Preparation method of potassium-sodium niobate ceramic with high piezoelectric property and high remnant polarization strength

A polarization strength and potassium sodium niobate technology, which is applied in the field of perovskite lead-free piezoelectric ceramics, can solve the problems of low remanent polarization, low density and poor piezoelectric performance of potassium sodium niobate ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

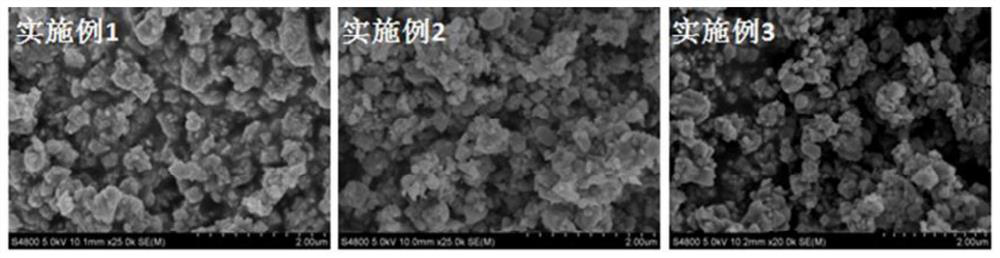

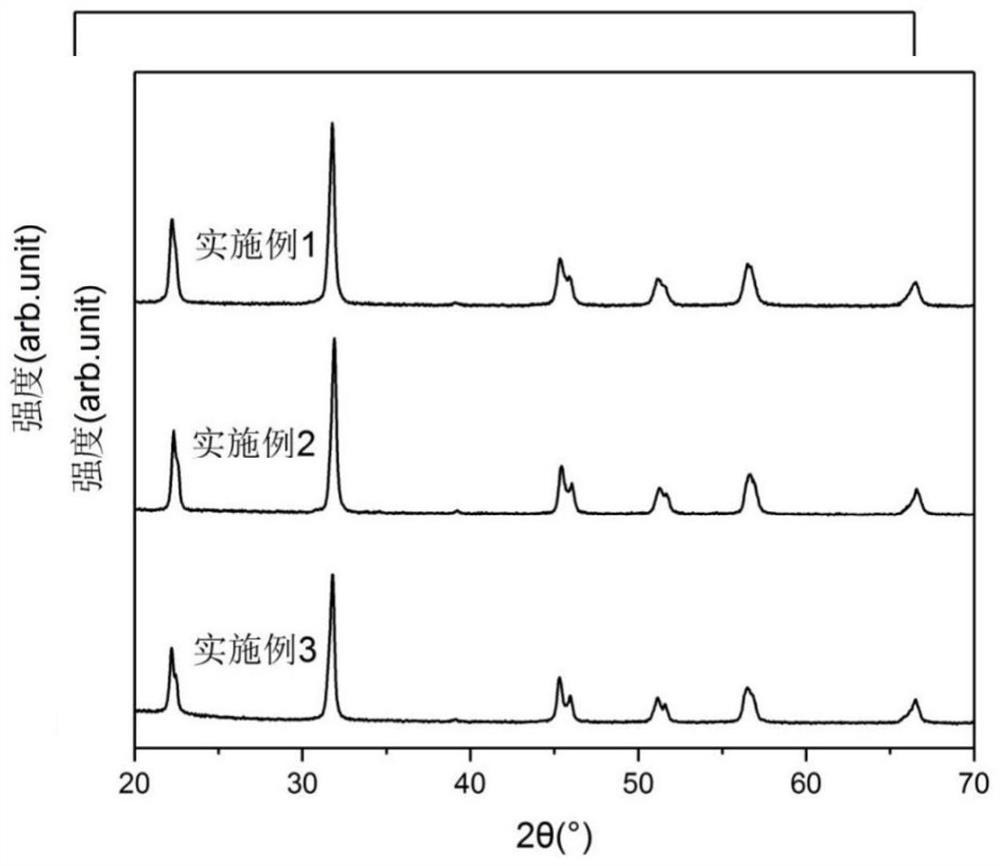

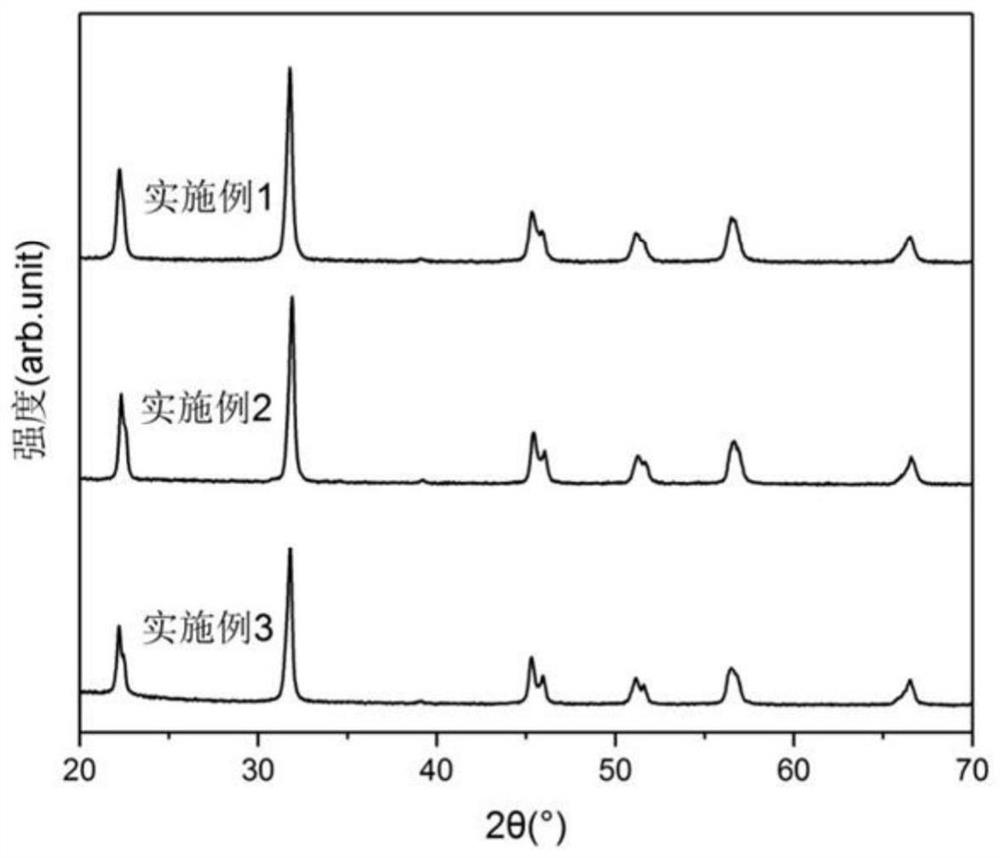

Embodiment 1

[0022] A method for preparing potassium sodium niobate ceramics with high piezoelectric performance and high remnant polarization, characterized in that the specific steps are as follows:

[0023] (1) Baking materials: put alkali metal salts K2CO3 and Na2CO3 that are easy to absorb moisture in an oven at 230°C for 3 hours to dry to remove moisture;

[0024] (2) Ingredients: according to the stoichiometric ratio of (Na0.5K0.5)NbO3, weigh the raw materials K2CO3, Na2CO3, Nb2O5 successively, put the weighed raw materials into the ball mill jar, use absolute ethanol as the ball mill medium, and use 5mm in diameter and The zirconia beads with a diameter of 2mm are mixed as the ball milling beads for the initial ball milling, the mass ratio of zirconia beads with a diameter of 5mm and 2mm is 1:2, raw materials: ball milling beads: anhydrous ethanol mass ratio is 1:8:4, in a planetary ball mill Perform primary ball milling at 400rpm for 10 hours to obtain wet slurry;

[0025] (3) Br...

Embodiment 2

[0031] A method for preparing potassium sodium niobate ceramics with high piezoelectric performance and high remnant polarization, characterized in that the specific steps are as follows:

