Molybdenum tailing dry-mixed mortar and application method thereof

A technology of dry-mixed mortar and molybdenum tailings, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of lack of building material resources, environmental pollution, etc., and achieve secondary utilization and circular economy , Improve the utilization rate and ensure the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

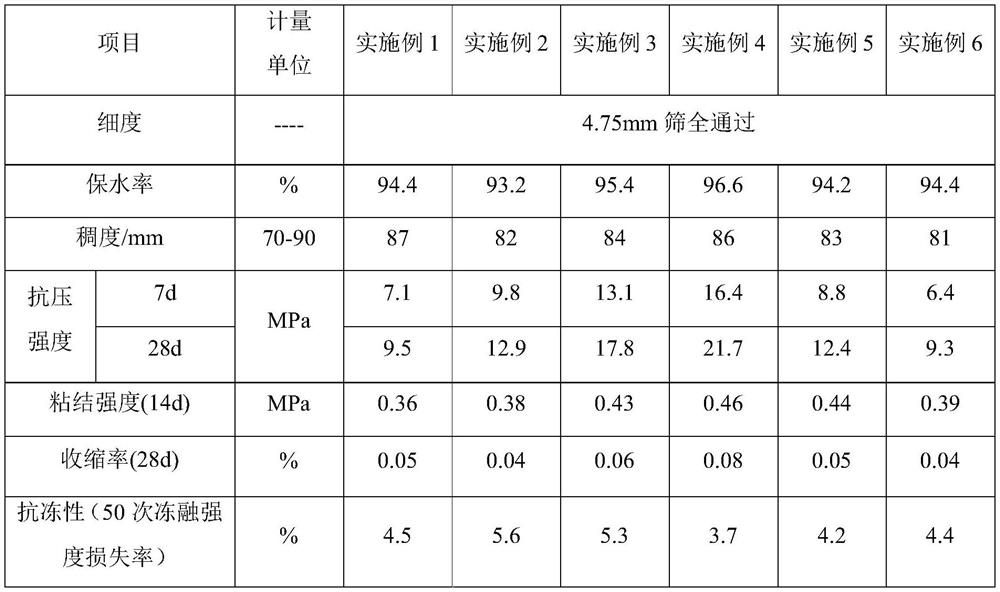

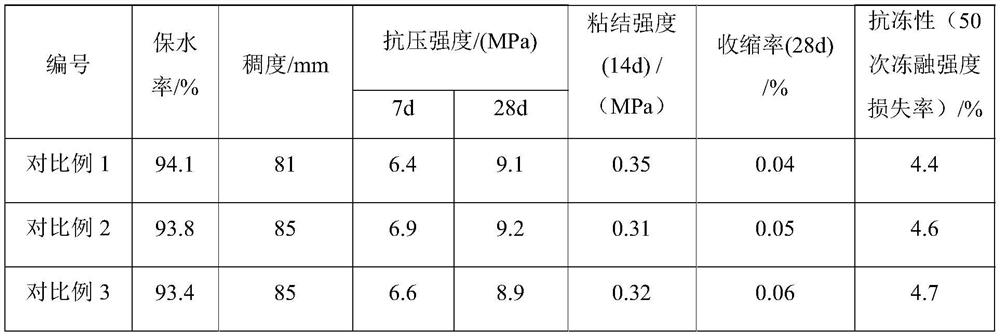

Embodiment 1

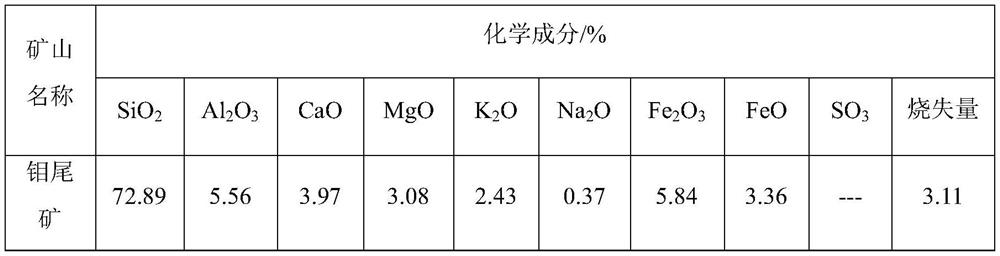

[0035] The composition of a molybdenum tailings dry-mixed mortar of the present embodiment is as follows: 6 parts of molybdenum tailings silicon micropowder, 8 parts of cement, 3 parts of fly ash, 2 parts of magnesium slag powder, 80 parts of molybdenum tailings sand, redispersible polymer 0.65 part of polymer latex powder, 0.06 part of cellulose ether, 0.08 part of modified starch ether (using S30 1 modified starch ether in this example), 0.03 part of CAS# sodium bentonite, 0.1 part of polycarboxylate water reducing agent, 0.01 part of air agent (existing air-entraining agent can be used, and dodecyl air-entraining agent can be used in this embodiment), 0.1 part of synergist (existing synergist can be used, CJS concrete synergist can be used in this embodiment) ). The composition and particle size distribution of the molybdenum tailing sand used are shown in Table 1 and Table 2 below, respectively.

[0036] Table 1 Mineral composition and chemical composition analysis table ...

Embodiment 2

[0044] The composition and weight ratio of the molybdenum tailings dry-mixed mortar of the present embodiment are as follows: 7 parts of molybdenum tailings silicon micropowder, 9 parts of cement, 3.3 parts of fly ash, 2.2 parts of magnesium slag powder, and 77 parts of molybdenum tailings sand , 0.96 part of redispersible polymer latex powder, 0.07 part of cellulose ether, 0.1 part of modified starch ether, 0.04 part of sodium bentonite, 0.13 part of water reducing agent, 0.02 part of air-entraining agent and 0.18 part of synergist.

[0045] In this implementation, the preparation process of the molybdenum tailings silicon micropowder is as follows: using hydrochloric acid with a mass concentration of 7% to carry out acid leaching on the screened molybdenum tailings powder to remove soluble oxides in the tailings; The hydrofluoric acid that the mass concentration is 9% is added in the middle, and the ammoniacal liquor that the mass concentration is 18% is then added dropwise a...

Embodiment 3

[0049] The composition and weight proportion of a molybdenum tailings dry-mix mortar of the present embodiment are as follows: 7.5 parts of molybdenum tailings silicon micropowder, 9.5 parts of cement, 3.6 parts of fly ash, 2.7 parts of magnesium slag powder, and 74 parts of molybdenum tailings sand , 1.47 parts of redispersible polymer latex powder, 0.08 part of cellulose ether, 0.12 part of modified starch ether, 0.06 part of sodium bentonite, 0.16 part of water reducing agent, 0.02 part of air-entraining agent and 0.25 part of synergist.

[0050] The preparation process of the molybdenum tailings silicon micropowder in this implementation is as follows: using hydrochloric acid with a mass concentration of 6.5% to carry out acid leaching on the screened molybdenum tailings powder to remove soluble oxides in the tailings; Add the hydrofluoric acid that the mass concentration is 8.5% in the middle, and then dropwise add the ammoniacal liquor that the mass concentration is 22% w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com