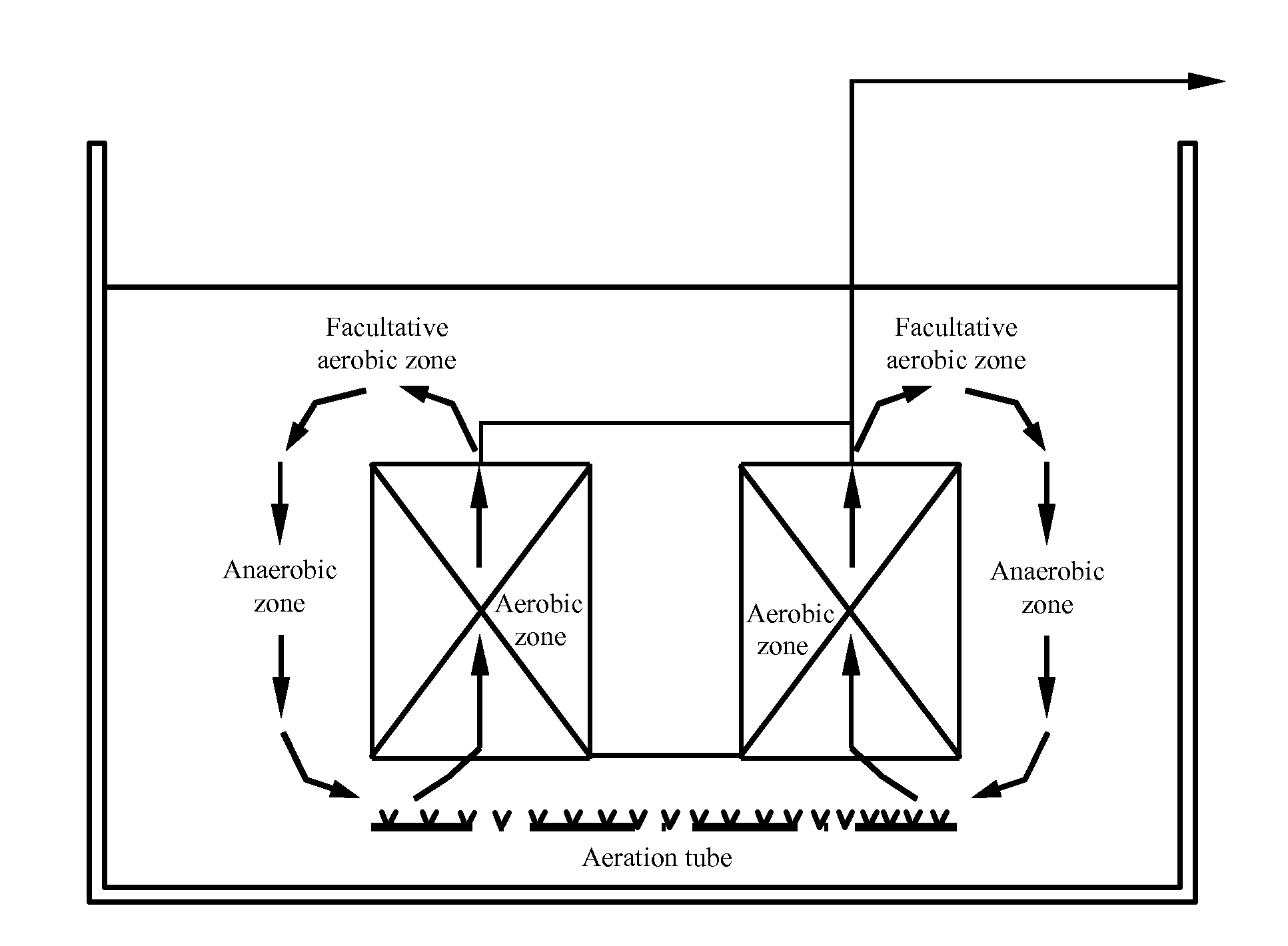

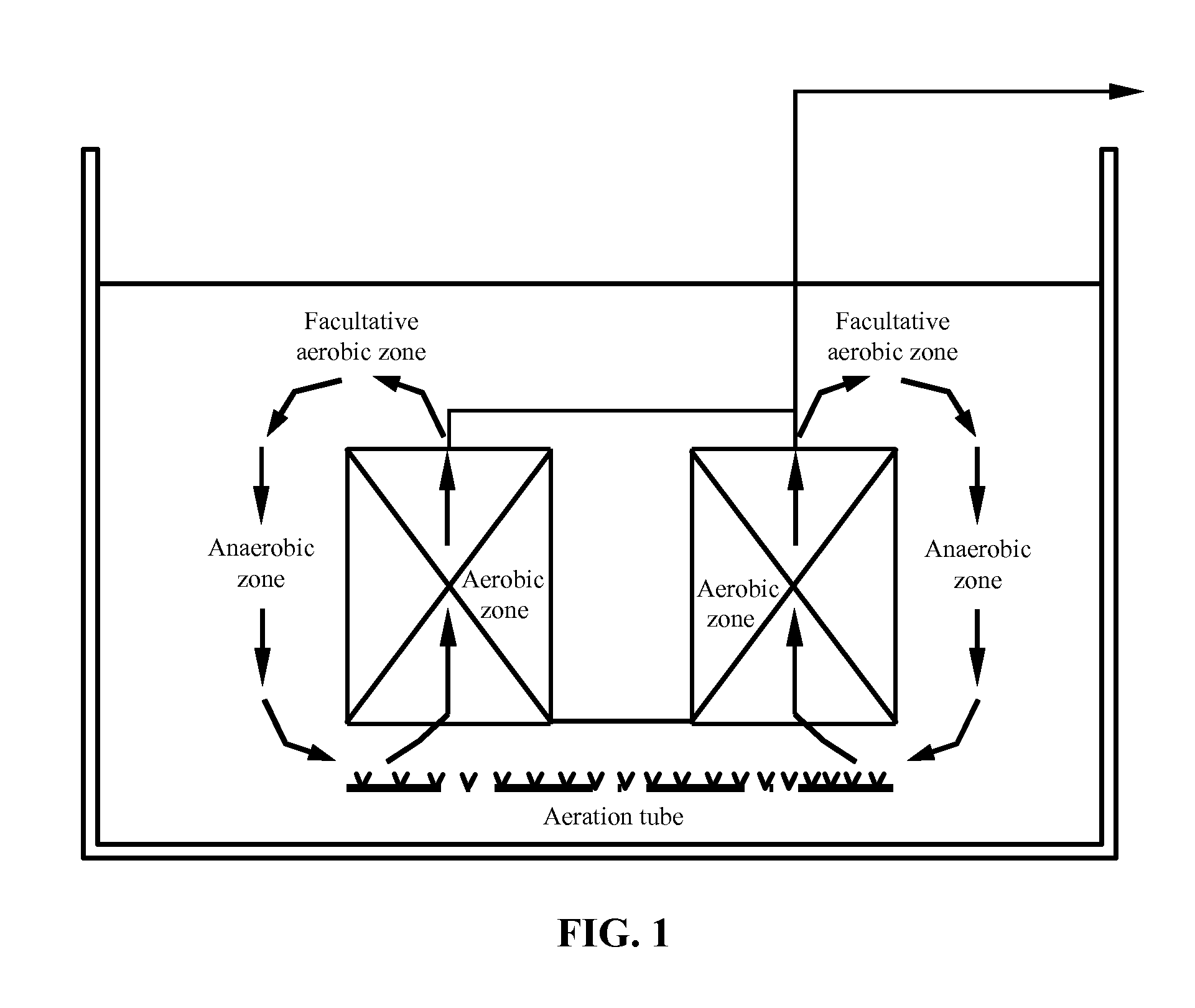

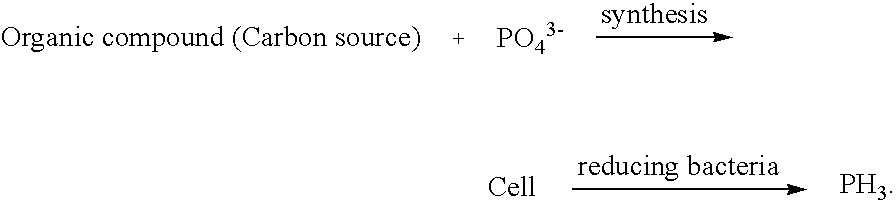

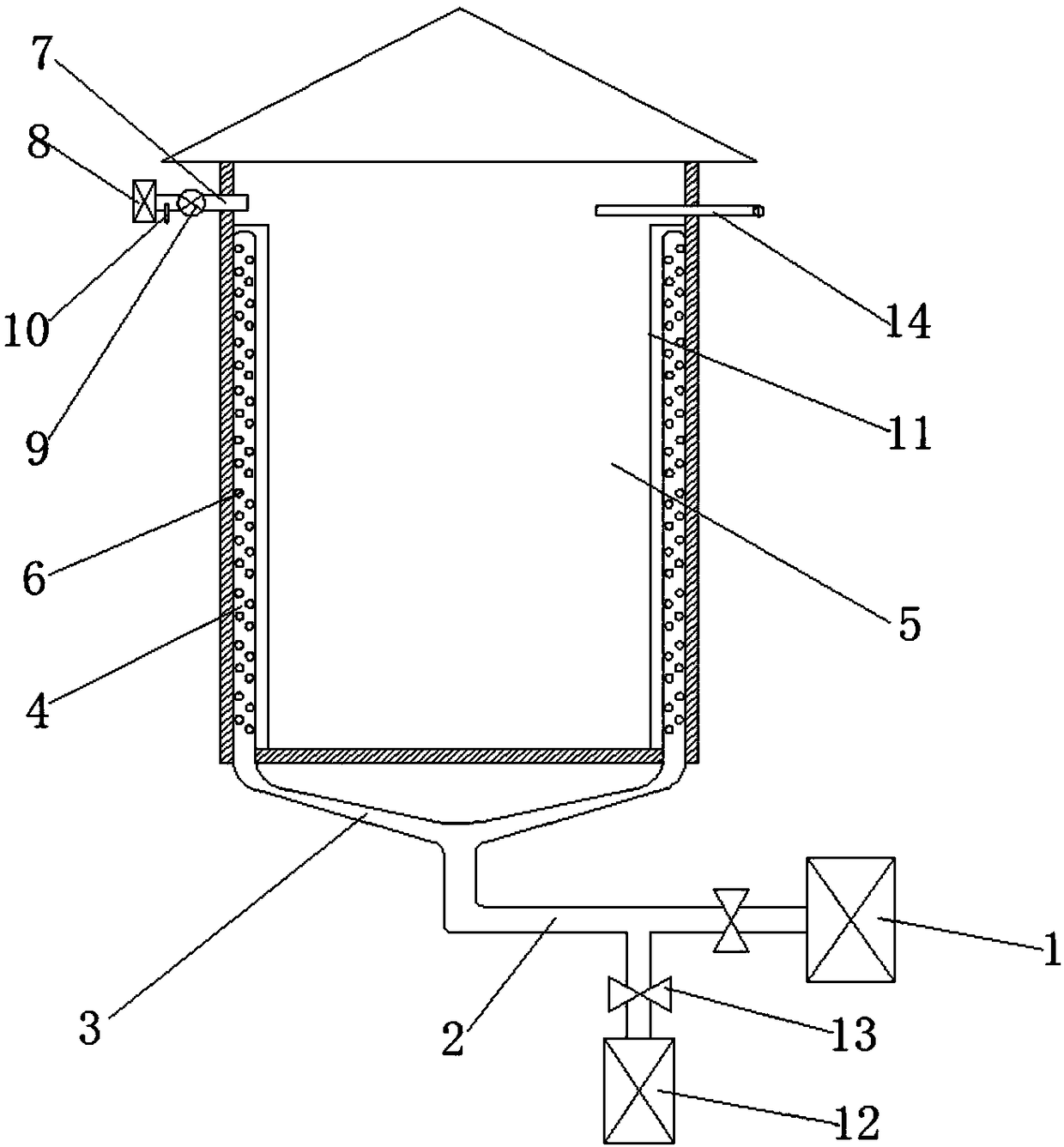

Method for removing phosphorus using membrane bioreactor

InactiveUS20100288698A1Easy to disassembleWater treatment parameter controlTreatment using aerobic processesMembrane bioreactorOxygen

A method for removing phosphorus having steps of a) providing a membrane bioreactor having a membrane module having a lower part; b) aerating intensively the lower part of the membrane module while controlling dissolved oxygen concentration around the membrane module at more than 2 mg / L and dissolved oxygen concentration in the rest zone at less than 1 mg / L so as to form an aerobic zone, a facultative aerobic zone, and an anaerobic zone; and c) introducing sludge having a concentration of between 10,000 mg / L and 30,000 mg / L and having an organic loading of between 0.08 and 0.07 Kg (COD) / (Kg (MLSS)·d) into the membrane reactor so that phosphorus is absorbed in the aerobic zone, released in the facultative aerobic zone, and reduced by phosphine-reducing bacteria into phosphine. The method for removing phosphorus does not include discharging sludge. An apparatus employed for the process does not take up much additional space.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

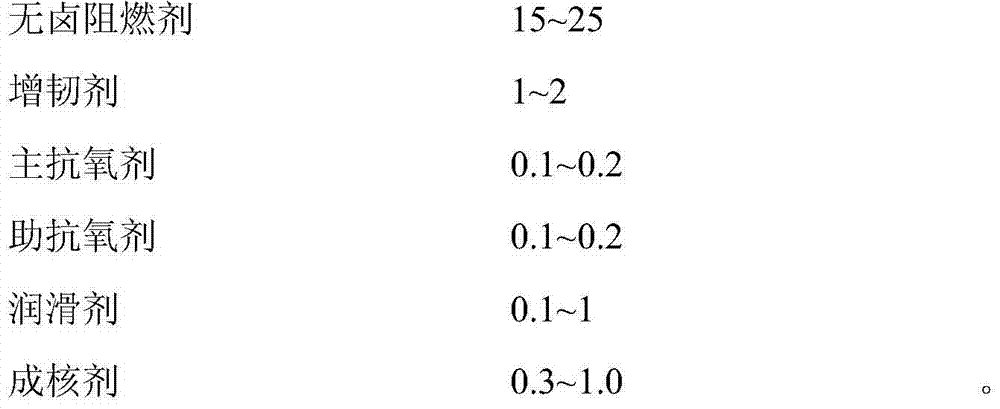

Halogen-free and phosphorus-free PBT enhanced composite material and preparation method thereof

ActiveCN104231575AExcellent resistance to precipitationImprove flame retardant performanceGlass fiberAntioxidant

The invention discloses a halogen-free and phosphorus-free PBT (polybutylece terephthalate) enhanced composite material and a preparation method thereof, and belongs to the technical field of composite flame-retardant enhanced materials. The halogen-free and phosphorus-free PBT enhanced composite material consists of the following components: 45-65 pats of