Red and orange light fluorescent powder with garnet structure and preparation method thereof

A phosphor, red-orange light technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of harsh preparation conditions, unstable luminescence color, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

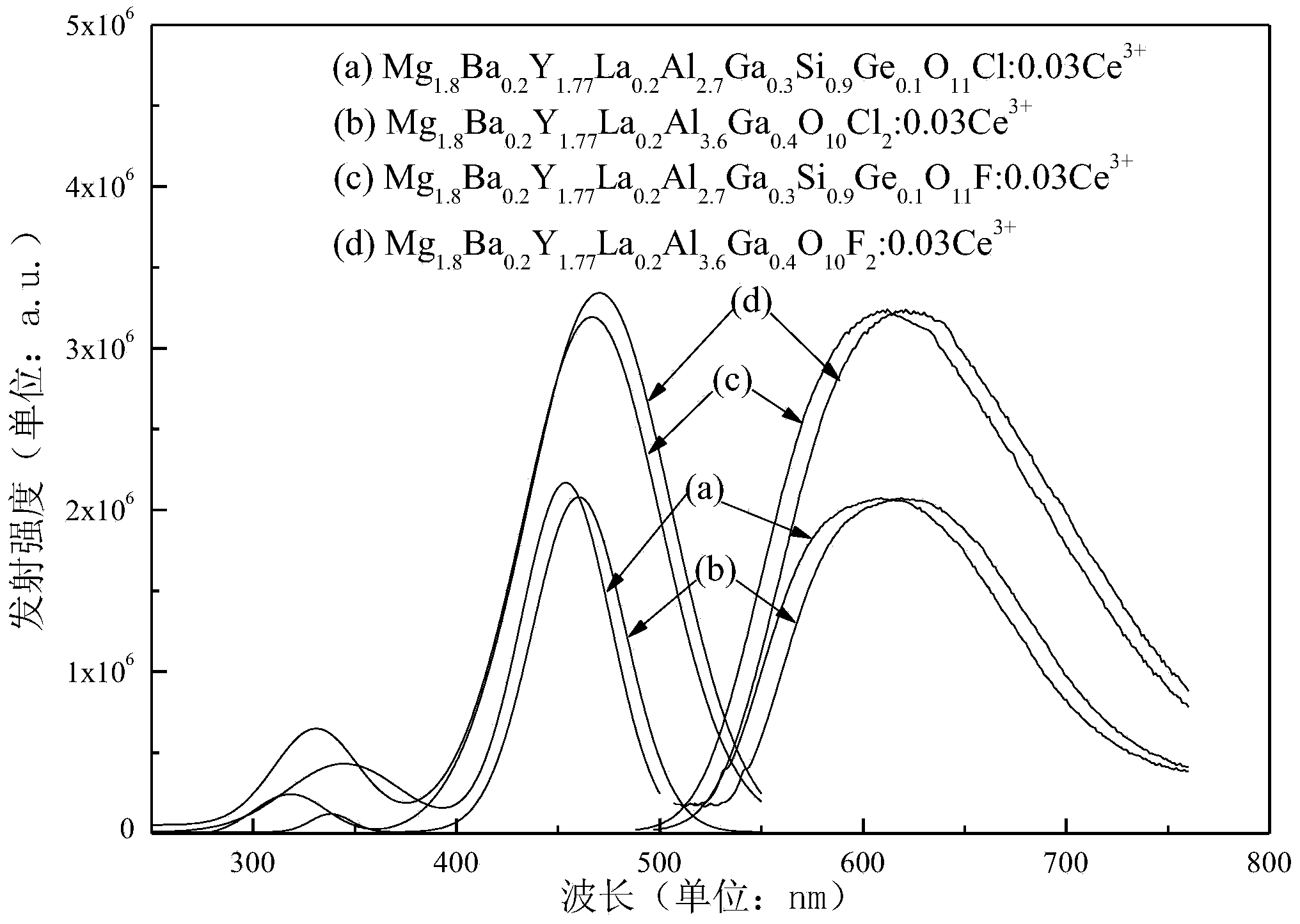

Embodiment 1

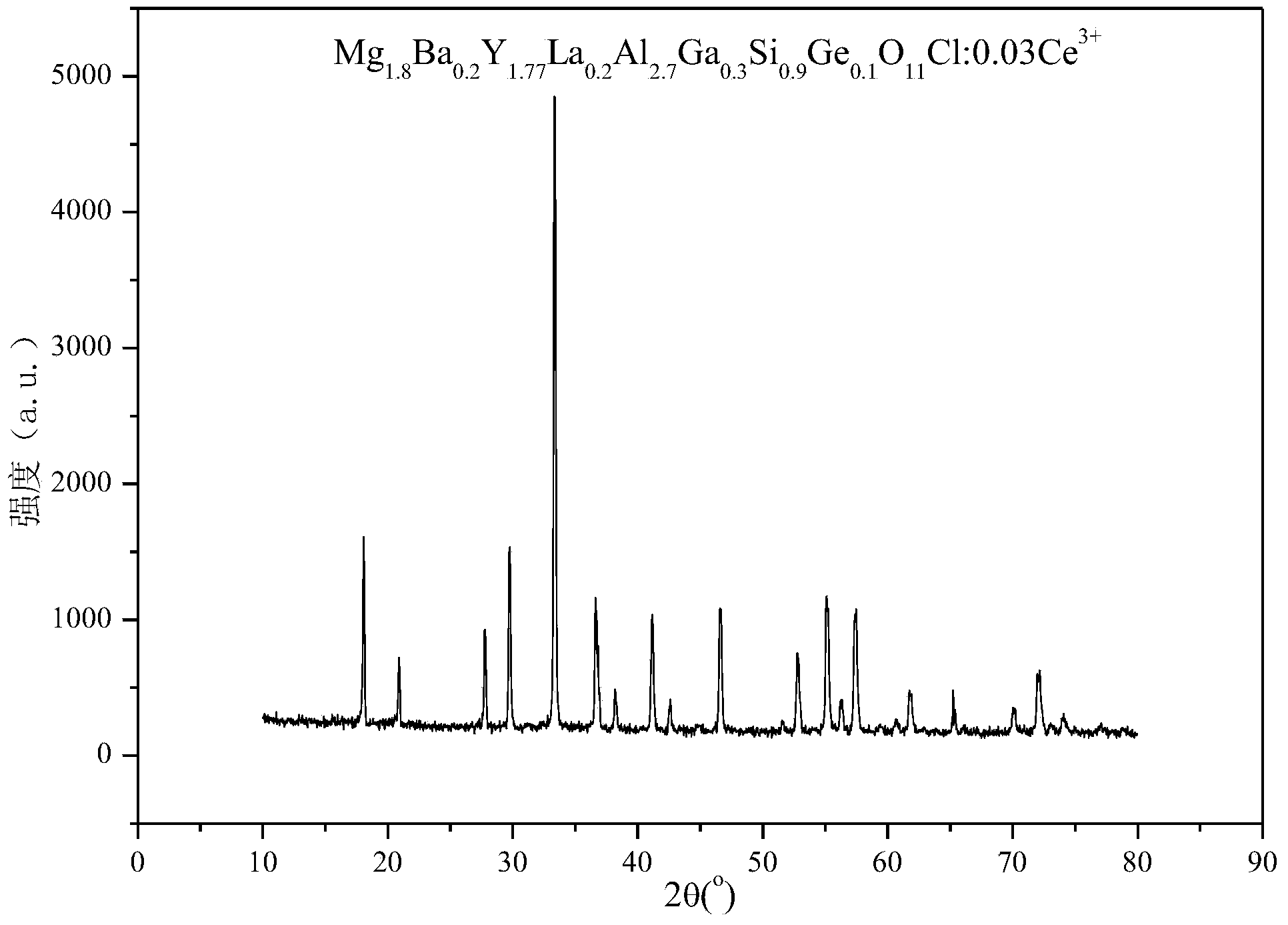

[0048] Mg 1.8 Ba 0.2 Y 1.77 La 0.2 al 2.7 Ga 0.3 Si 0.9 Ge 0.1 o 11 Cl:0.03Ce 3+ Phosphor powder preparation.

