Device for removing phosphor from phosphor-containing organic wastewater and producing hydrogen phosphide

A technology for organic wastewater and phosphine, applied in phosphine, water pollutants, biochemical fuel cells, etc., can solve problems such as difficulty in continuing research, low yield of phosphine, unclear mechanism of phosphine, etc. Achieve the effect of reducing energy consumption and improving economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

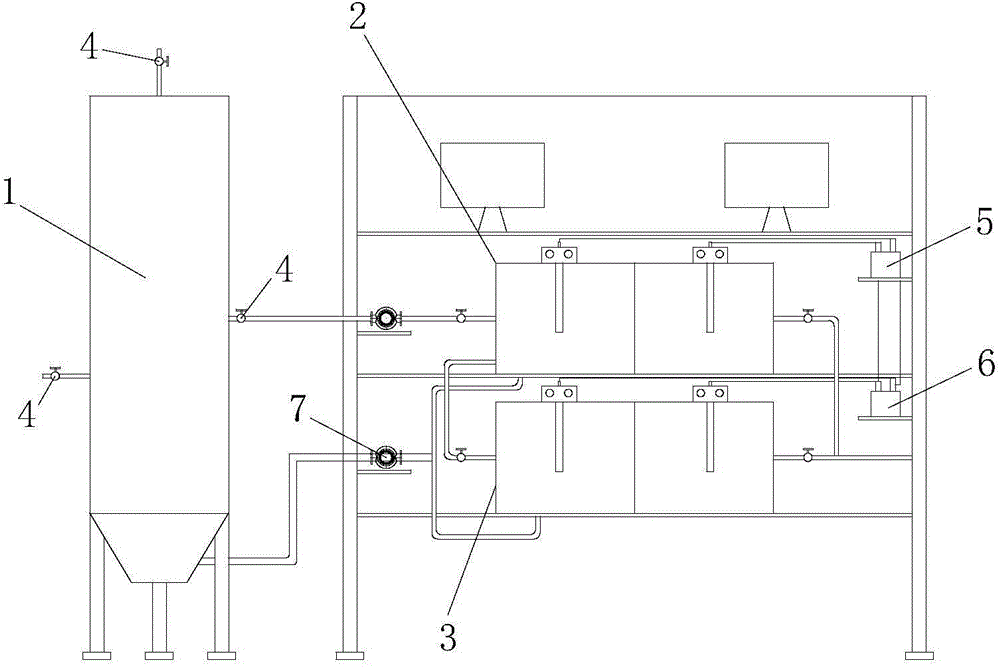

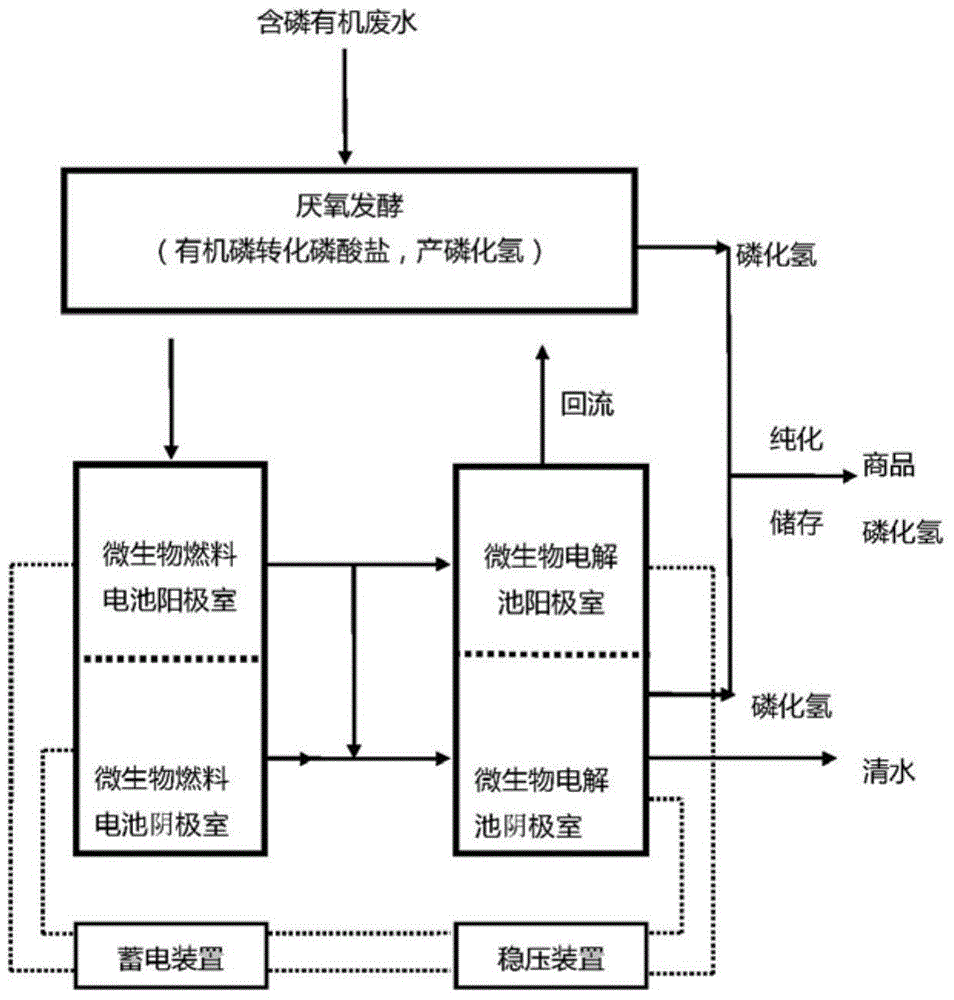

[0024] A device for multi-stage phosphorus removal and production of phosphine from phosphorus-containing organic wastewater, including an anaerobic reactor 1, a microbial fuel cell 2, and a microbial electrolysis cell 3. The outlet pipe of the anaerobic reactor is connected to the anode water inlet pipe of the microbial fuel cell The anode outlet pipe of the microbial fuel cell is connected to the water inlet pipe of the microbial electrolysis cell, and the power output terminal of the microbial fuel cell is connected to the power port of the microbial electrolysis cell.

[0025] Preferably, the anaerobic reactor is provided with top gas production area, clear water area, organic waste water area and sludge area successively from top to bottom, and the top gas production area, clear water area, organic waste water area and sludge area are respectively provided with Switch valve 4.

[0026] Preferably, anaerobic microbial sludge is placed in the sludge zone.

[0027] Preferab...

Embodiment 2

[0034] A method for producing phosphine by multi-stage phosphorus removal from organic wastewater:

[0035] (1) Anaerobic microbial phosphorus removal to produce phosphine

[0036] Inoculate the sludge of phosphine-producing bacteria in the anaerobic sequencing batch reactor, adjust the pH of phosphorus-containing organic wastewater to 6-7, add it to the anaerobic sequencing batch reactor, and control the hydraulic retention time in the reactor 20h, by anaerobic treatment, the organic phosphorus in the waste water is preliminarily degraded into phosphate and part of the phosphorus in the waste water is transformed into phosphine, and the phosphine is collected; the concentration of the sludge of the phosphine-producing bacteria in the reactor 4g / L;

[0037] Influent COD is 4000mg / L, TP is 5mg / L. Organic phosphorus is converted into inorganic phosphorus under the action of phosphine-producing bacteria, which increases the concentration of inorganic phosphorus in the effluent;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com