Safety crash helmet with resistance to cold, heat and impact

A technology that is resistant to cold and heat shock and safety protection. It is applied in the direction of hat products, applications, helmets, etc., and can solve problems that affect the performance of movements, the weight and rigidity of safety helmets, and the limitation of the wearer's mobility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

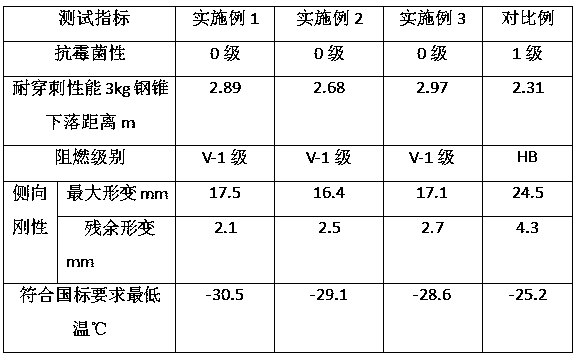

Embodiment 1

[0050] A cold and heat shock resistant safety helmet in this embodiment, the safety helmet includes an outer helmet body and an inner lining body, and the inner lining body is connected to the outer helmet body through a buffer bracket;

[0051] The preparation method of the exoskeleton comprises the following steps:

[0052] a. Mix 80 parts of novolac epoxy resin, 1 part of catalyst, and 2 parts of polymerization inhibitor by weight, raise the temperature to 95°C, add 30 parts of polyvinyl butyral and ethanol to form a solution in a weight ratio of 3:1 , then add 5 parts of ethyl orthosilicate, fully react, then add 2 parts of 20wt% dinonyl naphthalene disulfonic acid and 20 parts of 7-dimethyl-6-octenoic acid and acrylic acid according to the composition of 1:2 The mixed solution was kept at 100°C for 2 hours, and then cooled. During the cooling process, 4 parts of aniline and 3 parts of vegetable oleic acid were added and mixed evenly to obtain a modified novolac epoxy acry...

Embodiment 2

[0078] A cold and heat shock resistant safety helmet in this embodiment, the safety helmet includes an outer helmet body and an inner lining body, and the inner lining body is connected to the outer helmet body through a buffer bracket;

[0079] The preparation method of the exoskeleton comprises the following steps:

[0080] a. Mix 100 parts of novolac epoxy resin, 2 parts of catalyst, and 4 parts of polymerization inhibitor by weight, raise the temperature to 100°C, add 40 parts of polyvinyl butyral and ethanol to form a solution in a weight ratio of 3:1 , then add 7 parts of ethyl orthosilicate, fully react, then add 4 parts of 20wt% dinonyl naphthalene disulfonic acid and 30 parts of 7-dimethyl-6-octenoic acid and acrylic acid according to the composition of 1:2 The mixed solution was kept at 110°C for 4 hours, and then cooled. During the cooling process, 6 parts of aniline and 5 parts of vegetable oleic acid were added and mixed evenly to obtain a modified novolac epoxy a...

Embodiment 3

[0106] A cold and heat shock resistant safety helmet in this embodiment, the safety helmet includes an outer helmet body and an inner lining body, and the inner lining body is connected to the outer helmet body through a buffer bracket;

[0107] The preparation method of the exoskeleton comprises the following steps:

[0108] a. Mix 90 parts of novolac epoxy resin, 1.5 parts of catalyst, and 3 parts of polymerization inhibitor by weight, raise the temperature to 95-100°C, add 35 parts of polyvinyl butyral and ethanol according to the weight ratio of 3:1 configuration into a solution, then add 5-7 parts of ethyl orthosilicate, fully react, then add 3 parts of 20wt% dinonyl naphthalene disulfonic acid and 25 parts of 7-dimethyl-6-octenoic acid and acrylic acid according to A mixed solution composed of 1:2 was kept at 105°C for 3 hours, and then cooled. During the cooling process, 5 parts of aniline and 4 parts of vegetable oleic acid were added and mixed evenly to obtain a modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com