PAMMA-coated BT/PP nanocomposite dielectric film with controllable shell thickness and preparation method thereof

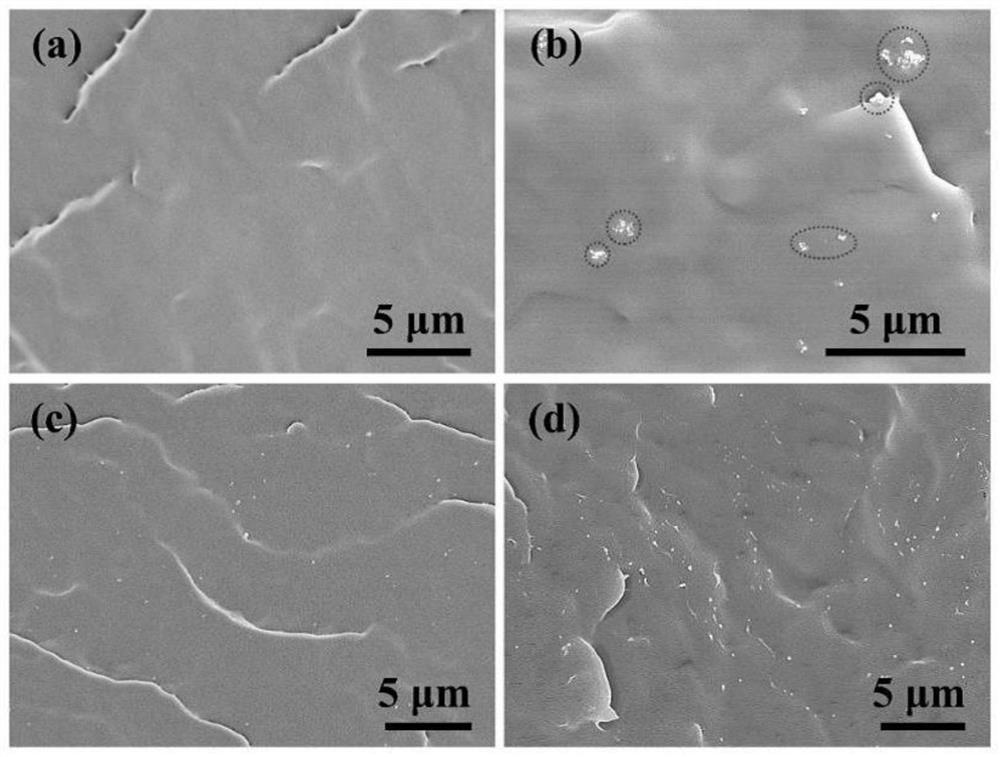

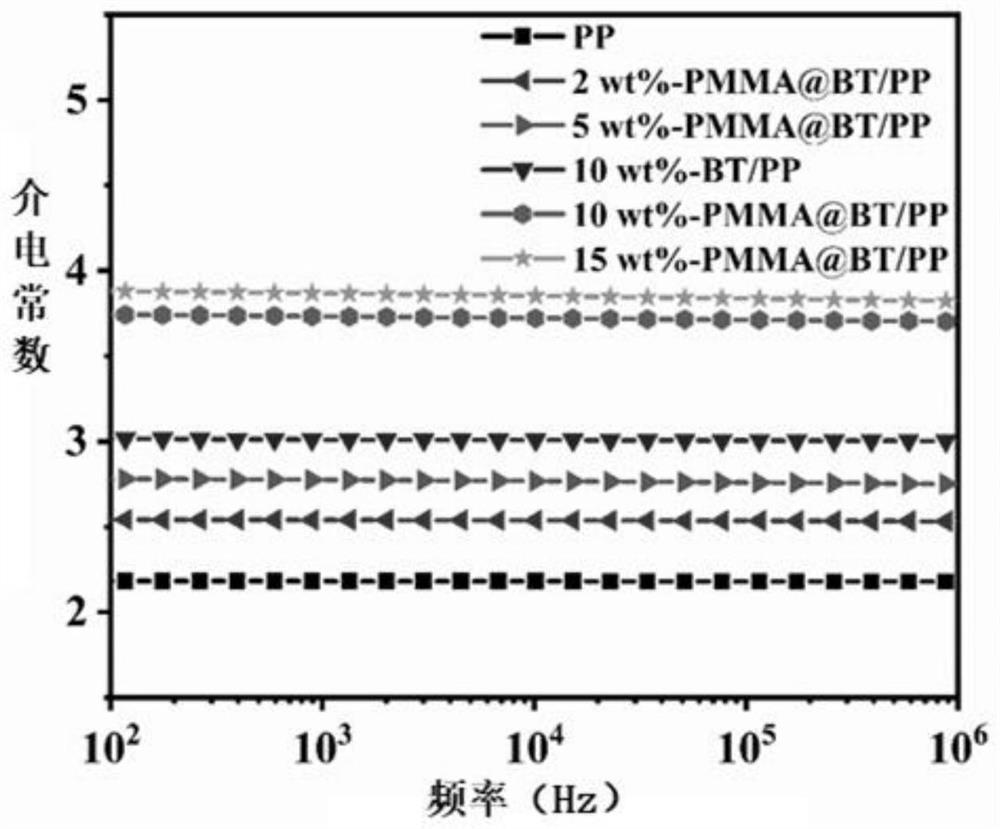

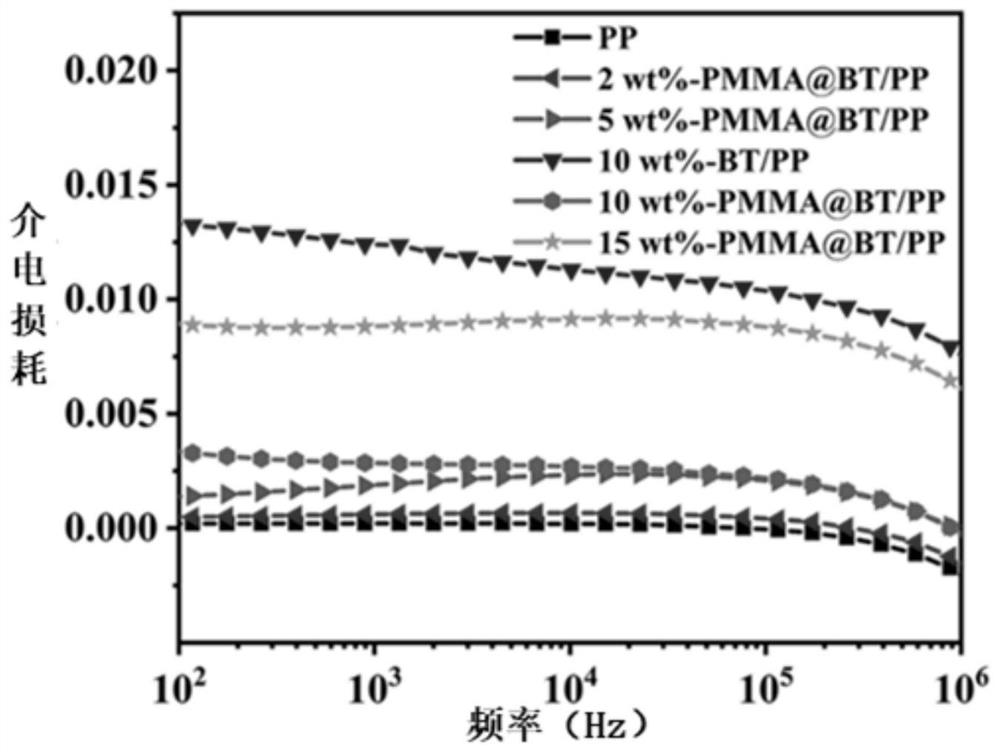

A nano-composite and dielectric technology, applied in the field of chemical materials, can solve the problems of difficult control of microscopic uniformity and interface characteristics of composite dielectrics, easy breakdown of heat concentration, and difficult processing and preparation, and achieves easy control implementation, simple preparation method, and mechanical good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the PAMMA@BT / PP nanocomposite dielectric film with controllable shell thickness provided in this example includes the following steps:

[0034] 1) Preparation of PMMA@BT core-shell nano-hybrid particles by in situ radical polymerization

[0035] 1.1) Hydroxylated barium titanate BT nanoparticles:

[0036] In order to allow more organic groups to be grafted on the surface of BT, we first oxidized the BT nanoparticles with hydrogen peroxide to make the surface have more active hydroxyl groups.

