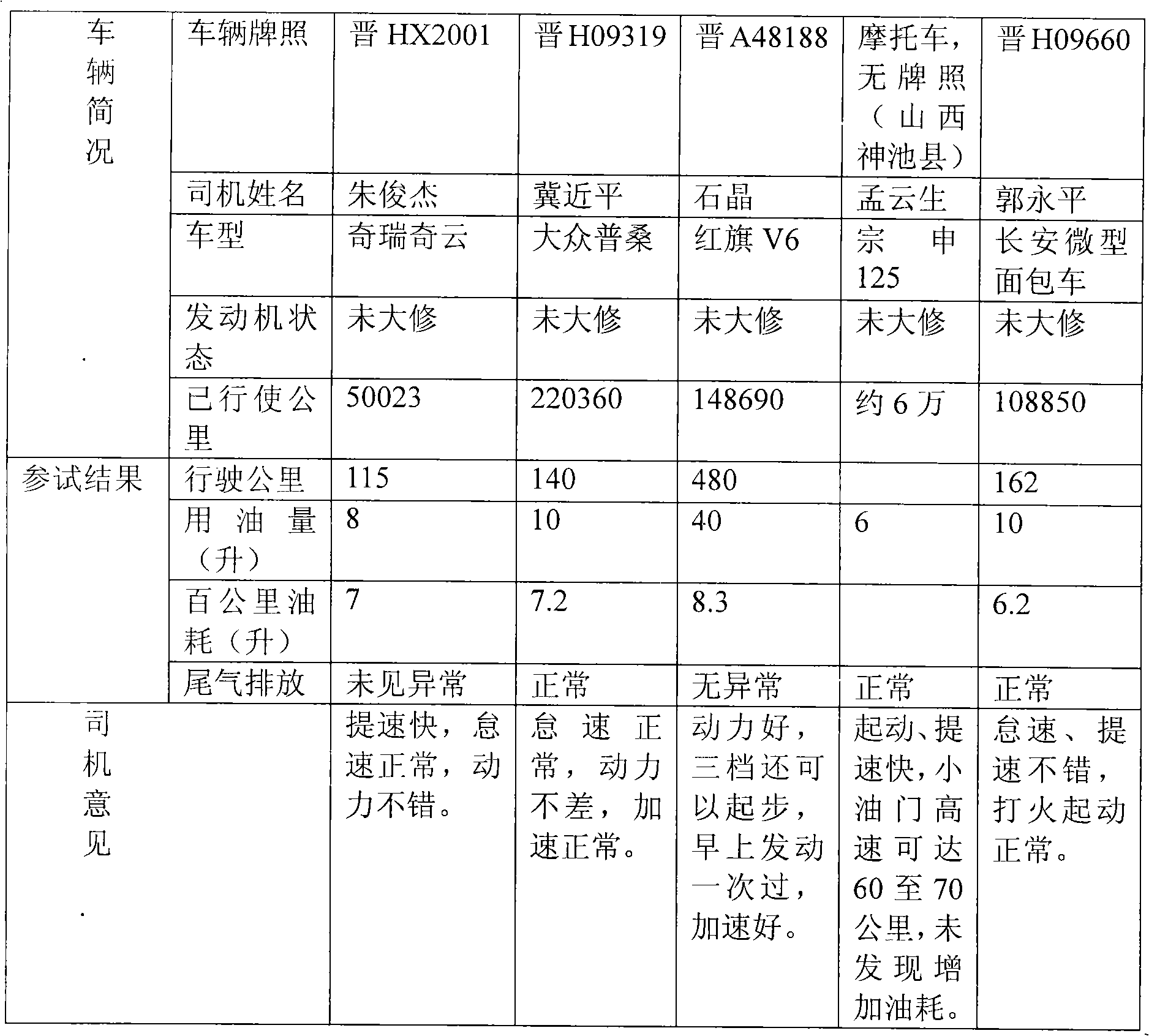

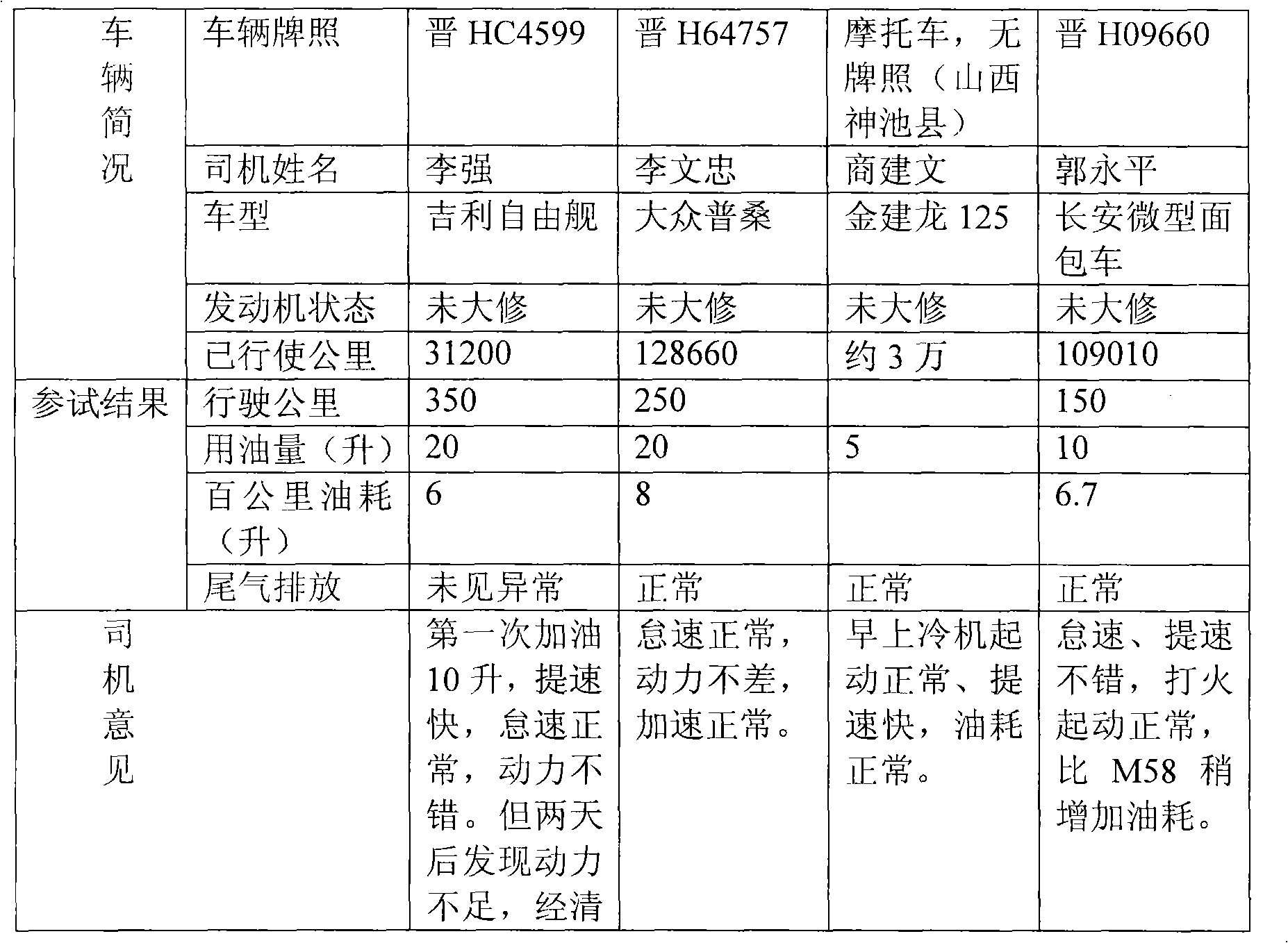

Patents

Literature

75results about How to "Solve the swelling problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethanol gasoline and preparation method thereof

ActiveCN101812332ALong stable periodSolve corrosiveLiquid carbonaceous fuelsFuel additivesSwelling capacityAlcohol

The invention discloses ethanol gasoline, which is characterized by consisting of the following raw materials in part by volume: 60 to 70 parts of regular gasoline, 2 to 10 parts of absolute ethanol, 10 to 20 parts of latent solvent, 13 to 23 parts of surfactant, 10 to 15 parts of combustion improver, 3 to 10 parts of corrosion inhibitor and 7 to 15 parts of detergent dispersant. The invention also discloses a preparation method of the ethanol gasoline. The ethanol gasoline has the advantages of high storage stability, high intersolubility, no corrosion, no swelling capacity and readily available raw materials, can be used together with other alcohol automobile gasoline such as methanol gasoline and the like in any ratio, and also can be directly used with common gasoline of the same standard in any proportion; the octane level reaches or exceeds the standards of No. 93 and No.95 clear gasoline; and the overall performance of the ethanol gasoline can meet standard requirements of the No.93 clear gasoline.

Owner:SHANDONG TAIDE NEW ENERGY

Methanol gasoline denaturant and preparation method thereof

InactiveCN102021053AGood corrosion resistanceEmission reductionLiquid carbonaceous fuelsFuel additivesChemistryFormic acid

The invention provides a methanol gasoline denaturant and a preparation method thereof. The methanol gasoline denaturant is composed of methanol gasoline phase separation inhibitor, methanol gasoline corrosion inhibitor, methanol gasoline vapour pressure regulator, formic acid, formaldehyde and methanol complete combustion improver, and a coordination mechanism is formed. The methanol gasoline phase separation inhibitor accounts for 30-50%, the methanol gasoline vapour pressure regulator accounts for 2-10%, the complete combustion improver accounts for 30-67%, and the methanol gasoline corrosion inhibitor accounts for 1-10%, and the four components are synthesized under specific production conditions. The amount of the methanol gasoline denaturant added to methanol gasoline is 0.5-2% (mass ratio), common gasoline No. 90 can be used for producing clean methanol gasoline No. 93 and clean methanol gasoline No. 97, all the performances of the methanol gasoline are improved, and long term storage and normal use of the methanol gasoline are realized.

