Patents

Literature

64results about How to "Good anti-cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance and single-component white waterborne adhesion primer and preparation method thereof

ActiveCN105505166AImprove adhesionGood strength and flexibilityPolyurea/polyurethane coatingsOrganosolvAcrylic acid

The invention belongs to the field of coatings and particularly relates to single-component white waterborne adhesion primer and a preparation method thereof. The high-performance and single-component white waterborne adhesion primer comprises a part A and water, wherein the part A comprises components in percentage by weight as follows: 25%-30% of waterborne single-component polyurethane, 8%-10% of a waterborne acrylic emulsion, 5%-10% of waterborne silica sol, 0.5%-1.0% of an adhesion promoter, 3.9%-6.3% of a function auxiliary, 31%-45% of filler and 10%-15% of water. The problems of hot sticking, cold shortness, high probability of cracking through thick coating and difficulty in adhesion of an oily substrate of conventional single-component white primer are solved, and the high-performance and single-component white waterborne adhesion primer contains few volatile organic solvents and meets the environment-friendly requirement.

Owner:AODA KOALA PAINT HUIZHOU

Modified asphalt for road and preparation method

InactiveCN106883626AImprove cold resistanceGood anti-crackingRoads maintainenceBuilding insulationsCelluloseEpoxy

The invention discloses modified asphalt for a road and a preparation method. The modified asphalt contains the following components: asphalt, SBS, polybutylene terephthalate, carbon powder, attapulgite clay, epoxy resin, waste rubber, polypropylene fibers, cellulose ether, nano titanium dioxide, sodium chloride, sodium silicate, filler, a compatilizer and a softener. The preparation method comprises the following steps: firstly, preparing pasty attapulgite clay; weighing asphalt and adding the same into a reaction tank; raising the temperature till the asphalt is in a dissolved flowable state; adding a polymer component, the cellulose ether, the compatilizer and the softener into the reaction tank to stir and mix to react for 2-4h; then adding the residual components into the mixture; then placing the mixture into a mixer to be mixed for 2-4h; and cooling the mixture to obtain the modified asphalt. The modified asphalt not only has the characteristics of better cold resistance, crack resistance, aging resistance and high strength, but also has a certain snow-melting and anti-freezing property, and greatly improves the using safety of an asphalt pavement.

Owner:合肥天沃能源科技有限公司

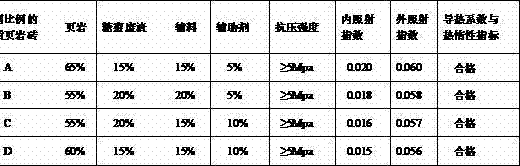

Light shale brick and production method thereof

The invention provides a light shale brick and a production method of the light shale brick. The light shale brick is characterized by comprising the following raw materials in percentage by weight: 60% of shale, 20 to 35% of organic matter flammable accessory, 5 to 20% of other accessories, and 50 to 60% of water at 40 to 45 DEG C; the production method comprises the steps of crushing the shale, adding the water, the organic matter flammable accessory and other accessories into the shale powder; uniformly agitating; preparing into blanks; parching the blank; roasting at 950 to 1,150 DEG C; and keeping for 8 to 12 hours so as to obtain the product; the other accessories are prepared by mixing 87.5% to 90% of shell and 10 to 12.5% of aluminum powder based on mass percentage, or prepared by mixing 87.5 to 90% of shell and 10 to 12.5% of iron powder; and the organic matter flammable accessory is the powder of one or the mixture of any two of saw dust, plant straw, urban garbage, fallen leaves, couch grass, shrub, firewood, branch and wood dust. The light shale brick provided by the invention has the advantages of heat preservation, heat insulation, fire proofingness, cracking prevention, sound insulation, low self weight, high anchoring performance, low cost, and light weight.

Owner:黄榜彪 +1

Water-resistant paint

InactiveCN104910812AImprove waterproof performanceGood anti-crackingRosin coatingsBituminous coatingsPolyesterPolymer science

The invention discloses a water-resistant paint. Three ingredients, including a flexibilizer, a compatibilizer, and a reinforcing agent, are added into a dispersion phase of the water-resistant paint; the flexibilizer is one or a mixture of a plurality of components selected from polyvinyl chloride, polyethylene, polypropylene, butadiene-styrene rubber, cis-butadiene rubber, butadiene-acrylonitrile rubber, vinylon, dacron, acrylon, polypropylene, ethylene-propylene rubber, polystyrene, polymethyl methacrylate, polyester, chlorinated polyethylene, chlorinated atactic polypropylene, chlorinated polypropylene, atactic polypropylene, 107 adhesive, polyvinyl alcohol, permalon, chloroprene rubber, chlorosulfonated polyethylene, polyethylene glycol, xytene formaldehyde resin, and reclaimed rubber. Using amount of the flexibilizer accounts for 2 to 50% of that of asphalt. The formula above is capable of improving water resistance, cracking resistance, and strength of asphalt emulsion greatly; the obtained asphalt emulsion is an excellent water-resistant paint, and can be taken as a paving material. It is beneficial for construction improvement, cost reducing, energy reducing, and avoiding of environmental pollution.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

A preparing process of an antifouling soft-light marble tile

A preparing process of an antifouling soft-light marble tile is disclosed and belongs to the technical field of tile preparation. The process is characterized in that the process includes steps of 1) preparing a green body, 2) applying ground coat, 3) performing ink-jet printing of marble pattern overglaze, 4) firing and 5) soft polishing; a green body material used in the green body preparing step includes, by weight, 30-35 parts of feldspar, 3-5 parts of crystal frit, 10-15 parts of pyrophyllite, 25-35 parts of white clay and 15-20 parts of high-aluminum rock; and a glaze material used in the overglaze includes, by weight, 25-30 parts of feldspar, 15-20 parts of crystal frit, 3-5 parts of corundum, 7-10 parts of kaolin, 8-10 parts of zinc oxide, 8-11 parts of wollastonite, 1-3 parts of barium oxide and 10-15 parts of quartz. The simulation degree between the tile and natural marble in the aspects of visual inspection and touch senses is high. The fouling resistance, wear resistance, coloring effects, crack resistance, and the like of the tile are superior to those of the natural marble.

