Patents

Literature

60results about How to "Does not affect production capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

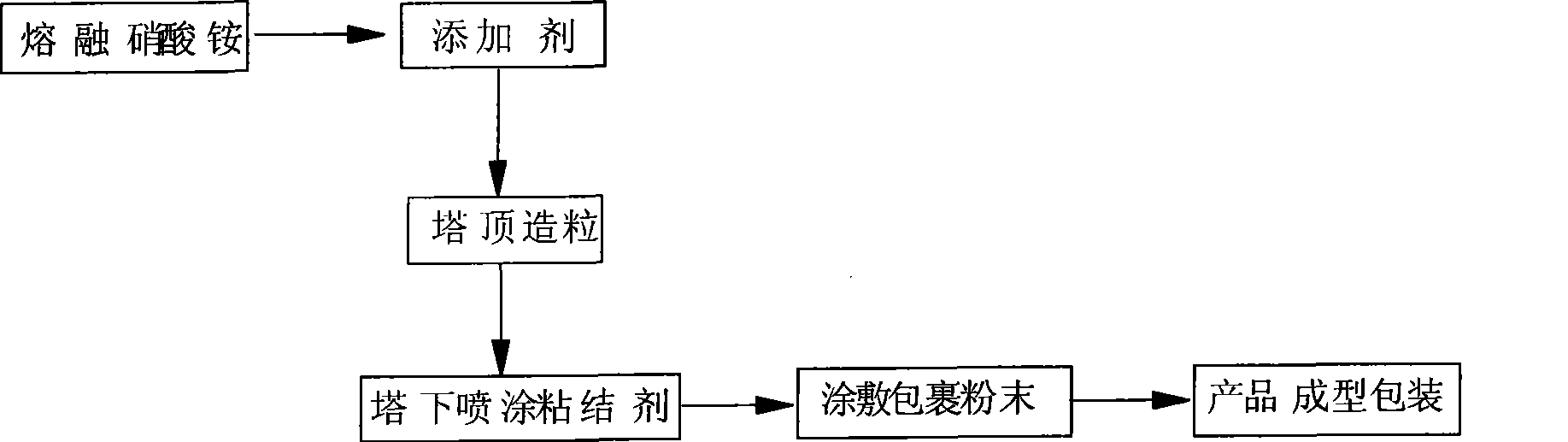

Surface treatment method for antiknocking and modifying granulated fertilizer containing ammonium nitrate

InactiveCN101445400ADoes not affect the granulation processDoes not affect production capacityAmmonium nitrate fertilisersFirming agentAmmonium nitrate

The invention discloses a surface treatment method for antiknocking and modifying granulated fertilizer containing ammonium nitrate. In the method, firstly, fused ammonium nitrate is granulated by a tower top to obtain the granulated fertilizer containing the ammonium nitrate, then the surface of the granulated fertilizer is coated with a liquid binding agent, and finally, the granulated fertilizer is coated and enwrapped with solid powder consisting of firming agent and powdering agent, so that the surface treatment for antiknocking and modifying the granulated fertilizer containing the ammonium nitrate is finished. Under the interaction of the binding agent, the firming agent and the powdering agent, the invention improves the antiknock performance of agricultural ammonium nitrate greatly to achieve the requirement of the standard of WJ-9050-2006 agricultural ammonium nitrate antiknock performance test method and judgement. The granulated fertilizer containing the ammonium nitrate is subject to the antiknocking and modifying surface treatment after the fused ammonium nitrate is granulated, thereby causing no influence on the matured ammonium nitrate granulating technology, not reducing the production capacity of an ammonium nitrate prilling tower and causing no potential safety hazard.

