Patents

Literature

63results about How to "Inhibition of swelling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of removing inorganic scales

InactiveUS20120325485A1Minimize corrosion potential on downhole metal tubularsImprove breathabilityCleaning apparatusFluid removalMining engineeringSilanes

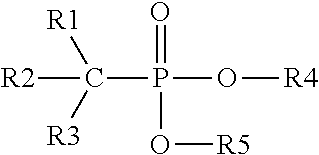

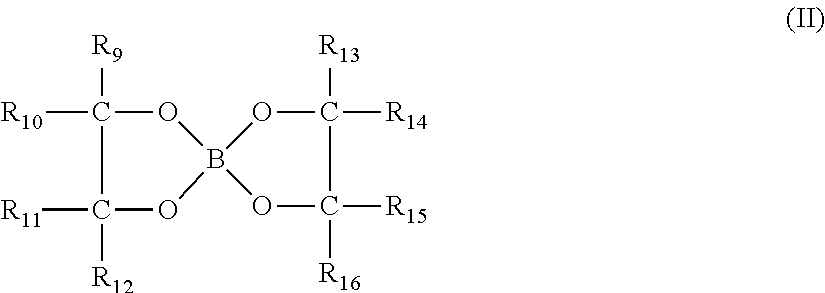

The productivity of hydrocarbons from hydrocarbon-bearing calcareous or siliceous formations is enhanced by contacting the formation with a well treatment composition which contains a hydrofluoric acid source, a phosphonate acid, ester or salt thereof, a quaternary ammonium salt and an organosilane and, optionally, a boron-containing compound.

Owner:BAKER HUGHES INC

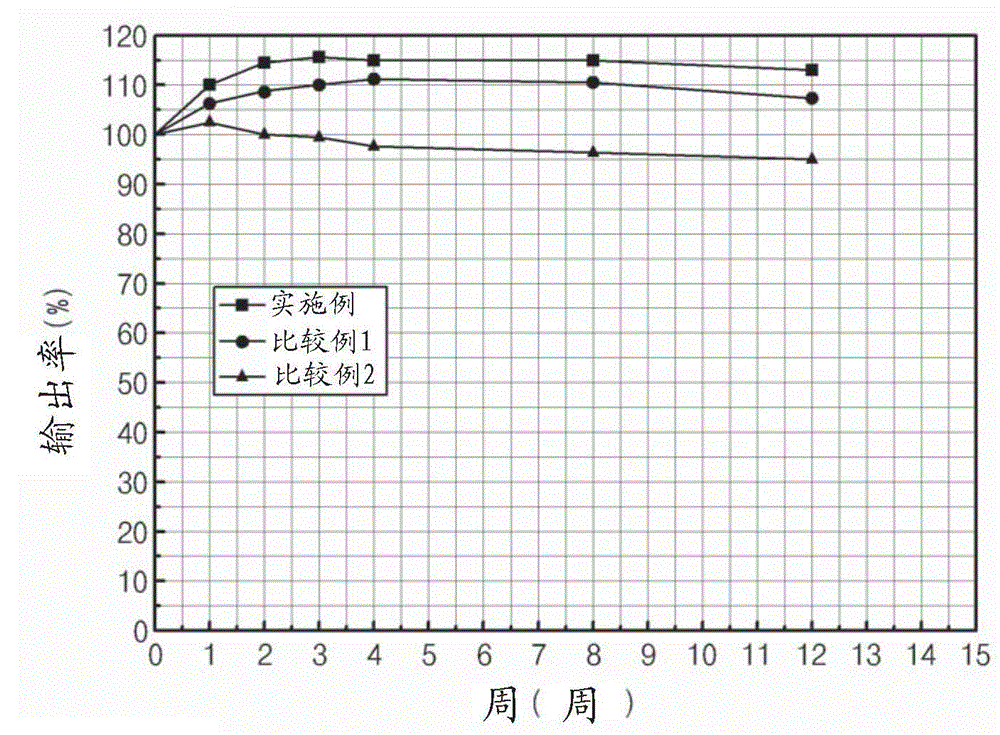

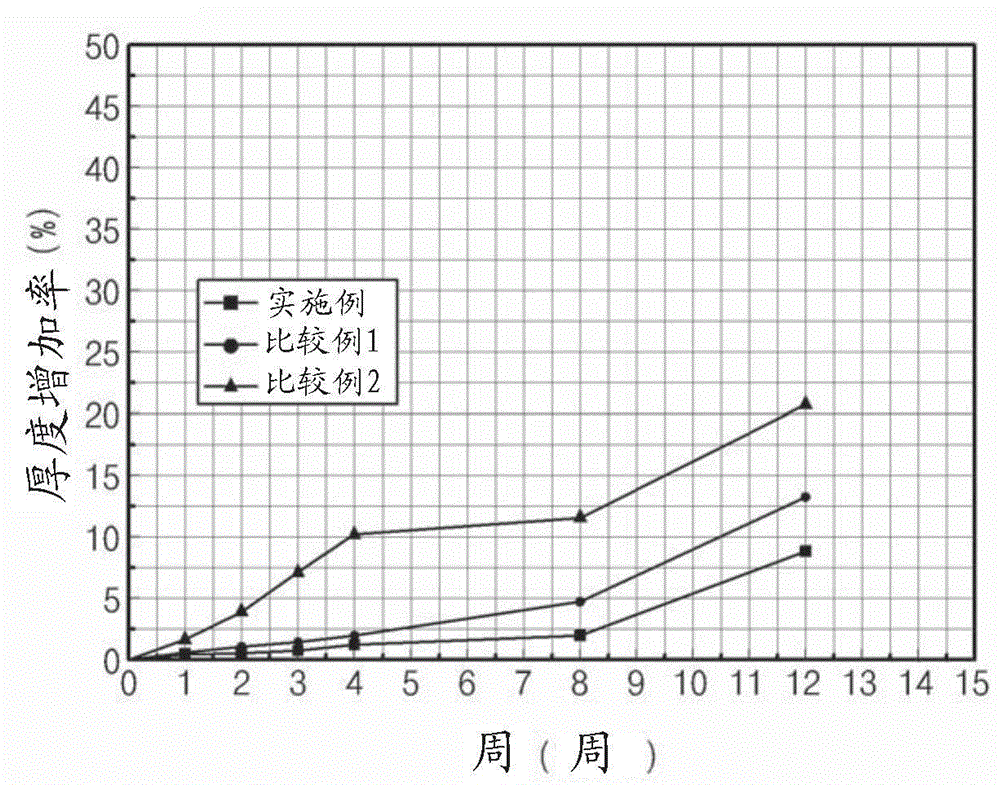

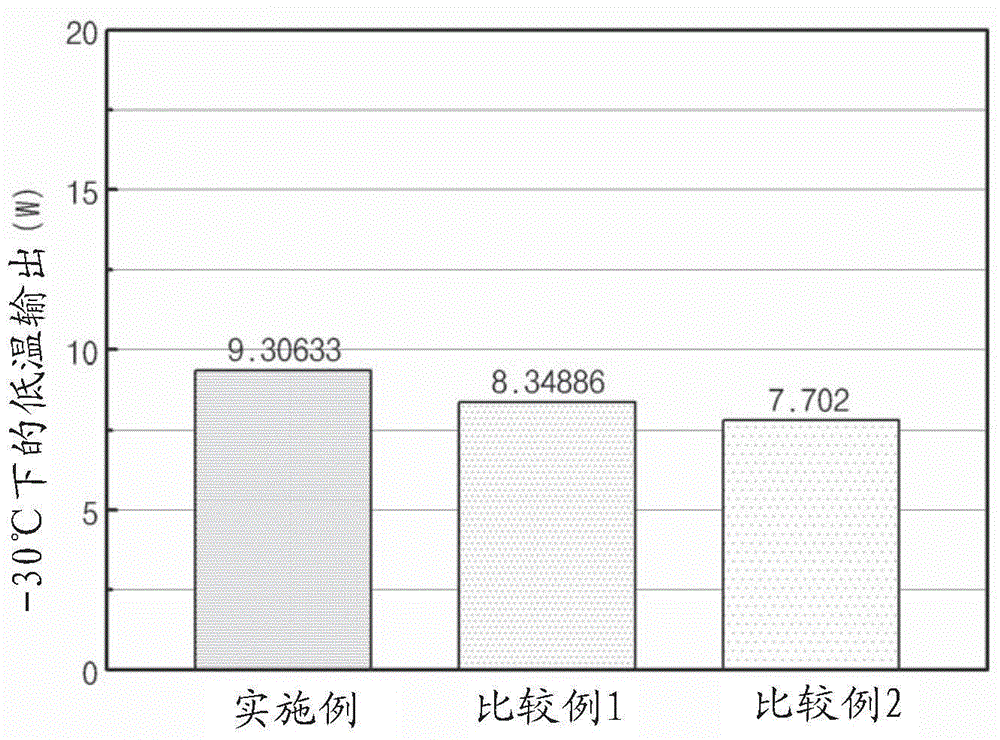

Electrolyte additive for lithium secondary battery, non-aqueous electrolyte comprising electrolyte additive, and lithium secondary battery

ActiveCN104823319AAvoid oxidation reactionsInhibition of swellingCell electrodesLi-accumulatorsImideOrganic solvent

The present invention provides a non-aqueous electrolyte comprising: a non-aqueous organic solvent; an imide-based lithium salt; and, as an electrolyte additive, at least one additive selected from the group consisting of lithium difluorooxalate phosphate (LiDFOP), trimethylsilylpropyl phosphate (TMSPa), 1,3-propenesultone (PRS), and ethylene sulfate (Esa). The electrolyte additive for a lithium secondary battery of the present invention can suppress the PF6- decomposition of a positive electrode surface, which may occur at the time of high-temperature cycle operation of a lithium secondary battery, and prevent an oxidation reaction of an electrolyte, thereby improving output characteristics at high and low temperatures and suppressing a swelling phenomenon.

Owner:LG ENERGY SOLUTION LTD

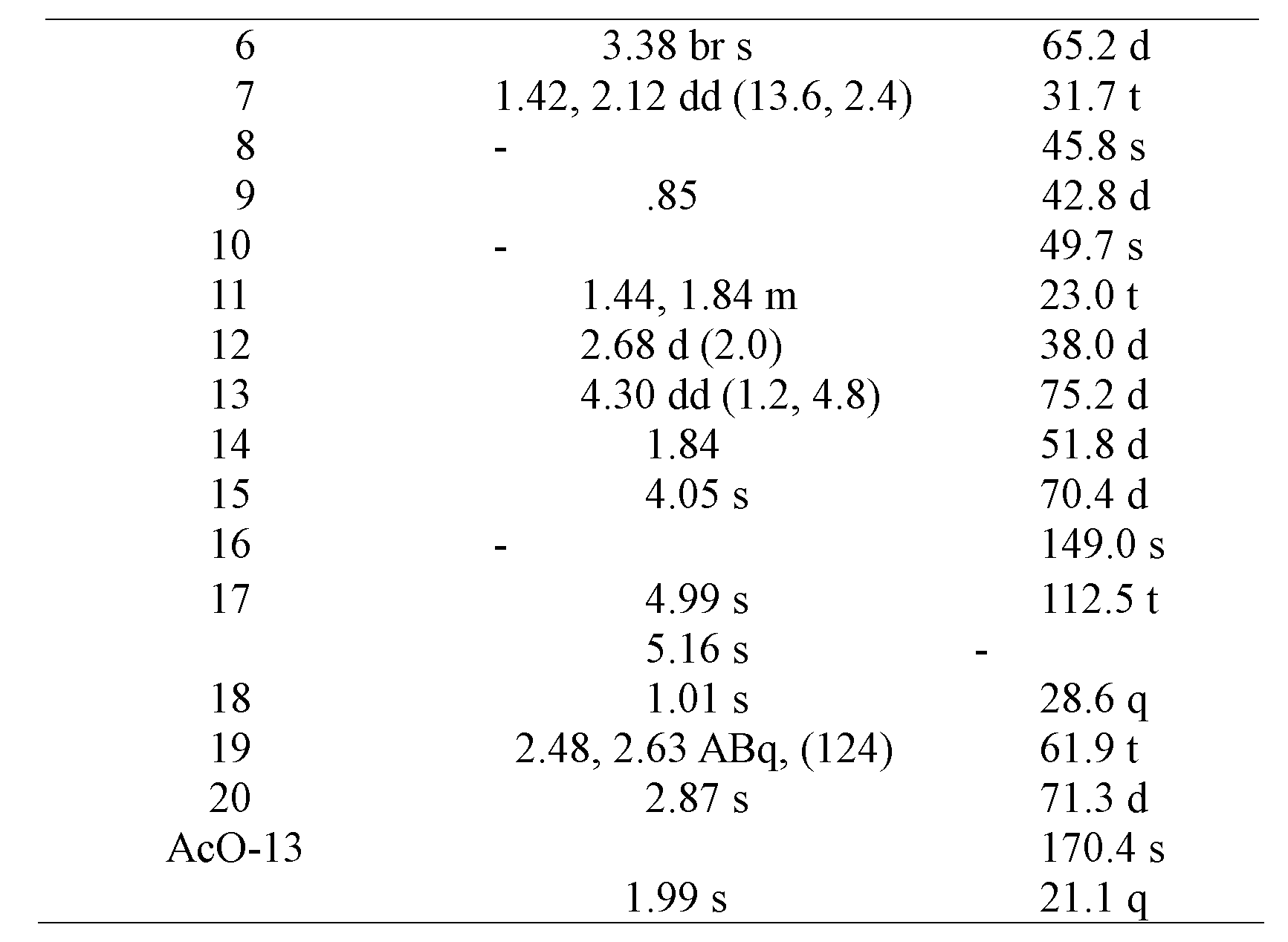

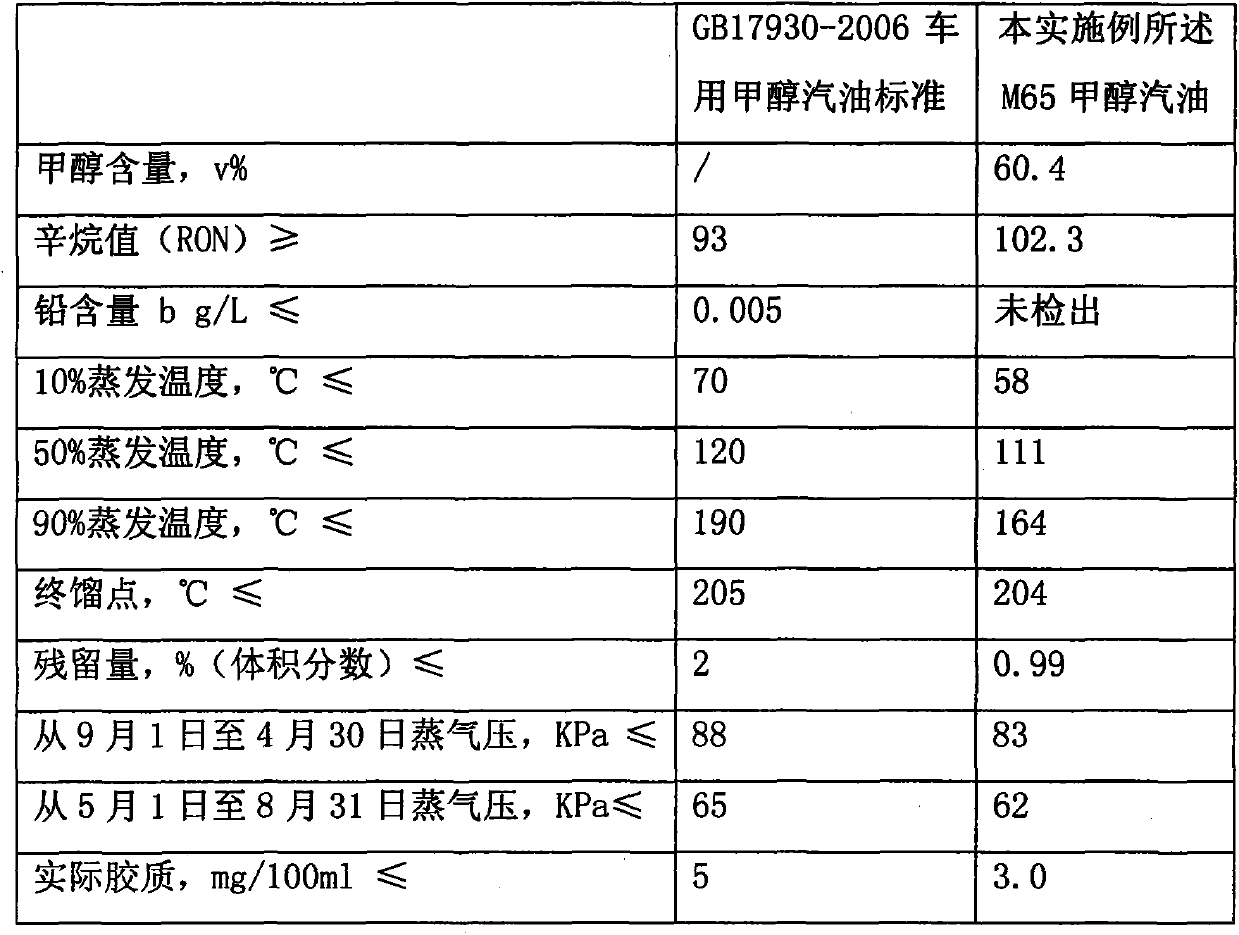

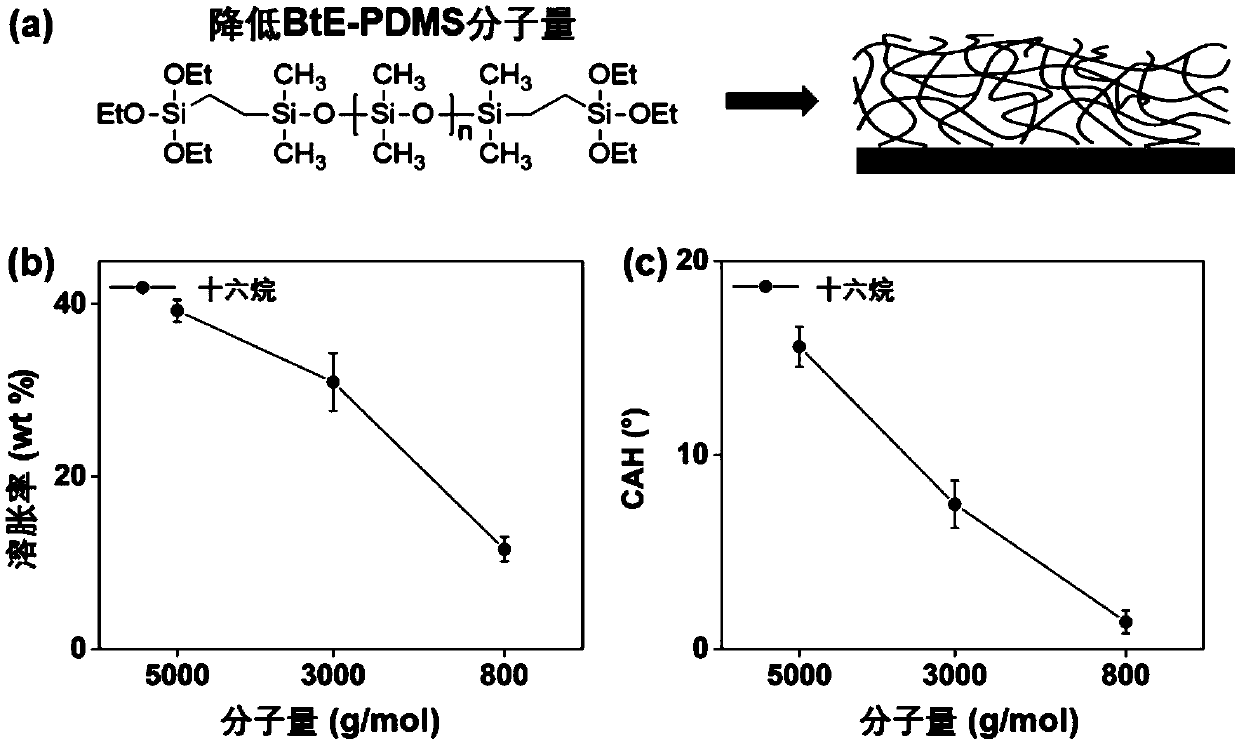

Energy-saving environment-protective methanol gasoline for vehicle and preparation thereof

InactiveCN101372636ACurb emissionsLower free energyLiquid carbonaceous fuelsGasolinePollutant emissions

The invention relates to an energy-saving and environment-friendly vehicle methanol gasoline and a preparation method thereof, belonging to the technical field of alternative energy sources. The vehicle methanol gasoline is prepared by the following materials by weight percentage: 30-88.5% of white gasoline component oil, 10-55% of methanol and 1.5-15% of composite additive; the composite additive is composed of the following components: 60-77.5% of latent solvent, 17-30% of heat value enriching substance, 0.08-1.3% of power synergistic agent, 3.5-10% of homogeneous catalysis combustion improver, 0.6-3.0% of corrosion and swelling inhibitor and 1.5-3.5% of vapor pressure regulator, after being evenly mixed, the materials are added into 10-55% of methanol, after being slightly stirred, the mixture is filled in 30-85.5% of white gasoline, evenly stirred and is subject to static reaction for 4-8 hours. The methanol gasoline can effectively solve the technical difficult problems of power reduction, high gasoline consumption, corrosiveness, swelling, difficult cold start, high-temperature air resistance, and the like, when the content of methanol gasoline is 10-55%; the vehicle methanol gasoline can be directly used on automobiles, while engines do not need to be modified; the vehicle methanol gasoline can also be mixed or interchanged with white gasoline and ethanol gasoline for application. The invention has the advantages of easily available raw materials, low cost, simple preparation technique and significant energy-saving benefit, and can greatly reduce tail gas pollutant emission.