Owner:淄博新博陶瓷有限公司 +1

Waterproof latex paint for reflective insulation and heat preservation of external walls

InactiveCN103275565AThermal insulation solutionImprove waterproof performanceReflecting/signal paintsSubstrate (building)Heat conservation

The invention relates to a waterproof latex paint for reflective insulation and heat preservation of external walls. The waterproof latex paint is a novel paint which is painted on the surfaces of substrates, such as external walls of buildings, outer surfaces of metal storage tanks and color steel tiles. Hollow glass spherical particles are directly added into the paint, and the paint can be used after being slightly stirred in the field without further extra addition, wherein due to specially added nano-scale silicon emulsion waterproofness-based molecules, the heat insulation and heat preservation problems of the external walls are solved, but also the paint has excellent performances, such as waterproofness, mold prevention, damp prevention and cracking resistance.

Owner:CHANGSHA DOFULL ENERGY SAVING TECH

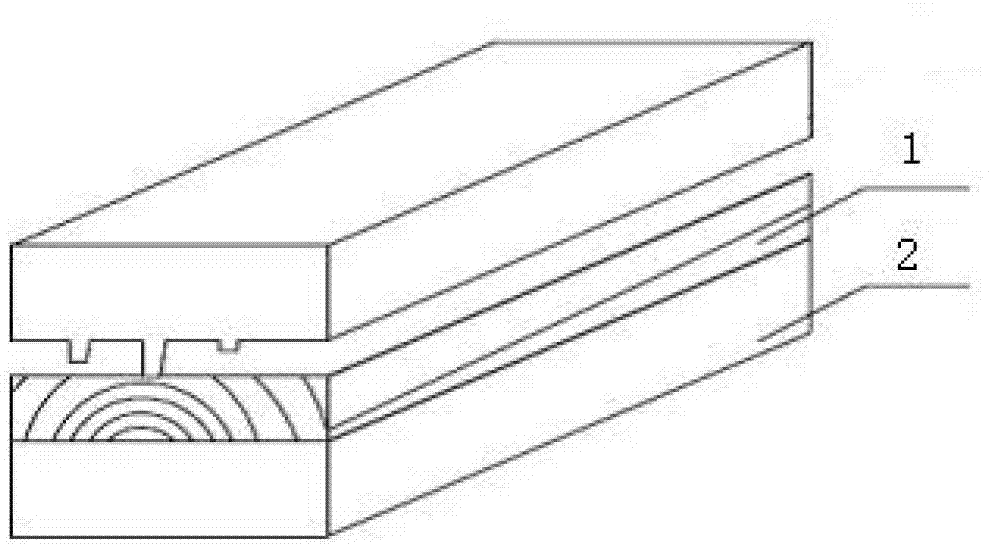

Embossing preparation process of wood for solid-wood doors and windows

InactiveCN103395108AGood anti-crackingDimensionally stableWood compressionWood treatment detailsCrack resistanceHigh surface

The invention discloses an embossing preparation process of wood for solid-wood doors and windows. The machining process comprises the steps of: firstly, machining a material according to size, wherein a log is sawn into a base material according to the discharging size; secondly, carrying out wet-humid softening on the material, wherein the base material is soaked in hot water and then dried to control the water content of the base material; thirdly, modifying the material, wherein the treated base material is immersed in a modifying agent for being subjected to dipping treatment to obtain a modified material; fourthly, dewatering the modified material, wherein the modified material is dewatered in an environment with low temperature so that the water content is lowered; and fifthly, mould-pressing the modified material and sizing resin, wherein the modified material is hot-pressed in a metal hot-pressing mould. By adopting the mode, according to the embossing preparation process of wood for solid-wood doors and windows, the solid-wood doors and windows are prepared by using a wood fiber cell lossless mould pressing method through modifying the wood, and are endowed with excellent dimensional stability, crack resistance, high density, high surface hardness, structure property and the like so as to be used for replacing and be superior to a conventional product.

Owner:苏州香山工坊建设有限公司

Electric porcelain insulator and preparation method thereof

ActiveCN108101526AImprove mechanical propertiesImprove insulation performanceClaywaresMulliteRare earth

The invention discloses an electric porcelain insulator and a preparation method thereof, and belongs to the field of electric porcelain insulators. The electric porcelain insulator mainly comprises the following raw materials in parts by weight: 40-60 parts of a ceramic powder, 20-30 parts of a mullite powder, 3-8 parts of a mineralizer, 8-15 parts of a dispersing agent, 0.5-1 part of a forming agent and 2-12 parts of a rare earth doping agent, wherein the mass density of the mullite powder is 2.82-3.24g / cm<3>. The preparation method of the electric porcelain insulator comprises the followingsteps: wet mixing, drying, pre-sintering, smashing, pressing, sintering, glazing and glaze firing. The electric porcelain insulator and the preparation method thereof, disclosed by the invention, have the advantages that cracking is prevented, the mechanical property is high, the stability is high, the yield is high.

Owner:萍乡强盛电瓷制造有限公司

Anti-fouling soft light overglaze of marble tile

The invention relates to an anti-fouling soft light overglaze of a marble tile and belongs to the technical field of tile preparation. The overglaze is characterized by comprising the following ingredients in parts by weight: 25-30 parts of feldspar, 15-20 parts of sparkling clinker, 3-5 parts of corundum, 7-10 parts of kaoline, 8-10 parts of zinc oxide, 8-11 parts of wollastonite, 1-3 parts of barium oxide and 10-15 parts of quartz. The glaze has high rigidity and presents a soft light effect naturally after firing; the surface roughness of the glaze is also like a touch sense of natural marble; and the fired glaze naturally presents the soft light effect and the touch sense of the marble, presents a highly simulated vision and a touch sense of the polished marble after soft polishing and shows better pollution emission performance.

Owner:淄博新博陶瓷有限公司 +1

Preparation process of waterproof material

The invention discloses a preparation process of a waterproof material. The preparation process comprises the following steps of (1) uniformly mixing the following components in parts by weight: 6 parts of tribromophenol, 5 parts of tert-amyl chloride, 1.3 parts of trimethylbenzyl ammonium chloride, 6 parts of a silicone-acrylate emulsion and 4.5 parts of water to prepare a component A; (2) uniformly mixing the following components in parts by weight: 5.3 parts of quartz sand, 0.8 part of high-alumina cement, 2.8 parts of ordinary portland cement, 2.4 parts of cellulose ether and 5.1 parts of sodium hydrogen sulfite to prepare a component B; and (3) mixing 7 parts by weight of the component A and 2 parts by weight of the component B, heating to 57 DEG C, then, uniformly stirring, and naturally cooling to prepare the waterproof material. The waterproof material prepared by using the preparation process is favorable in flexibility, water resistance and cracking resistance and is suitable for preparing kitchen and toilet products.