Owner:深圳市贝壳能源科技有限公司

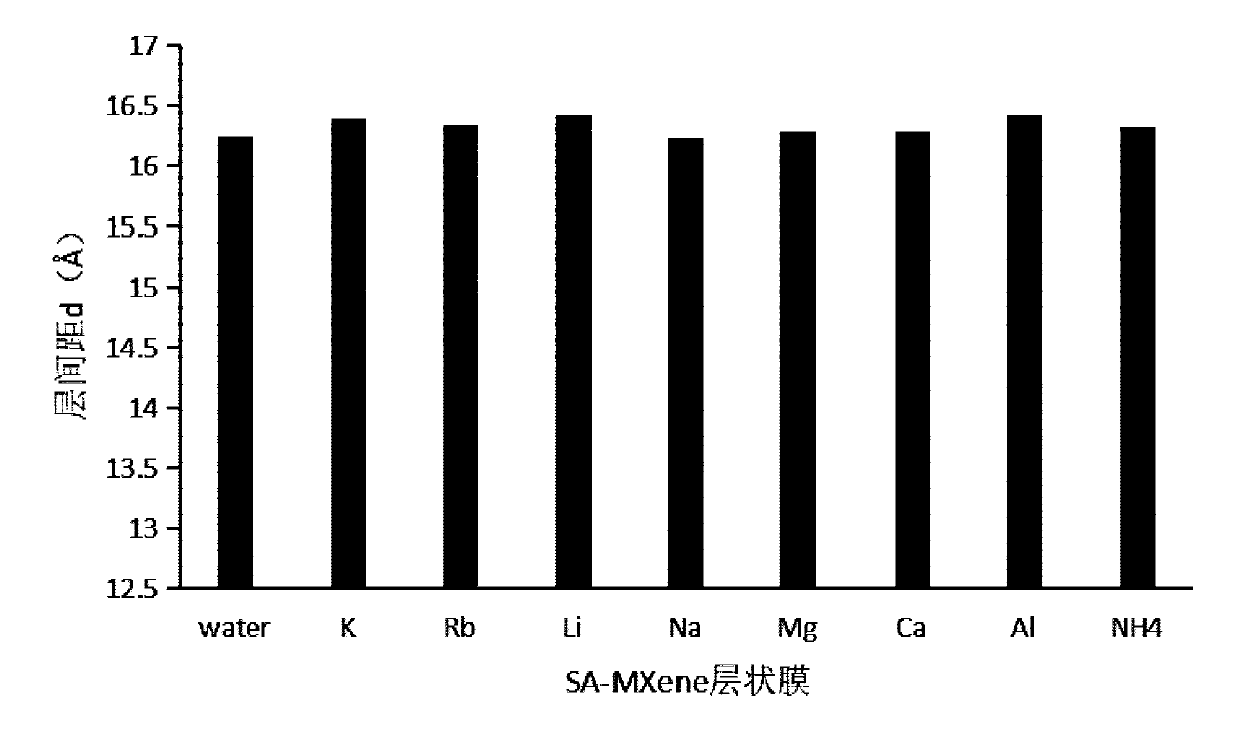

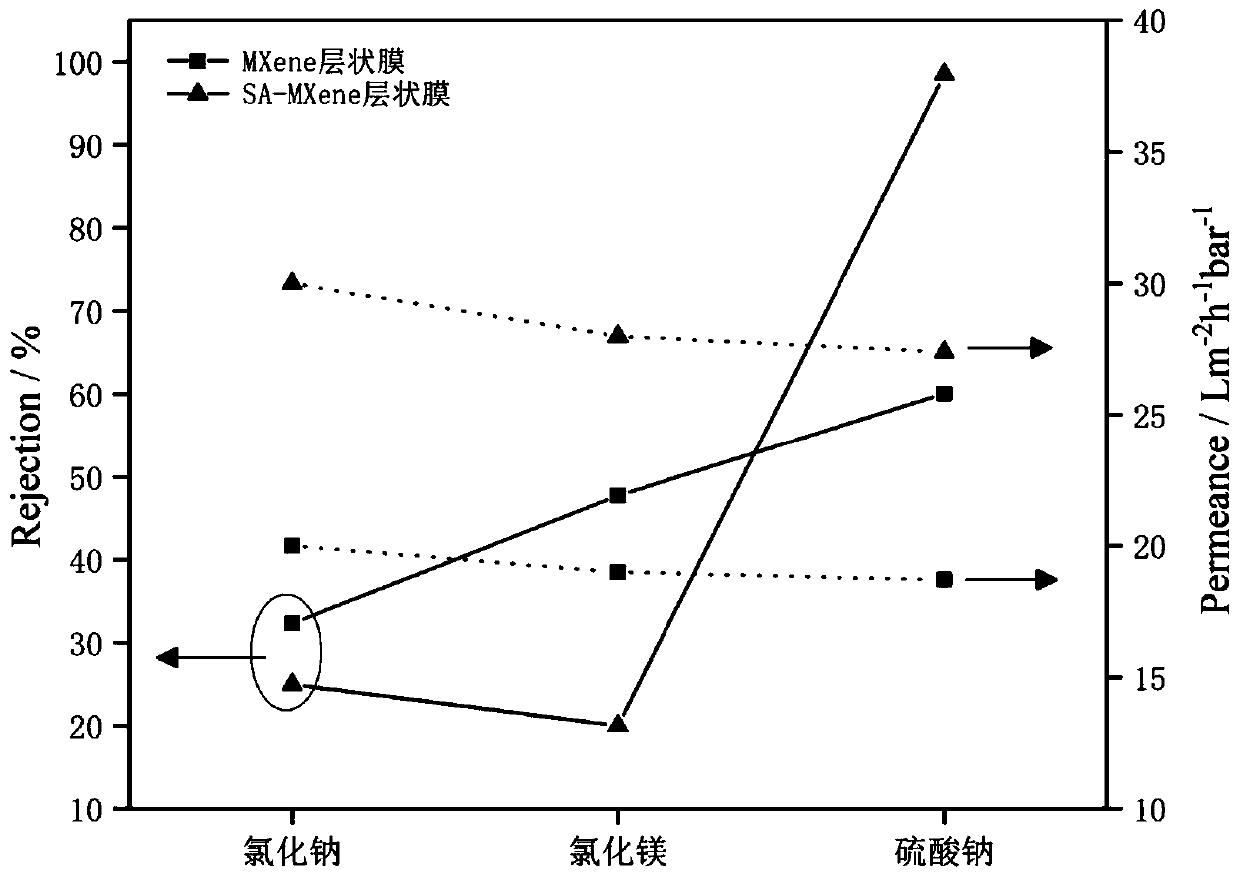

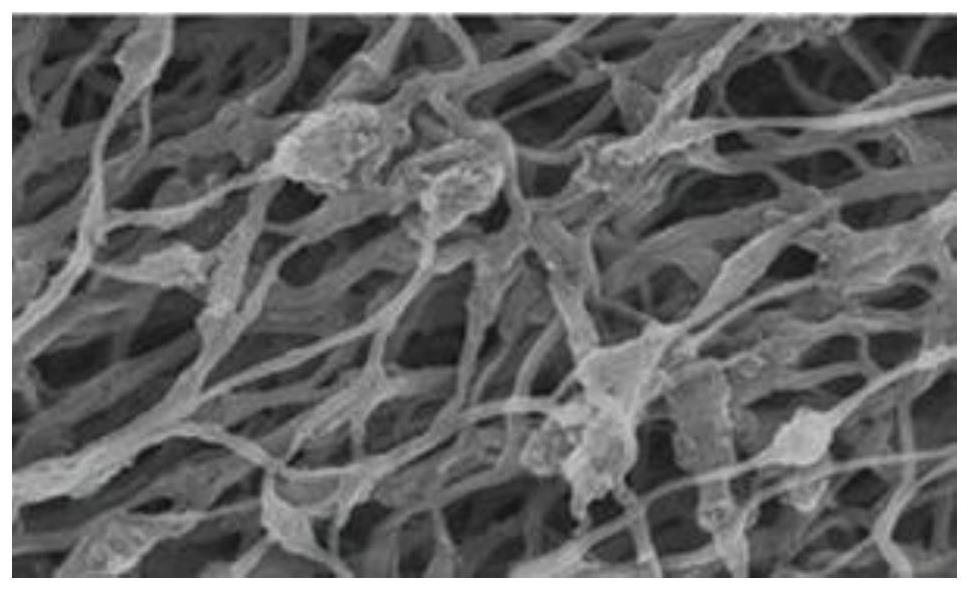

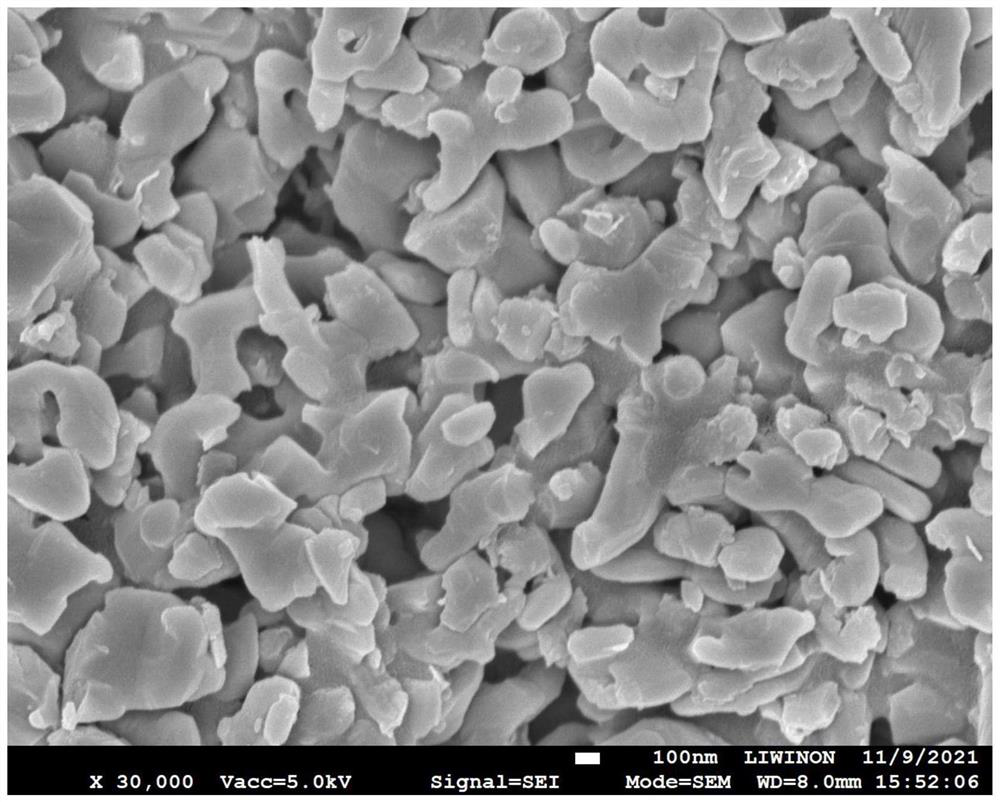

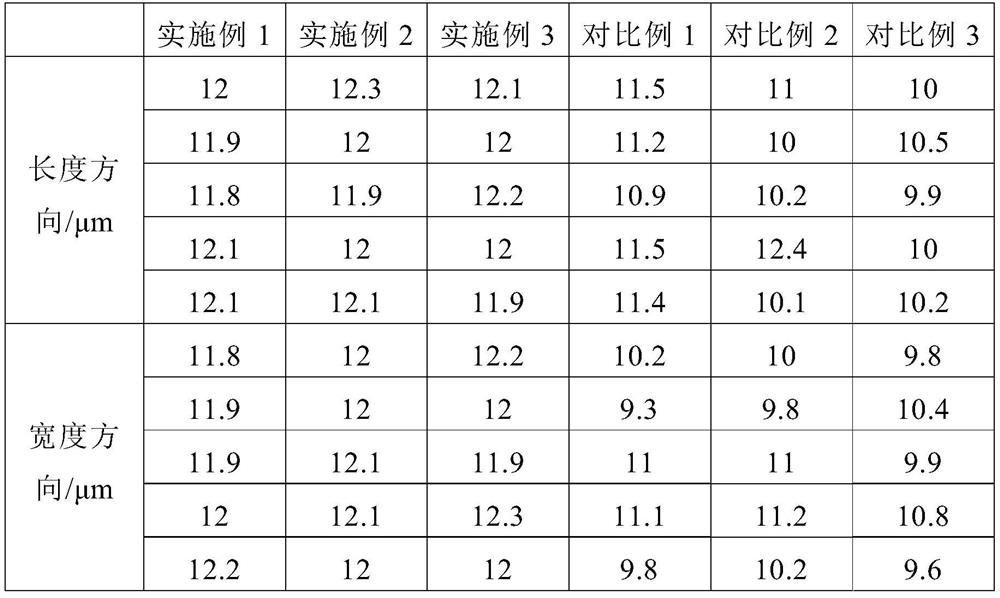

Swelling-resistant two-dimensional SA-MXene layered nanofiltration membrane, production and application

ActiveCN110449032ASolve the swelling problemInhibition of swellingMembranesReverse osmosisSelective filterIon

The invention discloses a production method of a swelling-resistant two-dimensional SA-MXene layered nanofiltration membrane. The production method of the swelling-resistant two-dimensional SA-MXene layered nanofiltration membrane comprises a first step of mixing MXene precursor powder and an etching agent solution, carrying out a stirring reaction, and conducting centrifugal washing to obtain a two-dimensional MXene nanosheet colloid solution; a second step of adding sodium alginate into the two-dimensional MXene nanosheet colloid solution, and evenly stirring and mixing an obtained mixture to obtain SA-MXene nanosheets; and a third step of stacking the SA-MXene nanosheets on a surface of a substrate to produce a membrane, and placing the membrane in a polyvalent metal solution for cross-linking to obtain the swelling-resistant two-dimensional SA-MXene layered nanofiltration membrane. According to the method, by evenly grafting the sodium alginate onto surfaces of MXene nanosheets, through a cross-linking effect of the sodium alginate and polyvalent metal ions, stable hydrophilic cross-linked networks are formed in interlayer channels of the nanosheets, thus the problem of swelling of a layered membrane is solved, meanwhile, due to the fact that the sodium alginate is doped, a large number of oxygen-containing functional groups are introduced onto surfaces of the mass transferchannels, the channel electronegativity is improved, and the layered membrane shows excellent selective filtering performance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

