Patents

Literature

99results about How to "Enhanced Micromixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vanadium-phosphorus-oxygen catalyst, and preparation method thereof

ActiveCN103769181AHigh reactivityEvenly distributedOrganic chemistryPhysical/chemical process catalystsPtru catalystPhysical chemistry

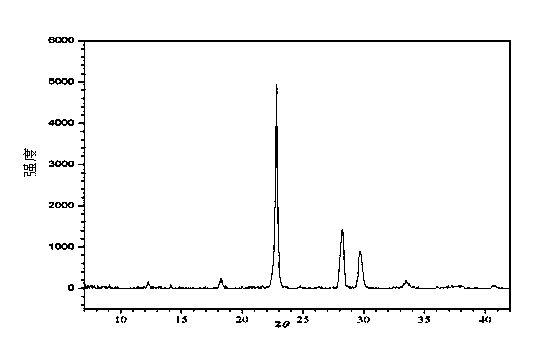

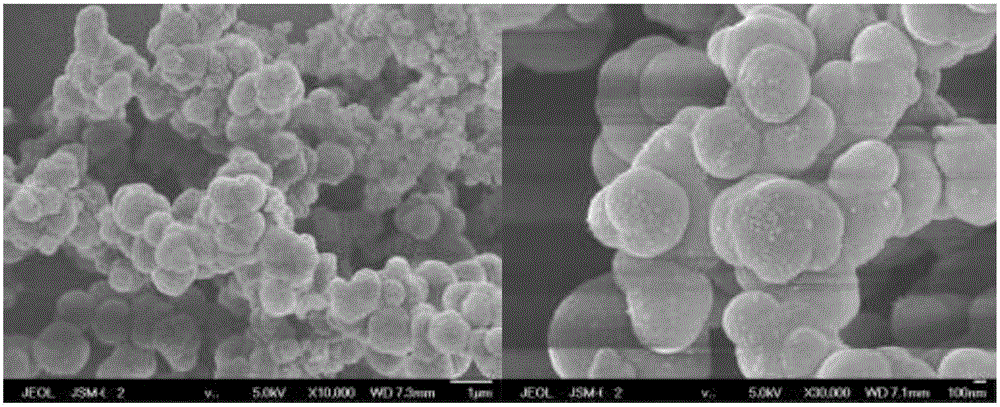

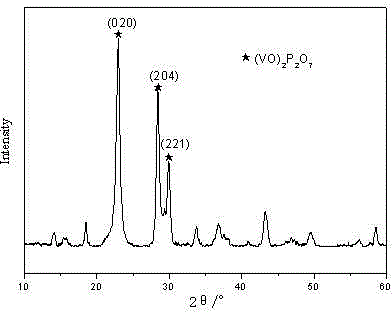

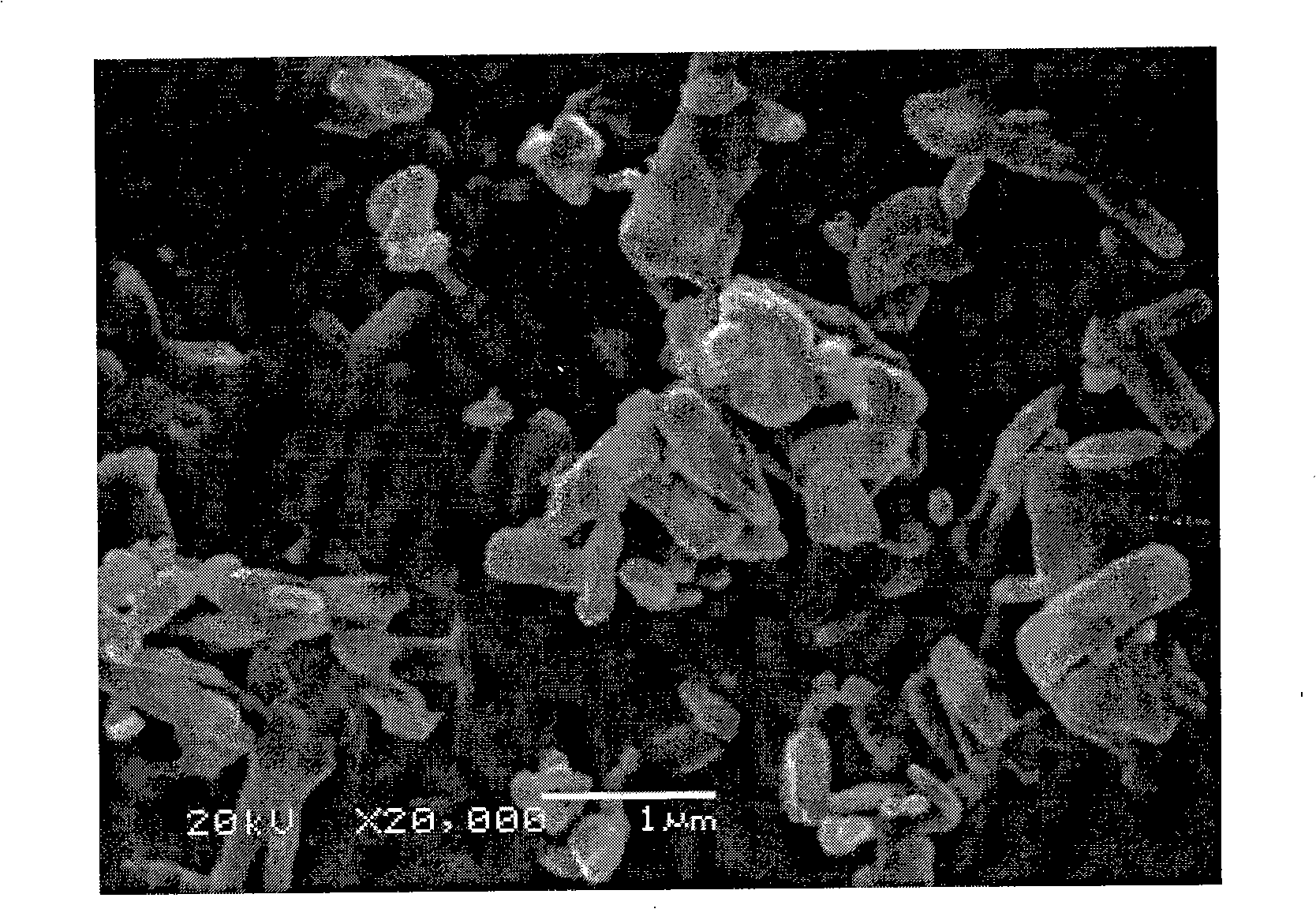

The invention discloses a vanadium-phosphorus-oxygen catalyst, and a preparation method thereof. According to the preparation method, a nano vanadium phosphorus oxide is taken as a precursor, is subjected to activating and then moulding, or is subjected to moulding and then activating so as to obtain the vanadium-phosphorus-oxygen catalyst; grain size of the nano vanadium phosphorus oxide is less than 100nm, and by volume, particles with a grain size of 30 to 50nm accounts for 7 to 14%, particles with a grain size of 50 to 70nm accounts for 54 to 79%, and particles with a grain size more than 70nm accounts for 7 to 39%. According to the vanadium-phosphorus-oxygen catalyst prepared by taking the nano vanadium phosphorus oxide as a precursor, octahedral structure of (VO)2P2O7 is neater, catalyst structure is stable, and catalytic activity and catalyst stability are higher. When the vanadium-phosphorus-oxygen catalyst is used for catalytic preparation of maleic anhydride via oxidation of n-butane, n-butane conversion rate reaches 87 to 95mol%, and maleic anhydride selectivity reaches 72 to 84mol%.

