Production process of biological diesel oil

A production method, biodiesel technology, applied to the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve the problems of low reaction rate, poor mutual solubility, etc., achieve simplified process flow, high conversion rate, and avoid catalyst separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

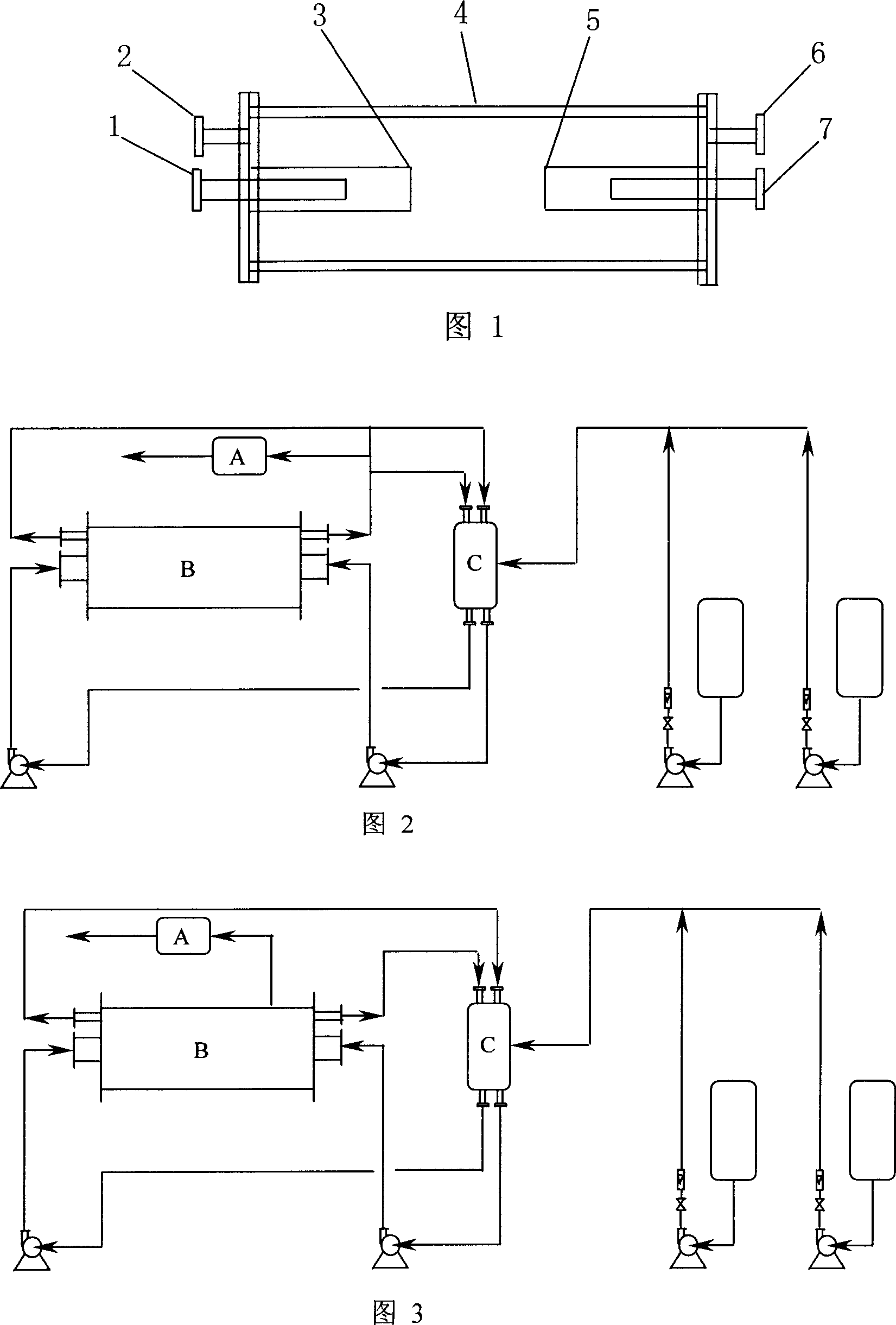

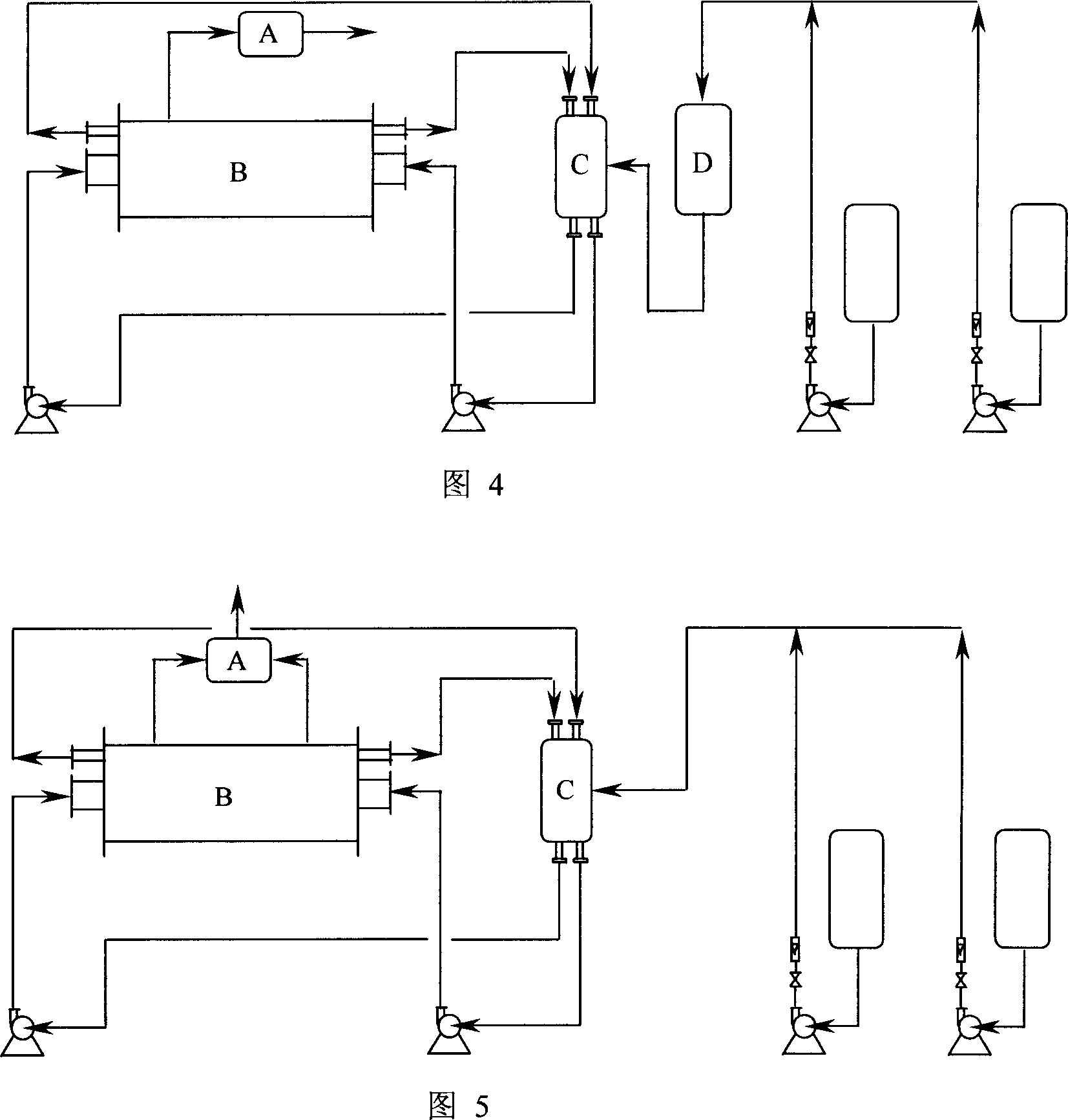

Image

Examples

Embodiment 1

[0028] Cottonseed oil is added to storage tank E, methanol is added to storage tank F, the molar ratio of methanol to cottonseed oil is 10, and the feed rate of cottonseed oil and methanol is equal to the impinging flow reaction volume (that is, the feed volume space velocity is 1h- 1, that is, the reaction time is 1h), the cottonseed oil and methanol are pumped into the intermediate tank C respectively, pre-mixed with the circulating material in the intermediate tank, and then pumped into the impinging flow reactor, and the transesterification occurs through the impact Reaction, the amount of recycled material is 95% of the feed amount. Control reaction temperature is 130 ℃, and reaction pressure is 0.8MPa, and the reaction product that flows out from static mixer discharge port is separated by standing, obtains fatty acid ester phase (upper layer), utilizes the 6890N gas chromatograph analysis of Agilent Company, records The conversion rate of fatty acid triglyceride is 100%...

Embodiment 2

[0030] According to the method of embodiment 1, only the feed rate is 1 / 2 of the impinging flow reactor, and the amount of recirculated material is 75% of the feed amount. The reaction product flowing out from the discharge port of the impinging flow reactor is separated by standing to obtain the fatty acid ester phase (upper layer), and analyzed by the 6890N gas chromatograph of Agilent Company, the conversion rate of fatty acid triglyceride is 100%, and the fatty acid triglyceride The content of methyl ester in the ester phase was 93.8%.

Embodiment 3

[0032] According to the method of Example 1, the feed rate is a ratio of 1 / 4 of the impinging flow reactor volume, and the circulating material rate is 150% of the feed amount. The reaction product flowing out from the discharge port of the impinging flow reactor is separated by standing to obtain the fatty acid ester phase (upper layer), and analyzed by the 6890N gas chromatograph of Agilent Company, the conversion rate of fatty acid triglyceride is 100%, and the fatty acid triglyceride The content of methyl ester in the ester phase was 94.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com