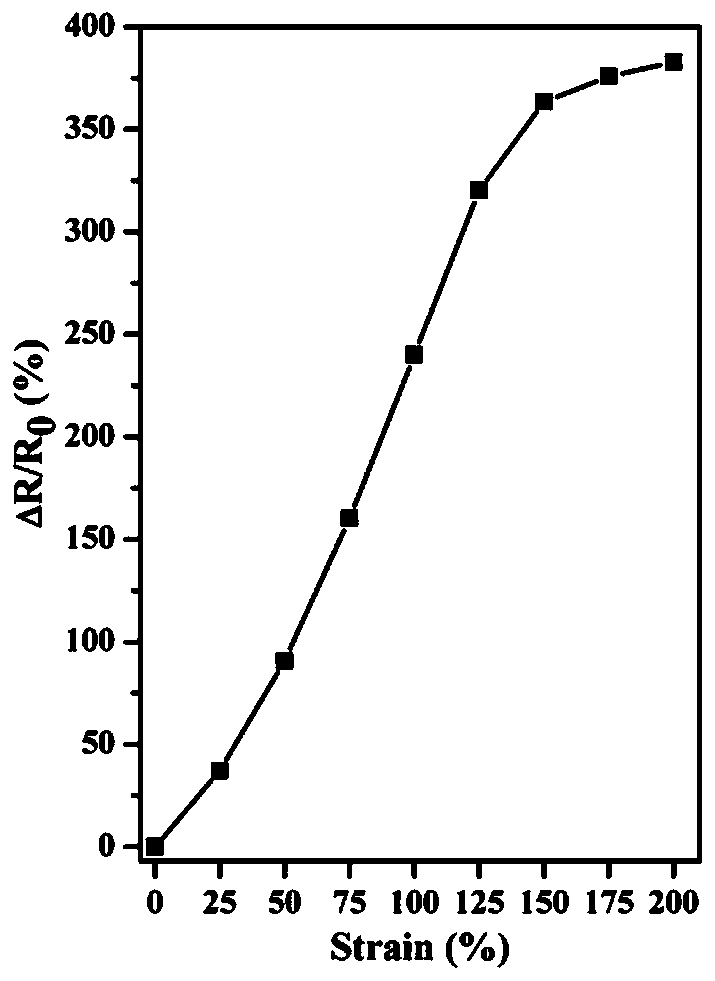

Alkali-soluble chitosan-polyacrylamide-polyaniline conductive hydrogel material with adjustable conductive polymer network structure

A technology of conductive polymer and polyacrylamide, which is applied in the field of alkali-soluble chitosan-polyacrylamide-polyaniline conductive hydrogel and its preparation, can solve the problems of being difficult to obtain at the same time, and achieve excellent biocompatibility, The effect of improving mechanical properties and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] 1) take each component according to mass percentage: chitosan 4%, lithium hydroxide monohydrate 8%, urea 6%, graphene oxide 0.1%, all the other are water; Described chitosan molecular weight is 2000000; After the above components are mixed and swollen, it is prepared through multiple freezing-thawing processes;

[0026] 2) Take 20g of the above-mentioned graphene oxide-chitosan solution, add 2.4g of acrylamide, 0.05g of N,N'-methylene bisacrylamide and 0.03g of ammonium persulfate in sequence, stir evenly, centrifugally defoam, and cast in In the mold, transfer it to a 60°C oven for 4 hours and take it out, dialyze and dehydrate to obtain an alkali-soluble chitosan-polyacrylamide gel;

[0027] 3) Transfer the alkali-soluble chitosan-polyacrylamide gel prepared in the above step 2) to a mass fraction of 3% aniline-1mol / L hydrochloric acid solution for 2 hours, then drop the mass fraction of 1.5% persulfuric acid The ammonium initiator solution was polymerized for 6 hour...

example 2

[0030] 1) take each component according to mass percentage: chitosan 4%, lithium hydroxide monohydrate 8%, urea 6%, graphene oxide 0.1%, all the other are water; Described chitosan molecular weight is 2000000; After the above components are mixed and swollen, it is prepared through multiple freezing-thawing processes;

[0031] 2) Take 20g of the above-mentioned graphene oxide-chitosan solution, add 2.4g of acrylamide, 0.05g of N,N'-methylene bisacrylamide and 0.03g of ammonium persulfate in sequence, stir evenly, centrifugally defoam, and cast in In the mold, transfer it to a 60°C oven for 4 hours and take it out, dialyze and dehydrate to obtain an alkali-soluble chitosan-polyacrylamide gel;

[0032] 3) Transfer the alkali-soluble chitosan-polyacrylamide gel prepared in the above step 2) to a mass fraction of 3% aniline-3% phytic acid-1mol / L hydrochloric acid solution for 2 hours, then drop the mass fraction It is a 1.5% ammonium persulfate initiator solution, and is polymeri...

example 3

[0035] 1) take each component according to mass percentage: chitosan 4%, lithium hydroxide monohydrate 8%, urea 6%, graphene oxide 0.1%, all the other are water; Described chitosan molecular weight is 2000000; After the above components are mixed and swollen, it is prepared through multiple freezing-thawing processes;

[0036] 2) Take 20g of the above-mentioned graphene oxide-chitosan solution, add 2.4g of acrylamide, 0.05g of N,N'-methylene bisacrylamide and 0.03g of ammonium persulfate in sequence, stir evenly, centrifugally defoam, and cast in In the mold, transfer it to a 60°C oven for 4 hours and take it out, dialyze and dehydrate to obtain an alkali-soluble chitosan-polyacrylamide gel;

[0037]3) Transfer the alkali-soluble chitosan-polyacrylamide gel prepared in the above step 2) to a mass fraction of 3% aniline-7% phytic acid-1mol / L hydrochloric acid solution for 2 hours, then drop the mass fraction It is a 1.5% ammonium persulfate initiator solution, and is polymeriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com