Owner:NANJING UNIV OF SCI & TECH

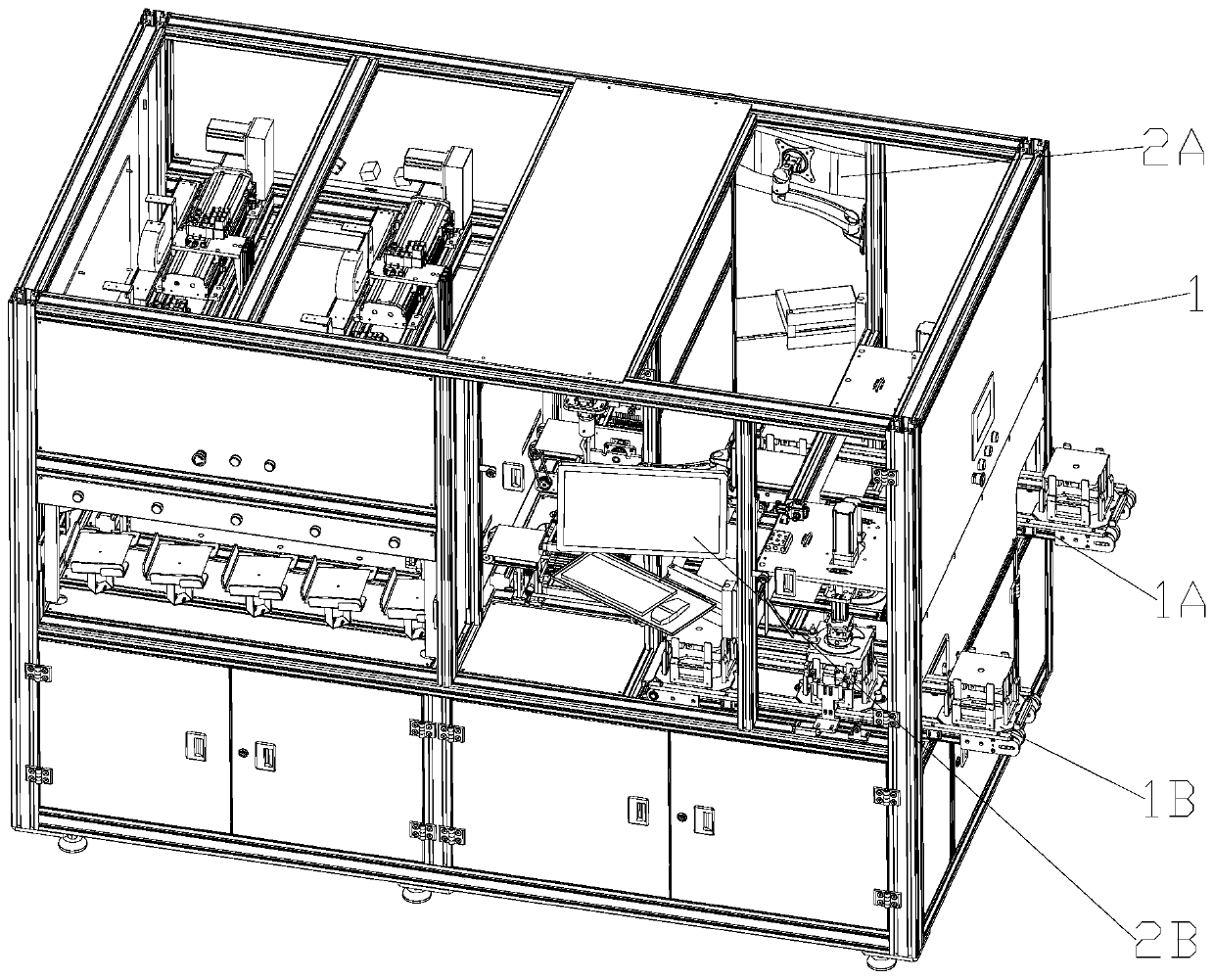

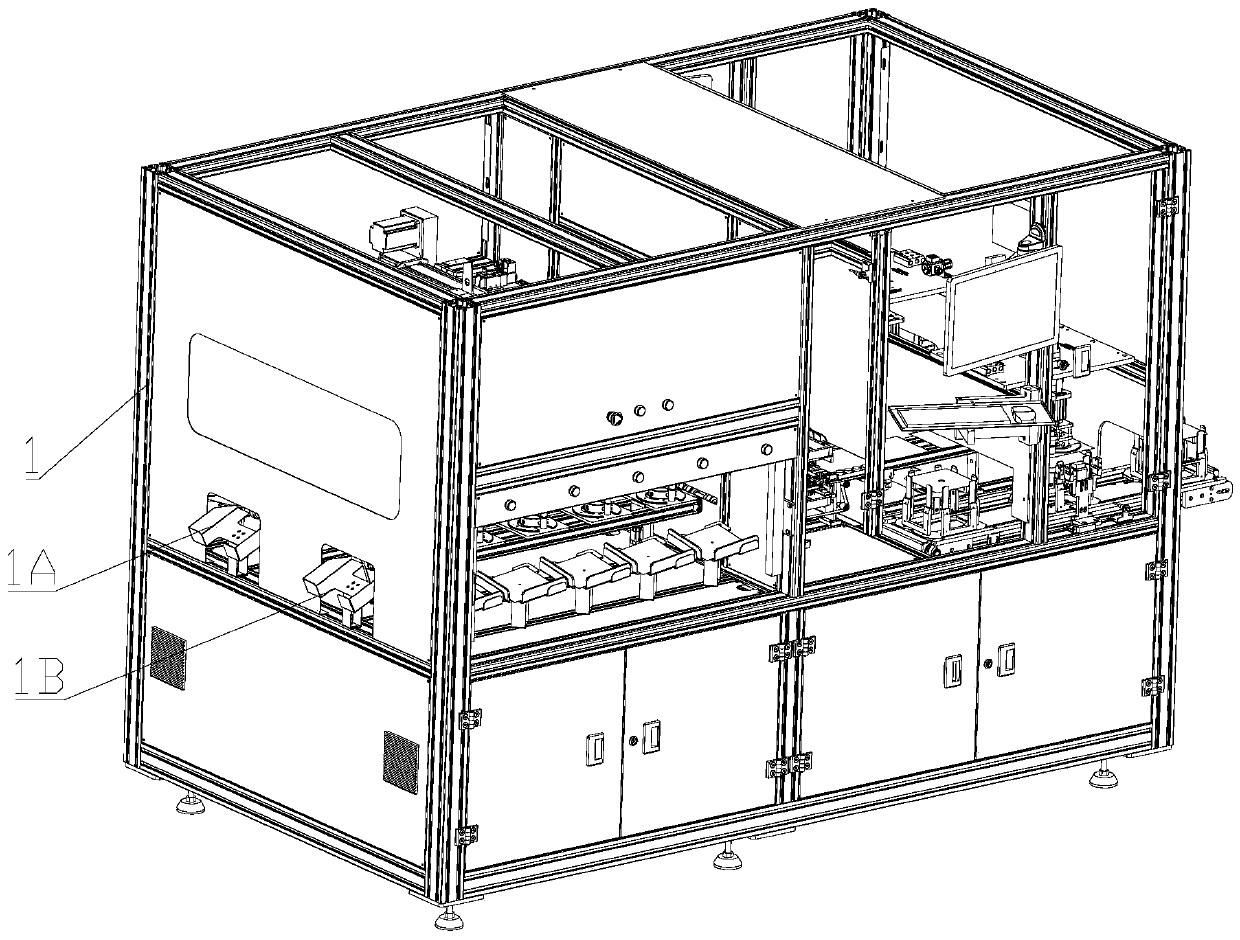

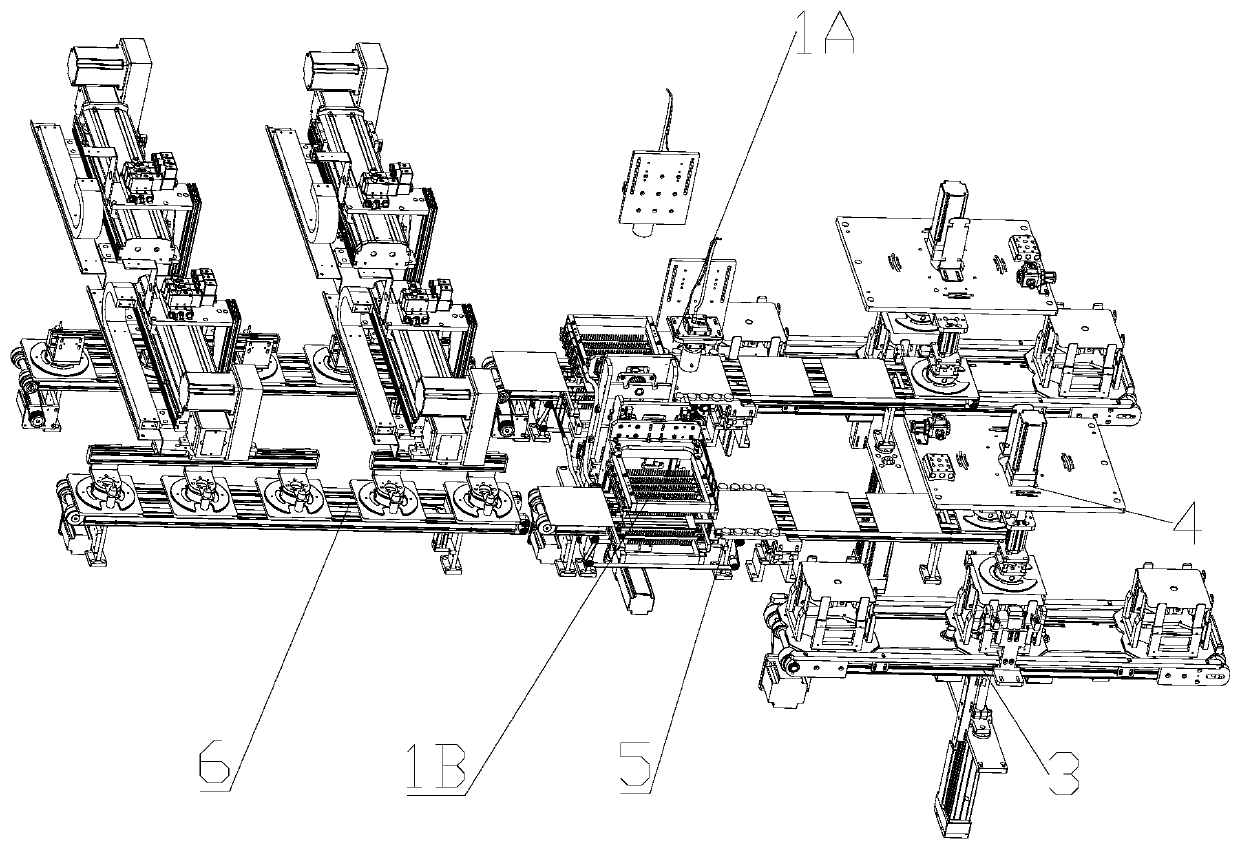

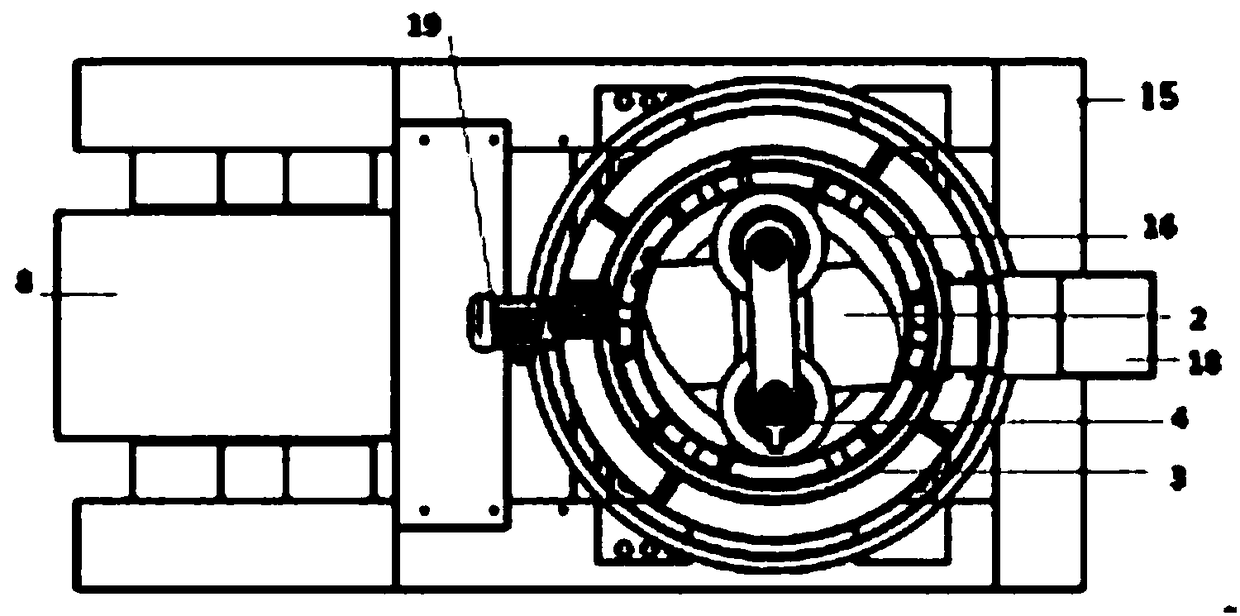

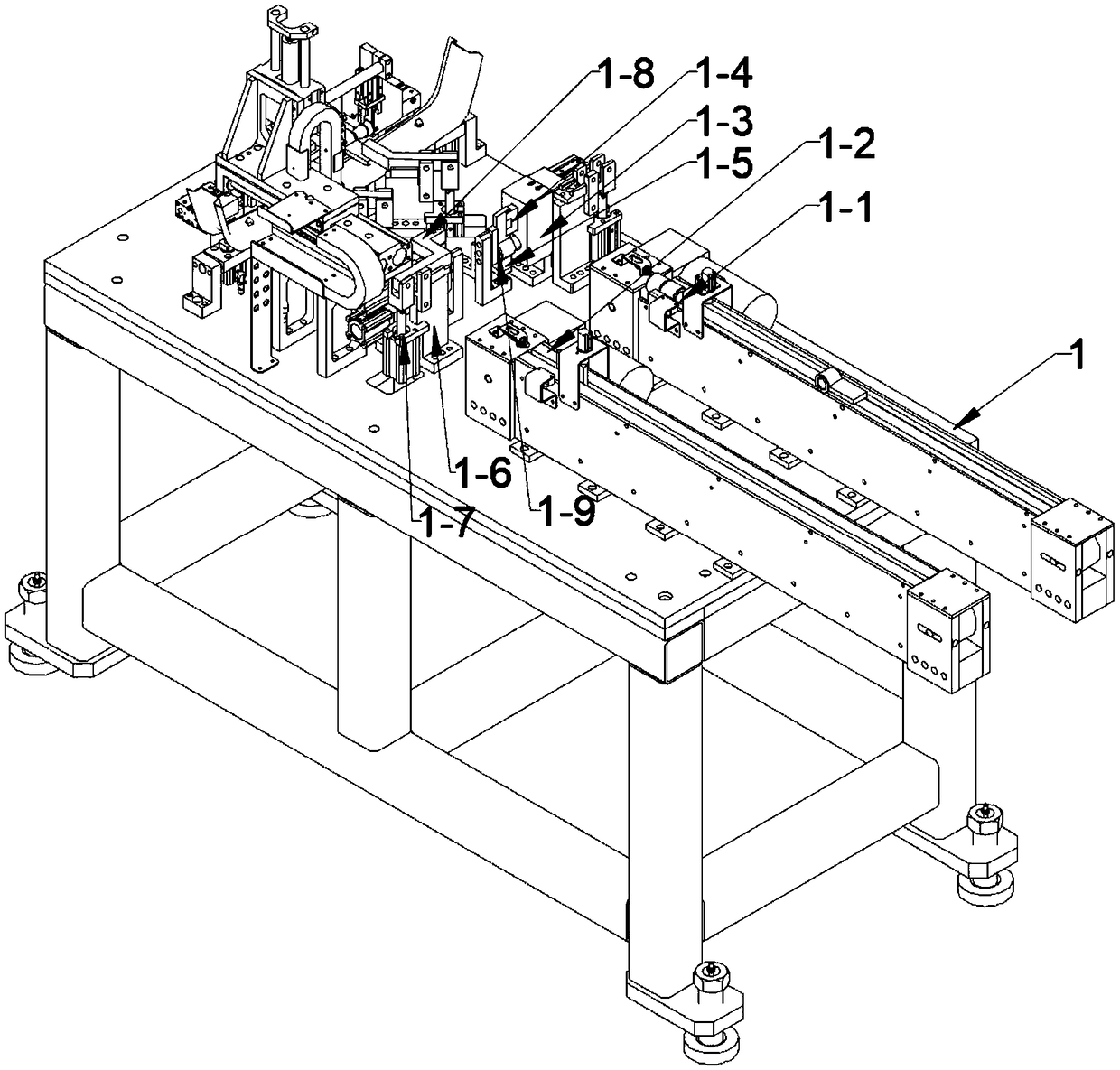

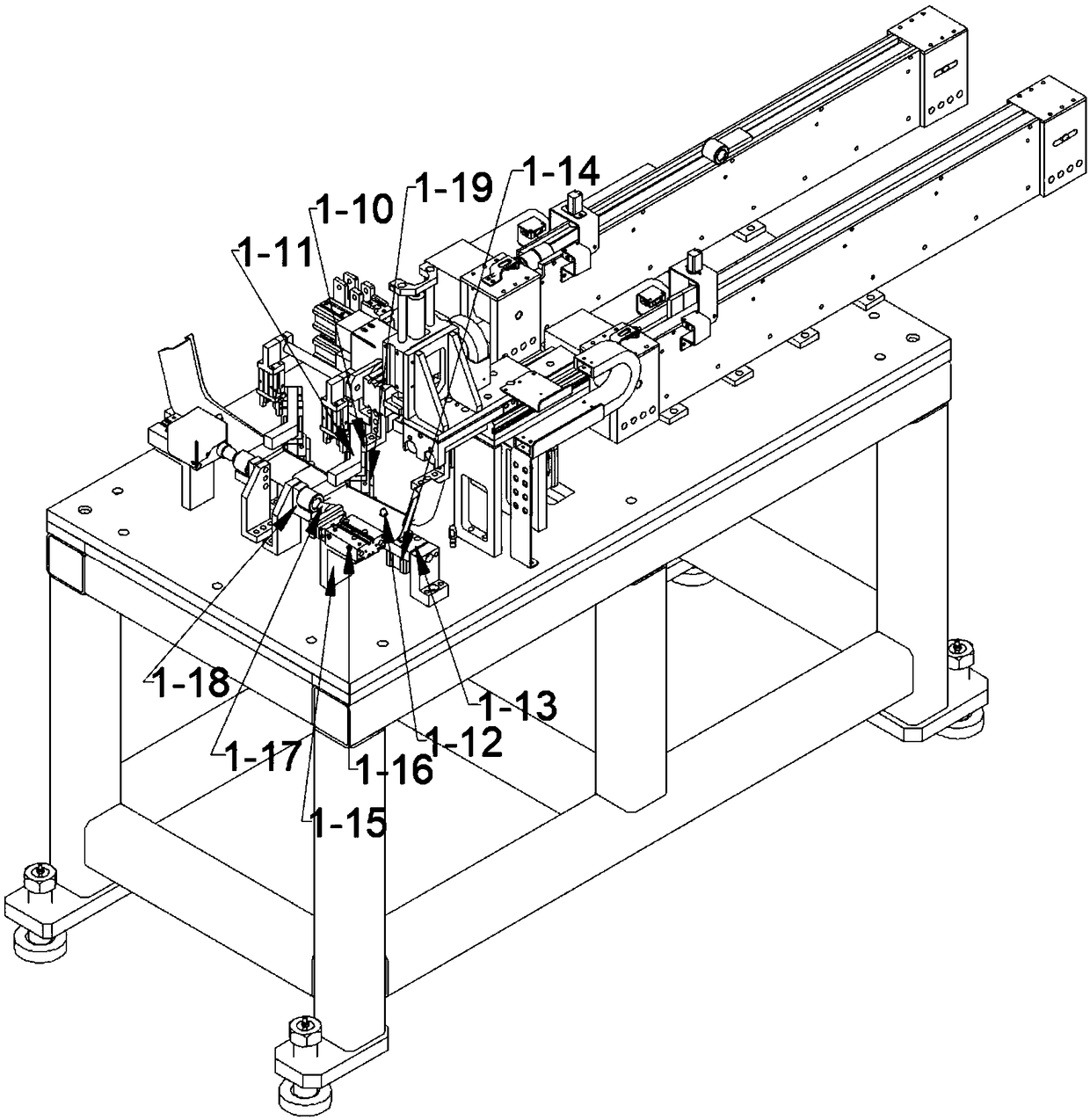

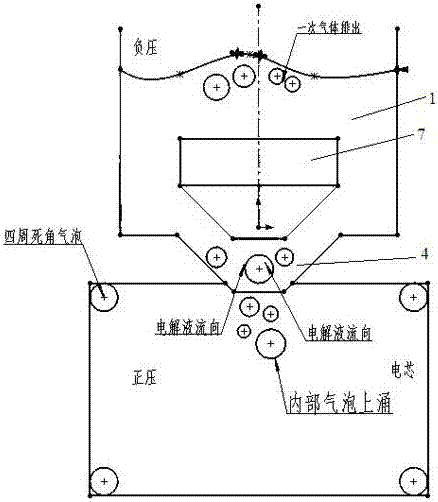

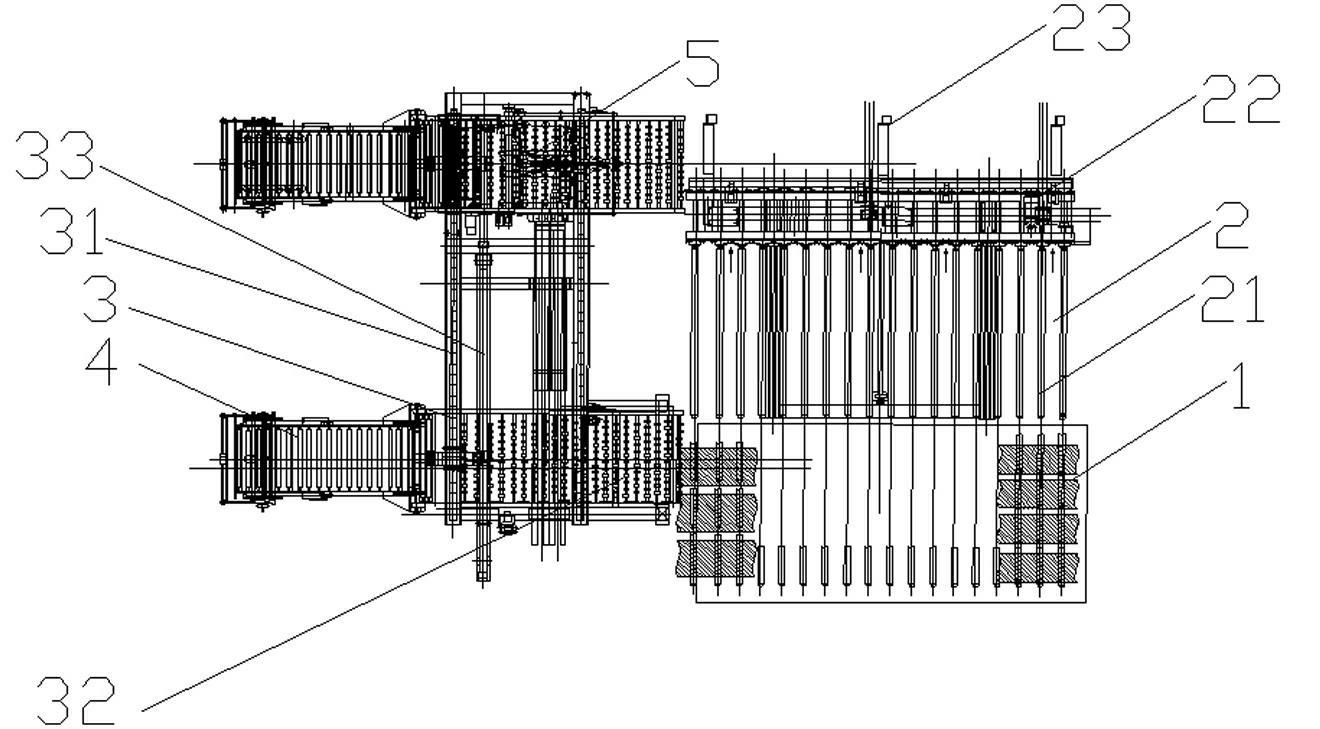

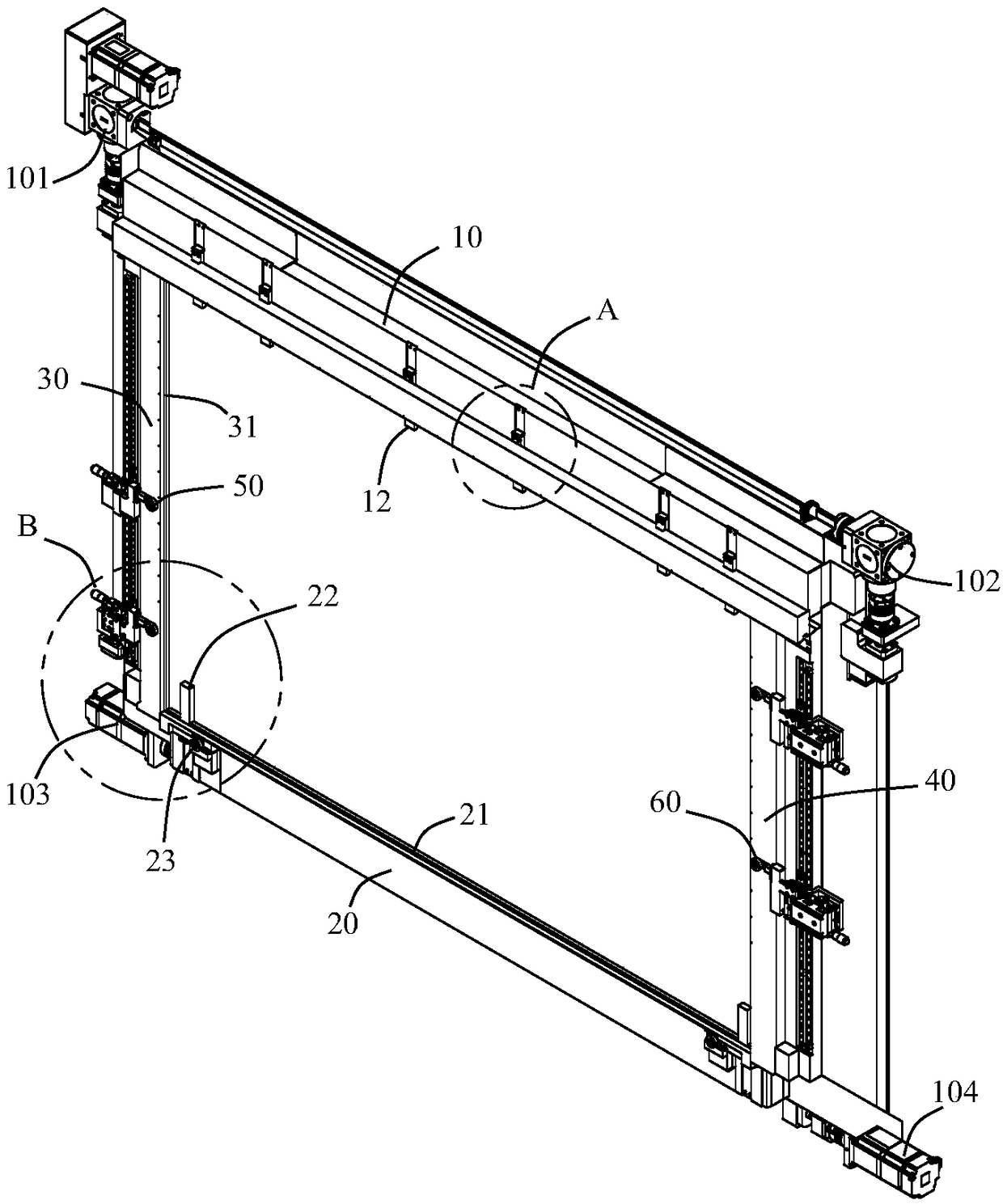

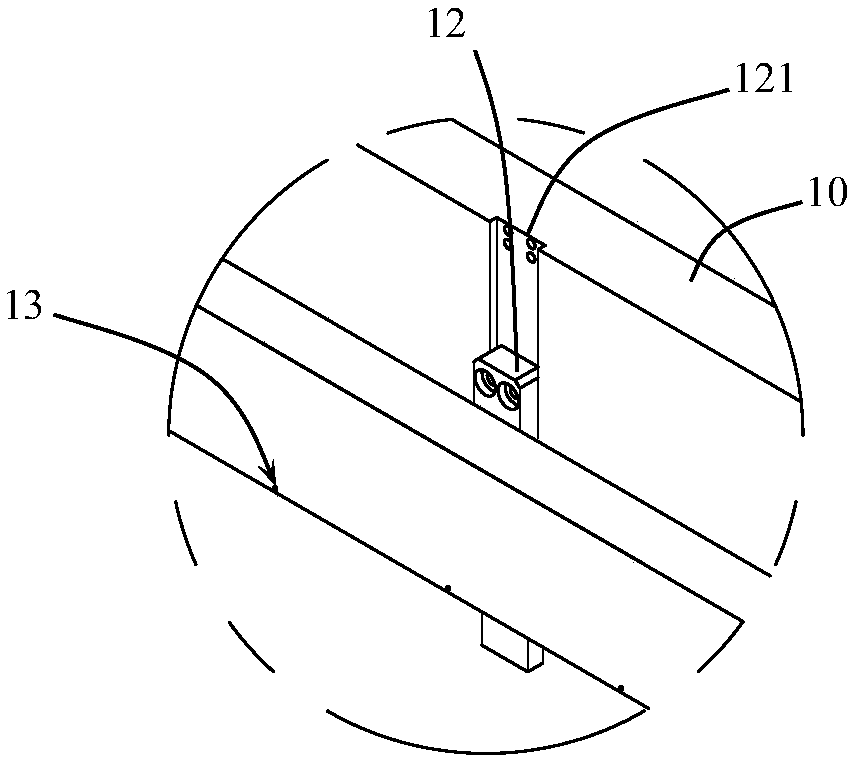

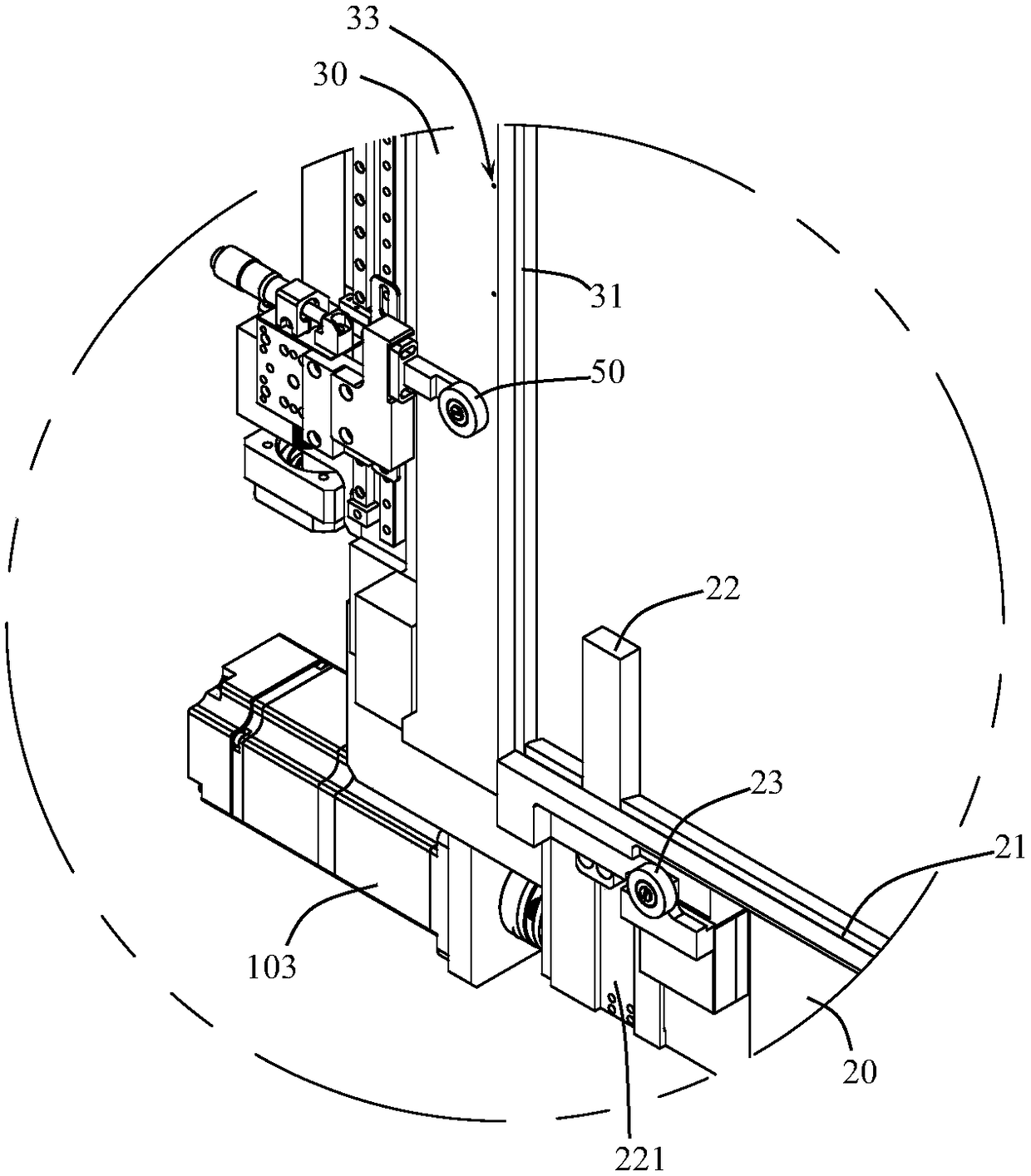

Double-station offline cell EL detection sorting device

PendingCN110600393AIncrease flexibilityEasy maintenanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingElectricityCells panel

The invention discloses a double-station offline cell EL detection sorting device, and the device comprises a frame structure capable of moving freely, a first station detection line and a second station detection line, wherein the first station detection line and the second station detection line are located in the frame structure, are the same and are symmetrically arranged. Each of the two station detection lines comprises a material box conveying and lifting device, a sucking and rotating device, an EL detection device and a sorting and transplanting device. The material box transporting and lifting device is used for conveying the battery plate material box filled with the to-be-detected cell panel material sheet to the lower part of the sucking and rotating device, lifting the to-be-detected cell panel material sheet to a required height; the to-be-detected cell panel sheet is sent to a feeding line of the EL detection device through the sucking and rotating device, then enters the EL detection device, and emits light after being powered on and are photographed, wherein obtained pictures are sent to a master control machine to be analyzed, and whether the corresponding cell panel sheet is qualified or not is judged according to the pictures, and the numbering is conducted; the detected cell panel material sheet enters a material line of the sorting and transplanting device, and the qualified material sheets and unqualified material sheets are separated out through the sorting and transplanting device.

Owner:南京卓胜自动化设备有限公司

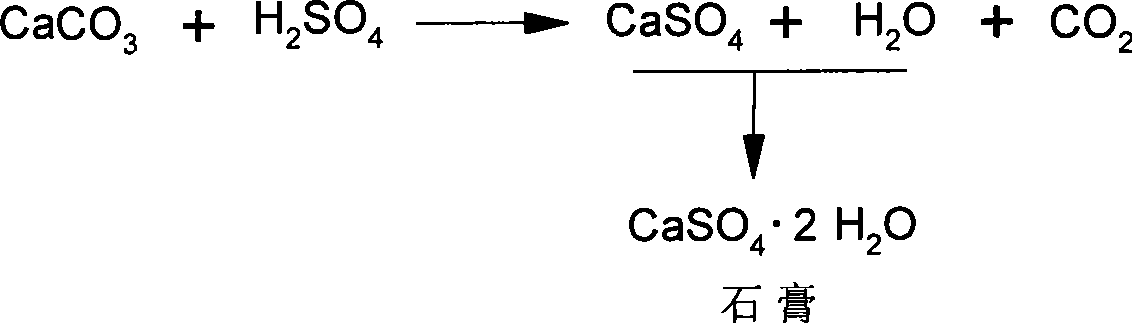

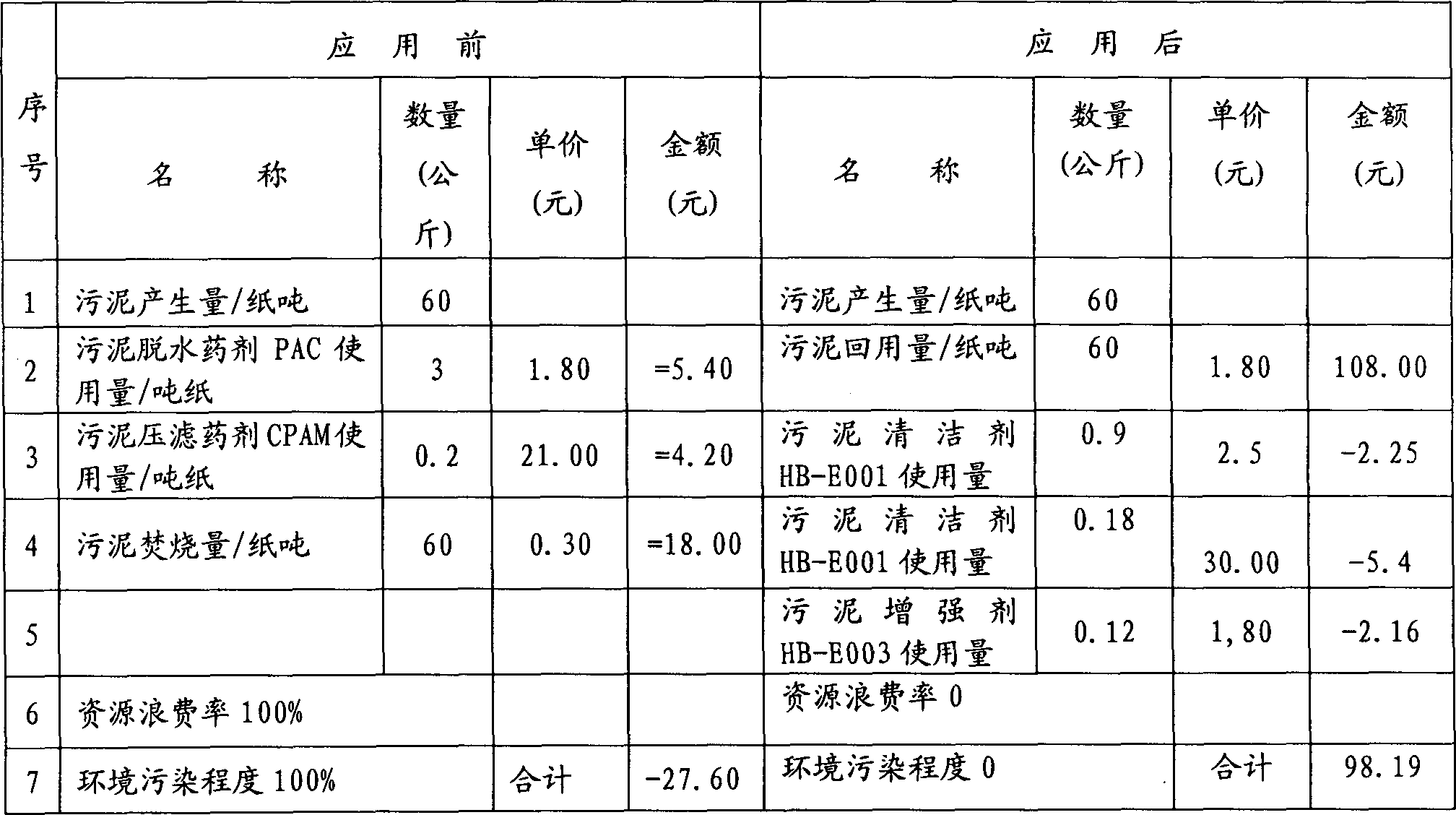

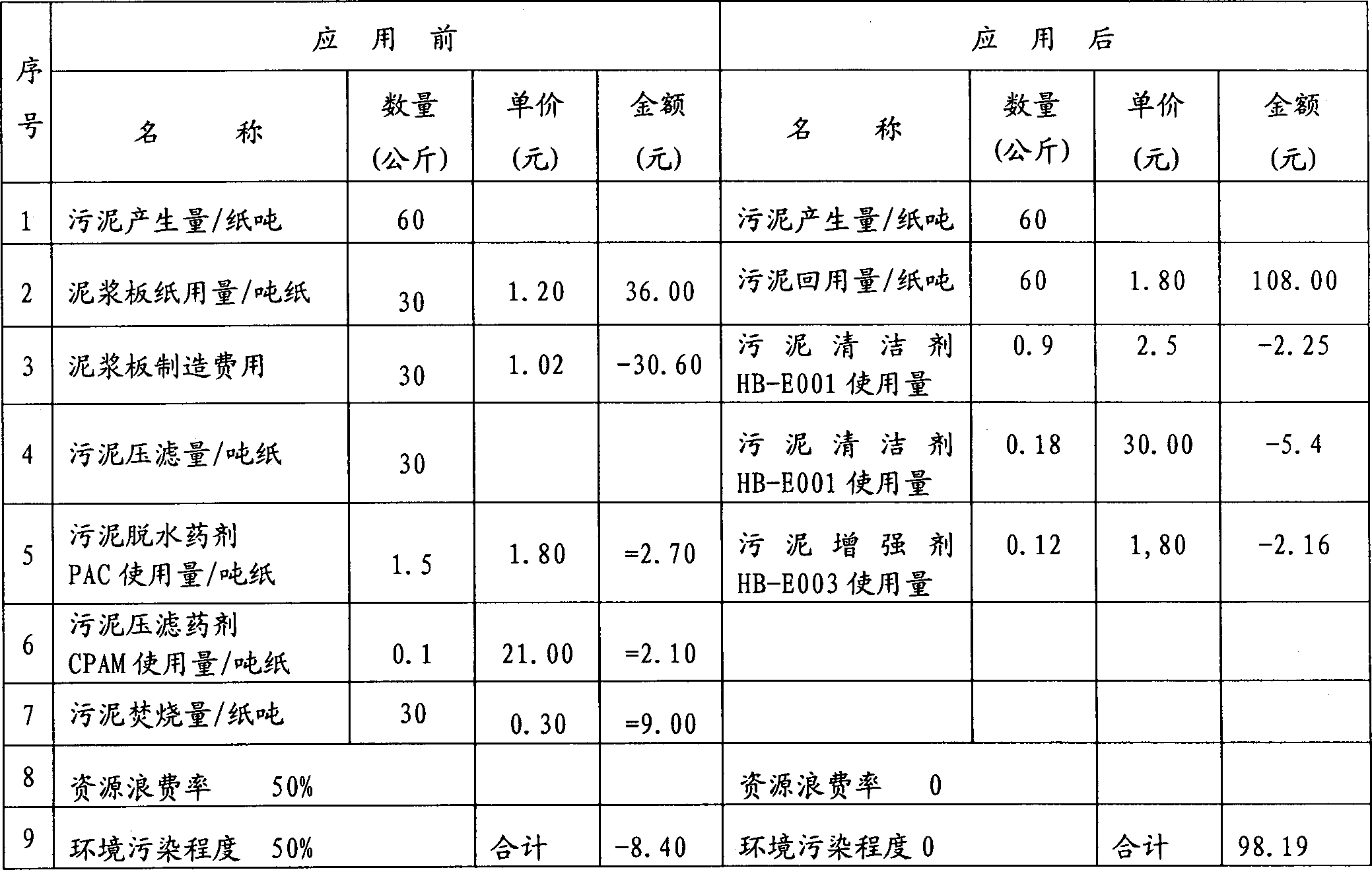

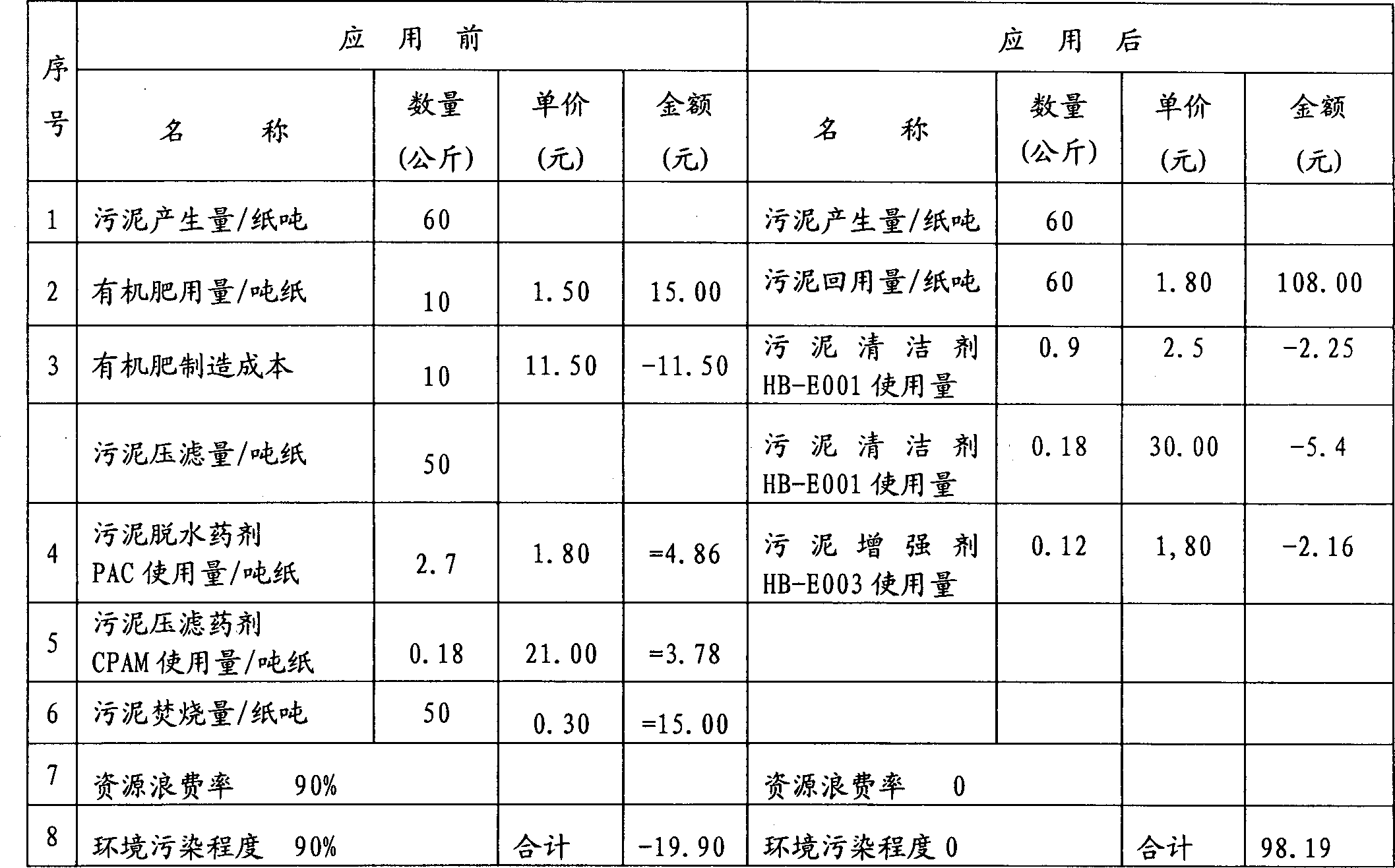

Chemical agent for treating and recycling paper sludge and treating method thereof

ActiveCN102432143ASolve the effect of not rowingIncrease added valueSludge treatment by de-watering/drying/thickeningWaste water treatment from plant processingSodium BentoniteSludge

The present invention relates to chemical agents for treating and recycling paper sludge and a treating method thereof. A sludge cleaning agent HB-E001 of the invention is prepared from 50 parts of CS-8 dissolved in deionized water, 20 parts of acrylamide, 4 parts of modified bentonite, 1 part of magnetized pig iron powder and 25 parts of aluminium sulfate. A sludge activator HB-E002 is prepared from 50 parts of CS-8 dissolved in deionized water, 30 parts of acrylamide, 18 parts of double octadecyl dimethyl ammonium chloride, 1 part of chitosan and 1 part of magnetized pig iron powder. A sludge reinforcing agent HB-E003 of the invention is prepared from 45 parts of deionized water, 30 parts of amphoteric polyacrylamides, 20 parts of modified starch, 4 parts of polyamide chloropropylene oxide resin and 1 part of guar gum. The chemical agents and the method provided by the invention have the advantages of overcoming defects of rising water concentration COD, SS, inorganic salt, conductivity and the like existed in the prior waste treatment, saving raw materials per ton paper by 6-6.5 per cent, reducing enterprise cost greatly, changing waste treatment of enterprise into initiative waste treatment because of an especially high additional value, saving resources and protecting environment simultaneously.