Owner:江苏格雷特复合材料有限公司

High-strength environmental-protection colored brick tile and preparing method thereof

InactiveCN106938905AGood mechanical strengthGood waterproof performanceRoof covering using tiles/slatesSodium silicateHigh intensity

The invention discloses a high-strength environmental-protection colored brick tile and a preparing method thereof, and belongs to the technical field of building materials. The colored brick tile comprises the following components: raw gypsum, diatomite, shale diatom mud, attapulgite, limestone, sodium silicate, glass fibers, fine river bottom sand, cement and an additive. The preparation method comprises the steps: respectively weighing the raw gypsum, diatomite, shale diatom mud, limestone, sodium silicate, fine river bottom sand and cement, and crushing and mixing to obtain a mixture a1; mixing evenly the mixture a1 with the attapulgite, adding water during stirring, then adding the glass fibers to the mixture, and fully stirring evenly to obtain a mixture a2; and carrying out extrusion molding of the mixture a2, curing, then spraying with a coating, and drying to obtain the colored brick tile. The colored brick tile has good mechanical strength and water permeable resistance, can effectively avoid the phenomenon of cracking in the process of using the colored brick tile, can greatly improve the service life of the colored brick tile, also has good anti-mildew effect, and effectively prevent the growth of algae around the colored brick tile.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

Honey lip balm

InactiveCN103040703AWith natural healthImprove breathabilityCosmetic preparationsMake-upFlavorNatural substance

The invention discloses honey lip balm. The lip balm adopts natural substances as main components, and honey is added therein, so that the lip balm has the benefits of nature, health and the like. The lip balm has good breathability and good effect of dryness prevention, and the lip becomes moist and glossy after being coated with the lip balm. And in addition, different natural perfumes can be added to prepare the lip balm with different fragrant so as to satisfy the requirements of different clients.

Owner:青岛博益特生物材料股份有限公司

Natural vegetable lip balm

InactiveCN104473850AImprove breathabilityFulfil requirementsCosmetic preparationsToilet preparationsBiotechnologyLanolin

The invention discloses natural vegetable lip balm. The natural vegetable lip balm comprises the following components: natural vegetable oil, animal oil and fat, natural honey and vitamins, wherein the natural vegetable oil is olive oil, grape seed oil, avocado oil, collagen and almond oil; the animal oil and fat is horse oil and lanolin. The natural vegetable lip balm adopts a purely natural formula, has no side effects on human bodies, has a good repair function, has unexpected effects on dry and chapped skins and lips in the cold winter, and has the functions of preventing pigmentation, reducing harms of ultraviolet rays, delaying skin aging and maintaining the health of lip skins.

Owner:QINGDAO HIFUN MARINE BIOLOGICAL TECH

Preparation process of waterproof material

The invention discloses a preparation process of a waterproof material. The preparation process comprises the following steps of (1) uniformly mixing the following components in parts by weight: 6 parts of sucrose fatty acid ester, 11 parts of a silicone-acrylate emulsion, 1.2 parts of polyoxyethylene-polyoxypropane block polymers, 1.2 parts of acyl glycerol ester derivatives and 8 parts of water to obtain a component A; (2) uniformly mixing the following components in parts by weight: 1.2 parts of high alumina cement, 2 parts of ordinary portland cement, 6 parts of quartz sand, 4.1 parts of cellulose ether and 2.1 parts of sodium carbonate to obtain a component B; and (3) mixing 5 parts of the component A and 4 parts of the component B, heating to 62 DEG C, then, uniformly stirring, and naturally cooling to obtain the waterproof material. The waterproof material prepared by using the preparation process is favorable in flexibility, waterproofness and crack resistance and suitable for preparing kitchen and toilet products.

Owner:江苏格雷特复合材料有限公司

Sculpture cement and preparation method thereof

The invention relates to sculpture cement which is prepared from the following components in parts by weight: 40-50 parts of ordinary Portland cement, 20-30 parts of gypsum, 40-50 parts of borax, 5-10parts of basalt powder, 8-12 parts of glue, 0.05-1 part of chitosan fibers and 0.3-0.8 part of an additive. The invention also discloses a preparation method of the sculpture cement. The sculpture cement disclosed by the invention is excellent in comprehensive performance, better in anti-cracking and shaping performance, longer in service lifetime, more excellent in waterproof and impermeable performance, better in construction performance and stability, good in sculptured stereoscopic impression and visual aesthetic feeling and remarkable in artistic effect.

Owner:SUZHOU GOLD MANTIS EXHIBITION DESIGN ENG

Manufacturing technology for carbonized strand woven bamboo floor

ActiveCN104139443AKeep it bright as newGood anti-crackingWood charring/burningManufacturing technologyCrack resistance

The invention discloses a manufacturing technology for a carbonized strand woven bamboo floor. The technology comprises the steps as follows: stick selection, carbonization, drying, gum dipping, drying, forging and pressing, cutting, slicing, balanced standing and shipment. According to the technology, bamboo sticks are carbonized firstly, and gum dipping is performed after the moisture is lowered to 8%, so that gum is completely absorbed by the carbonized bamboo sticks through gaps in surfaces of the carbonized bamboo sticks; forging and pressing are performed when the average moisture of the bamboo sticks dipped in the gum is lowered to be in a range of 12%-18%, so that a manufactured floor product is good in cracking resistance and moth damage resistance and environment-friendly and can be kept bright as a new one for a long time.