Owner:TIANJIN LANDUN PETRO CHEM TECH

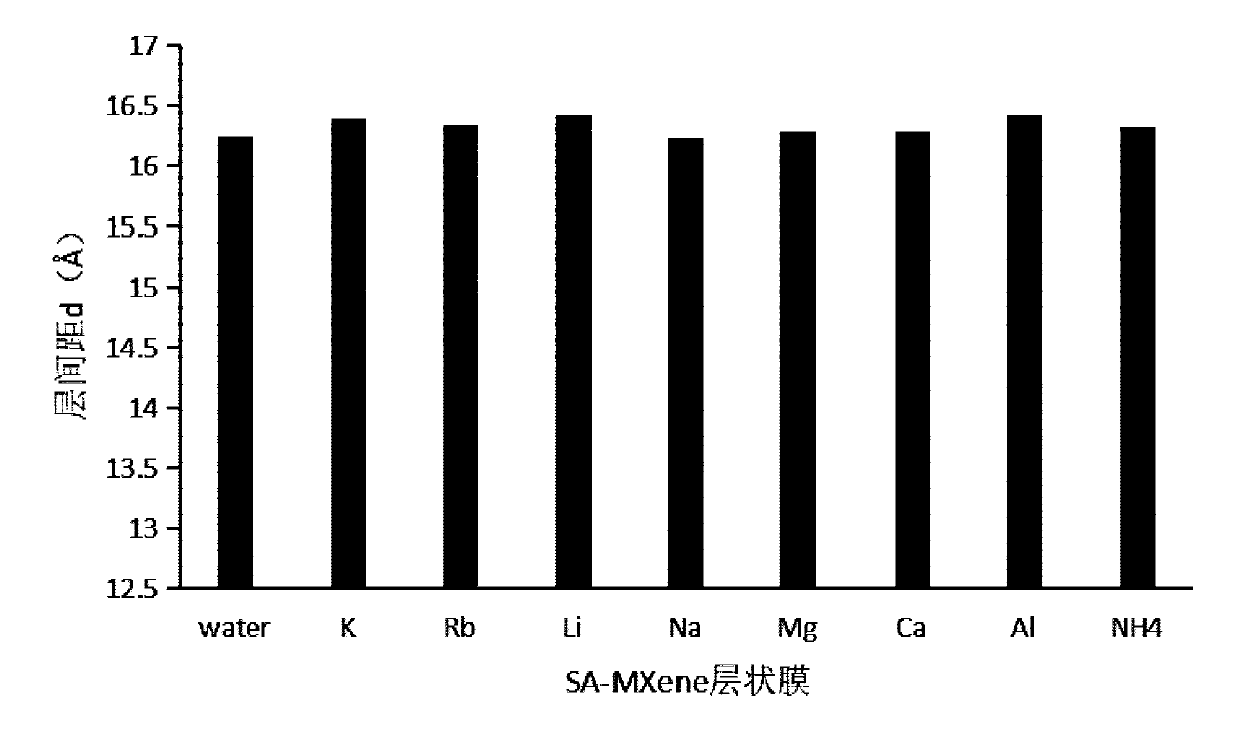

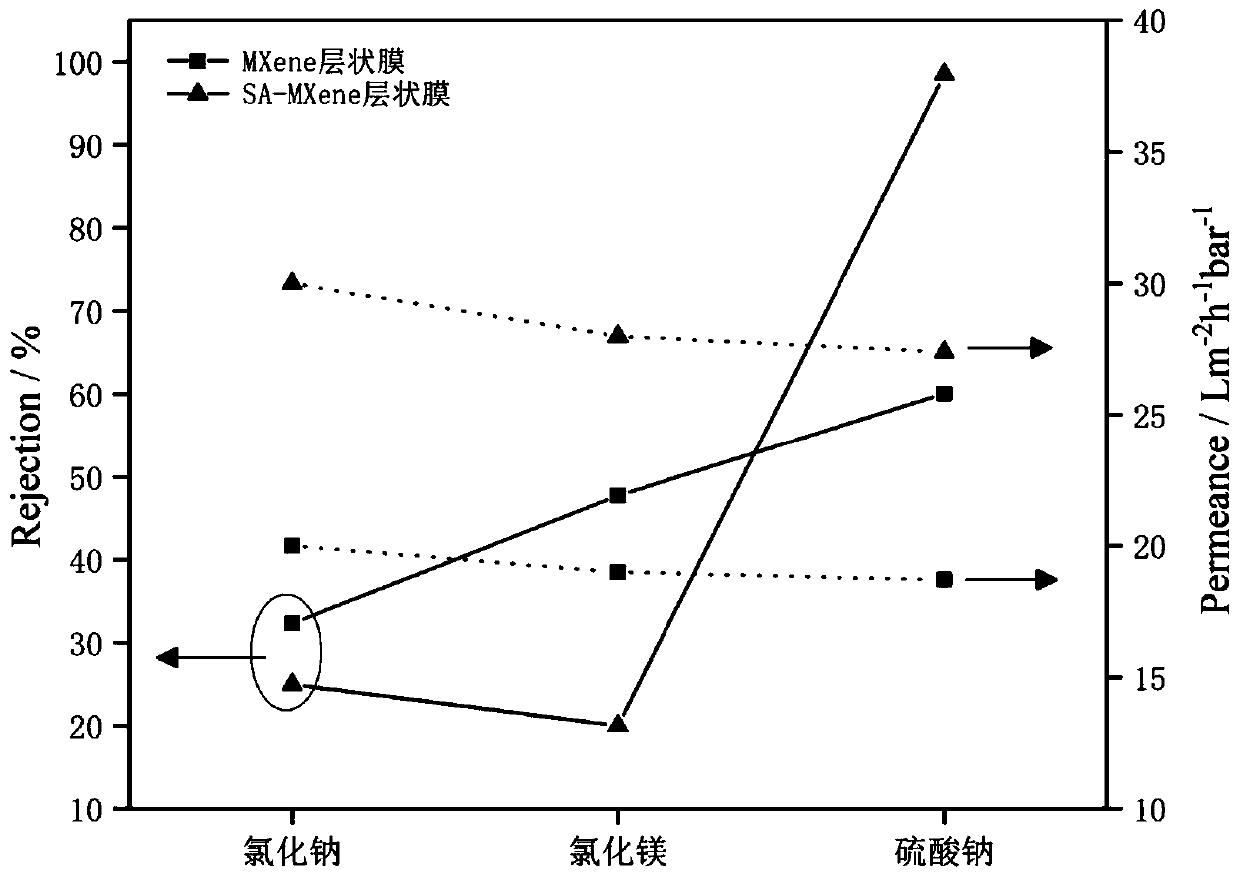

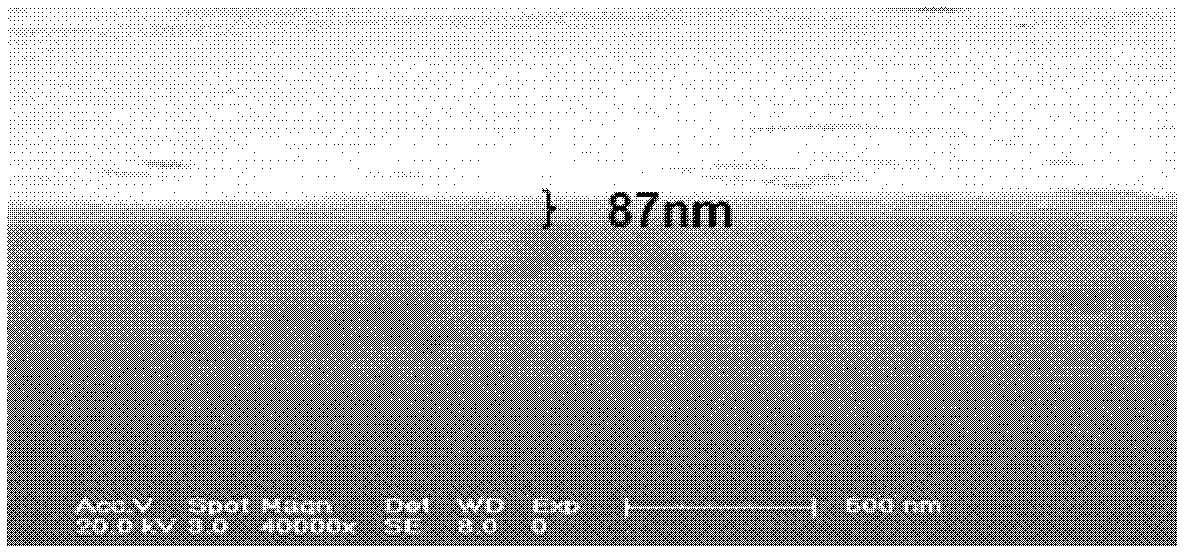

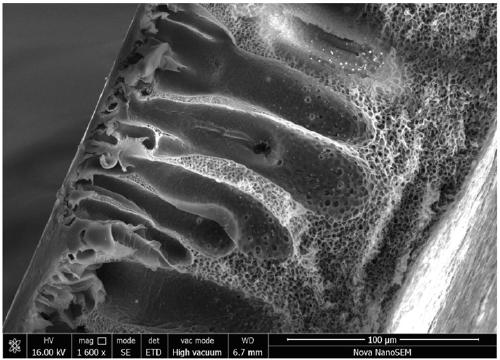

Swelling-resistant two-dimensional SA-MXene layered nanofiltration membrane, production and application

ActiveCN110449032ASolve the swelling problemInhibition of swellingMembranesReverse osmosisSelective filterIon

The invention discloses a production method of a swelling-resistant two-dimensional SA-MXene layered nanofiltration membrane. The production method of the swelling-resistant two-dimensional SA-MXene layered nanofiltration membrane comprises a first step of mixing MXene precursor powder and an etching agent solution, carrying out a stirring reaction, and conducting centrifugal washing to obtain a two-dimensional MXene nanosheet colloid solution; a second step of adding sodium alginate into the two-dimensional MXene nanosheet colloid solution, and evenly stirring and mixing an obtained mixture to obtain SA-MXene nanosheets; and a third step of stacking the SA-MXene nanosheets on a surface of a substrate to produce a membrane, and placing the membrane in a polyvalent metal solution for cross-linking to obtain the swelling-resistant two-dimensional SA-MXene layered nanofiltration membrane. According to the method, by evenly grafting the sodium alginate onto surfaces of MXene nanosheets, through a cross-linking effect of the sodium alginate and polyvalent metal ions, stable hydrophilic cross-linked networks are formed in interlayer channels of the nanosheets, thus the problem of swelling of a layered membrane is solved, meanwhile, due to the fact that the sodium alginate is doped, a large number of oxygen-containing functional groups are introduced onto surfaces of the mass transferchannels, the channel electronegativity is improved, and the layered membrane shows excellent selective filtering performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

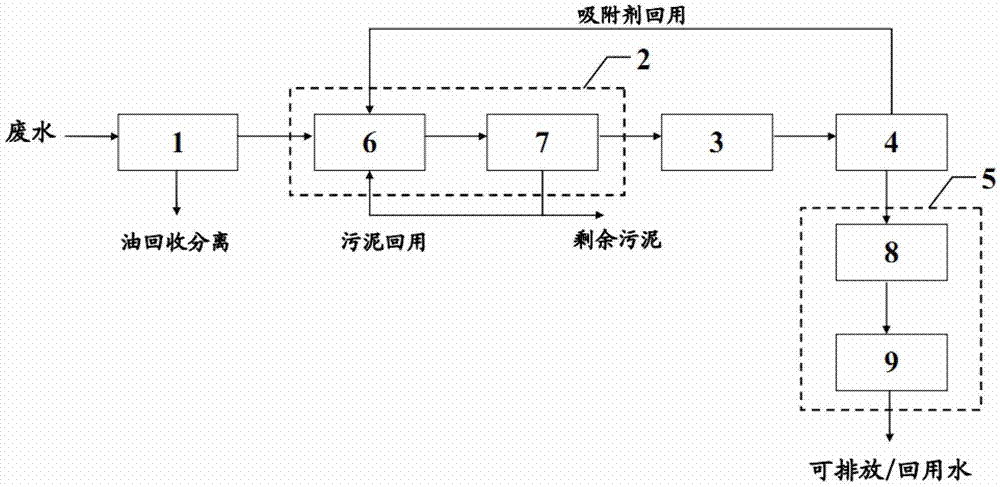

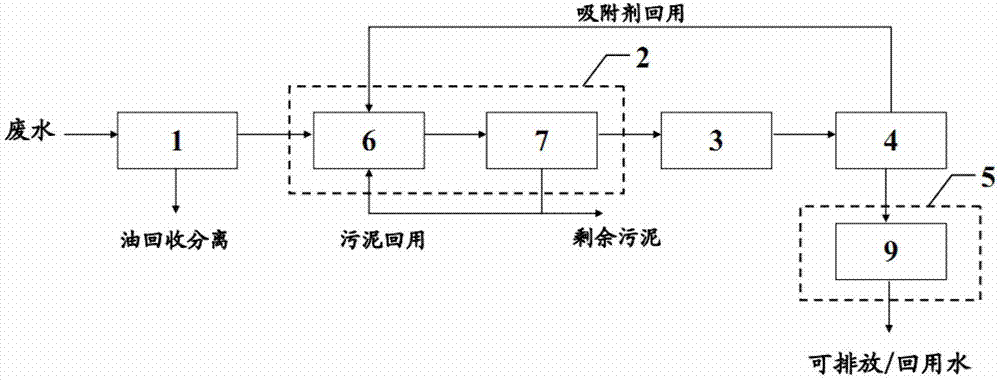

Slack coal pressure gasification wastewater resourceful treatment method and treatment system as well as application

InactiveCN103288311AAchieve reuseProportionally largeMultistage water/sewage treatmentFlocculationSludge

The invention provides a slack coal pressure gasification wastewater resourceful treatment method. The treatment method sequentially comprises the following steps of: (1) performing oil-water separation on the wastewater to obtain wastewater after the oil-water separation treatment; (2) treating the wastewater obtained by the step (1) by use of active sludge, and performing mud-water separation to obtain wastewater after the active sludge treatment; (3) adding an adsorbent into the wastewater obtained by the step (2), and performing solid-liquid separation to obtain wastewater after the adsorption separation treatment; (4) adding a flocculating agent and / or flocculation aid into the wastewater obtained by the step (3), and precipitating to obtain wastewater after the coagulation clarifying treatment; and (5) treating the wastewater obtained by the step (4) by use of a filter material loaded with microorganisms to obtain dischargeable / recyclable water. The invention also provides a system for the method to realize resourceful treatment on the wastewater, and application of the treatment method or treatment system in treating slack coal pressure gasification wastewater.

Owner:DATANG INT CHEM TECH RESINST

Application of external-use plaster composition in preparation of drug used for preventing, relieving and/or treating inflammatory diseases

InactiveCN104127687ASignificant effectDefinite curative effectAntipyreticAnalgesicsDiseaseSide effect

The invention discloses an application of an external-use plaster composition in preparation of a drug used for preventing, relieving and / or treating inflammatory diseases. A experiment proves that the external-use plaster composition is significant in effects on treatment of inflammatory diseases, is quick in the effects, is slight in toxic and side effects, is simple in the preparation method, is a drug used for treating inflammatory diseases safely, high-efficiently and stably, is suitable for industrial production, is easy to popularize. The invention provides a new drug source for preventing and treating the inflammatory diseases.

Owner:吕刚

Aluminium plastic composite pipe and its manufacturing method

The invention is an aluminum plastic composite tube and the preparing method. The said aluminum plastic composite tube contains an aluminum tape layer between high molecular plastic layers and such the characters of arranging a plurality of holes on the aluminum tape, containing a hot melt glue adhesive layer between the high molecular plastic layer and the aluminum tape layer, and adding additive crylic acid to the molecular plastics. The preparing method has the characters: firstly holing the aluminum tape, heating and determining the diameter and aligning the welding line and then welding into a tube; then fully mixing high molecular plastics, crylic acid and fillings, heating and extruding the high molecular plastic polymer to make inner plastic tube and outer plastic tube; feeding the inner and outer plastic tubes together with the holed aluminum tube uniformly coated with polypropylene hot melt glue into the die cavity of an extrusion head; heating to raise temperature and pressure, and then completing the copolymerization reaction at constant temperature and pressure. The invention improves the strength, low-temperature resisting performance, and cold-hot resistant alternative performance of the tubing by changing the structural form of the composite, able to better prohibit the swelling caused by hydrocarbon oil soaking.