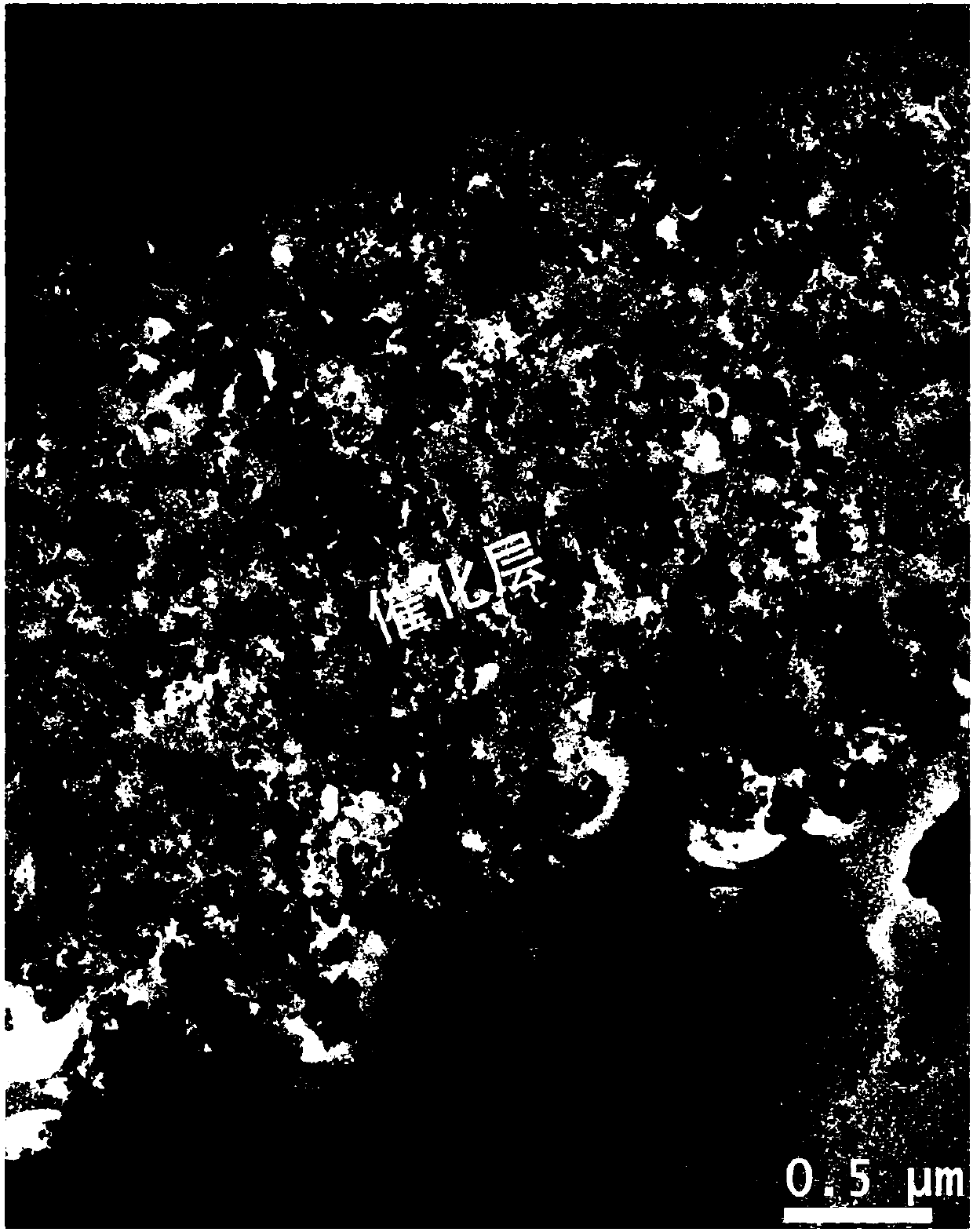

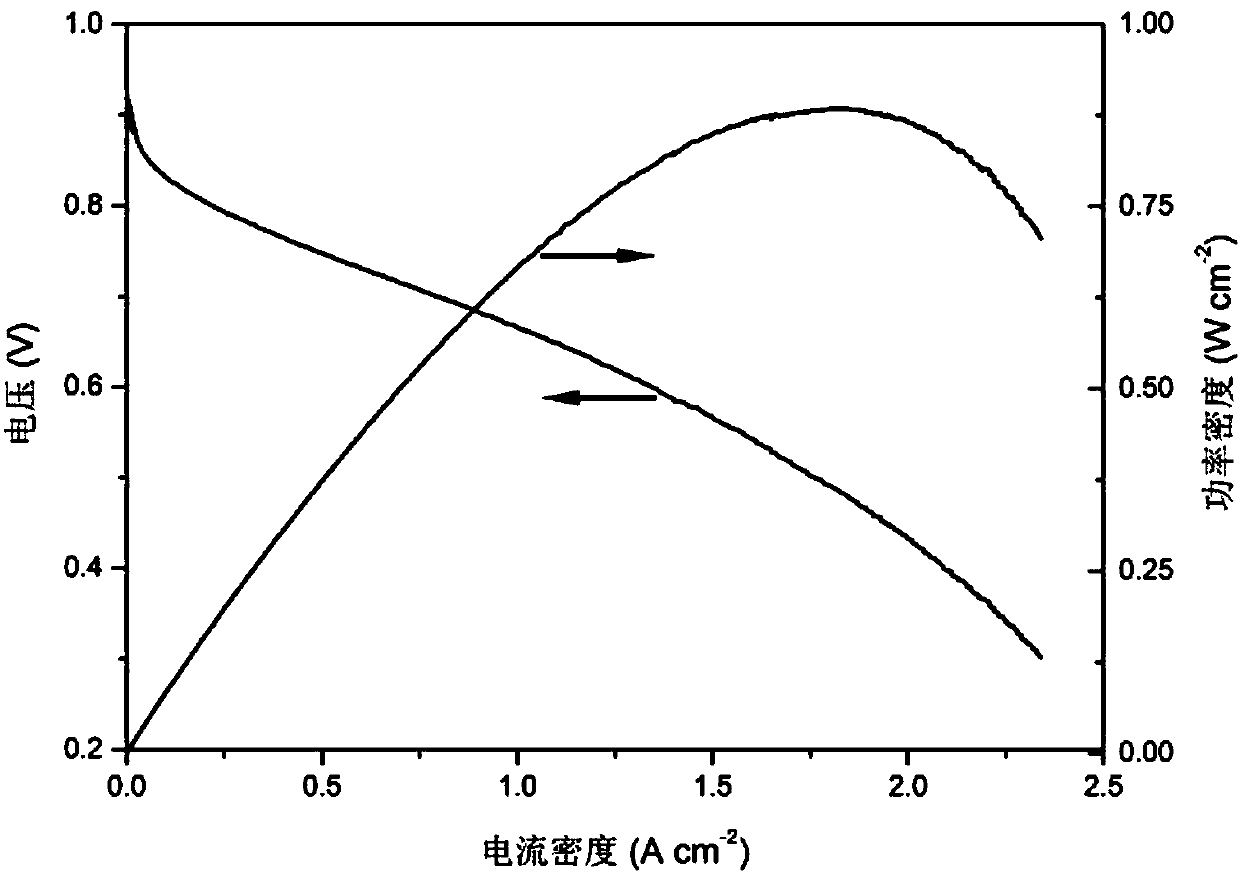

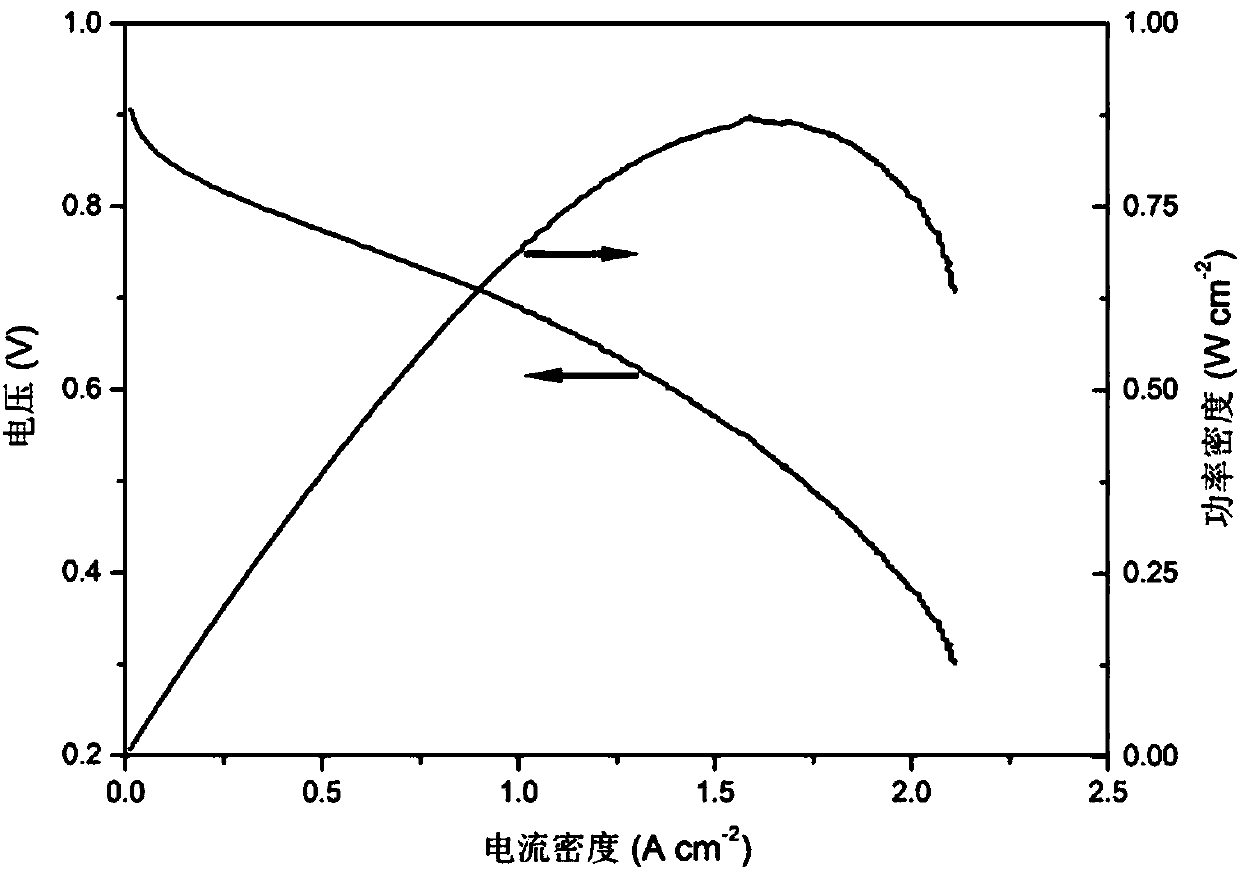

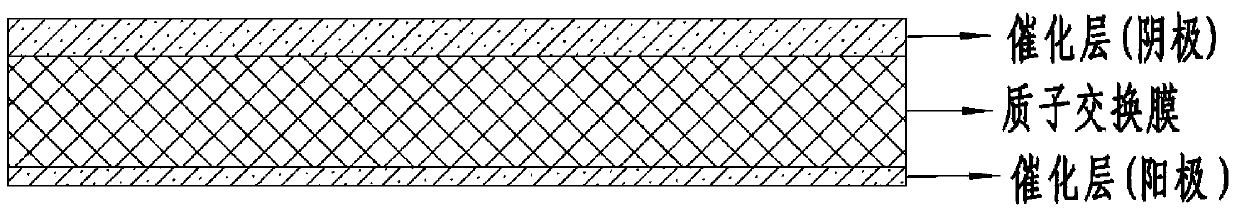

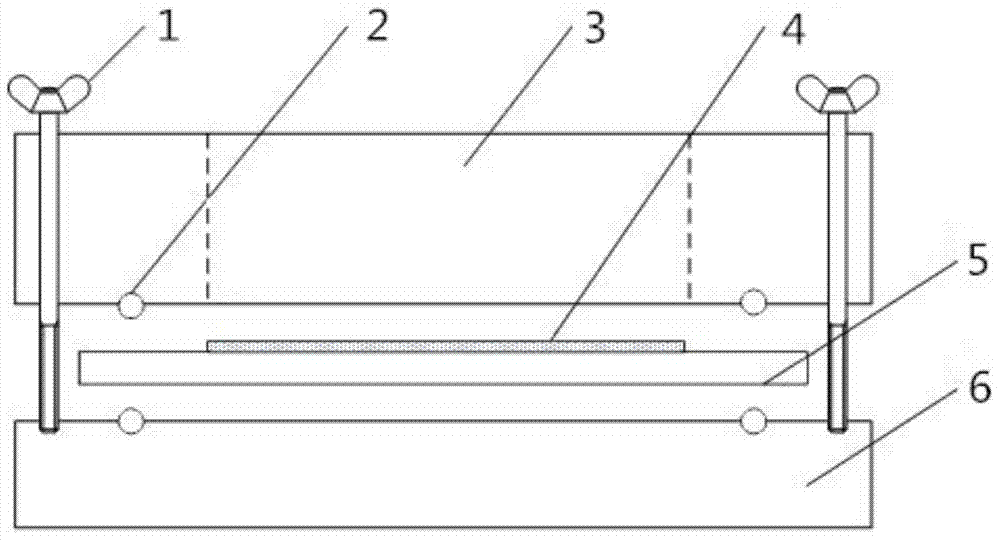

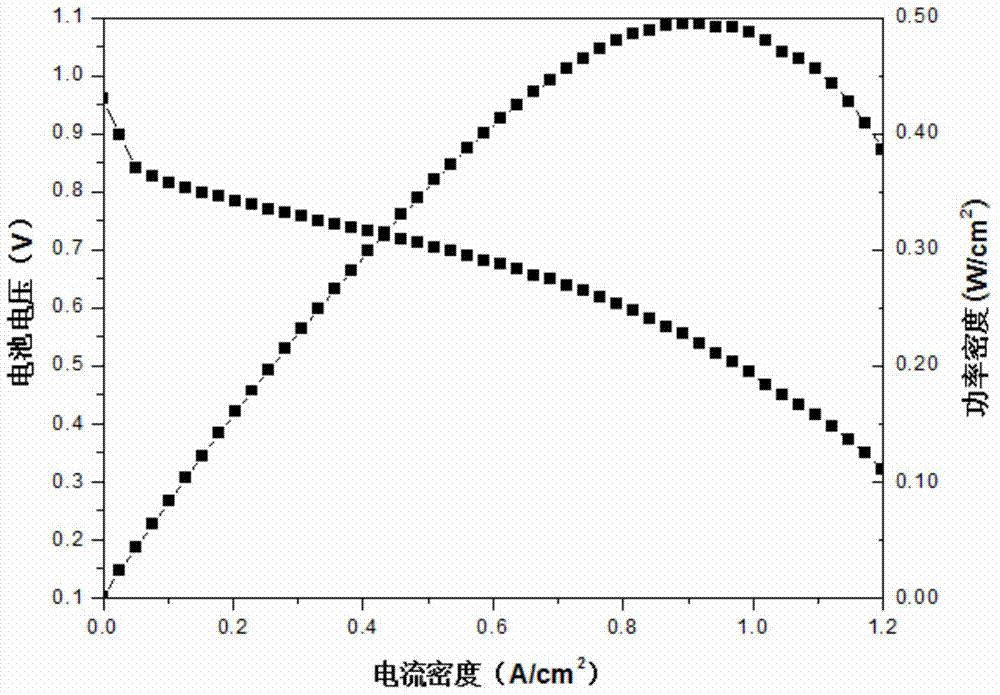

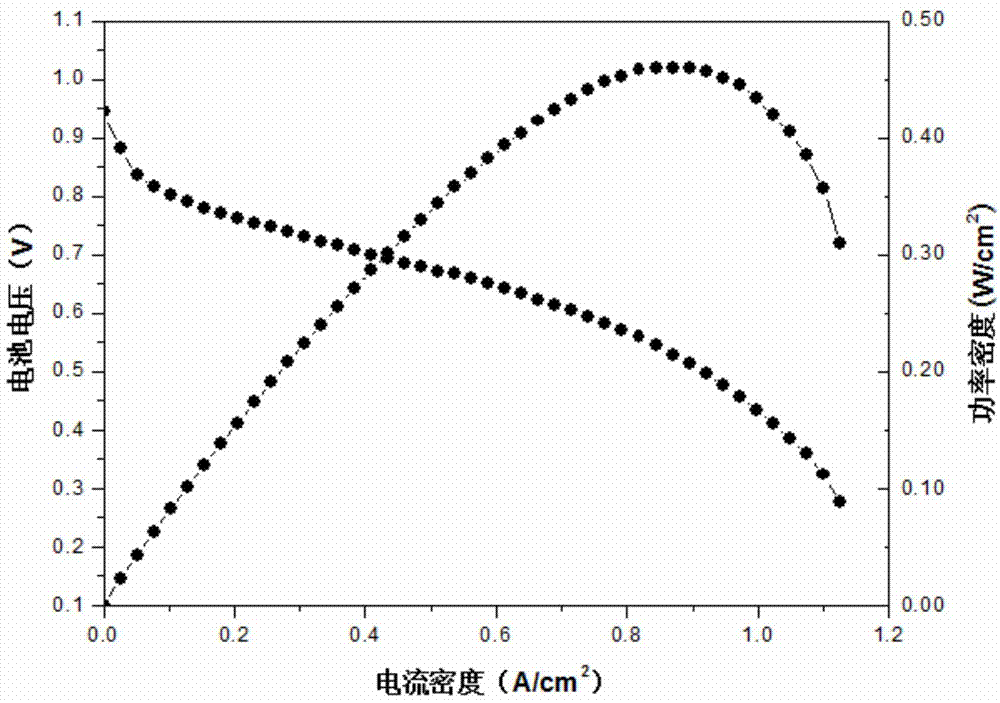

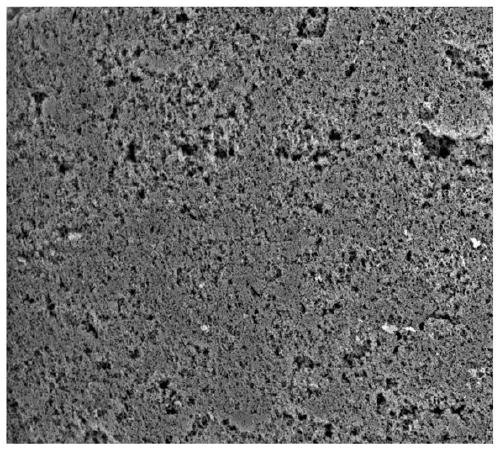

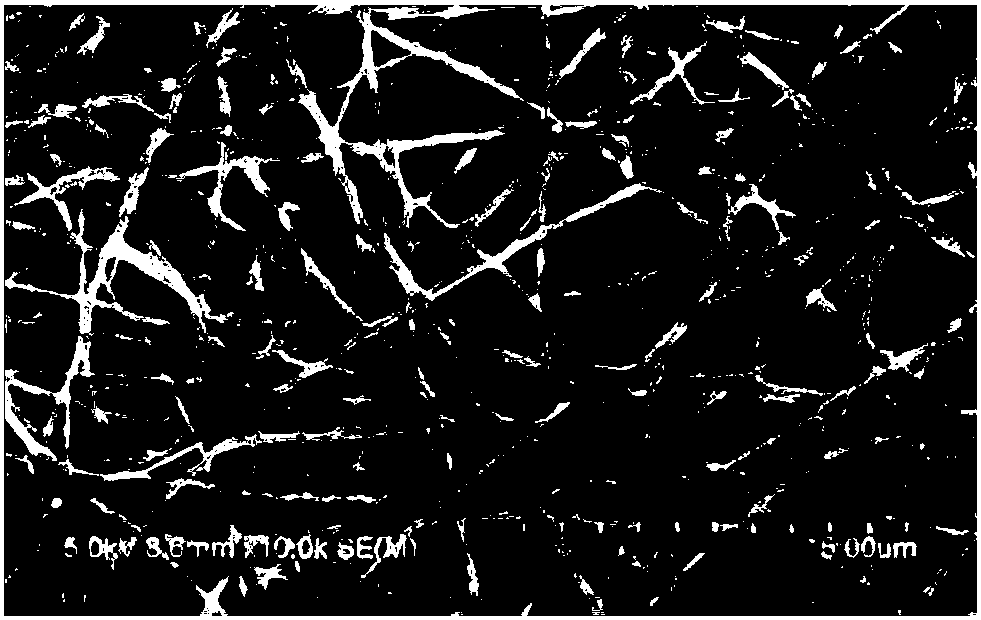

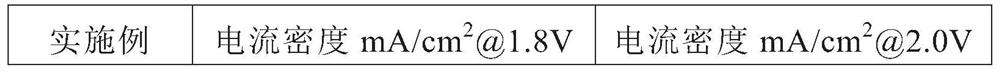

Membrane electrode of fuel cell and preparation method and application of membrane electrode

InactiveCN107681163AThin structureSolve the swelling problemCell electrodesFinal product manufactureElectrochemistryElectrical impedance

The invention discloses a preparation method of a membrane electrode of a fuel cell. The method comprises the steps of coating a transfer medium with a substrate layer; carrying out in-situ reduction-deposition of platinum nanoparticles on the substrate layer and then coating the platinum nanoparticles with a layer of proton conducting polymer to form an electrode catalyst layer; and finally transferring the catalyst layer to a proton exchange membrane by adopting a heat transfer process to prepare a membrane electrode. The invention further discloses the membrane electrode of the fuel cell and an application of the membrane electrode on a cathode or an anode of a proton exchange membrane fuel cell. The problem of contradiction between reduction time and electrochemical active area in thein-situ deposition process of platinum is relatively well solved and the yield of heat transfer is improved. The membrane electrode has the beneficial effects of high catalyst activity and utilizationrate, large electrochemical active area, low gas transmission impedance in the catalyst layer and the like, and is low in production cost, simple and fast in process and high in yield, and massive production is easy to implement.

Owner:SHANGHAI JIAO TONG UNIV

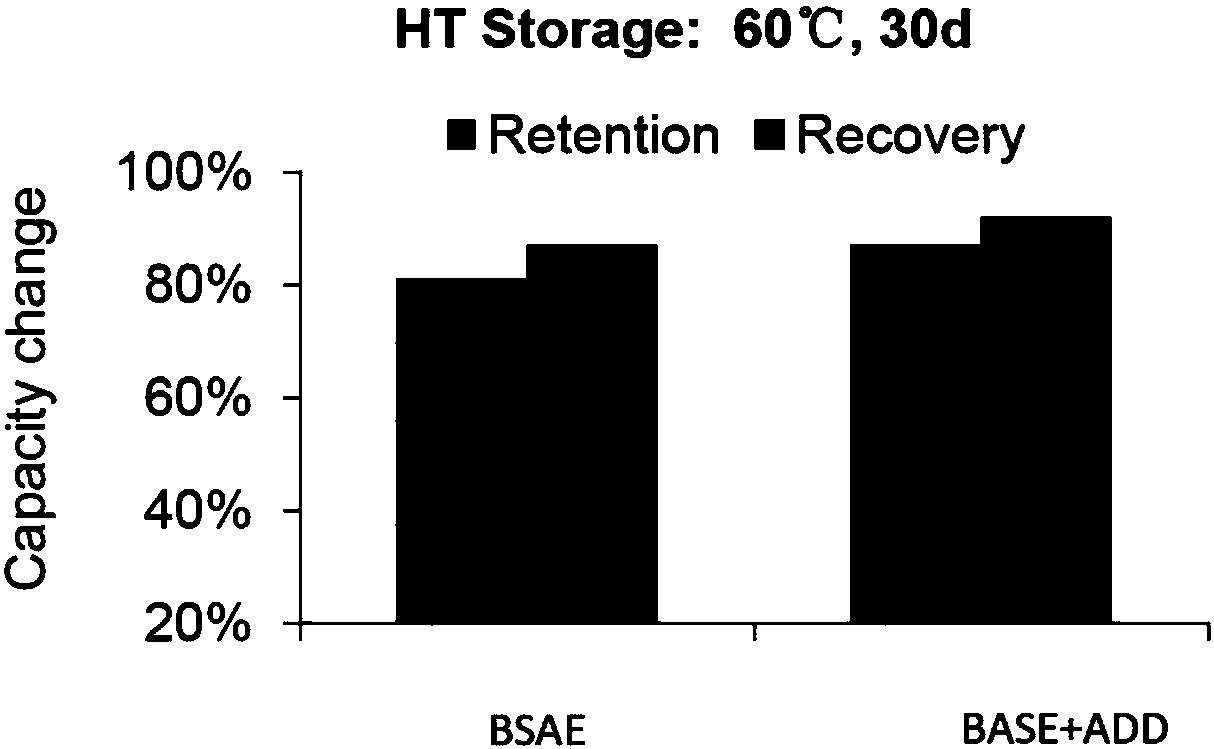

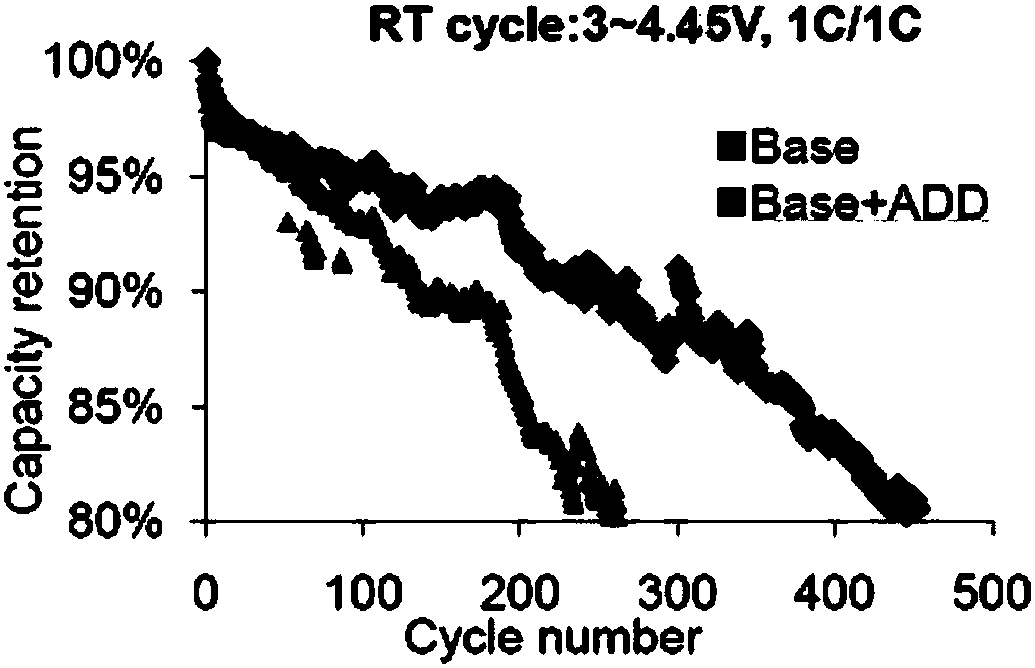

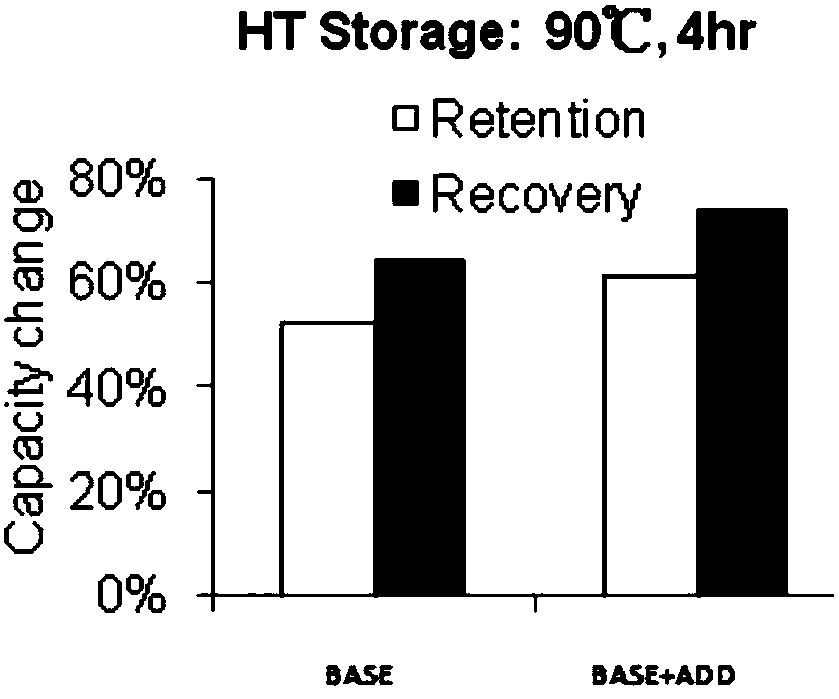

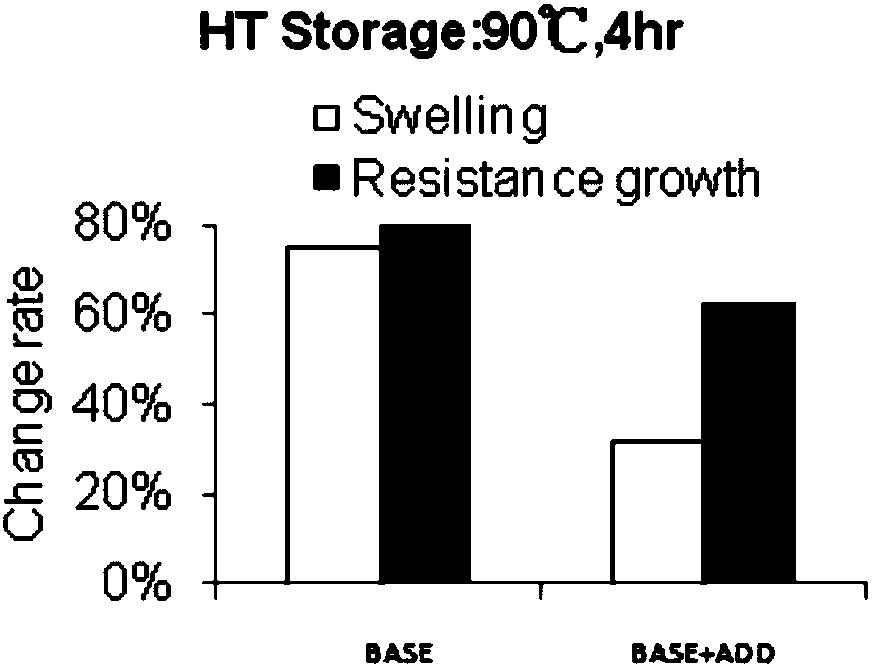

High-temperature resistant lithium ion electrolyte

ActiveCN107910591AImprove low temperature performanceImprove solubilitySecondary cellsDisiloxaneOrganic solvent

A high-temperature resistant lithium ion electrolyte belongs to the technical field of a lithium battery electrolyte and comprises a lithium salt and an organic solvent and also comprises 1,2-bi(trimethylsilyl) ethylene, 1,3-dimethyl-1,1,3,3-tetraethylene disiloxane, 2,4,6-triethylene-2,4,6-trimethylcyclotrisiloxane or 1,3-divinyl-1,1,3,3-tetramethyl-disilazane. In the battery electrolyte, the charge-discharge performance of a lithium battery can be effectively improved due to addition of the substance into the electrolyte, side reaction is reduced, so that the battery bubbling is reduced, andthe cycle lifetime of the battery is prolonged.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

Methanol and environment protecting composite methanol fuel as diesel oil substitute

InactiveCN1403543AChange the situation of dependence on oilAlleviate shortagesLiquid carbonaceous fuelsMethanol fuelEvaporation

The present invention relates to one kind of composite environment protecting methanol fuel as diesel oil substitute. The composite methanol fuel is especially suitable for in diesel truck and has a superior energy consumption ratio. The composite methanol fuel is composed with methanol as main material as well as petroleum ether; primer, ignitor; lubricant; additive of one of tea seed oil, castor oil, cottom seed oil and rape oil leftover; evaporation inhibitor and binary fuel crosslinking agent.

Owner:王方茂

High-clean vast-scale methanol gasoline

The invention belongs to the fuel technical field, in particular relating to synthetic gasoline which takes methanol as main material. The compositions by weight percentage of the synthetic gasoline are: 58 to 85 percent of methanol, 14.2 to 40 percent of merchantable gasoline and 0.8 to 2 percent of comprehensive additives. The product of the synthetic gasoline can directly replace No. 90, No. 93, No. 97 and No. 98 national standard motor petrol, and a motor can be normally started and operated at an extreme temperature of 30 DEG C below zero. The synthetic gasoline not only can be used for gasoline cars with high compression ratio (the ratio of the cylinder total volume to the compressed cylinder volume is more than or equal to 9.5) but also can be used for gasoline cars with low compression ratio (the compression ratio is less than 9.5), including motorcycles which use carburetors.