Owner:安徽至信竹业科技有限公司

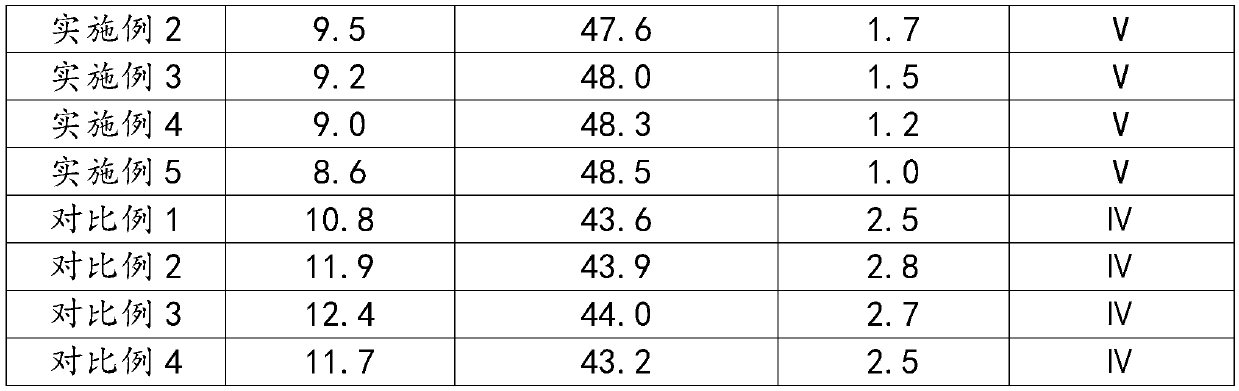

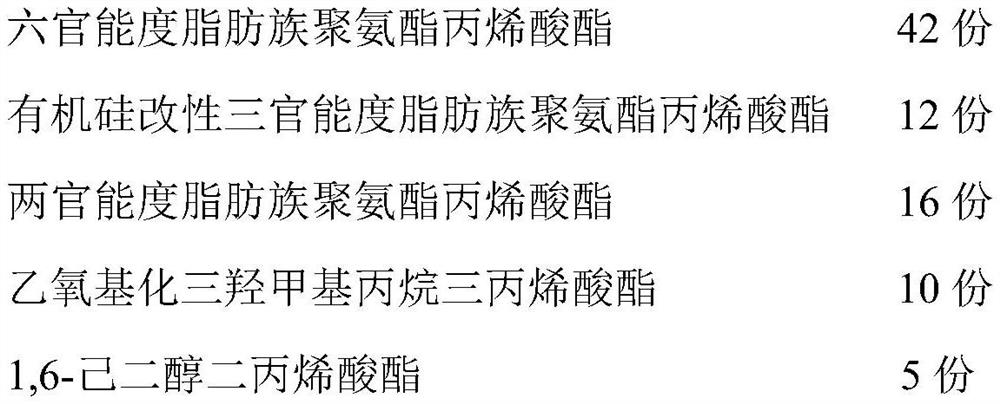

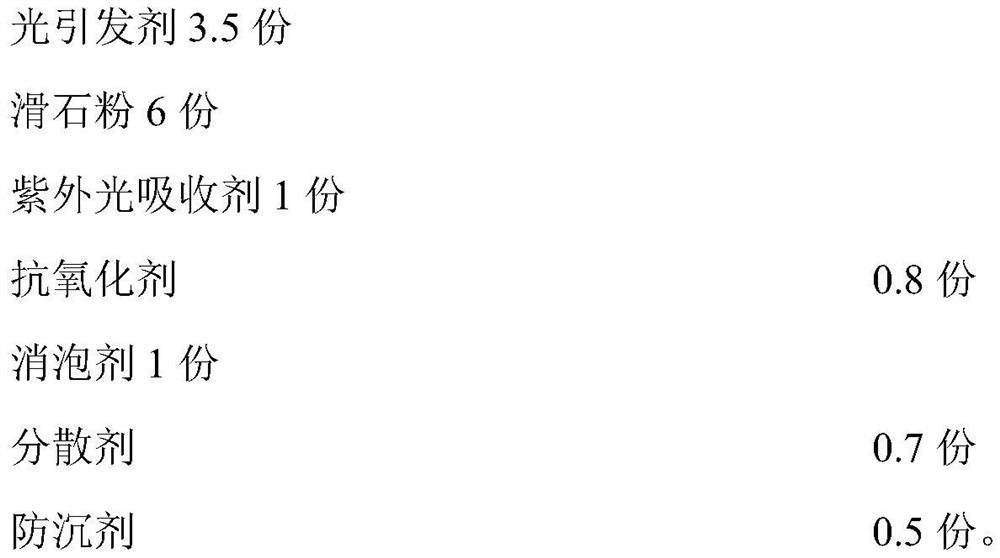

Low-yellowing material fading prevention UV primer and preparation method thereof

InactiveCN112940605AGood yellowing resistanceImprove heat resistancePolyurea/polyurethane coatingsPriming paintsMeth-Ultraviolet lights

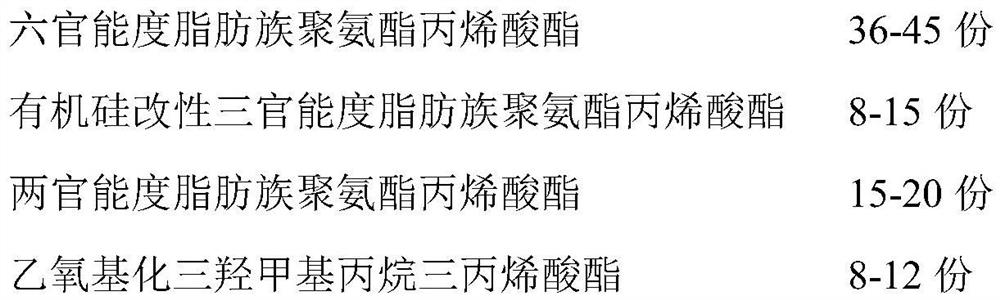

The invention relates to a low-yellowing material fading prevention UV primer and a preparation method thereof. The UV primer comprises, by weight, hexafunctional aliphatic polyurethane acrylate, organic silicon modified trifunctional aliphatic polyurethane acrylate, bifunctional aliphatic polyurethane acrylate, ethoxylated trimethylolpropane triacrylate, 1, 6-hexanediol diacrylate, a photoinitiator, talcum powder, an ultraviolet light absorber, an antioxidant, a defoaming agent, a dispersing agent and an anti-settling agent according to specific parts. The photoinitiator comprises methyl benzoylformate and 2, 4, 6-trimethylbenzoyl-diphenyl phosphine oxide according to the mass ratio of 1: (0.1-0.5); and the ultraviolet light absorber is composed of a benzotriazole ultraviolet light absorber and a hindered amine ultraviolet light absorber according to the mass ratio of 1: (0.3-0.8). The UV primer has low yellowing, can prevent color fading of dyed wood and has excellent adhesive force, and the defects that the dyed wood is easy to change color and fall off in the production and use processes can be effectively avoided.

