Red translucent crystal glue material and manufacturing method thereof

A translucent, crystal glue technology, applied in the field of crystal glue materials, can solve the problems of short service life, easy oxidation and discoloration, poor transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A red translucent crystal glue material, made of the following components by weight percentage:

[0046] PVA powder: 25%;

[0047] Water: 57.6%;

[0048] Borax: 0.7%;

[0049] Carboresin: 5%;

[0050] Propylene glycol: 8%;

[0051] Vanillin: 0.01%;

[0052] Clove oil: 0.02%;

[0053] Amyl acetate: 0.02%;

[0054] Carmine: 0.07%;

[0055] Tartaric acid: 0.03%;

[0056] Sorbic acid: 0.05%;

[0057] Sodium dodecylbenzenesulfonate: 0.5%;

[0058] Acrylamide-acrylate copolymer cross-linked product: 3%;

[0059] The acrylamide-acrylate copolymerized cross-linked product is made of 55% of acrylamide, 34% of potassium acrylate, 10% of water and 1% of N,N-methylenebisacrylamide.

[0060] Acrylamide-acrylate copolymerized cross-linked product is a water-retaining agent. Its preparation method is: add acrylamide to acrylic acid aqueous solution, stir at room temperature, then add N,N-methylenebisacrylamide (NNMBA), heat up To 35°C and keep the temperature constant at 3...

Embodiment 2

[0069] A red translucent crystal glue material made of the following components by weight percentage:

[0070] PVA powder: 28%;

[0071] Water: 54.54%;

[0072] Borax: 0.9%;

[0073] Carboresin: 8%;

[0074] Propylene glycol: 6%;

[0075] Vanillin: 0.02%;

[0076] Clove oil: 0.01%;

[0077] Amyl acetate: 0.02%;

[0078] Carmine: 0.05%;

[0079] Tartaric acid: 0.02%;

[0080] Sorbic acid: 0.04%;

[0081] Sodium dodecylbenzenesulfonate: 0.4%;

[0082] Acrylamide-acrylate copolymer cross-linked product: 2%;

[0083] The acrylamide-acrylate copolymerized cross-linked product is made of 56% of acrylamide, 34% of potassium acrylate, 9.5% of water and 0.5% of N,N-methylenebisacrylamide accounting for its total weight.

[0084] The preparation method of the acrylamide-acrylate copolymerized cross-linked product and the preparation method of the above-mentioned red translucent crystal glue material are the same as in Example 1.

Embodiment 3

[0086] A red translucent crystal glue material made of the following components by weight percentage:

[0087] PVA powder: 20%;

[0088] Water: 58.85%;

[0089] Borax: 0.6%;

[0090] Carboresin: 7%;

[0091] Glycerin: 9%;

[0092] Vanillin: 0.01%;

[0093] Clove oil: 0.03%;

[0094] Amyl acetate: 0.01%;

[0095] Carmine: 0.05%;

[0096] Tartaric acid: 0.04%;

[0097] Sorbic acid: 0.01%;

[0098] Sodium dodecylbenzenesulfonate: 0.4%;

[0099] Acrylamide-acrylate copolymer cross-linked product: 4%;

[0100] The acrylamide-acrylate copolymerized cross-linked product is made of 56% of acrylamide, 33% of potassium acrylate, 10% of water and 1% of N,N-methylenebisacrylamide.

[0101] The preparation method of the acrylamide-acrylate copolymerized cross-linked product and the preparation method of the above-mentioned red translucent crystal glue material are the same as in Example 1.

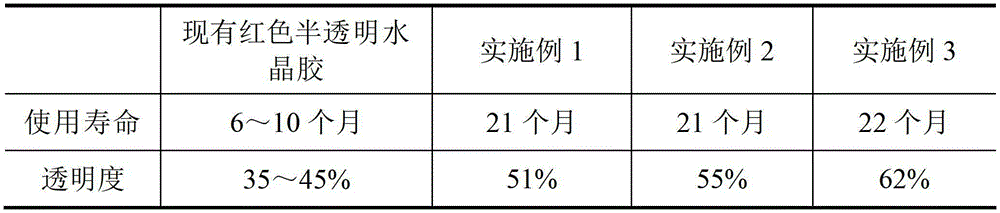

[0102] The following is a partial performance comparison table between the existing red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com