Owner:周凯亮

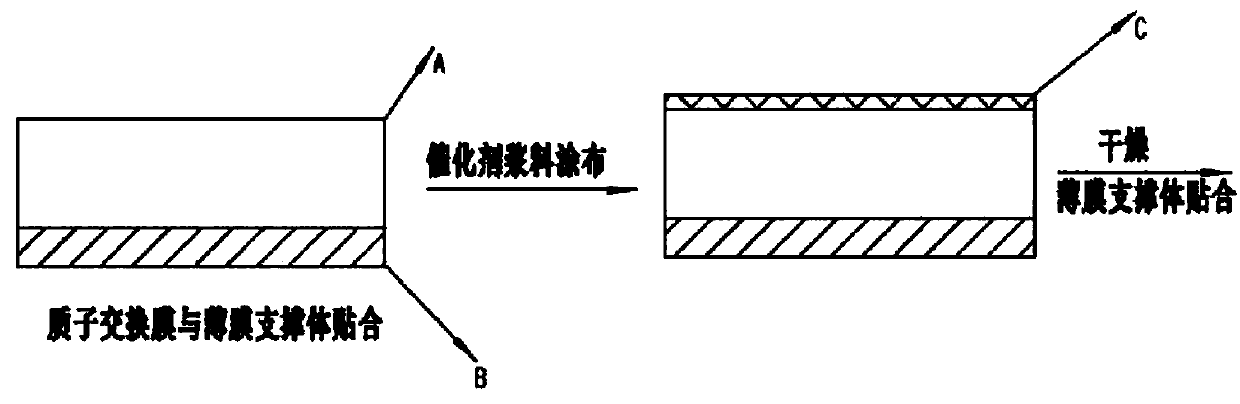

Preparation method of membrane electrode assembly of proton exchange membrane fuel cell

InactiveCN109585859AResolve shrinkageSolve the swelling problemFinal product manufactureCell electrodesProtonProton exchange membrane fuel cell

The invention discloses a preparation method of a membrane electrode assembly of a proton exchange membrane fuel cell. The preparation method comprises the steps of firstly, attaching a layer of a thin film support body onto one side of a proton exchange membrane, coating catalyst paste on the other side, and performing drying to obtain a catalyst layer; secondly, attaching the thin film support body onto one side of the catalyst layer, and stripping the thin film support body at the other side; thirdly, coating the catalyst paste on the side, and performing drying to obtain the catalyst layer; and removing the remaining thin film support body, thereby obtaining the membrane electrode assembly. By the method, the defects of swelling and deformation of the proton exchange membrane during direct coating of the catalyst paste are effectively overcome, the method has the advantages of simple and rapid process, low production cost and the like, and mass production is easy.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Infiltration vaporization blending composite film for removing phenols from waste water

InactiveCN101077799ASimple structureReduce manufacturing costSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSolventPhenols

The present invention belongs to the field of permeating and vaporizing film separation technology, and is especially composite film for treating phenol containing waste water. The composite film is prepared through dissolving polyether imide in solvent, forming base film, treating the base film with surfactant, dissolving trifluoro propyl silicone rubber and dimethyl silicone rubber in the same kind of solvent to form homogeneous mixture solution, adding silane surfactant and other additives, coating the mixture solution onto the base film, and heat treatment of the composite film to obtain the composite film comprising one porous polymer base film and one covering compact separating layer. In waste water treating test, the composite film can separate phenol containing waste water into retained water with low phenol content and permeated water with high phenol content.

Owner:INST OF CHEM CHINESE ACAD OF SCI

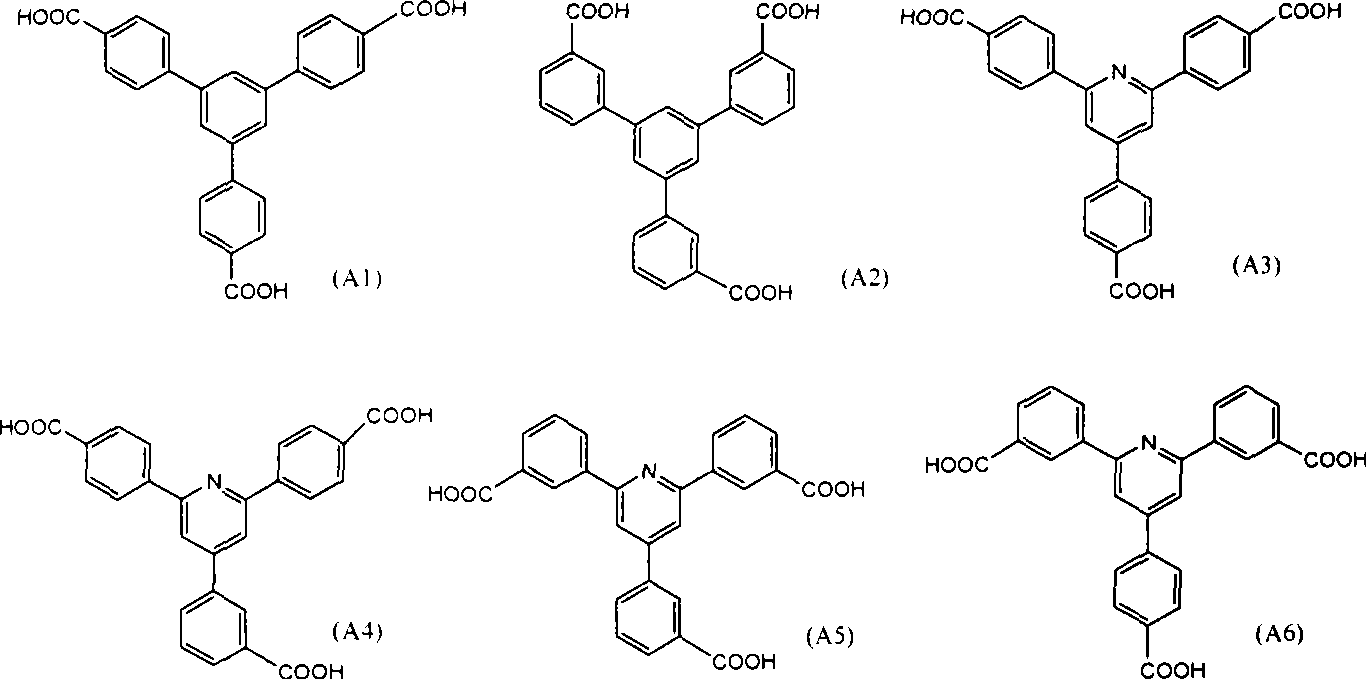

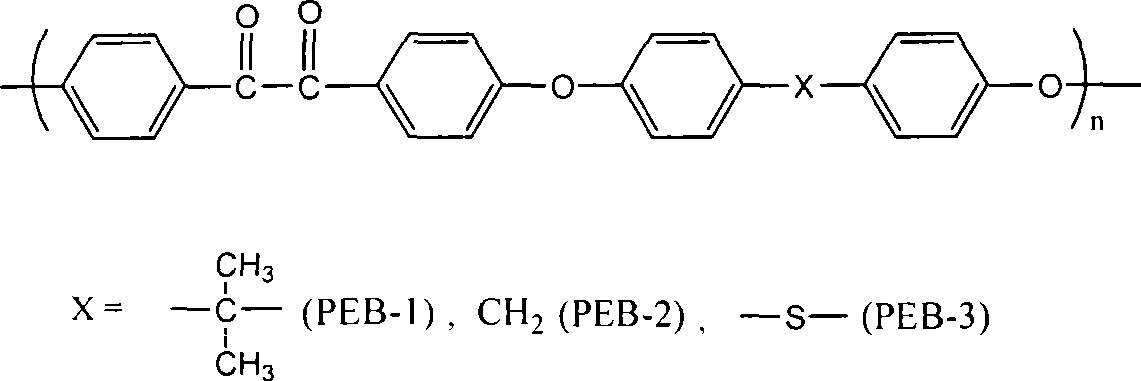

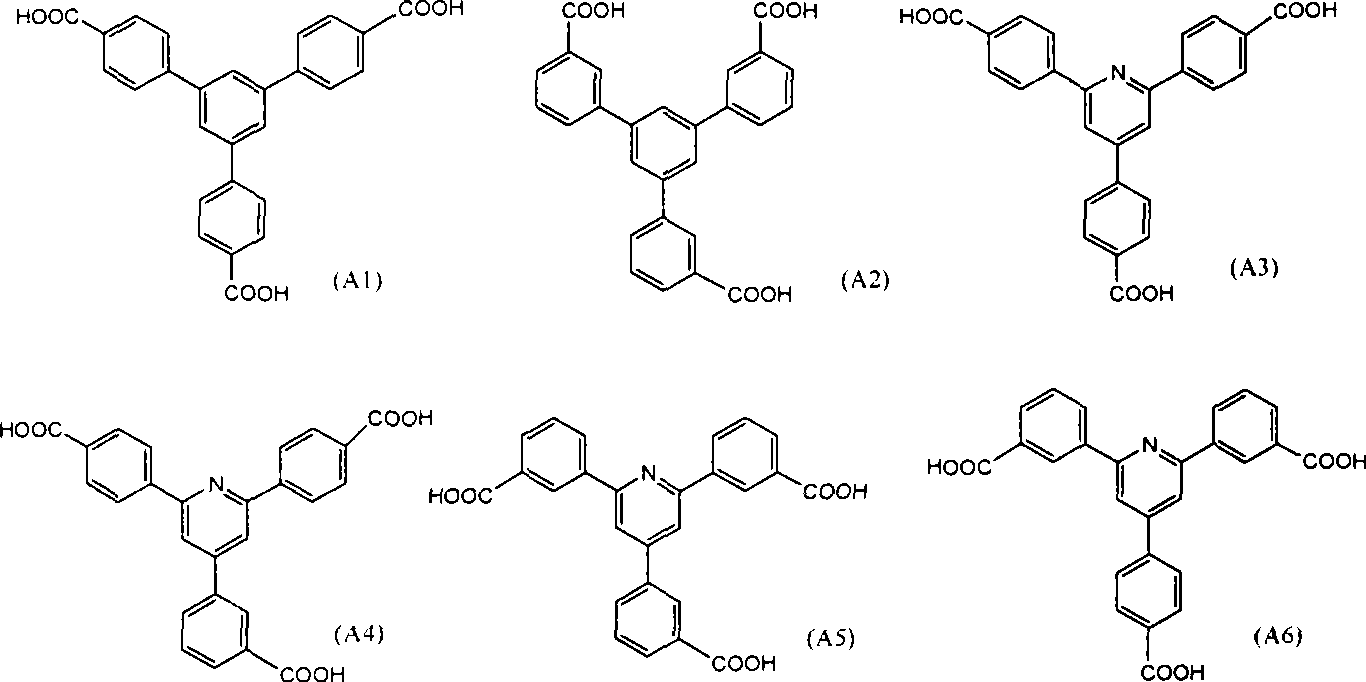

Crosslinked polybenzimidazoles thin film containing sulfonic group and preparation thereof

The invention relates to a crosslinked polybenzimidazole film containing sulfo group and a method for preparing the same. The invention is characterized in that the raw material proportions of the crosslinked polybenzimidazole film are as follows: (1) 10 proportions of 3,3',4,4'-tetraamino diphenyl ether by weight; (2) 5-10 proportions of aromatic triacid by weight; (3) 2-3 proportions of 1,2-naphthoquinone-4-ammonium sulphonate by weight; (4) 0.5-2 proportions of PEB by weight; (5) 100-200 proportions of organic solvent by weight; and (6) 200-300 proportions of polyphosphoric acid by weight. The film can effectively regulate the molecular weight of the branched polybenzimidazole and the structure of the crosslinked film by controlling the raw material proportions. The obtained polybenzimidazole has excellent solubility as well as higher thermal stability, better transparence, excellent corrosion resistance and high proton conduction rate, and the like.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Method for preparing fuel cell membrane electrode

The invention discloses a method for preparing a fuel cell membrane electrode. The method is characterized by comprising the steps of preparing a layer of carbon powder substrates on a transfer medium, depositing platinum nanowires, then coating a layer of electrolyte resin solution to form a catalyst layer, and transferring the catalyst layer to a proton exchange membrane by using a heat transfer method to obtain a platinum nanowire catalyst layer membrane electrode. Through the method for preparing the fuel cell membrane electrode, a series of problems caused due to swelling of the membrane in the preparation process of the substrates and depositing the platinum nanowires can be well solved. The prepared fuel cell membrane electrode has the beneficial effects of the platinum nanowire catalyst layer, also has the advantages of simple process, low production cost and good catalyst layer uniformity and is conducive to industrial production.

Owner:南京东焱氢能源科技有限公司

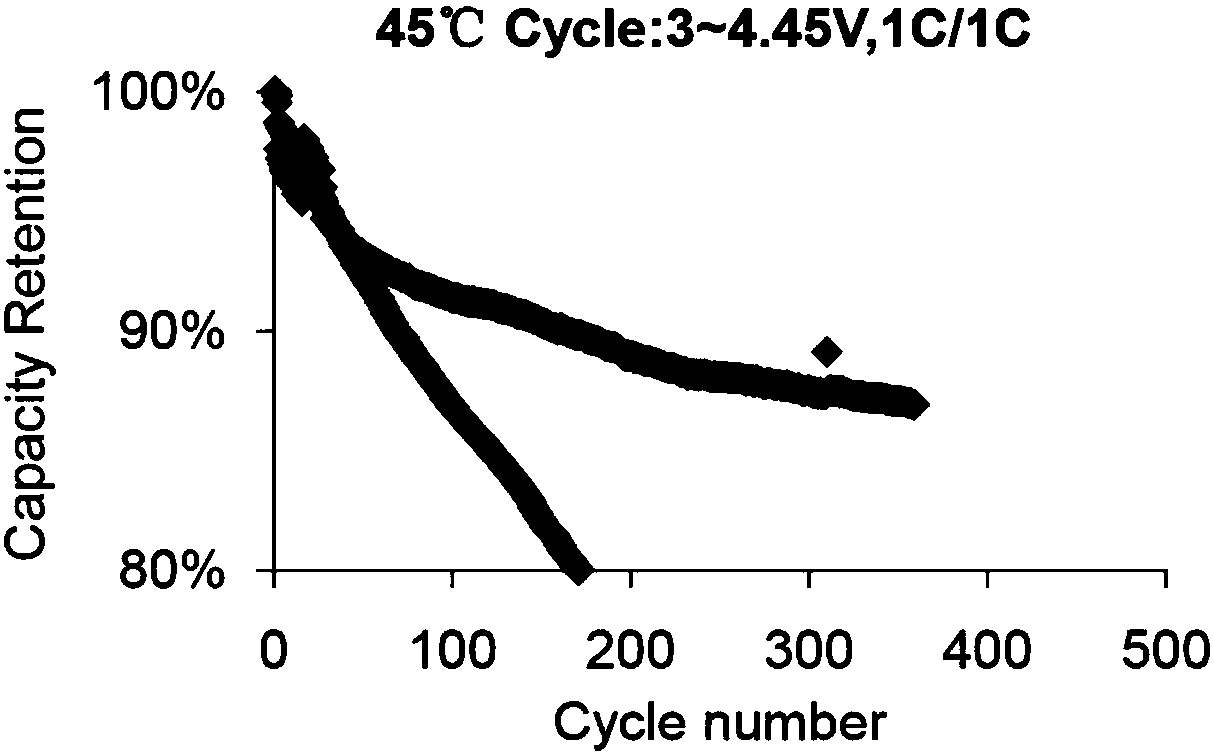

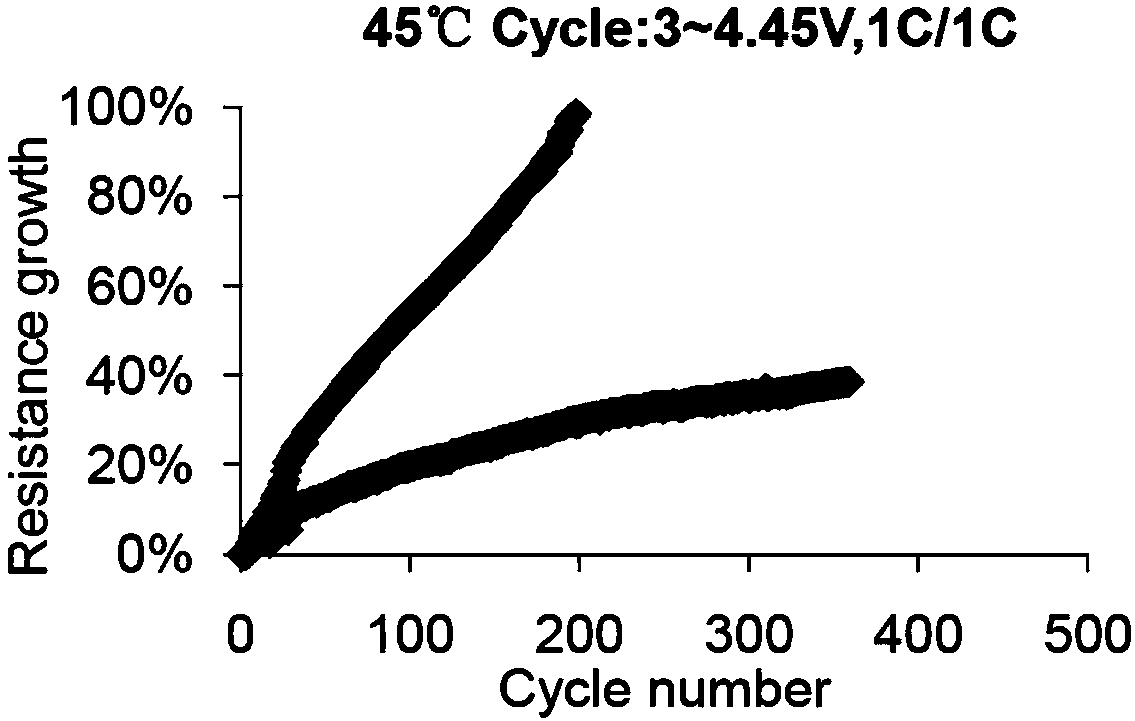

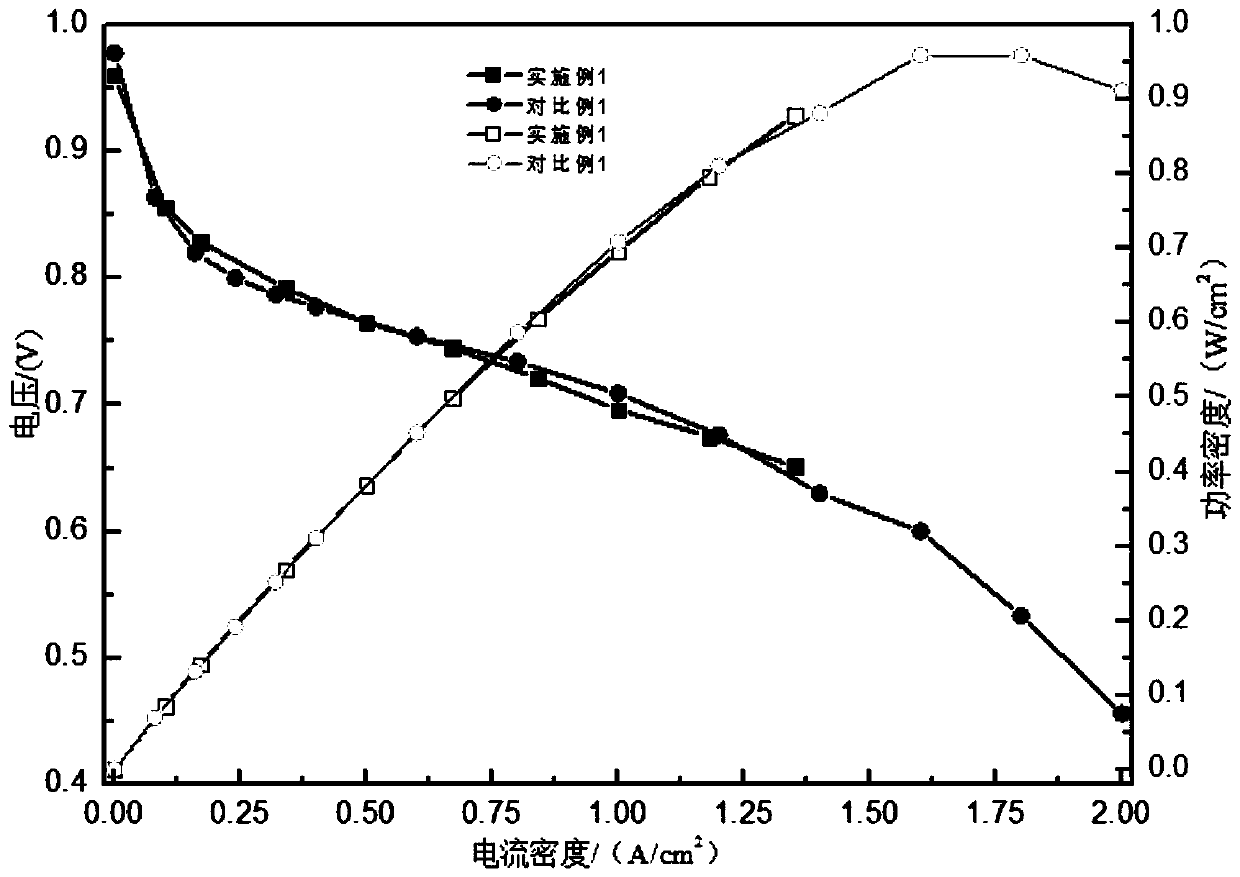

Low-platinum proton exchange membrane fuel cell membrane electrode and preparation method thereof

ActiveCN111584880AImprove adsorption capacityIncrease profitFinal product manufactureCell electrodesPlatinumPtru catalyst

The invention belongs to the technical field of fuel cells, and particularly relates to a low-platinum proton exchange membrane fuel cell membrane electrode and a preparation method thereof. The low-platinum proton exchange membrane fuel cell membrane electrode comprises catalyst layers coated on the two sides of a proton exchange membrane, each catalyst layer comprises a porous material and a catalyst filled in the porous material, and the catalyst is one or more of platinum-carbon catalysts with the platinum loading capacity of 40%-60%. The catalyst layer of the membrane electrode is prepared from the porous material and the catalyst filled in the porous material, the usage amount of platinum is reduced by adjusting the structure of the catalyst layer of the membrane electrode, the usageamount of platinum is reduced by adopting a partial structure ordering process and adjusting the structure of the catalyst layer of the membrane electrode, and the cost of the fuel cell is reduced. Compared with a traditional membrane electrode, the membrane electrode provided by the invention adopts a partially ordered structure, so that the catalyst utilization rate can be effectively improved,the catalyst loading capacity is reduced, the membrane electrode swelling problem is solved, amplification is easy, and batch production is facilitated.