Owner:CHINA PETROLEUM & CHEM CORP +1

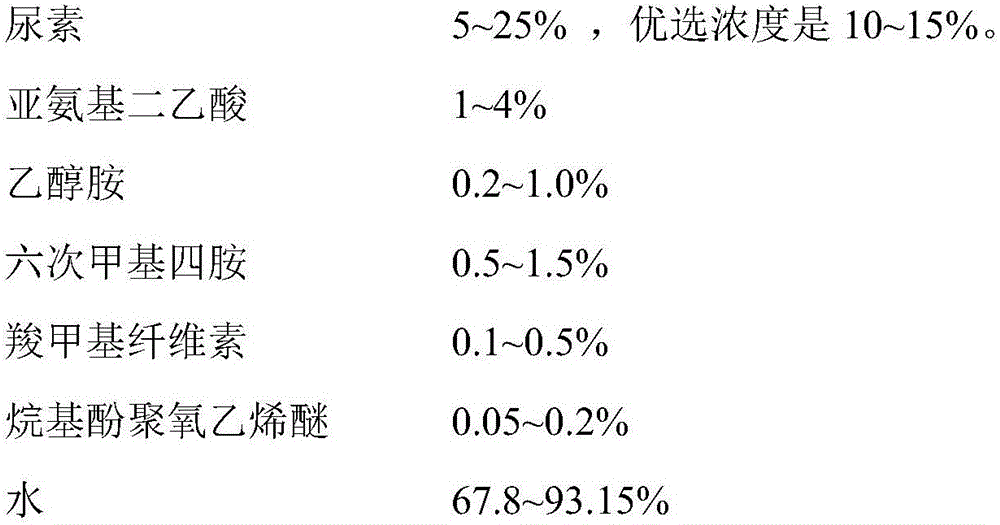

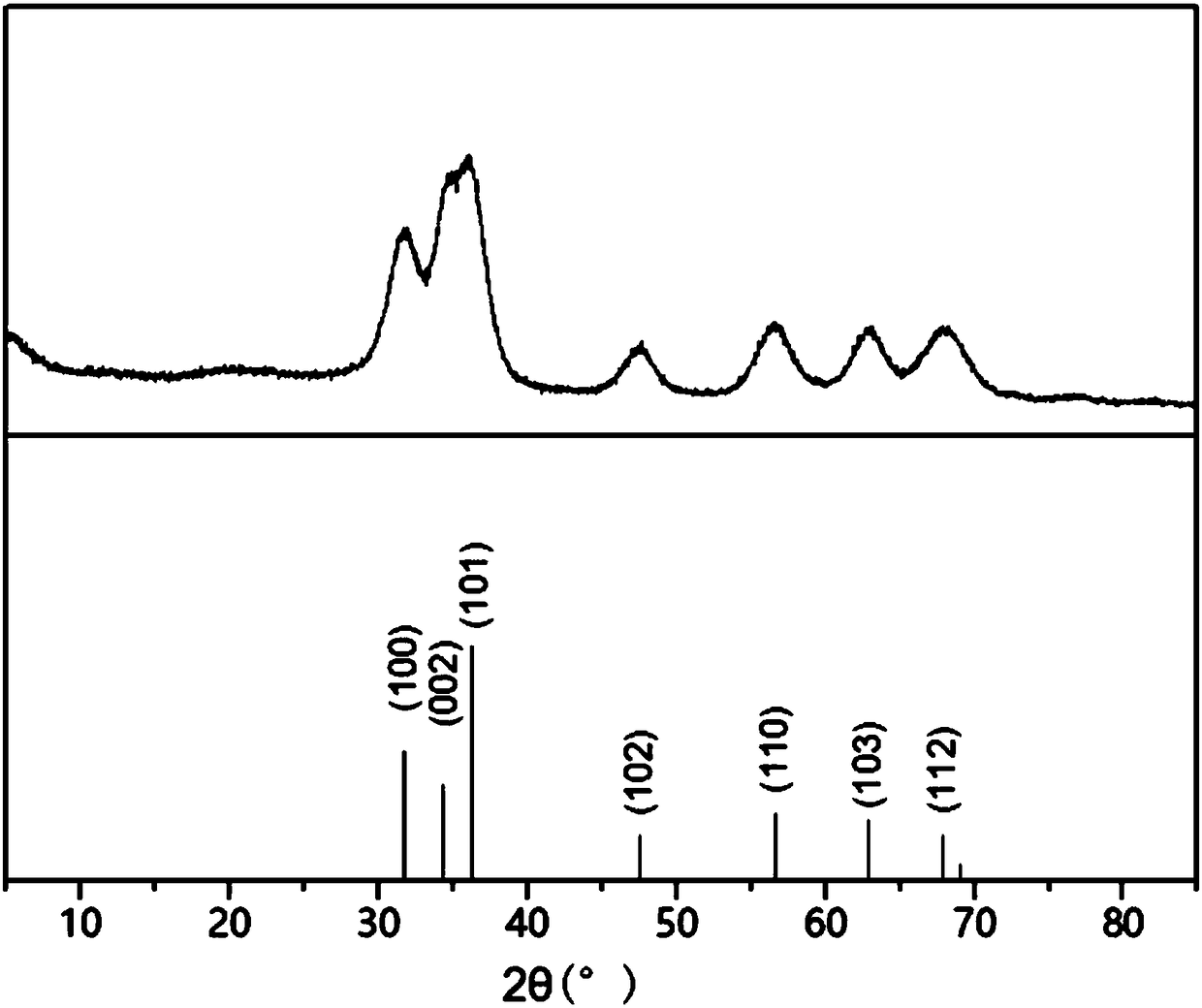

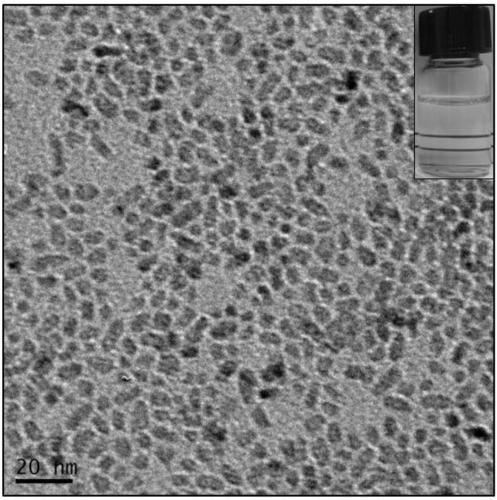

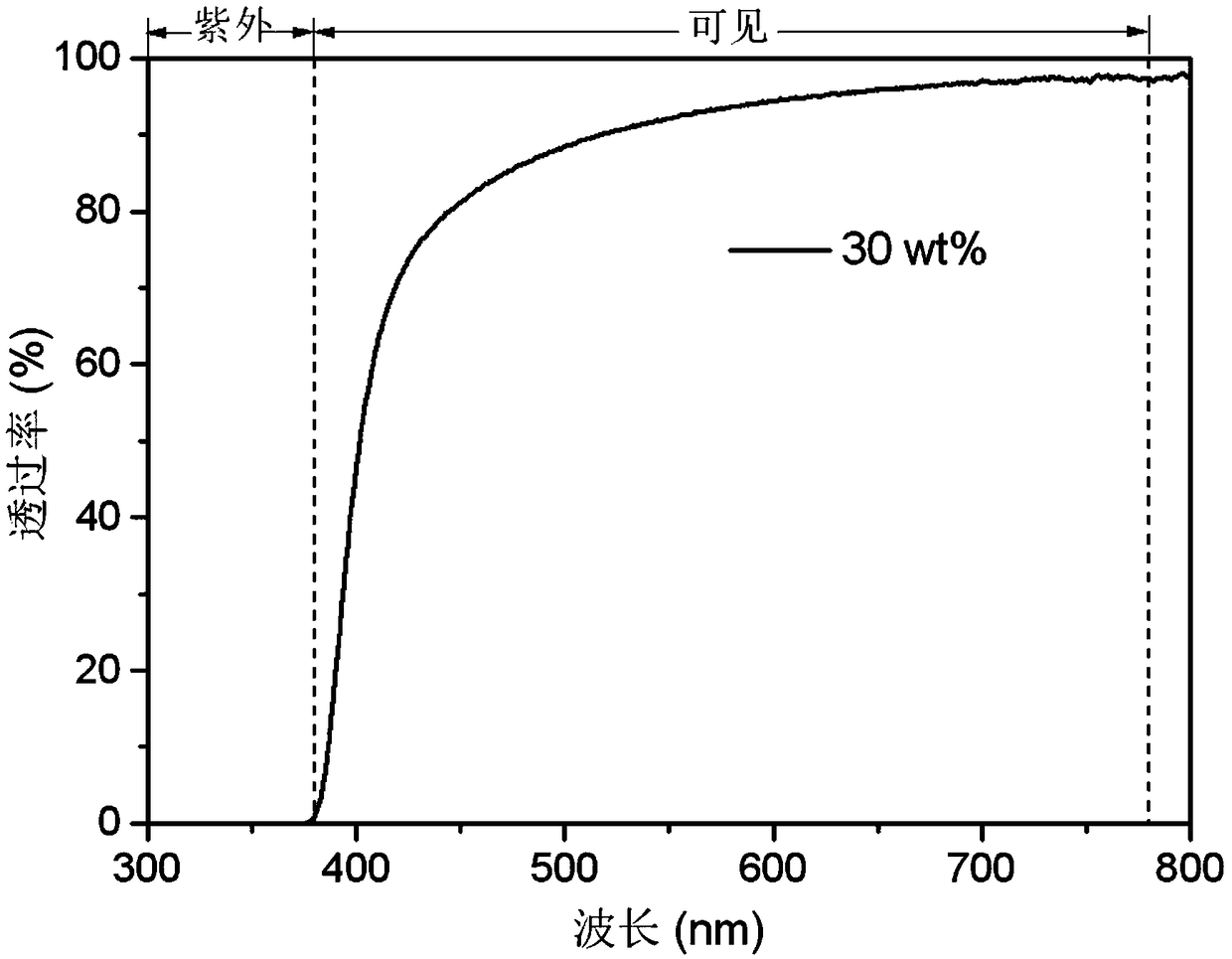

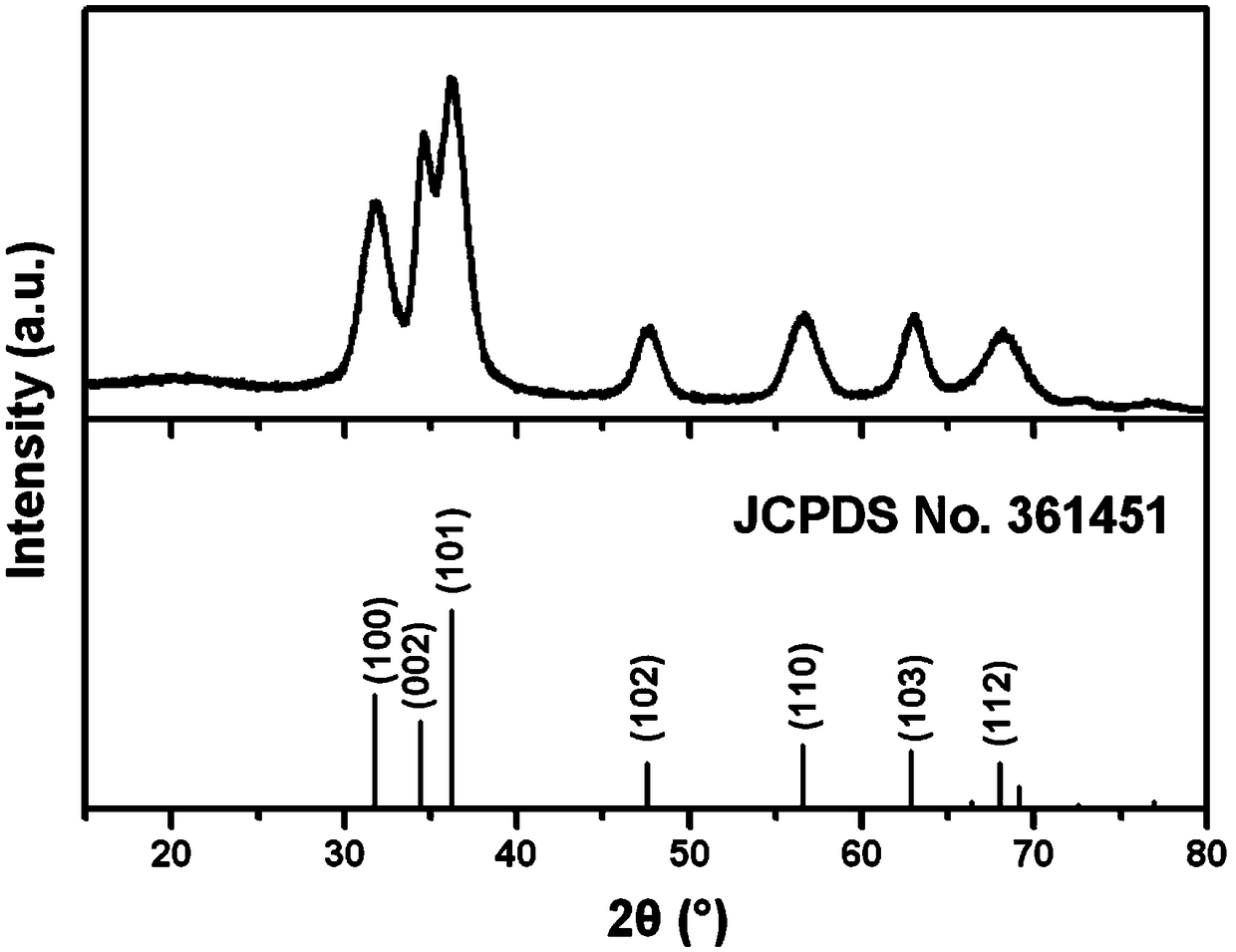

Method for preparing transparent magnesium hydroxide liquid phase dispersion

ActiveCN103910367AEnhanced mass transferEnhanced MicromixingMagnesium hydroxideDispersityOrganic solvent

The present invention relates to a method for preparing a transparent magnesium hydroxide liquid phase dispersion. The method comprises: 1) dissolving a magnesium salt in water or an organic solvent to obtain a magnesium salt solution, and dissolving an alkali in water or an organic solvent to obtain an alkali solution; 2) adding the magnesium salt solution and the alkali solution to a supergravity rotation filling bed or a casing type annular micro-channel reactor to carry out a reaction to obtain a magnesium hydroxide suspension; 3) adding a surfactant to the magnesium hydroxide suspension to modify, and standing the obtained modified solution; and 4) filtering and washing the modified solution, and dispersing in a liquid phase medium to obtain the transparent magnesium hydroxide liquid phase dispersion. According to the present invention, the method is performed in the supergravity rotation filling bed or the casing type annular micro-channel reactor so as to substantially enhance mass transfer and enhance micro-mixing; the product is transparent and has good dispersity; the magnesium hydroxide crystal has characteristics of small particle side, uniform distribution, and one-dimensional size of 0.5-30 nm; and the prepared product has the solid content of 1-50 wt% and good stability, and does not produce settlement after standing for over 10 months.

Owner:BEIJING UNIV OF CHEM TECH

Production process of biological diesel oil

ActiveCN1952048AImprove conversion rateAvoid Catalyst SeparationBiofuelsLiquid hydrocarbon mixture productionChemistryTransformation efficiency

The invention relates to a producing process of biological diesel oil by making the animal oil (or esters), vegetable oil (or esters) and low-carbon alcohol carry out the eater exchanging reaction in striking admixer to produce the biological diesel oil. Charge the animal oil (or esters), vegetable oil (or esters) and low-carbon alcohol into the striking admixer according to the reacting ratio, control the temperature and pressure of the admixer to make the materials mix and react quickly. The invention can be used in successive production and has high transformation efficiency in malacipeous conditions. Compared to the present technologies, the invention has the advantages of simple procedures, malacipeous conditions, high transformation efficiency and less by-products; besides, the invention can be used to produce diesel oil with different kinds of animal oil (or esters) and vegetable oil (or esters).

