Preparation method of functional chitosan, polyvinyl alcohol and polycaprolactam composite nanofibrous membrane

A technology of composite nanofibers and polycaprolactam, which is used in fiber processing, complete sets of equipment for the production of artificial threads, non-woven fabrics, etc., can solve the problems of high hygroscopicity, poor water resistance, low thermal stability, etc. Overcome swelling, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

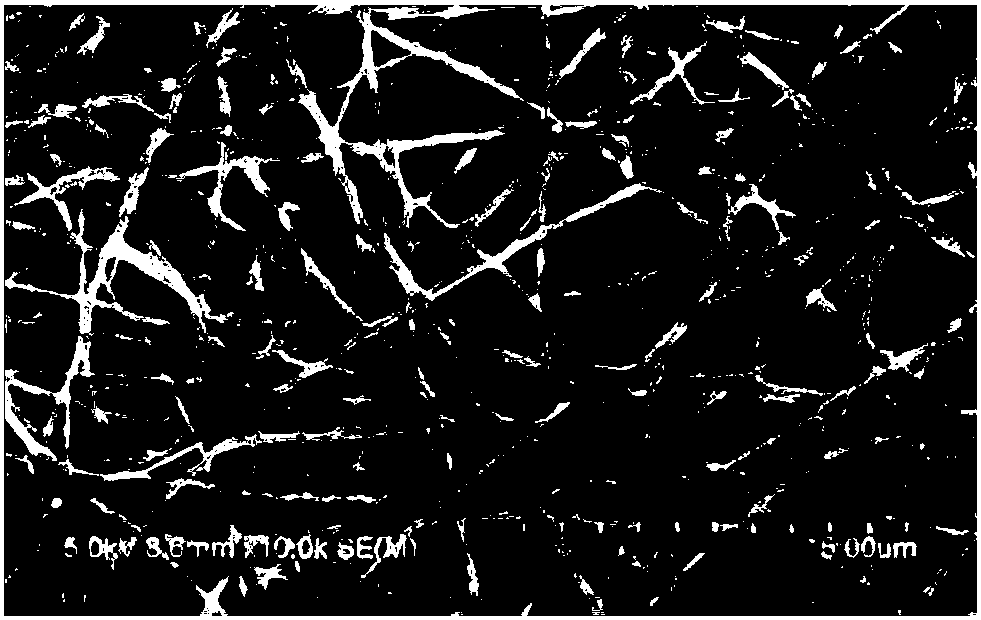

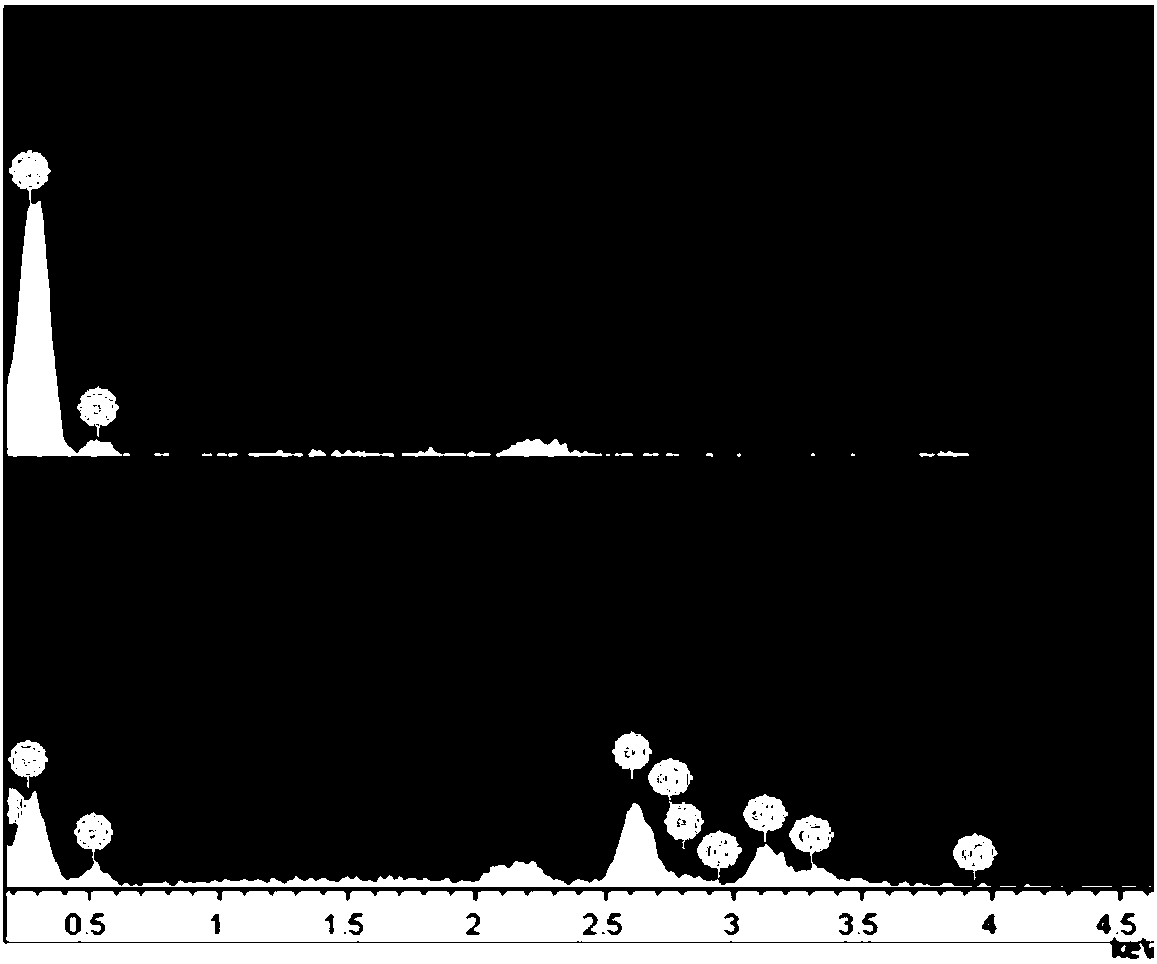

Image

Examples

Embodiment 1

[0029] A preparation method of functional chitosan, polyvinyl alcohol and polycaprolactam composite nanofibrous membrane, the specific steps are as follows:

[0030] 1) Raw material preparation: place CS, PVA and PA6 solid slices in a vacuum drying oven at 50°C for 12 hours;

[0031] 2) Preparation of CS and PVA composite spinning solution: Take the above-mentioned dry CS and PVA at room temperature and add them to the acetic acid solution with a mass fraction of 36%, and stir until the CS and PVA are completely dissolved in the acetic acid solution at a speed of 500r / min , wherein, the total mass fraction of CS and PVA is 8%, and the mass ratio of CS and PVA is 1:9 to obtain a composite spinning solution of CS and PVA;

[0032] 3) Preparation of PVA and PA6 composite spinning solution: take the above-mentioned dried PVA and PA6 at room temperature and add them to a formic acid solution with a mass fraction of 88%, and stir until PVA and PA6 are completely dissolved in the for...