Owner:东莞大宝化工制品有限公司 +2

High-toughness, durable and anti-skid steel bridge deck pavement structure and construction method thereof

InactiveCN110952447AIncrease stiffnessImprove stabilityBridge structural detailsBridge erection/assemblyEpoxyBridge deck

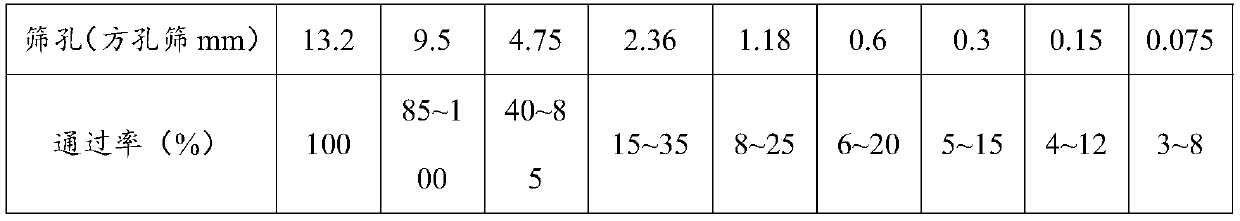

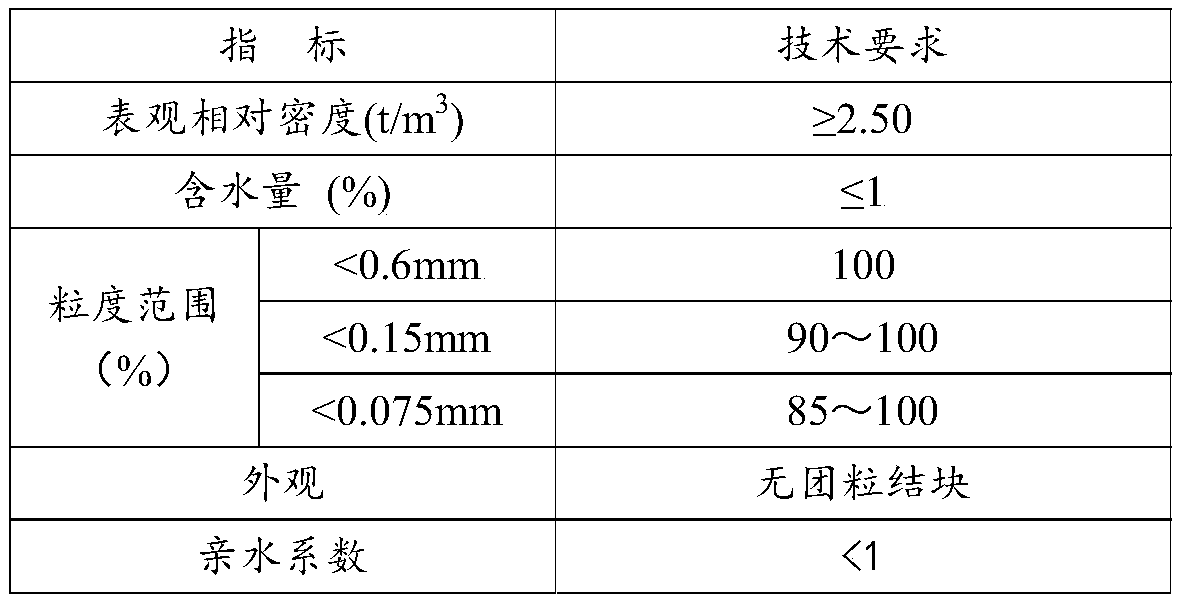

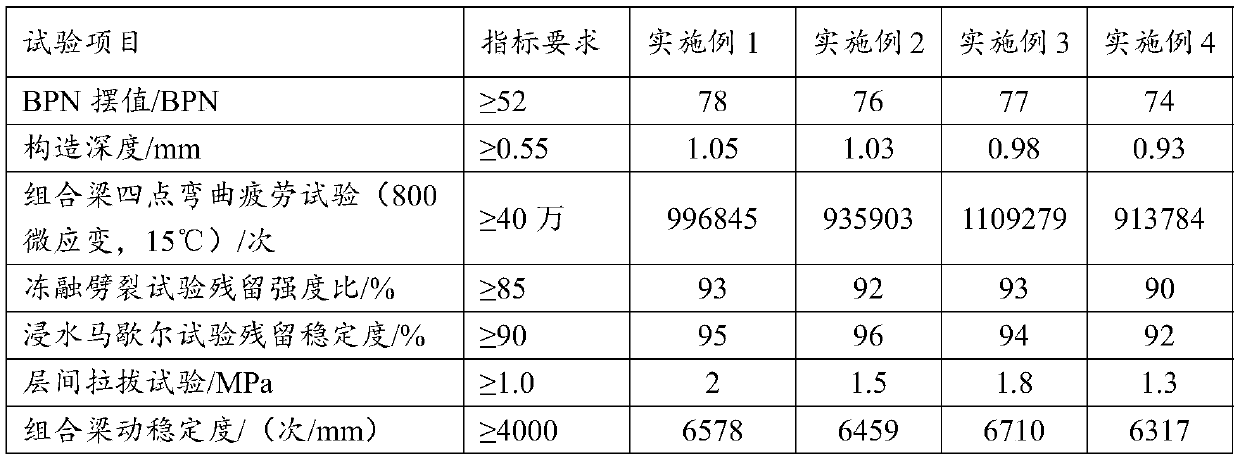

The invention discloses a high-toughness, durable and antiskid steel bridge deck pavement structure and a construction method thereof. The steel bridge deck pavement structure comprises a steel bridgedeck steel plate; a bonding bottom layer, a buffer layer, an adhesion layer and a wearing layer are sequentially laid on the surface of the steel bridge deck steel plate from bottom to top; the buffer layer and the wearing layer are both made of high-toughness modified asphalt concrete composed of aggregate, filler and asphalt cement, the thickness of the buffer layer is 1-3 cm, and the thicknessof the wearing layer is 2-3 cm. The bridge deck pavement structure has good high-temperature rut resistance, fatigue durability, skid resistance, bonding strength and deformation compliance, comparedwith epoxy asphalt concrete, the engineering cost is greatly reduced, the construction process is simple, and later maintenance is convenient.