[0037] Specifically, after drying the barium titanate BT nanoparticles in a vacuum oven at 80°C for 5 hours, inject 20 g of BT nanoparticles into 100 mL of H2O2 aqueous solution (concentration 30%) in a single-necked round-bottomed flask with a capacity of 250 mL, and ultrasonically disperse the mixture After 30 minutes of treatment, reflux in an oil bath at 105°C and stir mechanically, and react for 5 hours. After the reaction was finished, cool to roo...

Embodiment 2

[0051] The difference from Example 1 is that in step 1.4) of this example, 5 g of methyl methacrylate MMA was weighed (MMA / BT mass ratio is 0.25); the PMMA@BT prepared in this example has a core-shell structure, The shell thickness is 8nm;

[0052] In step 2) of this embodiment, the mass ratio of PMMA@BT / PMMA@BT / PP is 10%. The thickness of the PAMMA@BT / PP nanocomposite dielectric film is 40 μm.

Embodiment 3

[0054] The difference from Example 1 is that in this example, in step 1.4), 10 g of methyl methacrylate MMA (MMA / BT mass ratio is 0.5) is weighed; the PMMA@BT prepared in this example is a core-shell structure, the shell thickness is 6nm;

[0055] In this embodiment, the mass ratio of PMMA@BT / PMMA@BT / PP is 10%; the thickness of the PAMMA@BT / PP nanocomposite dielectric film is 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shell thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com