Owner:CHINA PETROLEUM & CHEM CORP +1

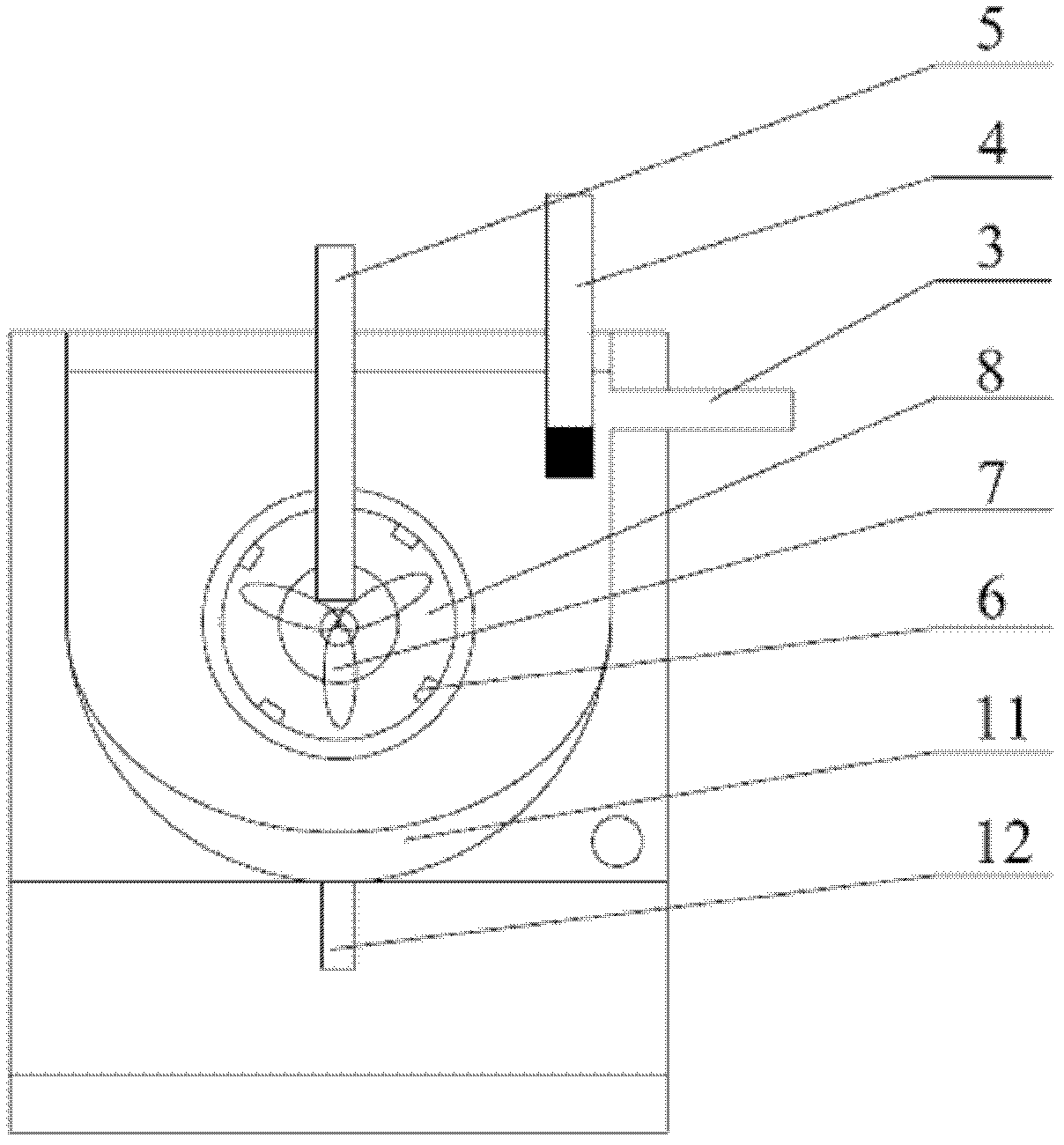

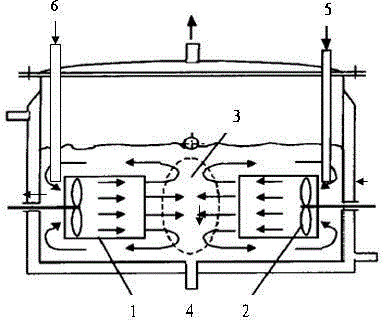

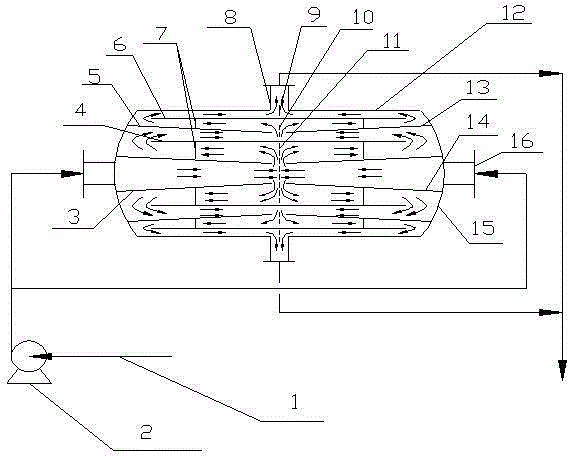

Liquid phase impinging stream reactor with controllable acidity

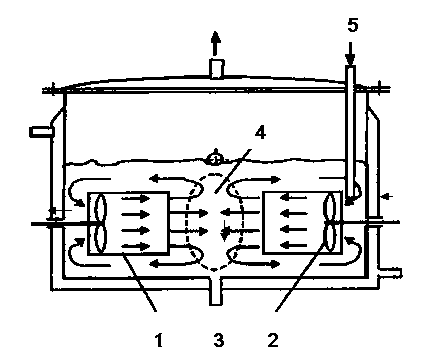

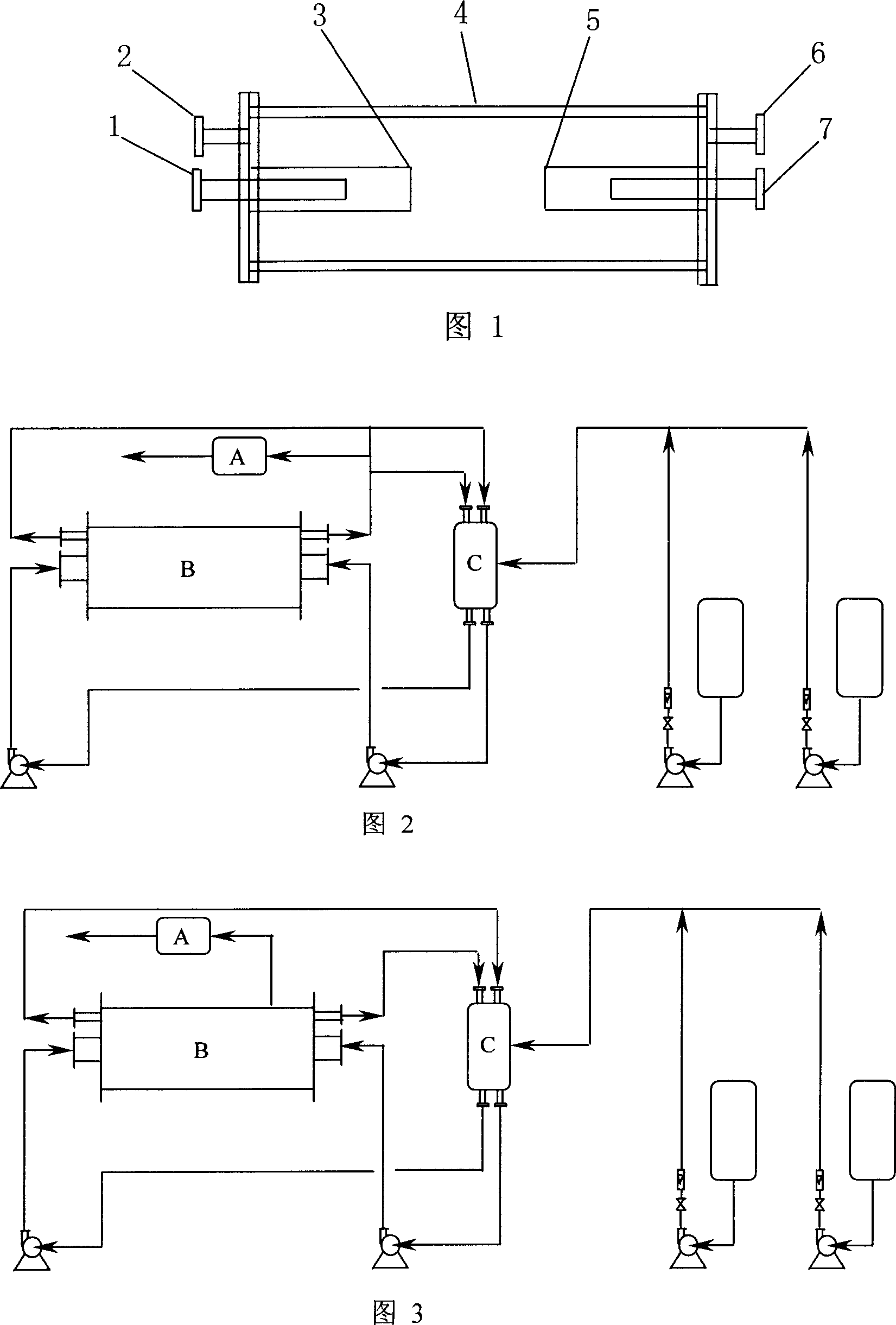

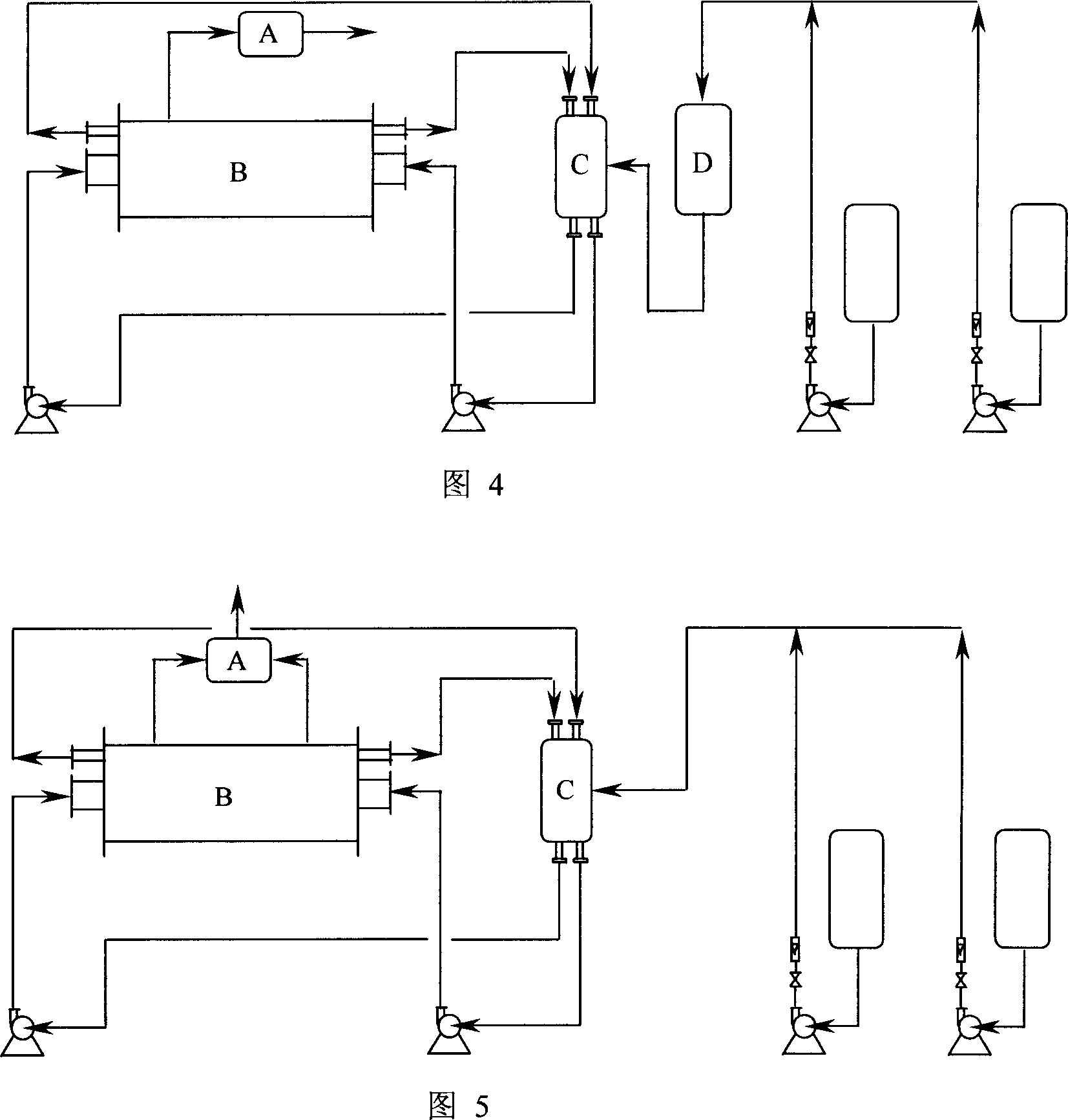

ActiveCN103203213AIncrease impact speedSuppress swirlChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

The invention discloses a liquid phase impinging stream reactor with controllable acidity, belonging to the field of chemical reaction technical equipment. In the reactor, 1-6 pairs of draft tubes with changeable diameters are horizontally arranged coaxially and oppositely; raw materials are introduced by feeding tubes with curved nozzles; fluid is accelerated by push-type three-blade stirrers at the entrance of the draft tubes; the rotation speed of the push-type three-blade stirrers is controlled by a controller; rotational flow is inhibited by deflection baffles; the inner diameters of the draft tubes become smaller gradually; cross-section area of a flow channel is decreased; flow speed is increased; the flow speed at the exits of the draft tubes is the maximum; two fluids impinge face to face at a high speed in the container and mixed efficiently and rapidly; the fluids flow to the entrance of the draft tubes from central impinging areas through the outer sides of the draft tubes, thus realizing circulation; motors are fixed and anti-vibrated by triangle support plates, the acidity of a reaction system is on-site monitored by a pH meter probe and displayed in real time by a pH meter display; constant acidity of the reaction system is realized by adjusting liquid inlet flow quantity; and materials in the contained are discharged from a material-discharging port after the reaction is finished. The liquid phase impinging stream reactor can be heated or cooled, and can be operated continuously, intermittently or semi-continuously.