Owner:WUXI WEIFU HIGH TECH CO LTD

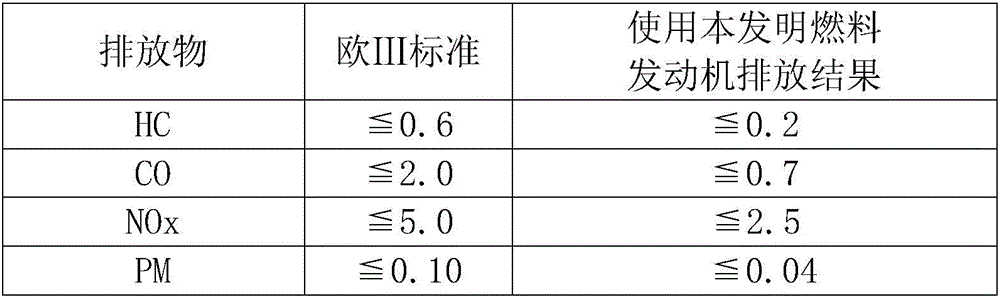

Methanol diesel fuel and preparation method thereof

ActiveCN101705116AUniform shapeHomogeneous shape stable periodLiquid carbonaceous fuelsParticulatesTO-18

The invention discloses methanol diesel fuel, which is prepared from the following raw materials in part by volume: 50 to 80 parts of diesel, 15 to 40 parts of methanol, 6 to 18 parts of surfactant, 3 to 12 parts of cosolvent, 2 to 8 parts of corrosion inhibitor and 1 to 4 parts of cetane improver. The invention also discloses a preparation method for the methanol diesel fuel. The product has good intersolubility stability, can be stored for more than six months stably and cannot demix at normal temperature and normal pressure, solves the problems of corrosion and swelling of metal parts and rubber and plastic pieces, and prolongs the service life of machines; after the methanol diesel fuel is burned, waste gas and particles are greatly reduced; and the methanol diesel fuel can serve as clean energy to replace the conventional diesel, is directly used for civil use and industrial production, and has wide application prospect.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

Method of fixing glucose oxidase by organic modification sol-gel

InactiveCN101054574AImprove adhesionSolve the swelling problemOxidoreductasesOn/in organic carrierWater bathsPolyvinyl alcohol

The present invention provides a method for fixing glucose oxidase using organic modified sol- gelatin. Mixing evenly of oxygen radix silane and dimethyl dimethoxy silane, adding HCl aqueous solution of same volume with tetramethyl silane, placing mixing liquor in bottle, covering with lid mounted with a hole, stirring in water bath, placing for 3-5min, reserving gel liquor, mixing prepared gel and polyvinyl alcohol water solution, placing for 3-5min, taking upper clear solution after lamination and mixing with phosphate buffer dissolved with glucose oxidase, applying it on surface of matrix, drying for molding. The invention successfully solves the problem of swelling property derived from using individual PVA embedment. The glucose oxidase is embedded in porous matrix hybridized by gel solution and PVA so it is not easy to be lost and can be stored in a long-term and keeps the activity and stability.

Owner:FUZHOU UNIV

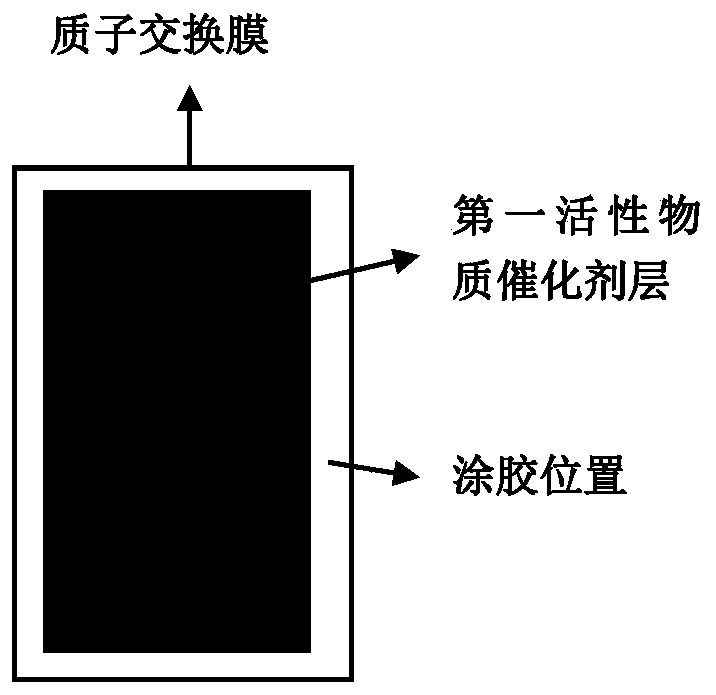

Method for preparing membrane electrode by direct coating method, and membrane electrode prepared by method

The invention relates to a method for preparing a membrane electrode by a direct coating method, and the membrane electrode prepared by the method. The method comprises the steps of (1) bonding a protective membrane on one side of a proton exchange membrane with a first active substance catalyst layer; (2) vacuumizing an interlayer gap between the first active substance catalyst layer and the protective membrane in the step (1); and (3) preparing a second active material catalyst layer on the other side of the proton exchange membrane. When the second active material catalyst layer is prepared, the protective membrane is bonded to one side of the proton exchange membrane with the first active material catalyst layer, and the protective membrane and the proton exchange membrane have an acting force by vacuumizing, so that the phenomenon of membrane swelling can be effectively prevented.

Owner:SUZHOU HYDROGINE POWER TECH CO LTD

High-performance lithium battery electrolyte

ActiveCN107946643AImprove low temperature performanceImprove solubilitySecondary cells servicing/maintenanceBenzeneOrganic solvent

A high-performance lithium battery electrolyte belongs to the technical field of lithium battery electrolytes. The high-performance lithium battery electrolyte comprises a lithium salt and an organicsolvent and also comprises a compound shown in the specification and / or a compound shown in the specification, wherein R1 is selected from alkyl, H or F, and R2 is selected from allyl, propargyl or benzene. Due to the addition of the substance in the battery electrolyte, the charge-discharge performance of a lithium battery can be effectively improved, side reaction is reduced, so that battery swelling is reduced, and the cycle lifetime of the battery is prolonged.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

