Process arrangement method for mixed jet cleaning

A layout method and jet technology, applied in the process layout field of mixed jet cleaning, can solve the problems of liquid residue, hard particle residue, descaling speed, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

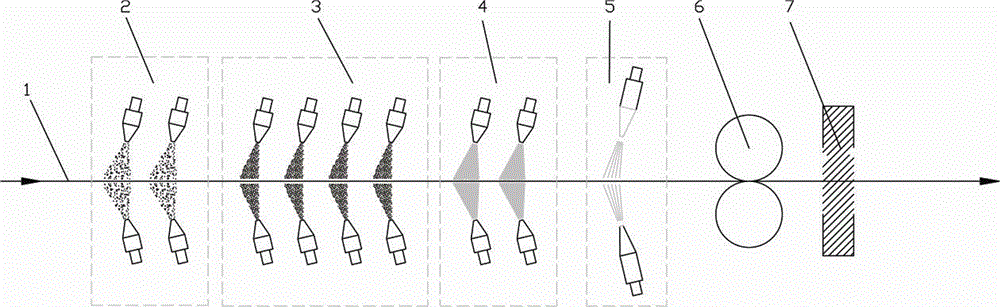

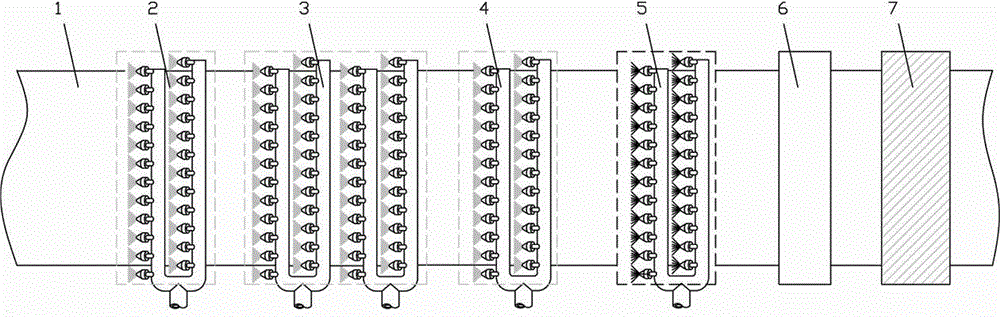

[0029] see figure 1 , figure 2 , the process layout method of mixed jet cleaning of the present invention adopts several high-pressure mixed jet descaling units 2, 3, and 4 of different particle size abrasives, which are arranged in sequence according to the belt running direction of the metal strip 1, wherein the high pressure of large particle size abrasives The mixed jet descaling unit 2 is arranged in the initial inlet area of the metal strip 1, its particle size is 20 mesh to 60 mesh, and the injection pressure is 15MPa to 80MPa; the high-pressure mixed jet descaling unit 3 for medium-grained abrasives is arranged at the high-pressure abrasive for large-grained abrasives. Downstream of the mixed jet descaling unit 2, the particle size is 40 mesh to 80 mesh, and the injection pressure is 10MPa to 60MPa; the high-pressure mixed jet descaling unit 4 of the small-grained abrasive is arranged in the high-pressure mixed jet descaling unit 3 of the medium-sized abrasive Down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com