Owner:NANJING HUHANG ENVIRONMENTAL PROTECTION

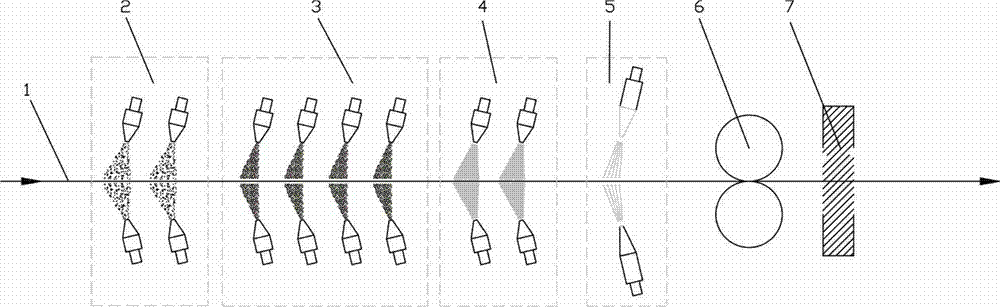

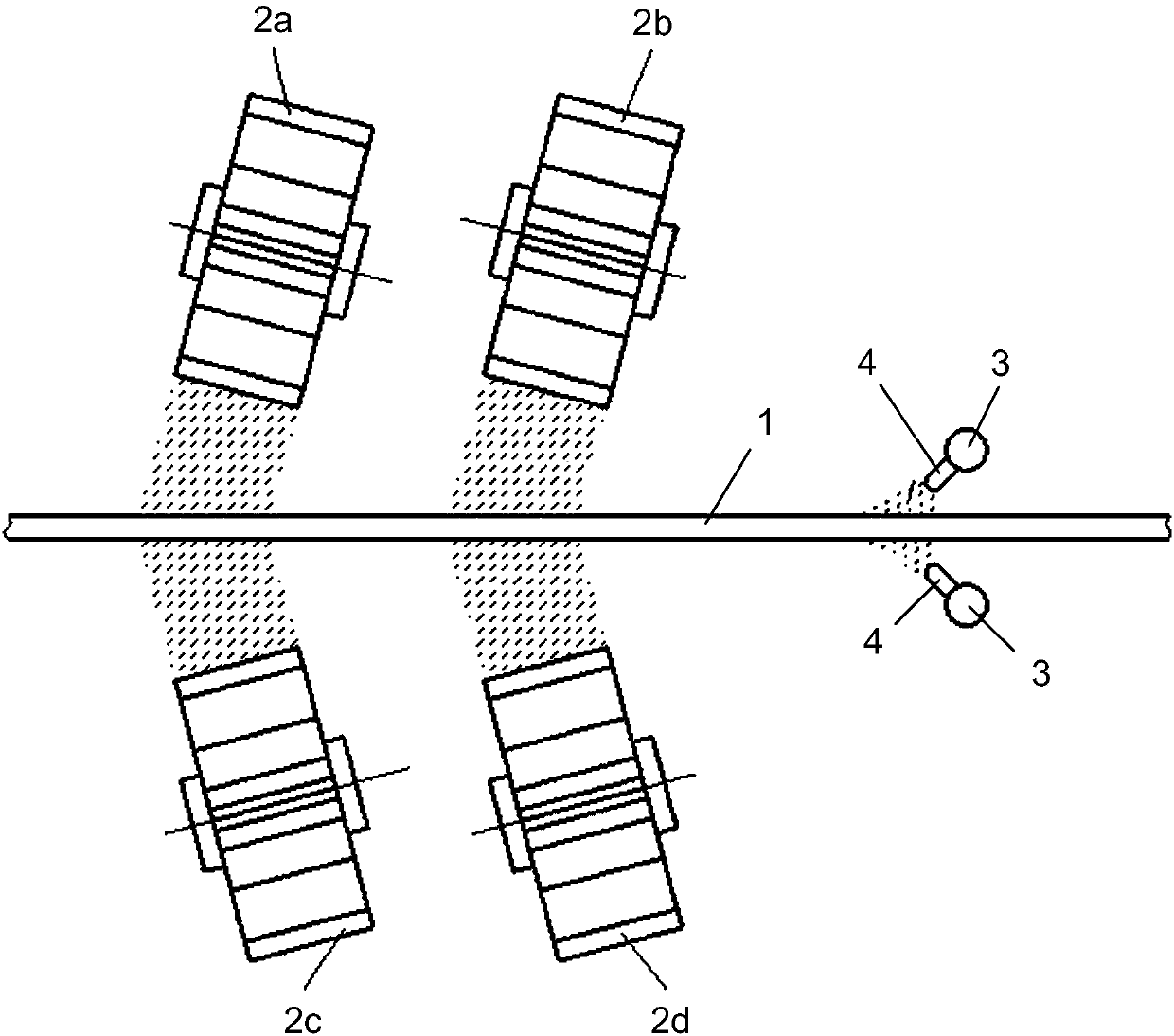

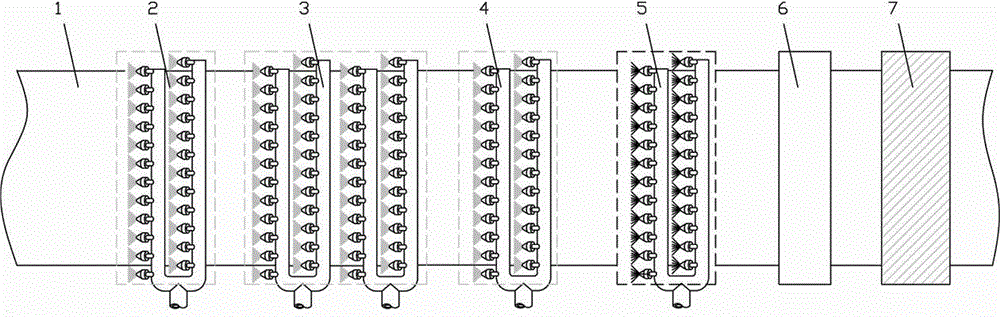

Process arrangement method for mixed jet cleaning

The invention relates to a process arrangement method for mixed jet cleaning. The method employs high-pressure mixed jet descaling units having a plurality of abrasive materials with different granularities. The high-pressure mixed jet descaling units are arranged along a tape transport direction of a metal plate. The high-pressure mixed jet with large granularity abrasive materials is arranged at an original inlet area of the metal plate, with the granularity of 20 meshes-60 meshes and inject pressure of 15 MPa-80 MPa; the high-pressure mixed jet with medium granularity abrasive materials is arranged at downstream of the high-pressure mixed jet descaling unit with the large granularity abrasive materials, with the granularity of 40 meshes-80 meshes and inject pressure of 10 MPa-60 MPa; the high-pressure mixed jet descaling unit with small granularity abrasive materials is arranged at downstream of the high-pressure mixed jet descaling unit with the medium granularity abrasive materials, with the granularity of 60 meshes-120 meshes and inject pressure of 10 MPa-50 MPa; the metal plate realizes the front and back descaling of the metal plate via the above jet descaling units; and the washing of the metal plate is finished by passing the descaled metal plate through a high-pressure pure water cleaning unit, a wiping unit and a compressed air blowing unit. The complete removing treatment of the scales on two sides of the coal metal plate is realized via a jet way.

Owner:BAOSHAN IRON & STEEL CO LTD

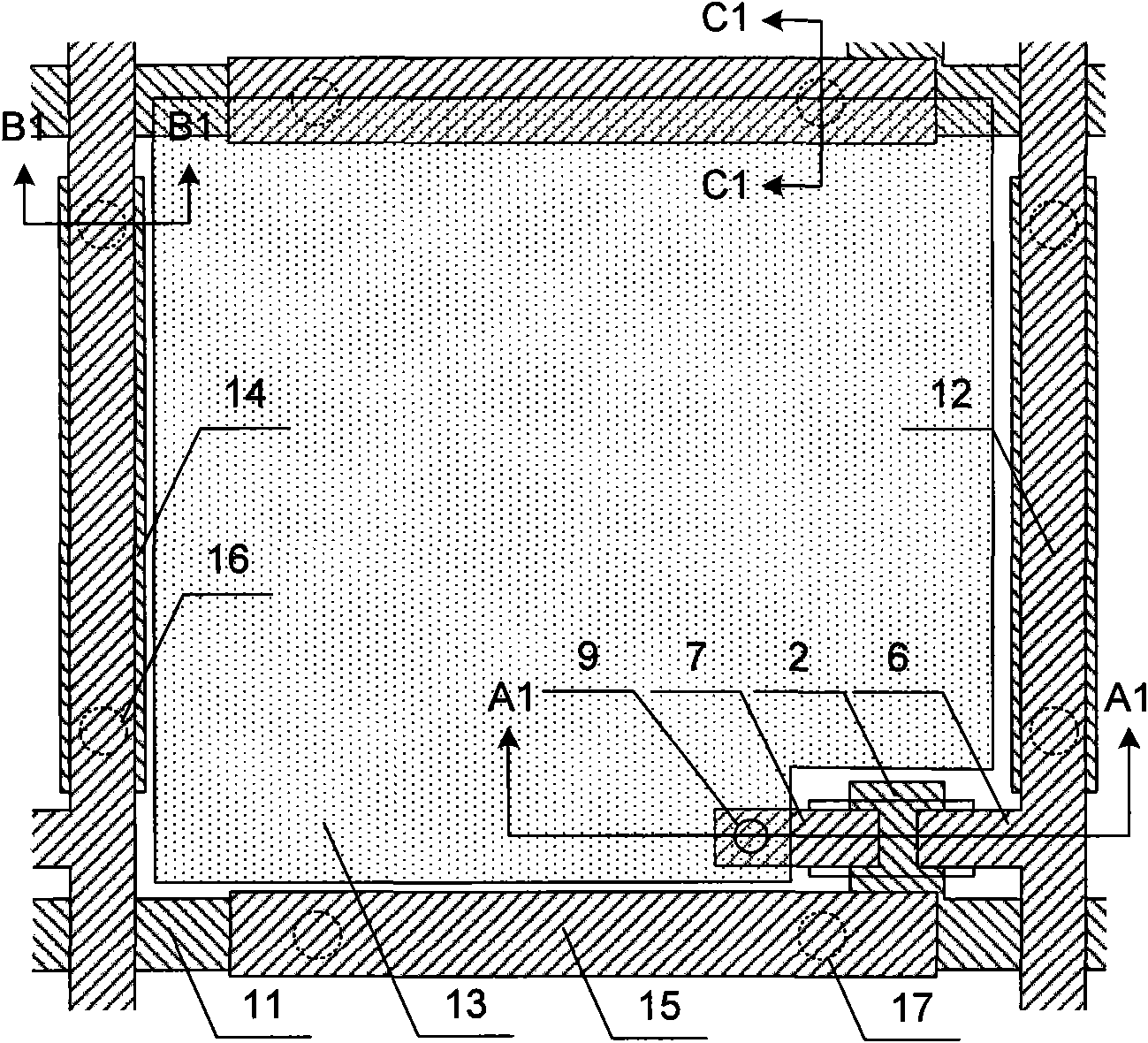

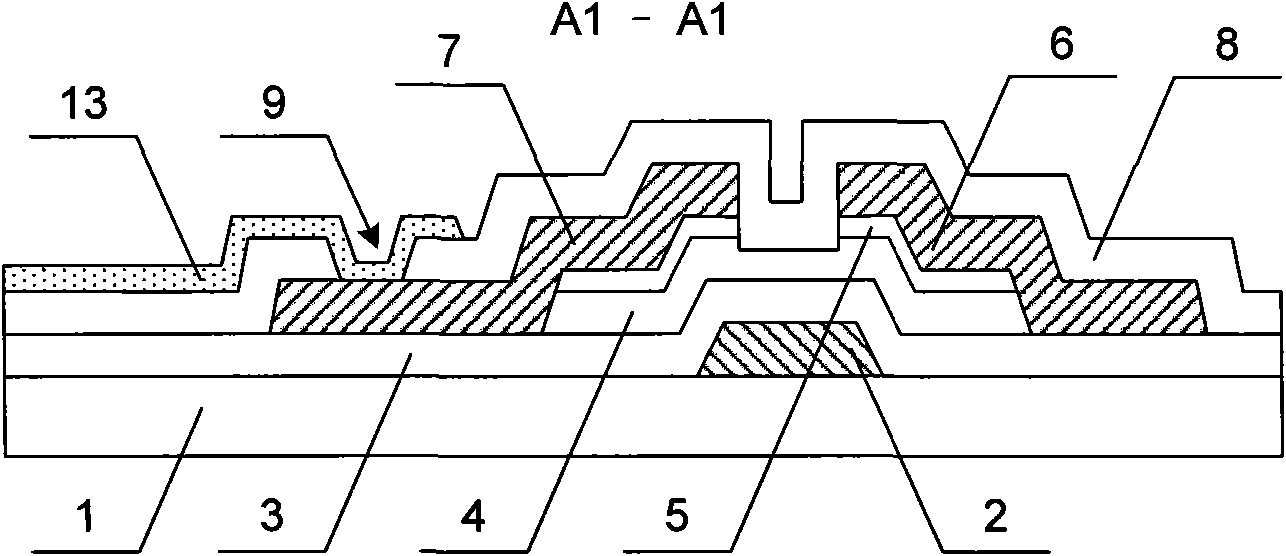

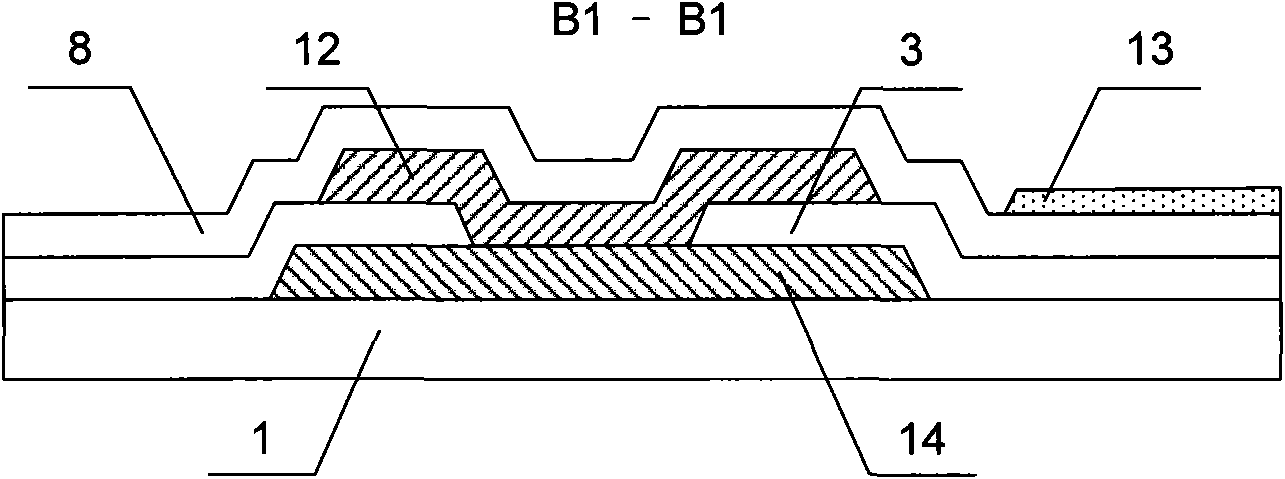

TFT-LCD (Thin Film Transistor Liquid Crystal Display) array base plate and manufacturing method thereof

InactiveCN101887898AIncrease opening ratioIncrease display brightnessSemiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

The invention relates to a TFT-LCD (Thin Film Transistor Liquid Crystal Display) array base plate and a manufacturing method thereof. The array base plate comprises a grid line and a data line, wherein a pixel electrode and a thin film transistor are formed in a pixel region limited by the grid line and the data line, and a connection electrode forming a double-layer structure for the grid line and / or the data line is also arranged in the pixel region. The manufacturing method comprises the following steps of: forming a figure including the grid line, the data line, an active layer, a source electrode and a drain electrode, wherein the grid line and / or the data line is in the double-layer structure; depositing a passivation layer to form a figure including the pixel electrode, wherein a passivation layer through hole is positioned in the same position of the drain electrode; and depositing a transparent conductive thin film to form a figure including the pixel electrode, wherein the pixel electrode is connected with the drain electrode through the passivation layer through hole. The TFT-LCD array base plate effectively reduces bad line breakage of the grid line and the data line to greatly improve the quality and the yield of the product, simultaneously improves the size of capacitance storage in unit area and is beneficial to improving the opening rate and the display luminance of a TFT-LCD.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

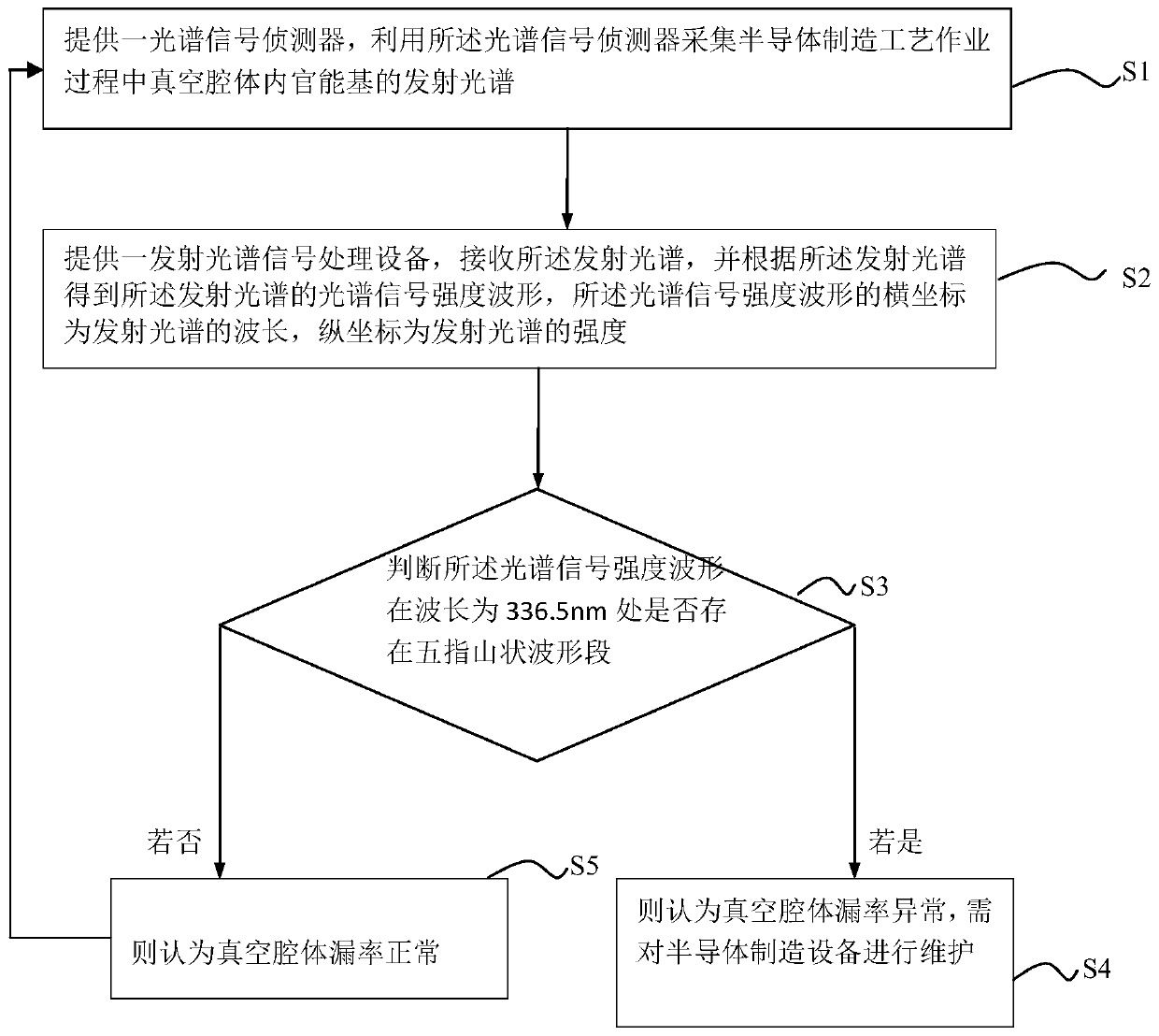

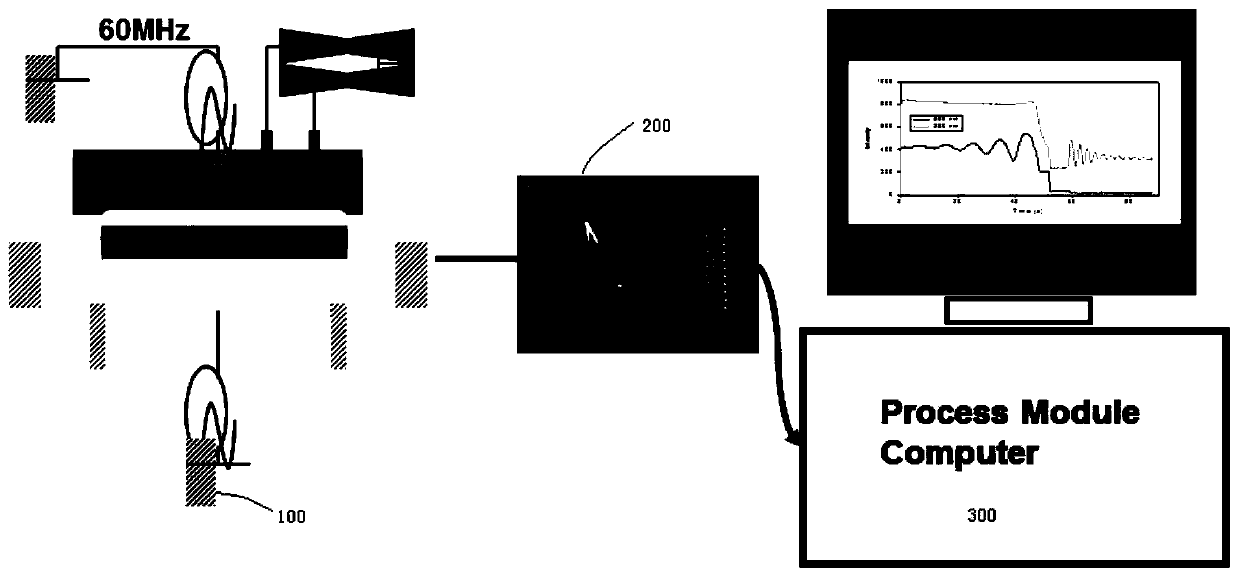

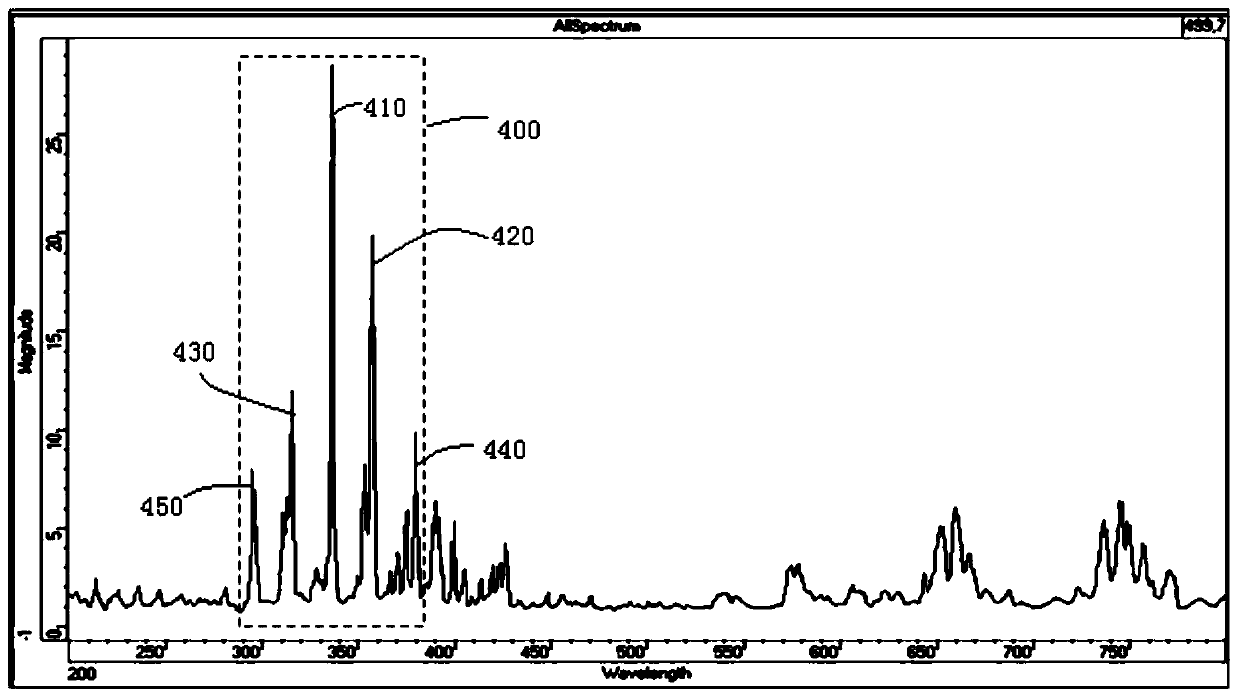

Method for monitoring leakage rate of vacuum cavity

ActiveCN110017955AContinuous monitoring of leak rateLow costFluid-tightness measurement using lightManufacturing technologyEngineering

The invention relates to a method for monitoring the leakage rate of a vacuum cavity and relates to a manufacturing technology of a semiconductor integrated circuit. An emission spectrum of a functional group in the vacuum cavity in the semiconductor manufacturing technology operation process is collected through a spectrum signal detector, the spectrum signal intensity waveform of the emission spectrum is obtained through emission spectrum signal processing equipment, the leakage rate of the vacuum cavity is monitored by judging whether the spectrum signal intensity waveform has a five-finger-mountain-shaped waveform section near 336.5 nm of the wave length of nitrogen or not, whether the leakage rate of the vacuum cavity is abnormal or not can be undoubtedly judged through the method, the cost is low, the leakage rate of a reaction cavity can be detected without the need of shutting down semiconductor manufacturing equipment, productivity is not affected, and thus the leakage rate ofthe vacuum cavity can be monitored continuously.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

