Method for preparing Ni2P by reducing nickel oxide precursor through thermal treatment at low temperature

A nickel oxide and precursor technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficulty in realizing temperature-programmed reduction, and achieve low equipment cost, short production cycle, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

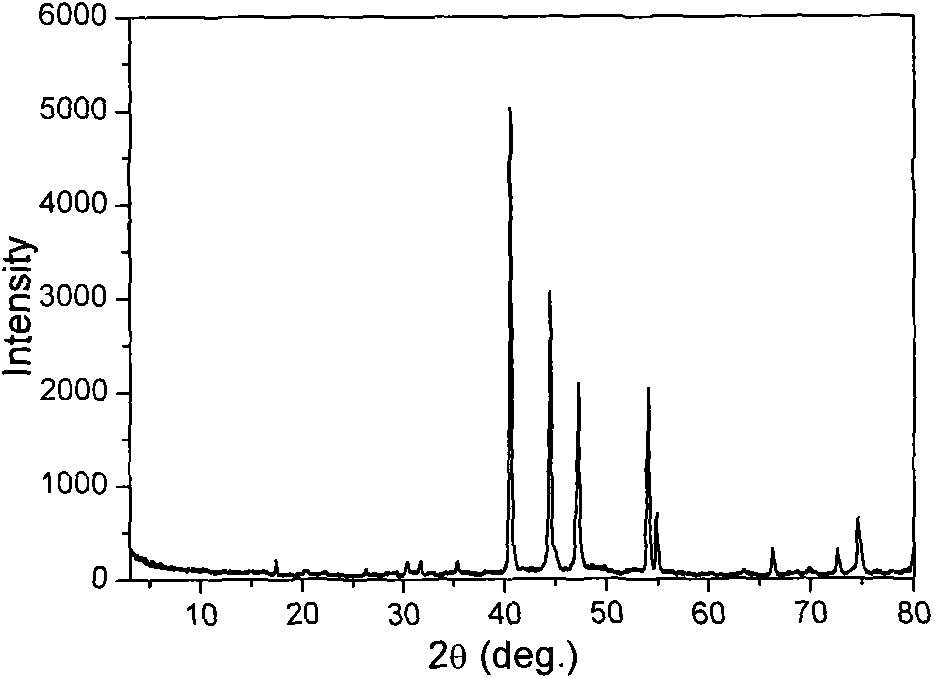

[0014] First, 5.89 g of sodium hypophosphite (NaH 2 PO 2 .H 2 O) was added into 18mL deionized water, and after dissolving for 10min, 1.49g of NiO was added. After continuing to stir for 2 hours, the resulting solution was put into a petri dish and dried at 80°C. Then put the dried precursor powder into the reactor, heat treatment at 250°C for 10 minutes in a static nitrogen protection, and then wash the product with water and dry it. The obtained sample is named A, and A has an attached figure 1 Characteristics.

Embodiment 2

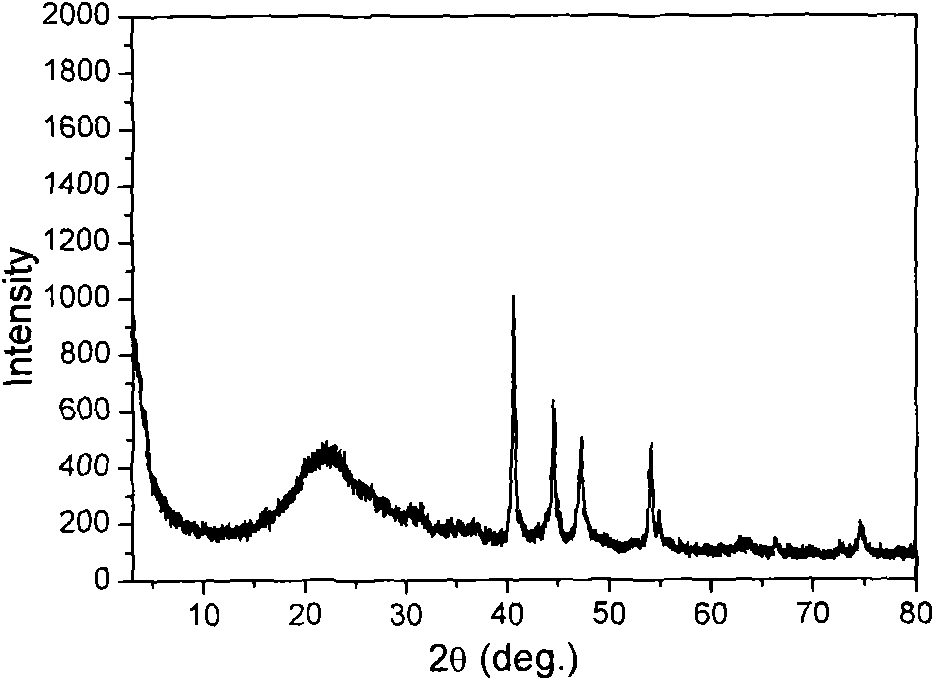

[0016] First, 5.93g of nickel nitrate (Ni(NO 3 ) 2 .6H 2 O) Added into 18mL deionized water, dissolved for 10min and then added 3.91g of MCM-41 molecular sieves. After continuing to stir for 2 hours, the resulting solution was put into a petri dish and dried at 100°C. Then put the dried precursor powder into a muffle furnace, and bake it in an air atmosphere at 550° C. for 2 hours to obtain supported nickel oxide (NiO / MCM-41). With stirring at room temperature, 5.89 g of NaH 2 PO 2 .H 2 O was added to 18 mL of deionized water, dissolved for 10 min and then added to the supported nickel oxide (NiO / MCM-41). After continuing to stir for 2 hours, the resulting solution was put into a petri dish and dried at 80°C. Then put the dried precursor powder into the reactor, heat treatment at 250°C for 10 minutes in a static nitrogen protection, and then wash the product with water and dry it. The obtained sample is named B, and B has an attached figure 2 Characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com