Owner:孙经尧

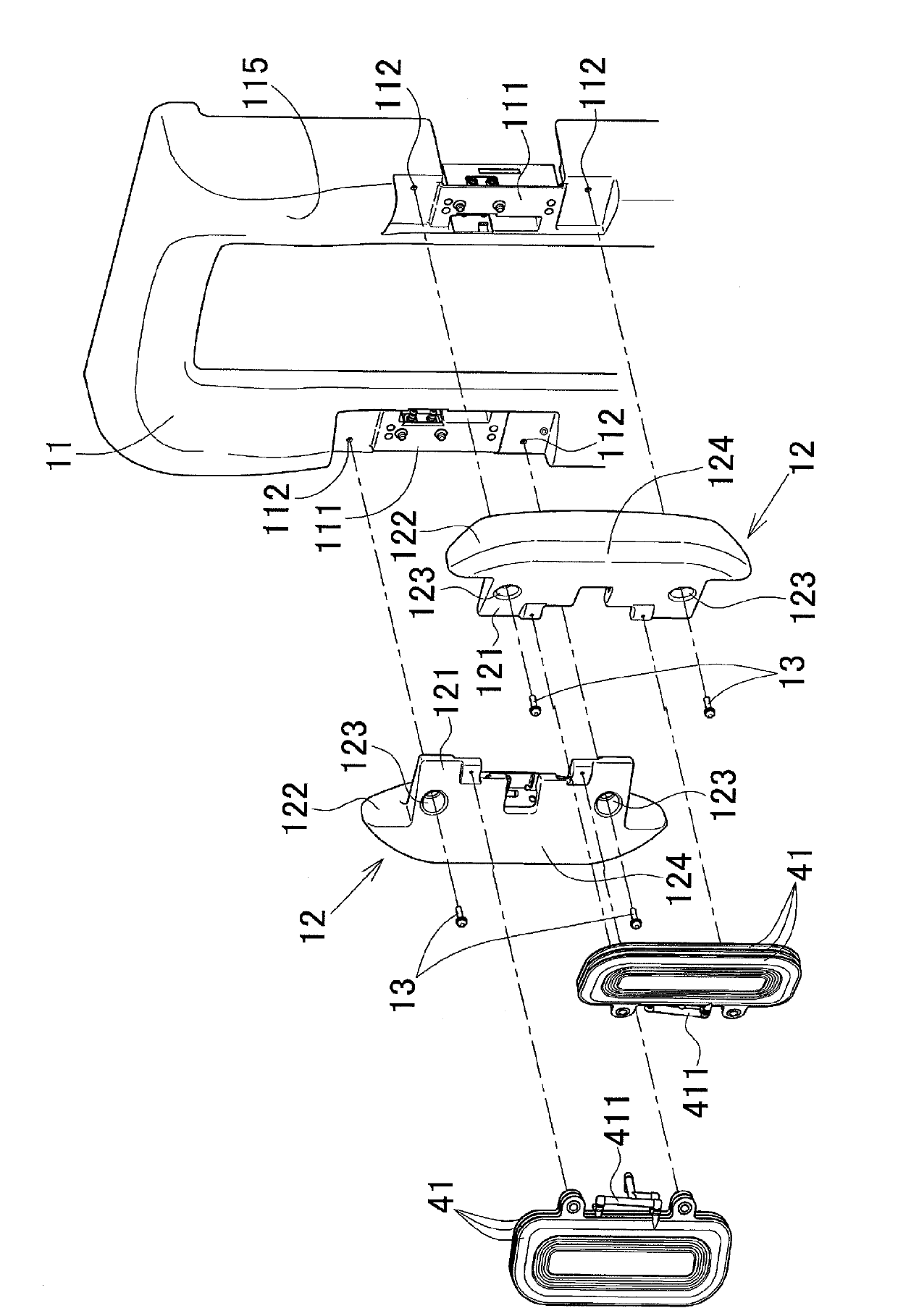

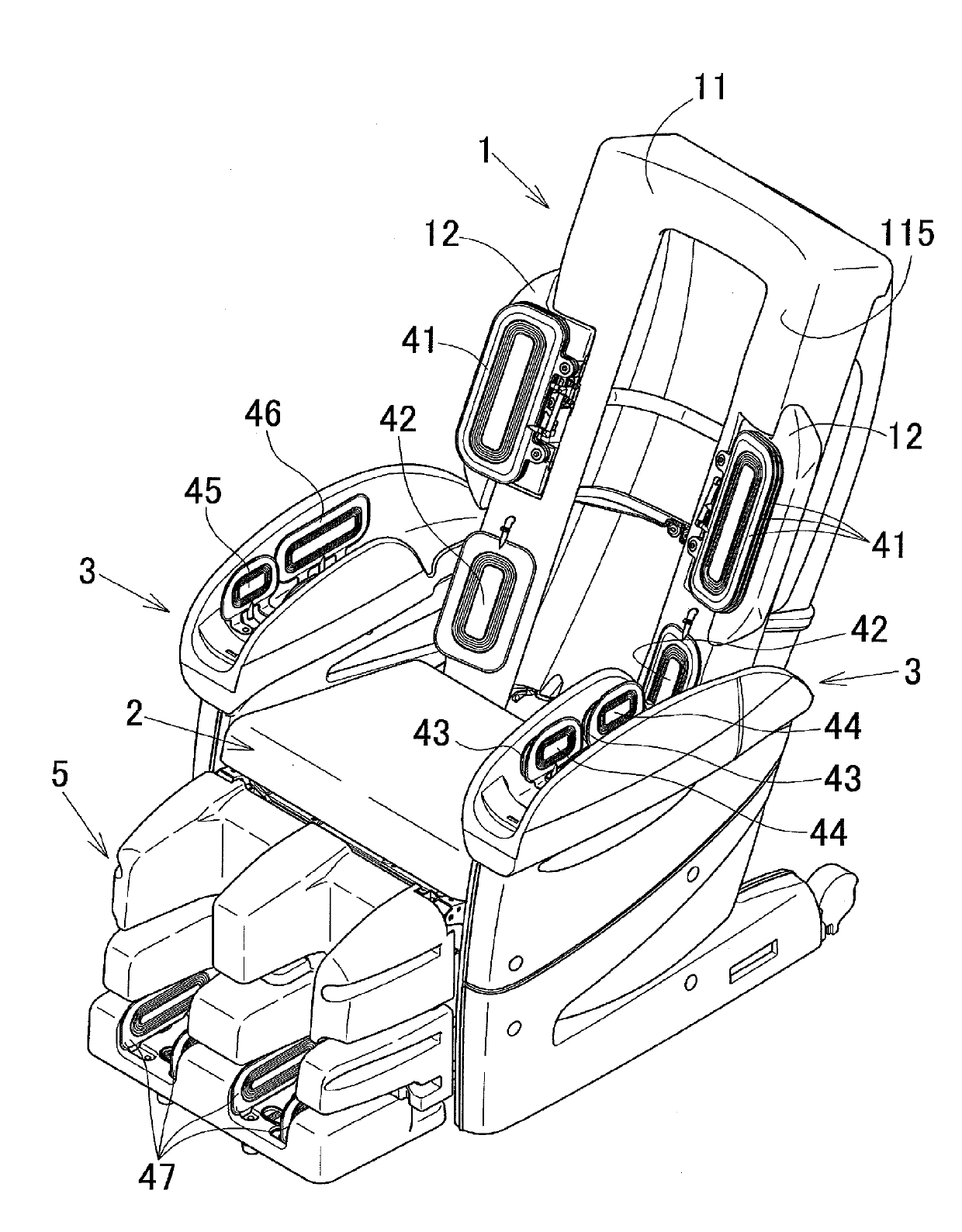

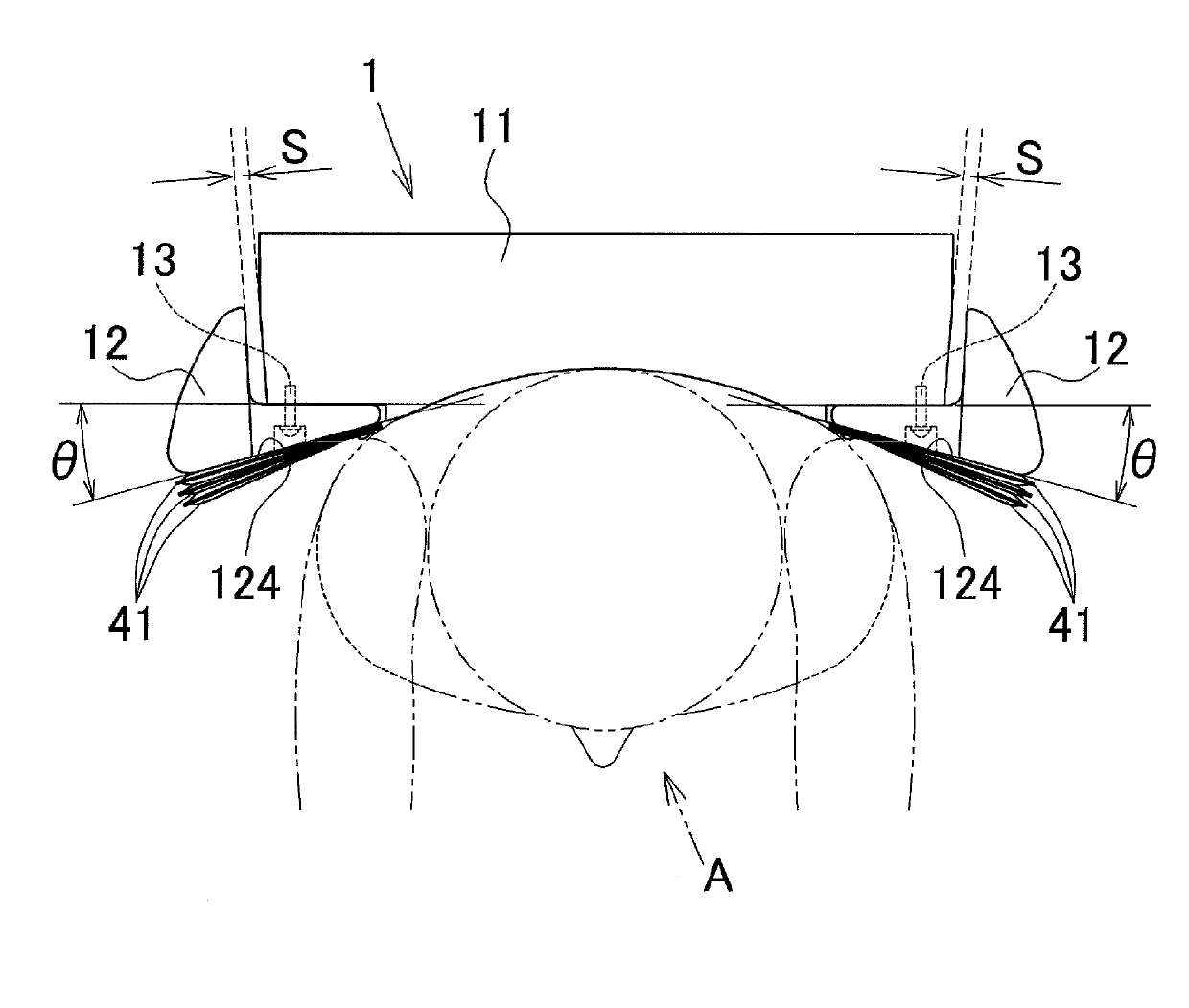

Chair-type massage machine

The invention provides a chair-type massage machine which comprises a backrest part, comprising a backrest plate supporting a user's body and inclining rearward from the right and left end part to a central part, and airbag support tables which is arranged in a recessed part recessedly provided at ends of right and left sides of the backrest part from the front of the backrest plate; and shoulder airbags respectively arranged at left and right airbag support tables. Therefore, the user's arms are integrally subjected to a relatively strong pressing therapy equal with a strength by manpower kneading. Even if the airbags at the arms of the pressing users is contracted, an uncomfortable feeling that the user's upper arms float through the airbags does not occur, and user' is embedded in a therapeutic component in the central part of the backrest part and is fully pressed. Even if the airbags repeatedly expand and contract, the chair-type massage machine can still rapidly carries out the continuous actions, and can be tightly packaged and easily transport and assemble.

Owner:FUJI MEDICAL INSTR MFG

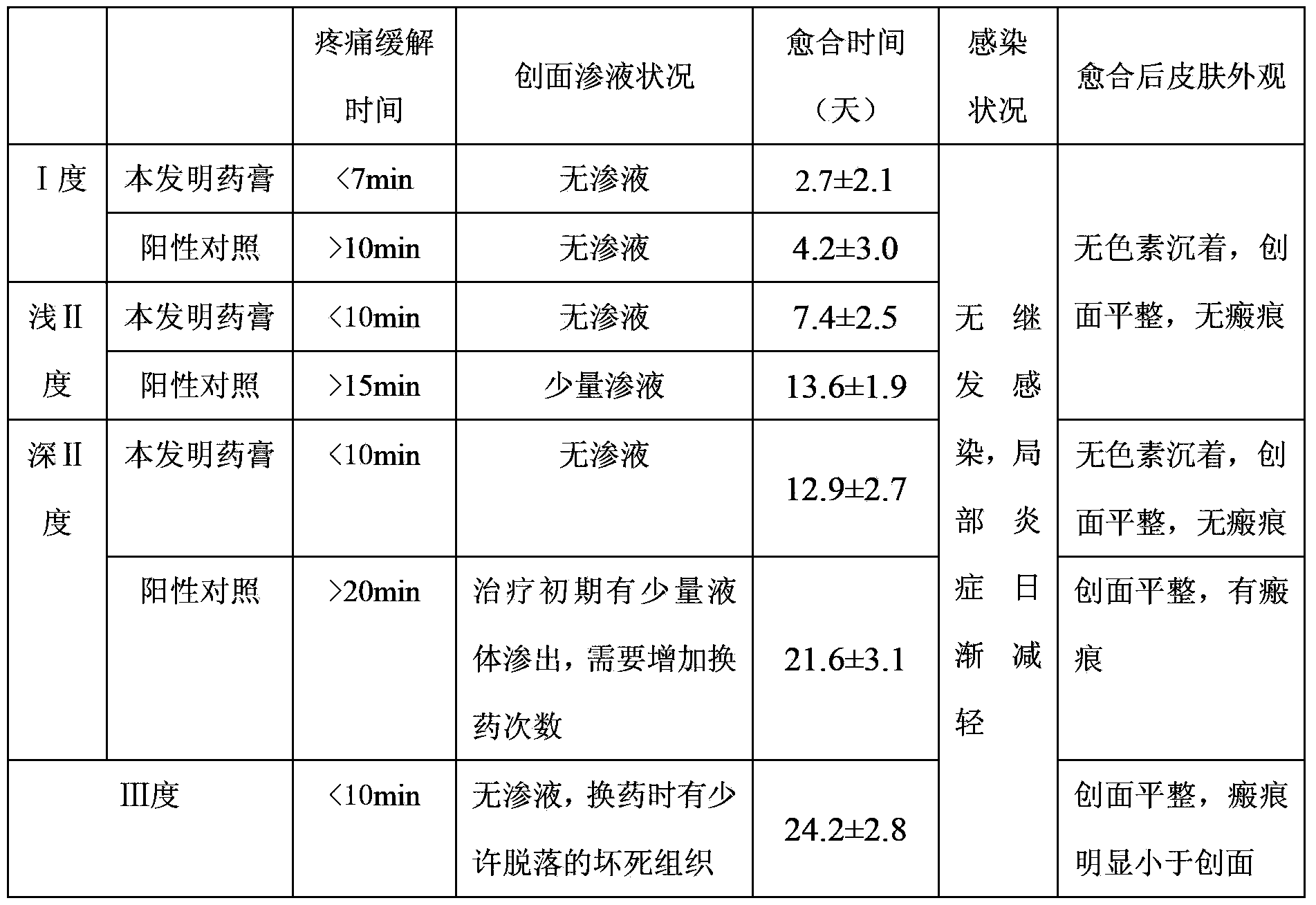

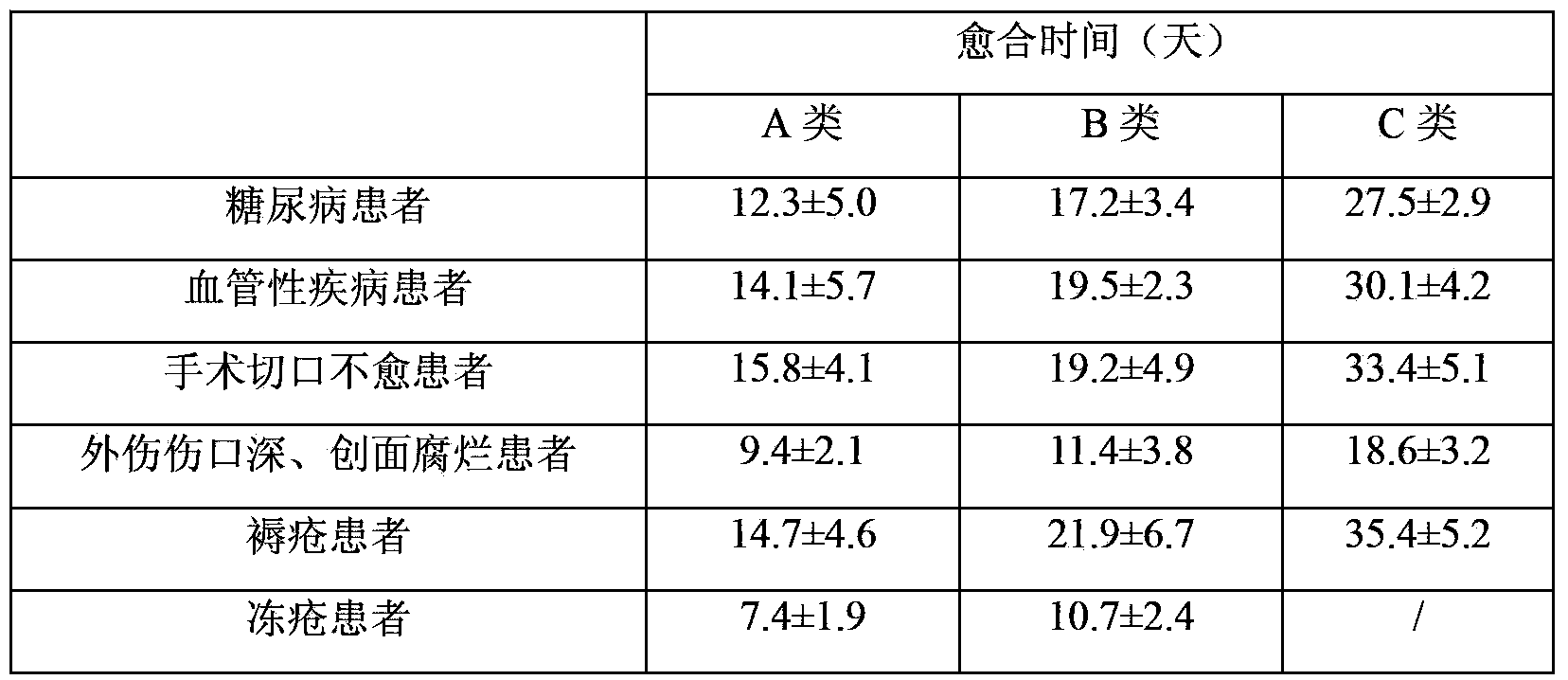

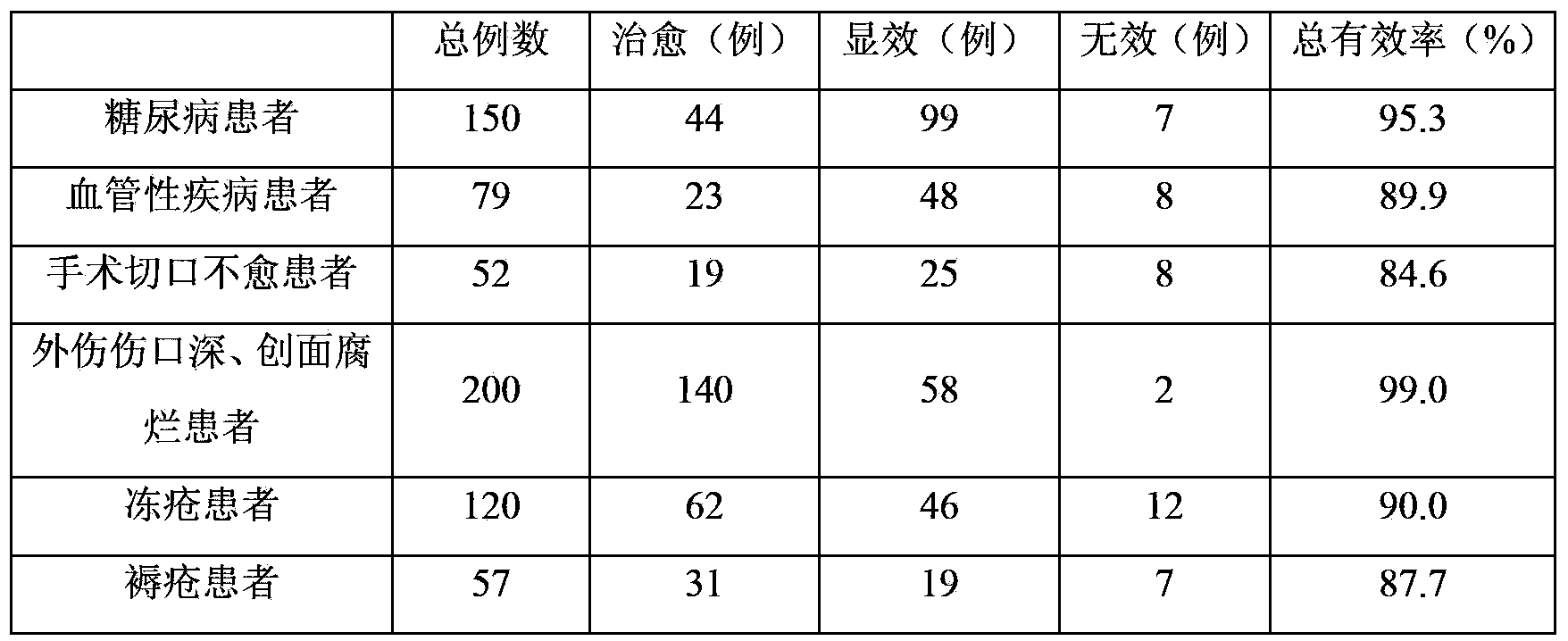

Application of external-use plaster composition in preparation of drug used for treating skin injury

InactiveCN104127685AEasy to useRelief the painAnthropod material medical ingredientsAerosol deliverySide effectSkin Injury

The invention discloses an application of an external-use plaster composition in preparation of a drug used for treating skin injury. A experiment proves that the external-use plaster composition is significant in effects on treatment of skin injury, is quick in the effects, is slight in toxic and side effects, is a drug used for treating skin injury and promoting skin injury to heal safely, high-efficiently and stably, is simple in preparation process, is suitable for industrial production, is easy to popularize. The invention provides a new drug source for preventing and treating the skin injury.