PBT, 15-30 parts of glass fibers, 15-25 parts of a halogen-free flame retardant, 1-2 parts of a toughening agent, 0.1-0.2 part of a main antioxidant, 0.1-0.2 part of an auxiliary antioxidant, 0.1-1 part of a lubricating agent and 0.3-1.0 part of a nucleating agent. The preparation method comprises the steps of uniformly mixing PBT, the halogen-free flame retardant, the toughening agent, the main antioxidant, the auxiliary antioxidant, the lubricating agent and the nucleating agent according to the weight part to obtain a mixture, and performing melting, coblending and extruding granulation on the mixture and the glass fibers to obtain the halogen-free and phosphorus-free PBT enhanced composite material. The halogen-free and phosphorus-free PBT enhanced composite material prepared by the method is excellent in anti-separation performance, flame retardancy, mechanical property and creepage cracking resistance, does not release hydrogen phosphide poisonous gas and can totally meet a limiting requirement of Samsung on hydrogen phosphide emission concentration.

Owner:JINAN TAIXING FINE CHEM

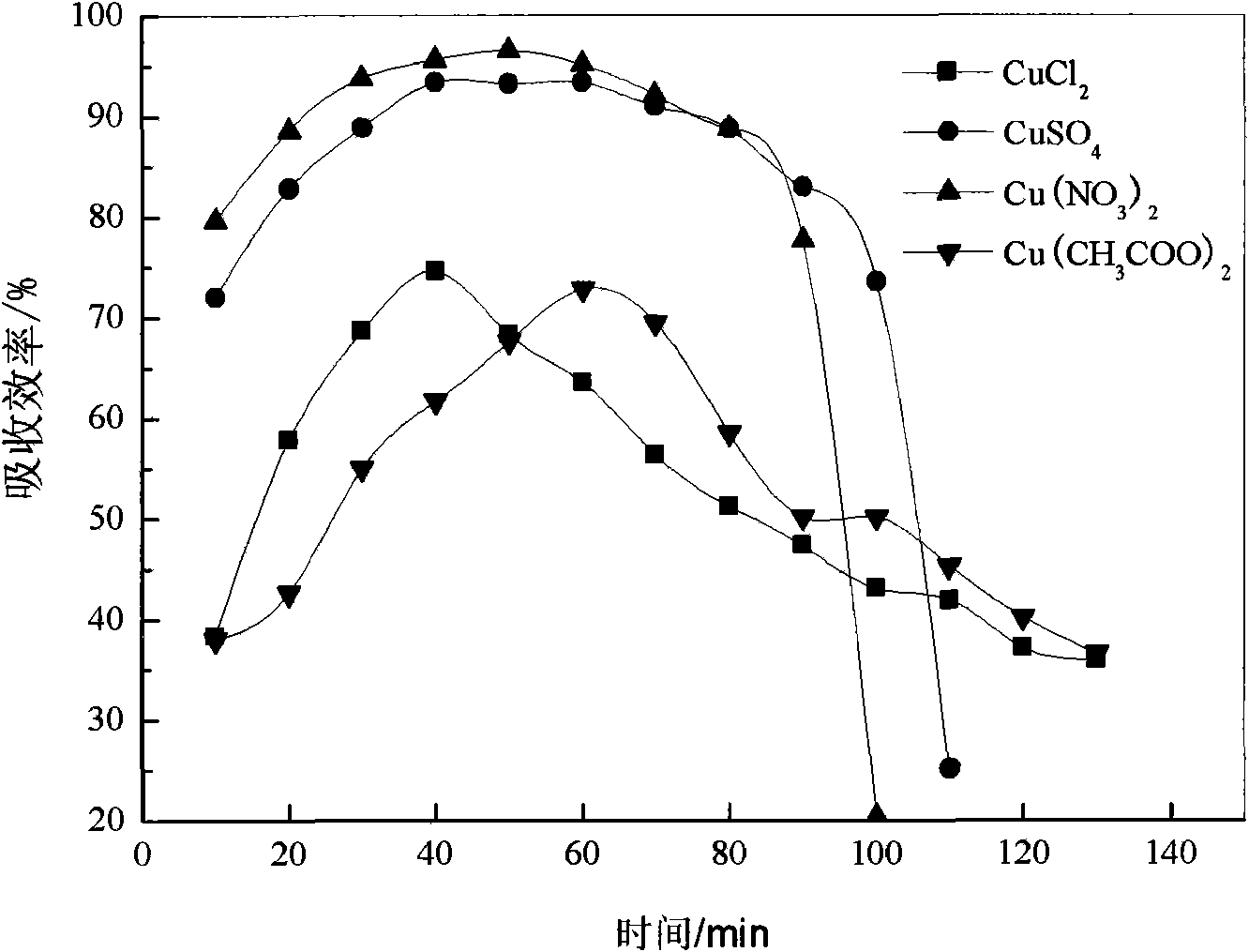

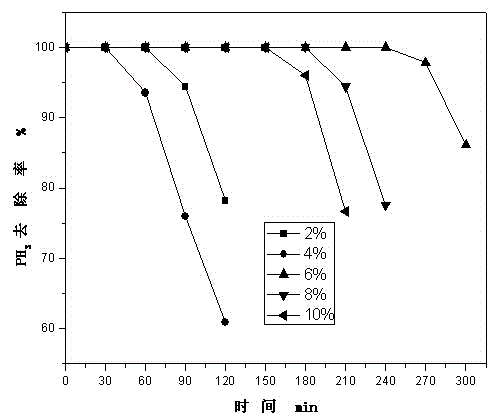

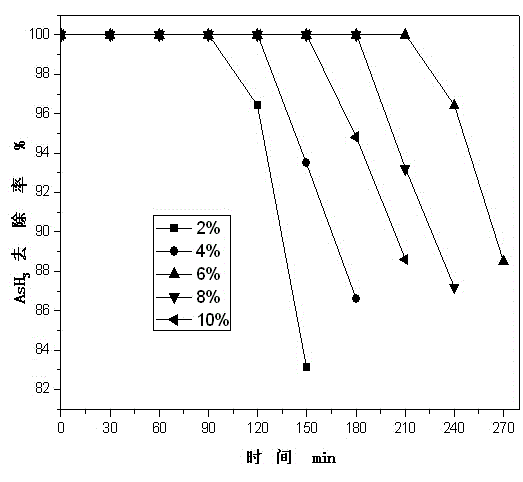

Absorption liquid used for purifying hydrogen phosphide by wet-catalytic oxidation

InactiveCN101574618ASimple ingredientsEasy accessDispersed particle separationHydrogen phosphideSimple component

The invention relates to an absorption liquid used for purifying gas, in particular to an absorption liquid used for purifying hydrogen phosphide by wet-catalytic oxidation, belonging to the technical field of applying the catalytic technology in purification of atmosphere pollution. The absorption liquid adopts salt solution containing Cu; and the pH value of the absorption liquid is 3 to 5. The absorption liquid has the advantages of simple components, low price and low using cost, and simultaneously has higher purification efficiency.