Embodiment 2

[0035] In this embodiment, the preparation method of functional chitosan, polyvinyl alcohol and polycaprolactam composite nanofibrous membrane is the same as in Example 1, except that in step (2), the total mass fraction of CS and PVA is 10%, and the mass fraction of CS and PVA is The ratio is 2:8; the total mass fraction of PVA and PA6 is 16% in the step (3), and the mass ratio of PVA and PA6 is 4:12; the high-voltage electrospinning condition process parameters in the step (4) are: spinneret and receiving The distance between the devices is 15cm, the flow rate of the spinning solution is 0.2mL / h, the applied voltage is 18kV, and the receiving device receives for 10h.

Embodiment 3

[0037] In this embodiment, the preparation method of functional chitosan, polyvinyl alcohol and polycaprolactam composite nanofibrous membrane is the same as in Example 1, except that the total mass fraction of CS and PVA in step (2) is 12%, and the mass fraction of CS and PVA is The ratio is 3:7; the total mass fraction of PVA and PA6 is 18% in the step (3), and the mass ratio of PVA and PA6 is 5:13; the high-voltage electrospinning condition process parameters in the step (4) are: spinneret and receiving The distance between the devices is 18cm, the flow rate of the spinning solution is 0.3mL / h, the applied voltage is 20kV, and the receiving device receives for 15h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com