Owner:吕刚

Process for preparing poly acrylic acid-poly glycol/cellulose acetate composite film

InactiveCN1943845AInhibition of swellingSimple processSemi-permeable membranesAluminum nitratePolyacrylic acid

The preparation process of polyacrylic acid-polyethylene glycol / cellulse acetate (PAA-PEG / CA) composite film is the application of film casting process in preparing composite film. Film casting solution is first prepared through mixing water solution of PAA PEG and adding ethylene glycol and aluminum nitrate as the cross linking agent; and then cast to the surface of supporting porous CA film at room temperature; and the PAA-PEG gel film on the CA film is finally dried and heat treated to obtain the PAA-PEG / CA composite film. The PAA-PEG / CA composite film is used in the permeating vaporization separation of water mixture with dimethyl carbonate in 90 wt% in the conditions of room temperature and downstream vacuum degree of 300-600 Pa, and can reach excellent separation of permeation flux of 96.30-313.74g / sq m.hr and separation factor of 52.06-1602.17. The present invention has simple preparation process, facile material and easy operation and control, and suitable for industrial production.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

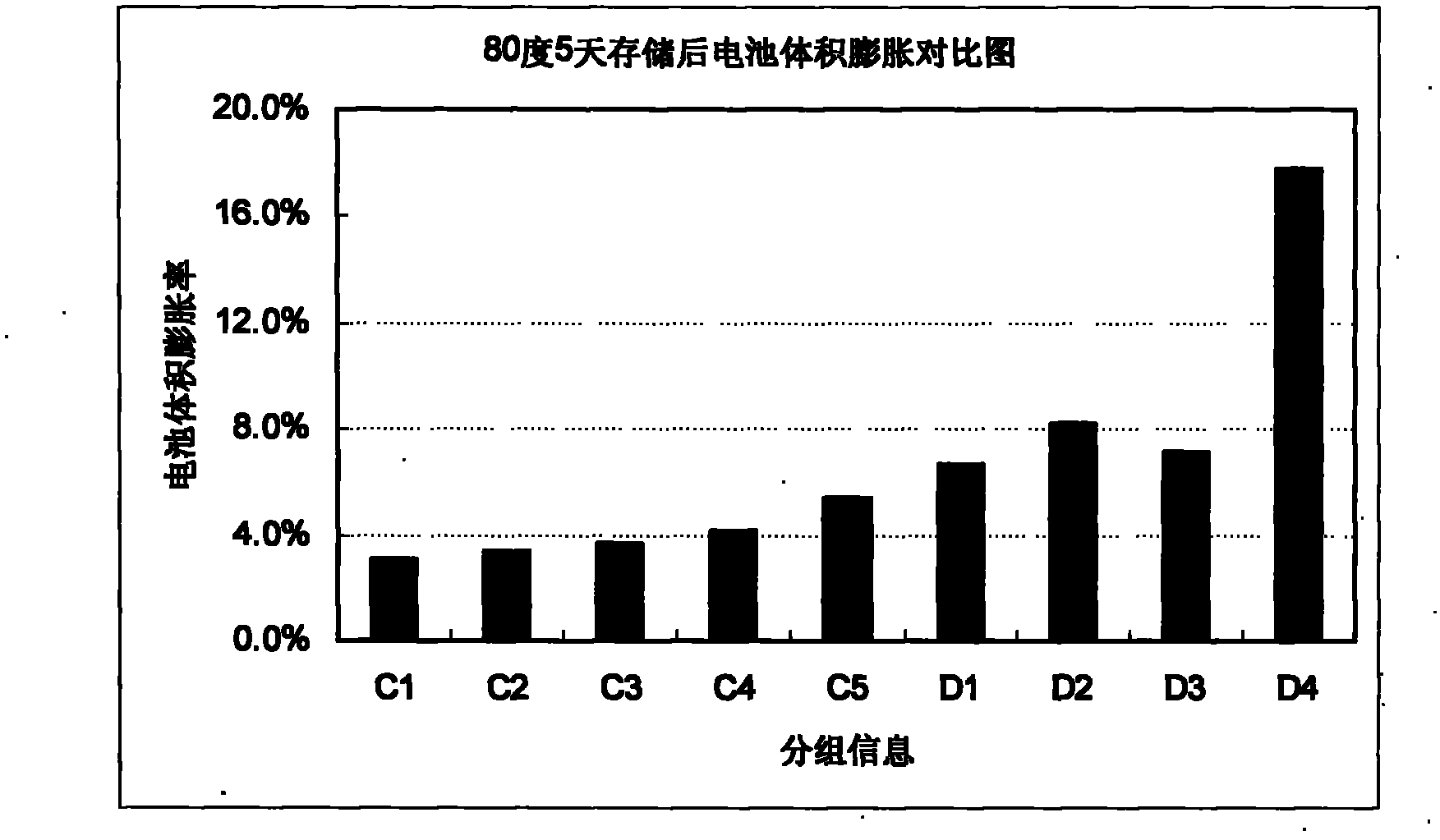

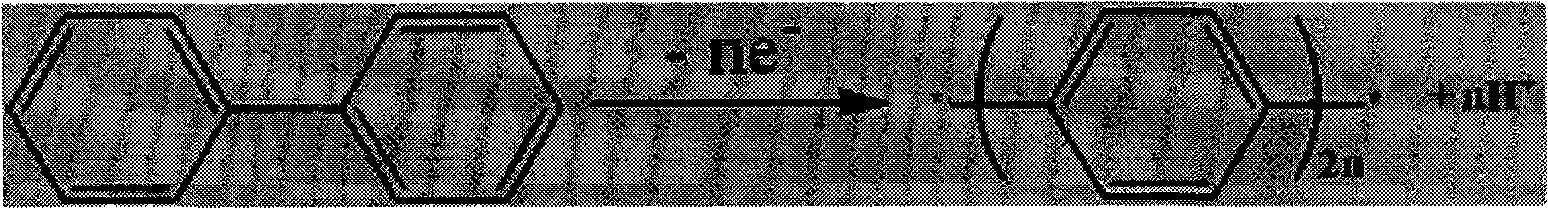

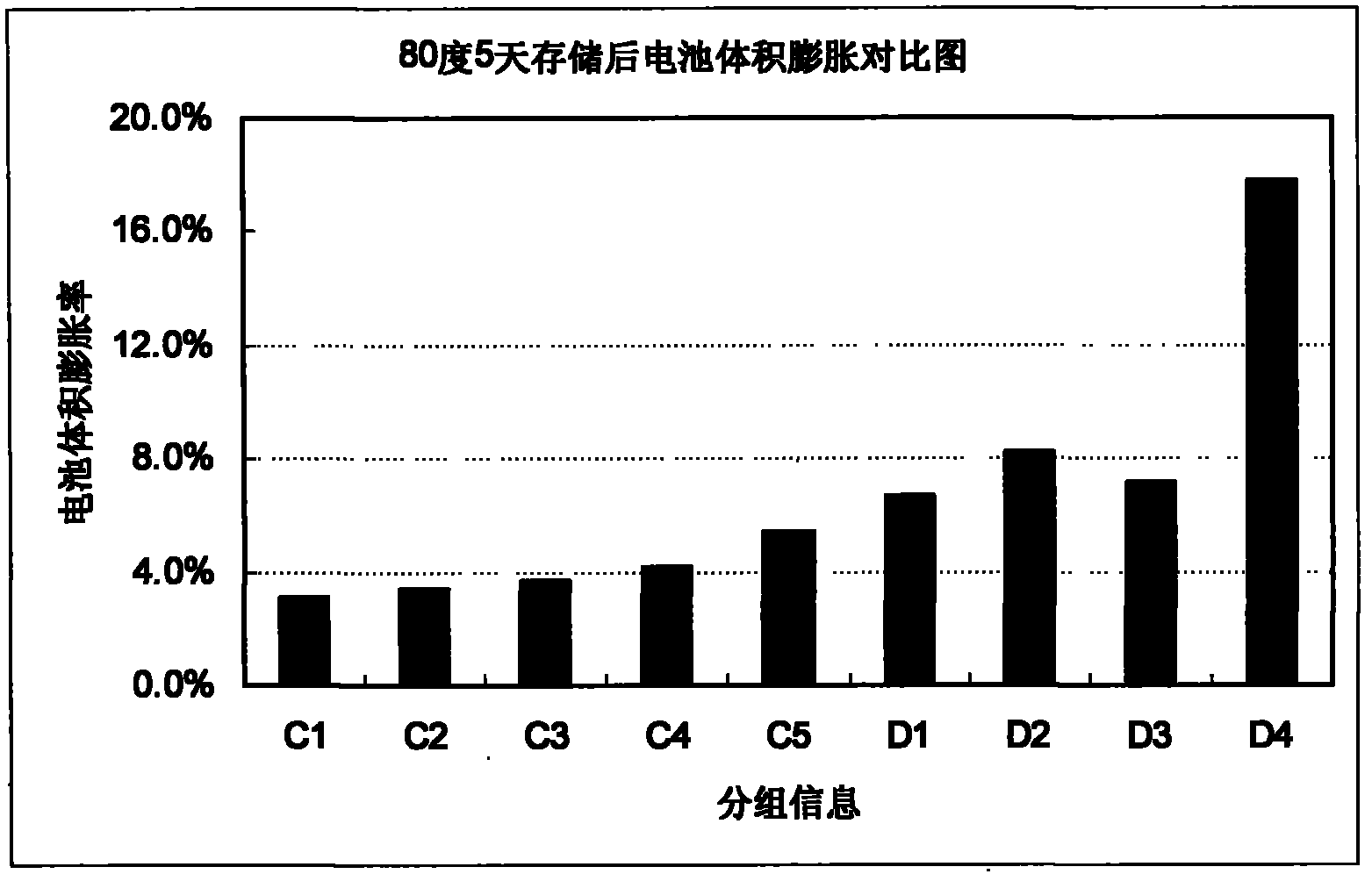

A kind of non-aqueous electrolyte battery

ActiveCN102280662AInhibition of swellingImprove high temperature performanceSecondary cellsPropylene carbonateSolvent

The present invention relates to the technical field of lithium ion batteries, in particular to a non-aqueous electrolyte battery, comprising a positive electrode and a positive electrode active material, a negative electrode and a negative electrode active material, a separator and a non-aqueous electrolyte, the non-aqueous electrolyte containing a solvent, an electrolyte and additives; the electrolyte is lithium hexafluorophosphate; the solvent is a mixture of ethylene carbonate (EC), propylene carbonate (PC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC), the carbonic acid The content of vinyl ester (EC) is 0%-40wt%, the content of the propylene carbonate (PC) is 10-40wt%, the content of the diethyl carbonate (DEC) is 5-50wt%, the carbonic acid The content of ethyl methyl ester (EMC) is 0-60wt%; the additive is biphenyl (BP), and the invention can suppress high-temperature expansion and improve high-temperature performance.

Owner:DONGGUAN AMPEREX TECH +1

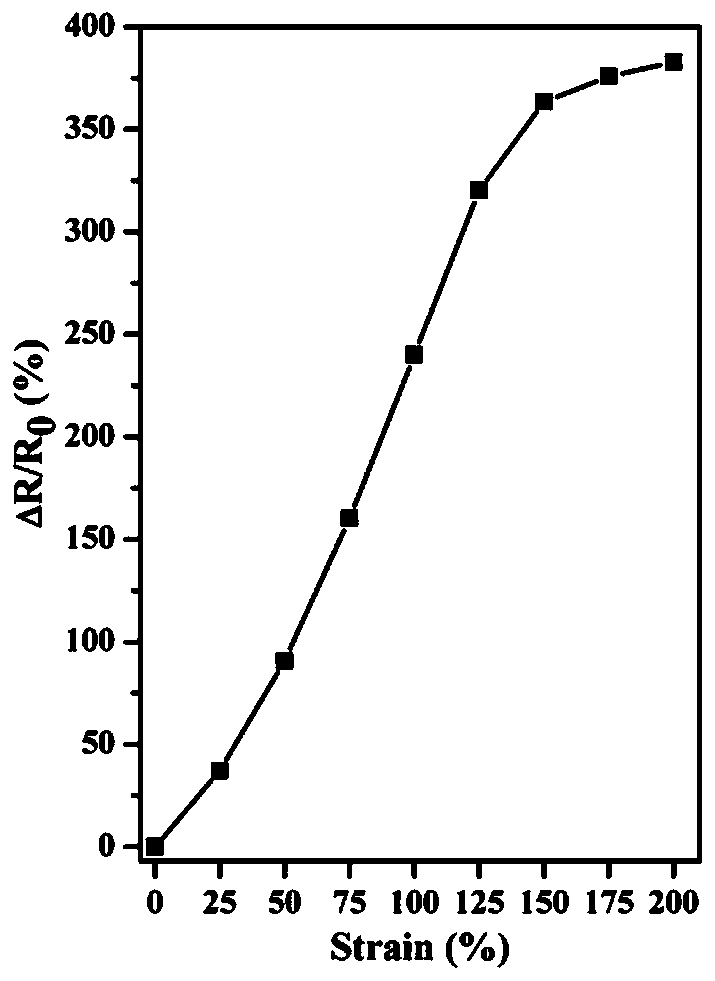

Alkali-soluble chitosan-polyacrylamide-polyaniline conductive hydrogel material with adjustable conductive polymer network structure

The invention discloses an alkali-soluble chitosan-polyacrylamide-polyaniline composite conductive hydrogel material with an adjustable conductive polymer network structure. A preparation method comprises the following steps: dissolving chitosan powder in a mixed aqueous solution of lithium hydroxide monohydrate, urea and graphene oxide to obtain a graphene oxide / alkali-soluble chitosan solution;then adding acrylamide, N, N '-methylene bisacrylamide and ammonium persulfate sequentially to obtain an alkali-soluble chitosan-polyacrylamide gel through in-situ polymerization; after dialysis and dehydration, transferring an obtained product into an aniline-phytic acid / hydrochloric acid solution for soaking, and dropwise adding an ammonium persulfate solution to initiate aniline polymerization,so as to obtain the alkali-soluble chitosan-polyacrylamide-polyaniline composite conductive hydrogel material. The polyaniline conductive polymer network structure can be adjusted by changing the ratio of phytic acid to hydrochloric acid, so that the conductivity and the mechanical property of the hydrogel are adjusted. The material is expected to be applied to the fields of electronic skin, electronic devices and the like by virtue of excellent mechanical properties and conductivity.

Owner:ZHEJIANG UNIV

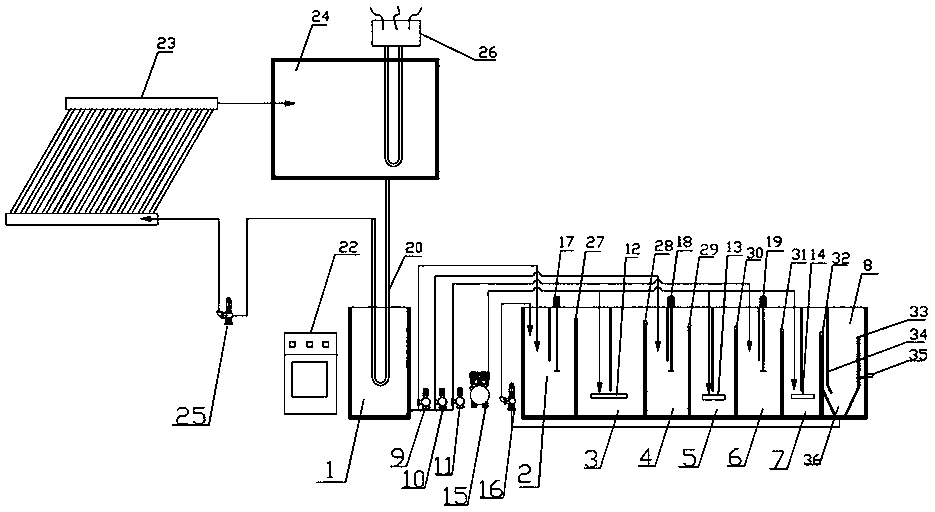

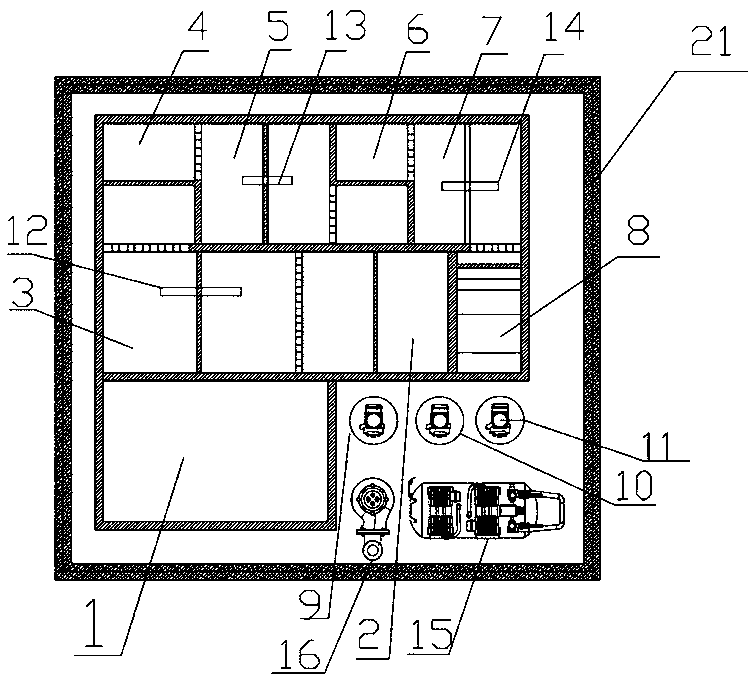

Low-temperature-resistant dispersing type sanitary sewage treatment integrated device and treatment method thereof

InactiveCN110282741AInhibition of swellingNo refluxBiological treatment apparatusTreatment with aerobic and anaerobic processesThermal insulationCollection system

Owner:沈阳工大蓝金环保产业技术研究院有限公司

Medicine for promoting gastrointestinal function and its prepn process

InactiveCN1608645AAnti-inflammatoryImprove permeabilityDigestive systemUnknown materialsCure rateFlatulence

The present invention is medicine for promoting gastrointestinal function and its preparation process. The present invention features that the medicine is prepared with rhubarb in 2-5 weight portions, magnolia bark in 3-6 weight portions and tree peony bark in 2-4 weight portions, and may be prepared into common orally taken preparation forms. The medicine of the present invention has the functions of cleaning up stomach and intestinal, keeping the adverse energy downwards, eliminating fluid retention and promoting blood circulation to disperse blood clots, and is used in treating gastrointestinal bradytalsis, vital energy stagnation caused abdominal flatulence and abdominal fullness in high curative rate.

