Liquid injection device and liquid injection method

A technology of liquid injection device and liquid injection cup, which is applied to electrical components, circuits, battery pack components, etc., can solve problems such as residual liquid bubbles, and achieve the effect of improving the qualification rate and improving the quality of battery cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

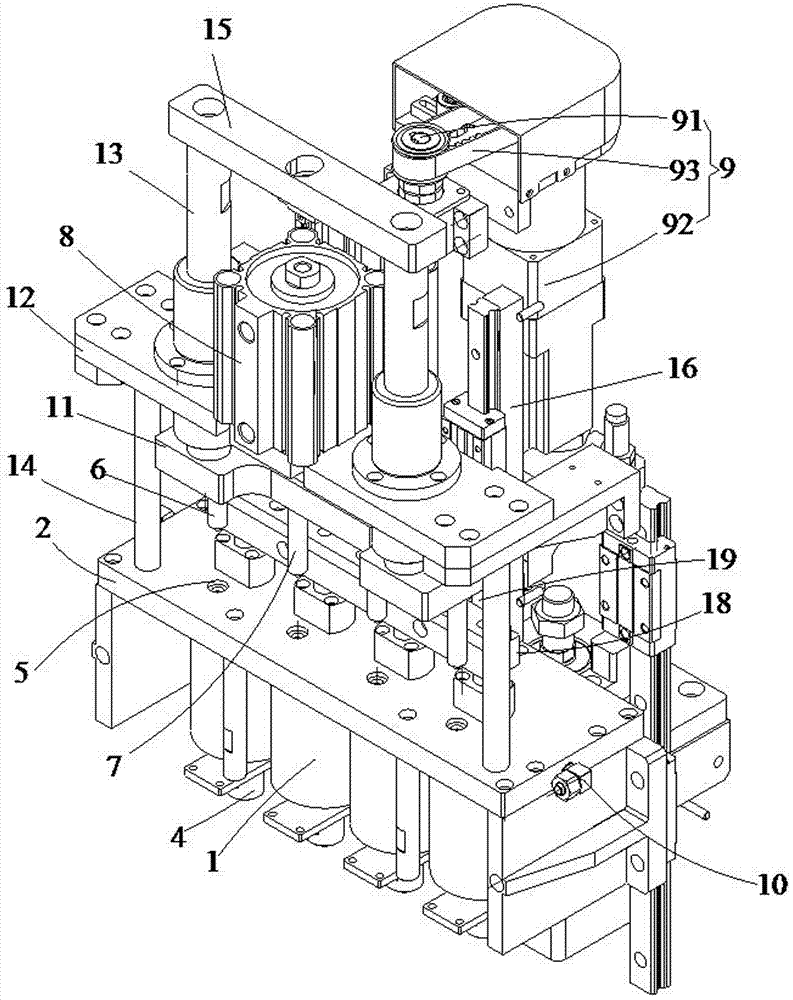

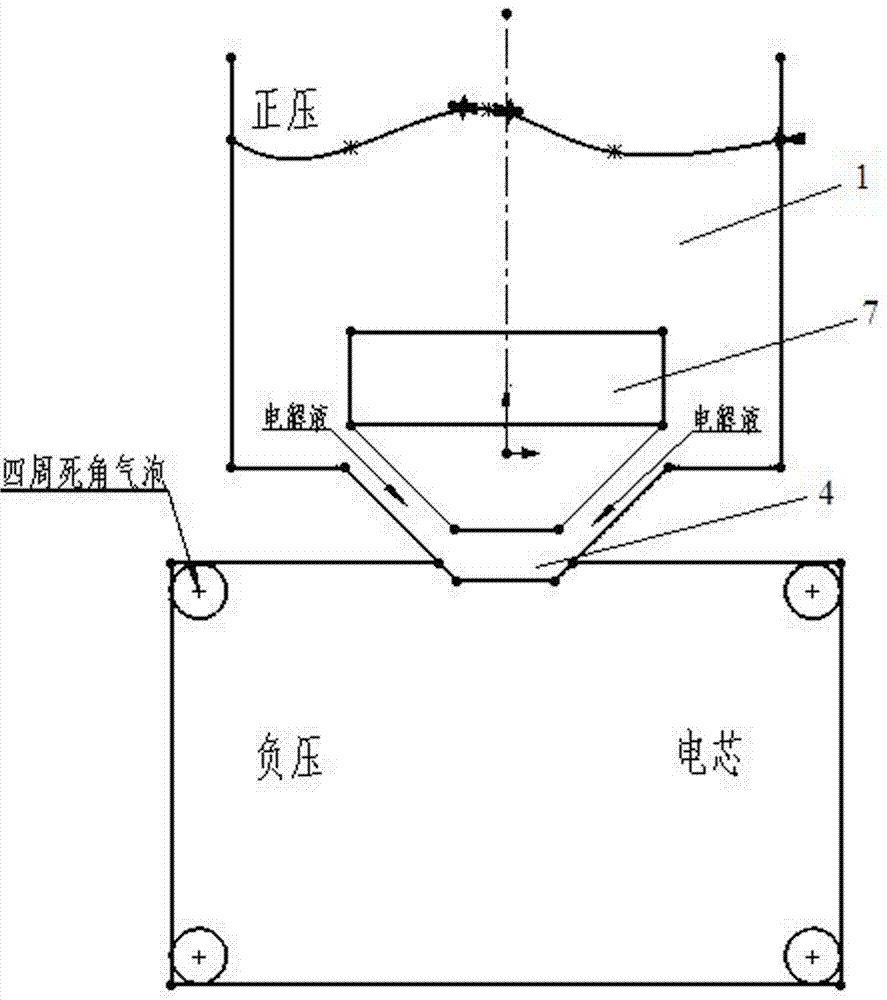

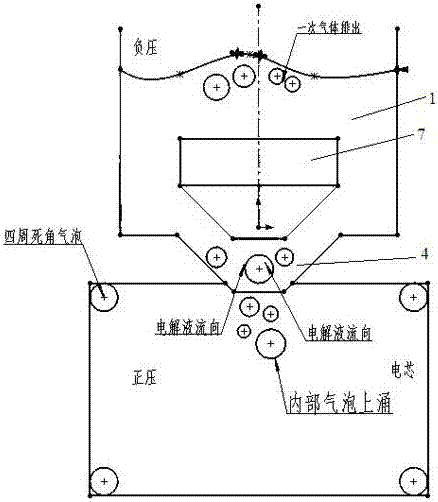

[0025] Such as figure 1 As shown, a liquid injection device provided by the present invention includes a liquid injection cup cavity 1, an upper fixing plate 2, a lower fixing plate (not shown in the figure), a liquid injection nozzle 4, a liquid injection port 5, a first plug Rod 6, second blocking rod 7, first drive assembly 8 and second drive assembly 9, wherein, liquid injection cup cavity 1 is used to store electrolyte injected from the external liquid injection part, upper fixed plate 2 and lower fixed plate For fixing the liquid injection cup cavity 1, a through hole communicating with the liquid injection nozzle 4 is provided on the lower fixing plate, and the lower end of the liquid injection cup cavity 1 is embedded in the through hole, and the upper end of the liquid injection cup cavity 1 The end face and the lower end face are in close contact with the upper fixing plate 2 and the lower fixing plate respectively. The liquid injection port 5 is arranged on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com