High-combustion-value alcohol-based fuel for vehicles

A technology of alcohol-based fuel and combustion value, applied in fuel, fuel additive, liquid carbon-containing fuel, etc., can solve the problem of low calorific value, achieve the effect of protecting the fuel system, protecting engine equipment, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

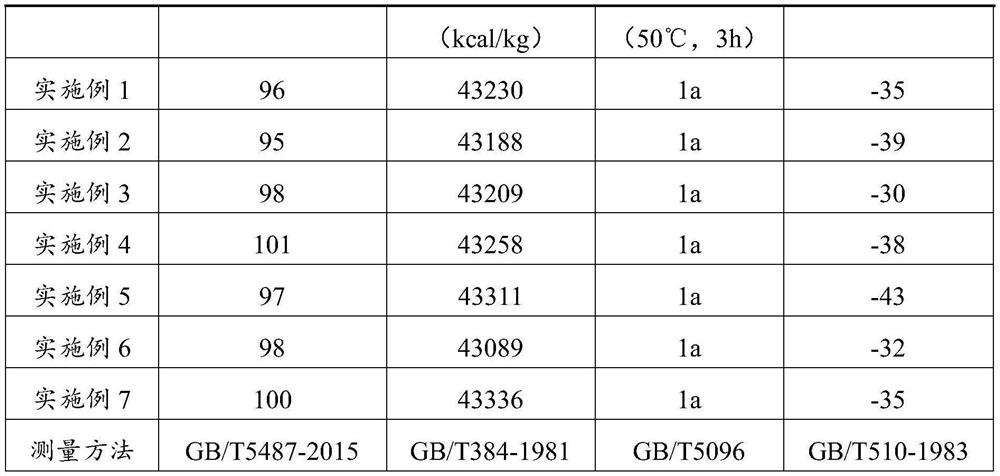

Examples

preparation example Construction

[0038] The present invention also provides the above technical solution of the high fuel value of the vehicle fuel alcohol production method comprising the steps of:

[0039] The xylene, a monohydric alcohol and a hydrocarbon compound were placed in a vacuum environment for 30 to 60 min, sequentially added with methacrylamide, 4-tert-butyl-2,6-diisopropylphenol and a combustion, resulting in the high combustion value. Car alcohol-based fuel.

[0040] In the present invention, the xylenes, monohydric alcohols and hydrocarbons is placed in a vacuum environment 30 ~ 60min process is preferably carried out in a pressure vessel.

[0041] In the present invention, after the addition of methacrylamide, preferably 60 ~ 180min was stirred at 40 ~ 60 ℃.

[0042] In the present invention, the addition of 4-t-butyl-2,6-diisopropyl phenol and oxidant, preferably 30 ~ 90min stirring at 40 ~ 60 ℃. After completion of the stirring, the present invention also preferably includes a cooling and sequ...

Embodiment 1

[0045] raw material:

[0046] 20 parts of methanol, 50 parts of pentane, 29.5 parts of xylene, 0.18 parts of methacrylamide, 4-tert-butyl-2,6-diisophenol 0.04 parts and combustion (0.28 parts of the combustion (mass ratio 12: 5) : 8 of isooctane, diisopropyl ether and dimethyl ether);

[0047] making process:

[0048] The xylene, methanol, and pentane were sequentially placed in a pressure-resistant vessel to draw a vacuum, and a methacrylamide was added; stirred at 40 ° C for 180 min; 4-tert-butyl-2,6-diisputene Bympophenols and combustion agents were stirred at 40 ° C for 30 min, fell to room temperature, and were placed for 18 h to give the high-combustible car alcohol-based fuel.

Embodiment 2

[0050] raw material:

[0051] 10 parts of methanol, 8.6 parts of ethanol, 36 parts of pentane 10, 35 parts of xylene, 0.14 parts of methacrylamide, 4-tert-butyl-2,6-diisophenol 0.03 parts and combustion 0.23 Part (mass ratio is 11: 6: 6 isooctane, diisopropyl ether and dimethyl ether);

[0052] making process:

[0053] Teta, methanol, ethanol, pentane, and hexane were sequentially pumped into the pressure-resistant vessel to draw a vacuum, placed for 55min; add methacrylamide, stirred at 45 ° C for 160min; sequentially added 4-tert-butyl-2, 6 - Diisopropylphenol and a combustion agent, stirred at 45 ° C for 40 min, fell to room temperature, and placed 17 h to give the high-combustible car alcohol-based fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com