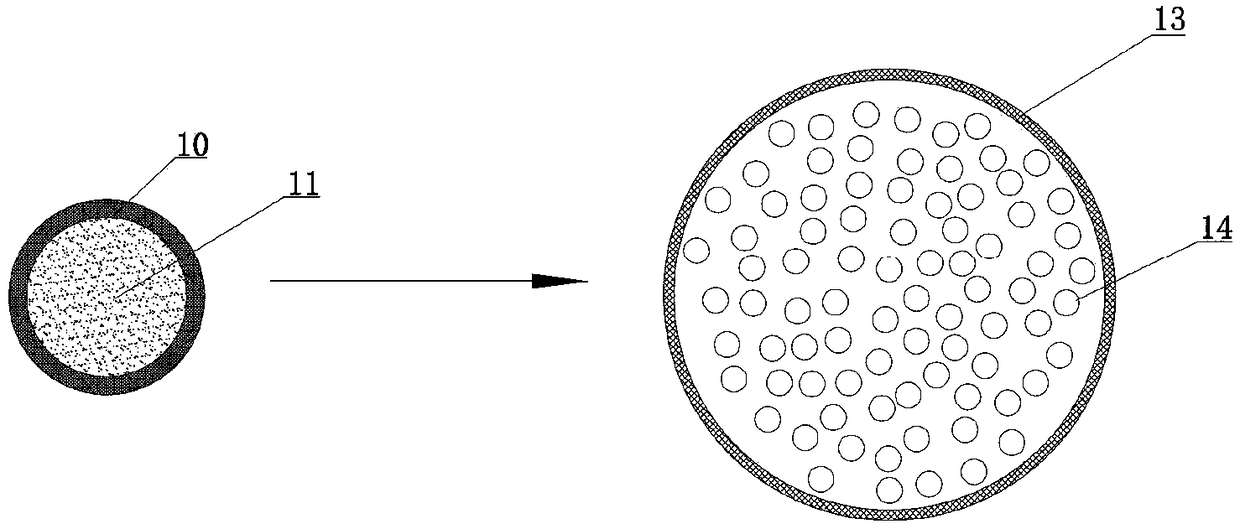

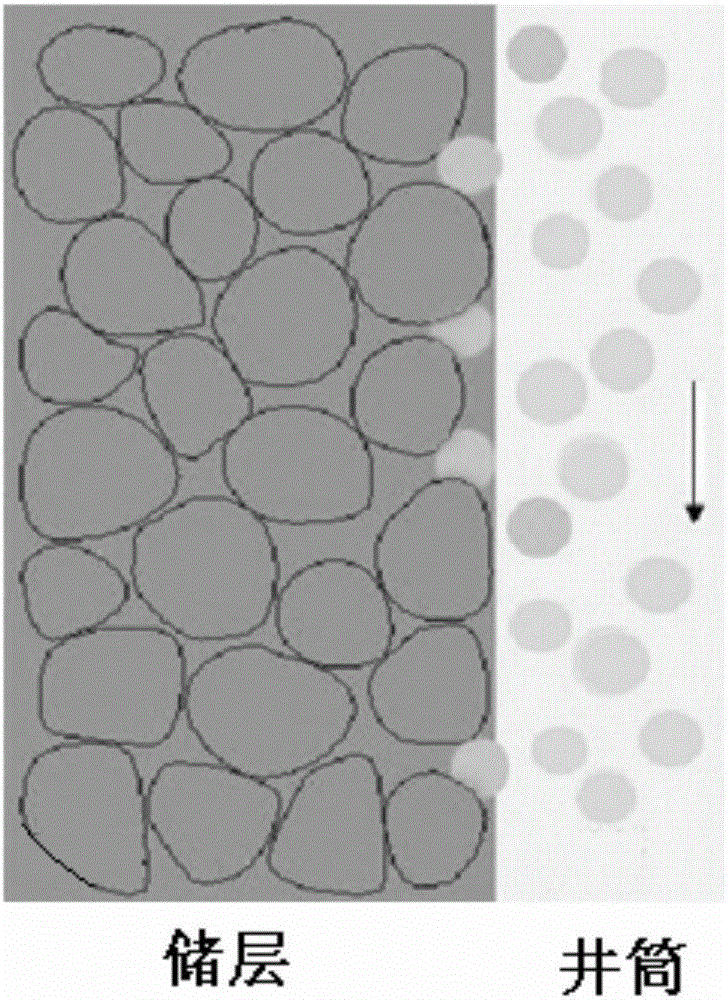

Capsule-type expansion body heated based on ground temperature and method for plugging formation leakage and improving bearing capability of formation

ActiveCN109097011AImprove pressure bearing capacityBloat doesn't happenDrilling compositionSealing/packingGround temperatureChemical reaction

The invention discloses a method for plugging formation leakage and improving bearing capability of a formation based on the capsule-type expansion body heated at ground temperature. The capsule-typeexpansion body consists of a capsule-type expansion body shell and a liquid or solid temperature control expansion material, enters a well circumference and formation cracks and holes far away from the body with drilling fluid circulation, is heated to a certain temperature range with the ground temperature, then quickly and remarkably expands, elastically deforms to self-adapt to plugging of various types of leaked formations and improve the bearing capability of the formations. The capsule-type expansion body is divided into a physical gasification type or chemical decomposition reaction type according to the expansion principle of the liquid or solid temperature control expansion material, is kept in a non-expanding state during relatively low-temperature ground transportation and in-shaft circulating flow, and has the advantages of quick and effective plugging, self adaptation, long distance, dismounting and the like when producing quick and remarkable volume expansion and pluggingformation leakage at physical and chemical reaction temperatures.

Owner:SOUTHWEST PETROLEUM UNIV

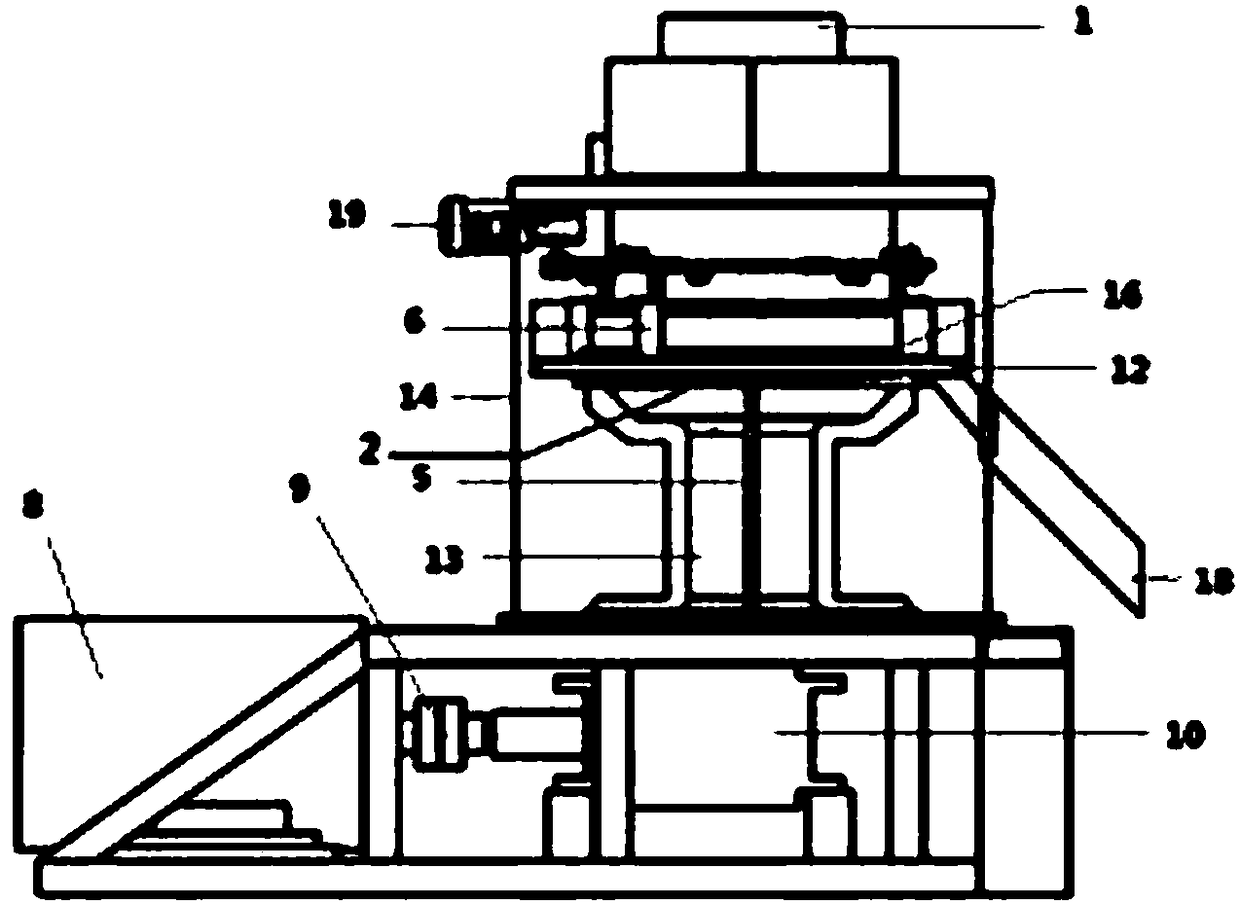

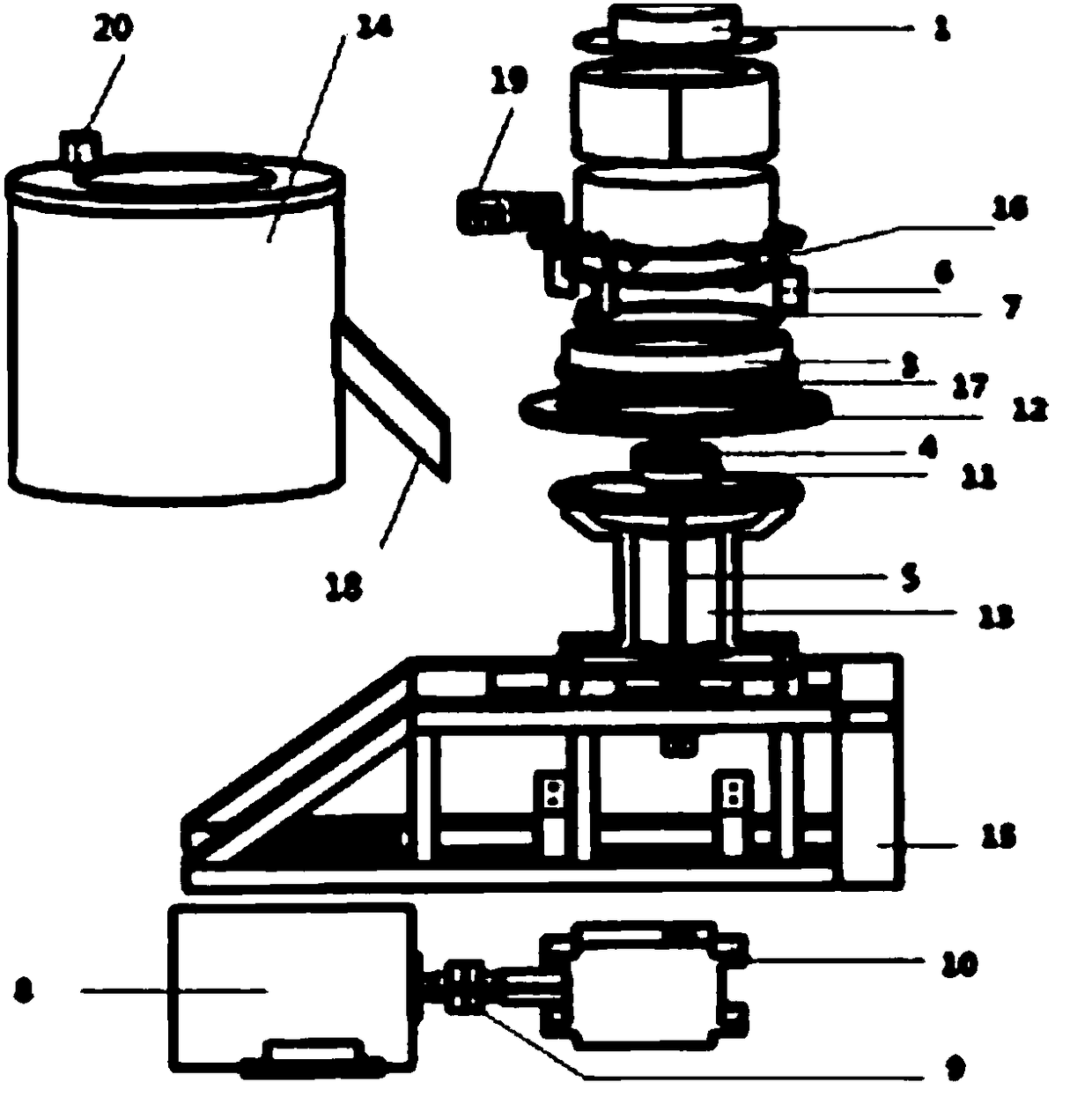

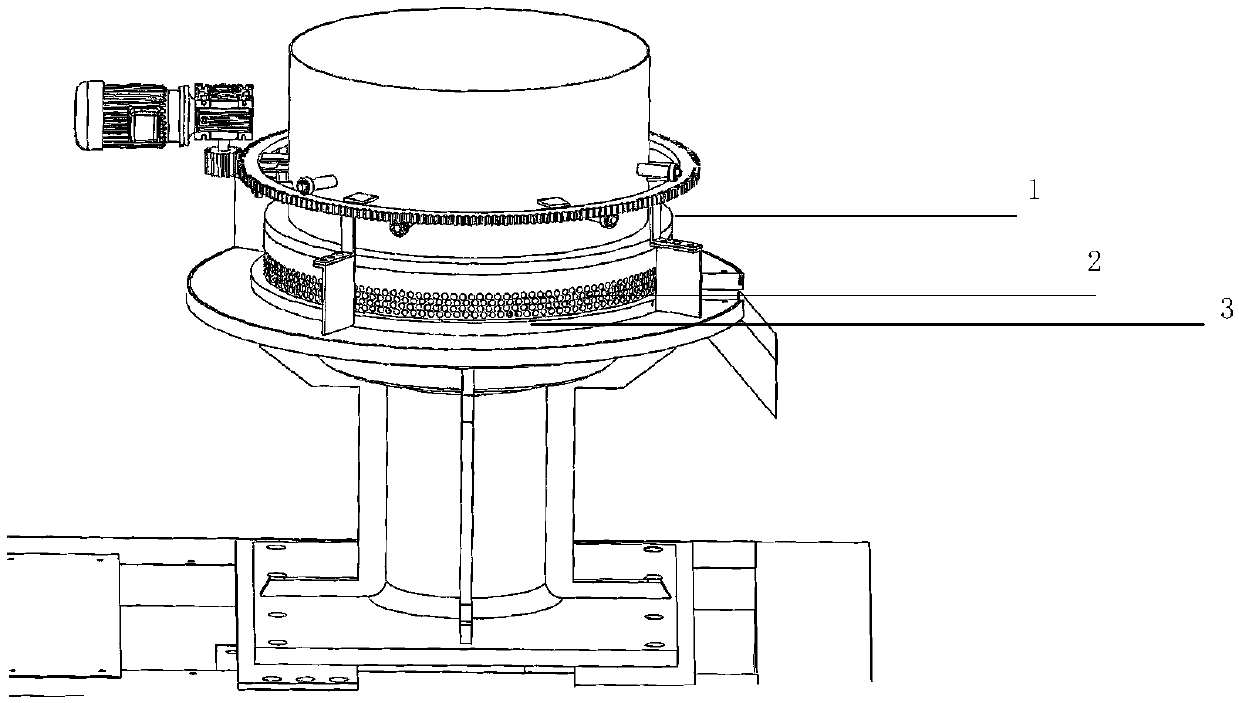

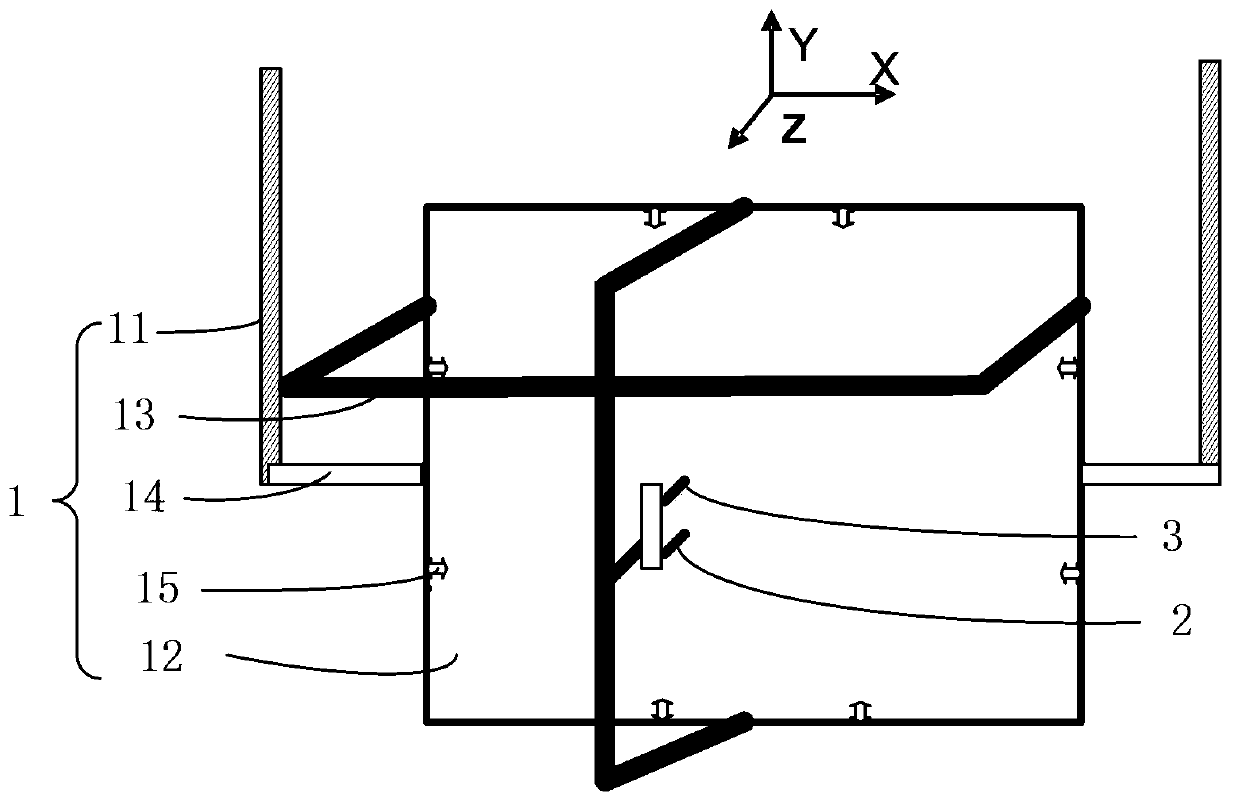

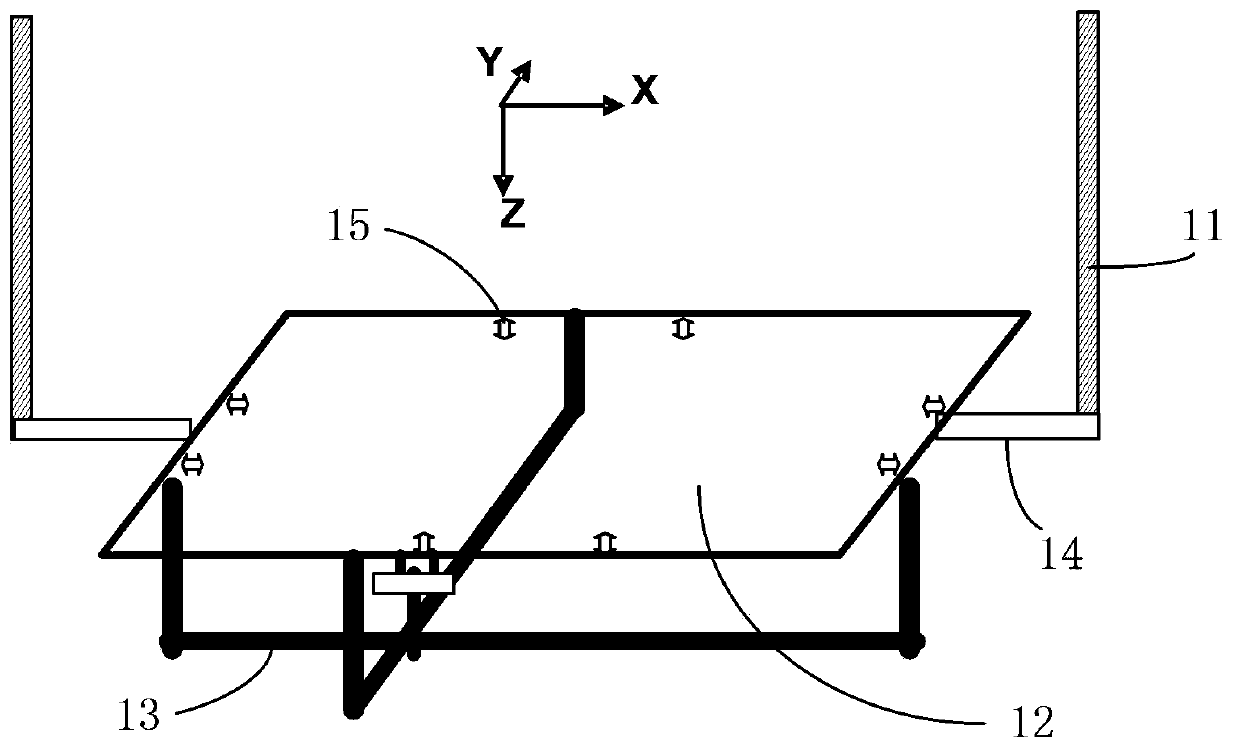

Straw biomass granulator

The invention discloses a straw biomass granulator which comprises a feeding port, a material turning plate and an annular mold assembly, wherein the material turning plate is located below a pressureroller assembly and is mechanically connected with a bottom supporting plate; the pressure roller assembly is arranged within a circumference of a mold assembly by a spindle; the spindle coincides with an axis of the mold assembly; a scraper is arranged below the pressure roller assembly; heating elements are arranged above and / or below the annular mold assembly; a groove is formed in an upper part of the annular mold assembly; the groove, a compressing flange and an annular mold base plate act together to prevent the heating elements from directly contacting dry materials to cause a fire andother safety hazards; the heating elements can be an electrical heating rod or PTC; the straw biomass granulator provided by the invention is further provided with a power system which comprises a motor and a speed reducer connected with the motor by a coupling; and the spindle is connected to the speed reducer. The straw biomass granulator provided by the invention has a yield increased by about30% compared with products having the same power in the market, and expands a range of water content of compressed materials to 25%; experimental tests show that a 55 kW granulator provided by the invention has properties superior to those of a 90 kW granulator in the market.

