Light-weight shale brick manufactured from alcohol wastewater of sugar refinery and production method thereof

A technology of alcohol waste liquid from sugar factory and light shale, applied in the field of light shale bricks, can solve the problems of heavy self-weight, high energy consumption in the production process, poor thermal insulation and other problems of ordinary shale bricks, and achieves excellent anchoring performance , low cost, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

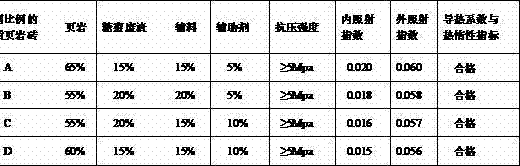

[0019] A lightweight shale brick made from alcohol waste liquid from sugar factories, mainly made of the following raw materials in mass ratio: 55%-65% of shale, 15%-25% of molasses waste residue from sugar factories with PH=7, auxiliary materials 15%-20%, auxiliary agent 5%-10%, the mass ratio between auxiliary agents is: slag 85%-95%, potassium chloride 5%-15%, the above raw material shale is crushed to 80 mesh, and the Add water at a temperature of 40°C~45°C to the shale powder, accounting for 50%~60% of the raw material quality, stir the water, molasses waste residue and other auxiliary materials evenly, stir and stand for 1~1.5 hours, make bricks, and dry them , roasting, heat preservation and cooling to make lightweight shale bricks.

[0020] The mass ratio of the auxiliary materials is: quicklime 87.5%-90%, iron powder 10%-12.5%.

[0021] The sintering temperature of the calcination is controlled at 950°C-1150°C and kept for 8-12 hours.

[0022] A method for producing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com