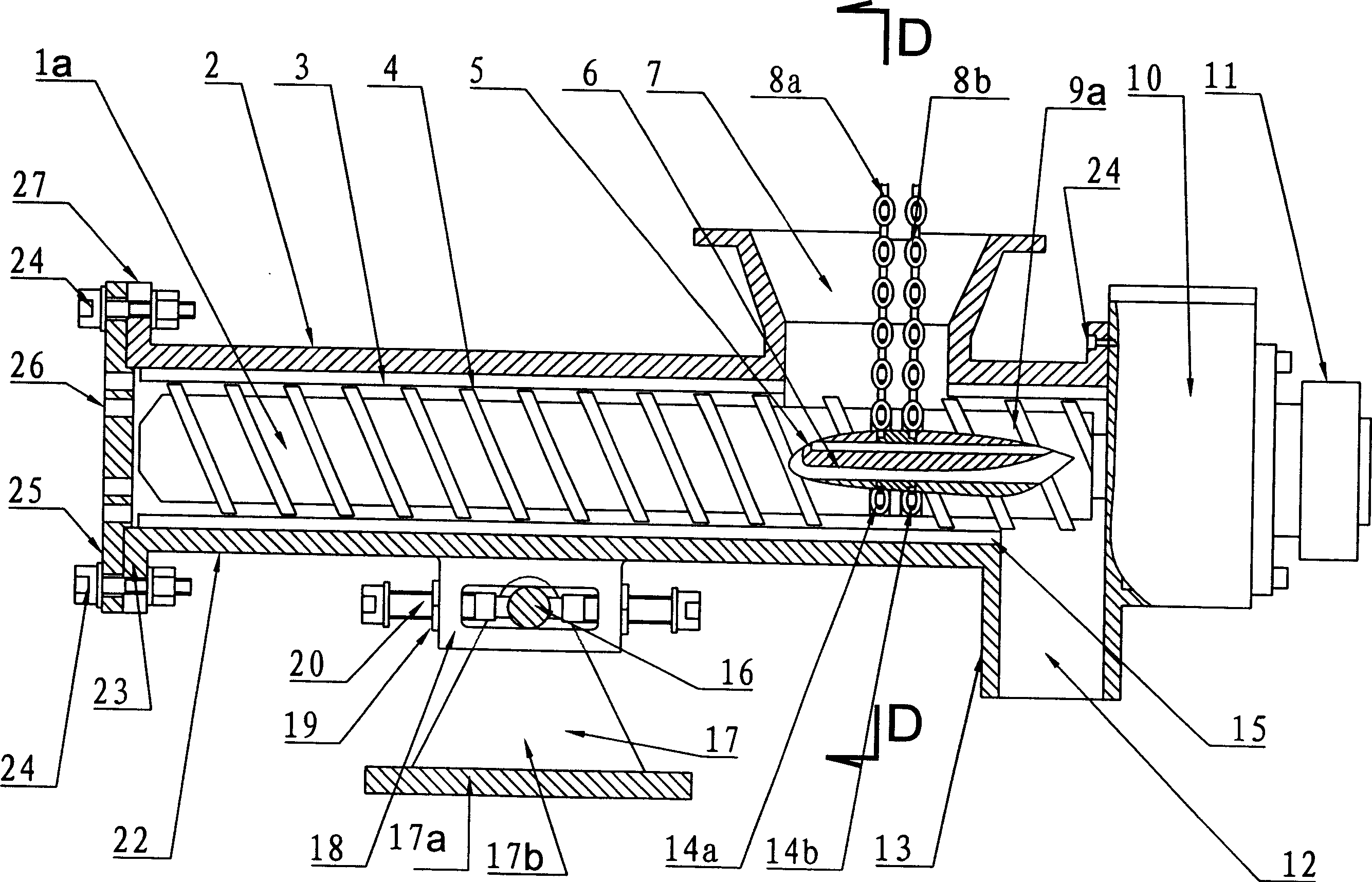

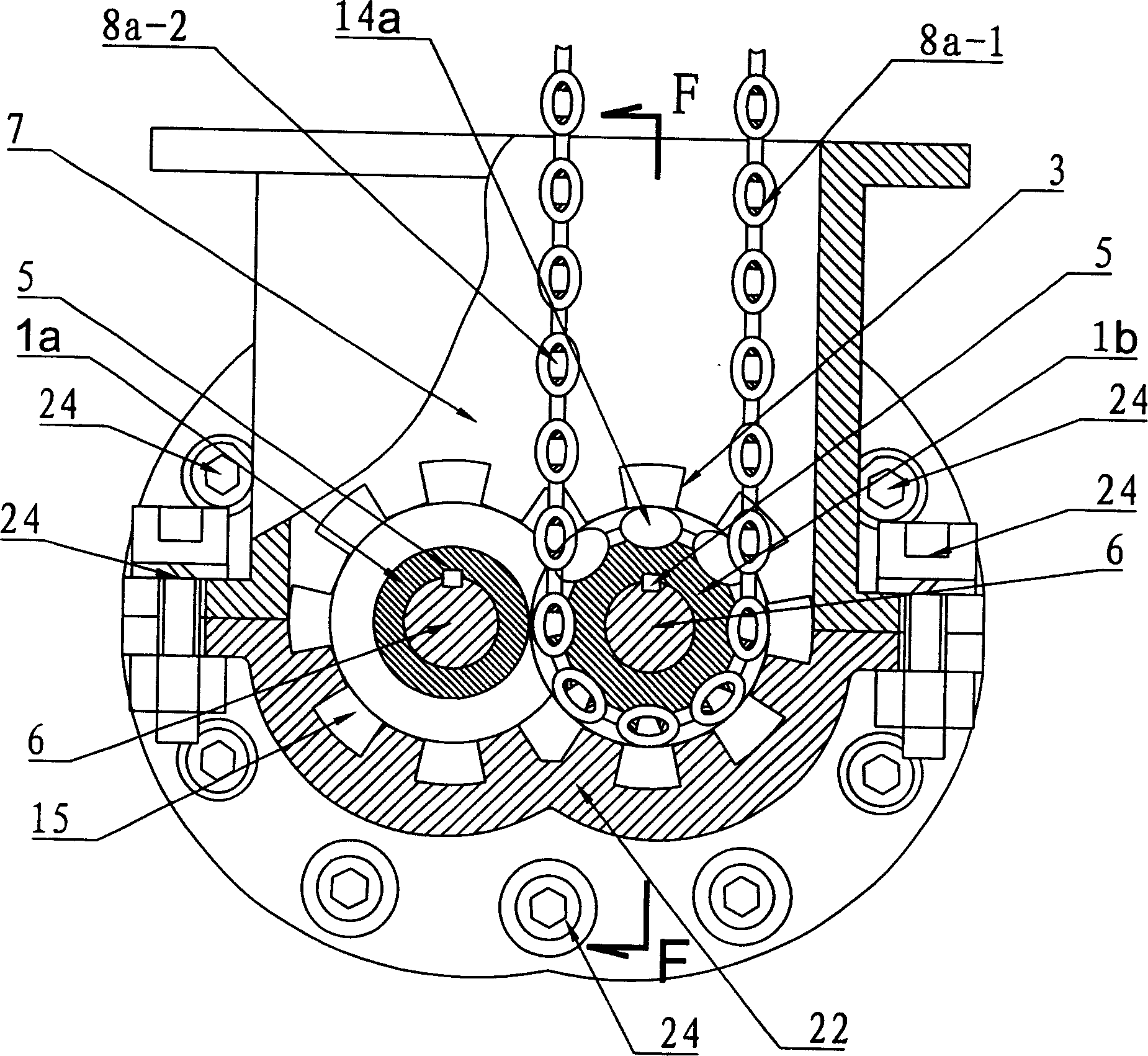

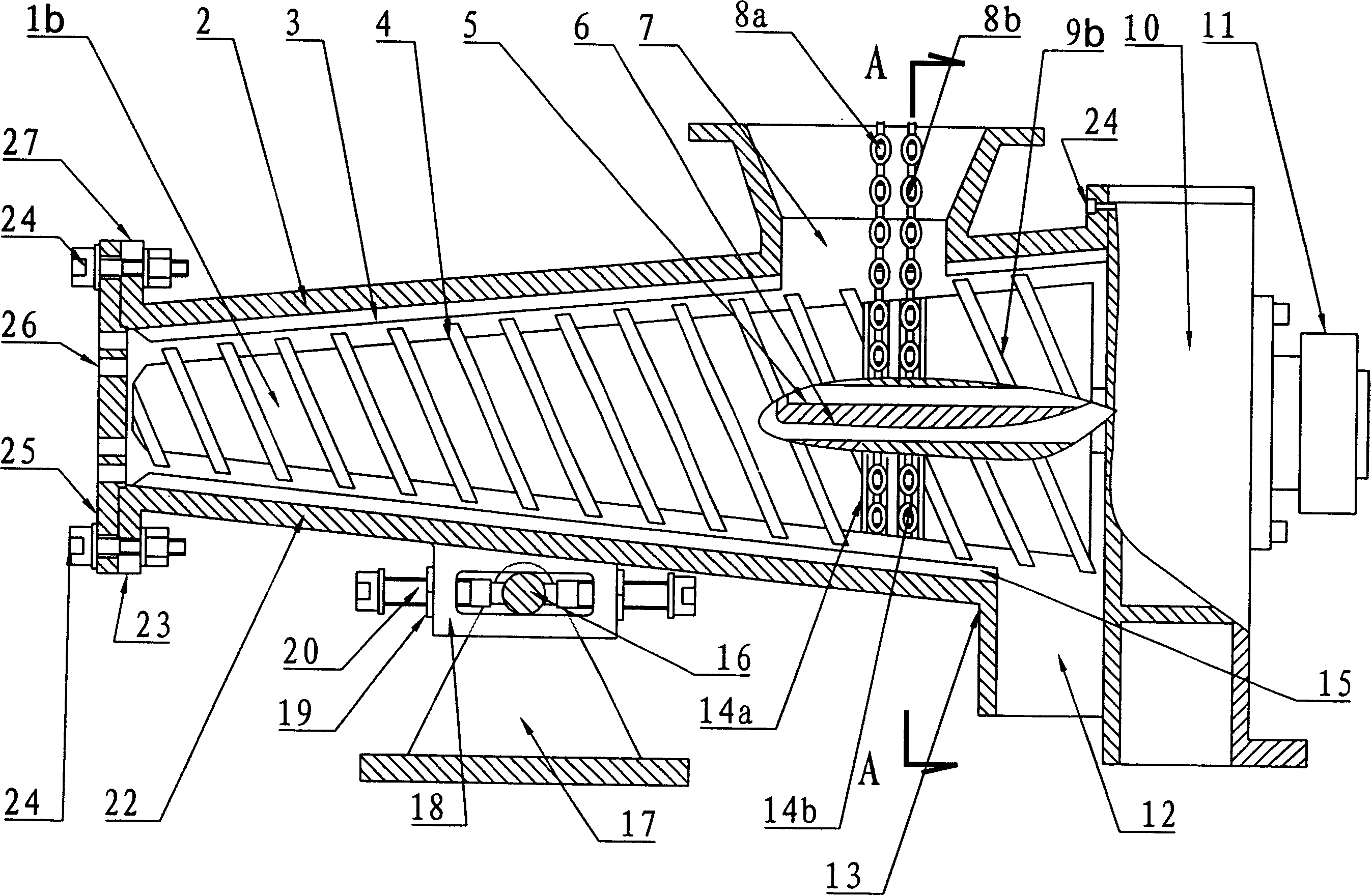

Vibration chain type feeding screw rod kneading extruder

Owner:天津市石化通用机械研究所有限公司

Vehicular methanol petrol

Owner:CRPC INNOVATION ENERGY

Liquid fuel additive

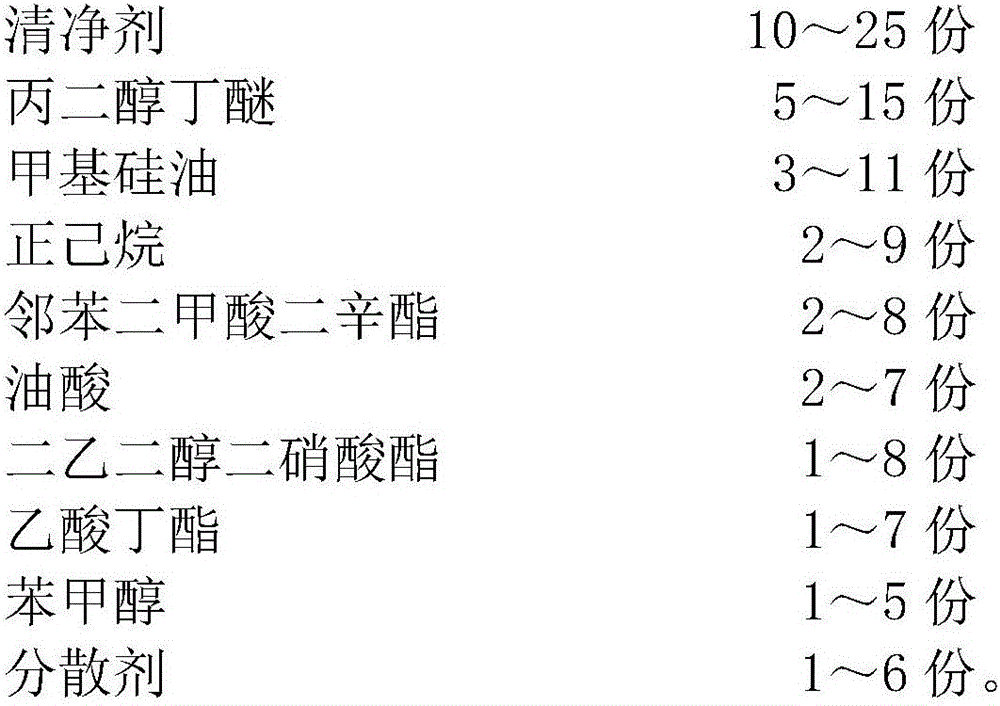

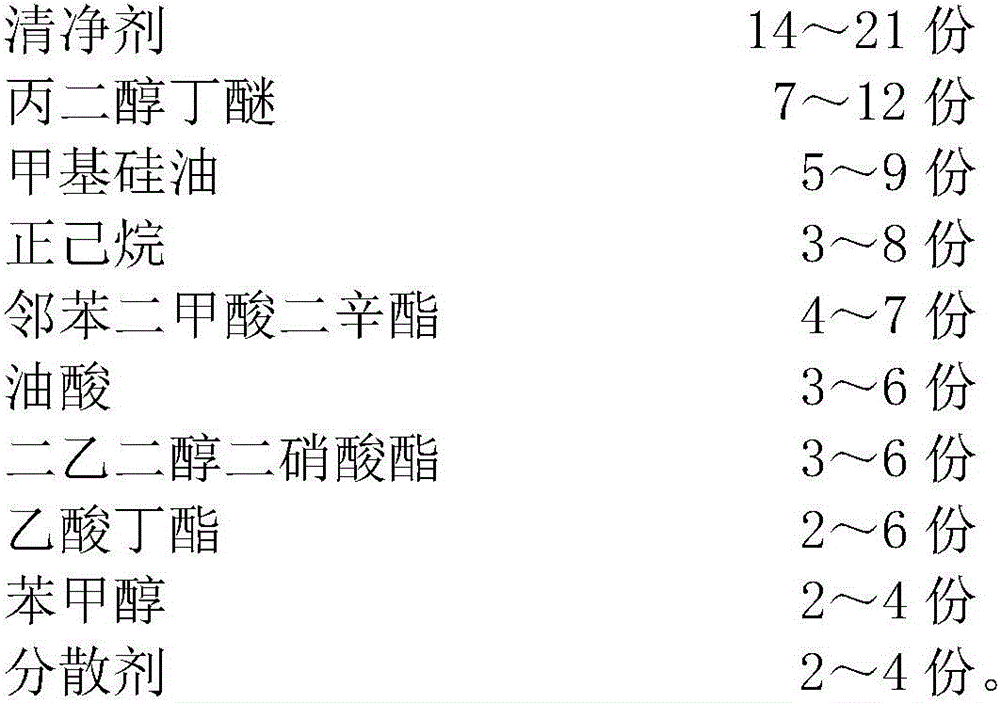

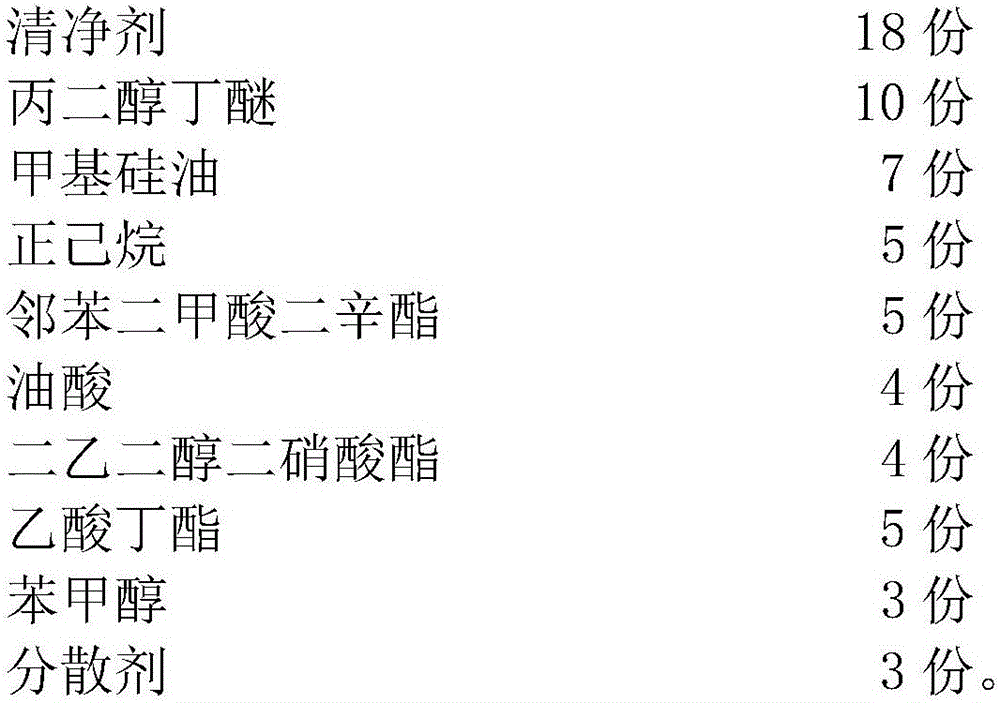

InactiveCN106190363AReduce carbon depositionReduce combustionLiquid carbonaceous fuelsChemistryBENZYL ALCOHOL/WATER

The invention belongs to the technical field of fuel additives and particularly relates to a liquid fuel additive. The additive is prepared from, by weight, 10-25 parts of cleaning agent, 5-15 parts of propanediol butyl ether, 3-11 parts of methylsilicone oil, 2-9 parts of n-hexane, 2-8 parts of dioctyl phthalate, 2-7 parts of methyl cyclopentadiene, 1-8 parts of diethylene glycol dinitrate, 1-7 parts of butyl acetate, 1-5 parts of benzyl alcohol and 1-6 parts of dispersion agent. The liquid fuel additive effectively improves the power and the cetane number of fuel, improves diesel storage stability, improves combustion performance and combustion efficiency of fuel, and achieves energy conservation and emission reduction.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Preparation method of composite proton exchange membrane for fuel cell

ActiveCN114006018AEvenly distributedImprove adhesionFinal product manufactureFuel cellsPtru catalystActive agent

The invention discloses a preparation method of a composite proton exchange membrane for a fuel cell, and belongs to the technical field of fuel cells. The preparation method comprises the steps of performing H < + > conversion treatment on F < + > type perfluorinated sulfonic acid resin particles to convert the F < + > type perfluorinated sulfonic acid resin particles into H < + > type perfluorinated sulfonic acid resin, dissolving the H < + > type perfluorinated sulfonic acid resin, and adding water and a high-boiling-point solvent to prepare a perfluorinated sulfonic acid resin solution; adding water, a high-boiling-point solvent, a surfactant and a catalyst Pt40 / C60 into part of the perfluorinated sulfonic acid resin solution, and performing ultrasonic dispersion to obtain catalyst slurry; coating the surface of a base material with the perfluorinated sulfonic acid resin solution, and pre-drying at 50-80 DEG C to obtain a viscoelastic proton exchange membrane; and coating the surface of the viscoelastic proton exchange membrane with the catalyst slurry, and carrying out primary drying and secondary drying to obtain the composite proton exchange membrane. According to the preparation method disclosed by the invention, the catalyst can be uniformly distributed on the surface of the proton exchange membrane, the adhesive force of catalyst particles on the proton exchange membrane is effectively improved, and the thickness uniformity is improved.

Owner:长园泽晖新能源材料研究院(珠海)有限公司

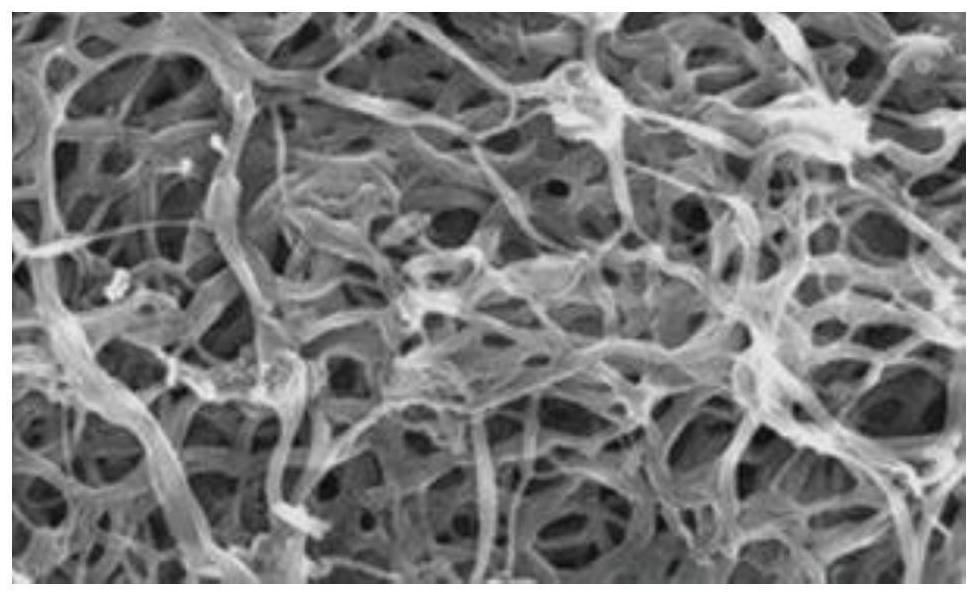

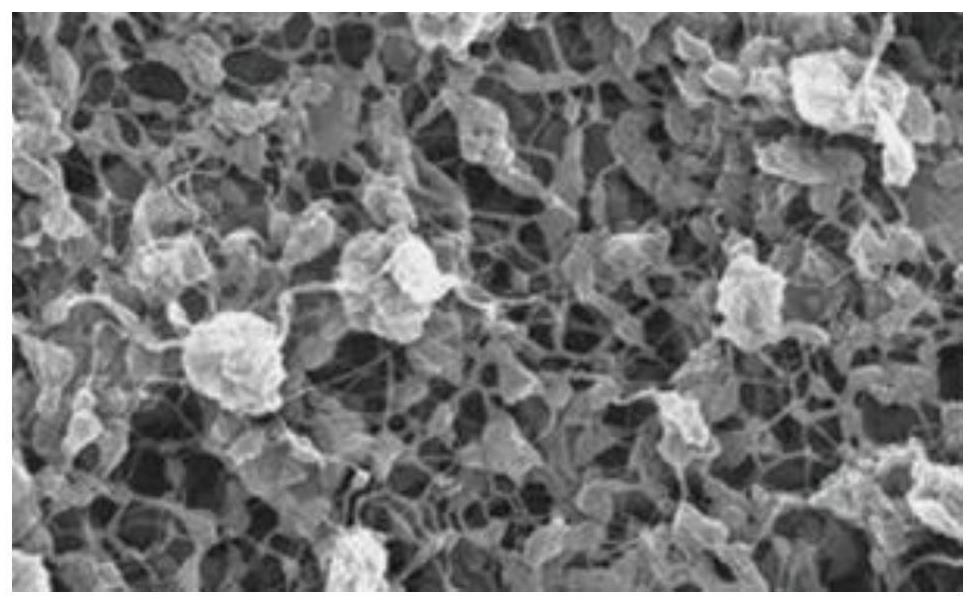

Preparation method of functional chitosan, polyvinyl alcohol and polycaprolactam composite nanofibrous membrane

ActiveCN107904782ALow priceImprove spinnabilityArtificial thread manufacturing machinesElectro-spinningMetal ion adsorptionChemistry

The invention discloses a preparation method of a functional chitosan, polyvinyl alcohol and polycaprolactam composite nanofibrous membrane and relates to the field of composite nanofibrous membranes.The preparation method comprises the following steps that firstly chitosan, polyvinyl alcohol and polycaprolactam are sliced and dried, and then chitosan and polyvinyl alcohol are dissolved in aceticacid to prepare a chitosan and polyvinyl alcohol composite spinning solution; polyvinyl alcohol and polycaprolactam are dissolved in formic acid to prepare a polyvinyl alcohol and polycaprolactam composite spinning solution, finally the two composite spinning solutions are subjected to high-pressure electrostatic spinning at the same time, composite fiber sediment is received, and the functionalchitosan, polyvinyl alcohol and polycaprolactam composite nanofibrous membrane is obtained. The prepared functional chitosan, polyvinyl alcohol and polycaprolactam composite nanofibrous membrane has good adsorption effect on heavy metal and is mainly applied to fields such as macromolecule filtering, enzyme immobilization and metal ion adsorption.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Multifunctional methanol fuel

InactiveCN106433820AHas anti-knock effectBoost octaneLiquid carbonaceous fuelsFuel additivesDetonationPolyvinyl alcohol

The invention belongs to the technical field of fuels and particularly relates to a multifunctional methanol fuel, prepared from, by weight, 60-90 parts of methanol, 20-44 parts of gasoline, 1-7 parts of 3-tert-butyl-4-hydroxyanisole, 0.5-2.3 parts of ethyl levulinate, 0.5-2.3 parts of 4-tert-butyl-2,6-diisopropylphenol, 0.4-2.2 parts of polyvinyl alcohol, 0.2-1.4 parts of dimethyl carbonate, 0.2-1.4 parts of a clearing agent, 0.1-1.3 parts of a corrosion inhibitor, 0.03-0.21 part of dicycloheptadiene, and 0.02-0.2 part of glyceryl monostearate. The multifunctional methanol fuel has the functions, such as clearing, anti-oxidation, combustion supporting, corrosion inhibition and detonation resisting, has good combustion performance, and can combust fully such that energy is saved and emission is reduced.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

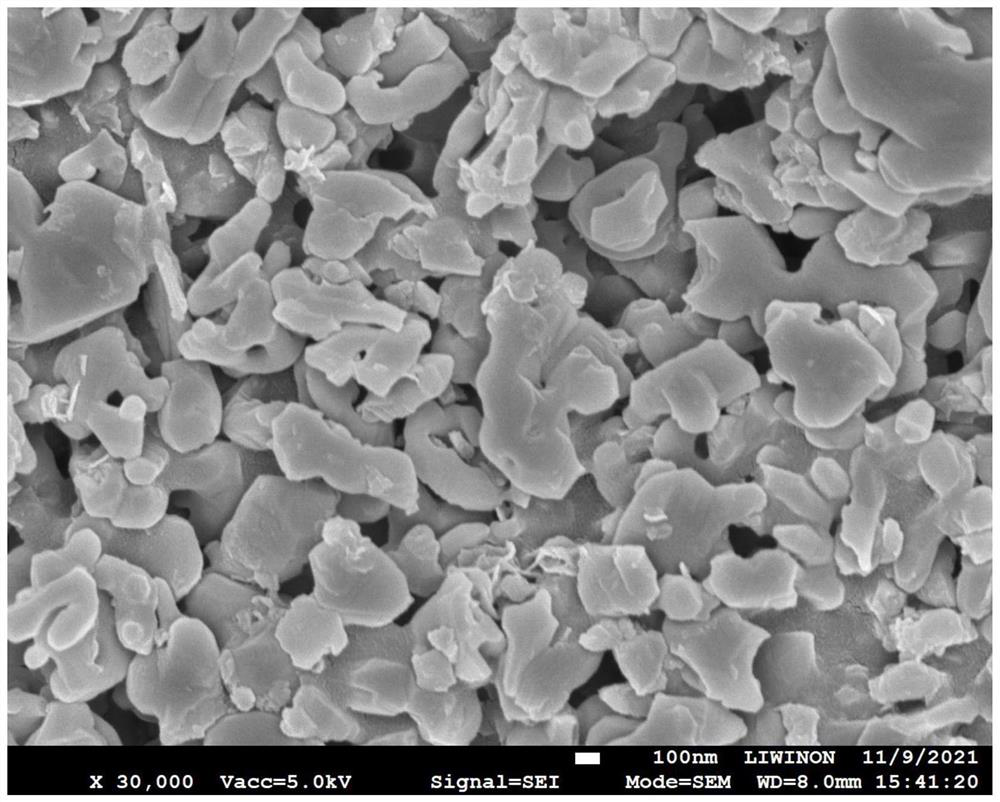

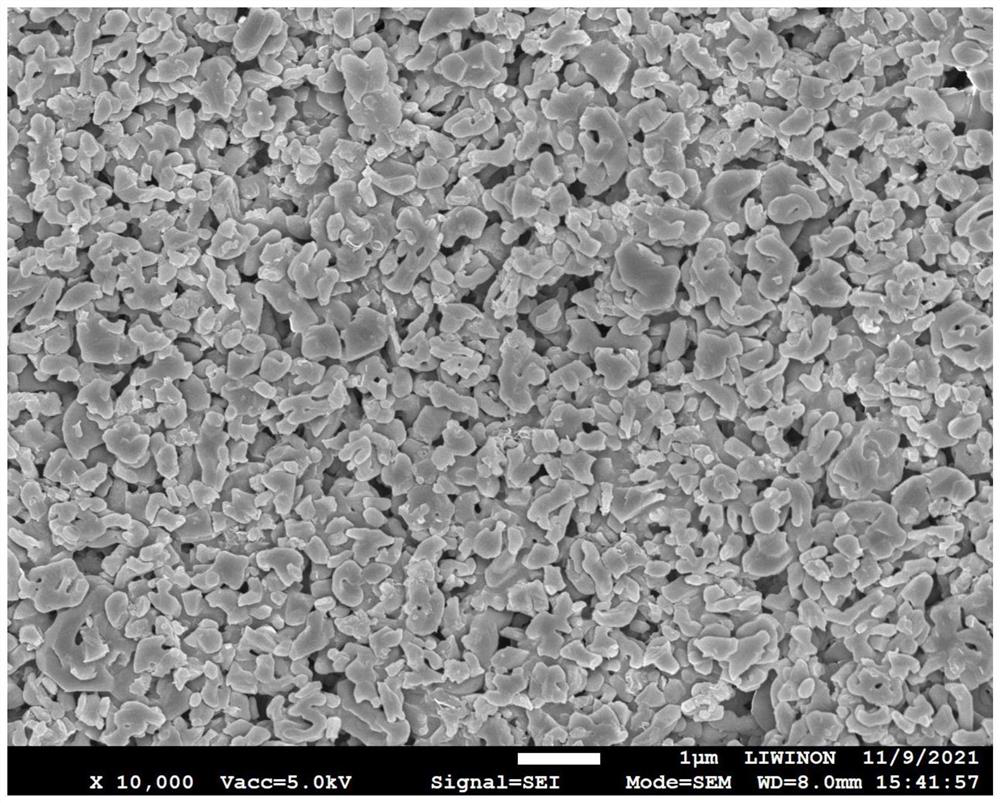

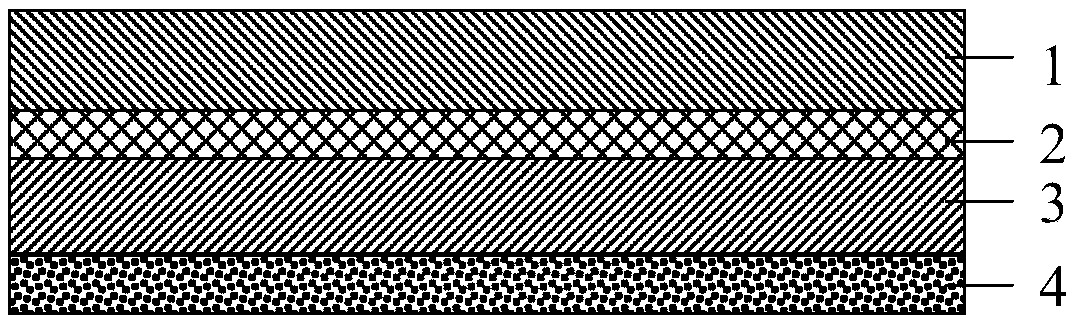

Diaphragm, preparation method thereof and secondary battery

PendingCN114520398AImprove heat resistanceImprove wettabilitySecondary cellsCell component detailsElectrolytic agentPolymer science