Owner:KUNMING UNIV OF SCI & TECH

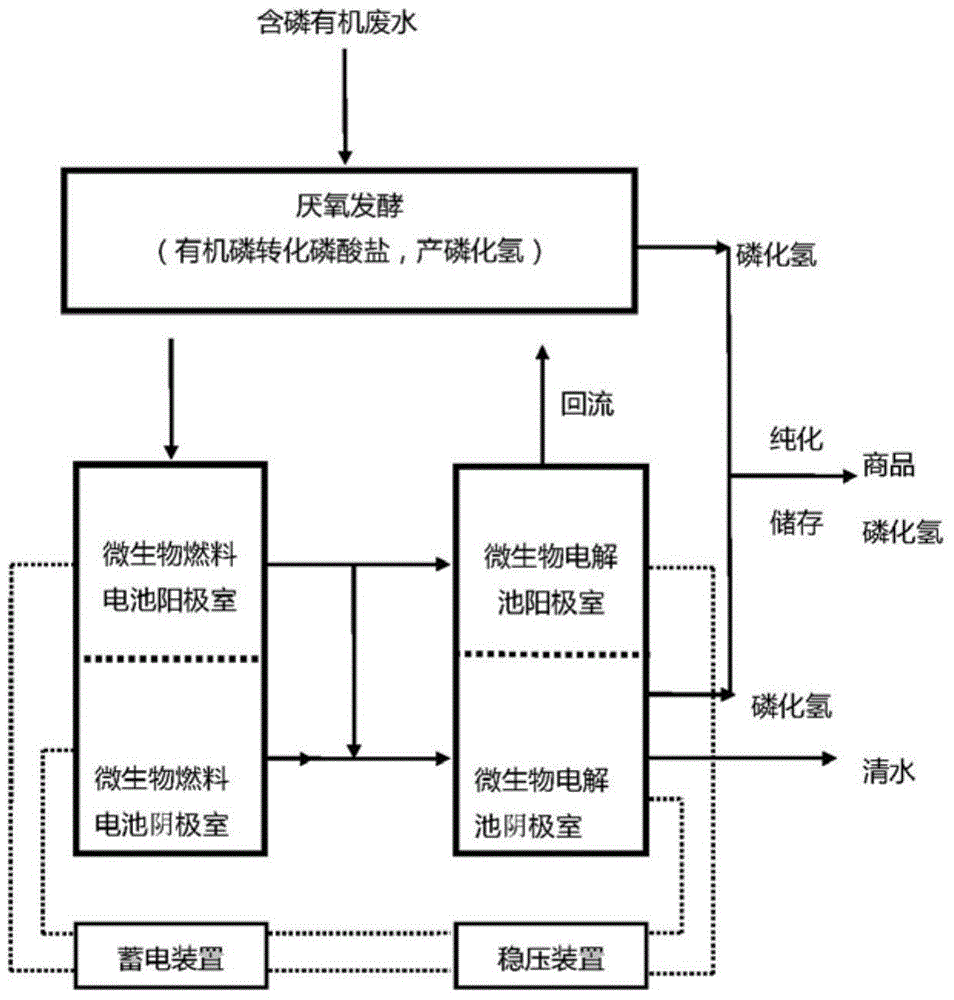

Device for removing phosphor from phosphor-containing organic wastewater and producing hydrogen phosphide

ActiveCN104828938AAvoid the problem of low phosphorus removal efficiencyHigh purityWater contaminantsTreatment with anaerobic digestion processesSequencing batch reactorElectricity

The invention discloses a device for removing phosphor from phosphor-containing organic wastewater and producing hydrogen phosphide. The device comprises an anaerobic reactor, a microbial fuel cell and a microbial electrolytic bath; the water outlet pipe of the anaerobic reactor is connected to the anode water inlet pipe of the microbial fuel cell; the anode water outlet pipe of the microbial fuel cell is connected to the water inlet pipe of the microbial electrolytic bath; and the electricity output terminal of the microbial fuel cell is connected to the power supply port of the microbial electrolytic bath. The organic wastewater is introduced into the anaerobic sequencing batch reactor, the organic phosphor and occluded phosphor in organic wastewater are converted into phosphate through the metabolism of microbes, and then the wastewater is processed by the microbial fuel cell and microbial electrolytic bath. In the prior art, the phosphor removing efficiency is very low because the microbial anaerobic process is taken as the main process of hydrogen phosphide production, and the provided device solve the problem mentioned above.

Owner:SOUTH CHINA UNIV OF TECH

Preparation and preparation process for purifying storage environment and regulating environmental humidity

ActiveCN102284270ALow costStrong adsorption functionOther chemical processesLighting and heating apparatusPerfect stateChemistry

The invention provides a preparation process of a preparation for purifying a storage environment and regulating environmental humidity. The preparation can be used for absorbing ammonia, formaldehyde, residual hydrogen phosphide and other gases in the storage environment, and regulating the humidity of local storage space, so that the storage space is maintained in a perfect state. The preparation comprises the following main components: calcium chloride, starch, perlite, activated carbon, diatomaceous earth and zeolite. The preparation process mainly comprises the following steps: deep physical modification (enhancement of a specific surface area), crushing and granulation, and mixed package. The preparation is in accordance with natural green, environment-friendly and low-carbon concepts, has obvious effects on purifying the storage environment and regulating the humidity of the storage environment, and has a simple process.

Owner:BEIJING YINGFENG LITAI TECH TRADE

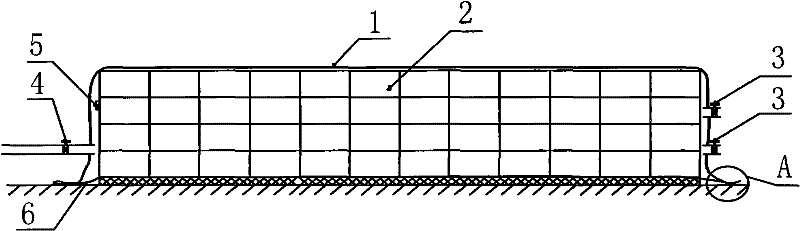

Fumigation device for grain storage

InactiveCN108260582AIncrease contact areaSolve the problem of uneven diffusion and low fumigation efficiencyFumigatorsMaterial analysisGrain storageHydrogen phosphide

The invention provides a fumigation device for grain storage. The fumigation device comprises a chemical gas box positioned outside a granary, and a fumigation mechanism connected with the chemical gas box, wherein the fumigation mechanism comprises a main pipe connected with the chemical gas box, a plurality of branch pipes communicated with the main pipe, and a fumigation pipe communicated witheach branch pipe; the fumigation pipes are vertically fixed on the inner wall of the granary; the tail end of the fumigation pipes are closed, and the pipe walls of the fumigation pipes are evenly provided with a plurality of fumigation holes; the wall of the upper part of the granary is also provided with an exhaust device communicated with the exterior of the granary. The fumigation device for grain storage solves the problems of long chemical dosing time and uneven hydrogen phosphide concentration distribution in the existing grain fumigation process, and increases the fumigation efficiency.