Owner:TSINGHUA UNIV

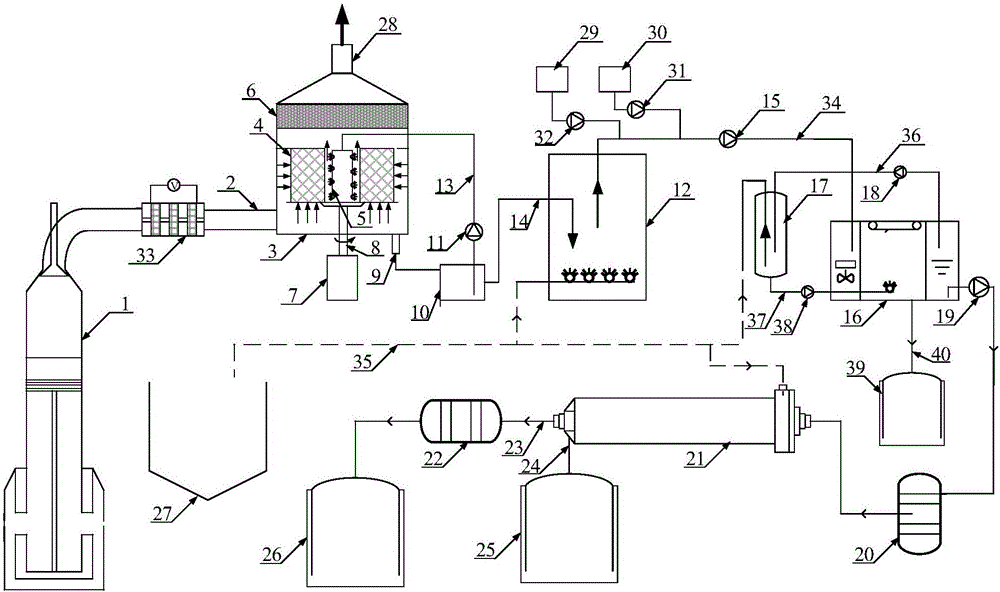

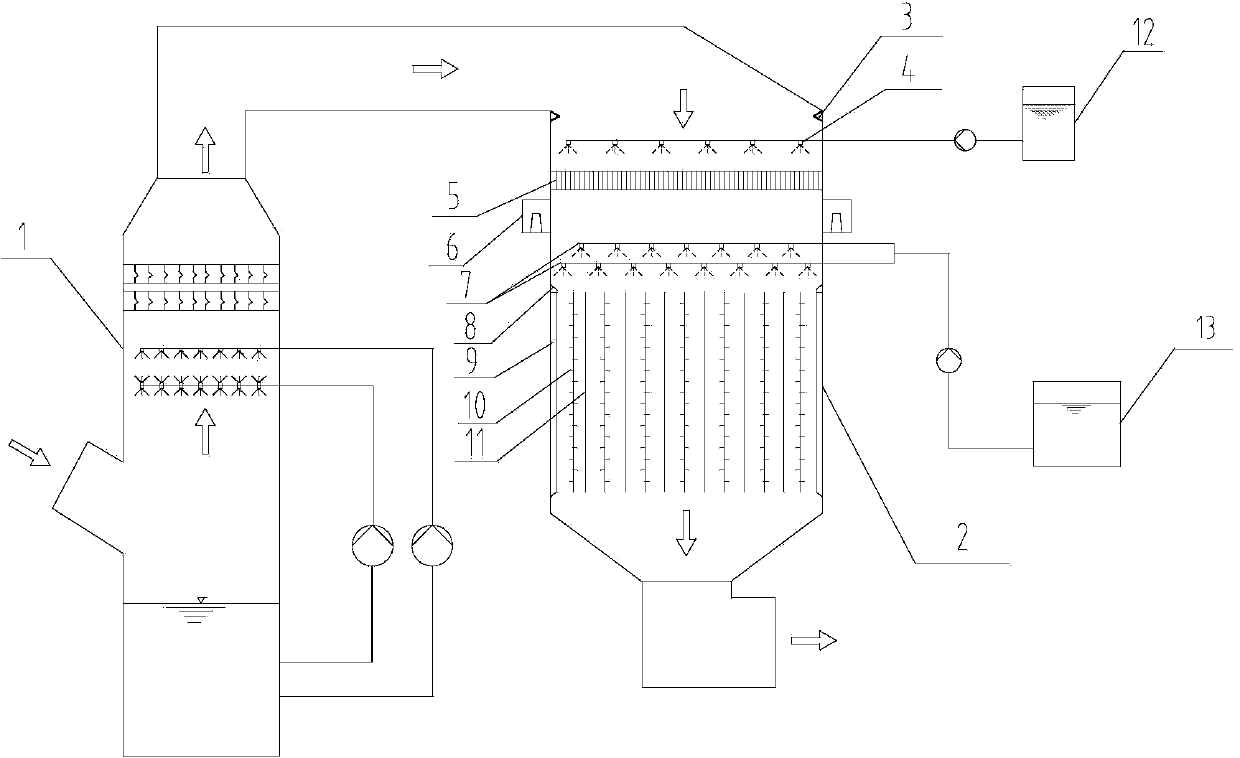

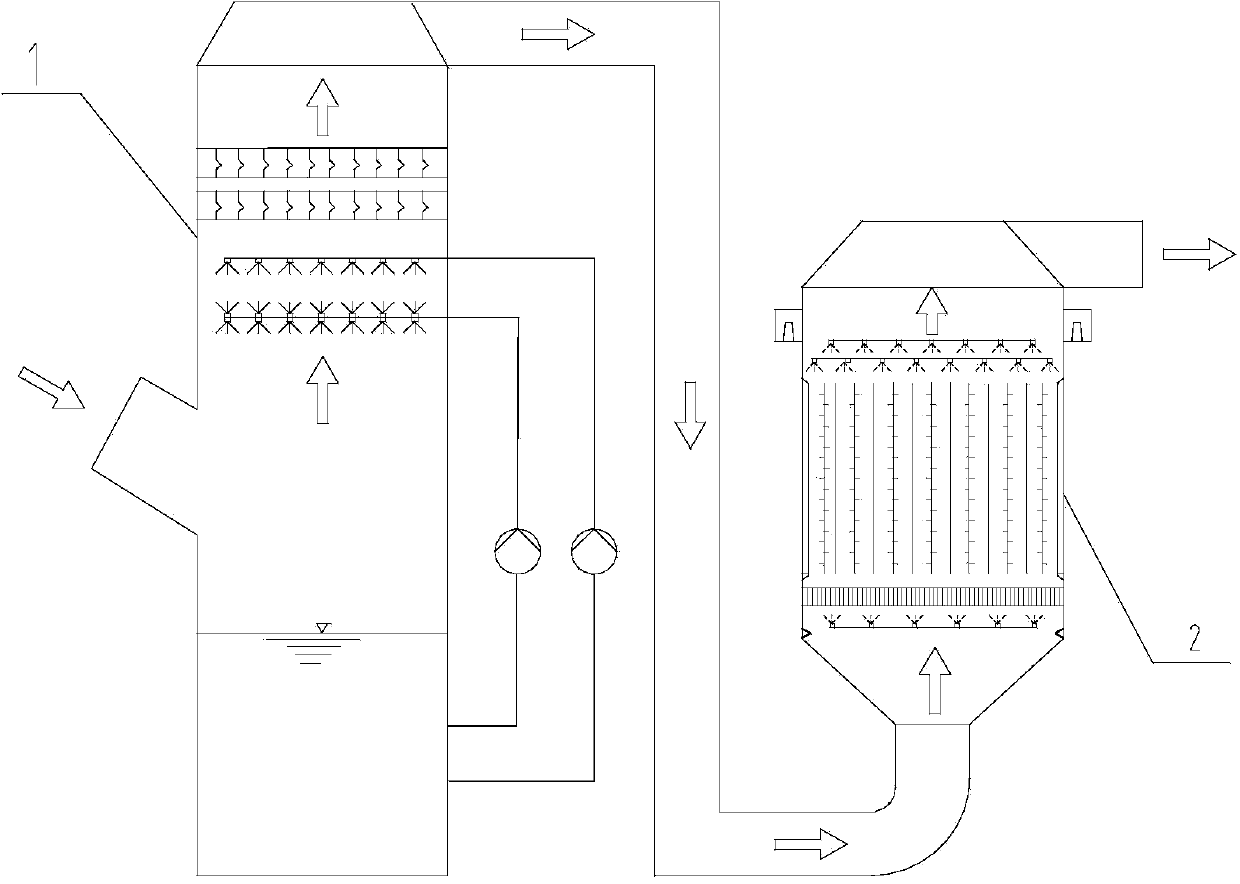

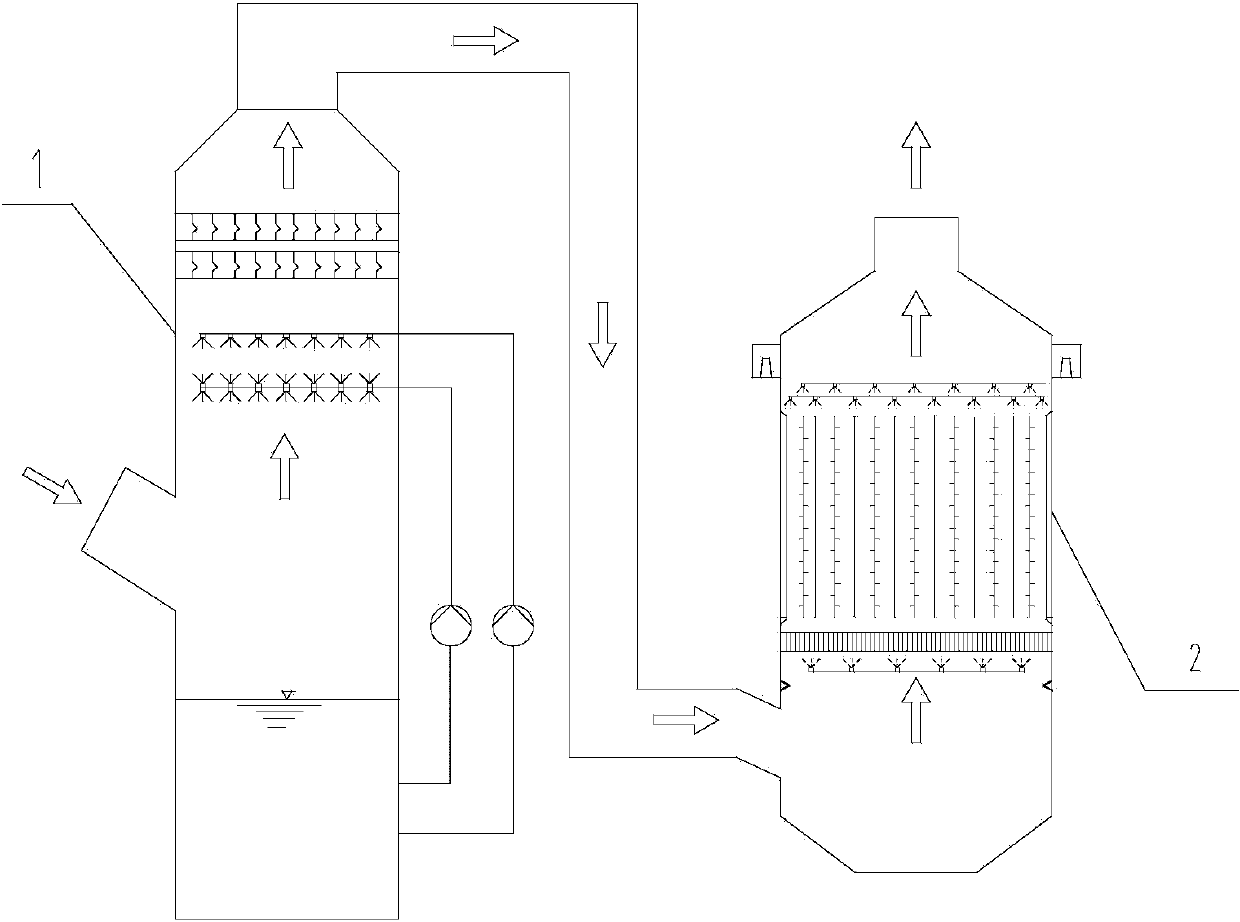

Combined device for washing tail gas and treating waste water of low-speed diesel engine of ship

