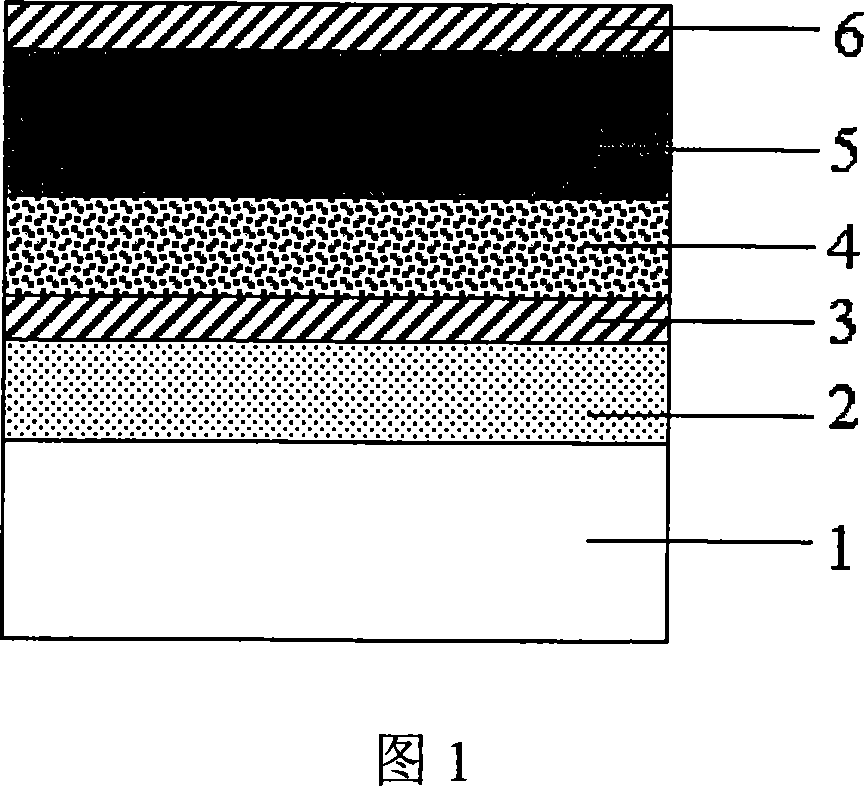

Bismuth ferric/bismuth titanate laminated construction electric capacity and method for preparing the same

A laminated structure, bismuth titanate technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as poor capacitance characteristics and affect capacitance performance, and achieve low power consumption, low preparation temperature, and excellent resistance. Effects of fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] BXT in the capacitor of the present embodiment is neodymium-doped bismuth titanate Bi 4-x Nd x Ti 3 o 12 , its chemical composition and components are: Bi 3.15 Nd 0.85 Ti 3 o 12 (i.e. BNT), x in said Nd is 0.85; Bi in said neodymium-doped bismuth titanate, relative to said composition formula Bi 3.15 Nd 0.85 Ti 3 o 12 The content of Bi should be added in excess, and the excess percentage of the Bi element is 20% of the total amount of each element; the thickness of the BNT film is 10nm, and the thickness of the BFO film is 100nm. Specific steps are as follows:

[0048] 1) Prepare the BNT precursor sol:

[0049] 11) Dissolving 1.366g neodymium acetate (commercially available product) in 10ml ethanolamine (commercially available product) is mixed with completely dissolved neodymium acetate solution;

[0050] 12) Dissolving 15.422g bismuth hexanoate (commercially available product) in 25ml hexanoic acid (commercially available product) is made into completely d...

Embodiment 2

[0078] BXT in the capacitor of the present embodiment is neodymium-doped bismuth titanate Bi 4-x Nd x Ti 3 o 12 , its chemical composition and components are: Bi 3.15 Nd 0.85 Ti 3 o 12 (i.e. BNT), x in said Nd is 0.85; Bi in said neodymium-doped bismuth titanate, relative to said composition formula Bi 3.15 Nd 0.85 Ti 3 o 12 The content of Bi should be added in excess, and the excess percentage of the Bi element is 20% of the total amount of each element; the thickness of the BNT film is 20nm, and the thickness of the BFO film is 200nm. Specific steps are as follows:

[0079] 1) Prepare the BNT precursor sol:

[0080] 11) Dissolving 1.366g neodymium acetate (commercially available product) in 10ml ethanolamine (commercially available product) is mixed with completely dissolved neodymium acetate solution;

[0081]12) Dissolve 11.712g of bismuth nitrate (commercially available product) in 50ml of acetic acid (commercially available product), add 10ml of ethanolamine,...

Embodiment 3

[0109] BXT in the capacitor of the present embodiment is neodymium-doped bismuth titanate Bi 4-x Nd x Ti 3 o 12 , its chemical composition and components are: Bi 3.15 Nd 0.85 Ti 3 o 12 (i.e. BNT), x in said Nd is 0.85; Bi in said neodymium-doped bismuth titanate, relative to said composition formula Bi 3.15 Nd 0.85 Ti 3 o 12 The content of Bi should be added in excess, and the excess percentage of the Bi element is 20% of the total amount of each element; the thickness of the BNT film is 50nm, and the thickness of the BFO film is 300nm. Specific steps are as follows:

[0110] 1) Prepare the BNT precursor sol:

[0111] 11) Dissolving 1.366g neodymium acetate (commercially available product) in 10ml ethanolamine (commercially available product) is mixed with completely dissolved neodymium acetate solution;

[0112] 12) Dissolve 9.394 bismuth acetate (commercially available product) in 40ml of glacial acetic acid (commercially available product), and fully stir at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com