Owner:郑州龙威电气安装有限公司

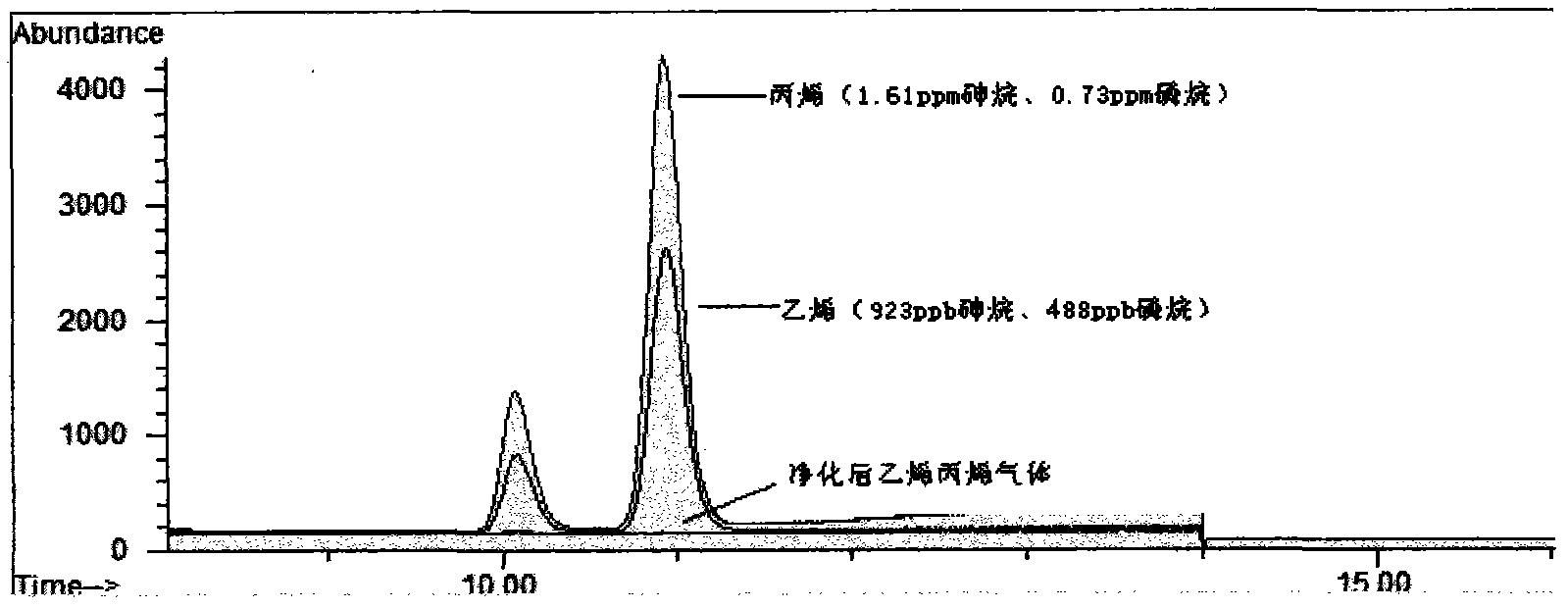

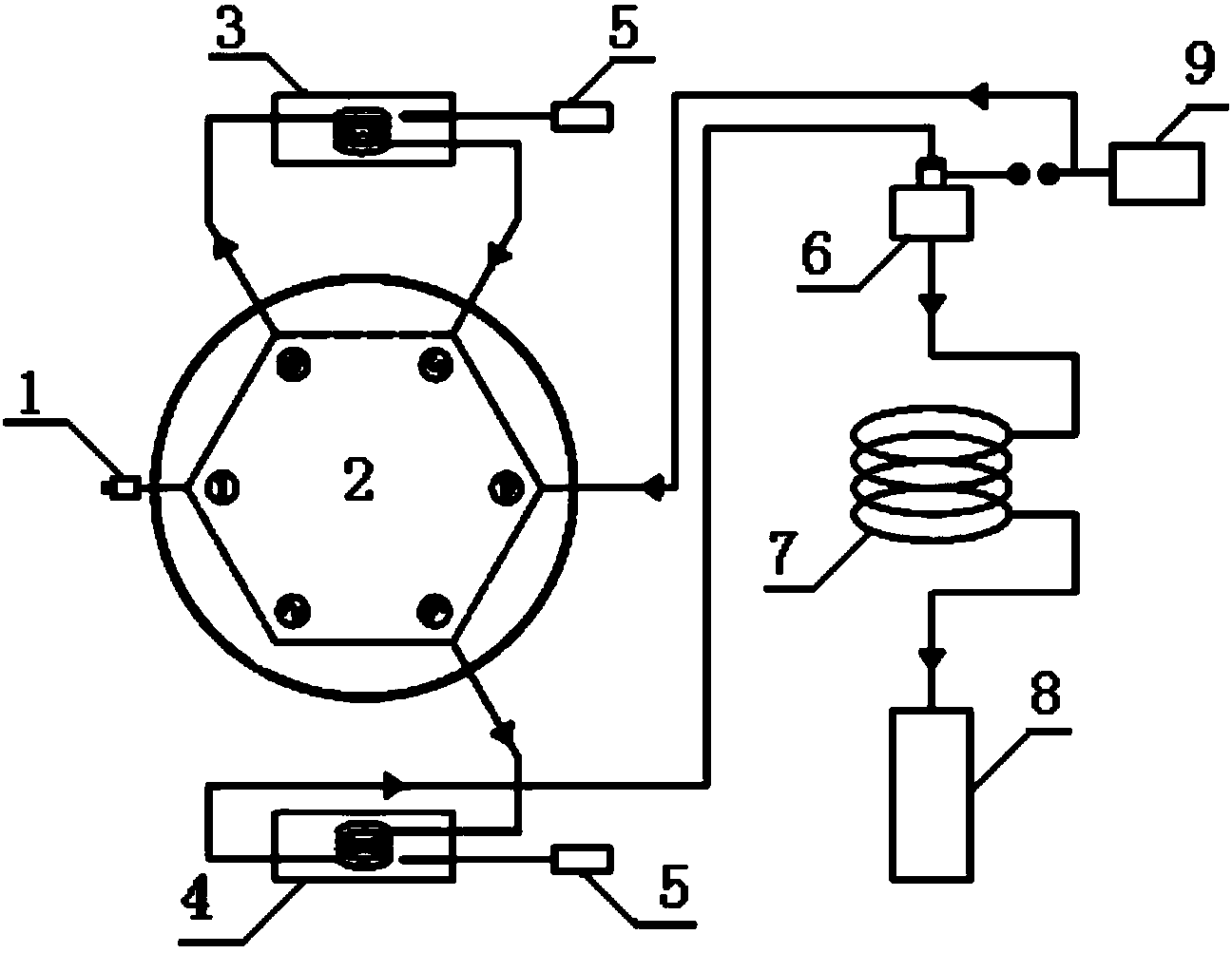

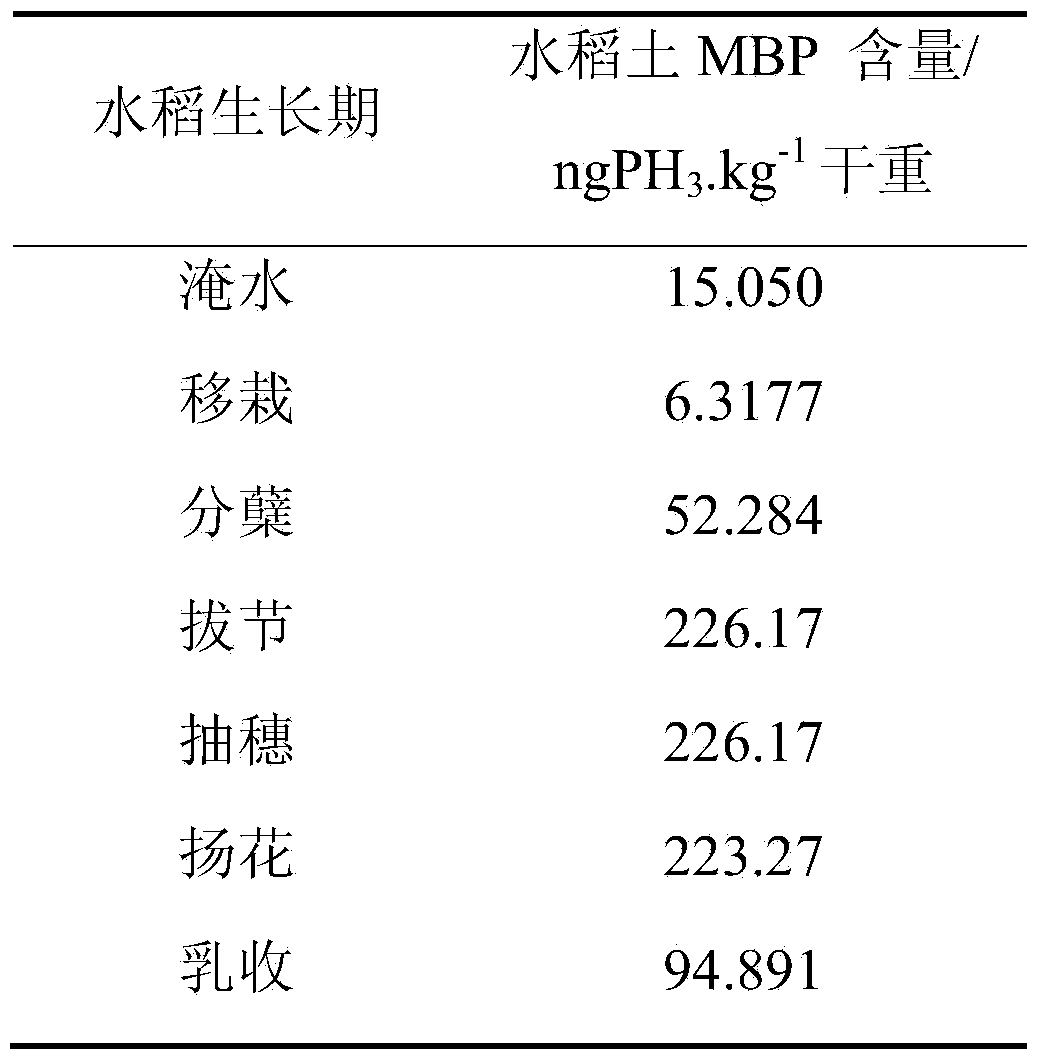

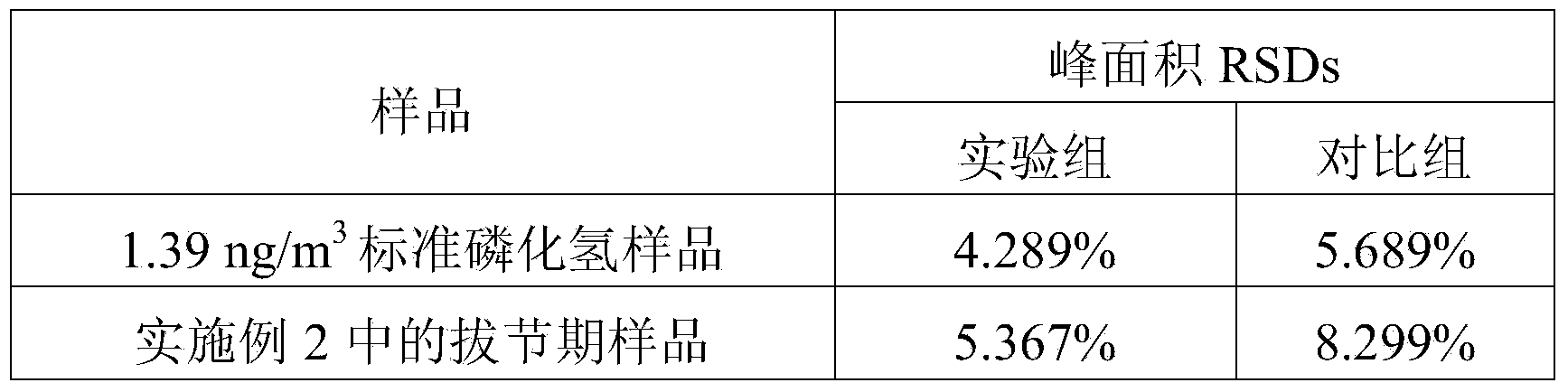

Secondary cold trap enrichment and GC-FID (Gas Chromatography-Flame Ionization Detector) combining device and method for detecting trace hydrogen phosphide