Owner:广州市市维新材料科技有限公司

Waterproof material production method

InactiveCN105503073AGood flexibilityImprove waterproof performanceCrack resistancePolyethylene glycol

The invention discloses a waterproof material production method. The method comprises the steps of 1, evenly mixing 1-2 parts by weight of hexyldecanol, 3.5 parts by weight of chlorinated paraffin, 1.8 parts by weight of lauryl sodium sulfate, 8.5 parts by weight of silicone acrylic emulsion and 15 parts by weight of water, so that a component A is obtained; 2, evenly mixing 2.6 parts by weight of amorphous state alpha-olefin copolymer, 2.3 parts by weight of portland cement, 1.7 parts by weight of polyethylene glycol octylphenol ether, 2.4 parts by weight of hydroxy propyl methylcellulose and 8.1 parts by weight of quartz sand, so that a component B is obtained; 3, mixing 6.7 parts by weight of component A and 3.5 parts by weight of component B, increasing temperature to 50 DEG C, and conducting even stirring and natural cooling, so that a waterproof material is obtained. The waterproof material prepared with the method has high flexibility, water resistance and cracking resistance and is suitable for manufacturing kitchen and toilet products.

Owner:江苏格雷特复合材料有限公司

Light-weight shale brick manufactured from alcohol wastewater of sugar refinery and production method thereof

The invention discloses a light-weight shale brick manufactured from alcohol wastewater of a sugar refinery. The light-weight shale brick is mainly prepared from the following raw materials in percentage by mass: 55-65% of shale, 15-25% of molasses waste residue with a pH value of 6.5-7.5 of the sugar refinery, 15-20% of auxiliary materials and 5-10% of adjuvants, wherein the adjuvants comprise, in proportioning ratio by mass, 85-95% of slag and 5-15% of potassium chloride; the raw materials are added in water at a temperature of 40-45 DEG C and occupying 50-60% of the mass of the raw materials, stirred and stood for 1-1.5 hours to prepare a brick blank, and the brick blank is dried, roasted, insulated and cooled to prepare the light-weight shale brick. The light-weight shale brick has the following advantages that: the molasses waste residue and other auxiliary materials are added, after high-temperature sintering, the auxiliary materials are burnt thoroughly to form lots of micropores in the brick, therefore, the light-weight shale brick is good in thermal insulation, heat isolation, fireproof, anti-cracking, soundproof performances and the like; moreover, the dead weight is greatly reduced, and the light-weight shale brick is excellent in anchoring performance, low in cost, light in dead weight, convenient to construct, and capable of meeting the needs of secondary decoration for buildings.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

A kind of electric porcelain insulator and preparation method thereof

ActiveCN108101526BImprove mechanical propertiesImprove insulation performanceInsulatorsClaywaresMetallurgyMullite

The invention discloses an electric porcelain insulator and a preparation method thereof, and belongs to the field of electric porcelain insulators. The electric porcelain insulator mainly comprises the following raw materials in parts by weight: 40-60 parts of a ceramic powder, 20-30 parts of a mullite powder, 3-8 parts of a mineralizer, 8-15 parts of a dispersing agent, 0.5-1 part of a forming agent and 2-12 parts of a rare earth doping agent, wherein the mass density of the mullite powder is 2.82-3.24g / cm<3>. The preparation method of the electric porcelain insulator comprises the followingsteps: wet mixing, drying, pre-sintering, smashing, pressing, sintering, glazing and glaze firing. The electric porcelain insulator and the preparation method thereof, disclosed by the invention, have the advantages that cracking is prevented, the mechanical property is high, the stability is high, the yield is high.

Owner:萍乡强盛电瓷制造有限公司

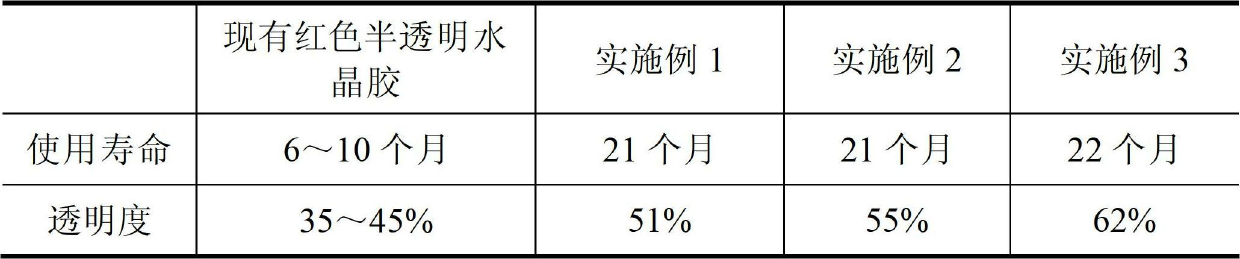

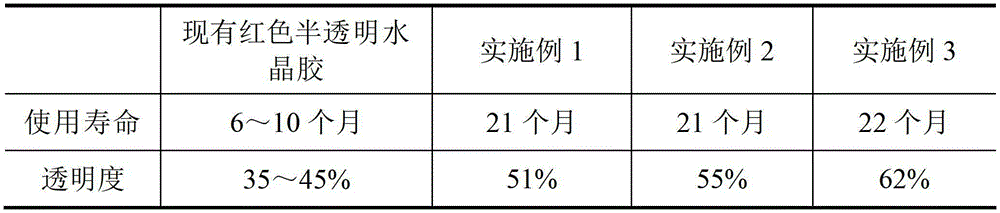

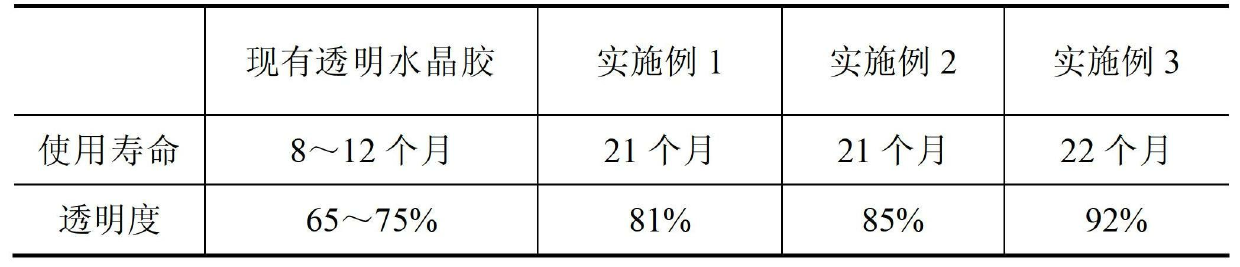

Red translucent crystal glue material and manufacturing method thereof

The invention relates to a red translucent crystal glue material and a manufacturing method of the red translucent crystal glue material. The red translucent crystal glue material is manufactured by a way that PVA (polyvinyl acetate) powder, water, sodium borate, carbomer resin, propylene glycol or glycerol, vanillin, clove oil, amyl acetate, carmine, tartaric acid, sorbic acid, sodium dodecyl benzene sulfonate and an acrylamide-acrylate copolymerized crosslinked material are sequentially mixed, emulsified and stirred, and finally sodium borate water is added in the mixed solution for solidification. The translucent crystal glue material has the advantages of good moisturizing effect, bright color, stable color, high transparency and long service life, and is unlikely to crack in the air and unlikely to discolor. The transparency of the red translucent crystal glue material provided by the invention is up to above 50%, and the service life is up to above 18 months.