Owner:BENGBU HUOHE PHARMA +1

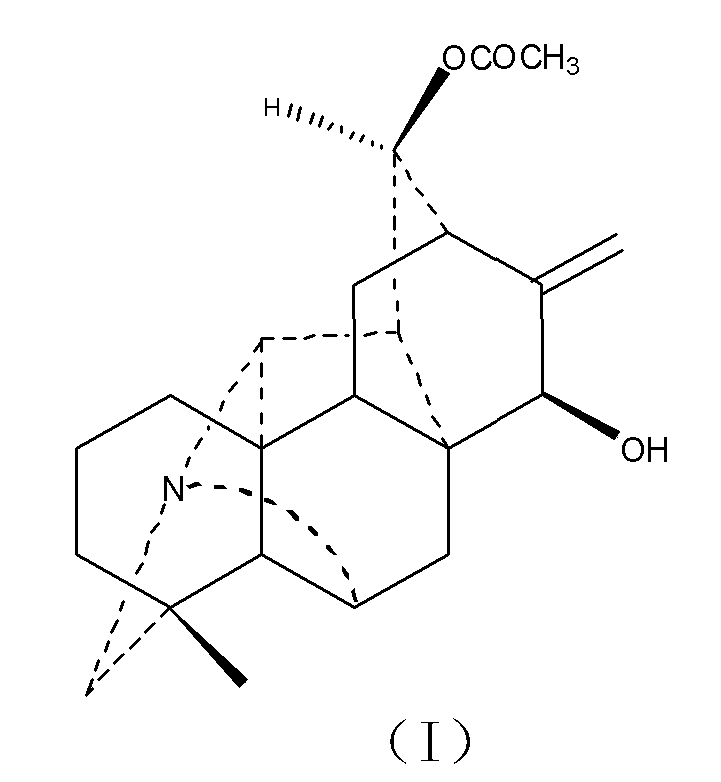

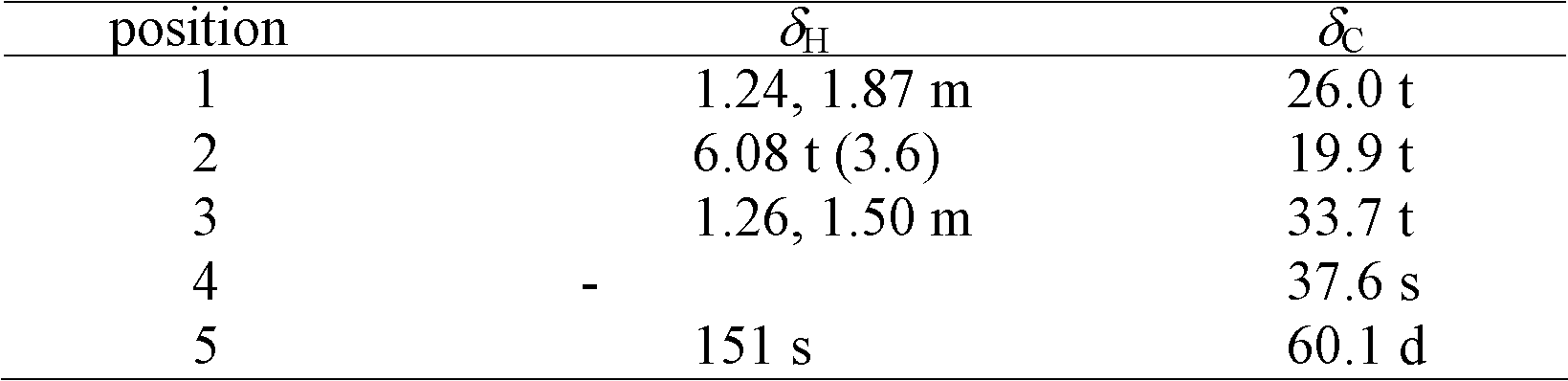

Hetisin type diterpenoid alkaloid and preparation method and application thereof

InactiveCN102127016AInhibition of swellingAnti-inflammatoryOrganic active ingredientsOrganic chemistryAnti-inflammatoryChemistry

The invention discloses hetisin type diterpenoid alkaloid and a preparation method thereof and application of the alkaloid as anti-inflammatory medicaments. The diterpenoid alkaloid is prepared from buttercup aconitum plant monkshood serving as a raw material by the steps of acid water extraction, alkalization, organic solvent extraction, silica gel short column chromatography and elution. According to authentication by a chromatographic method, the compound is novel hetisin type diterpenoid alkaloid carmichaeline A. An animal test shows that the new compound has certain anti-inflammatory activity on a mouse inflammation model caused by various inflammatory agents.

Owner:CHENGDU UNIV

M60-M85 methanol gasoline additive for high cleaning vehicles and methanol gasoline thereof

InactiveCN104178233AGood compatibilityStrong water resistanceLiquid carbonaceous fuelsFuel additivesManganeseTert-butyl methyl ether

The invention provides a M60-M85 methanol gasoline additive for high cleaning vehicles and a methanol gasoline thereof. After the M60-M85 methanol gasoline additive for high cleaning vehicles is added into the M60-M85 methanol gasoline, the methanol gasoline has the advantages of favorable compatibility, high water resistance, no air resistance, high heat value, high combustion safety and the like, enables the automobile to perform cold starting easily, and inhibits the rubber plastic from swelling and cracking. The additive is free of any tert-butyl methyl ether component, or lead, aluminum, manganese or any other nonferrous metal ion, and is environment-friendly. The M60-M85 methanol gasoline additive can be directly used under the condition of not modifying the existing automobile engine.

Owner:周亦鹏

Power additive used for automobile, and preparation method thereof

InactiveCN108251171AMake up for the problem of insufficient calorific valueIncrease motivationLiquid carbonaceous fuelsFuel additivesP-NitroanilineEthyl tert-butyl ether

The invention discloses a power additive used for an automobile, and a preparation method thereof. The power additive is prepared from the following ingredients: methyl alcohol, C12, xylene, ethyl tert butyl ether, an emulgator OP-10, n-octyl alcohol, paranitroaniline, imidazoline petroleum barium sulfonate, laurinol, propargyl alcohol and dioctyl phthalate. The additive is hydrogen-rich carbon-containing combustible liquid, the additive is added into gasoline at the volume fraction of 30-40%, the additive can partially replace the gasoline as fuel, the quality of the gasoline can be improved,the quality of the gasoline is improved, the cost of the gasoline is lowered, the octane value of the gasoline is improved, and dynamic performance is enhanced. The ingredients of the additive are abundant and are completely combustible, in addition, an ignition point is low, carbon deposition and series problems caused by carbon deposition can be avoided, the corrosion of the methyl alcohol forautomobile metal components can be prolonged, and the swelling function of the methyl alcohol for automobile rubber components is lowered. The additive is safe and environmentally friendly, tail gas emissions are reduced by 60% than the gasoline, and each index is superior to the index of common gasoline.

Owner:曹玉会

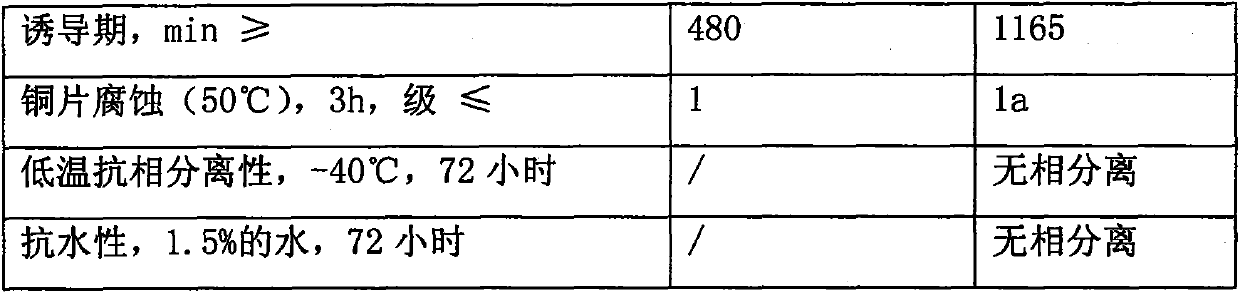

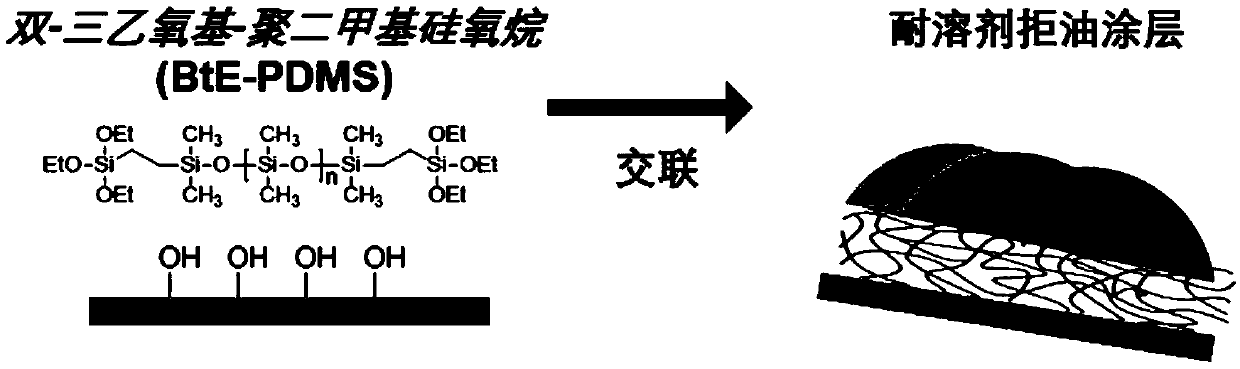

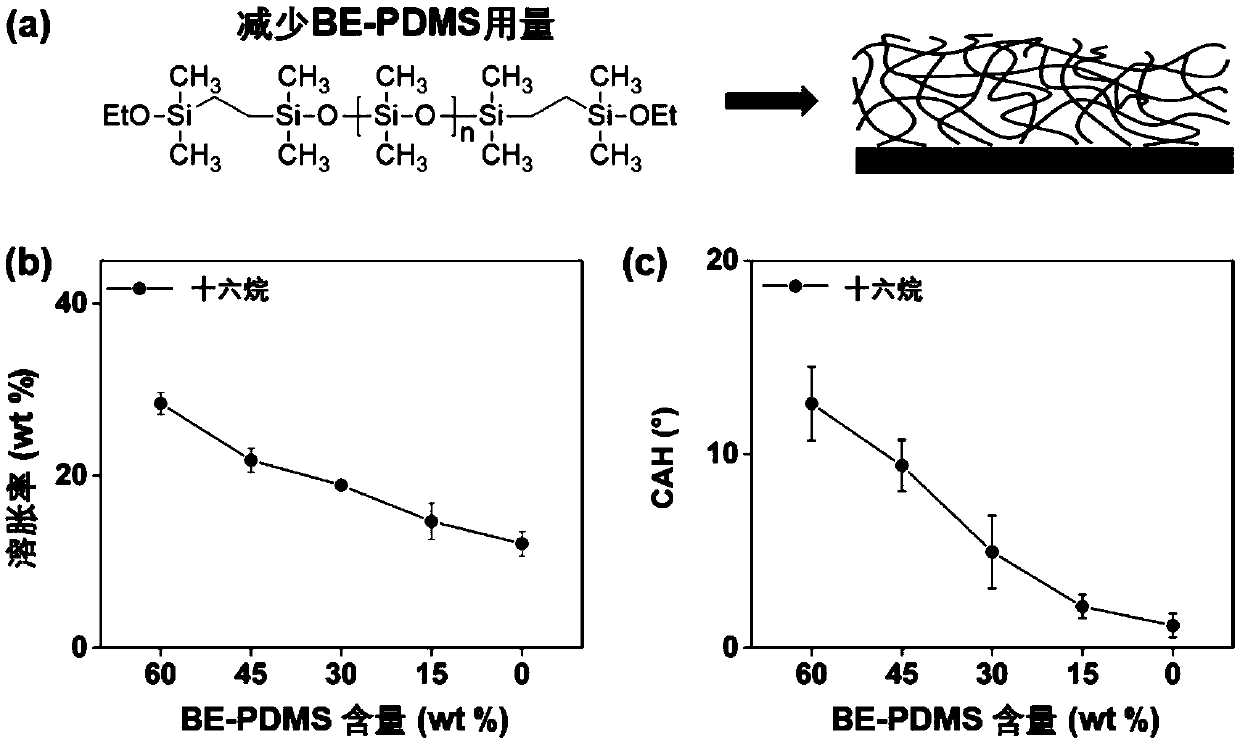

Solvent-resistant polydimethylsiloxane polymer having oil repellency, and production method thereof

The present invention provides a solvent-resistant polydimethylsiloxane polymer having oil repellency, and a production method thereof, wherein the polymer is prepared by curing a viscous fluid mixture through chemical cross-linking, the viscous fluid mixture is formed from a cross-linkable precursor having a formula comprising a reactive molecule and one or a plurality of optional solid or liquidadditives, and the reactive molecule comprises a dimethylsiloxane main chain and one or a plurality of side chain reactive silane motifs.

Owner:香港城市大学深圳研究院

High-transparency and high-heat-resistance copolyester resin and preparation method thereof

The invention relates to a polyester high polymer material, and discloses a high-transparency and high-heat-resistance copolyester resin and a preparation method thereof. The copolyester resin comprises the following components: (1) a binary acid component comprising: (a) 80-100 mol% of terephthalic acid residue, (b) 0-20 mol% of aromatic diacid residues; and (2) a dihydric alcohol component comprising: (a) 20-85 mol% of 2, 2, 4, 4-tetramethyl-1, 3-cyclobutanediol residues, (b) 15-80 mol% of a first diol residue, and (c) 0-30 mol% of a second diol residue. According to the copolyester resin disclosed by the invention, pentanediol residues or propylene glycol residues are introduced, so that blockage is avoided in the preparation process, the intrinsic viscosity is increased, the loss of CBDO monomers is inhibited, and the obtained copolyester has high glass transition temperature and excellent strength, toughness and thermal stability; and the foaming, foaming and expansion phenomena caused by thermal decomposition can be effectively inhibited in the melt processing process.

Owner:ZHEJIANG UNIV

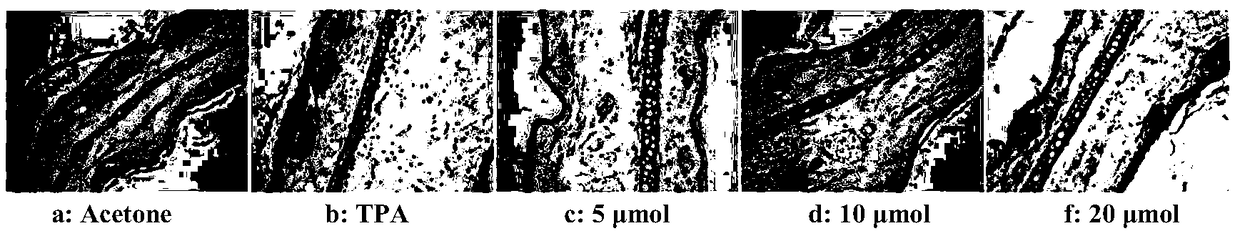

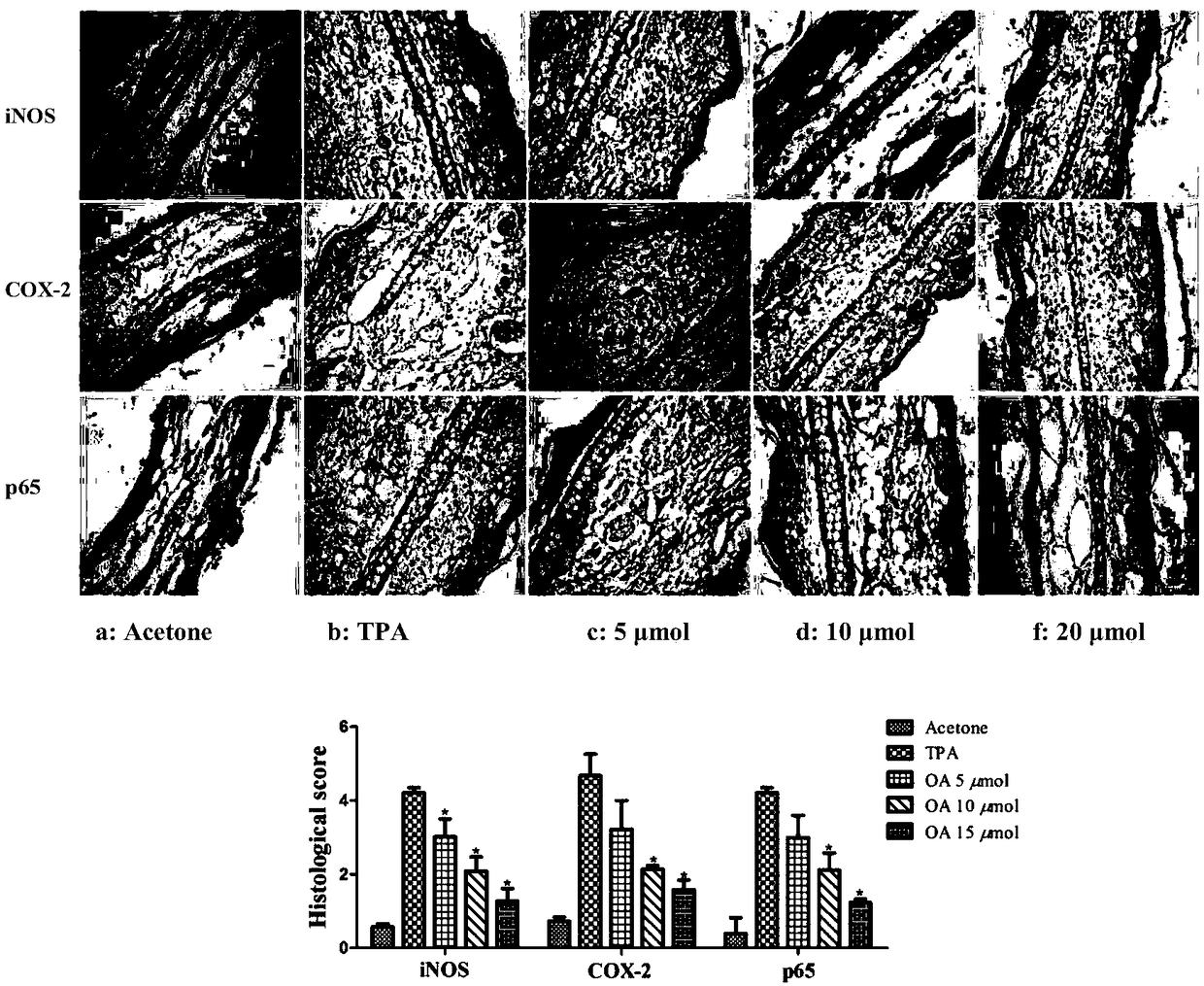

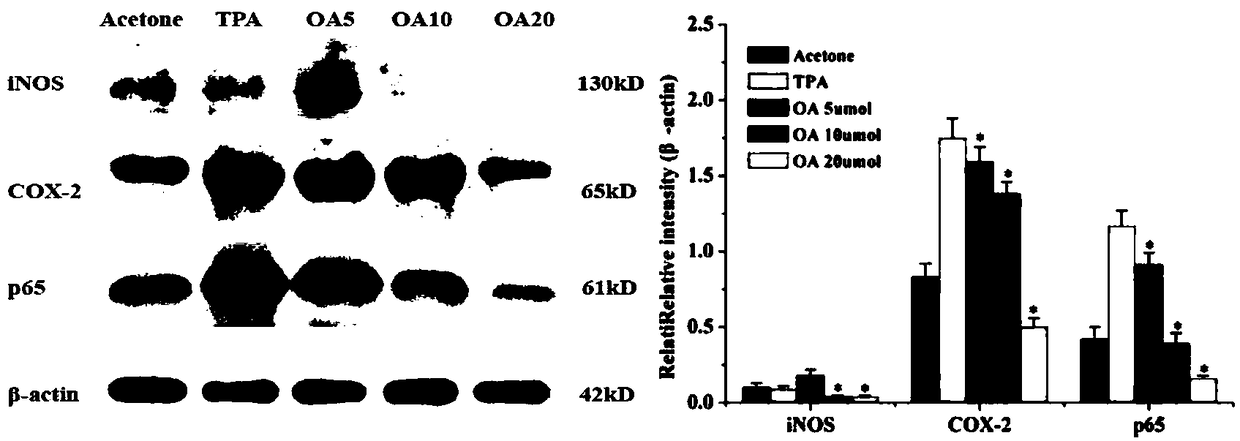

Novel application of oleanolic acid

InactiveCN109010346AInhibition of swellingReduce swellingOrganic active ingredientsNervous disorderInflammatory factorsMedicine

The invention relates to the field of medicines, in particular relates to novel application of oleanolic acid and especially relates to application of preparation of a medicine for inhibiting skin inflammations. An experiment shows that the oleanolic acid can be used for effectively inhibiting the release of inflammatory factors, so that the inflammation diminishing aim is realized. The result shows that the oleanolic acid can be used for preparing a skin inflammation inhibitor.