InactiveCN104007196ACooperate wellImprove reproducibility and stabilityComponent separationGas chromatography flame ionization detectorGas phase

The invention belongs to the technical field of detection of hydrogen phosphide and discloses secondary cold trap enrichment and GC-FID (Gas Chromatography-Flame Ionization Detector) combining device and method for detecting trace hydrogen phosphide. A gas loading system of the secondary cold trap enrichment and GC-FID combining device is connected with a six-way valve of a cold trap secondary enrichment system; an outlet of a secondary cold trap is connected to a gas-phase sample feeding device of a GC-FID analyzing system through a capillary tube. The detection conditions of a method for detecting the trace hydrogen phosphide by using the combining device are as follows: the gas loading flow is 1.5mL / min; the trap enrichment temperature is -90 DEG C; the chromatographic column separation temperature is 90 DEG C; the temperature of a flame ionization detector is 220 DEG C. The device and the method disclosed by the invention are used for detecting the trace hydrogen phosphide and have the advantages of good repeatability and stability and high detection precision.

Owner:SOUTH CHINA UNIV OF TECH

Production of complexing iron catalyzer and application of polyphase photocatalysis hydrogen phosphide

InactiveCN101130169AImprove decomposition rateHigh salinityOrganic-compounds/hydrides/coordination-complexes catalystsWater/sewage treatment by oxidationHydrogen phosphideMulti phase

The invention discloses a making method of complex ferric catalyst and application of multi-phased optical catalyzed hydrogen peroxide to solve the problem of low-decomposing speed of the multi-phased optical catalyzed hydrogen peroxide in the water, which comprises the following steps: complexing trivalent ferric ion and complex to form trivalent ferric complex; immersing the predisposed cation exchange resin particle or film in the trivalent complex; vibrating under indoor temperature for 0. 5-24h; separating resin from complex solution; using clean water to wash reciprocally until the ferric doesn't be dissolved out; the complex ferric catalyst can be applied for multi-phased optical catalyzed hydrogen peroxide with decomposing rate to 100%. The invention can increase the mineralization rate of organics with mineralization rate over 705, which simplifies the operation obviously.

Owner:HARBIN INST OF TECH

Method for preparing adsorbent capable of simultaneously removing hydrogen sulfide, hydrogen phosphide and arsenic hydride

ActiveCN104888692AEasy to operateEase of industrial applicationOther chemical processesDispersed particle separationArsineSorbent

The invention discloses a method for preparing an adsorbent capable of simultaneously removing hydrogen sulfide, hydrogen phosphide and arsenic hydride and belongs to the adsorbent preparation field. The method comprises the steps of grinding, washing and drying the diatomaceous earth, adding the dried diatomaceous earth in the HCl solution, stirring and standing the solution, washing the solution by utilizing distilled water till the pH value of the solution to be neutral, filtering the solution and drying the filtrate; adding the dried diatomaceous earth in a metal salt solution for ultrasonic impregnation, standing the impregnated diatomaceous earth at the normal temperature, drying and calcinating the diatomaceous earth, adding the calcined diatomaceous earth in an acidic solution for ultrasonic immersion, and drying the impregnated diatomaceous earth to obtain a mesoporous silica-based adsorbent. According to the technical scheme of the invention, the preparation method is simple in operation, wherein the HCl solution and the metal salt impregnant are cheap and readily available. Therefore, the method is suitable for industrial application. At a low temperature, the removal effect is still good. In this way, the method can be widely applied to the simultaneous removal of hydrogen sulfide, hydrogen phosphide and arsenic hydride for all kinds of gas sources.

Owner:KUNMING UNIV OF SCI & TECH

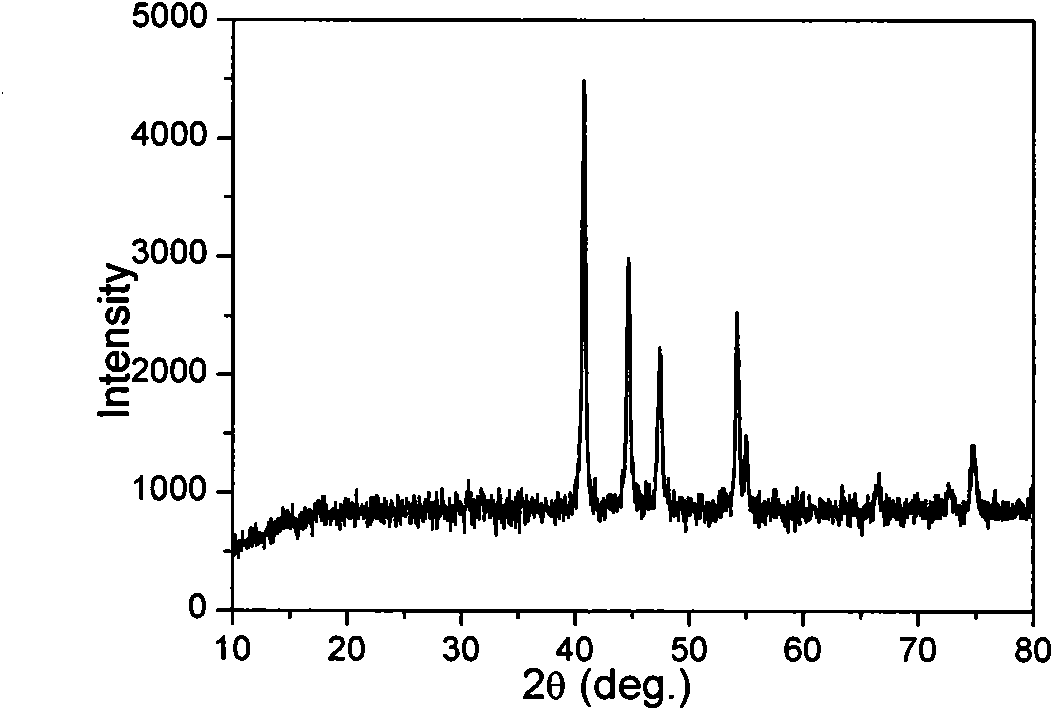

Method for controllably preparing supported and non-supported Ni2P under mild conditions

ActiveCN102030317AImprove catalytic performanceThe preparation process is safe and simplePhosphidesSodium Hypophosphite MonohydrateHydrogenation reaction

The invention provides a new method for controllably preparing supported and non-supported Ni2P under mild conditions. In the method, two tube furnace reactors connected in series are adopted; and sodium hypophosphite aqueous solution is subjected to thermal decomposition in the first reactor to generate phosphine gas, and later, carried by argon, the phosphine gas is dried and then enters into the second reactor to react with nickel salt to generate the required Ni2P. The invention is characterized in that the preparation process is safe and concise; the preparation conditions are mild and controllable; simple thermal treatment under normal pressure is only needed in the preparation process; and the supported and non-supported Ni2P can be controllably prepared by controlling the amount of the sodium hypophosphite. With excellent catalytic performances, such type of phosphides can be widely applied to various hydrogenation reactions.

Owner:NANKAI UNIV

Rare earth-Cu-Fe active carbon adsorbent, preparation method and application thereof

InactiveCN101693193ASimple methodEasy to operateOther chemical processesDispersed particle separationCeriumLanthanum

The invention relates to a method for preparing a rare earth-Cu-Fe active carbon adsorbent. The method is characterized by comprising the following steps: (1) washing coal active carbon with distilled water, and then washing with ultrasound; and thermostatically drying for 12-24 hours under the temperature condition of 80-120 DEG C; (2) dipping the coal active carbon of the step (1) into a mixed brine solution containing rare earth cerium or lanthanum and transition metal copper or iron, wherein the molar ratio of the rare earth to the copper to the iron is (0.25-0.8):20:1; mixing the active carbon and the brine solution according to the weight ratio of 1:1-1:2, carrying out ultrasound dipping for 40 minutes and then drying for 12-24 hours at a temperature of 80-100 DEG C; and (3) roasting the coal active carbon dried through the step (2) for 2-8 hours at a temperature of 200-600 DEG C so as to obtain the active carbon adsorbent for adsorbing low-concentration hydrogen phosphide gas. Compared with the prior art, the invention has the advantages of simple method and strong operability, improves the purifying efficiency and reduces the purifying cost. When the active carbon adsorbent is in saturated state, waste gas dephosphorization and waste reclamation can be realized. The method has moderate reaction condition and is easy to realize.