The invention belongs to the technical field of secondary batteries, and particularly relates to a diaphragm and a preparation method thereof and a secondary battery, and the preparation method of the diaphragm comprises the following steps: S1, mixing and dispersing a ceramic material, a dispersing agent, a wetting agent, a part of active diluting monomer and a cross-linking agent to obtain ceramic slurry; s2, mixing and dissolving an initiator and the residual active diluted monomer to obtain a mixed solution; s3, mixing the ceramic slurry with the mixed solution to obtain composite slurry; and S4, coating at least one surface of a base membrane with the composite slurry to obtain the diaphragm. The composite slurry contains the initiator, the active diluent monomer and the ceramic material, the active diluent monomer can be cured and crosslinked with the ceramic material to form a heat-resistant skeleton, the formed cured material cannot swell with an electrolyte, and the swelling problem of a polyacrylate binder used by a traditional diaphragm is solved.

Owner:HUIZHOU LIWINON ELECTRONIC TECH CO LTD

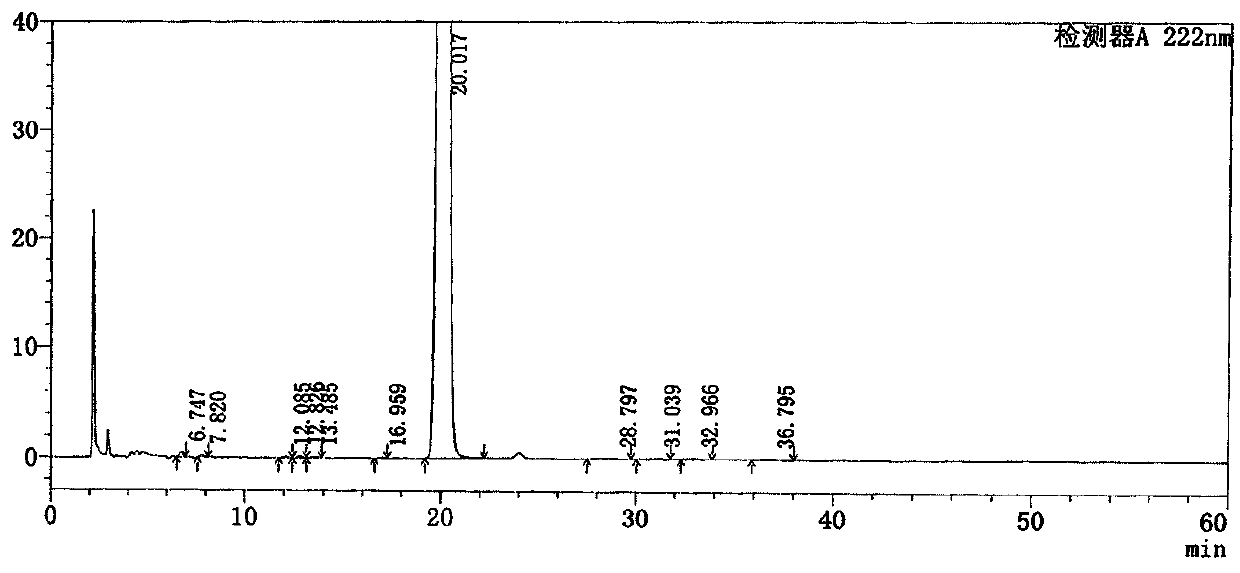

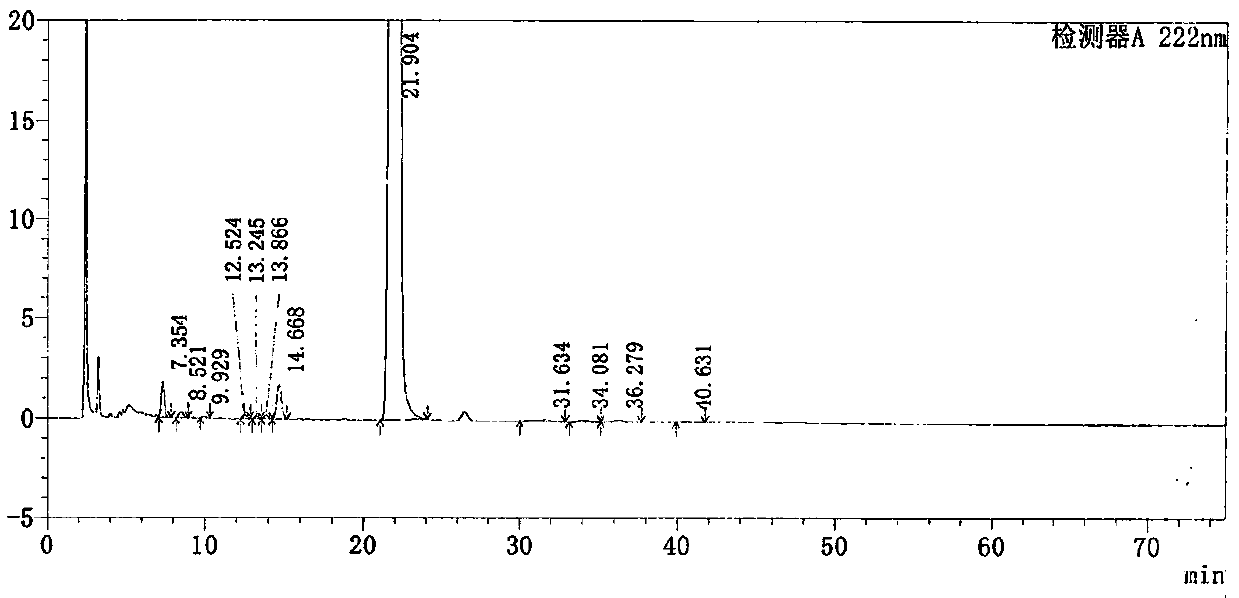

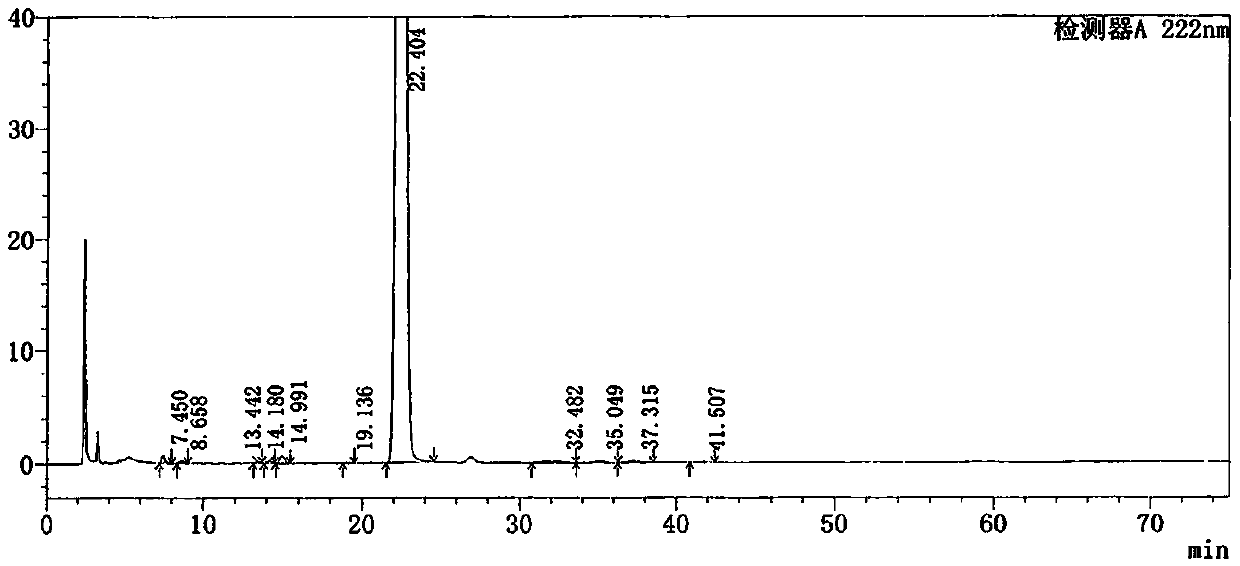

Method for separating related substances in loxoprofen or sodium salt thereof

ActiveCN110907583ASolve the swelling problemReduce experiment costComponent separationReversed-Phase Liquid ChromatographyBiochemistry

The invention discloses a method for separating related substances in loxoprofen or sodium salt thereof. According to the method, unique chromatographic conditions are used, and the related substancesin the loxoprofen sodium salt are successfully separated. According to the method, reversed-phase chromatography is used for detection, the peak shape is good, the degree of separation from adjacentchromatographic peaks is high, the research and development cost is saved, the experimental difficulty is reduced, and the reproducibility is good.

Owner:HUNAN JIUDIAN PHARMA

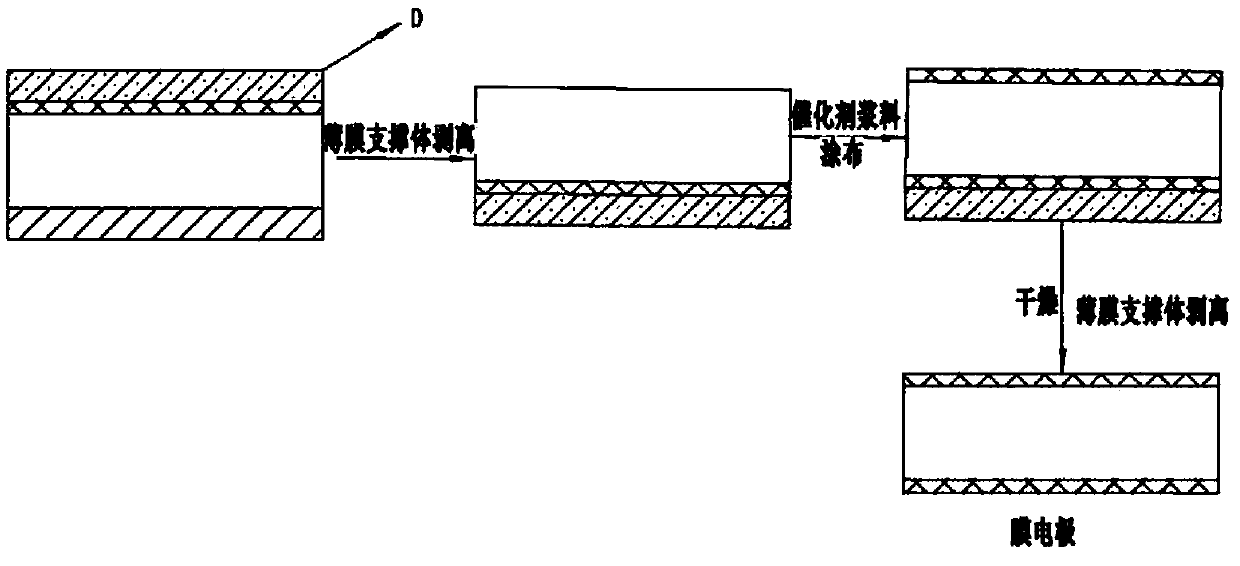

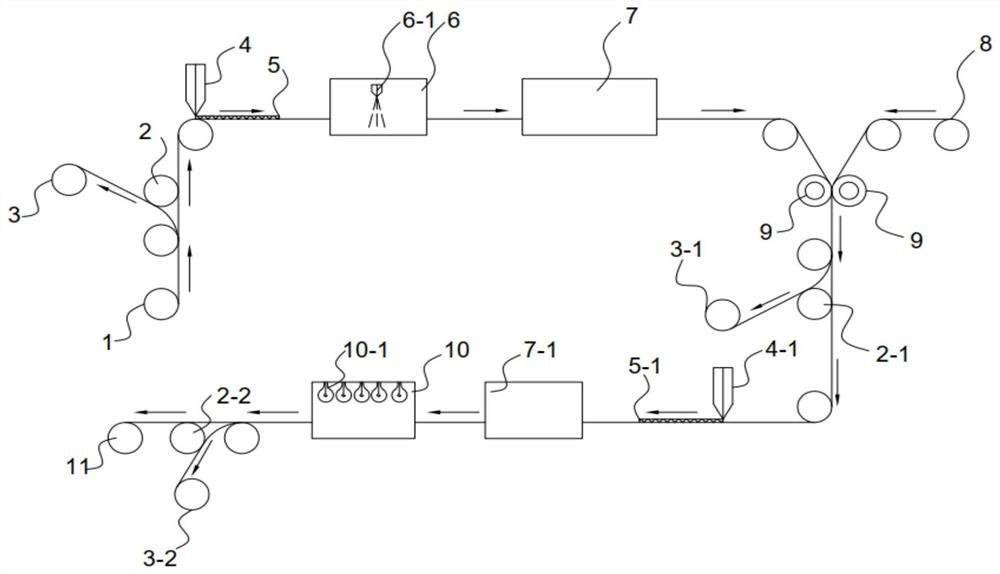

CCM coating process for realizing swelling resistance by using protective back film

ActiveCN112599793AEasy to makeReduce productionMaterial nanotechnologyCell electrodesPtru catalystPhysical chemistry

The invention discloses a CCM coating process for realizing swelling resistance by using a protective back film. The process comprises the following steps: coating a first surface of a proton exchangemembrane with a catalyst slurry, and performing drying to form a first catalyst layer; preparing a protective film with a flexible carrier layer, laminating a layer of protective film with the flexible carrier layer on the first surface of the proton exchange membrane containing the first catalyst layer, and laminating the protective film with the proton exchange membrane; coating the second surface of the proton exchange membrane with the catalyst slurry, and performing drying to form a second catalyst layer, so as to obtain a membrane electrode with a temporary protective membrane; finally,carrying out heat treatment or ultraviolet (UV) irradiation on the membrane electrode with the temporary protective film, and stripping the temporary protective layer to obtain the membrane electrode; and if heat treatment is selected, spraying a nano oxide solution on the surface of the first catalyst layer before the first catalyst layer is dried. In the membrane electrode preparation process,the swelling of the proton exchange membrane is effectively avoided, the preparation process is simple, the production efficiency is high, and the battery performance is excellent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Release film for circuit board

ActiveCN109435390AStable hot meltImprove sealingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAcrylic resinPolyvinyl alcohol