Owner:庞中化

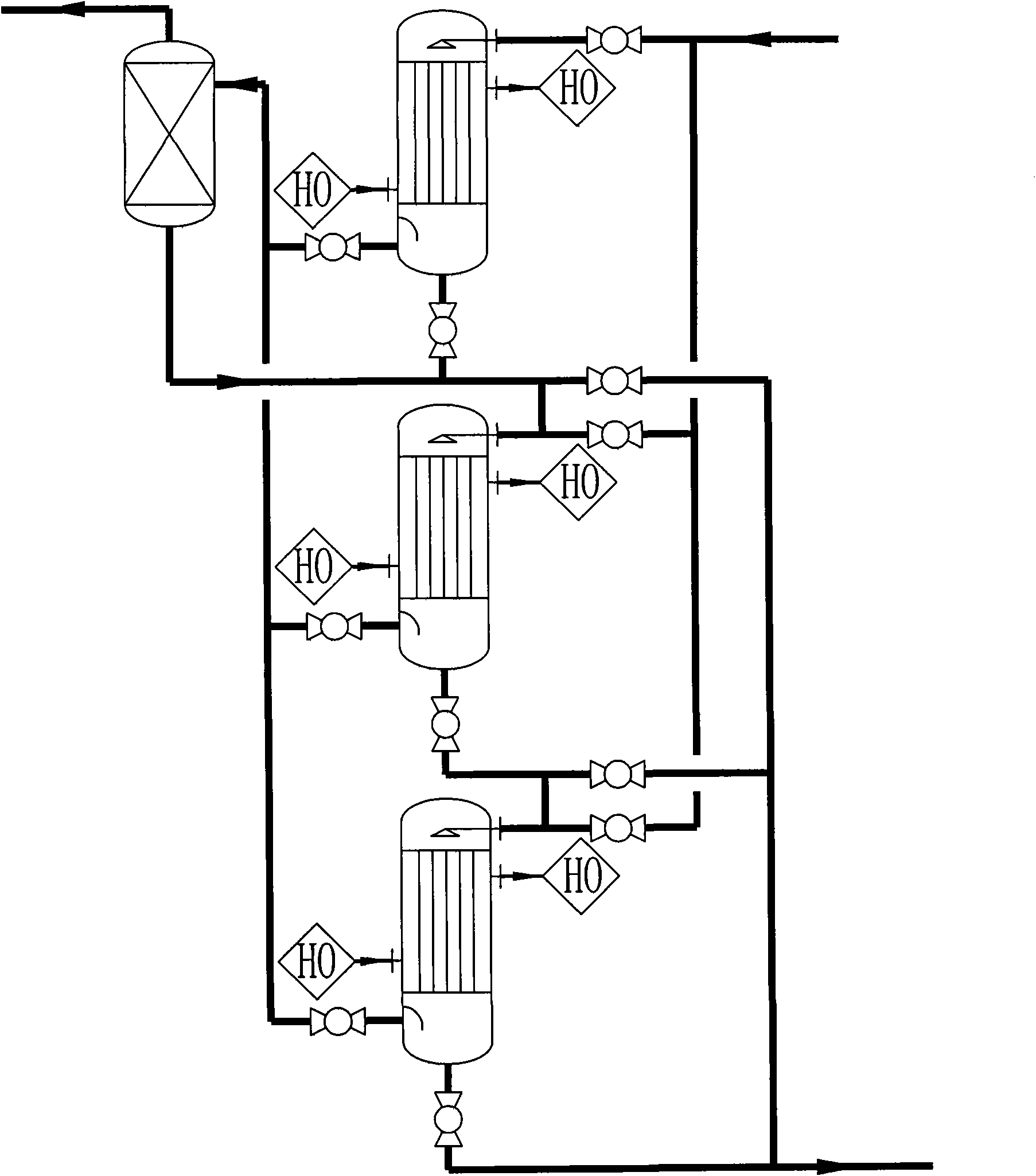

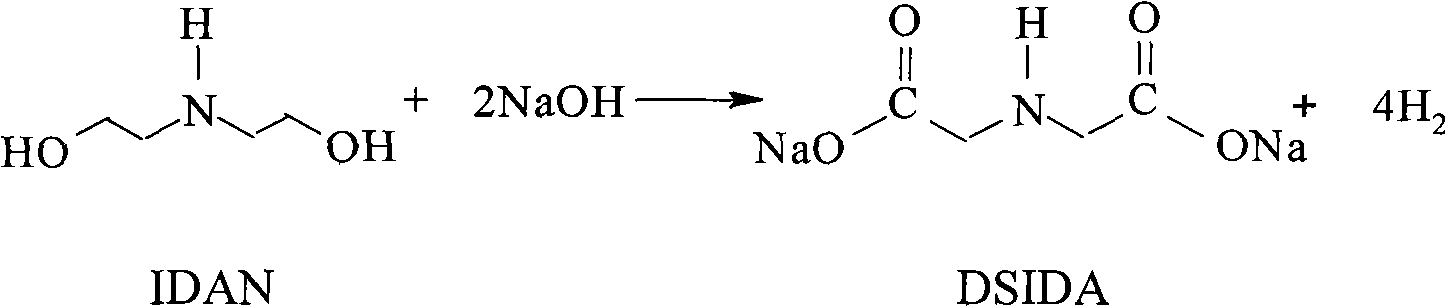

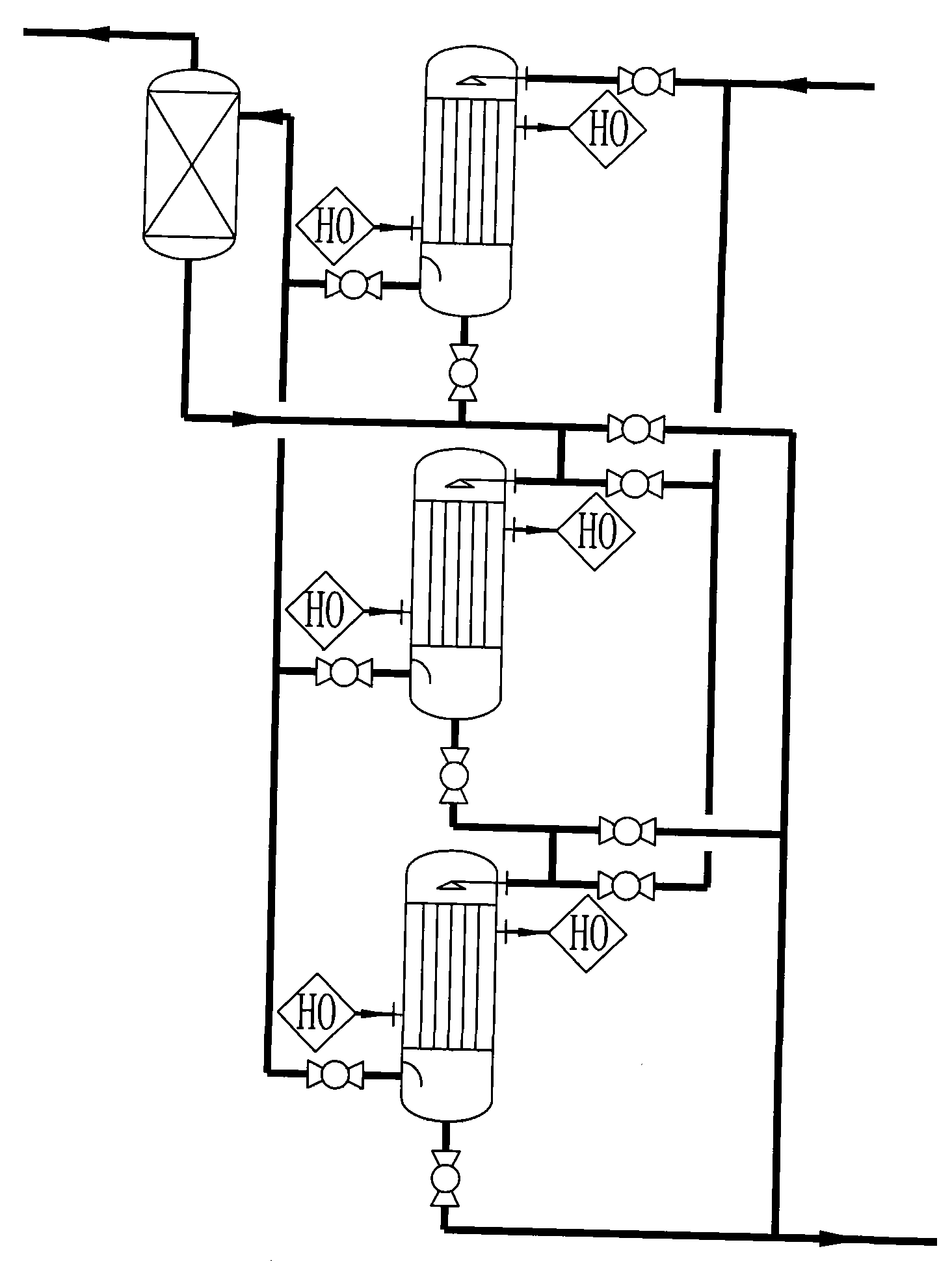

Synthesis as well as tail gas treatment technology and device of iminodiacetate

InactiveCN102050751AReduce typesEfficient removalOrganic compound preparationHydrogen separation using liquid contactDehydrogenationDiethanolamine

The invention relates to a synthesis technology and device of iminodiacetate. The technology uses diethanol amine as a main raw material and comprises the following steps: dissolving the diethanol amine, mixing with a caustic soda solution and deionized water evenly to prepare a feed liquid the mass concentration of which is 10-30%, and transferring the feed liquid into a multistage tubular reactor loaded with a solid catalyst through a metering pump to perform catalytic dehydrogenation reaction to obtain iminodiacetate; and treating the gas generated through catalytic dehydrogenation and the tail gas separated from the discharged liquid to recycle hydrogen. The device comprises the multistage tubular reactor which is designed on the basis of a kinetic model of isothermal constant-pressure reaction, wherein the multistage tubular reactor is formed by connecting 2 to 5 tubular reactors in series; each reactor is formed by a plurality of tubes; the same amount of catalyst is evenly filled in each tube; the upper part or lower part of each reactor is provided with a gas-liquid separator which is used for separating the gas generated through the dehydrogenation reaction from the discharged liquid; and the back of the gas-liquid separator is connected with a demister which is connected with a tail gas treatment device used for purification treatment through a regulating valve. The device provided by the invention has the characteristics that the technological operation is simple, the product yield is no less than 98%, the continuous production can be realized, the work efficiency can be increased, and the like.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Method for recycling treatment and denitration of municipal domestic garbage with dry rotary kiln

ActiveCN103042024AReduce coal consumptionEliminate secondary pollutionSolid waste disposalWater contentCoal

A method for recycling treatment and denitration of municipal domestic garbage with a dry rotary kiln comprises the following steps of pretreating and dividing the municipal domestic garbage into a combustible component material mainly comprising organic matters, and a residue component material mainly comprising inorganic matters, taking the combustible component material as fuel for a decomposing furnace of the dry rotary kiln to substitute fire coal and a hydrocarbon raw material for denitration, feeding the combustible component material to a space from the lower part to the middle upper part in the decomposing furnace with a feed device for treatment and denitration, and taking the residue component material subjected to chemical analysis as an alternative raw material for a batching flour mill of a raw material vertical mill system, wherein the combustible component material is in a bulk form, and is less than or equal to 200mm in side length and less than or equal to 30% in water content. With the adoption of the method for treating the municipal domestic garbage, the operation is simple, the coal consumption is low, the kiln performance stability is good, the combustion of pulverized coal in a production kiln and the furnace of the dry rotary kiln is unaffected, the treatment cost is low, and the pollution to the environmental is low.

Owner:长沙紫宸科技开发有限公司

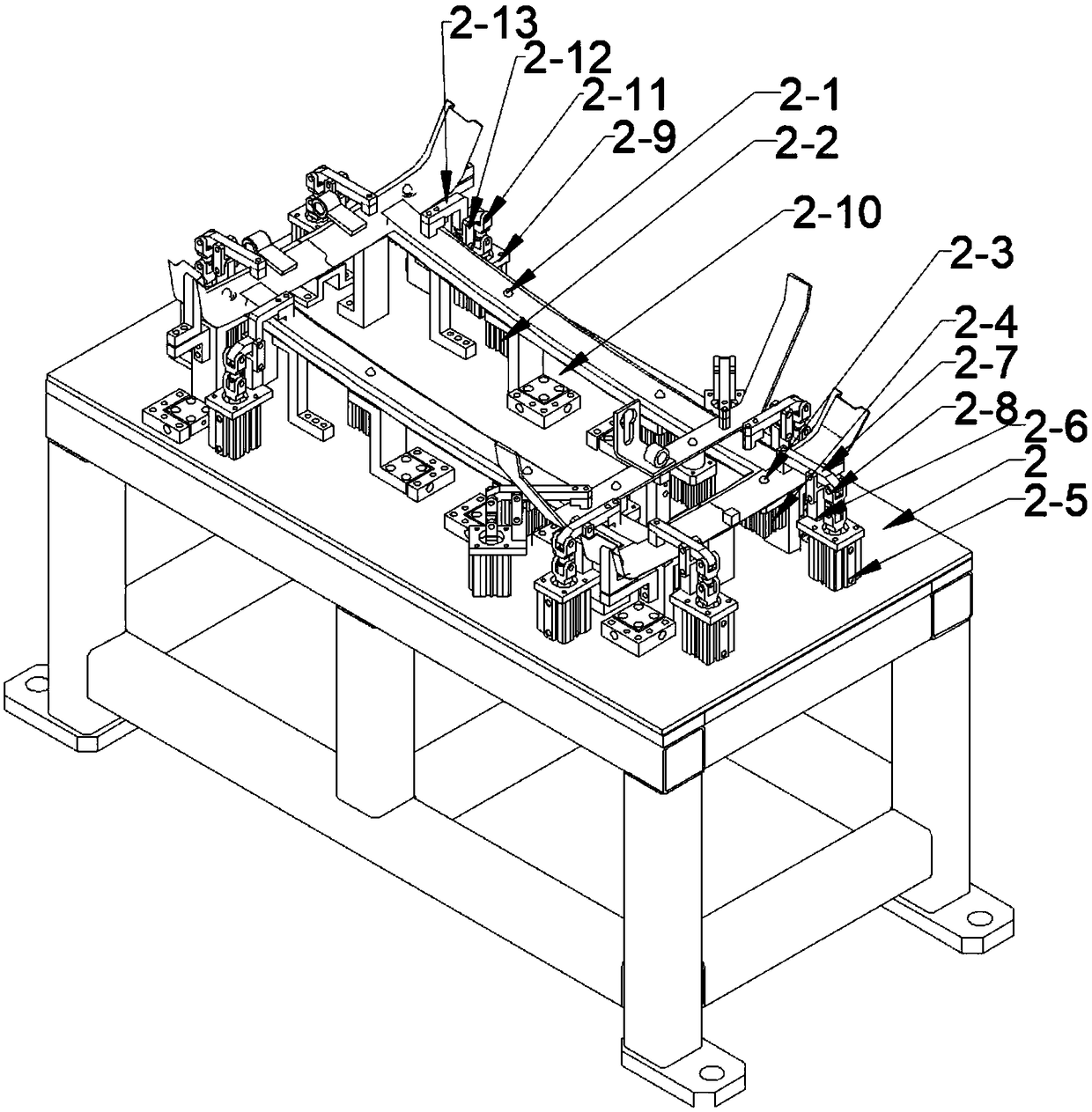

Hood welding unit

PendingCN109352200ALow costBig timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAnnular array

The invention relates to a hood welding unit, which includes a feeding module, a transporting module, a welding supporting module, a welding module and a gripper temporary storage module. The feedingmodule takes a working radius of a transfer robot of the transporting module as the radius and a fixing point of the transfer robot as an annular array with a circle center, and includes a first reinforcing rib storing mechanism, a second reinforcing rib storing mechanism, an upper cover storing mechanism, a third reinforcing rib storing mechanism, a first supporting frame storing mechanism, a left side plate storing mechanism and a right side plate storing mechanism; the gripper temporary storage module successively includes four sets of temporary storage brackets clockwise, wherein the firsttemporary storage bracket is provided with a reinforcing rib compression tool gripper, the second temporary storage bracket is provided with left and right side plate grippers, the third temporary storage bracket is provided with a hinge gripper and an upper cover gripper, and the fourth temporary storage bracket is provided with a rear side reinforcing rib compression tool gripper; and the welding supporting module includes a hood supporting bracket seaming tool, an upper hood reinforcing rib assembling welding tool and an upper hood combined assembling welding tool.

Owner:卓弢机器人盐城有限公司

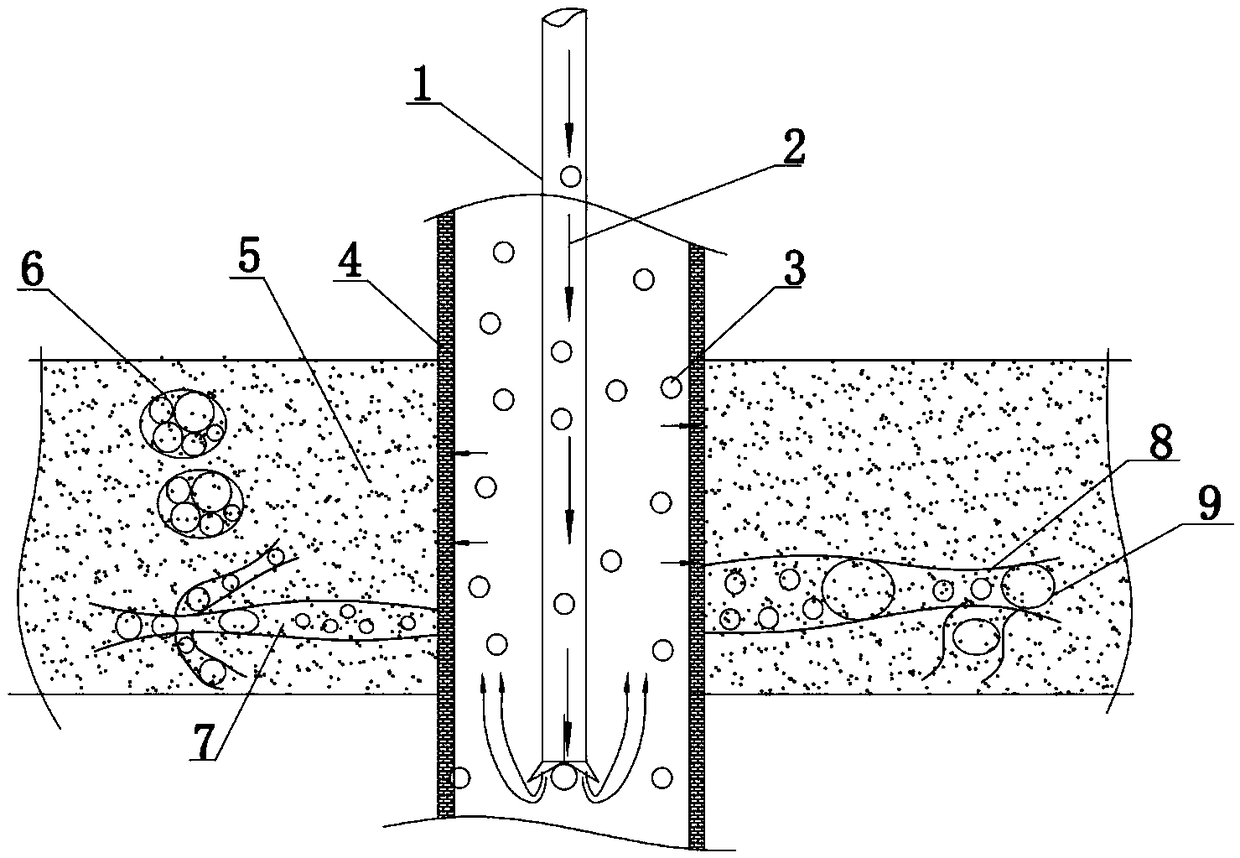

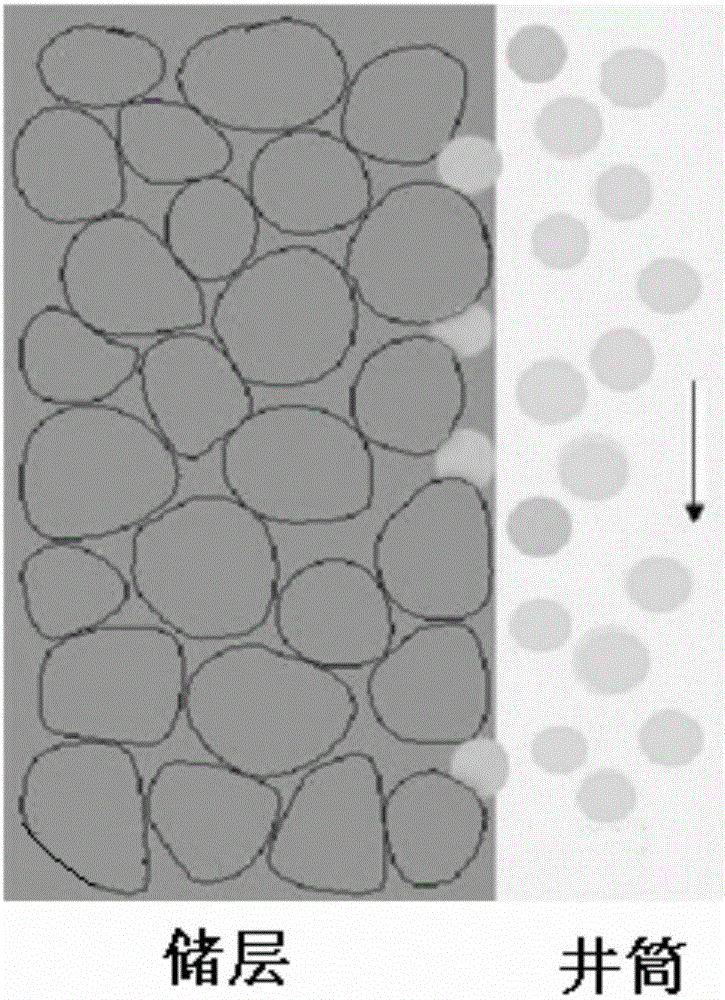

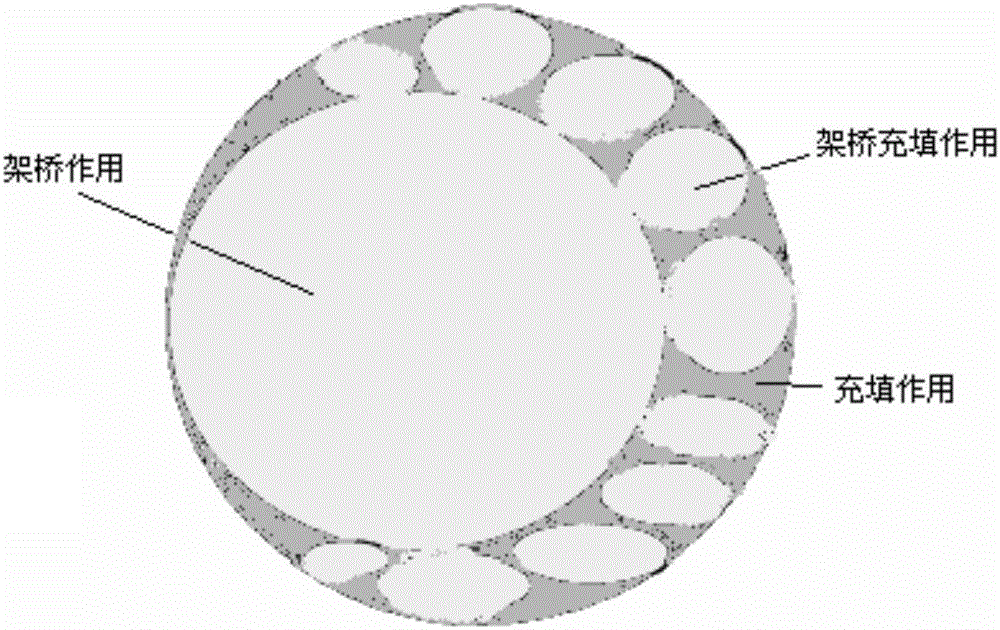

Horizontal well sand prevention and water control pipe string and oil production increasing method

ActiveCN112302580ASpeed up entryReduce post-processing costsFluid removalSealing/packingSocial benefitsHorizontal wells

The invention discloses a horizontal well sand prevention and water control pipe string and an oil production increasing method. The pipe string comprises a sand prevention pipe assembly and a plurality of packers; the sand prevention pipe assembly comprises an inner pipe, a supporting particle layer and an outer pipe; and a hydrophobic oleophylic laminating propping agent is arranged in the supporting particle layer. The method comprises the steps that a water plugging experimental section is selected from a horizontal part of a horizontal well and a reservoir around the horizontal part; thesand prevention pipe assembly is prepared; the sand prevention pipe assembly is installed, and a plurality of packing sections are arranged; and oil in the reservoir is gradually conveyed out, and theoutput of water is controlled. According to the horizontal well sand prevention and water control pipe string and the oil production increasing method, after an oil layer discharges water, an instrument or a tool does not need to be lowered to independently find and control water, the oil layer can be effectively prevented from producing water and allowing oil to pass through the hydrophobic oleophylic laminating propping agent, the productivity is not affected, manual intervention is not needed, and operation procedures are reduced. The method not only can prevent sand, but also can controlwater and convey oil; and the method is simple and effective and has remarkable economic benefits and social benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

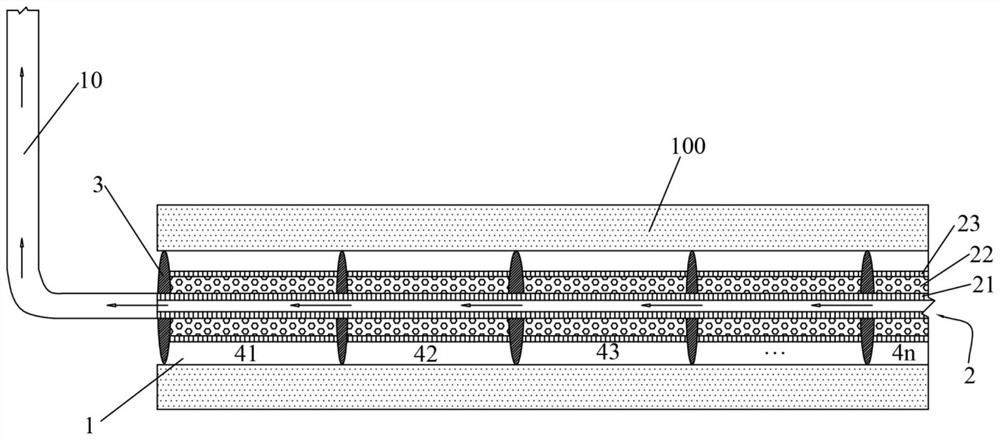

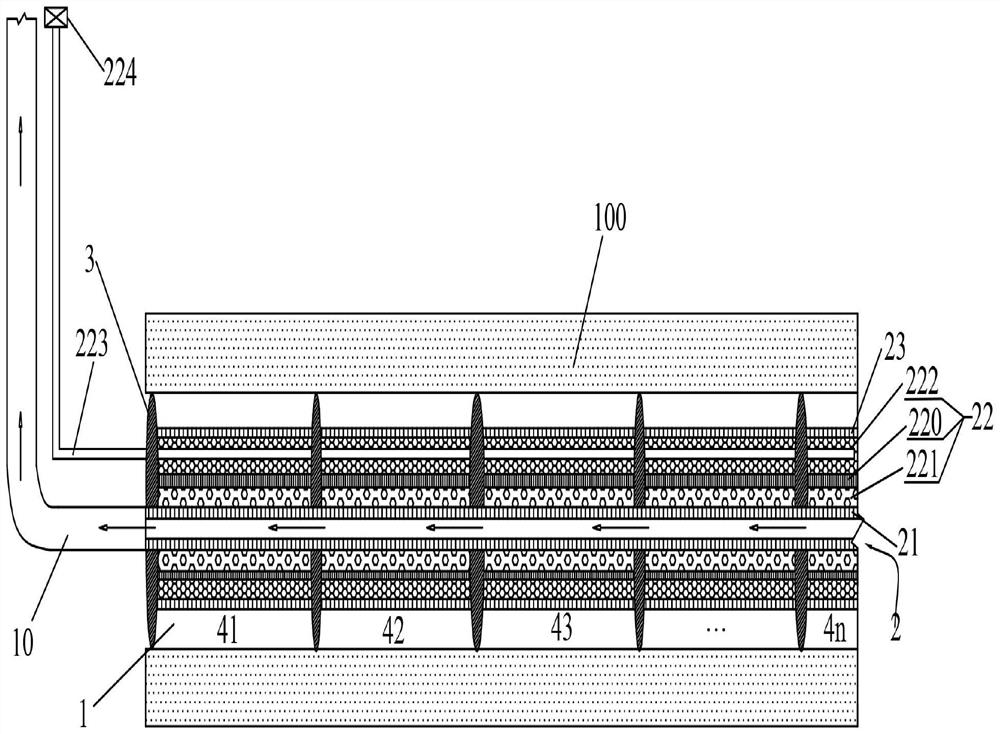

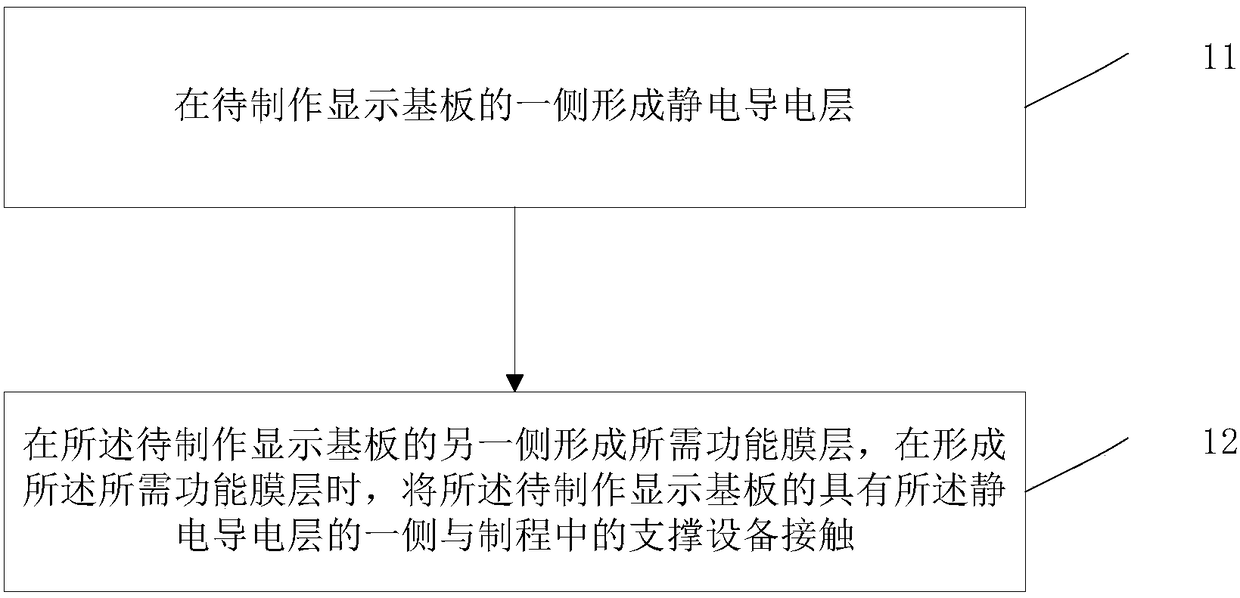

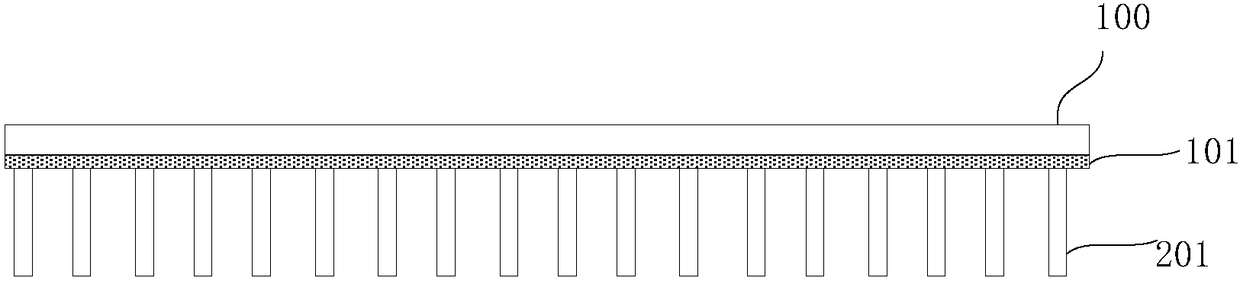

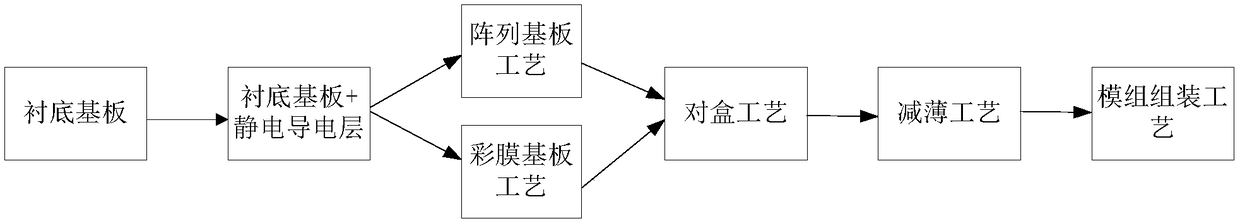

Display substrate, display panel and manufacture method thereof

InactiveCN108196410AImprove yieldPrevent breakdownNon-linear opticsIdentification meansEngineeringStatic electricity

