Multifunctional methanol fuel

A methanol fuel, multi-functional technology, applied in the direction of fuel, fuel additive, liquid carbon-containing fuel, etc., can solve the problems such as the inability to improve the combustion efficiency of diesel oil, reduce the normal operation of the internal combustion engine, and the effect is not very ideal, and solve the problem of rubber Swelling problem, improved storage stability, good combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

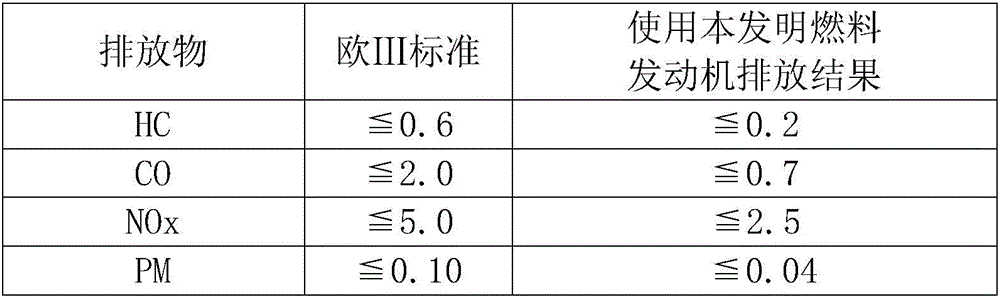

Image

Examples

Embodiment 1

[0026] Multifunctional methanol fuel, made from the following raw materials in parts by weight (at room temperature, just stir well): 60 parts of methanol, 44 parts of gasoline, 1 part of 3-tert-butyl-4-hydroxyanisole, ethyl levulinate 2.3 parts of ester, 0.5 part of 4-tert-butyl-2,6-diisopropylphenol, 2.2 parts of polyvinyl alcohol, 0.2 part of dimethyl carbonate, 1.4 parts of detergent, 0.1 part of corrosion inhibitor, amino trimethylene phosphonic acid 0.21 parts, glyceryl monostearate 0.02 parts.

[0027] The above detergent is a mixture of 20 parts by weight of dimethylacetamide, 7 parts by weight of 2-heptadecylimidazole and 11 parts by weight of 2,4-dimethylaniline.

[0028] The anticorrosion agent mentioned above is a mixture of 10 parts by weight of triacetin, 20 parts by weight of benzotriazole and 5 parts by weight of aminotrimethylene phosphonic acid.

Embodiment 2

[0030] Multifunctional methanol fuel, made from the following raw materials in parts by weight (at room temperature, just stir well): 65 parts of methanol, 40 parts of gasoline, 2 parts of 3-tert-butyl-4-hydroxyanisole, ethyl levulinate 2 parts of ester, 0.8 part of 4-tert-butyl-2,6-diisopropylphenol, 1.9 parts of polyvinyl alcohol, 0.4 part of dimethyl carbonate, 1.2 parts of detergent, 0.3 part of corrosion inhibitor, dicycloheptadiene 0.18 parts, glyceryl monostearate 0.05 parts.

[0031] The above detergent is a mixture of 18 parts by weight of dimethylacetamide, 9 parts by weight of 2-heptadecylimidazole and 10 parts by weight of 2,4-dimethylaniline.

[0032] The anticorrosion agent mentioned above is a mixture of 12 parts by weight of triacetin, 18 parts by weight of benzotriazole and 6 parts by weight of aminotrimethylene phosphonic acid.

Embodiment 3

[0034] Multifunctional methanol fuel, made from the following raw materials in parts by weight (at room temperature, just stir well): 70 parts of methanol, 36 parts of gasoline, 3 parts of 3-tert-butyl-4-hydroxyanisole, ethyl levulinate 1.7 parts of ester, 1.1 parts of 4-tert-butyl-2,6-diisopropylphenol, 1.7 parts of polyvinyl alcohol, 0.6 parts of dimethyl carbonate, 1 part of detergent, 0.5 parts of corrosion inhibitor, dicycloheptadiene 0.15 parts, glyceryl monostearate 0.08 parts.

[0035] The above detergent is a mixture of 16 parts by weight of dimethylacetamide, 11 parts by weight of 2-heptadecylimidazole and 9 parts by weight of 2,4-dimethylaniline.

[0036] The anticorrosion agent mentioned above is a mixture of 14 parts by weight of triacetin, 16 parts by weight of benzotriazole and 7 parts by weight of aminotrimethylene phosphonic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com