Owner:浙江银太郎动漫文化股份有限公司

Blue translucent crystal adhesive material and preparation method thereof

The invention relates to a crystal adhesive material and a preparation method thereof. The blue translucent crystal adhesive material is prepared through the following steps: mixing, emulsifying and stirring PVA (polyvinyl acetate) powder, water, borax, Carbomer resins, propylene glycol or glycerin, vanillin, clove oil, amyl acetate, gardenia blue, propionic acid, benzoic acid, sodium dodecyl benzene sulfonate and an acrylamide-acrylate copoly-crosslink; and finally adding borax water and solidifying. The translucent crystal adhesive material has the following advantages: the translucent crystal adhesive material has a good moisturizing effect, is not easy to crack in the air, has bright color, is not easy to discolor and has stable hue, good transparency above 50% and service life longerthan 18 months.

Owner:浙江银太郎动漫文化股份有限公司

Red translucent crystal glue material and manufacturing method thereof

The invention relates to a red translucent crystal glue material and a manufacturing method of the red translucent crystal glue material. The red translucent crystal glue material is manufactured by a way that PVA (polyvinyl acetate) powder, water, sodium borate, carbomer resin, propylene glycol or glycerol, vanillin, clove oil, amyl acetate, carmine, tartaric acid, sorbic acid, sodium dodecyl benzene sulfonate and an acrylamide-acrylate copolymerized crosslinked material are sequentially mixed, emulsified and stirred, and finally sodium borate water is added in the mixed solution for solidification. The translucent crystal glue material has the advantages of good moisturizing effect, bright color, stable color, high transparency and long service life, and is unlikely to crack in the air and unlikely to discolor. The transparency of the red translucent crystal glue material provided by the invention is up to above 50%, and the service life is up to above 18 months.

Owner:浙江银太郎动漫文化股份有限公司

Highly-wear-resistant plastic sheave liner and preparation method thereof

ActiveCN105482447AGood thermodynamic compatibilityImprove impact resistanceCrack resistanceWear resistant

The invention discloses a highly-wear-resistant plastic sheave liner and a preparation method thereof. The liner consists of the following components in parts by weight: 100 parts of nylon, 10-20 parts of aramid fiber, 15-20 parts of hollow glass beads, 5-15 parts of bauxite, 5-15 parts of barite, 1-3 parts of magnesium stearate, 0.5-1.5 parts of a titanate coupling agent, 10-15 parts of dioctyl phthalate, 1-3 parts of antimony trioxide, 5-10 parts of decabromodiphenyl ether, 10-15 parts of conductive carbon black and 0.5-1.5 parts of an antioxidant. The preparation process is simple, and the prepared plastic liner has good antistatic and flame-retardant properties, can keep relatively high tensile property, and is long in service life; and the sheave liner is good in seasoning crack resistance and moisture resistance, and is particularly suitable for use in severe environments with sprinkling water, strong corrosivity and the like in mines.

Owner:中实洛阳机械工程科技有限公司

anti chapped lipstick

InactiveCN102274135AImprove breathabilityGood anti-crackingCosmetic preparationsMake-upWhite BeeswaxOlive oil

The invention discloses an anti-drying and chapping lipstick, which is characterized in that the raw material components for making the lipstick include metronidazole, vaseline, white beeswax, vitamin E and olive oil. The lipstick of the invention has good air permeability, moist and glossy lips after rubbing, and good anti-cracking effect; the preparation method is simple, and the production cost is low.

Owner:NINGXIA MEDICAL UNIV

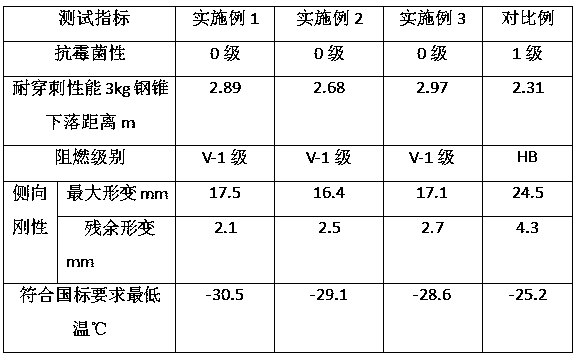

Safety crash helmet with resistance to cold, heat and impact

The invention relates to the technical field of safety equipment manufacturing, and in particular relates to a safety protective crash helmet with resistance to cold, heat and impact The safety protective crash helmet with resistance to cold, heat and impact of the invention comprises an outer helmet body and an inner liner body, wherein the inner liner body is connected with the outer helmet body through a buffer bracket;the outer helmet body is prepared by mixing modified phenolic epoxy acrylic resin and a wire mesh with other added substances to perform injection molding pressing; the inner lining layer is formed by first weaving and forming a net by using a fiber composite material and modified carbon fiber, and then curing through an adhesive formed by the combination of modified ultrahigh molecular weight polyethylene and other additives. According to the safety protective crash helmet with resistance to cold, heat and impact, the strength of the helmet body is improved; the helmet has excellent high-pressure-resistant, water-proof, flame-retardant and radiation-proof effects; meanwhile, through the preparation of t he inner lining layer, the tensile strength and mechanical property of a wearing material are improved, and a certain antibacterial effect is also realized; the manufacturing cost is reduced; relatively high practical value and good application prospects are realized.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

Anti-crack concrete

An anti-crack concrete is prepared from the following raw materials in parts by weight: 3-6 parts of basalt fibers, 4-9 parts of a light-silicon fiber anti-crack reinforcing agent, 100-120 parts of cement, 1-3 parts of cellulose fibers, 120-190 parts of pebbles, 2-6 parts of calcium carbonate, 3-6 parts of polyurethane particles, 2-4 parts of bauxite clinker, 3-7 parts of water glass, 0.5-2 parts of a naphthalene-based efficient water reducer, 3-6 parts of silicon dioxide, 2-5 parts of zirconia, 0.5-3 parts of Grace fibers and 50-80 parts of coal ash. The anti-crack concrete has the benefits that the anti-crack effect is very good, as the fibers are added, the strength of the concrete is enhanced, and a certain heat preservation effect is achieved.