InactiveCN105854602APromote oxidationAchieve simultaneous absorptionGas treatmentUsing liquid separation agentLow speedGas phase

The purpose of the present invention is to provide a composite device for marine low-speed diesel engine tail gas washing and wastewater treatment, including a high-gravity tail gas washing system, a wastewater treatment system, and a plasma catalytic reactor to oxidize nitrogen oxides to achieve the purpose of simultaneous absorption of exhaust gas pollutants. The high-gravity washing tower uses high-speed rotating packing to generate a super-gravity field that is hundreds to thousands of times the acceleration of gravity, so that the flow rate of the liquid film is 10 times higher than that in the gravity field. It strengthens the microscopic mixing between the gas and liquid phases, and greatly enhances the mass transfer between the gas and liquid. It has the characteristics of small equipment volume, small gas phase pressure drop, and convenient installation and maintenance. The wastewater treatment system adopts the combination of classic water treatment technology and reverse osmosis membrane treatment technology to meet the discharge standards of polycyclic aromatic hydrocarbons, turbidity, nitrates, heavy metals and other pollutants in ship wastewater stipulated by IMO.

Owner:HARBIN ENG UNIV

Spherical calcium carbonate and preparation method thereof

InactiveCN109824077ANarrow particle size distributionSmall particle sizeCalcium/strontium/barium carbonatesCarbonizationSlurry

The invention discloses a spherical calcium carbonate and a preparation method thereof. The preparation method comprises following steps: mixing quicklime with water according to a ratio, carrying outdigestion and aging, then sieving the solution to remove impurities, adding ethanol into the slurry, carrying out refining and regulating to obtain calcium hydroxide slurry; transferring the preparedslurry to a super gravity reactor, adding a crystal form controller, controlling the carbonization temperature, CO2 gas flow, and super gravity level to carry out countercurrent contact between the calcium hydroxide slurry and CO2 gas to trigger carbonization reactions; after carbonization, carrying out centrifugation, drying obtained precipitates, and grinding to obtain spherical calcium carbonate. Calcium hydroxide is taken as the raw material, alcohol and water are taken as the solvents, the cost is low, the spherical calcium carbonate is prepared in a super gravity field by a carbonization method, the microscopic mixing and mass transfer process are greatly enhanced, the carbonization time is short, the production efficiency is high, the particle size distribution range is narrow, theparticle size is small, the morphology is uniform, the dispersing property is good, and the spherical calcium carbonate is suitable for industrial application.

Owner:GUANGXI UNIV +1

Method for purifying nitrogen-containing oxide tail gas

ActiveCN105854542ASuitable for handlingIncrease contact areaGas treatmentDispersed particle separationNitrogenPhysical chemistry

The invention relates to a method for purifying nitrogen-containing oxide tail gas. In a static supergravity-ultrasonic reaction absorption device, air is used as an oxidant, NOx-containing oxide tail gas and a denitration solution perform contact reaction at the room temperature. The NOx removing process can be quickly and efficiently completed, so that the NOx concentration in the tail gas is reduced to be 30 mg / m<3> or below. The method is suitable for various NOx-containing treatments.

Owner:天津市翼腾云拓科技有限公司

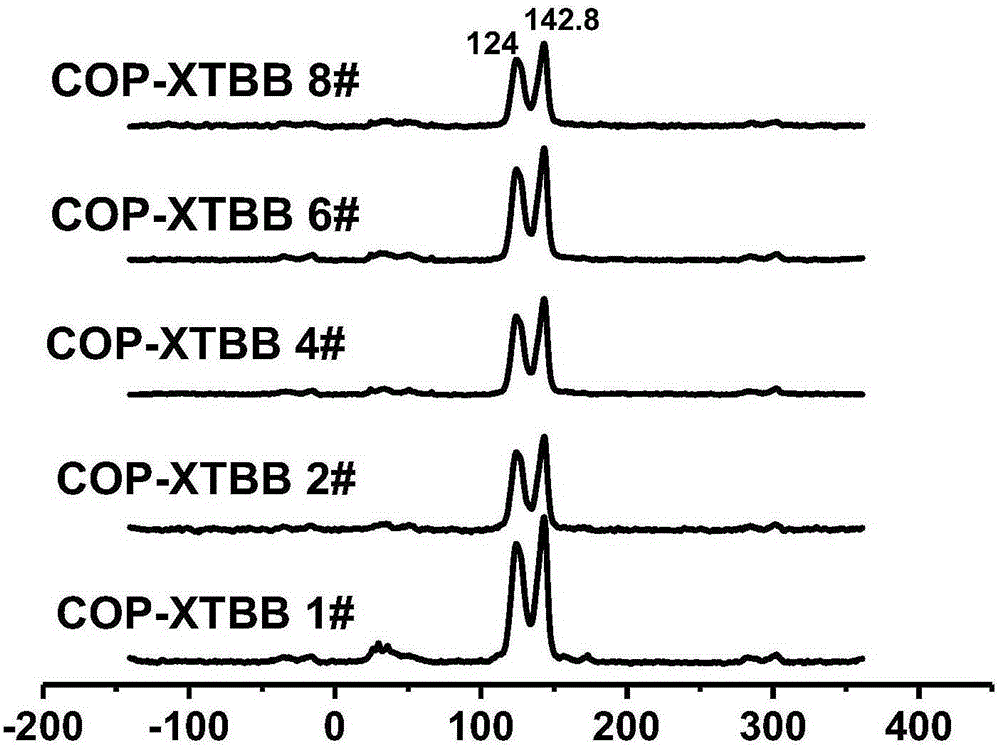

Method for preparing porous covalent organic material by using ultra-gravity method

The invention discloses a method for preparing a porous covalent organic material by using the ultra-gravity method, and belongs to the technical field of preparation of porous covalent organic materials. The method comprises the following steps: under a high gravity field, the micromixing and mass transferring process is strengthened, materials in a cavity of a preferable over-gravity rotary bed are sucked into a rotor of the rotary bed through a rotating inner spiral pipe, and the materials are sheared by, mixed and reacted with a filler rotating at a high speed in the rotor. Compared with reaction under a normal gravity filed, the method is greatly increased in reaction rate, and shortened in reaction time; besides, as for reaction systems sensitive to air, the water-free and oxygen-free reaction condition can also be achieved without a glove box, and compared with low-dosage preparation in the glove box, the method is greater in preparation amount and higher in production efficiency.

