Swelling-resistant two-dimensional SA-MXene layered nanofiltration membrane, production and application

A swelling-resistant, nanofiltration membrane technology, applied in membranes, membrane technology, semi-permeable membrane separation, etc., can solve the problems of increased nano-sheet spacing, membrane swelling, etc., to improve separation performance, solve swelling problems, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Lithium fluoride is dissolved in hydrochloric acid to obtain an etchant, and Ti is added to the solution 3 AlC 2 For the precursor, ensure that the mass ratio of the precursor to the etchant is 1:1, stir and react at 45°C for 36 hours; after the reaction is completed, wash it repeatedly with ultrapure water until the pH of the solution is about 5, and finally centrifuge at 3500rpm. Collect the supernatant to obtain stable two-dimensional Ti 3 C 2 T X Nanosheet solution;

[0032] Step 2: At Ti 3 C 2 T X Add 200mPa.s sodium alginate powder with a mass of 5% of the nanosheets to the nanosheet solution, stir and react at room temperature for 12 hours to obtain SA-Ti 3 C 2 T X mixture;

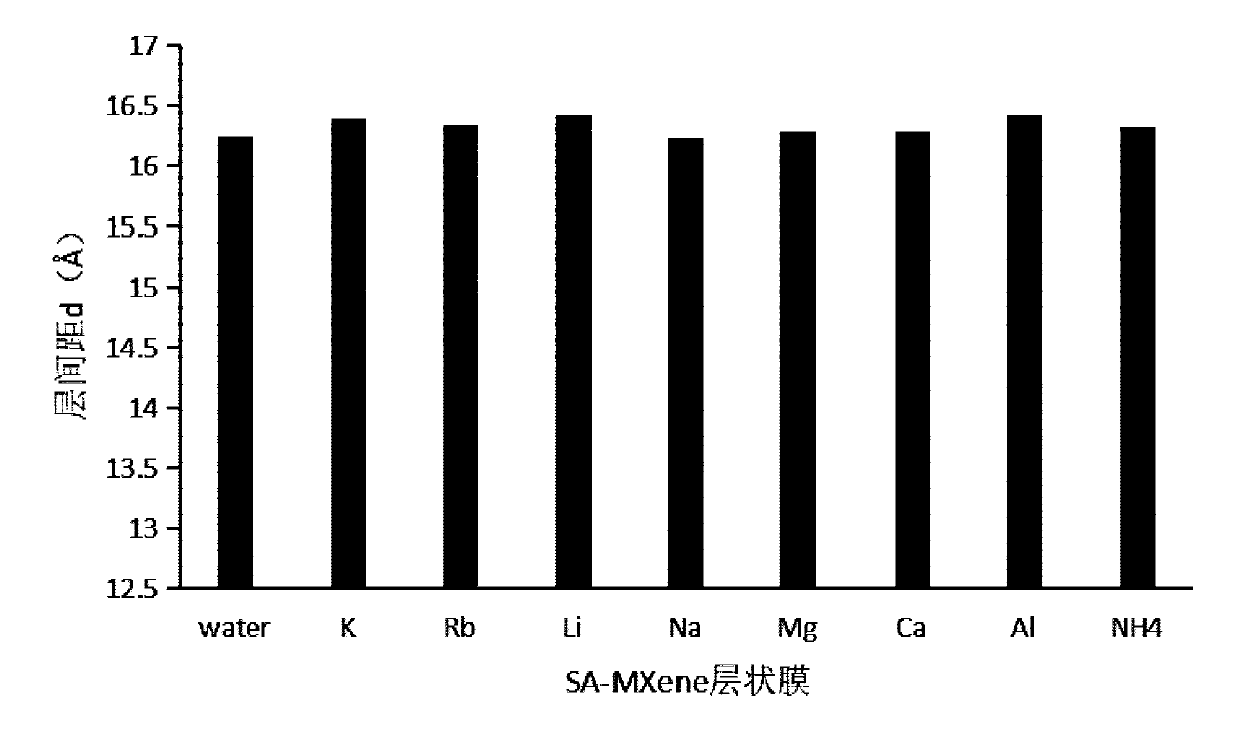

[0033] Step 3: Use suction filtration to make SA-Ti 3 C 2 T X The nanosheets are regularly deposited on a polyvinylidene fluoride film with a pore size of 220nm, and the prepared film is immersed in 10g / L MnCl 2 After the solution was cross-linked for 5 hours, it was dr...

Embodiment 2

[0042] The steps of this example are the same as Example 1, the difference is that the precursor used in Step 1 of this example is Ti 2 AlC.