Owner:QINGDAO XIANGJIA INTPROP SERVICE CO LTD

Transparent crystal glue material and preparation method of transparent crystal glue material

The invention relates to a transparent crystal glue material and a preparation method of the transparent crystal glue material. The transparent crystal glue material is prepared by PVA (polyvinyl alcohol) powder, water, borax, carbomer resin, propylene glycol or glycerin, vanillin, clove oil, amyl acetate, sorbic acid, sodium dodecyl benzene sulfonate and acrylamide-acrylate crosslinked copolymerthrough the steps of mixing, emulsification, stirring, adding of borax water, and solidification. The transparent crystal glue material has the advantages of being excellent in moisturizing effect, not prone to crack when placed in the air, good in transparency and long in service life, the transparency can reach over 80%, and the service life is over 18 months.

Owner:浦江县富盛塑胶新材料有限公司

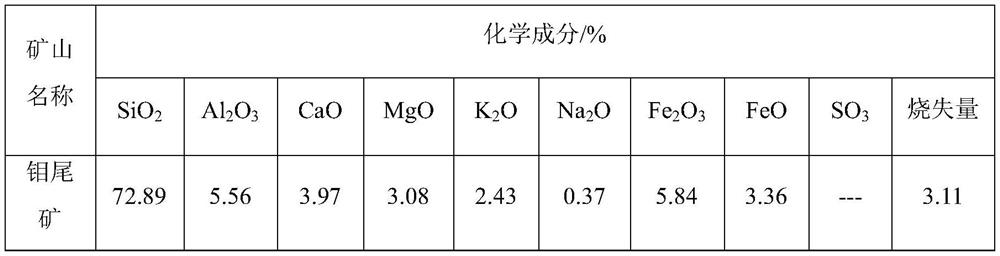

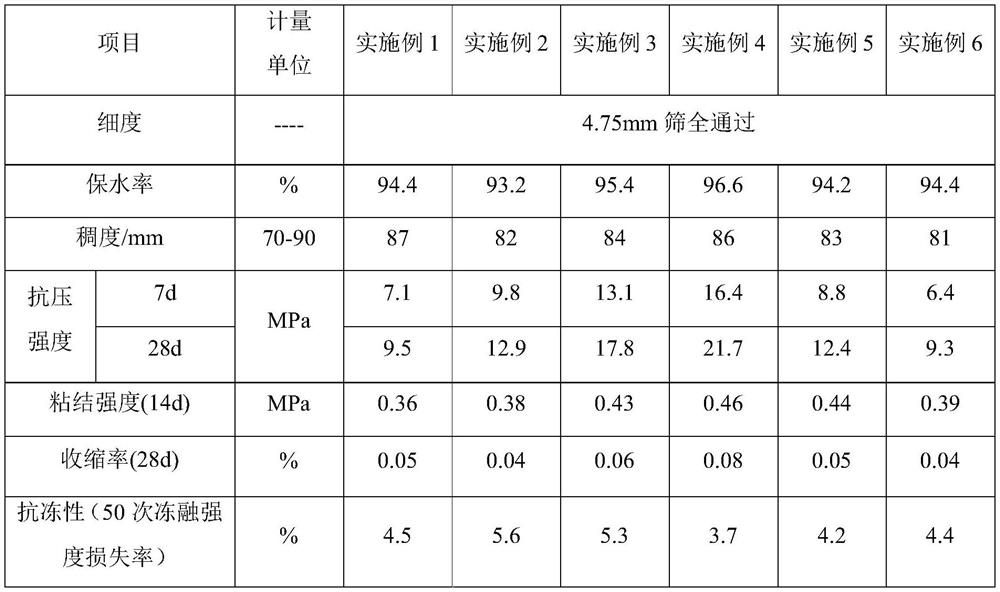

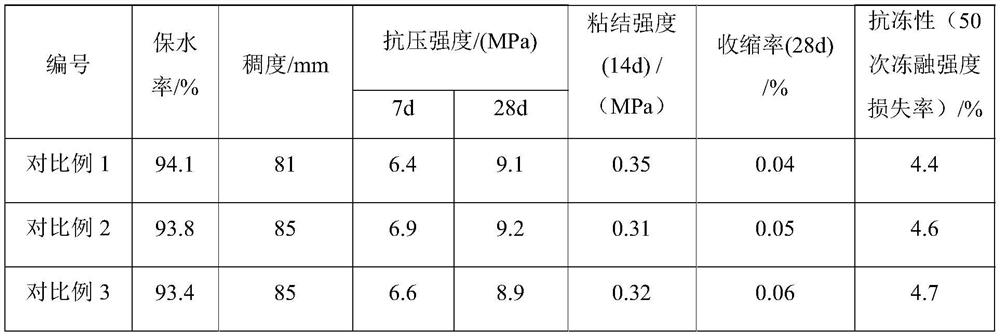

Molybdenum tailing dry-mixed mortar and application method thereof

ActiveCN114873961AIncrease profitIncrease dosageSolid waste managementMaterials preparationLatex rubber

The invention discloses molybdenum tailing dry-mixed mortar and an application method thereof, and belongs to the technical field of building material preparation. The dry-mixed mortar is composed of the following components: molybdenum tailing sand, a cementing material, redispersible polymer latex powder, a water-retaining thickening agent, a water reducing agent, an air entraining agent and a synergist, and the cementing material is composed of 6-8 parts of molybdenum tailing silica powder, 8-10 parts of cement, 3-4 parts of fly ash and 2-3 parts of magnesium slag powder. By adopting the mortar formula, the utilization rate of the molybdenum tailings can be increased, the serious environmental pollution problem caused by industrial waste residues such as the molybdenum tailings, the fly ash and the magnesium slag powder is relieved, the application range of the molybdenum tailings is expanded, cost reduction and efficiency improvement are facilitated, and the environmental, economic and social benefits are remarkable.

Owner:CHINA MCC17 GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com