[0032] (1) Drying material: put alkali metal salts K2CO3 and Na2CO3 that are easy to absorb moisture in an oven at 200°C for 5 hours to dry to remove moisture;

[0033] (2) Ingredients: according to the stoichiometric ratio of (Na0.5K0.5)NbO3, weigh the raw materials K2CO3, Na2CO3, Nb2O5 in turn, put the weighed raw materials into the ball milling tank, use absolute ethanol as the ball milling medium, and use a 5mm diameter Zirconia beads are used as ball milling beads for the initial ball milling, raw materials: ball milling beads: dehydrated alcohol mass ratio is 1:8:4, and the initial ball milling is carried out at 400rpm in a planetary ball mill for 10h to obtain a wet slurry;

[0034] (3) Briquette pre-firing: Put the obtained slurry into a 60°C oven for 9 hours to dry to obtain a dry ...

Embodiment 3

[0040] A method for preparing potassium sodium niobate ceramics with high piezoelectric performance and high remnant polarization, characterized in that the specific steps are as follows:

[0041] (1) Baking materials: put alkali metal salts K2CO3 and Na2CO3 that are easy to absorb moisture in an oven at 250°C for 2 hours to dry to remove moisture;

[0042] (2) Ingredients: according to the stoichiometric ratio of (Na0.5K0.5)NbO3, weigh the raw materials K2CO3, Na2CO3, and Nb2O5 in sequence, put the weighed raw materials into a ball mill tank, use absolute ethanol as the ball mill medium, with a diameter of 10mm and a diameter of 5mm agate beads are mixed as the ball milling beads of the first ball milling, the mass ratio of diameter 10mm and diameter 5mm agate beads is 1: 2, raw material: ball milling beads: absolute ethanol mass ratio is 1: 8: 4, in planetary ball mill with 400rpm rotating speed is carried out initial ball milling 10h, obtains wet process slurry;

[0043] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com