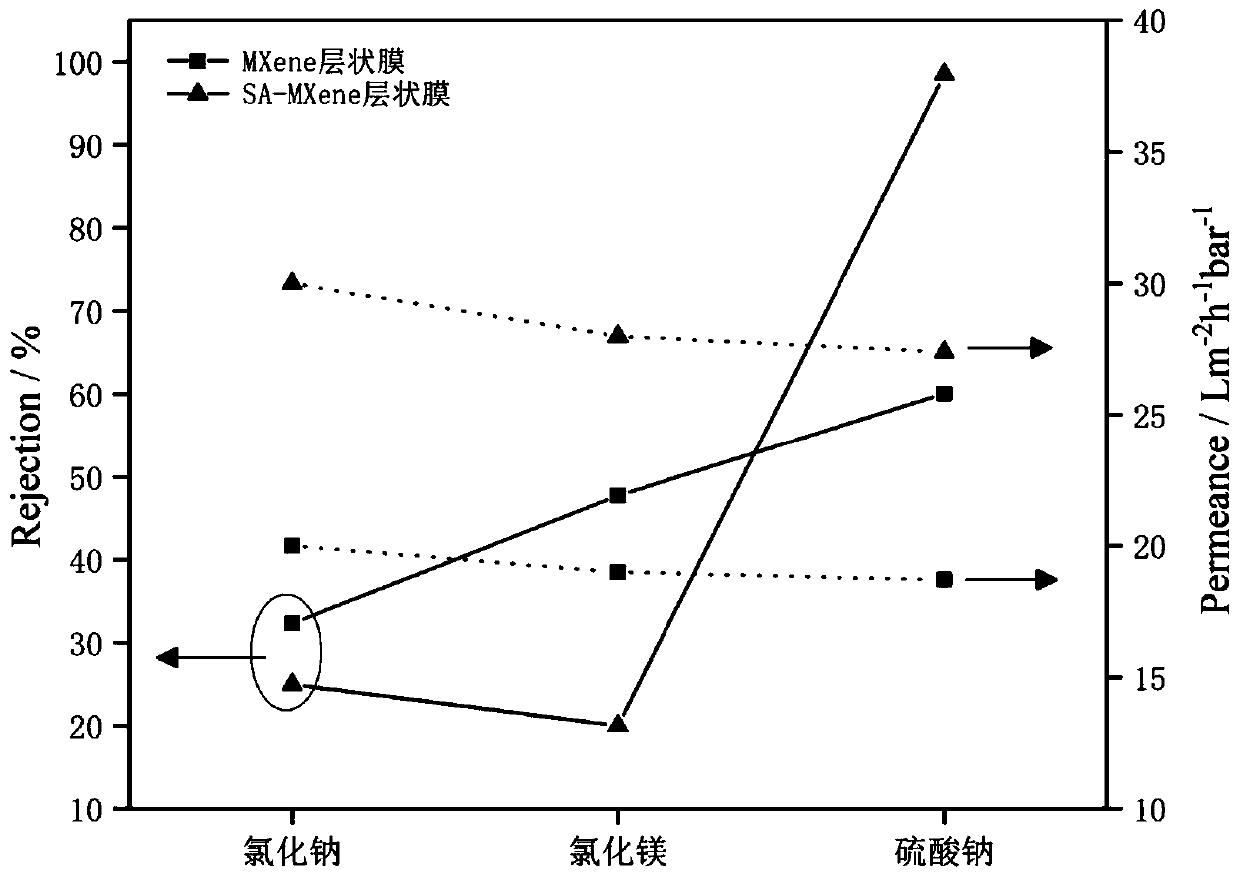

[0043] The layered membrane prepared in this example and the layered membrane prepared in Example 1 are controlled at 1.60 ± 0.03nm, have good swelling resistance, and have the same ion selectivity in the filtration process. The rejection rates of magnesium chloride, magnesium chloride and sodium sulfate are 94.5%, 35.0% and 33.5% respectively, which can realize the separation of different valence anions. Similarly, Ti, which is also a transition metal carbon / nitride 3 SiC 2 、Ti 3 AlC 2 、Ti 4 AlN 3 and Nb 4 AlC 3 , V 2 AlC etc. are used as precursors to form films, all of which have the same effect.

Embodiment 4

[0045] The procedure of this example is the same as that of Example 1, except that the reaction temperature in this example is 30° C., and the stirring time is 24 hours. The conditions of this embodiment can also prepare the same layered film as in Example 1, but due to the low reaction temperature and stirring time, Ti 3 C 2 T X The yield of nanosheets was slightly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com