Owner:KUNMING UNIV OF SCI & TECH

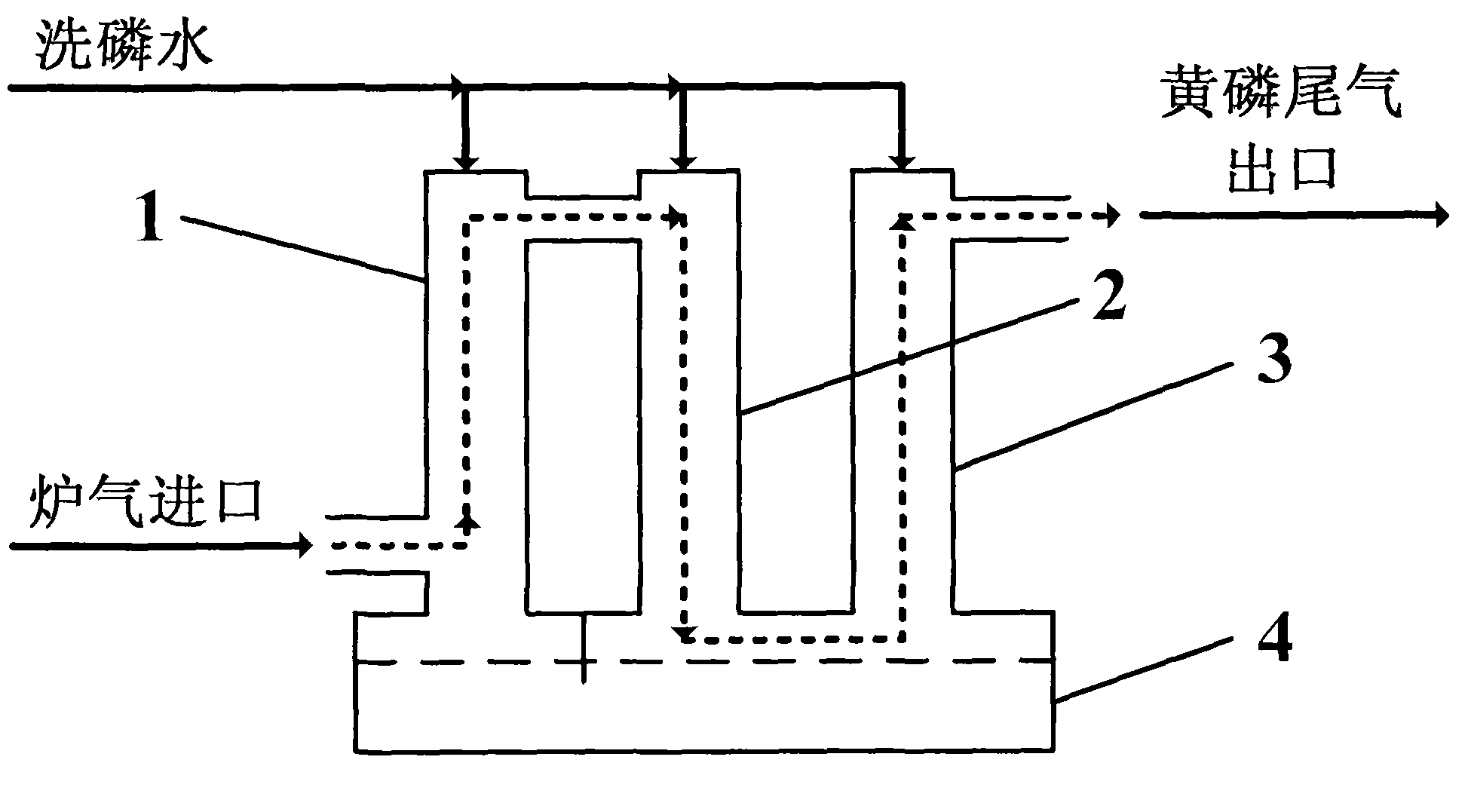

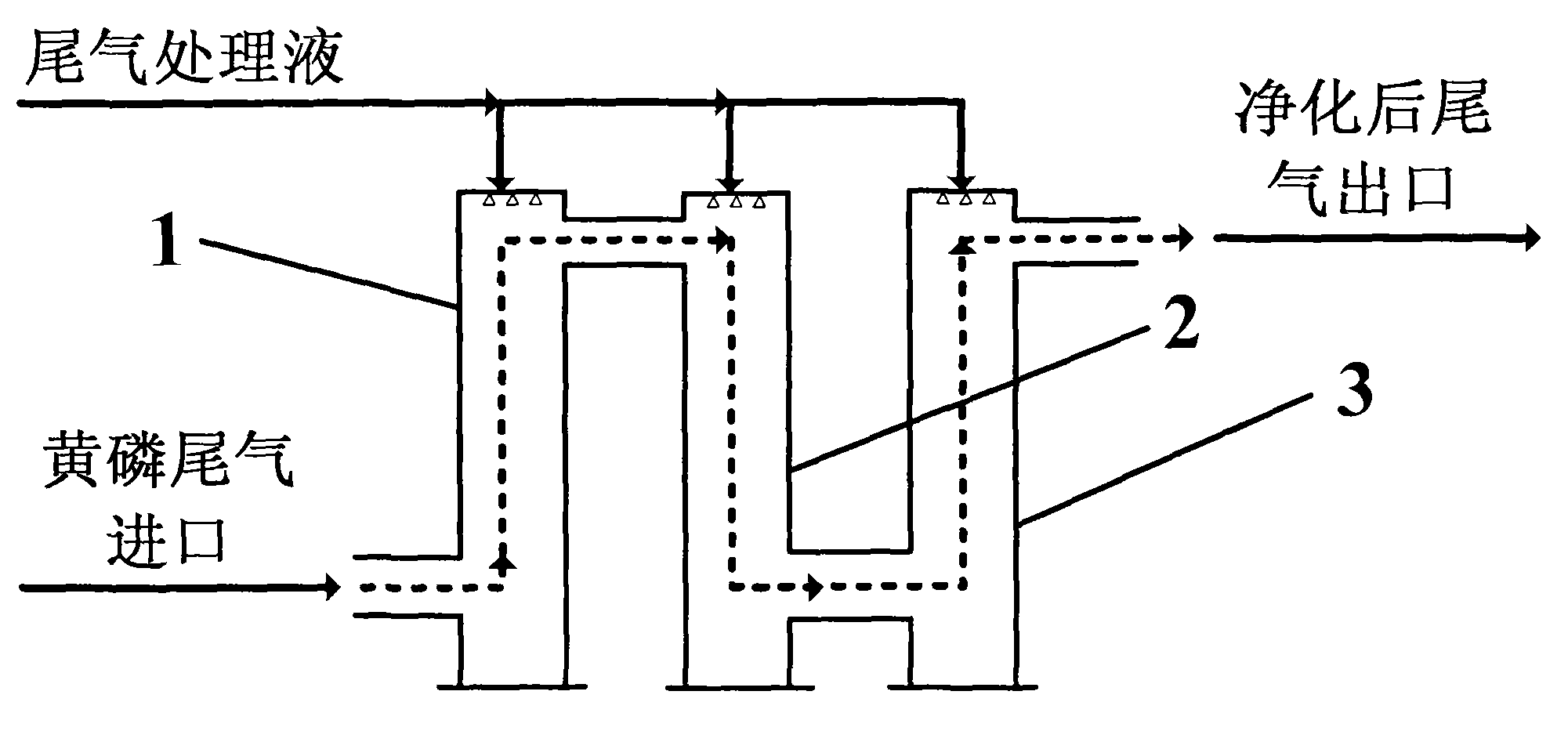

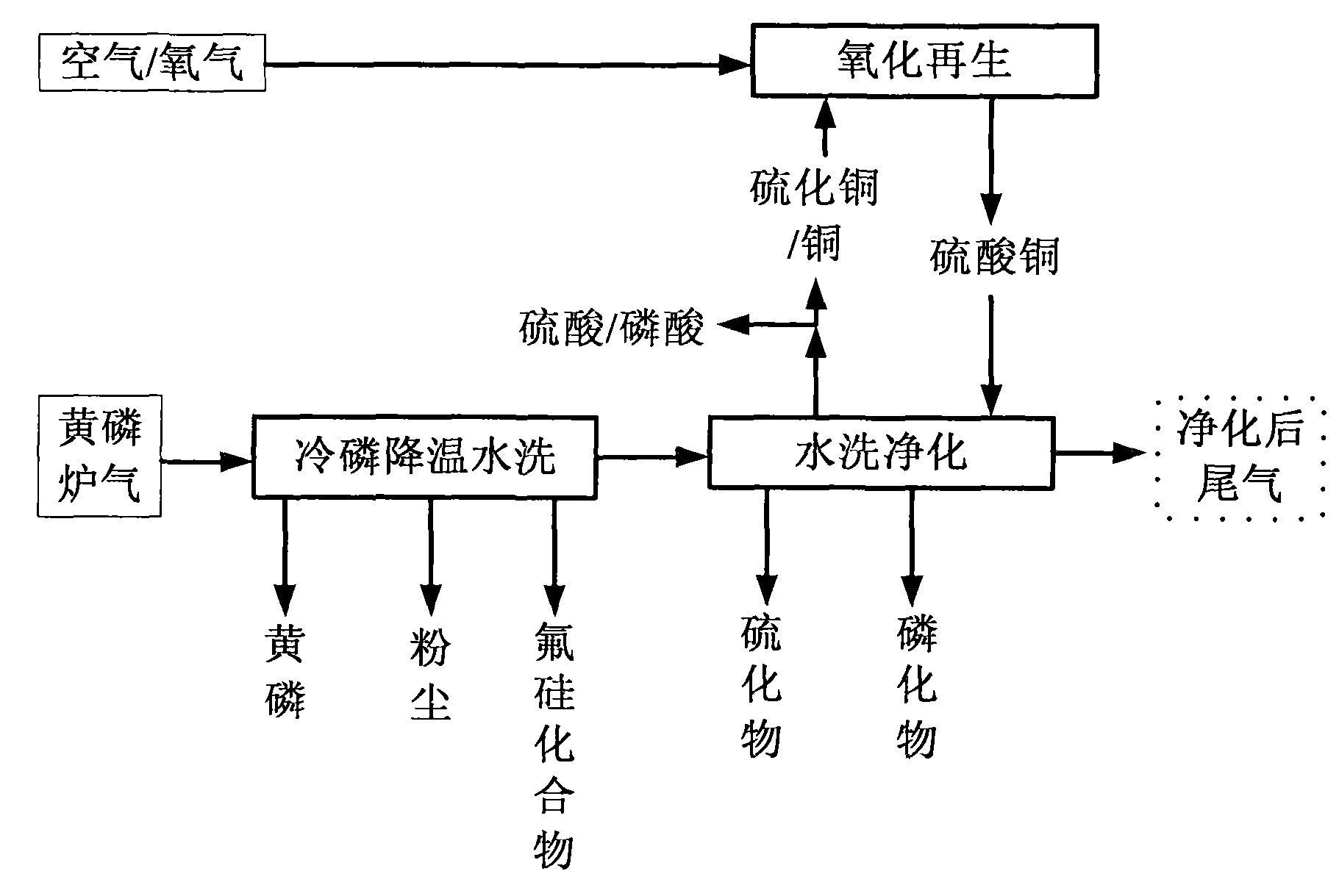

Novel technology for yellow phosphorus tail gas purification

The invention provides a novel technology for purifying yellow phosphorus tail gas to obtain fuel gas or raw material gas. Through a novel swirling technology, tail gas is fast cooled and shrunk in a tower, fully contacts with rotatingly-dispersed liquid drops and is raised spirally so that a centrifugal force is produced and throws the liquid drops, dust and yellow phosphorus to a tower wall and thus yellow phosphorus recovery, dust removal, silicon fluoride hydrolysis and fluorosilicone removal are substantially improved. Under the conditions of acidity, a normal temperature and a surfactant, a copper sulphate solution and hydrogen sulfide / hydrogen phosphide in tail gas undergo a reaction to fast produce a nanometer copper sulphide / copper suspension fluid, and the atomized nanometer copper sulphide / copper suspension fluid can undergo a fast oxidation-reduction reaction under the action of air to produce copper sulphate, and according to the above characteristics, the novel purifying technology for removing hydrogen sulfide and hydrogen phosphide by copper sulphate purification-air regeneration recycle is developed. The novel technology is verified in a million-ton level production line. The novel technology improves a yellow phosphorus production technical level, promotes tail gas resource utilization, reduces discharge of acidic gas and dust causing haze and has substantial economic, social and environmental protection benefits.