Owner:WUYI UNIV +1

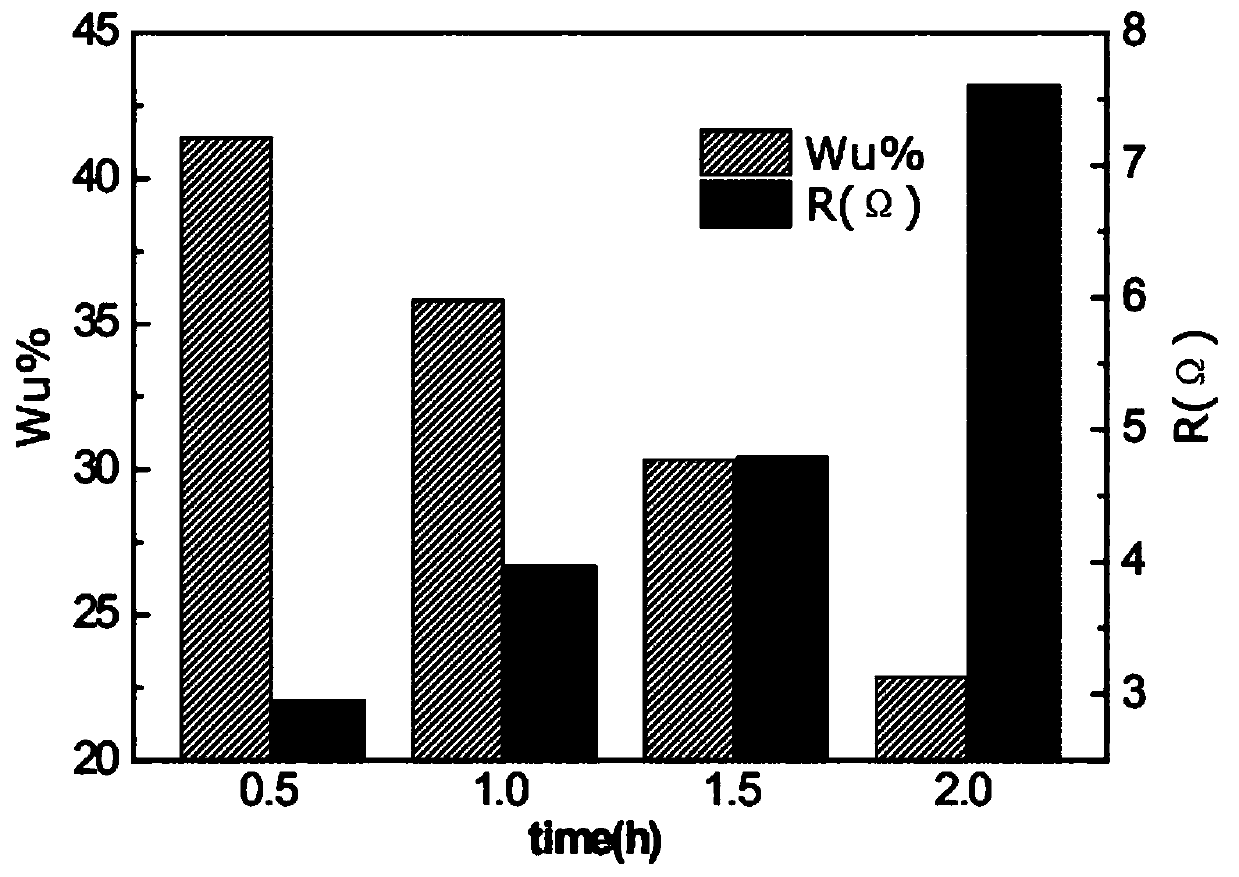

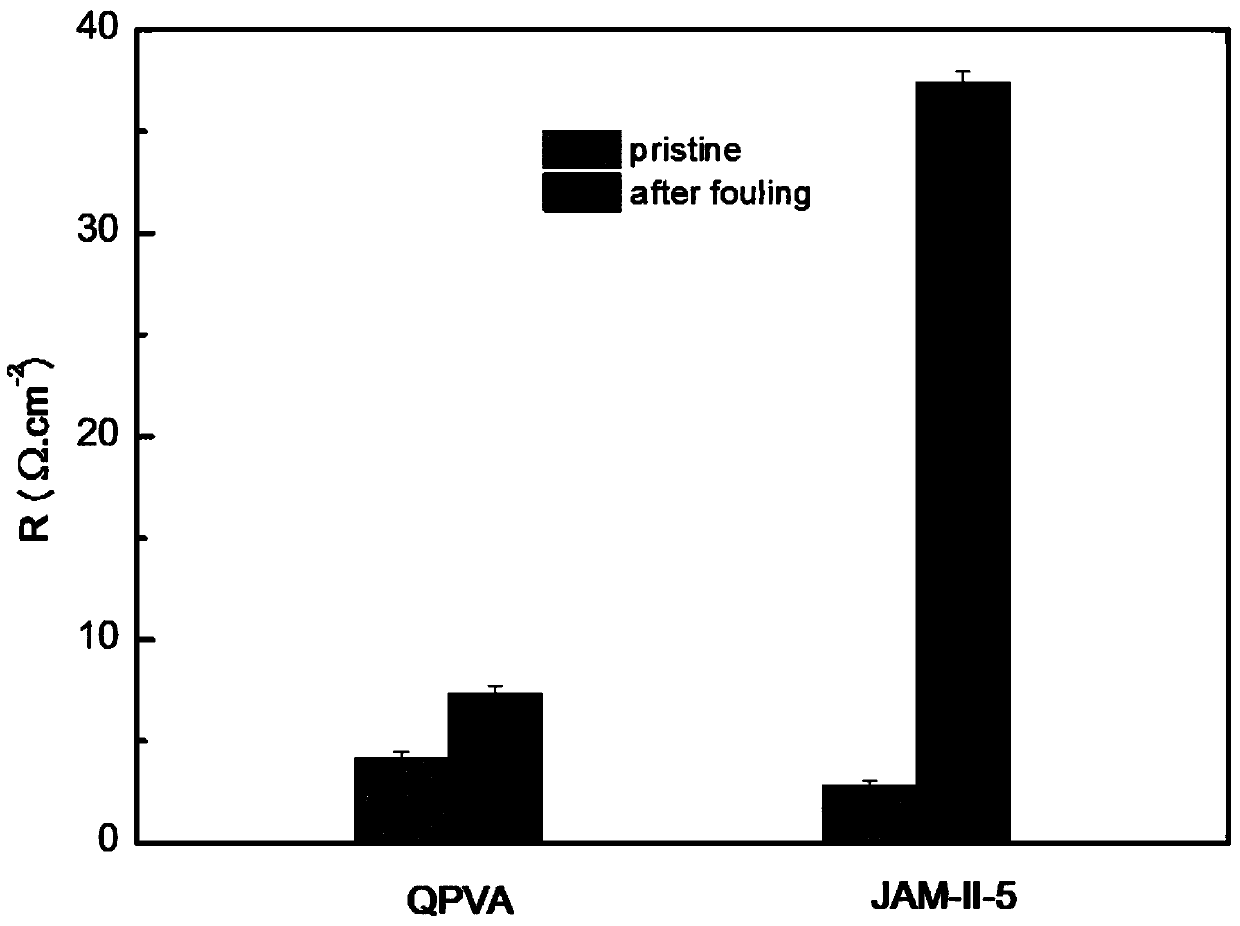

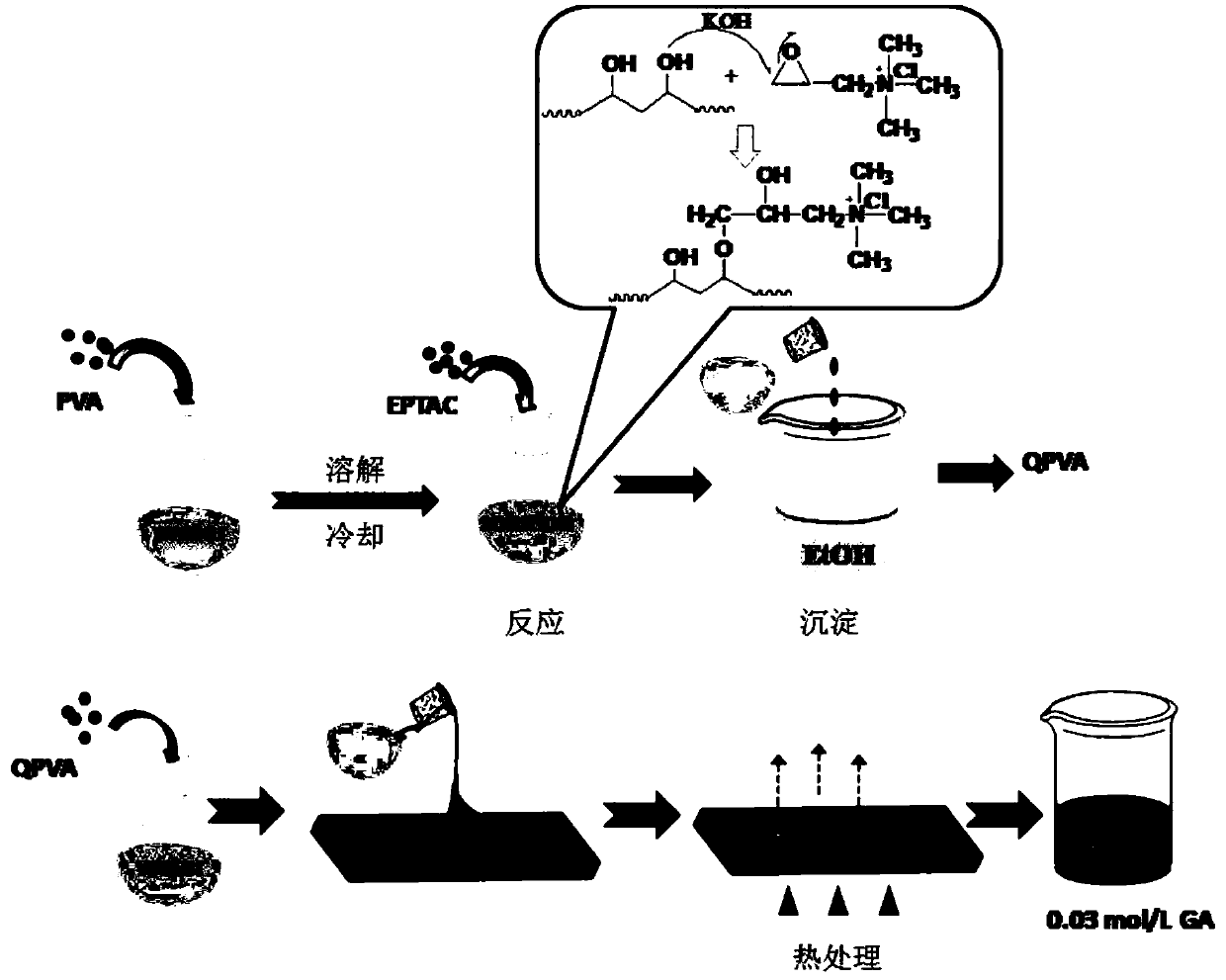

Preparation method of anti-fouling anion-exchange membrane

InactiveCN109675448AImprove performanceInhibition of swellingMembranesSemi-permeable membranesIon-exchange membranesAqueous solution

The invention provides a preparation method of an anti-fouling anion-exchange membrane. The preparation method of the anti-fouling anion-exchange membrane comprises the steps that (1) PVA powder is added into deionized water to enable the PVA to be fully dissolved to obtain a PVA water solution; (2) EPTAC is added into the PVA water solution, stirring is carried out under 55-65 DEG C for reactionfor 3-5h, sedimentation and washing are carried out by absolute ethyl alcohol to neutral after the reaction is completed, and drying is performed to constant weight to obtain QPVA; (3) the prepared QPVA is dissolved into the deionized water to obtain a QPVA transparent solution with 5-10% of mass percent concentration, and defoaming is carried out at a room temperature; a plastic plate is coated with the QPVA water solution after defoaming to form a membrane, the membrane is placed on a flat heater for drying for 6-9h at 55-65 DEG C to obtain a QPVA anion-exchange membrane; (4) the QPVA anion-exchange membrane is placed into a vacuum oven, vacuum pumping is carried out to heat to 160-190 DEG C, heat preservation is carried out for 0.5-2 hours, and the QPVA anion-exchange membrane after heat treatment is obtained after cooling to the room temperature; and (5) the QPVA anion-exchange membrane after the heat treatment is placed into a saturated sodium sulfate solution containing glutaraldehyde and H2SO4 for chemical crosslinking to obtain the anti-fouling anion-exchange membrane. The anti-fouling anion-exchange membrane has excellent anti-fouling performance and a low swelling degree.

Owner:ZHEJIANG UNIV OF TECH

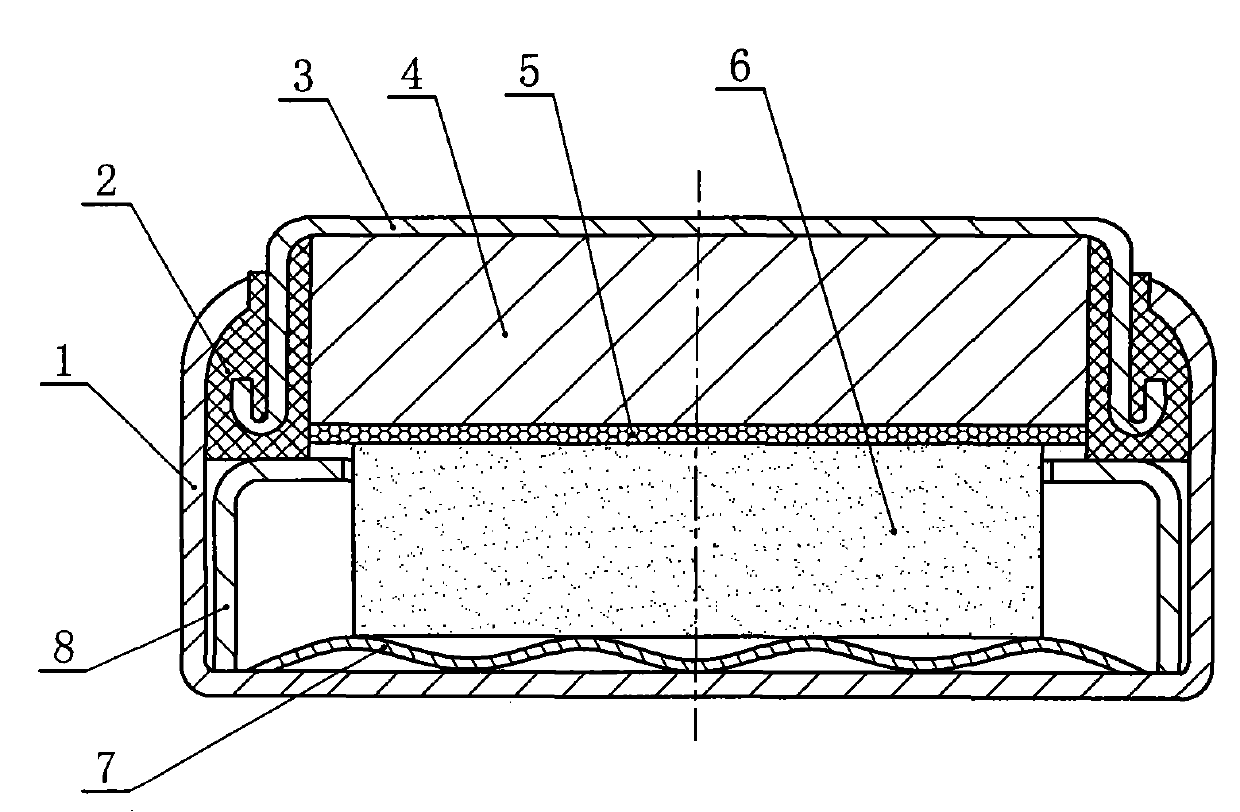

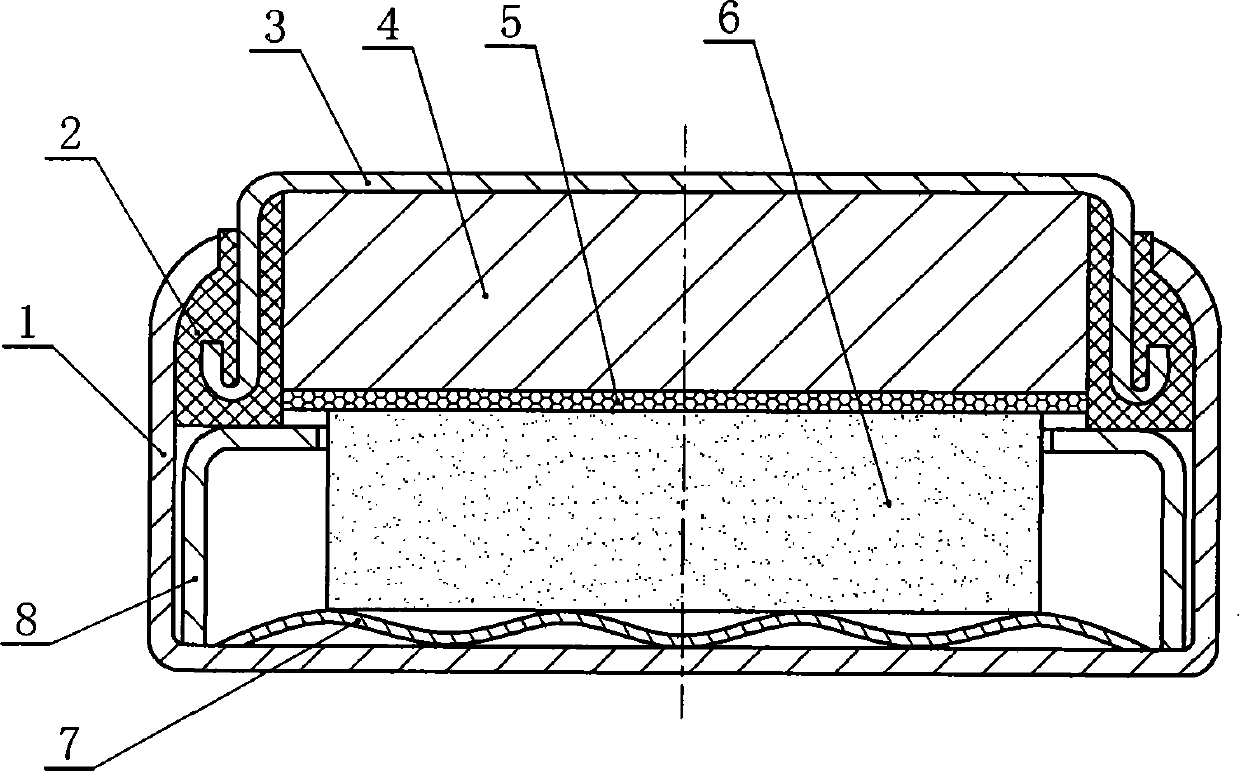

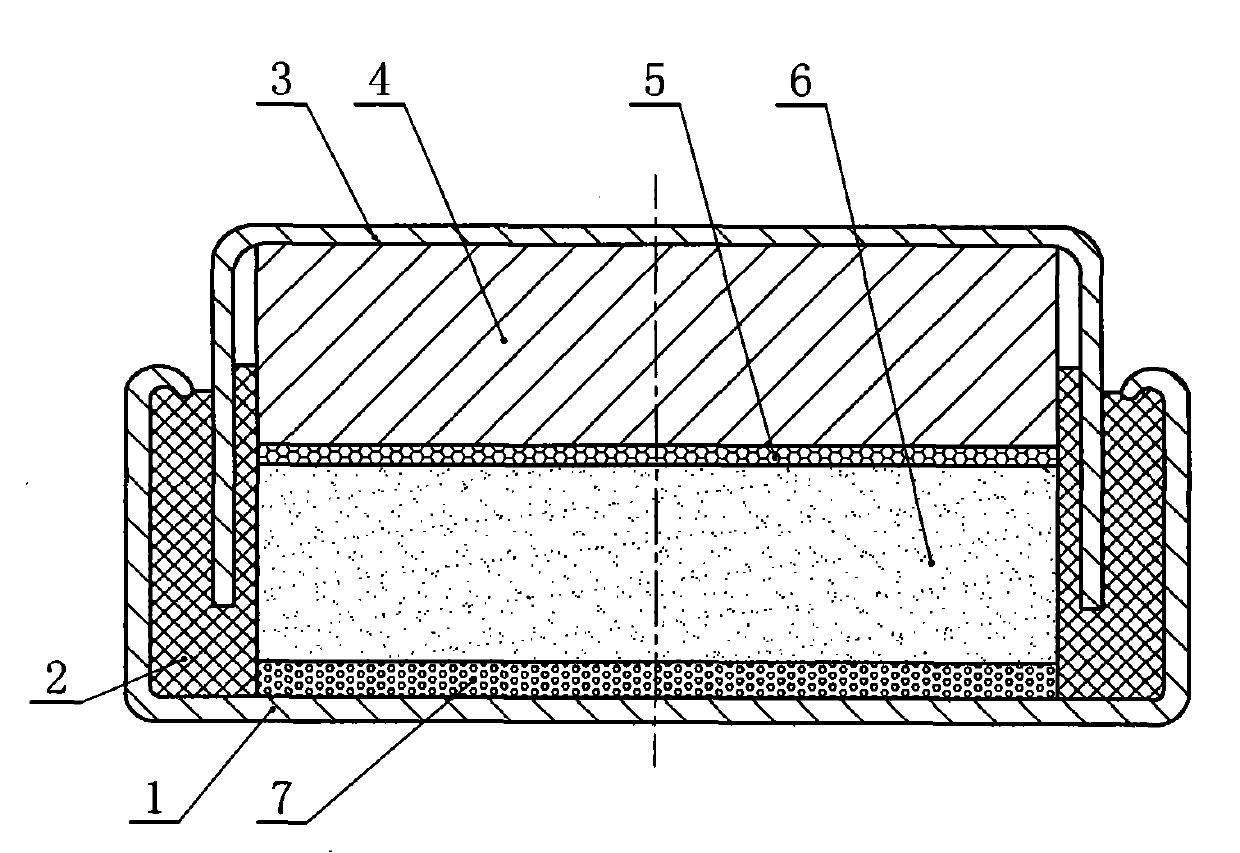

Bulge-prevention type buckle type lithium pyrite battery and manufacturing method thereof

