Working table for display panel testing

A technology for display panels and workbenches, which is applied to workbenches, manufacturing tools, optical test defects/defects, etc., can solve the problems of increased maintenance personnel, increased floor space, increased equipment cost investment, etc., to reduce detection costs and reduce The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The workbench for display panel inspection of the present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the present invention.

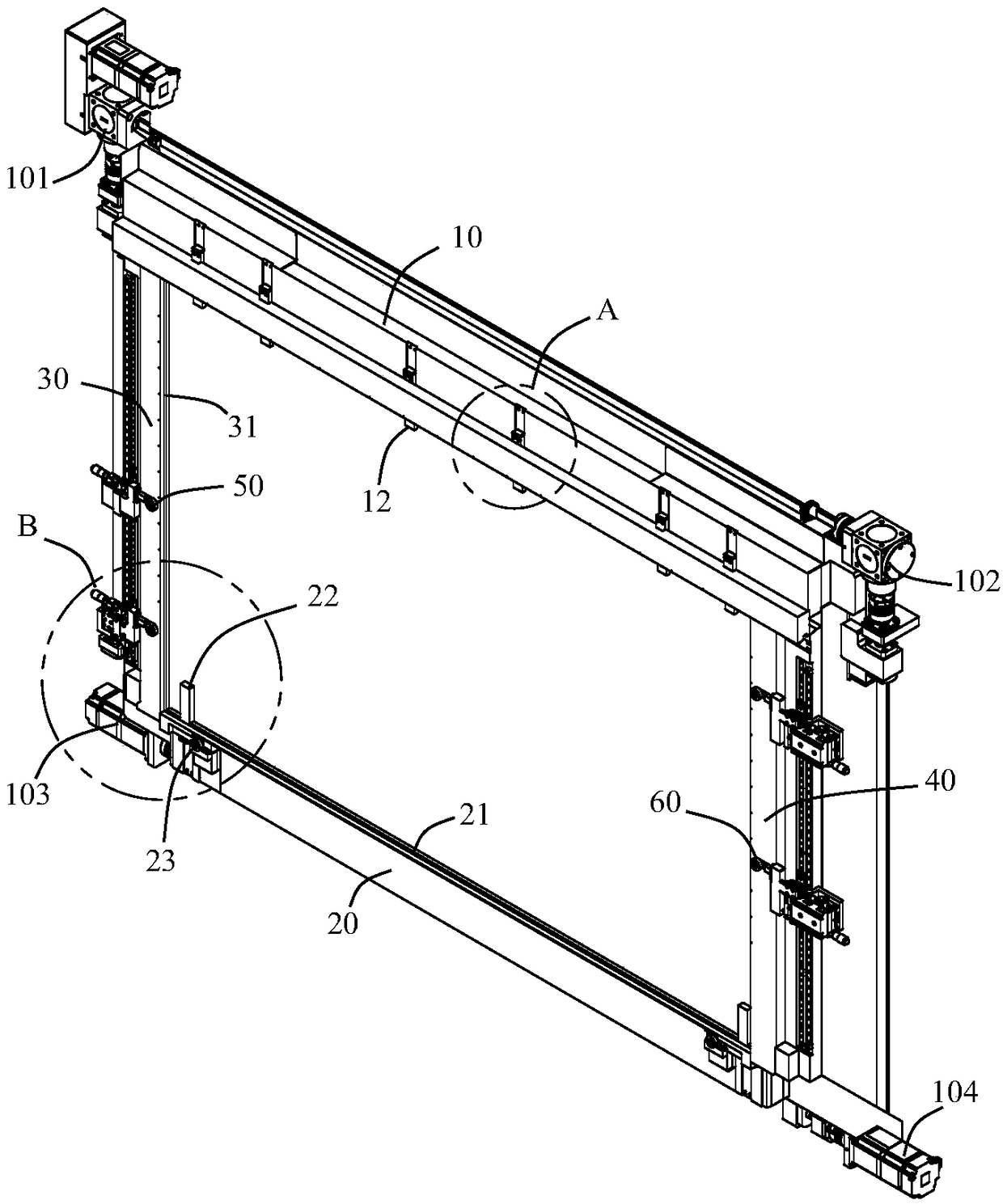

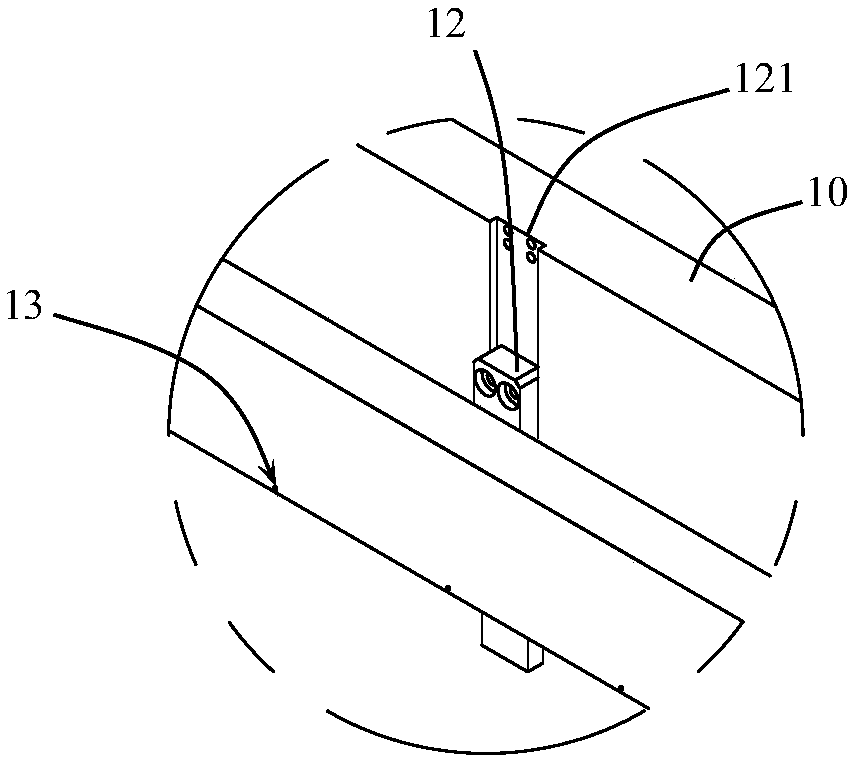

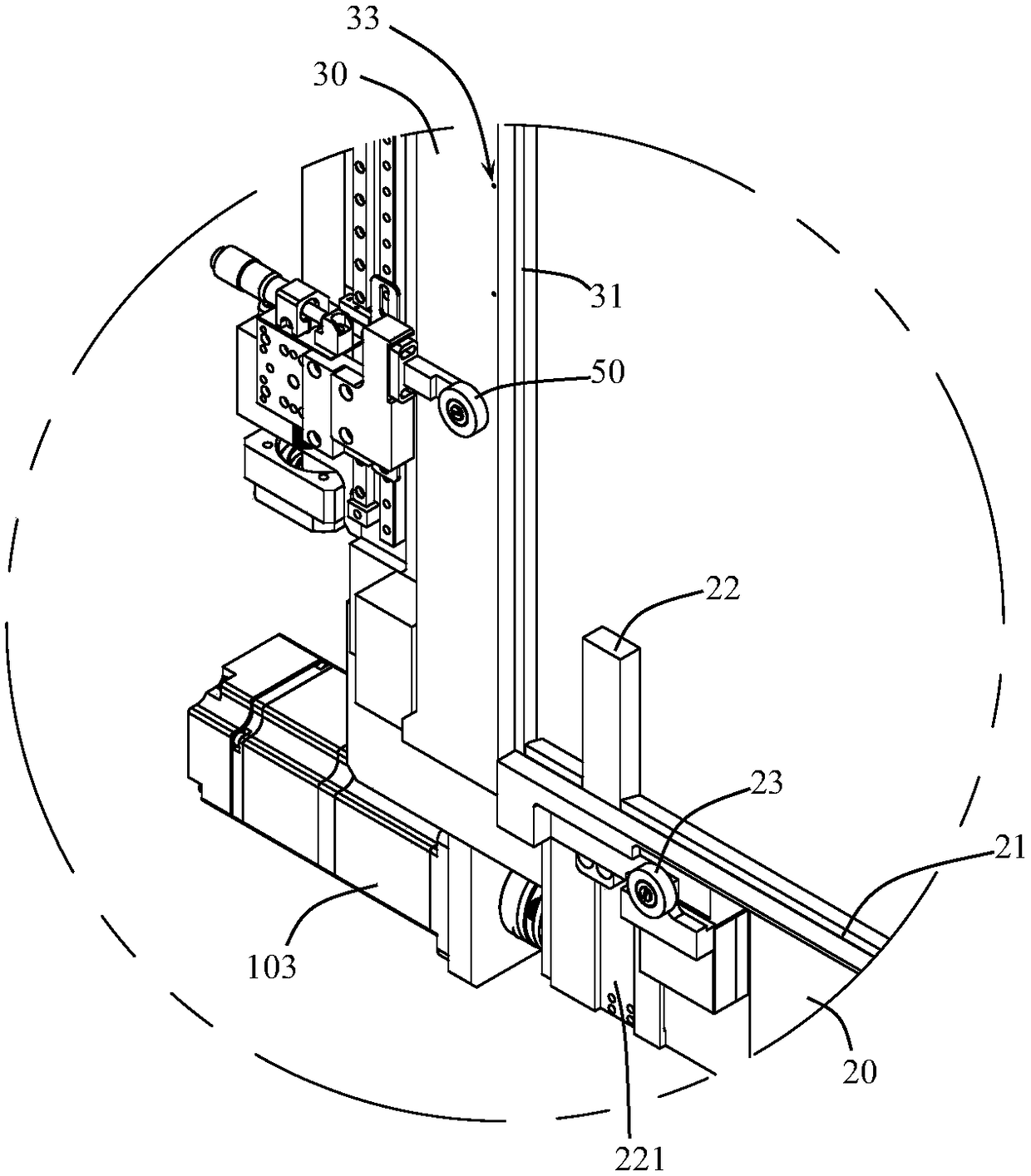

[0026] see Figure 1-8 , the display panel detection workbench according to the embodiment of the present invention includes an upper support block 10, a lower support block 20, a left support block 30 and a right support block 40 for fixing a display panel 100 to be detected, and the upper support block 10 and the distance between the lower support block 20 is adjustable, the distance between the left support block 30 and the right support block 40 is adjustable, by adjusting the distance between the upper support block 10 and the lower support block 20 and the The distance between the left support block 30 and the right support block 40 can adapt to the detection of display panels 100 of different sizes.

[0027] Described upper support block 10, lower supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com