Cast-flow cleaning system and method for surface cleaning of cold-rolled steel strip

A technology for surface cleaning and cold-rolling strip steel, which is applied to workpiece surface treatment equipment, metal rolling, metal rolling, etc., can solve the problems of easy loss of liquid pressure, large power consumption, and complicated devices, and meet high surface requirements. quality, realize energy conservation and environmental protection, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

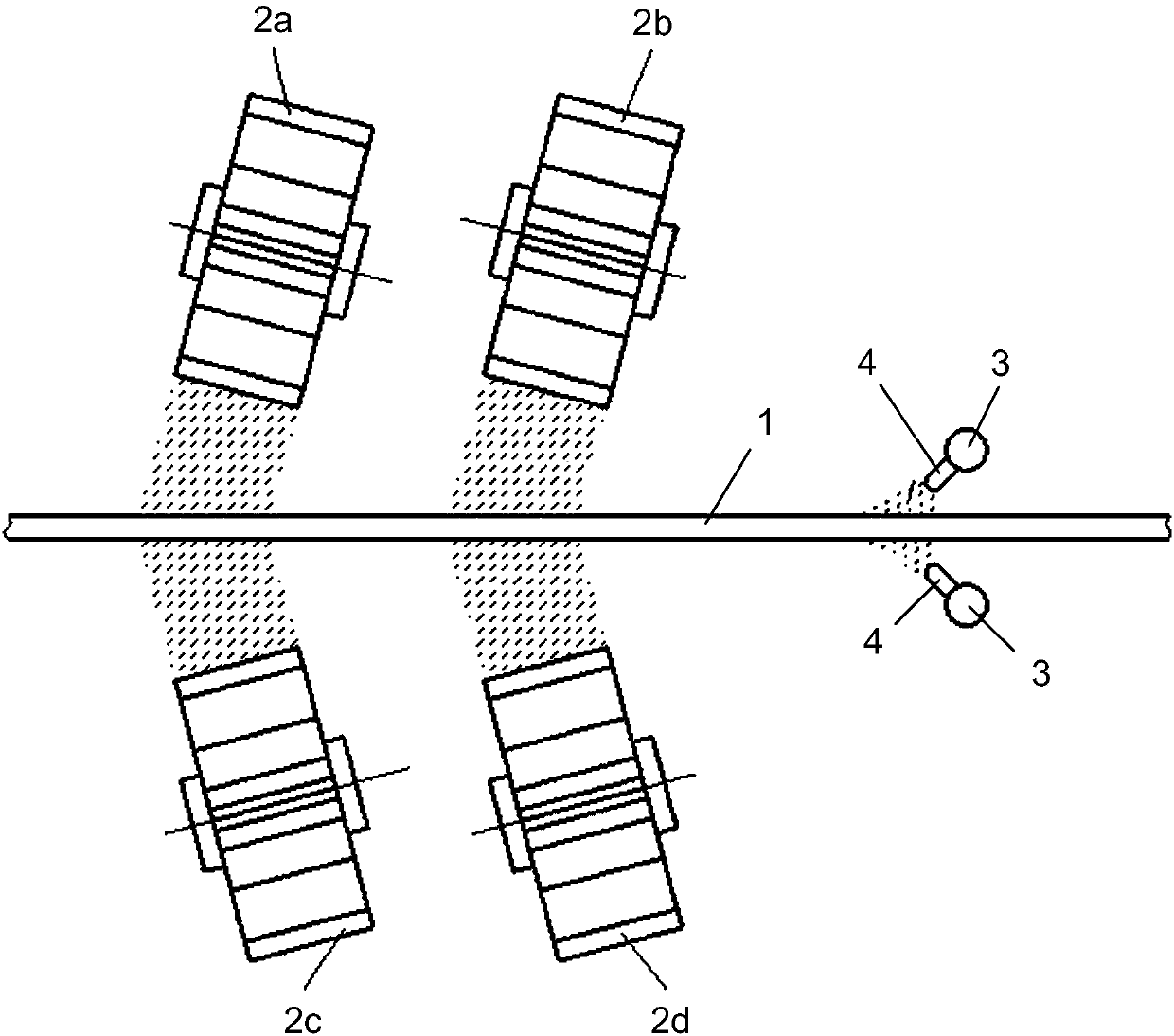

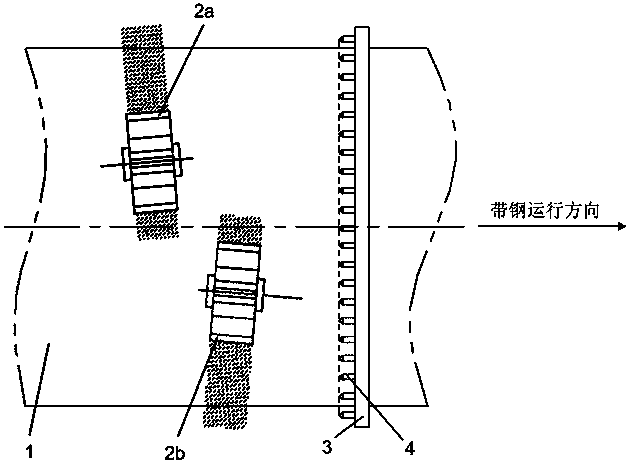

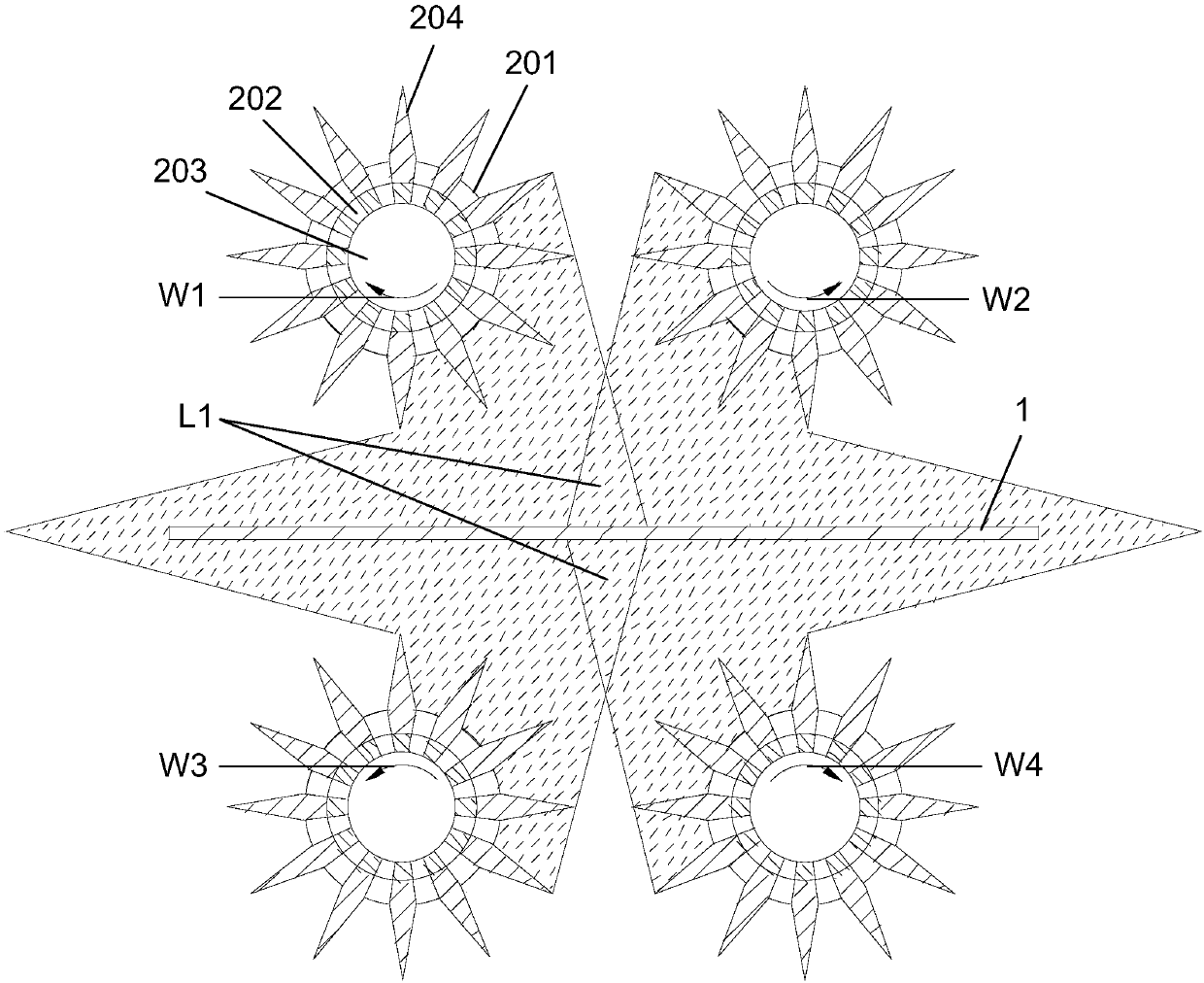

[0031] Please combine Figure 1 to Figure 3 As shown, a throwing flow cleaning system provided by the present invention for cleaning the surface of cold-rolled strip steel includes multiple sets of cleaning units 100 arranged on the strip steel 1, and each set of cleaning units 100 includes centrifugal projection devices 2a, 2b . , and the centrifugal projection devices 2a, 2b above the strip steel 1 are arranged symmetrically with the centrifugal projection devices 2c, 2d below the strip steel 1. Consistent, thereby ensuring that the cleaning quality of the lower and lower surfaces of the strip steel 1 is exactly the same. In the actual cleaning process, the upper and lower surfaces of the strip steel 1 need to be cleaned with the same quality, so the same type of centrifugal ejection devices 2a, 2b, 2c, 2d are required to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com