ActiveCN101299462BImprove discharge capacityImprove qualityCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsMetallic lithiumElectrolytic agent

Provided is an anti-expansion type button li-fes 2 battery and the manufacture method, including an anode case and a cathode case, wherein an anode and a cathode are arranged in the case, and a film is arranged between the anode and the cathode. The case is filled with electrolyte; an elastic metal sheet is arranged between the anode and the opposite anode case. The film is polypropylene with themicropore, or polyethylene with the micropore. The anode material is composed of iron disulphide, conduction agent and adhesive; the cathode is composed of metallic lithium, lithium aluminum alloy oraluminum silicon alloy. The electrolyte is the solution in which lithium salt is dissolved in the ethylene carbonate. The elastic metal sheet is selected from one of foaming nickel, fiber nickel, foaming copper, foaming aluminum, stainless steel spring sheet, aluminium spring sheet and nickel spring sheet. The invention causes the active material fully to contact with the current collector, advances the utilance of the active material, refrains expansion of the anode in the cell discharging process, reduces the falling of the active material, reinforces the discharging ability of the large current of the cell, advances the discharging capacity of the cell, simplifies the production technology of the cell, which is suitable for the large-scale industrialization production.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

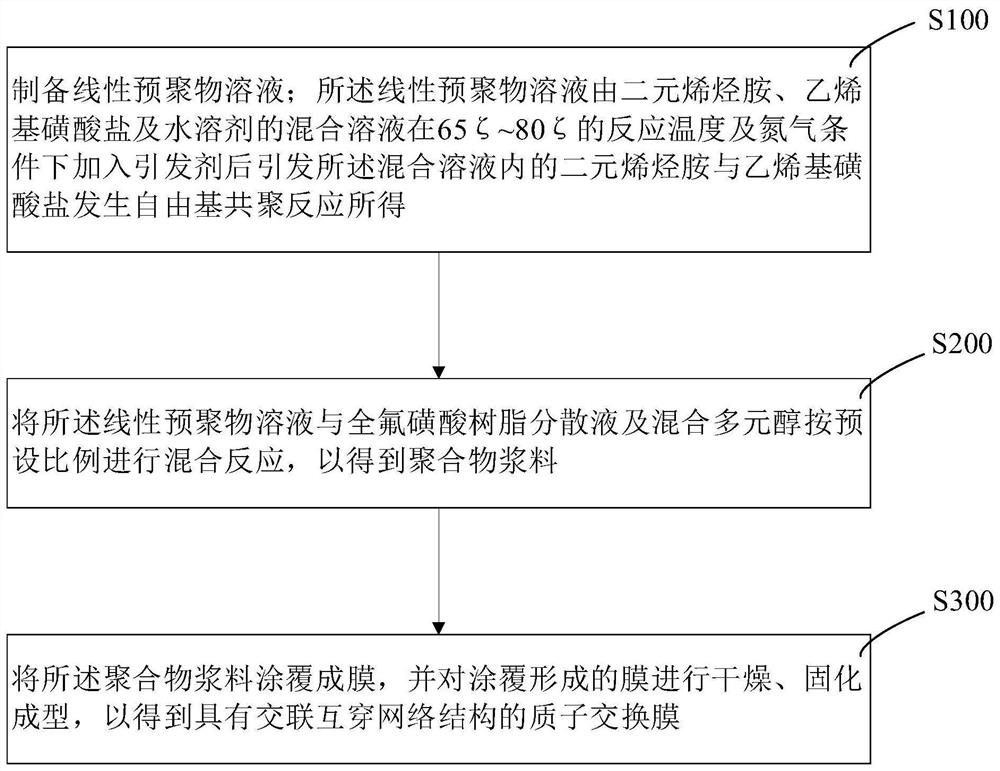

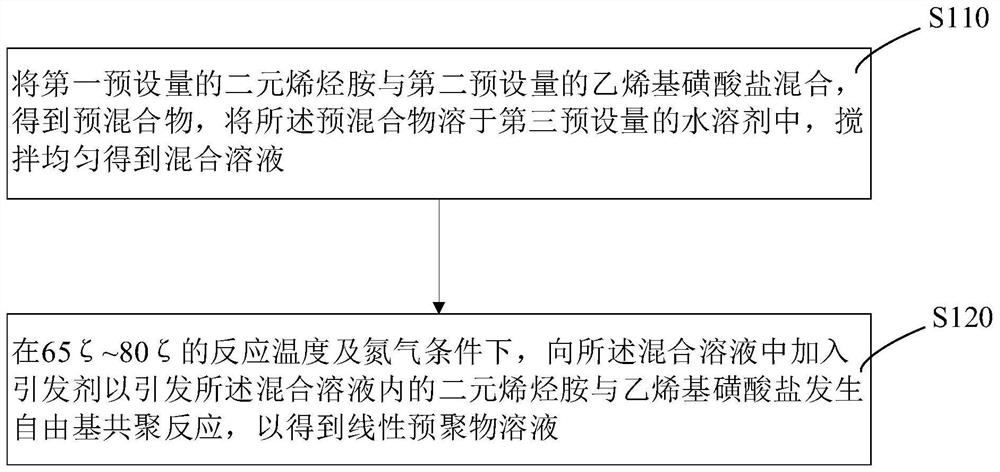

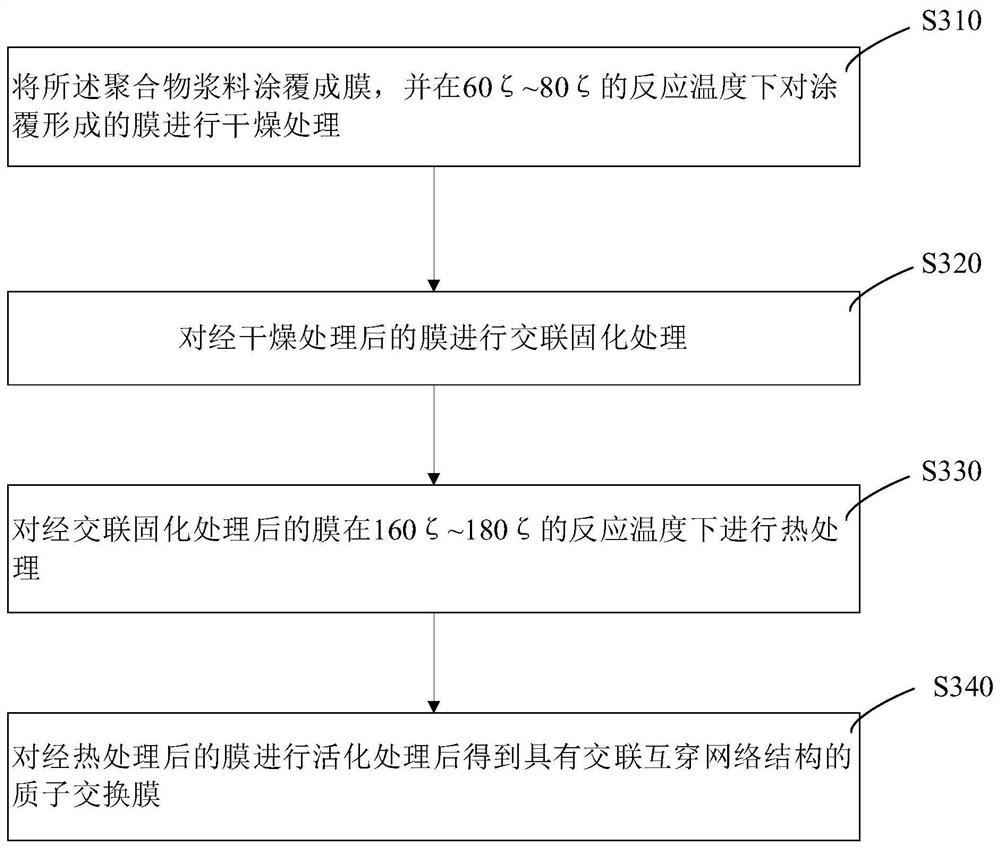

Proton exchange membrane, preparation method thereof and fuel cell

The invention discloses a preparation method of a proton exchange membrane, and the method comprises the following steps: adding an initiator into a mixed solution of binary olefin amine, vinyl sulfonate and a water solvent at the reaction temperature of 65-80 DEG C under the nitrogen condition to initiate free radical polymerization reaction of the binary olefin amine and the vinyl sulfonate to obtain a linear prepolymer solution; then mixing the linear prepolymer solution with a perfluorinated sulfonic acid resin dispersion liquid and mixed polyol according to a preset proportion for reaction to obtain polymer slurry; and finally, coating the polymer slurry to form a membrane, and drying and curing the membrane formed by coating to obtain the proton exchange membrane with a cross-linked interpenetrating network structure. According to the preparation method, a high-stability cross-linked polymer network is taken as a framework, an interpenetrating network is realized with perfluorosulfonic acid polymer molecules, the swelling degree of the proton exchange membrane is inhibited macroscopically and microcosmically, and the invention also discloses the proton exchange membrane prepared by the preparation method and a fuel cell comprising the proton exchange membrane.

Owner:SHENZHEN GENERAL HYDROGEN ENERGY TECH CORP LTD

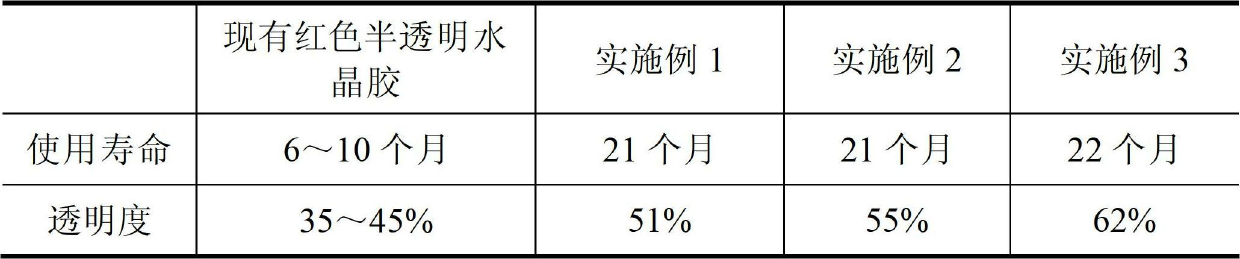

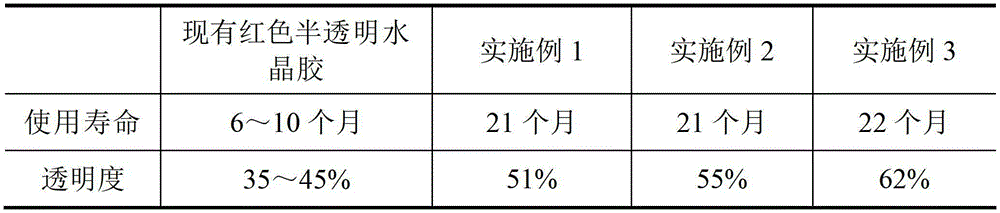

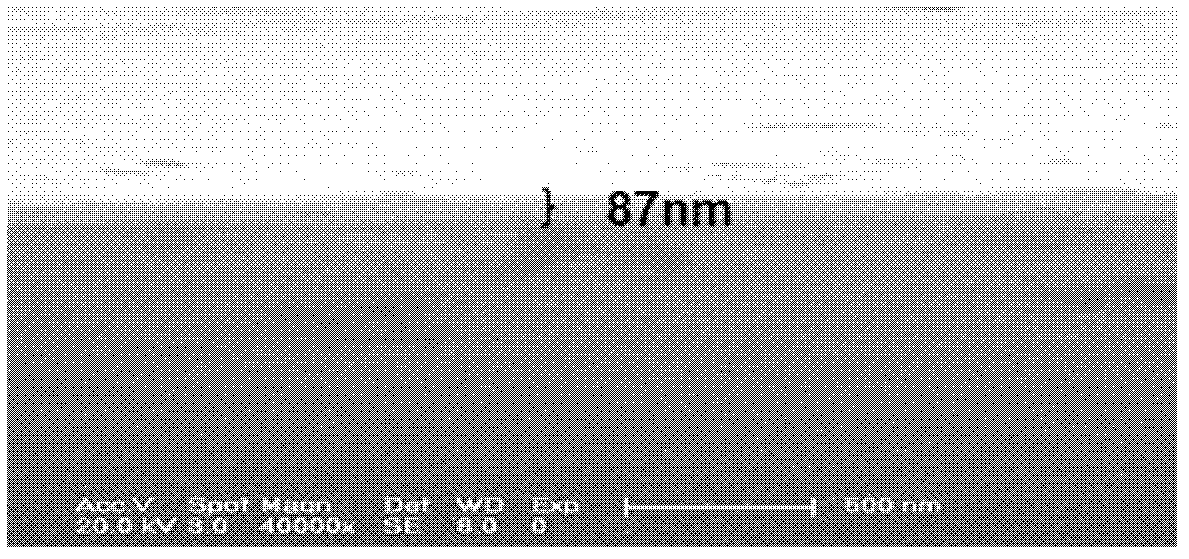

Red translucent crystal glue material and manufacturing method thereof

The invention relates to a red translucent crystal glue material and a manufacturing method of the red translucent crystal glue material. The red translucent crystal glue material is manufactured by a way that PVA (polyvinyl acetate) powder, water, sodium borate, carbomer resin, propylene glycol or glycerol, vanillin, clove oil, amyl acetate, carmine, tartaric acid, sorbic acid, sodium dodecyl benzene sulfonate and an acrylamide-acrylate copolymerized crosslinked material are sequentially mixed, emulsified and stirred, and finally sodium borate water is added in the mixed solution for solidification. The translucent crystal glue material has the advantages of good moisturizing effect, bright color, stable color, high transparency and long service life, and is unlikely to crack in the air and unlikely to discolor. The transparency of the red translucent crystal glue material provided by the invention is up to above 50%, and the service life is up to above 18 months.

Owner:浙江银太郎动漫文化股份有限公司

Red translucent crystal glue material and manufacturing method thereof

The invention relates to a red translucent crystal glue material and a manufacturing method of the red translucent crystal glue material. The red translucent crystal glue material is manufactured by a way that PVA (polyvinyl acetate) powder, water, sodium borate, carbomer resin, propylene glycol or glycerol, vanillin, clove oil, amyl acetate, carmine, tartaric acid, sorbic acid, sodium dodecyl benzene sulfonate and an acrylamide-acrylate copolymerized crosslinked material are sequentially mixed, emulsified and stirred, and finally sodium borate water is added in the mixed solution for solidification. The translucent crystal glue material has the advantages of good moisturizing effect, bright color, stable color, high transparency and long service life, and is unlikely to crack in the air and unlikely to discolor. The transparency of the red translucent crystal glue material provided by the invention is up to above 50%, and the service life is up to above 18 months.

Owner:浙江银太郎动漫文化股份有限公司

Proton exchanging composite film and preparation method thereof

InactiveCN102432903AImprove mechanical propertiesImprove proton conductivityFuel cell detailsComposite filmTransmittance

The invention discloses a preparation method of a proton exchanging composite film, comprising the following steps: mixing organosilane containing aminoalkyl and water to form mixed solution; adding acid into the mixed solution and reacting to obtain modification solution; and immersing a proton exchanging film into the modification solution to obtain the proton exchanging composite film. Compared with the prior art, the preparation method has the advantages that: the proton exchanging film is modified under an acidic condition by utilizing the hydrolyzed organosilane containing the aminoalkyl, the organosilane containing the aminoalkyl and acid are subjected to sol-gel reaction on the surface of the proton exchanging film, and the organosilane is modified on the surface of the proton exchanging film. The organosilane containing the amionalkyl has favorable mechanical property, therefore, the swelling property of the proton exchanging film and the methanol transmission property are inhibited, and meanwhile, the favorable mechanical property of the proton exchanging composite film is ensured. Test results prove that the proton exchanging composite film prepared by the invention hasfavorable proton transmission property, lower methanol transmittance and favorable mechanical property.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