The invention provides a display substrate, a display panel and a manufacture method thereof. The manufacture method for the display substrate comprises the steps of forming an electrostatic conductive layer on the side of the to-be-manufactured display substrate; forming a desired functional film layer on the other side of the to-be-manufactured display substrate, and conducting contact processing on the side where the electrostatic conductive layer is formed of the to-be-manufactured display substrate and supporting equipment in the manufacture process when the desired functional film layeris formed. The electrostatic conductive layer is a whole layer of the conductive film layer, so that the static electricity on the supporting equipment can be diffused on the entire display substrate,static single point release dose not occur to avoid electrostatic single point breakdown, and the product yield of the display substrate is effectively improved.

Owner:BOE TECH GRP CO LTD +1

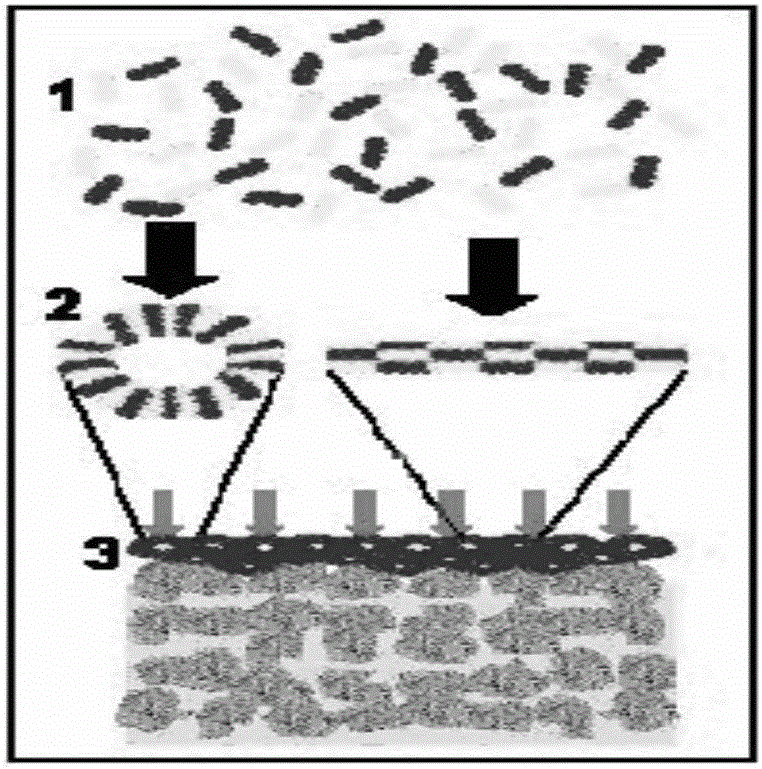

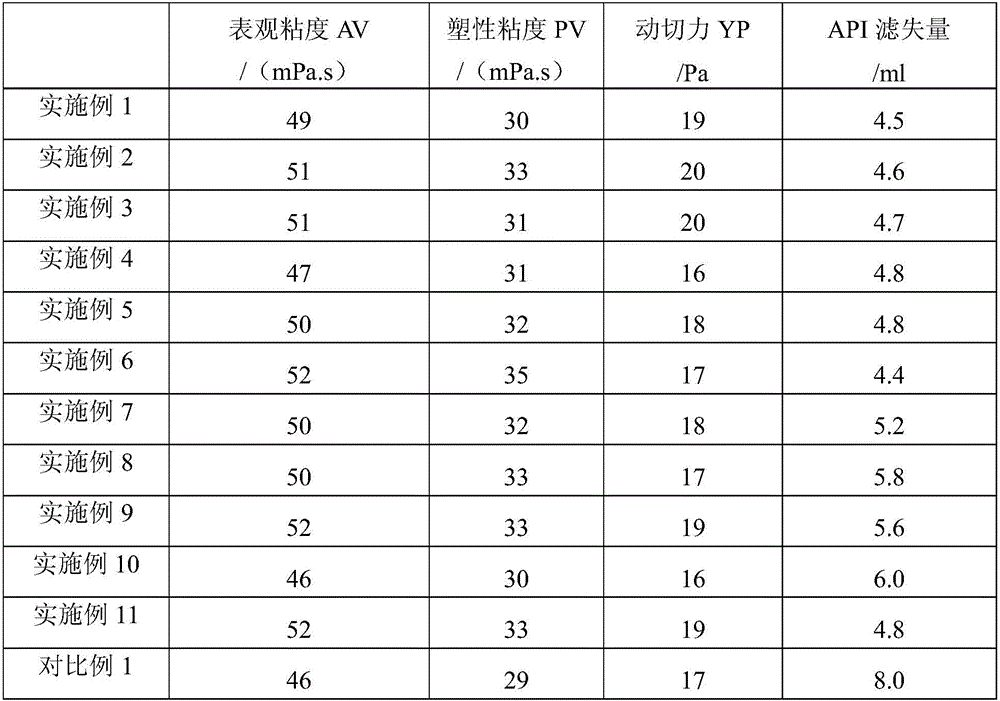

Reservoir protection agent composition, drilling fluid containing reservoir protection agent composition and application thereof

ActiveCN106566484AAvoid breakingPlay adaptabilityFlushingDrilling compositionCross-linkFilm-forming agent

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

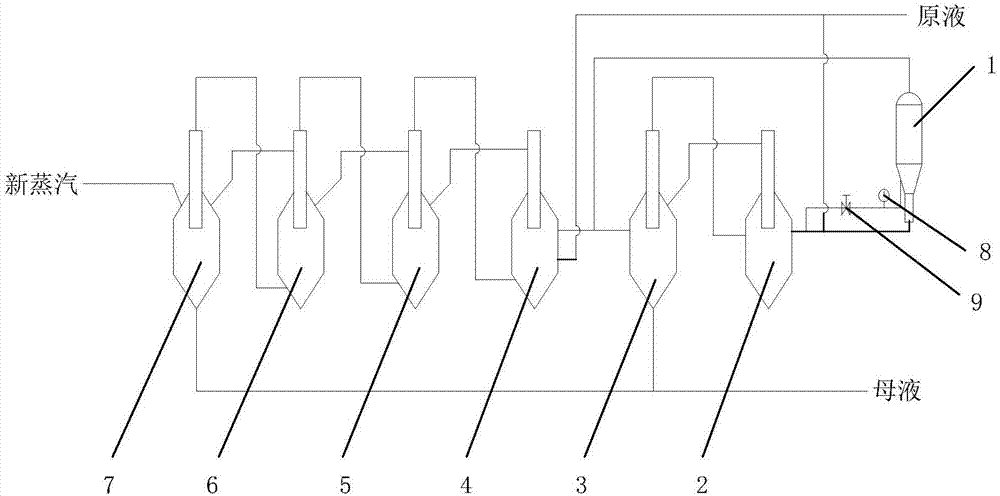

Evaporating unit and solution evaporating method

InactiveCN107497128ASimple and reasonable designReduce the temperatureMultiple-effect evaporationProcess engineeringMultiple-effect evaporator

The invention relates to the technical field of solution evaporation and especially relates to an evaporating unit and a solution evaporating method. The evaporating unit comprises a stock solution flash evaporator and a six-effect evaporator set, wherein the six-effect evaporator set comprises a sixth effect evaporator, a fifth effect evaporator, a fourth effect evaporator, a third effect evaporator, a second effect evaporator and a first effect evaporator; the stock solution flash evaporator is connected with the sixth effect evaporator through a flash liquid conveying pipeline; the stock solution flash evaporator is connected with the fourth effect evaporator or the fifth effect evaporator through a secondary stock solution flash steam pipeline. The original device is forcefully reformed into the stock solution flash evaporator which is organically combined with the six-effect evaporator set, so that the stock solution temperature is reduced, the stock solution concentration is increased, the full flashing of the materials is guaranteed, the evaporation efficiency is increased, the purposes of saving energy and reducing consumption are achieved, the reforming operation for the equipment is simple, the cost is low, the evaporation steam consumption is reduced under the condition that the capacity of the evaporation unit is not influenced, the cost is saved for the enterprise and the profit is increased.

Owner:SHANDONG NANSHAN ALUMINUM +1

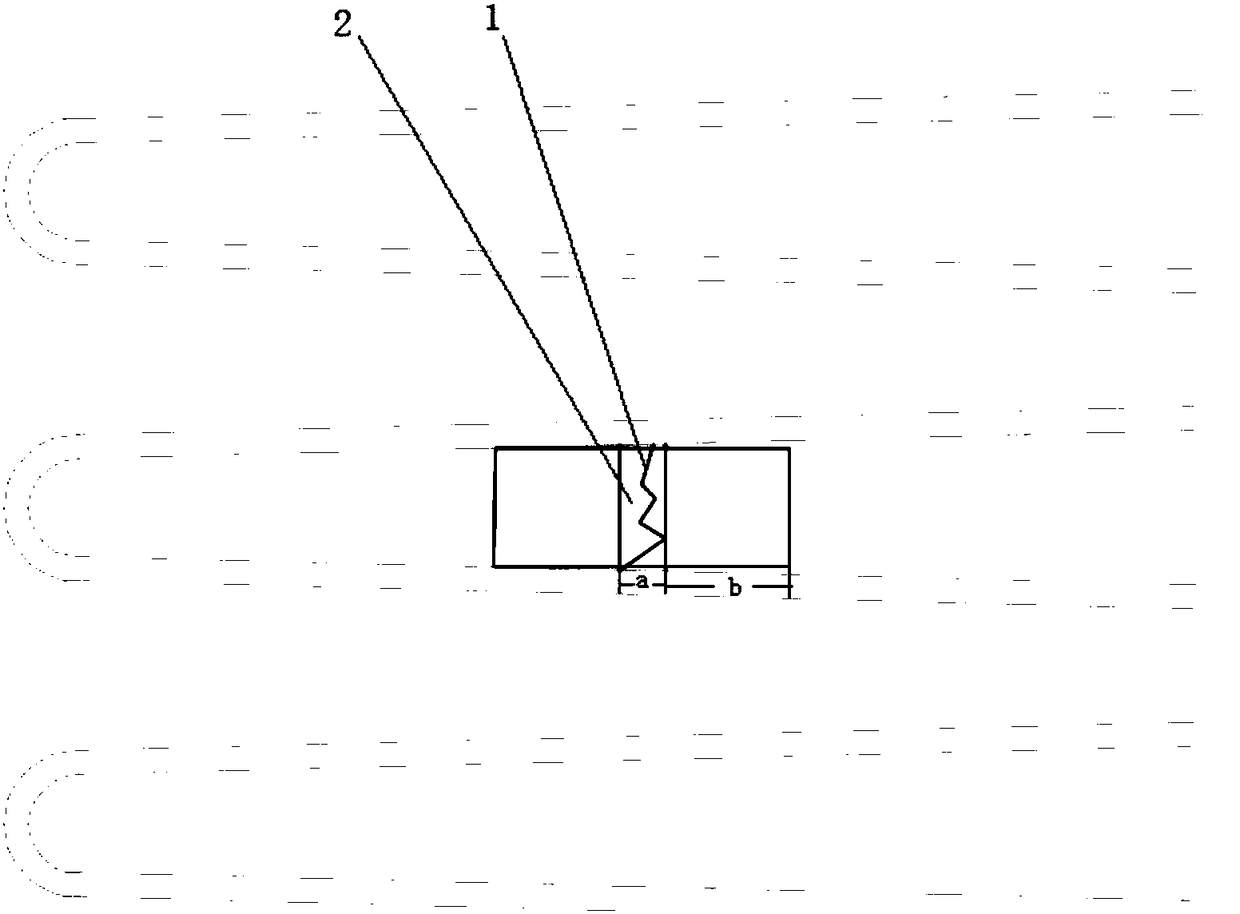

Repairing method for damaged conducting core plate of MWT photovoltaic solar assembly

InactiveCN108598209ASimple homeworkDoes not affect production capacityFinal product manufacturePhotovoltaic energy generationAdhesiveEngineering

The invention discloses a repairing method for a damaged conducting core plate of an MWT photovoltaic solar assembly. For a conducting core plate with a broke conductive foil, a tearing opening is pasted by a conductive foil adhesive tape and thus the broken part is repaired to meet the original technical requirement. Because of the conductive foil adhesive tape, the double-sided double-directionconducting is realized, so that the production staff can use the adhesive tape conveniently during the actual conductive foil repairing process. After testing, the conducting core plate repaired by using the conductive foil adhesive tape has the contact resistant slightly larger than that of a normal A type of conducting core plate.

Owner:JIANGSU SUNPORT POWER CORP LTD

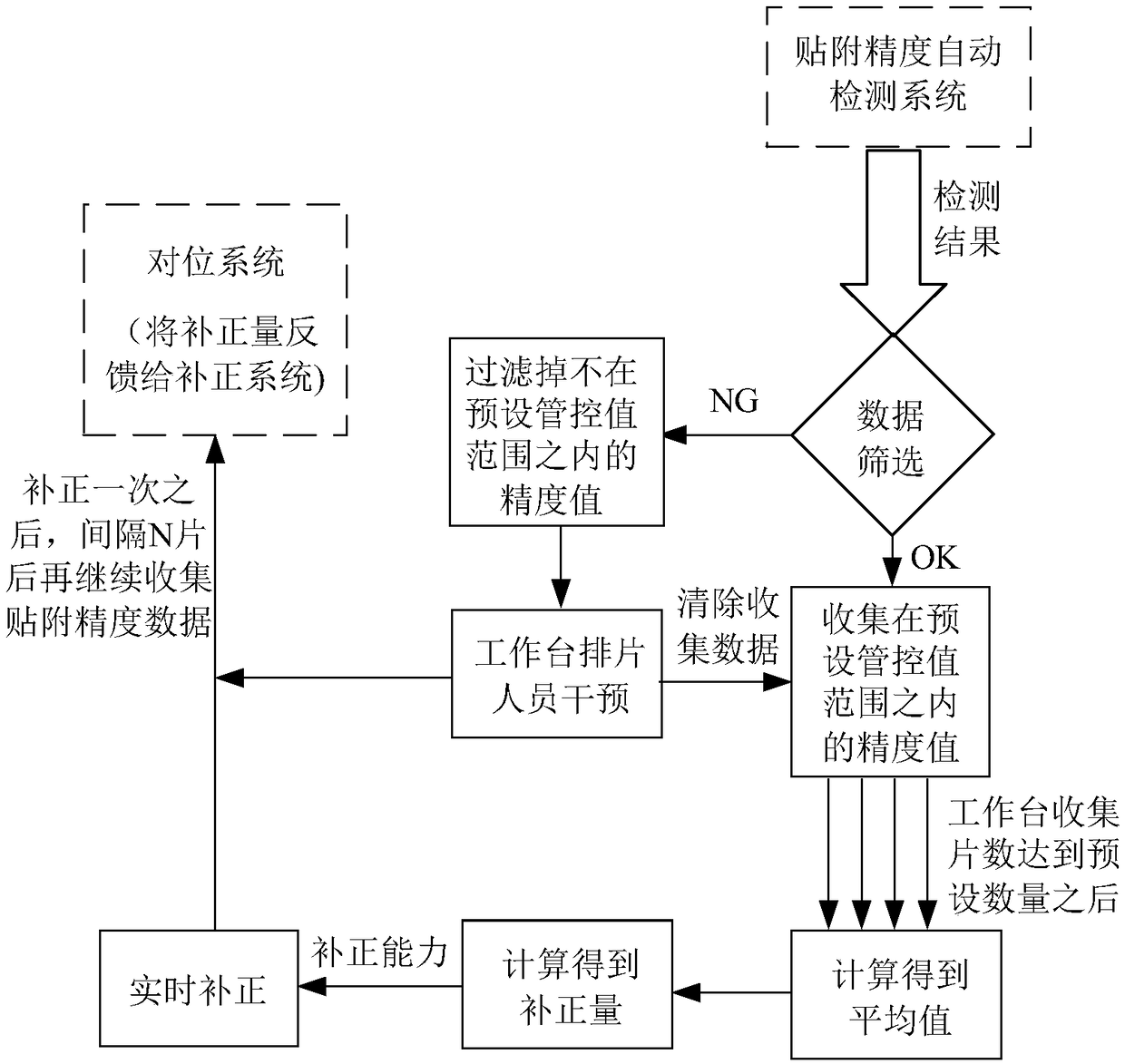

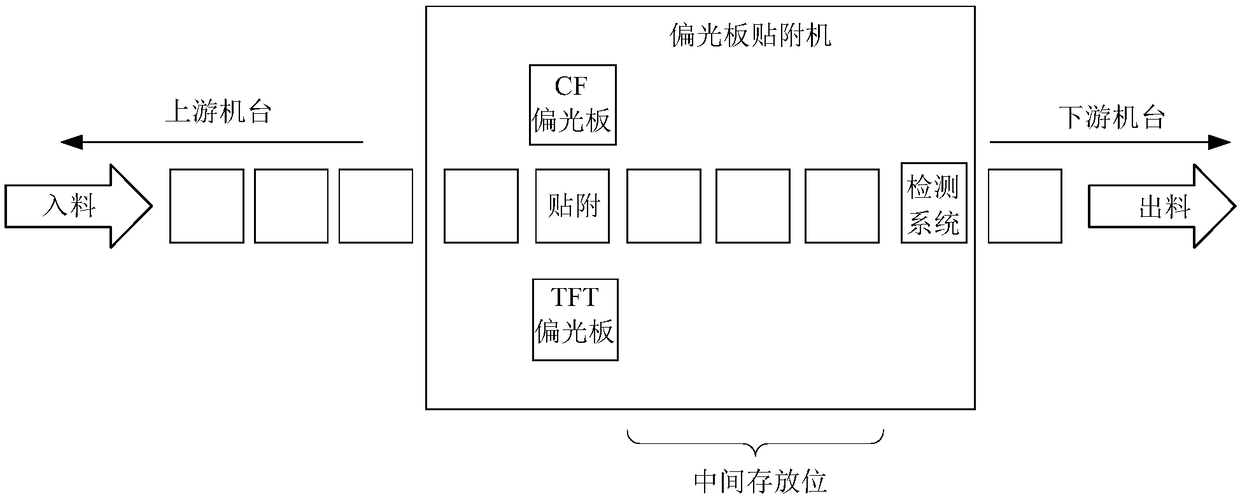

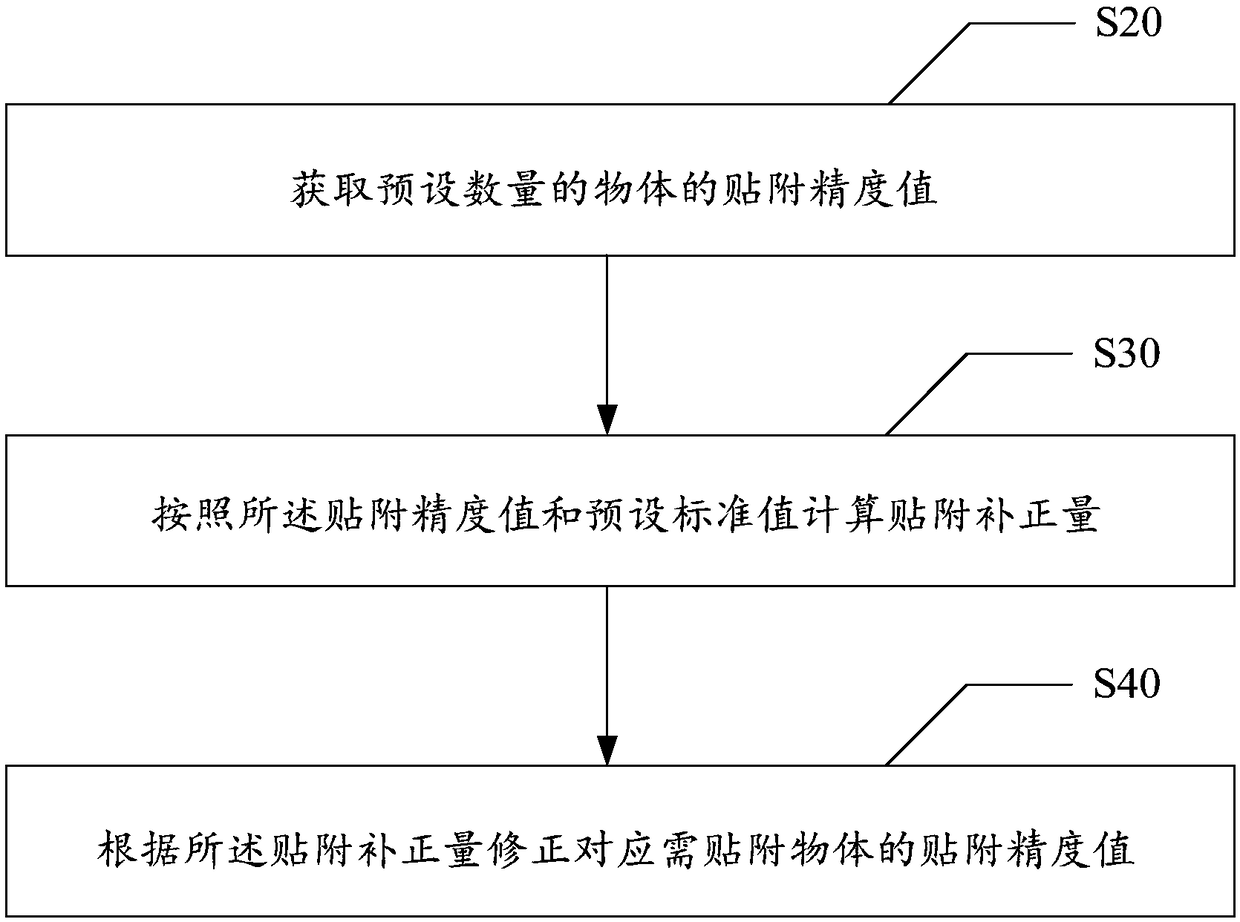

Attaching control method of object, attaching machine and storage medium

ActiveCN109353103ARealize automatic correctionGood steady stateLaminationLamination apparatusStable stateEmbedded system

The invention discloses an attaching control method of an object, an attaching machine and a storage medium, and the attaching control method for the object comprises the following steps of: obtainingan attaching precision value of a predetermined number of objects; according to the attaching precision value and a preset standard value, calculating an attaching correction value. Correcting the attaching precision value of the objects to be attached according to the attaching correction value. The attaching control method of the object does not need to stop when the attaching precision is corrected, thus does not affect the productivity of the machine, and can avoid the problem of error due to manual calculation and manual operation, and can monitor and correct automatically in real time.The attaching precision of the object can be kept in a good and stable state.