Owner:HUBEI YAOZHIHE CHEM +1

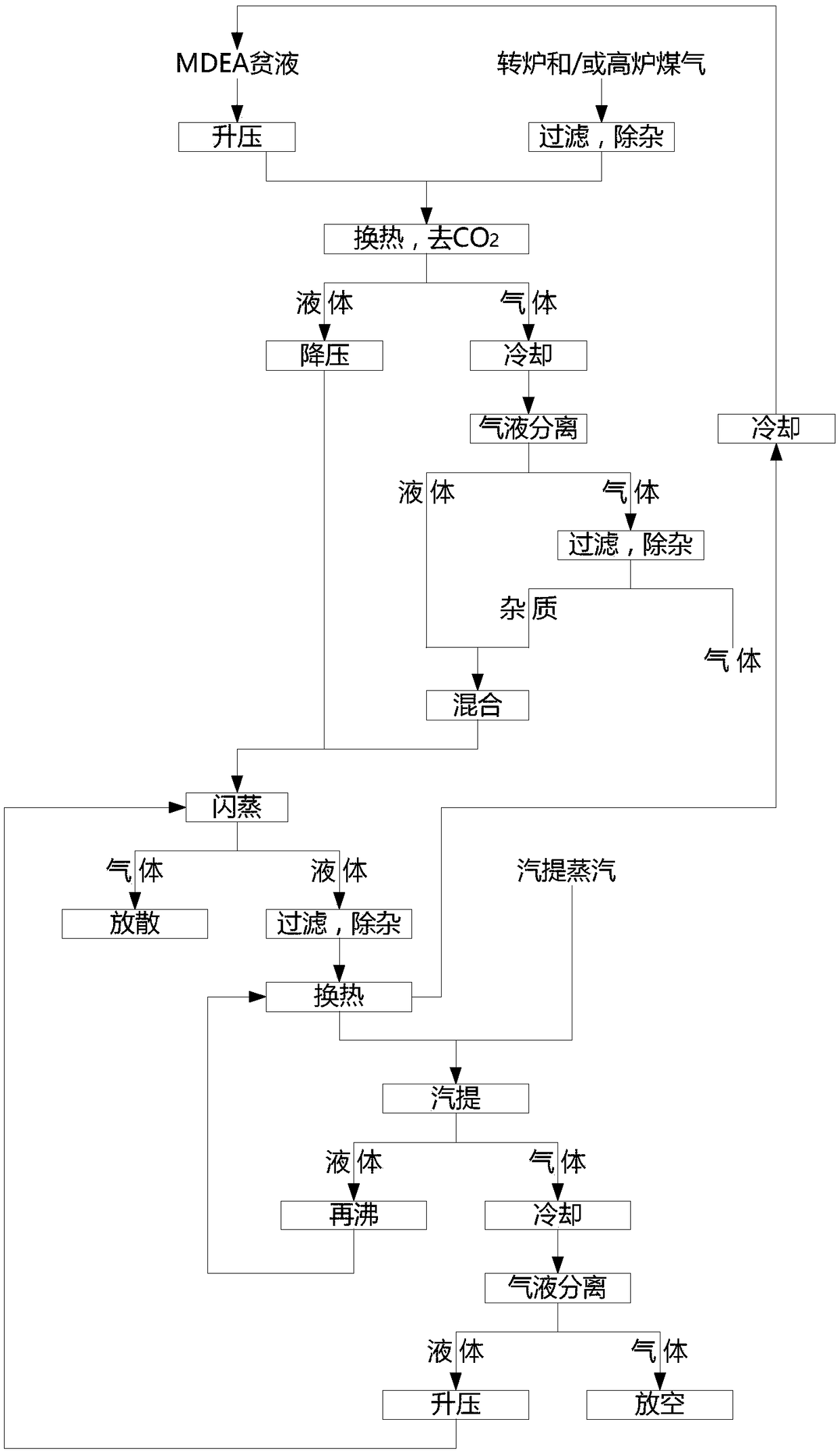

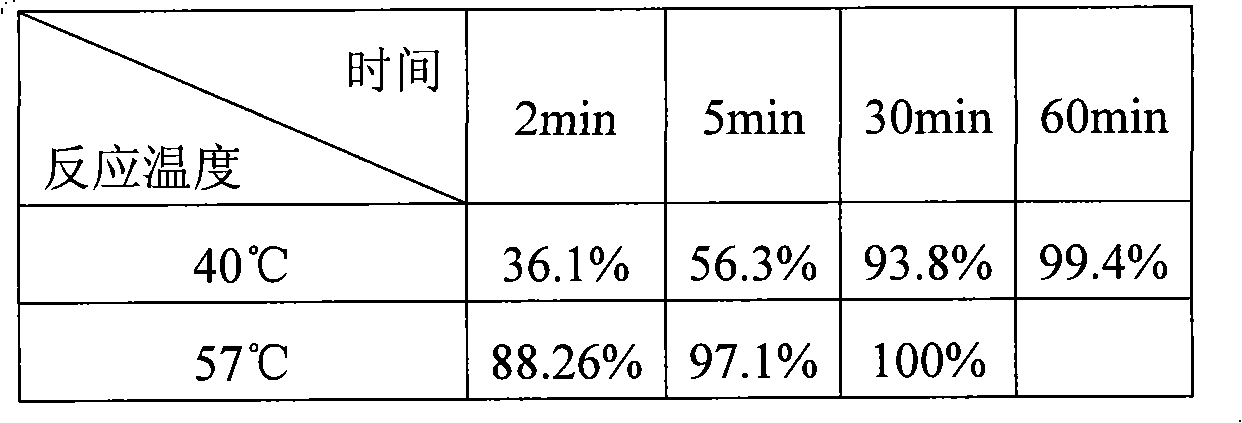

Converter and/or blast furnace gas decarbonizing method

ActiveCN108970332ADecarbonization achievedEasy loadingDispersed particle separationGas purification by liquid washingHydrogen phosphideEngineering

The invention discloses a converter and / or blast furnace gas decarbonizing method which comprises the following steps: coarsely decarbonizing: utilizing a pressure swing adsorption mode to coarsely decarbonize converter and / or blast furnace gas and remove hydrogen phosphide; making the carbon dioxide volume fraction of the pressure swing absorption converter and / or blast furnace gas as 5.8 to 6.2%and the hydrogen phosphide content as 1 to 5 PPM; finely decarbonizing: utilizing an MDEA solution to decarbonize the converter and / or blast furnace gas in the S1 and making the carbon dioxide volumefraction of the converter and / or blast furnace gas as 0.0015 to 0.0019%. According to the converter and / or blast furnace gas decarbonizing method disclosed by the invention, two steps of work procedures of pressure swing adsorption decarbonization and MDEA solution fine decarbonization are creatively utilized for finishing decarbonizing the converter and / or blast furnace gas, breakthrough in converter and / or blast furnace gas decarbonization is achieved, and very important significance in promoting technological advance of China steel industry and economic development are achieved.

Owner:戴乐亭 +3

Method for decomposing hydrogen phosphide cumene to prepare phynol and acetone

ActiveCN101343212AEasy to separateThe progress of the reaction is easy to controlPhysical/chemical process catalystsOrganic chemistryRecyclable catalystDecomposition

The invention provides a method for preparing phenol and acetone by composing hydrogen peroxide iso-propyl benzene, which is characterized in that the method adopts a smectite solid-acid catalyst modified by inorganic ammonium salt as a reaction catalyst to make the hydrogen peroxide iso-propyl benzene have the decomposition reaction, with a decomposition temperature of between 35 and 80 DEG C, and a decomposition pressure of 0.1 to 5atm. The method makes the reaction under a mild condition, and has advantages of easy control of extent of reaction, less by-products, non corrosion, easy separation of products, recyclable catalyst, and non phenolic wastewater.