[0049] The preparation method is as follows:

[0050] Weigh respectively 0.3627 gram of magnesium oxide (MgO), 0.1973 gram of barium carbonate (BaCO 3 ), 0.9992 grams of yttrium oxide (Y 2 o 3 ), 0.1629 grams of lanthanum oxide (La 2 o 3 ), 0.6063 grams of alumina (Al 2 o 3 ), 0.1406 grams of gallium oxide (Ga 2 o 3), 0.2703 grams of silicon dioxide (SiO 2 ), 0.0523 grams of germanium dioxide (GeO 2 ), 0.2222 grams of aluminum chloride (AlCl 3 ), 0.0258 grams of cerium oxide (CeO 2 ), the above raw material purity is more than 99%. Grind the above-mentioned raw material mixture in an agate mortar evenly, put it into a corundum crucible, use a nitrogen mixture containing 5v% hydrogen as a reducing atmosphere, heat up at a rate of 10°C / min, bake at 1350°C for 8 hours, and cool to room temperature. After crushing, the obtained sintered product is...

Embodiment 2

[0053] Mg 1.8 Ba 0.2 Y 1.77 La 0.2 al 3.6 Ga 0.4 o 10 Cl 2 :0.03Ce 3+ Phosphor powder preparation.

[0054] The preparation method is as follows:

[0055] Weigh respectively 0.3627 gram of magnesium oxide (MgO), 0.1973 gram of barium carbonate (BaCO 3 ), 0.9992 grams of yttrium oxide (Y 2 o 3 ), 0.1629 grams of lanthanum oxide (La 2 o 3 ), 0.7567 grams of alumina (Al 2 o 3 ), 0.1874 grams of gallium oxide (Ga 2 o 3 ), 0.4445 grams of aluminum chloride (AlCl 3 ), 0.0258 grams of cerium oxide (CeO 2 ), the above raw material purity is more than 99%. Grind the above raw material mixture evenly in an agate mortar, put it into a corundum crucible, use a nitrogen mixture containing 5v% carbon monoxide as a reducing atmosphere, heat up at a rate of 5°C / min, bake at 1300°C for 10h, and cool to room temperature. Take the sintered product, grind it and then raise the temperature, and roast it once according to the above-mentioned roasting conditions. The sintered pro...

Embodiment 3

[0057] Mg 1.8 Ba 0.2 Y 1.77 La 0.2 al 2.7 Ga 0.3 Si 0.9 Ge 0.1 o 11 F:0.03Ce 3+ Phosphor powder preparation.

[0058] The preparation method is as follows:

[0059] Weigh respectively 0.3627 gram of magnesium oxide (MgO), 0.1973 gram of barium carbonate (BaCO 3 ), 0.9992 grams of yttrium oxide (Y 2 o 3 ), 0.1629 grams of lanthanum oxide (La 2 o 3 ), 0.6063 grams of alumina (Al 2 o 3 ), 0.1406 grams of gallium oxide (Ga 2 o 3 ), 0.2703 grams of silicon dioxide (SiO 2 ), 0.0523 grams of germanium dioxide (GeO 2 ), 0.1340 grams of aluminum fluoride (AlF 3 ), 0.0258 grams of cerium oxide (CeO 2 ), the above raw material purity is more than 99%. Grind the above-mentioned raw material mixture evenly in an agate mortar, put it into a corundum crucible, use a nitrogen mixture containing 5v% hydrogen as a reducing atmosphere, heat up at a rate of 20°C / min, bake at 1340°C for 10h, and cool to room temperature. After crushing, the obtained sintered product is groun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com