Owner:HKC CORP LTD

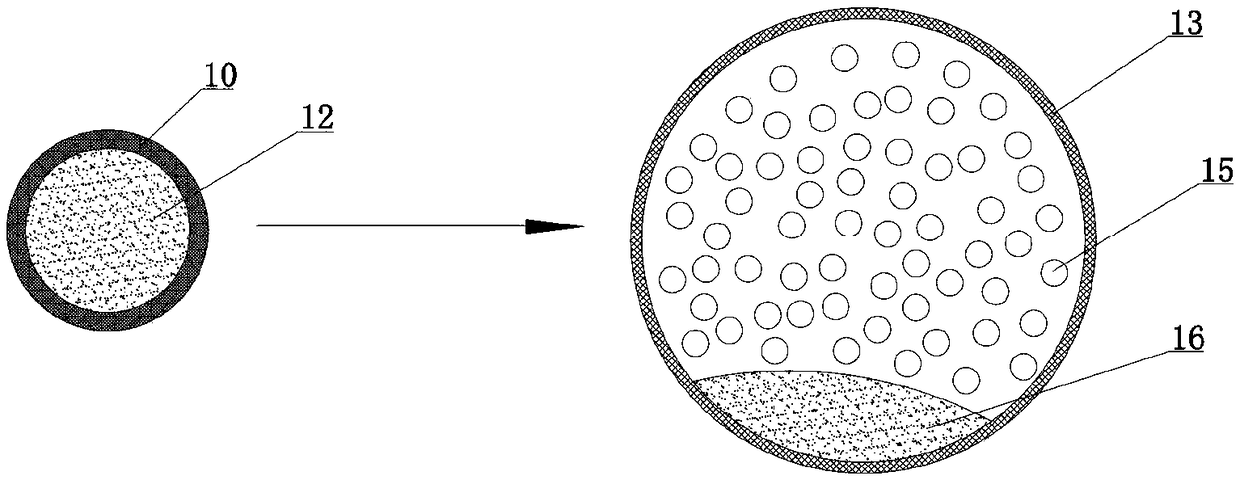

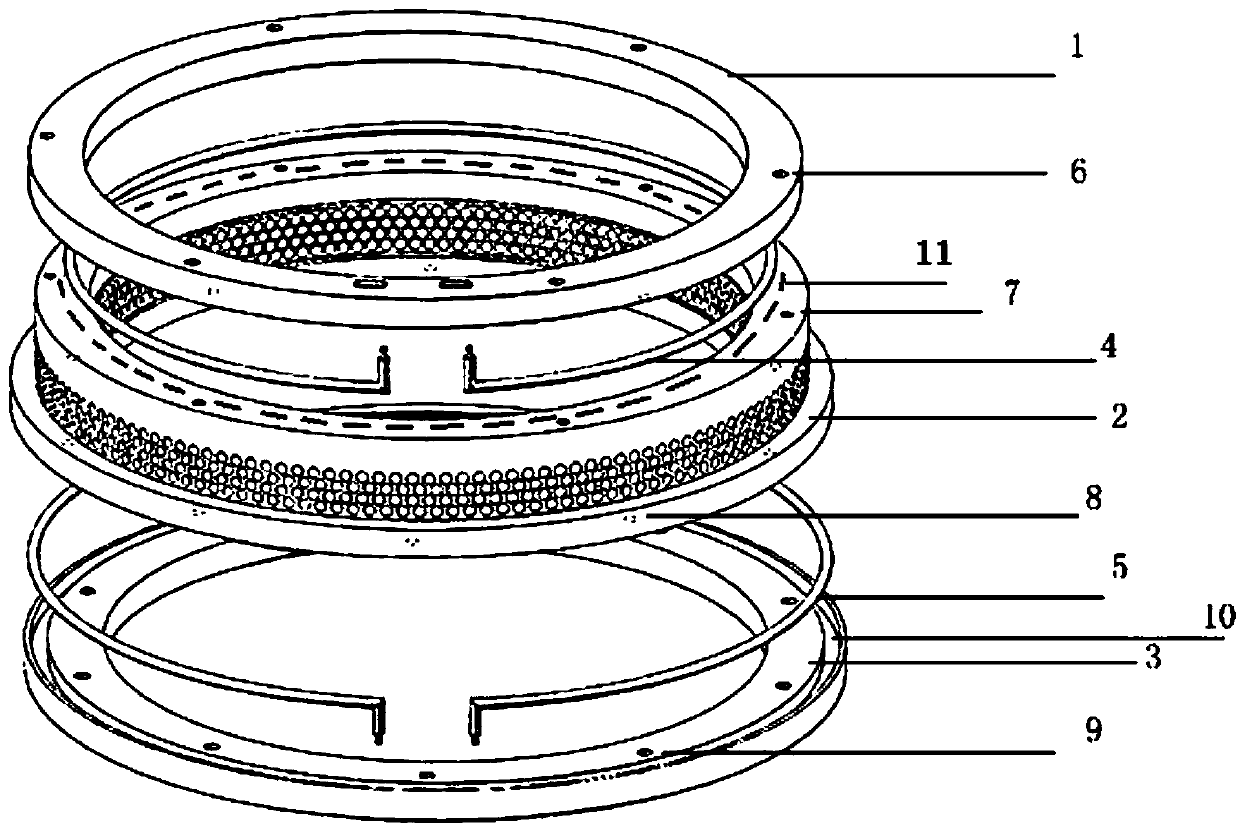

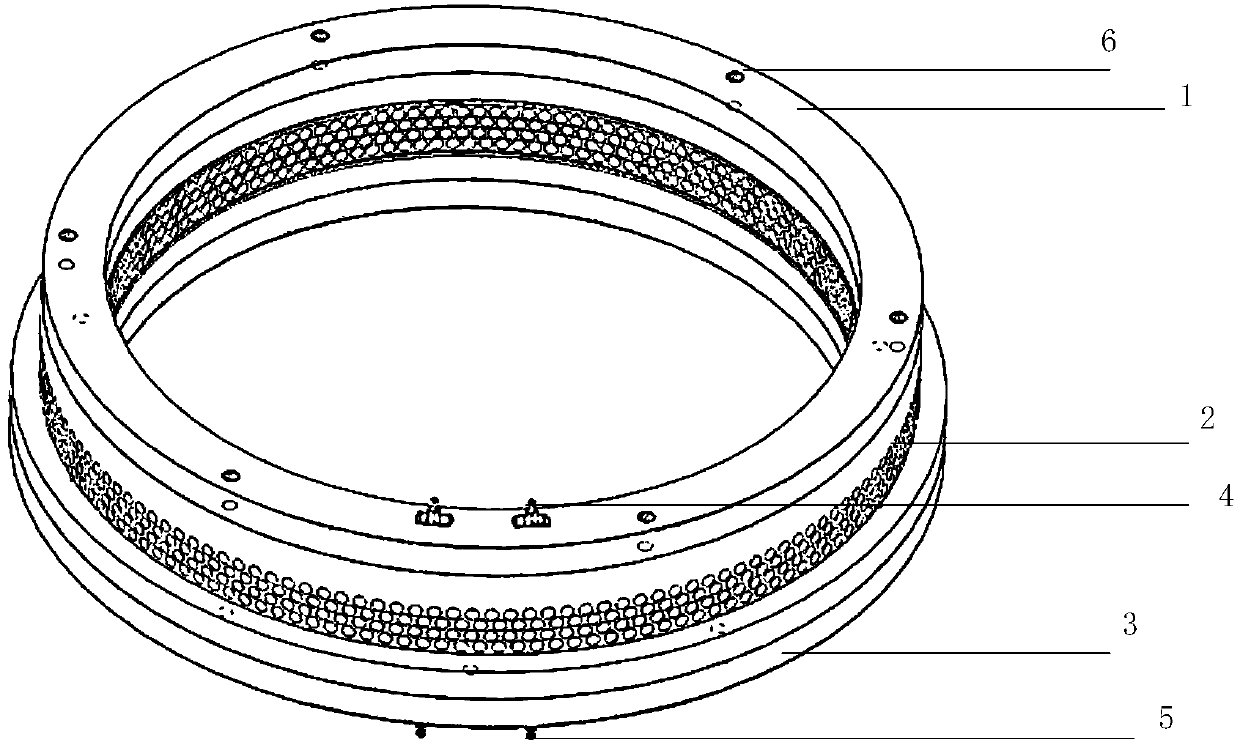

Heating ring die system for straw biomass granulator

The invention belongs to the field of biofuel manufacturing devices, and provides a special heating ring die system device for a biomass granulator to improve the production efficiency and increase the raw material adaptability of the biomass granulator. The system device sequentially includes a torus pressing flange, an upper heating element, a torus ring die, a lower heating element and a torusring die baseboard from top to bottom, the upper part of the ring die is provided with an upper groove for accommodating the upper heating element, the upper part of the ring die baseboard is providedwith a lower groove for accommodating the lower heating element, and the pressing flange, the upper heating element, the ring die, the lower heating element and the ring die baseboard are fixed by fastening bolts, through holes and fixing holes in order to make the upper heating element and the lower heating element respectively sealed in the upper groove and the lower groove and isolated from the outside. The upper heating element and the lower heating element adopt electric heating rods or PTC heating rods, and are closely attached to the pressing flange, the ring die and the ring mold baseboard to ensure good heat conduction. The granulator using the device does not need to be preheated for mixing, so the turn-on time is obviously saved.

Owner:庞中化

Scratched mask repair apparatus and method

ActiveCN103969945ATimely and fast repairDoes not affect production capacityPhotomechanical exposure apparatusMicrolithography exposure apparatusSoftware engineeringMechanical engineering

The present invention discloses a scratched mask repair apparatus and a method. The apparatus comprises a bracket device, a defect detection device and a repair module, wherein the bracket device is arranged in a photolithography machine chamber, the defect detection device and the repair module are arranged on the bracket device, and the repair module comprises a plurality of repair refills with different sizes. According to the present invention, the bracket device of the scratched mask repair apparatus is directly arranged in the photolithography machine chamber, and can timely and rapidly perform repair in the photolithography machine during mask scratching without influence on productivity of the photolithography machine, such that the function of the photolithography machine is complete, the automation degree of the photolithography machine is high, the mask repair can be directly completed in the photolithography machine, and the internal space of the photolithography machine is completely utilized so as to substantially shorten the repair period and provide characteristics of simpleness, rapidness, low cost, and no influence on productivity.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

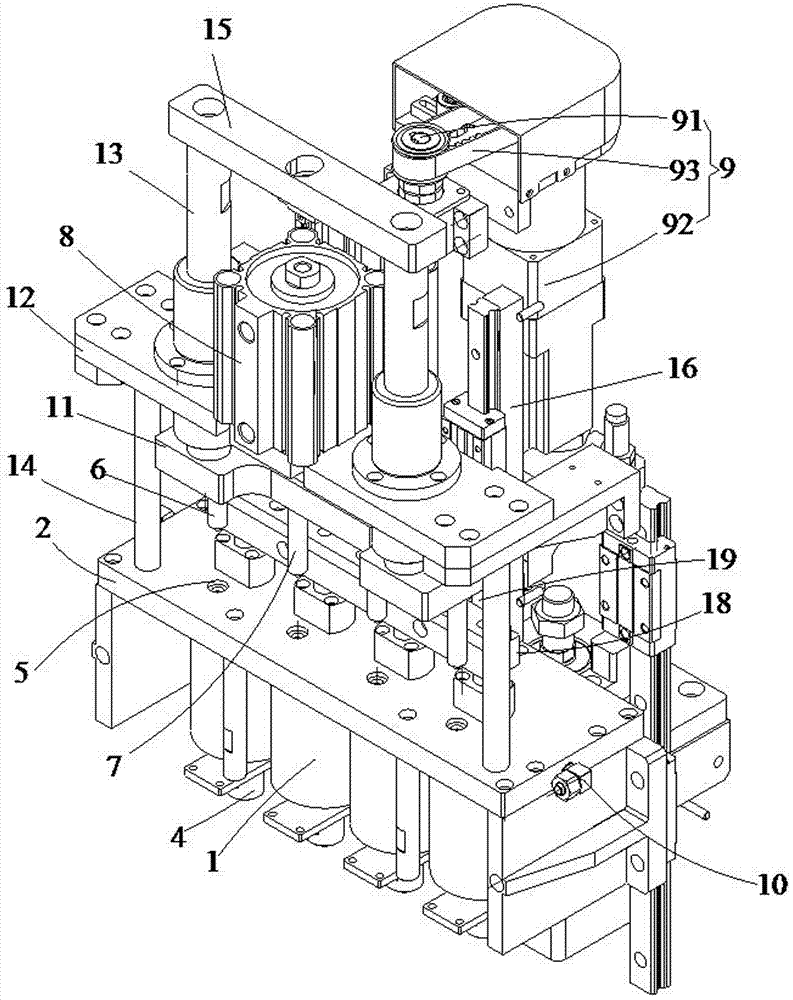

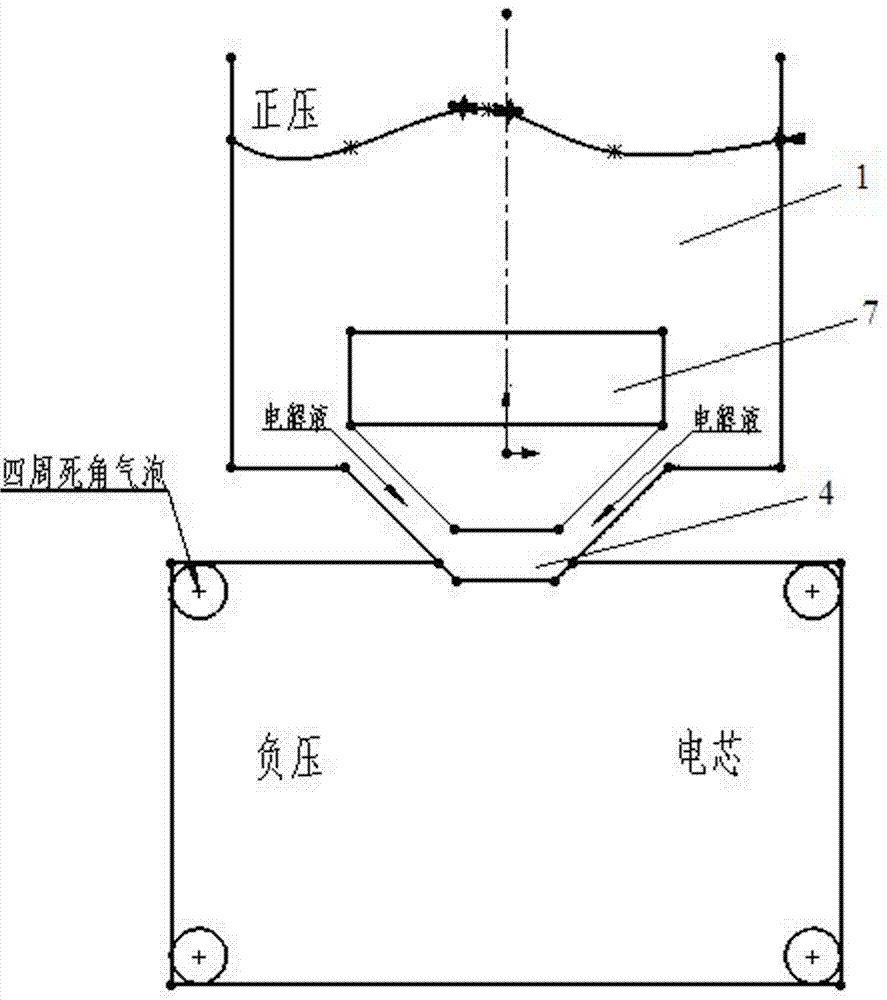

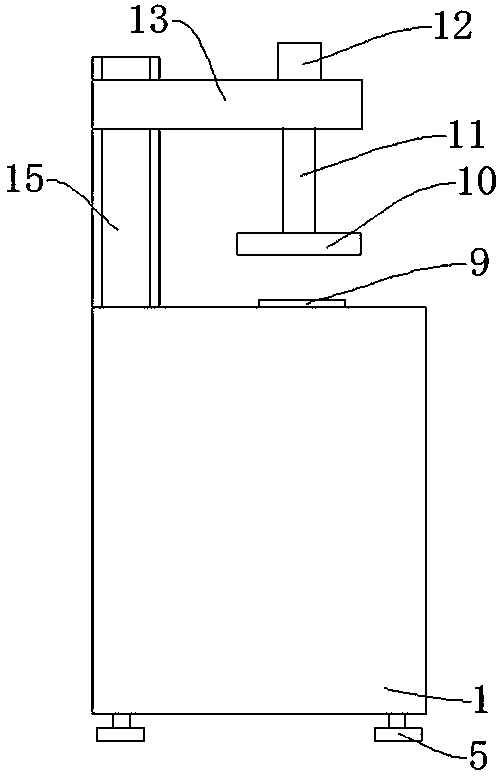

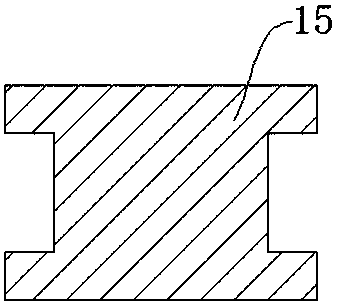

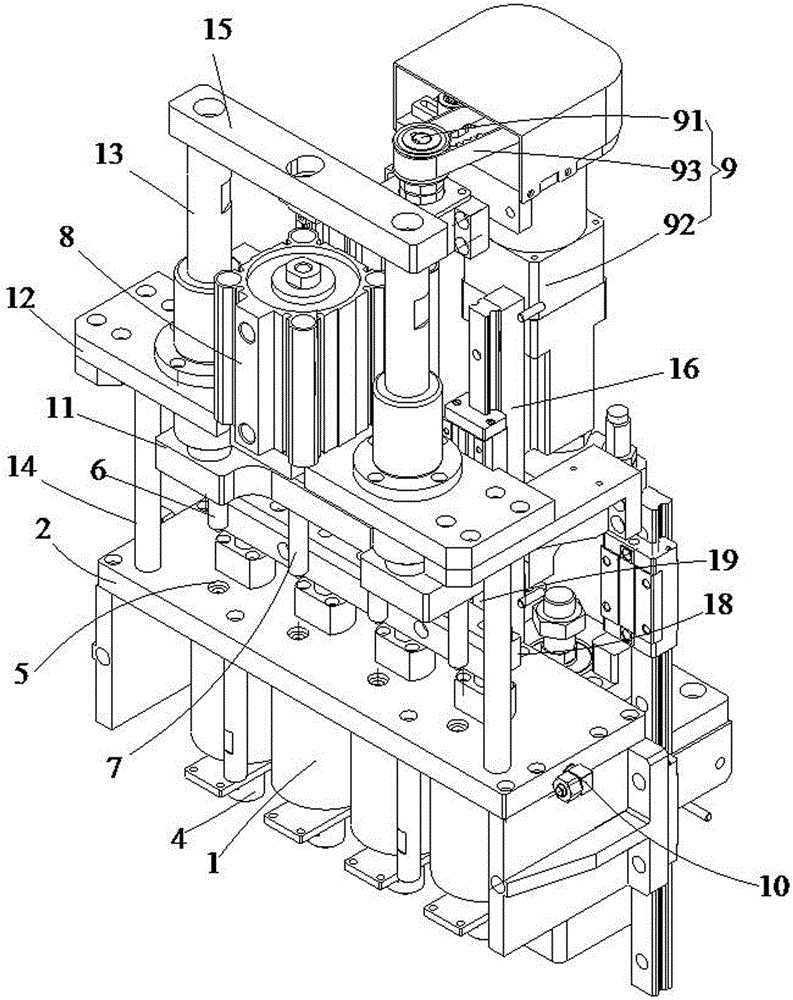

Liquid injection device and liquid injection method

InactiveCN105406021BImprove pass rateQuality improvementCell component detailsEngineeringLithium-ion battery

Owner:DONGGUAN ALI AUTOMATION CO LTD

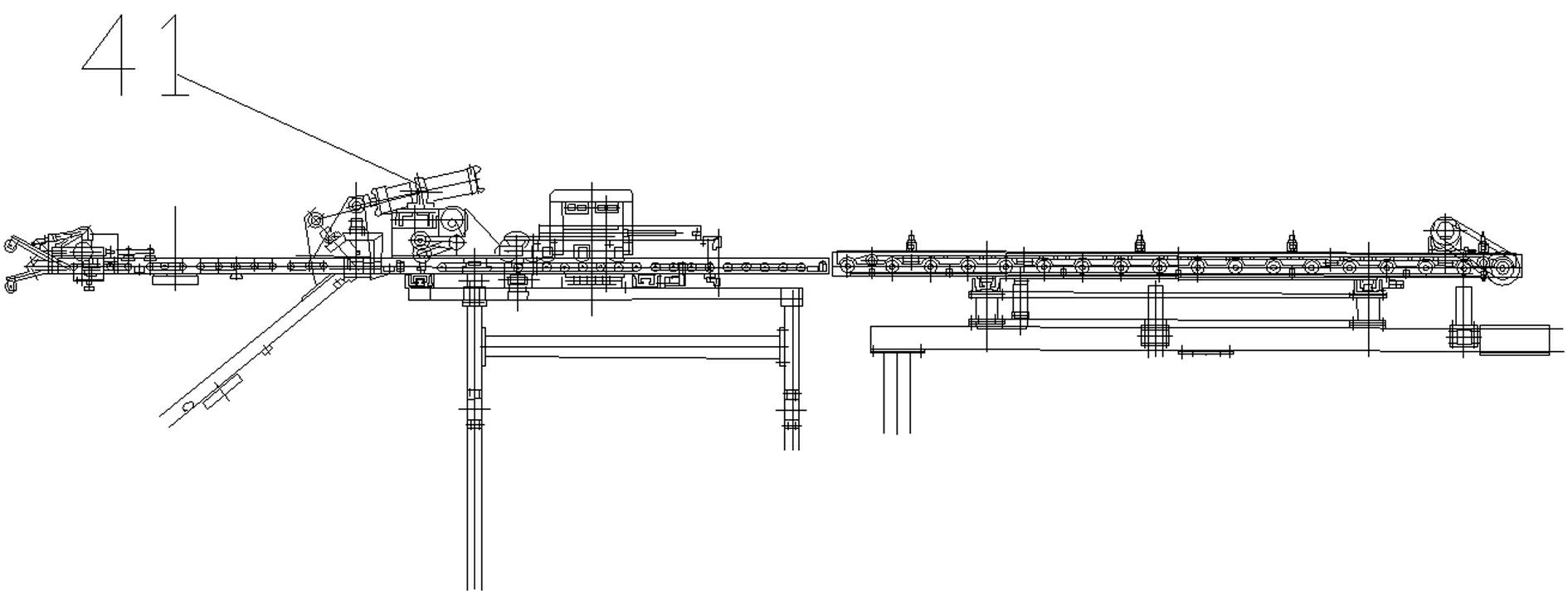

All-steel radial tire building machine feeding rack for automatically and laterally moving upper tread

InactiveCN102161445AHigh degree of automationManual labor intensity noFeed tablesAutomatic controlRadial tire

The present invention relates to an all-steel radial tire building machine feeding rack for automatically and laterally moving an upper tread. The feeding rack comprises a hydraulic elevator, an automatic drum-type fetching device, a lateral movement device, a front feeding device and a tread automatic deviation rectifying device. The hydraulic elevator and the automatic drum-type fetching device are adjacently arranged on the back of the lateral movement device, the tread automatic deviation rectifying device is fixedly installed above the lateral movement device, one end of which is provided with the front feeding device. During the process of being rolled out and moved, the tread is subjected to uniform force and is free from deformation, thereby guaranteeing the tread quality. Moreover, the feeding rack is automatically controlled and operated at a high efficiency, the tread quality is stable, all executive components are pneumatic components which are suitable for reciprocating and repeated movement, and have rapid, stable and reliable movement.