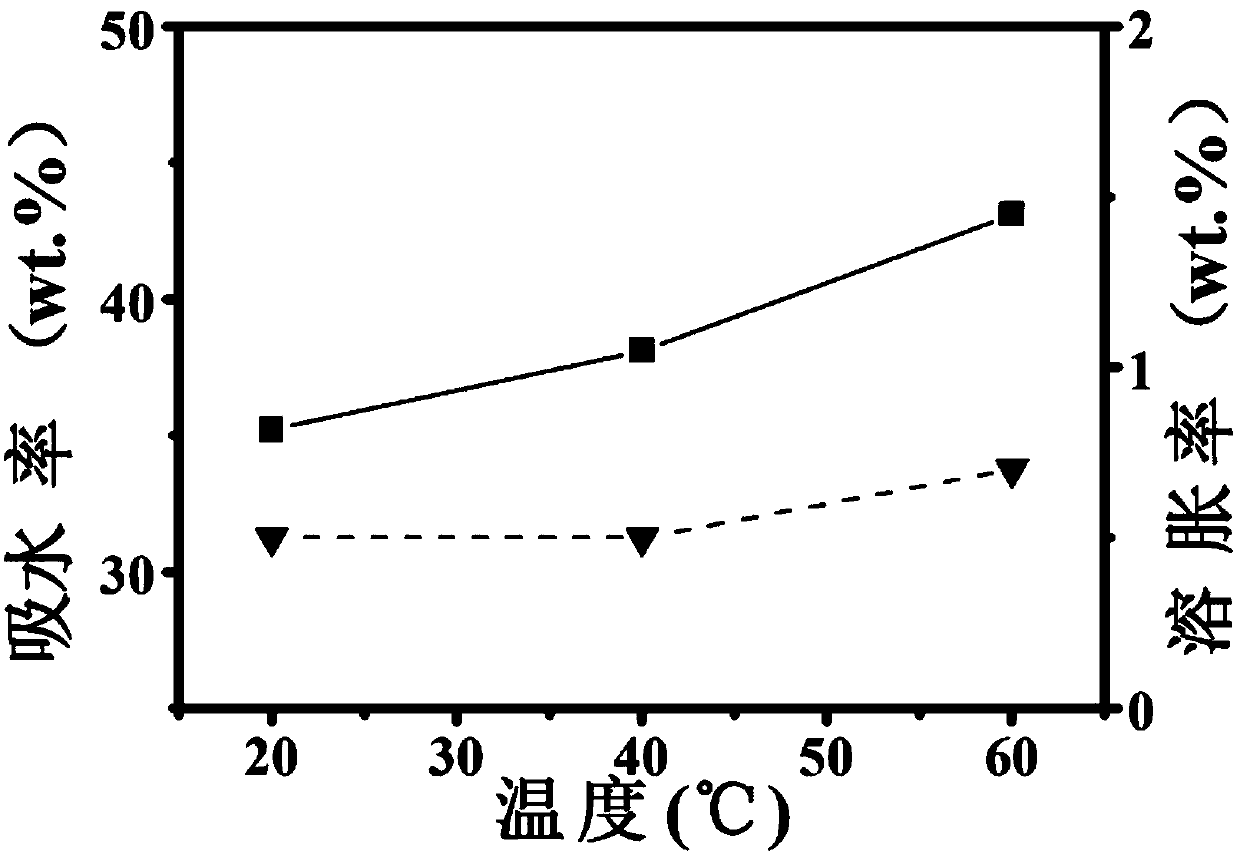

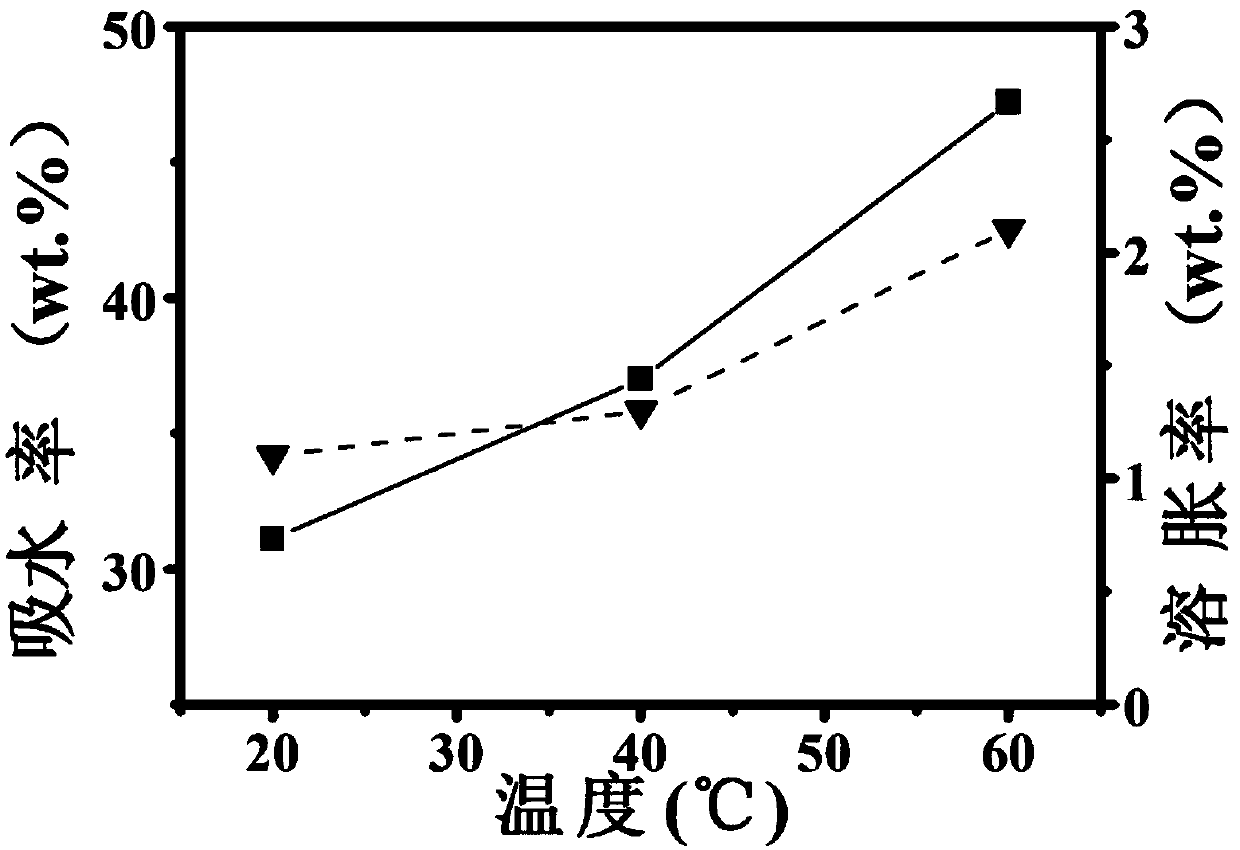

High water absorption, low swelling and anti-condensation film material, preparation method and application thereof

The invention provides a high water absorption, low swelling and anti-condensation film material, a preparation method and an application thereof, which belong to the technical field of condensation resistance. The film material comprises a hydrophobic polymer porous membrane and an ion exchange resin, the hydrophobic polymer porous membrane is a matrix, the hydrophobic polymer porous membrane hasa plurality of pores, and the pores of the hydrophobic polymer porous membrane is filled with the ion exchange resin. The ion exchange resin is first dissolved in an organic solvent, the pores of thehydrophobic polymer porous membrane is filled with the ion exchange resin under the effect of the organic solvent, the solvent is volatilized, and the anti-condensation film material is obtained. Theanti-condensation film material of the invention has strong water absorption and low swelling ratio, and is used for the surface of air conditioners, purifiers and fresh air fans to avoid condensation phenomenon, the phenomenon that water droplets blow onto the user cannot be generated, the surface is not sticky with dust, bacteria breeding is not generated, the usage is convenient, and the material is safe and beautiful, the structural design of the original home appliances is not changed, the cost is low, and the user experience can be enhanced.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

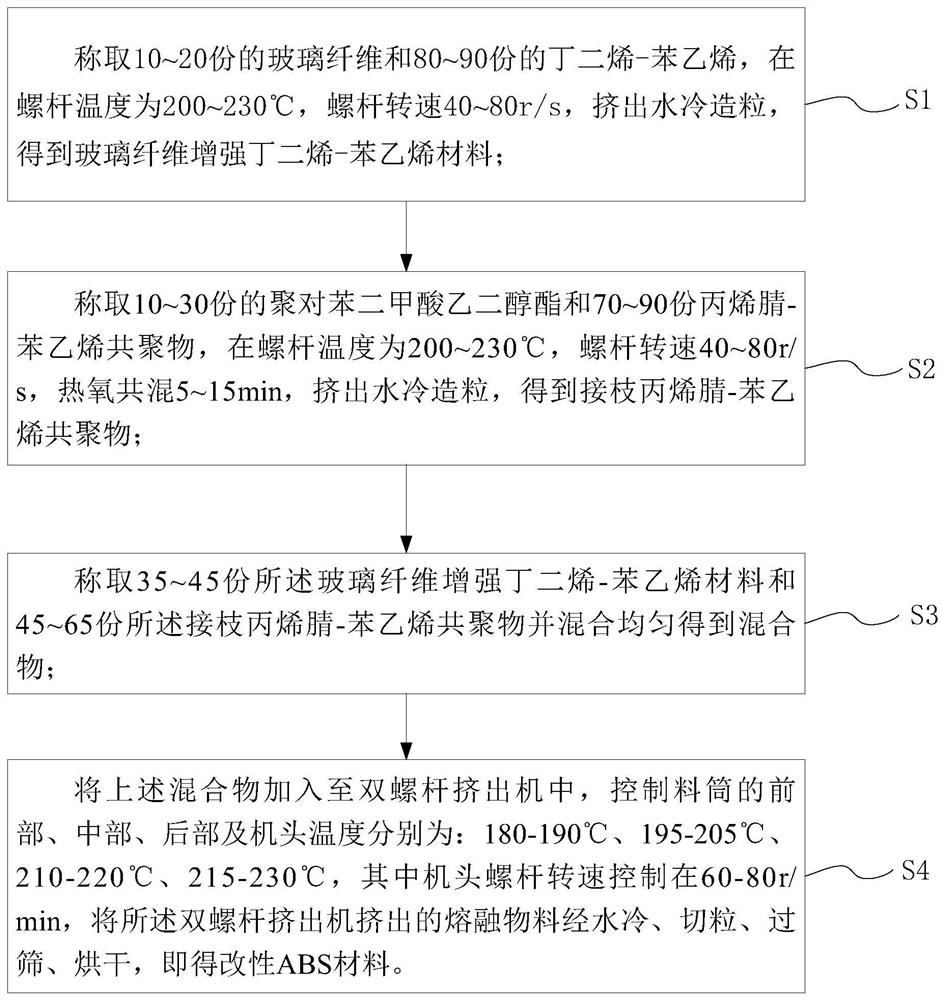

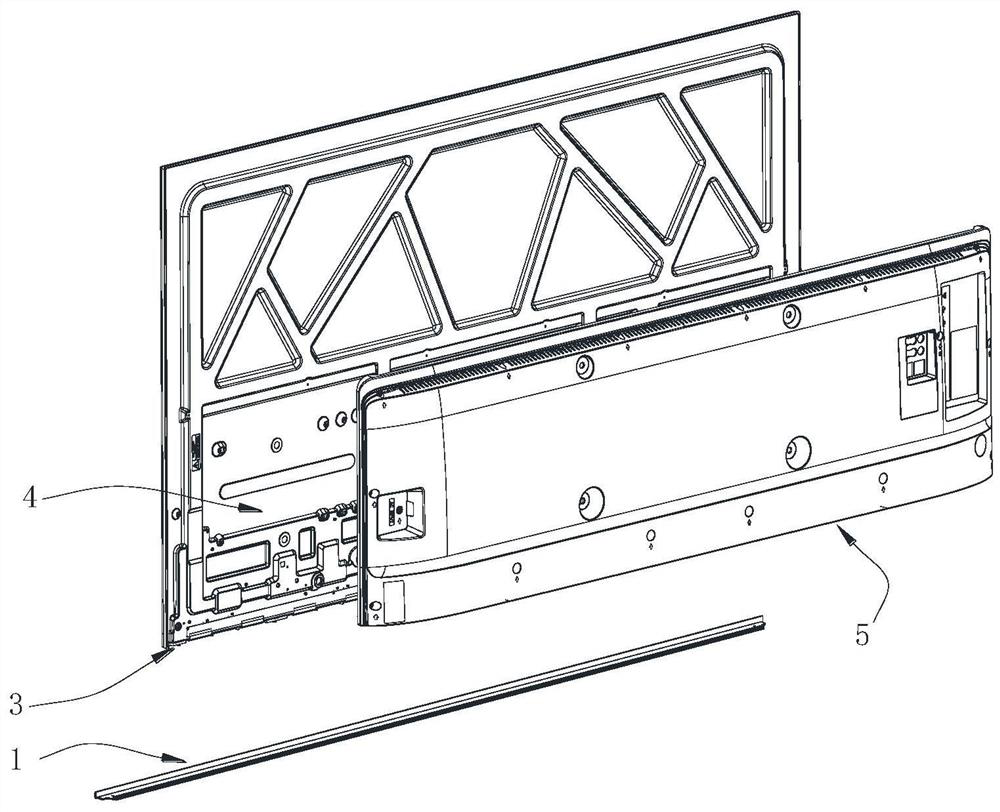

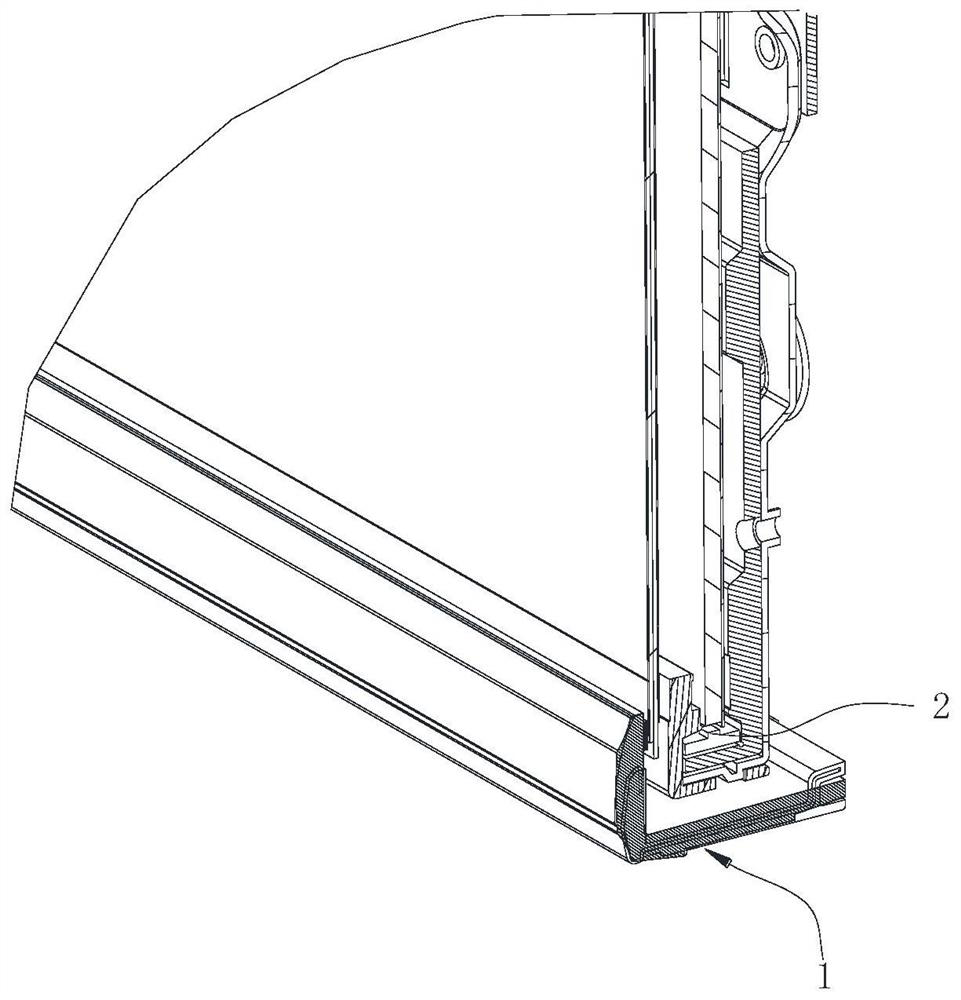

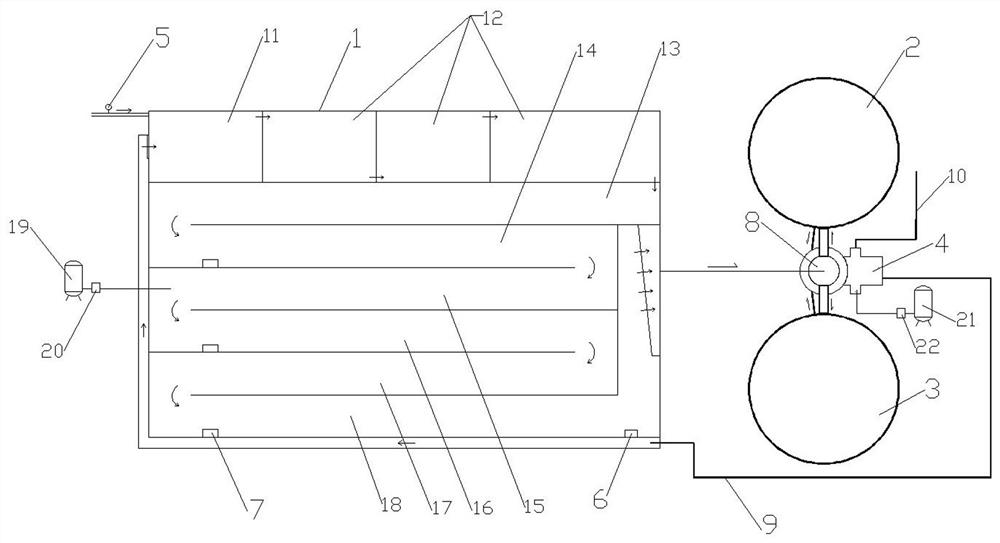

Display equipment, modified ABS material and preparation method of modified ABS material

ActiveCN113214594AAchieve oil resistanceInhibition of swellingPolytetramethylene terephthalatePolymer science

The invention provides a display device, a modified ABS material and a preparation method of the modified ABS material . The modified ABS material comprises the following components in parts by weight: 35-45 parts of a glass fiber reinforced butadiene-styrene material and 45-65 parts of a grafted acrylonitrile-styrene copolymer, wherein the glass fiber reinforced butadiene-styrene material comprises 10 to 20 parts of glass fibers and 80 to 90 parts of butadiene-styrene; and the grafted acrylonitrile-styrene copolymer comprises 10 to 30 parts of polyethylene glycol terephthalate and 70 to 90 parts of an acrylonitrile-styrene copolymer. According to the modified ABS material, an ordered microphase is generated through polybutylene terephthalate, and the swelling effect of grease on a plastic body is inhibited, so the oil resistance of the acrylonitrile-styrene copolymer is realized, and the oil resistance of the modified ABS material is further realized.

Owner:HISENSE VISUAL TECH CO LTD

Sewage treatment method for inhibiting activated sludge bulking

ActiveCN112266071AInhibition of growth and reproductionInhibition of stabilitySustainable biological treatmentBiological water/sewage treatmentNocardiaSodium hypochlorite

The invention discloses a sewage treatment method for inhibiting activated sludge bulking. An adopted sewage treatment system comprises a biological tank, effluent of the biological tank is communicated to a water distribution well, and the water distribution well averagely distributes the effluent of the biological tank into two secondary sedimentation tanks; sludge in the secondary sedimentationtank is introduced into a residual sludge tank in the residual sludge pump room, and a residual sludge pump set and an outer reflux pump set are mounted in the residual sludge tank; a composite agentadding device is arranged beside a biological tank, a sodium hypochlorite agent adding device is arranged beside a residual sludge pump room, and the method for inhibiting activated sludge bulking comprises the steps of adjusting the sludge concentration, adjusting the water inlet amount, inhibiting microthrix sludge bulking and inhibiting nocardia sludge bulking. Sludge bulking caused by microthrix parvicella and nocardia in the sewage treatment process can be effectively inhibited, the occurrence rate of sludge bulking is reduced, the influence of sludge bulking on the sewage treatment efficiency and effluent quality is avoided, and the normal operation of a sewage treatment biological treatment system is ensured.

Owner:中原环保股份有限公司

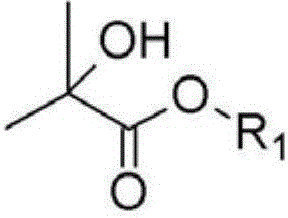

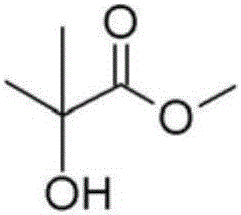

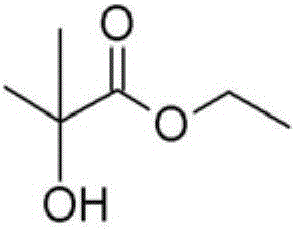

Composition for cleaning photodegradable polyimide alignment film

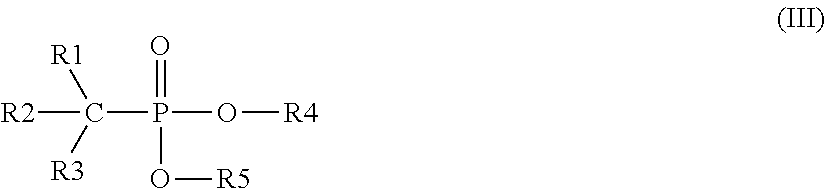

ActiveCN105969554AEasy to cleanInhibition of swellingDetergent mixture composition preparationOrganic non-surface-active detergent compositionsCarbon numberSolvent

The invention provides a composition for cleaning a photodegradable polyimide alignment film. Specifically, the composition can satisfy cleaning property and swelling rejection capability through a solvent in a specific structure. The invention provides a composition for cleaning a photodegradable polyimide alignment film. The composition contains a butyl-hydroxylic solvent represented by the following chemical formula. In the chemical formula, R1 is alphatic hydrocarbon with 1-6 carbon number.

Owner:DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com