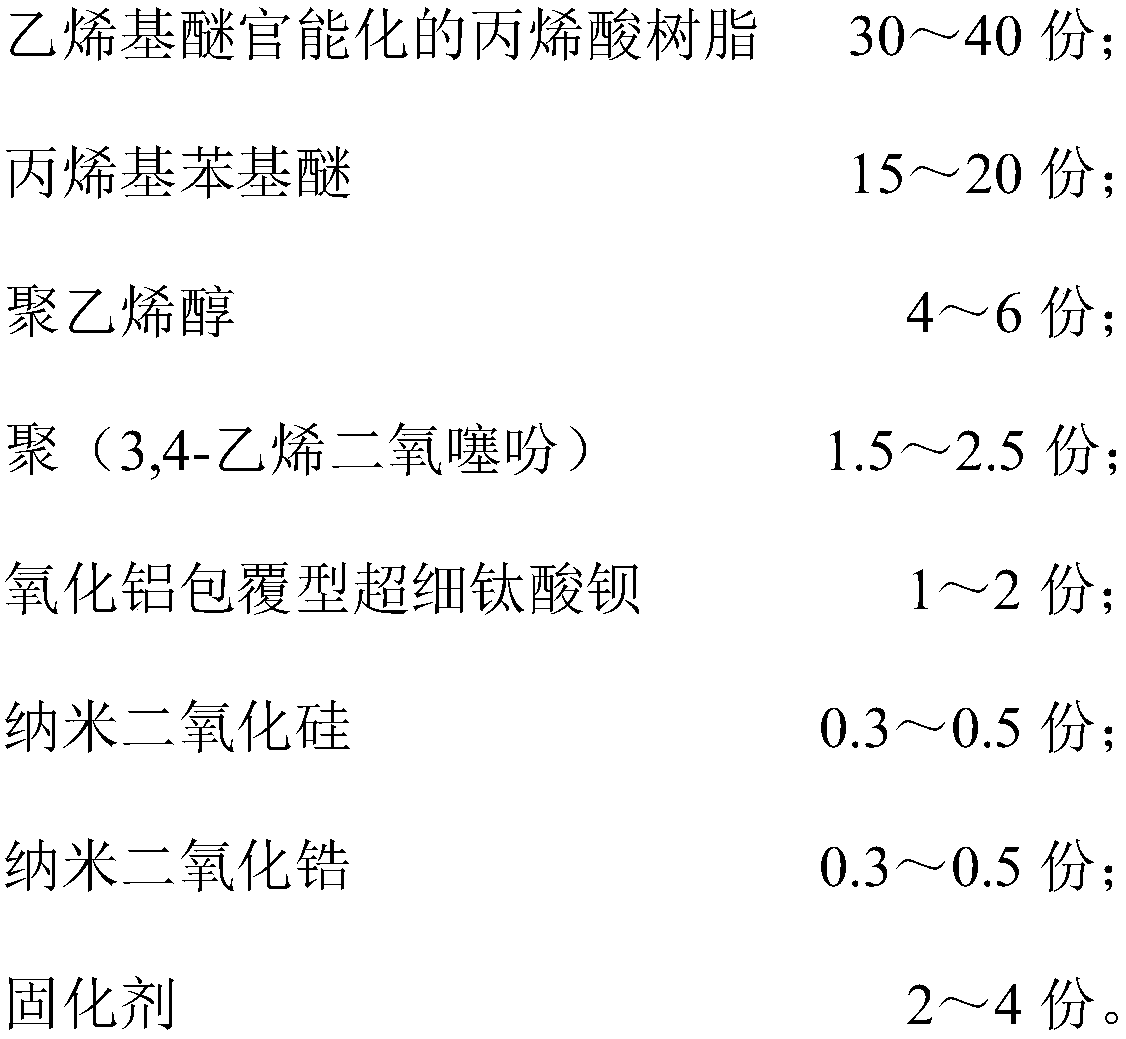

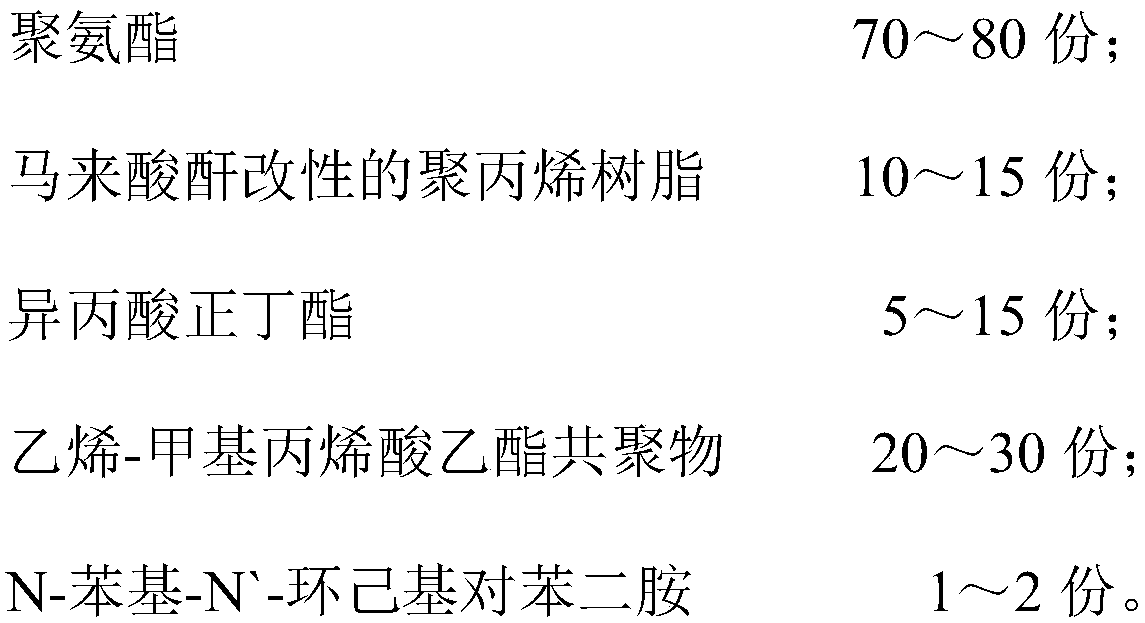

The invention belongs to the technical field of electronic materials, and particularly relates to a release film for a circuit board. The release film comprises a supporting layer, an adhesive layer,an aluminum foil layer and a release heat sealing layer. The release heat sealing layer comprises vinyl functionalized acrylic resin, allyl phenyl ether, polyvinyl alcohol, poly(3, 4-ethylene dioxythiophene), alumina coated superfine barium titanium, nano silicon dioxide, nano zirconium dioxide and curing agent. The release film has stable hot melting performance within a wide temperature range, thereby having high sealability with the circuit board; adhesion strength of the release heat sealing layer to the aluminum foil layer is higher than that of the same to the circuit board, so that stripping of the release heat sealing layer from the circuit board is facilitated, the release heat sealing layer cannot be transferred onto a circuit board material when being torn off, and appearance uniformity of the circuit board is ensured.

Owner:浙江海顺新材料有限公司 +1

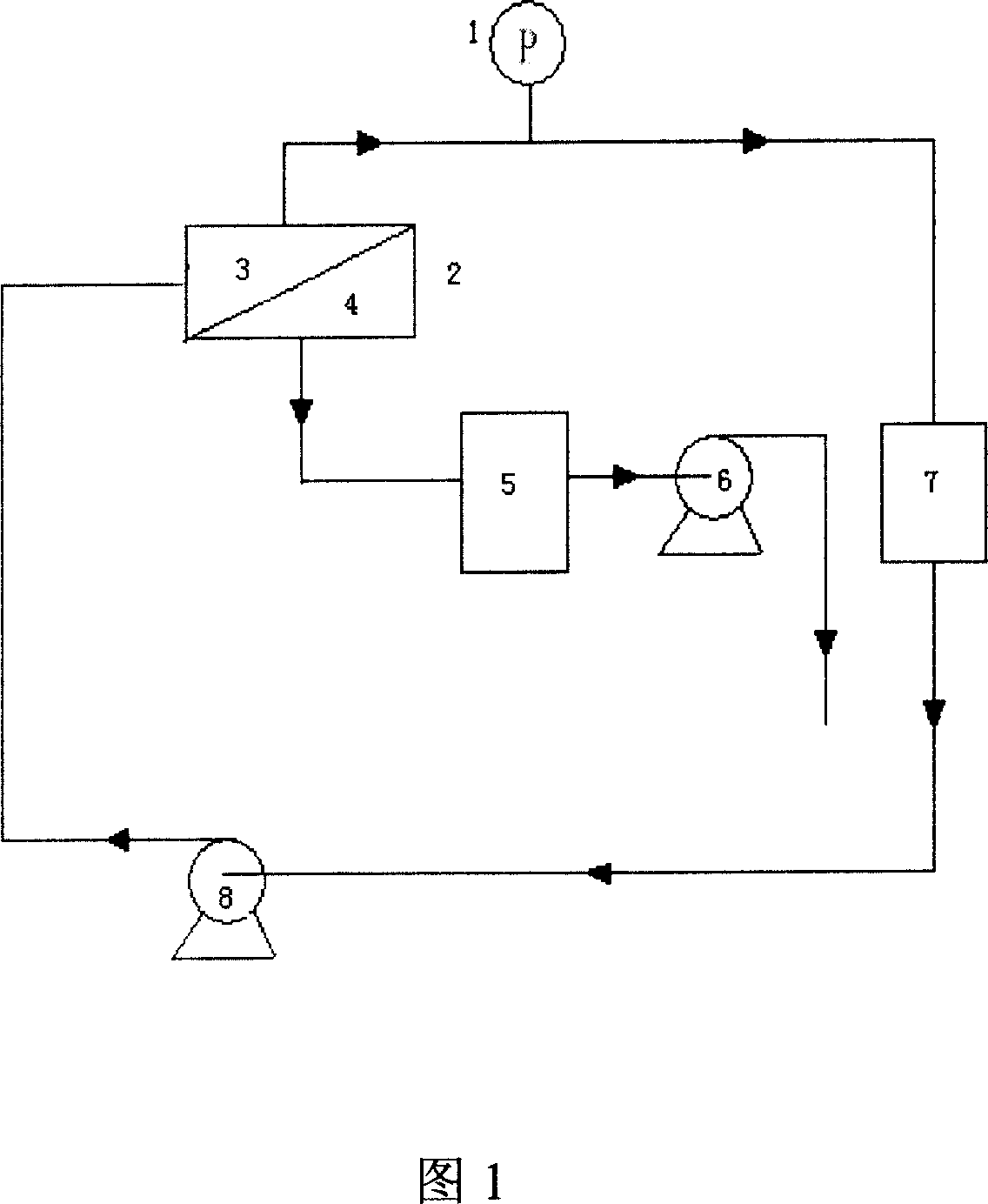

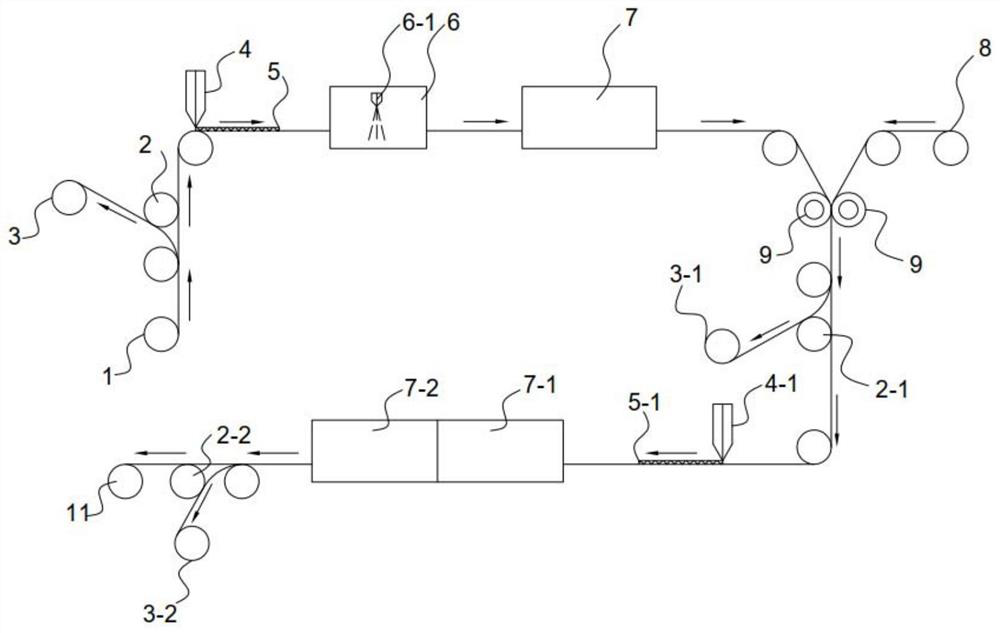

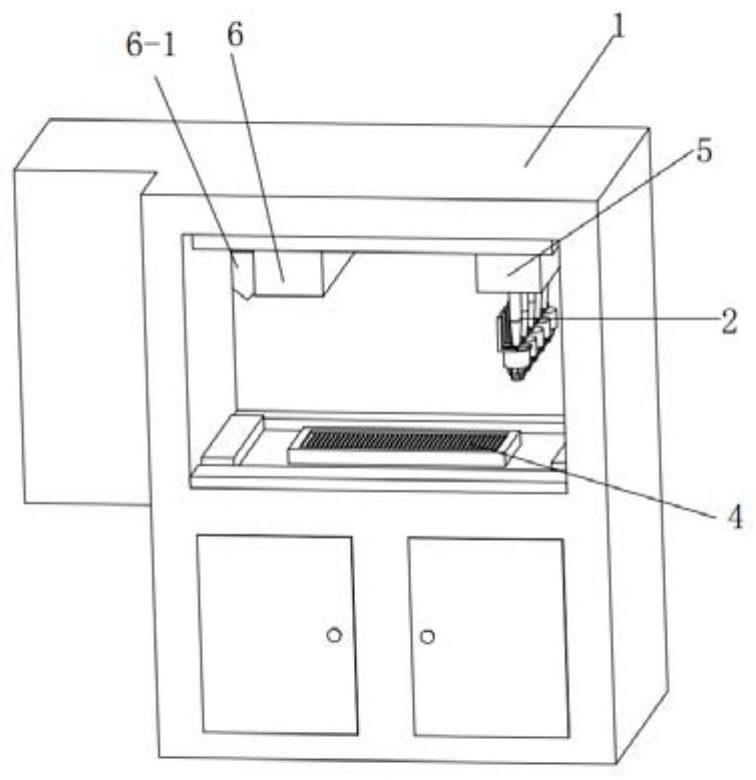

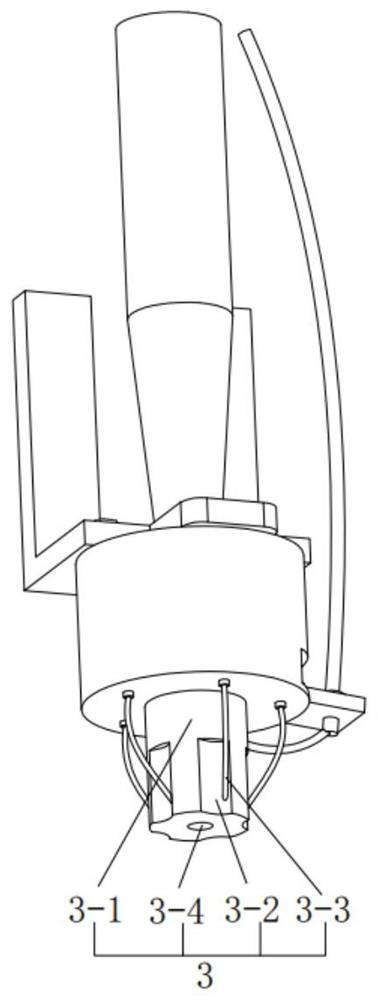

Proton membrane for PEM water electrolysis and CCM integrated preparation process and equipment

ActiveCN114196965AShort manufacturing timeIncrease productivityCellsLiquid spraying plantsPtru catalystElectrolysed water

The invention discloses a PEM water electrolysis proton membrane and CCM integrated preparation process and equipment, the equipment adopts a combination of multiple nozzles and a slit type coating head, the multiple nozzles can independently spray different components of a catalyst layer multi-component composite slurry within an ultra-short time, the spraying rate and atomization degree of the different components are accurately controlled, and the production efficiency is improved. The problem of poor dispersibility of different catalysts and binders in the catalyst slurry in the same solution is solved; the preparation process comprises the following steps of: sequentially compounding the base membrane pretreatment layer, the catalyst layer 1, the functional layer 1, the composite reinforced membrane, the functional layer 2, the catalyst layer 2 and the like on the substrate to realize the integrated preparation of the PEM water electrolysis composite reinforced membrane and the CCM catalyst layer; and finally, the PEM membrane electrode has relatively low surface resistance, relatively high conductivity, mass transfer rate and chemical durability, so that the cost of PEM electrolyzed water is reduced, and the service life is prolonged.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

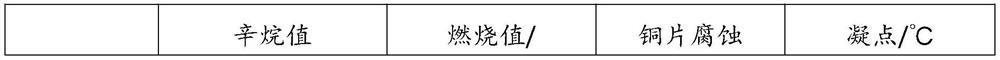

High-combustion-value alcohol-based fuel for vehicles

PendingCN113355139AImprove storage stabilityInhibit corrosionLiquid carbonaceous fuelsFuel additivesMethacrylamideAutomotive engineering

The invention relates to the technical field of vehicle fuels, in particular to a high-combustion-value alcohol-based fuel for vehicles. The invention provides a high-combustion-value alcohol-based fuel for vehicles, which is prepared from the following components in parts by mass: 15-30 parts of monohydric alcohol, 35-56 parts of a hydrocarbon compound, 25-35 parts of xylene, 0.03-0.15 parts of methacrylamide, 0.01-0.12 parts of 4-tert-butyl-2, 6-diisopropyl phenol and 0.04-0.28 parts of a combustion improver. The combustion improver comprises isooctane, diisopropyl ether and dimethyl ether. The high-combustion-value alcohol-based fuel for vehicles can overcome the problem of low calorific value, and also has the characteristics of oxidation resistance, corrosion resistance, swelling resistance, stable performance and the like.

Owner:东奇能源技术有限公司

Efficient and energy-saving vehicle fuel

InactiveCN106367136AHas a cleansing effectEffective carbon depositionLiquid carbonaceous fuelsFuel additivesDiisononyl adipateHexamethylenetetramine

The invention belongs to the technical field of fuel and particularly relates to an efficient and energy-saving vehicle fuel. The efficient and energy-saving vehicle fuel is prepared from, by weight, 62-86 parts of methanol, 12-24 parts of gasoline, 0.6-1.8 part of hexamethylenetetramine, 0.5-1.7 parts of methyl acrylamide, 0.4-1.6 parts of 2-tertiary butyl hydroquinone, 0.3-0.9 part of ferrocene, 0.1-0.7 part of benzotriazole, 0.01-0.07 part of diisononyl adipate, 0.03-0.15 part of glycerol monostearate and 0.1-1.3 parts of anti-explosion agent. The efficient and energy-saving vehicle fuel has anti-explosion, combustion-supporting, corrosion resistance, oxidation resistance and cleaning effect, is full to burn, high in thermal efficiency and efficient achieves energy saving and emission reduction.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

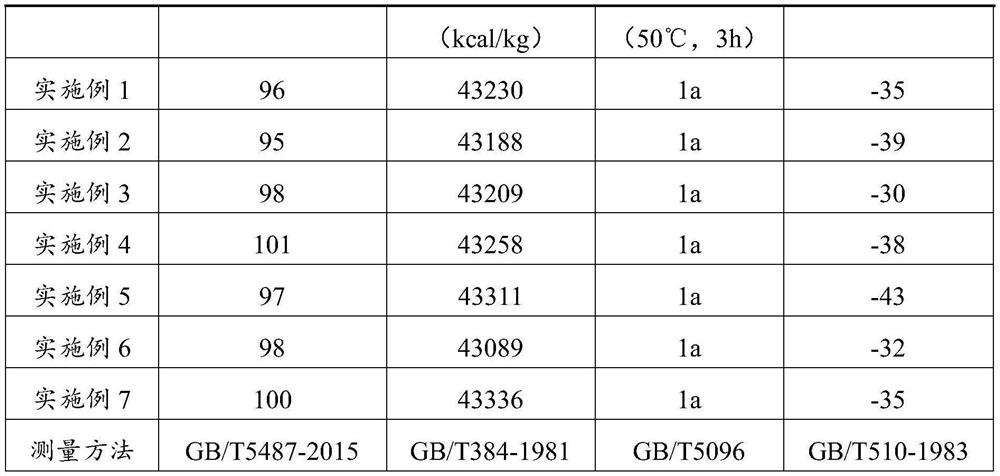

Novel environment-friendly high-energy alcohol-based industrial fuel and preparation method thereof

InactiveCN103232868ASolve corrosiveSolve the swelling problemLiquid carbonaceous fuelsLiquid gasMethanol

The invention relates to a novel environment-friendly high-energy alcohol-based industrial fuel and a prepration method thereof. The industrial fuel consists of the following components by weight percent: 65 to 70 percent of methanol; 10 to 15 percent of sugar pressing waste liquor; 5 to 8 percent of rosin water; 1 to 3 percent of hydrogen peroxide with the mass concentration of 27.5 percent; 1.5 to 3 percent of dimethylbenzene; 1 to 3 percent of phytate; 1.5 to 2 percent of benzotriazole; 3 to 5 percent of acetone; 0.01 to 0.05 percent of ferrocene; 0.1 to 0.5 percent of lavender oil; and 1.5 to 2 percent of rubber swelling inhibitor. The fuel is a renewable energy and can completely substitute the diesel, natural gas, liquefied gas, coal and electicity in the field of the industrial thermal burning, the raw materials can be widely sourced, and the price is low. Not only can the high efficiency and environmental protection be realized, but also safety, energy conservation and stable performance can be realized, the difficulty that the industrial energy is in short and has high pollution and high cost can be effectively solved, and the important social and economic benefit can be achieved.

Owner:深圳源圭能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com