Owner:PETROCHINA CO LTD

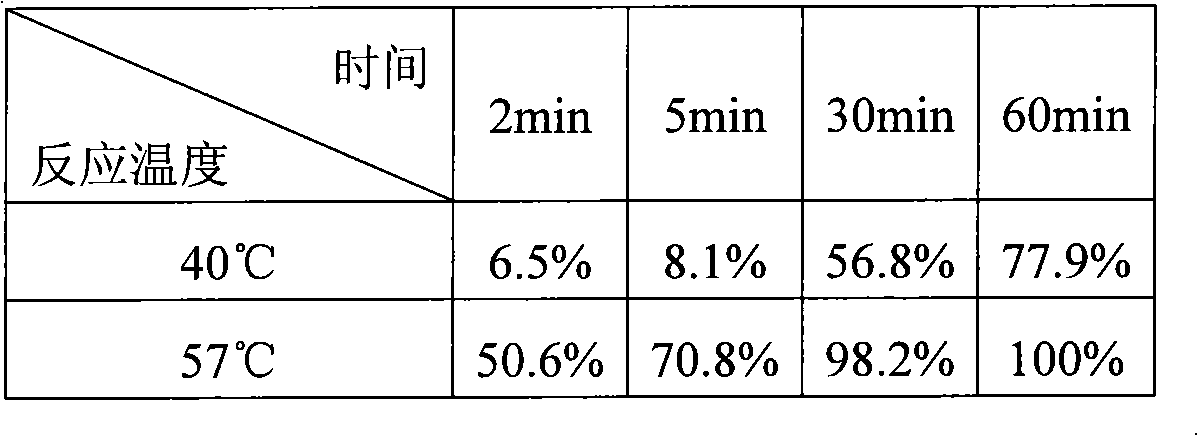

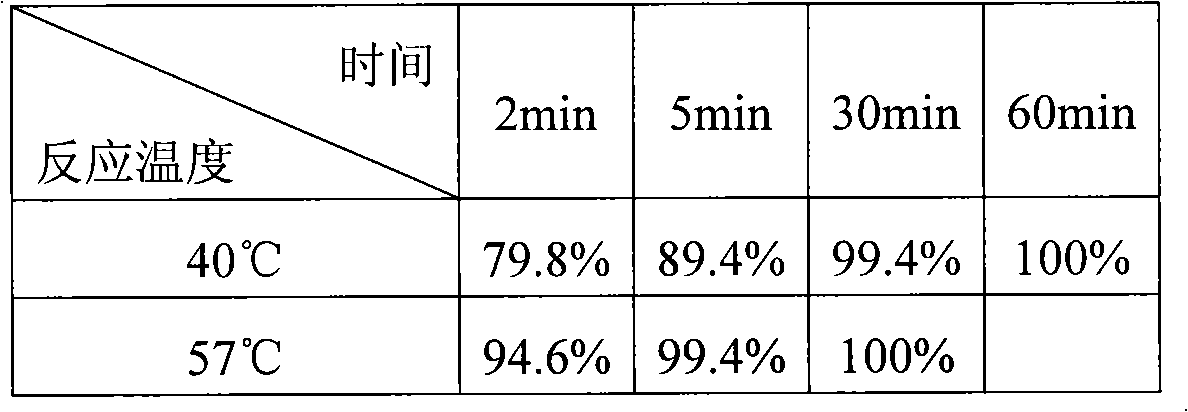

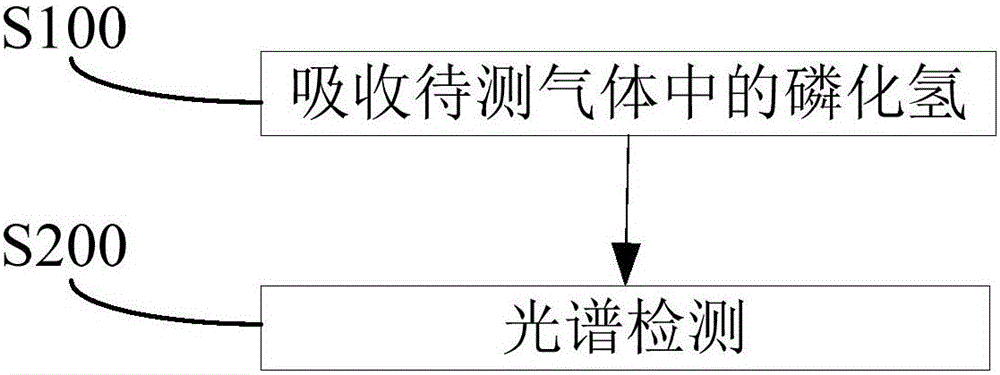

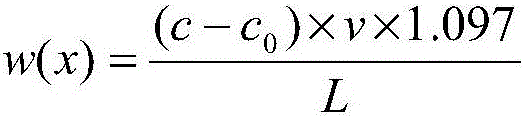

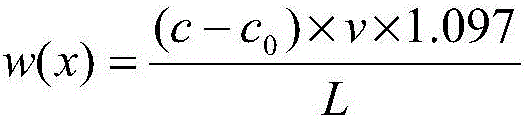

Method for measuring hydrogen phosphide content in gas to be measured

The invention discloses a method for measuring the hydrogen phosphide content in gas to be measured. The method comprises: collecting gas to be measured in a predetermined volume, and absorbing hydrogen phosphine in the gas to be measured to obtain absorbed liquid; and conducting spectral detection on the absorbed liquid by using an ICP-AES detector; and based on the spectrum detection results, determining the content of hydrogen phosphine in the gas. The method uses hydrogen phosphide absorption liquid for absorption and enrichment of hydrogen phosphide in the gas to be tested, then uses high-precision ICP-AES detector for enrichment of concentration of phosphorus elemtn in the phosphine absorbed solution, so as to obtain the content of hydrogen phosphide in the gas to be measured. Compared with the method for direct detection of hydrogen phosphide in the gas to be tested by analysis instrument without enrichment in the prior art, the method has significantly improved the accuracy and precision, and can be used for the detection of phosphorus content in the gas containing low-concentration hydrogen phosphide.

Owner:云南冶金云芯硅材股份有限公司

Passivating treatment process of electronic grade arsenic hydride, hydrogen phosphide and mixture gas steel cylinder

ActiveCN106185850ANo reduction in purityArsenic/antimony hydridesSolid state diffusion coatingVacuum pumpingMetallurgy

The invention relates to a passivating treatment process of a super-high-purity arsenic hydride, hydrogen phosphide and mixture gas steel cylinder. The process comprises the following steps that a first steel cylinder to be subjected to passivating treatment is heated and baked at a high temperature of 100 to 200 DEG C; the first steel cylinder is subjected to vacuum pumping treatment through an exhaust fan; the first steel cylinder is continuously subjected to heating and baking treatment at a high temperature of 100 to 200 DEG C; when the first steel cylinder is pumped into a vacuum state, scavenging and replacement are performed; the first steel cylinder is subjected to vacuum pumping treatment through the exhaust fan, and the first steel cylinder is continuously subjected to heating and baking treatment at a high temperature of 100 to 200 DEG C; when the first steel cylinder is pumped into a vacuum state, the inner wall is passivated; the first steel cylinder is subjected to vacuum pumping treatment through a gas pumping-back device; extracted arsenic hydride and hydrogen phosphide gas is recovered to a gas recovery steel cylinder.

Owner:HEFEI ZHENGFAN ELECTRONICS MATERIAL

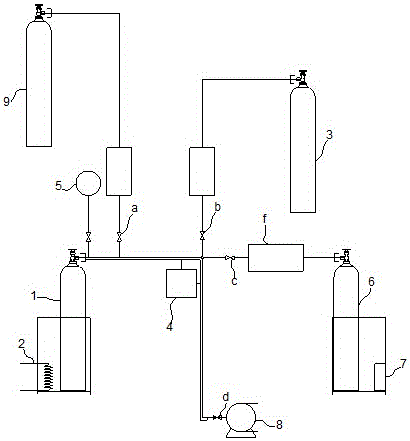

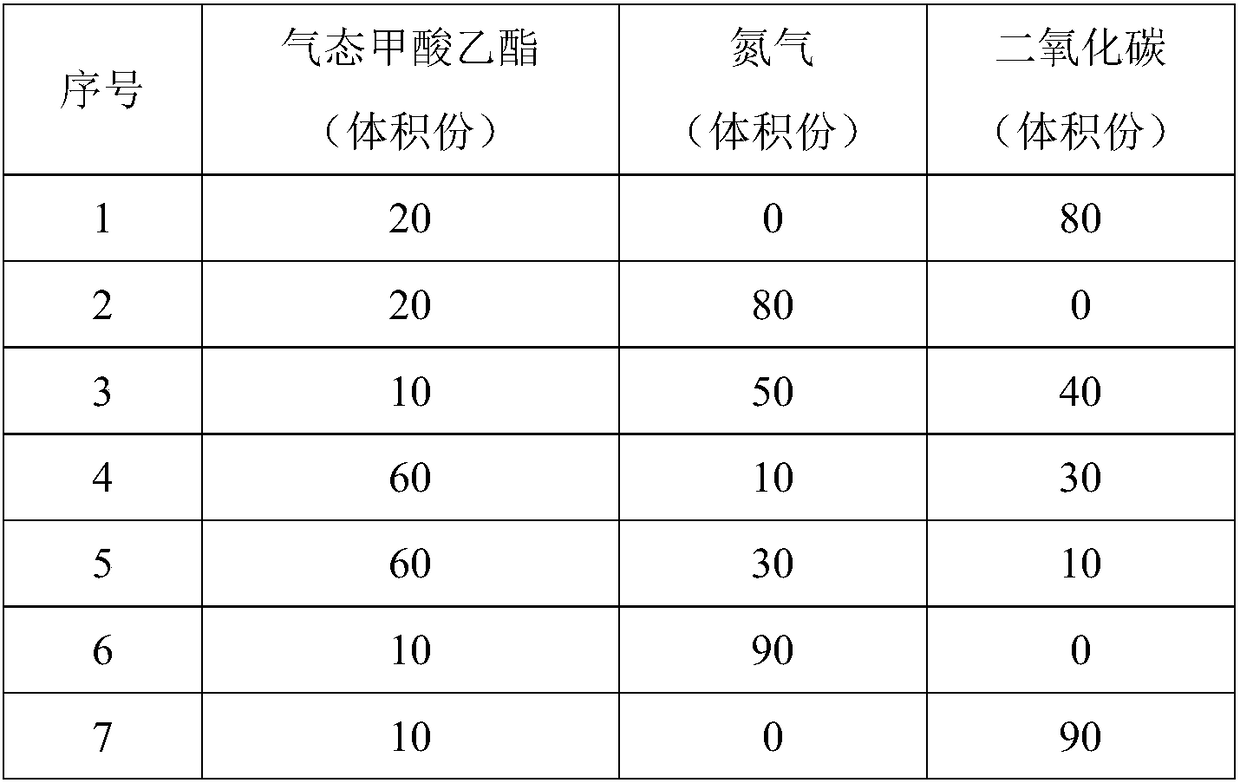

Composition for pest control and its preparation method and application

The invention discloses a composition for pest control and its preparation method. The composition can solve the problems that pests cannot be rapidly killed by the prior art and main quarantine pestscan generally resist hydrogen phosphide and is poor in pest killing effect. The composition is prepared from, by volume, 10-60 parts of gaseous ethyl formate and 40-90 parts of inert gas. The invention further provides an application of the composition in preparing pesticide for pest control. The composition can rapidly kill pest and is environment-friendly. The preparation method is simple and convenient to operate, and suitable for popularization and application.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com