Owner:赵志东

Reservoir protection agent intermediate product, reservoir protection agent, preparation methods and applications thereof, as well as drilling fluid and application thereof

The invention relates to the technical field of petroleum drilling, and discloses a reservoir protection agent intermediate product, a reservoir protection agent, preparation methods and applications thereof, as well as drilling fluid and an application thereof. The reservoir protection agent intermediate product is prepared by the following raw materials: acrylamide, a cationic monomer, a cross-linking agent, an initiator, a toughening material and water, based on 100 parts by weight of the raw materials, the raw materials comprise the following components in parts by weight: 8-30 parts of acrylamide, 1-10 parts of the cationic monomer, 0.01-0.5 parts of the cross-linking agent, 0.01-0.1 parts of the initiator, and 5-25 parts of the toughening material. The reservoir protection agent comprises the intermediate product, alkali, salt and water, based on 100 parts by weight of the reservoir protection agent, the reservoir protection agent comprises 5-40 parts by weight of the intermediate product, 1-10 parts of alkali, and 1-12 parts by weight of salt. The reservoir protection agent has good sealing effects, improves reservoir protection capability of drilling fluid, and enhances capability of drilling fluid for stabilization of borehole walls.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Working table for display panel testing

ActiveCN108214416AReduce equipment investmentReduce testing costsOptically investigating flaws/contaminationWork benchesSoftware engineering

Owner:BOE TECH GRP CO LTD +1

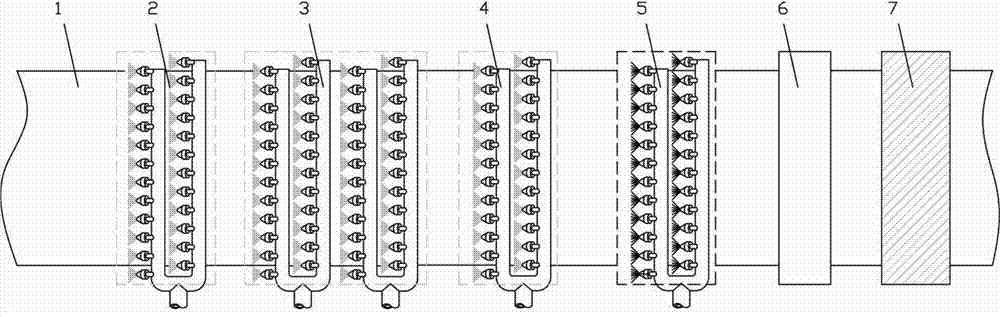

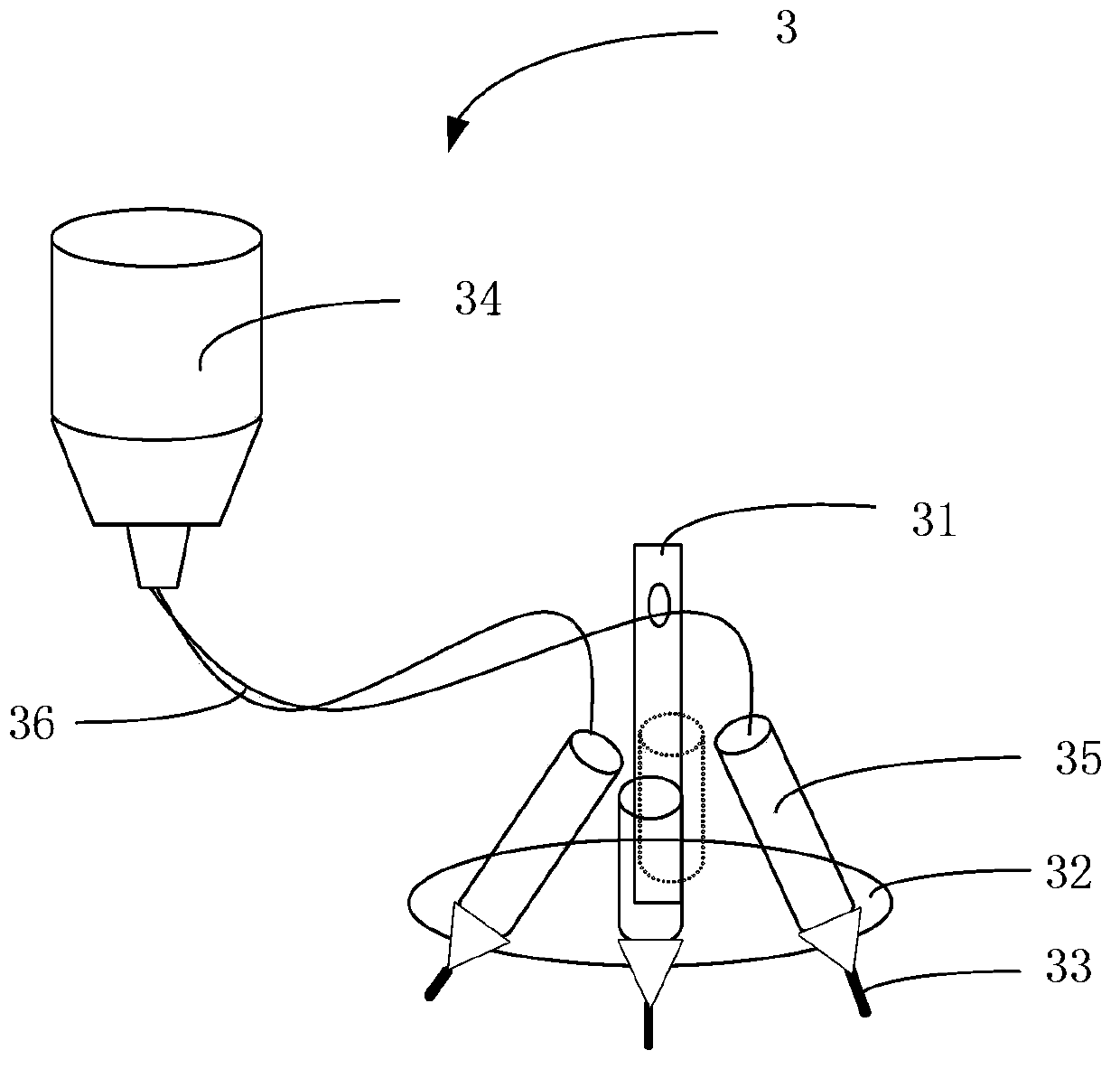

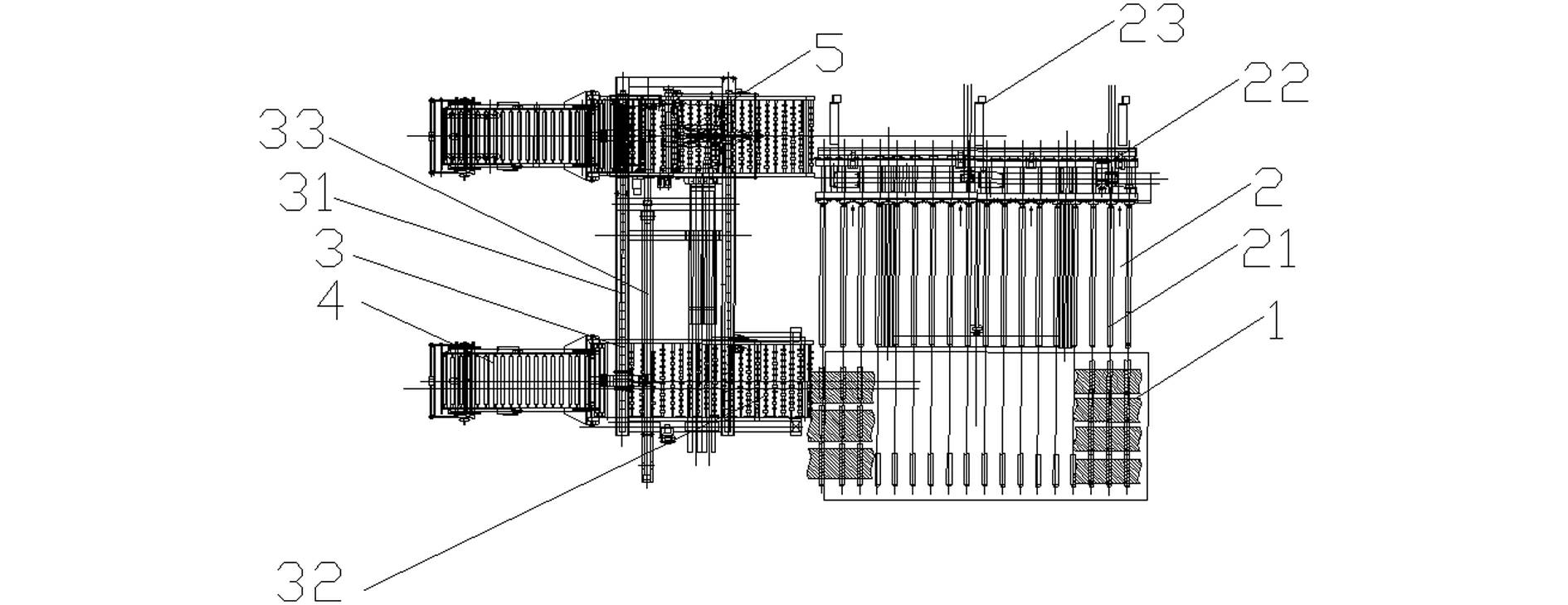

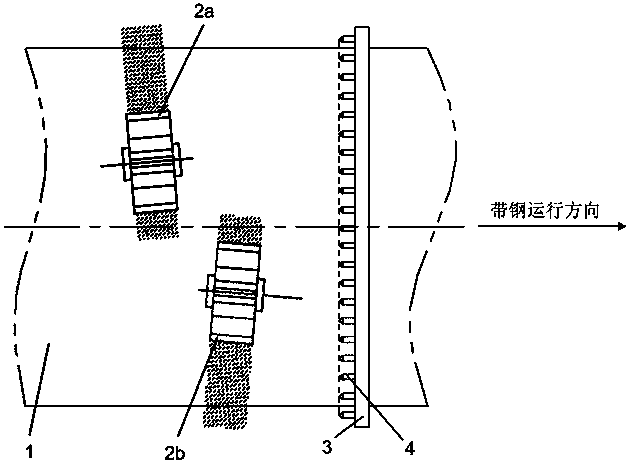

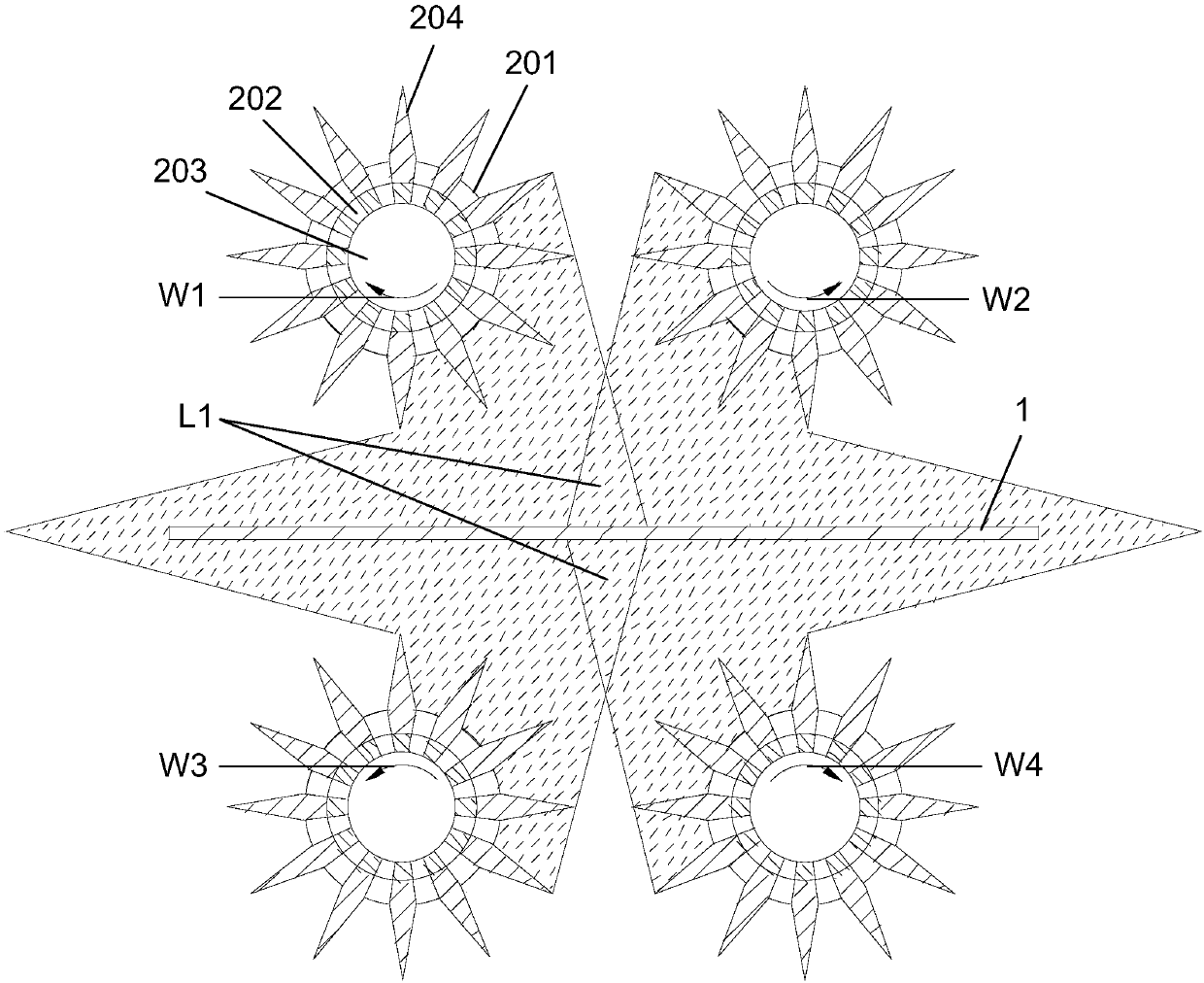

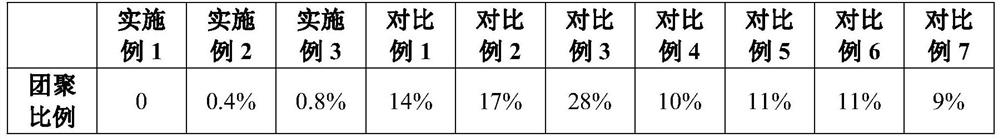

Cast-flow cleaning system and method for surface cleaning of cold-rolled steel strip

ActiveCN107755437AAchieve cleaningReduce consumptionWork treatment devicesMetal rolling arrangementsSurface cleaningAngular velocity

The invention discloses a cast-flow cleaning system and method for surface cleaning of a cold-rolled steel strip. The cast-flow cleaning system comprises a plurality of sets of cleaning units arrangedon the steel strip, wherein each cleaning unit comprises a centrifugal casting device and a purging mechanism; the centrifugal casting devices are arranged above and below the steel strip in a staggered manner; the centrifugal casting devices above the steel strip are symmetrical with the centrifugal casting devices below the steel strip; the purging mechanisms are also arranged above and below the steel strip; each centrifugal casting device comprises a casting head, a rotating shaft, a liquid inlet pipe and a plurality of centrifugal blades; each casting head sleeves the corresponding rotating shaft, so that each casting head can perform an angular-velocity rotation around the corresponding rotating shaft; the centrifugal blades are uniformly arranged on the outer side of the corresponding casting heads at intervals to form a circular shape; each liquid inlet pipe is arranged on the corresponding rotating shaft; and each purging mechanism comprises a compressed air pipe and a plurality of sprayers arranged on the compressed air pipe. The cast-flow cleaning system can realize complete cleaning of two sides of the steel strip after cold rolling and before plating, and the technological process in the current steel strip cleaning technology is simplified.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for leakage pre-plugging of well cemented through lining pipe

InactiveCN108825158AHigh blocking rateHigh compressive strengthBorehole/well accessoriesCement slurryWell cementing

The invention relates to the technical field of oilfield lining pipe reinforcing operation, in particular to a method for leakage pre-plugging of a well cemented through a lining pipe. The method comprises the following steps that 1, a drill rod is tripped to 30-50 m of the upper portion of a perforation interval or a sleeve leakage point, and a packer is arranged on the position with 80-120 m distance from the upper portion of the perforation interval or the sleeve leakage point; 2, well flushing fluid is positively injected for one week, and then the packer is set; and 3, a plugging agent Ais injected to plug the perforation interval or the sleeve leakage point in advance, and the plugging agent A is composed of a water-based drive-adjusting reagent, a lignin particle plugging agent andwater. According to the method, before well cementing construction, chemical agents are injected to pre-plug the well sections, with cement slurry prone to loss, of the perforation interval, a leakage loss point, the sleeve leakage point and the like, the chemical agents in use are high in plugging rate and high in compression strength, a leakage loss layer can be efficiently plugged, leakage loss of cement slurry in well cementing construction through lining pipe reinforcing is avoided, meanwhile, the plugging agent does not damage the oil layer, the oil well production capacity is not affected, and smooth conducting of well cementing construction is ensured.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

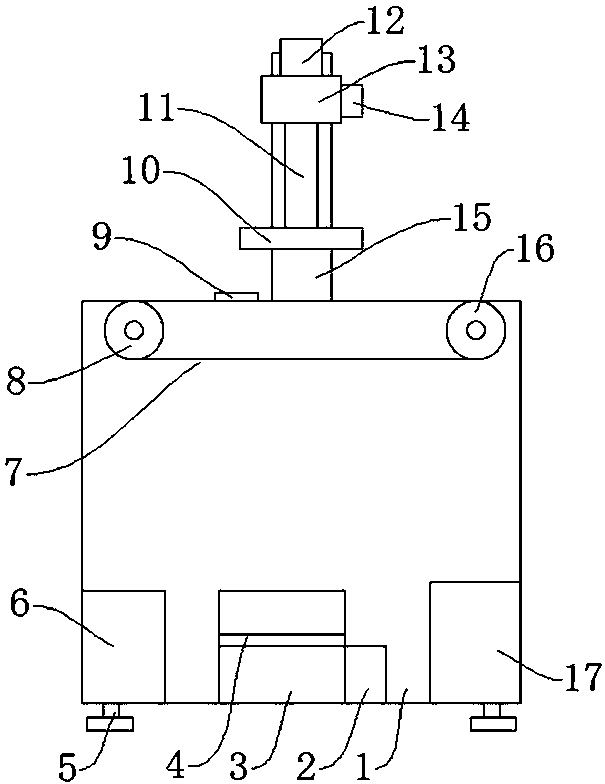

Rapid polishing device for computer fittings

InactiveCN108326654AImprove grinding efficiencyDoes not affect production capacityGrinding drivesGrinding feedersDrive shaftBiochemical engineering

The invention discloses a rapid polishing device for computer fittings. The rapid polishing device comprises a tank body, a stepping motor, a servo motor and a dust accumulation tank; supporting seatsare arranged under the tank body; the stepping motor is arranged on the inner side of the tank body; the dust accumulation tank is arranged on the inner side of the tank body, close to the stepping motor and is internally provided with an adsorption net; a suction pump is arranged on the inner side of the tank body, close to the dust accumulation tank; a control tank is arranged on the inner sideof the tank body, far away from the stepping motor; an upright column is arranged on the tank body; a beam is arranged above the upright column; the servo motor is arranged on the beam, close to theupright column; a drive motor is arranged on the beam, far away from the upright column; and a transmission shaft is arranged on the beam and below the drive motor; and a polishing wheel is arranged under the transmission shaft. The rapid polishing device for the computer fittings has the beneficial effects that the polishing efficiency of the computer fittings is improved, fetching and placing ofthe fittings do not influence the productivity, and the polishing environment quality is improved.

Owner:四川乐为科技有限公司

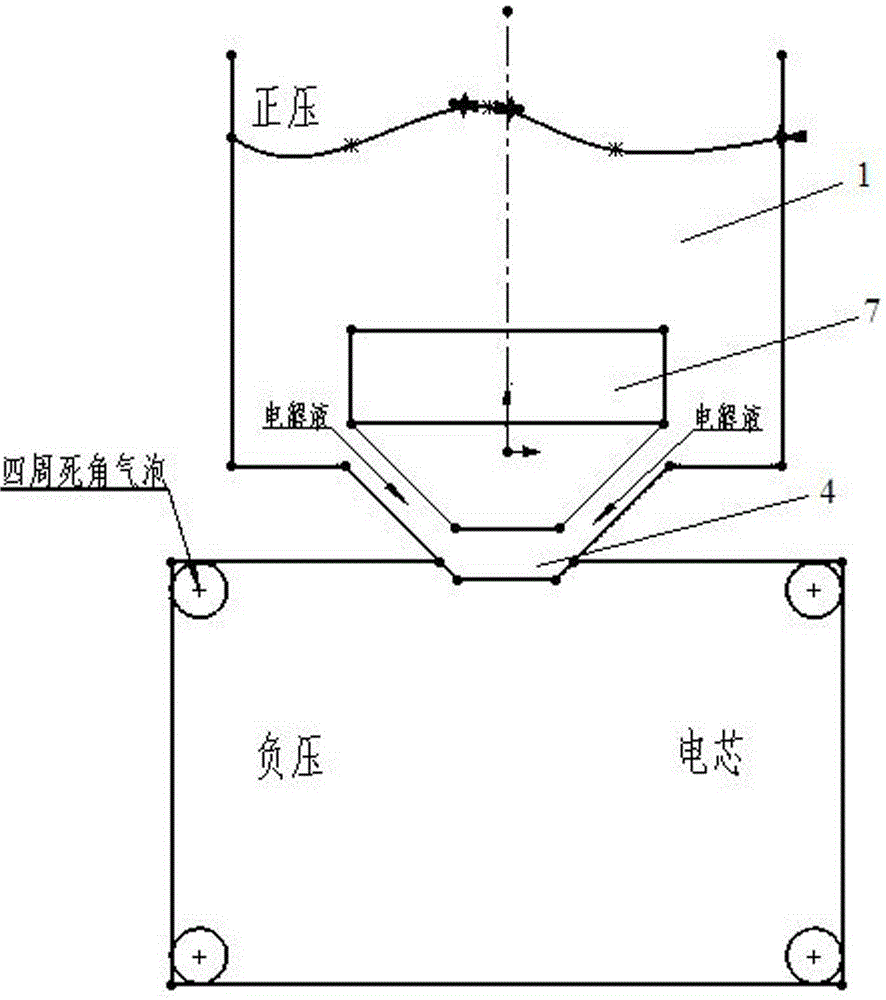

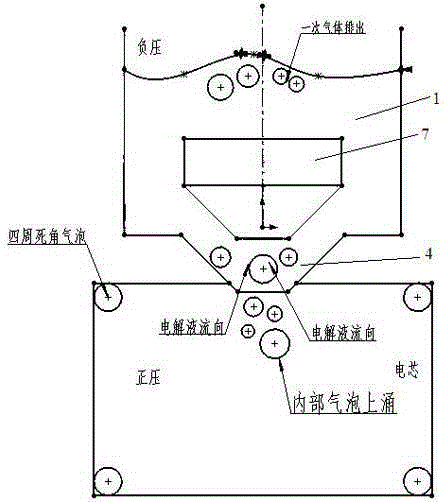

Liquid injecting device and liquid injecting method

InactiveCN105406021AImprove pass rateQuality improvementCell component detailsSmall amplitudeLithium-ion battery

The invention belongs to the technique field of lithium ion battery production equipment, and especially relates to a liquid injecting device. The liquid injecting device comprises liquid injecting cup cavities, an upper fixing plate, a lower fixing plate, liquid injecting nozzles, liquid injecting openings, first blocking rods, second blocking rods, a first drive assembly and a second drive assembly; the upper end faces and lower end faces of the liquid injecting cup cavities are in close contact with the upper fixing plate and the lower fixing plate; the liquid injecting openings are formed in the upper fixing plate and communicate with the liquid injecting cup cavities; the liquid injecting nozzles are located under the lower fixing plate and communicate with the liquid injecting cup cavities; a through hole communicated with the liquid injecting cup cavities is formed in the upper fixing plate; an air tap is connected to the end of the through hole. According to the invention, the liquid injecting principle of the existing liquid injecting device of lithium ion batteries is improved, and existing single liquid injection is changed into reciprocating small-amplitude repeated liquid injection so as to prevent residual air bubbles at dead angles in the battery core, therefore the qualified rate of the liquid injection process of the battery cores is greatly improved and quality of the battery cores in the liquid injection process is improved without influencing the overall productivity.

Owner:DONGGUAN ALI AUTOMATION CO LTD

Drug for papermaking sludge and preparation and using method thereof

InactiveCN106758463AExtensive sources of raw materialsRaw materials are cheapPulp liquor regenerationSludge treatmentTetraethyl orthosilicateSludge

The invention discloses a drug for papermaking sludge. The drug is prepared from a sludge cleanser, a sludge activating agent and a sludge reinforcing agent, wherein a weight ratio of the sludge cleanser, the sludge activating agent and the sludge reinforcing agent is (3 to 5) to (1 to 3) to 1; the sludge cleanser is prepared from the following raw materials of mung bean powder, modified kieselghur, acrylamide, polyethylene glycol, refined yellow iron ore powder and vinylidene fluoride; the sludge activating agent is prepared from the following raw materials of methanol, tetraethyl orthosilicate, urea, potassium sulfate and vitamin C; the sludge reinforcing agent is prepared from the following raw materials of cellulose, epoxy resin, acetic acid and modified starch. The invention also discloses a preparation method and a using method of the drug. According to the drug disclosed by the invention, the source of the raw materials is wide, the production cost is low, a preparation technology is simple, the investment cost of equipment is reduced, and the drug is suitable for large-scale industrial production; the drug prepared by the invention cannot affect the capacity of a paper machine, sludge is changed into a papermaking raw material, the production cost of an enterprise is greatly reduced, the environment cannot be polluted any more, and the resource is also saved.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

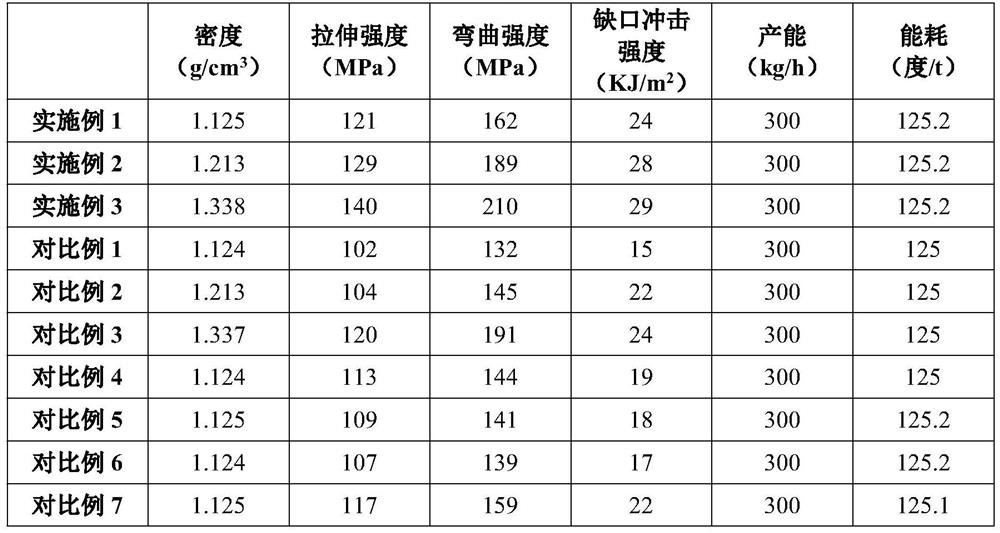

High-impregnation-degree long glass fiber reinforced polypropylene composite material and preparation method thereof

The invention discloses a high-impregnation-degree long glass fiber reinforced polypropylene composite material and a preparation method thereof. The high-impregnation-degree long glass fiber reinforced polypropylene composite material is prepared from the following raw materials in parts by weight: 43.2 to 63.2 parts of polypropylene resin, 30 to 50 parts of glass fibers, 1 to 10 parts of a compatilizer, 1 to 10 parts of a flexibilizer, 0.1 to 1 part of an antioxidant and 0.2 to 2 parts of a lubricant. The glass fibers pass through a glass fiber heating pre-dispersing device and a cooling device on line, then are electrified through friction of silk, and finally pass through a static electricity generating device to directly enter a dipping tank for production. The high-impregnation-degree long glass fiber reinforced polypropylene composite material disclosed by the invention has the following technical effects that each glass fiber is wrapped by the polypropylene resin, so that the glass fibers are prevented from being damaged in a pellet plasticizing process, the length of the glass fibers in a product is reserved, and the tensile strength, flexural modulus, impact strength and other properties are greatly improved.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

Process arrangement method for mixed jet cleaning

The invention relates to a process arrangement method for mixed jet cleaning. The method employs high-pressure mixed jet descaling units having a plurality of abrasive materials with different granularities. The high-pressure mixed jet descaling units are arranged along a tape transport direction of a metal plate. The high-pressure mixed jet with large granularity abrasive materials is arranged at an original inlet area of the metal plate, with the granularity of 20 meshes-60 meshes and inject pressure of 15 MPa-80 MPa; the high-pressure mixed jet with medium granularity abrasive materials is arranged at downstream of the high-pressure mixed jet descaling unit with the large granularity abrasive materials, with the granularity of 40 meshes-80 meshes and inject pressure of 10 MPa-60 MPa; the high-pressure mixed jet descaling unit with small granularity abrasive materials is arranged at downstream of the high-pressure mixed jet descaling unit with the medium granularity abrasive materials, with the granularity of 60 meshes-120 meshes and inject pressure of 10 MPa-50 MPa; the metal plate realizes the front and back descaling of the metal plate via the above jet descaling units; and the washing of the metal plate is finished by passing the descaled metal plate through a high-pressure pure water cleaning unit, a wiping unit and a compressed air blowing unit. The complete removing treatment of the scales on two sides of the coal metal plate is realized via a jet way.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com