Owner:BEIJING UNIV OF CHEM TECH

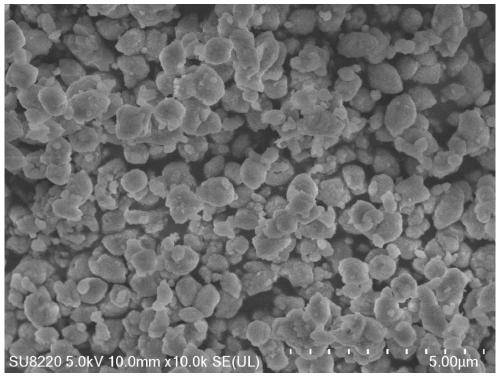

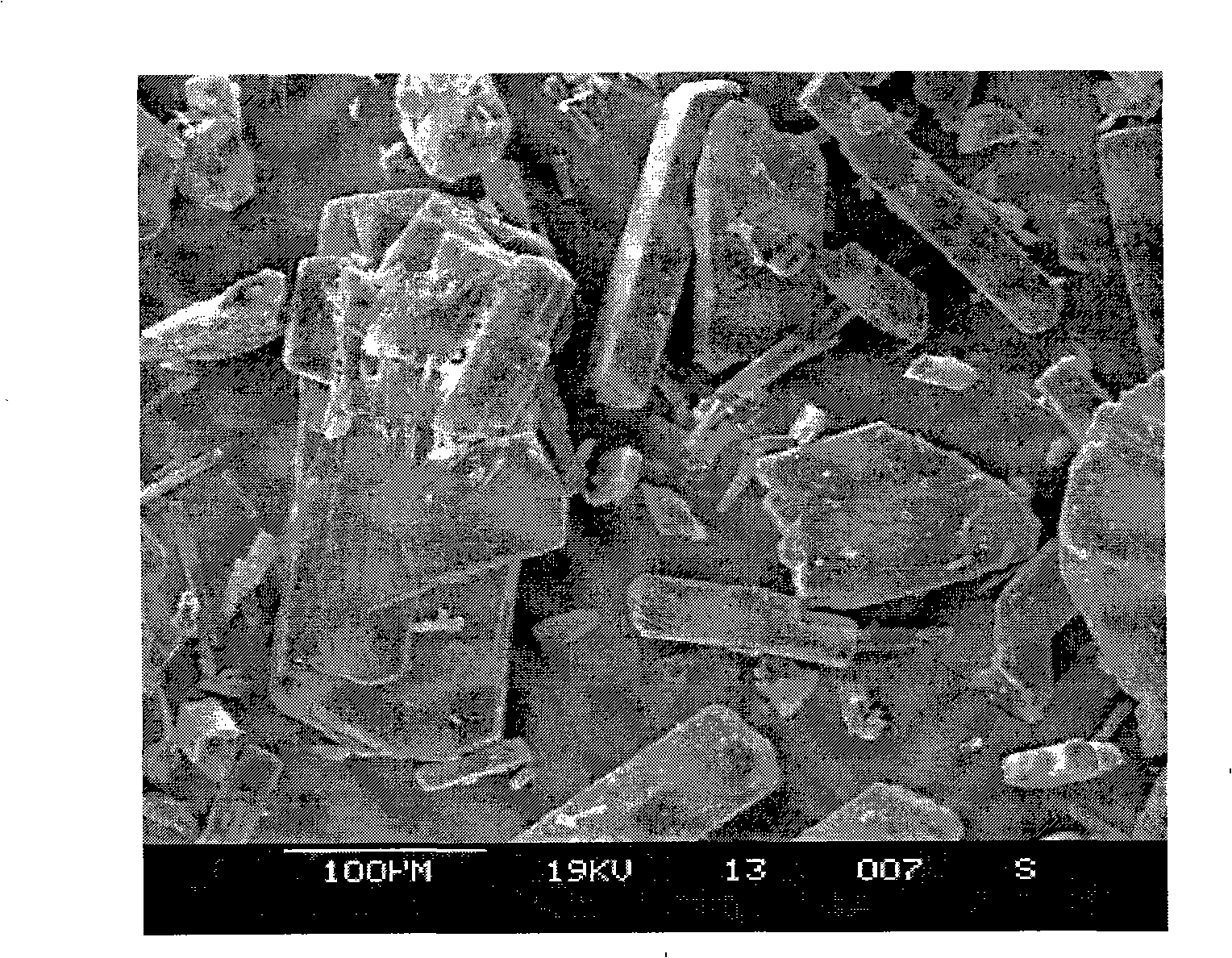

Vanadium-phosphorus oxide catalyst for preparing maleic anhydride through cyclohexane oxidation, and preparation method thereof

ActiveCN104607220AHigh reactivityEvenly distributedMaterial nanotechnologyPhysical/chemical process catalystsOctahedronBiological activation

The present invention discloses a vnadium-phosphorus oxide catalyst for preparing maleic anhydride through cyclohexane oxidation, and a preparation method thereof. According to the vanadium-phosphorus oxide catalyst, a nanometer vanadium-phosphorus oxide is adopted as a precursor, and is sequentially subjected to activation and forming or forming and activation to prepare the vanadium-phosphorus oxide catalyst, wherein the grain size of the nanometer vanadium-phosphorus oxide is less than 100 nm, and the grain size distribution adopting the volume as the benchmark is that the content of the particles with the grain size of 10-70 nm is 7-25%, the content of the particles with the grain size of 70-85 nm is 60-88%, and the content of the particles with the grain size of more than 85 nm is 5-15%; in the catalyst prepared by adopting the nanometer vanadium-phosphorus oxide as the precursor, the octahedron structure of the (VO)2P2O7 crystal phase is regular, the catalyst structure is stable, and the catalysis activity and the catalyst stability are high; and with the application of the catalyst of the present invention to catalyze the maleic anhydride preparation reaction through the cyclohexane oxidation, the cyclohexane conversion rate can achieve 57-70 mol%, and the maleic anhydride selectivity can achieve 65-74 mol%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vertical flow wet-type electric precipitator and wet electric precipitation method

The invention provides a vertical flow wet-type electric precipitator and wet electric precipitation method. The vertical flow wet-type electric precipitator comprises an annular plate, a spray humidifying layer, a flue gas uniform distribution device, a dust removing electric field area, washing and spraying layers, a plurality of insulator boxes, an atomization water tank and a process water tank, wherein the spray humidifying layer comprises a fine atomizing nozzle and a spray pipeline; flue gas sequentially passes through the annular plate, the spray humidifying layer and the flue gas uniform distribution device; the dust removing electric field area is used for blocking a baffle board of a flue gas blind area; the washing and spraying layers are arranged above the dust removing electric field area; the wet electric precipitation method comprises the following steps: a continuous manner is adopted to conduct atomization and humidification on inlet flue gas and conduct uniformly distributed optimization treatment on the flue gas; an intermittent or continuous manner is adopted to conduct sprinkling and cleaning on a dust-collecting electrode and a discharge electrode; a method of hot air sweeping is adopted to ensure insulation. The vertical flow wet-type electric precipitator and the wet electric precipitation method can effectively ensure the high-efficient and stable operation of the vertical flow wet-type electric precipitator, optimize the fluid field, and strengthen turbulence and atomization of the flue gas; local micro-mixing, and collision as well as crash coagulation of fine particles are promoted; the dust removal efficiency is improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

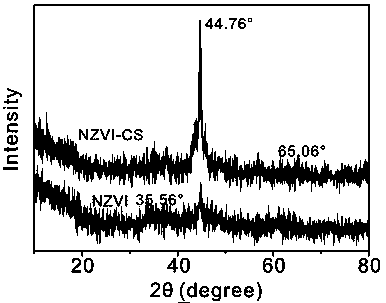

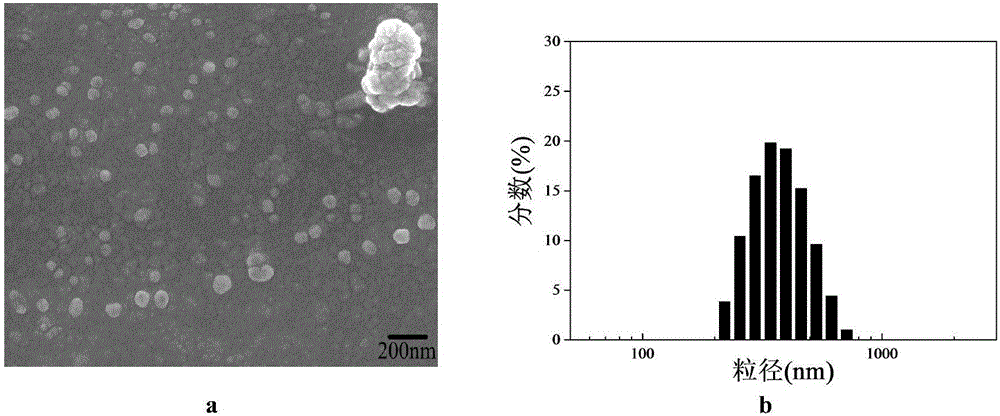

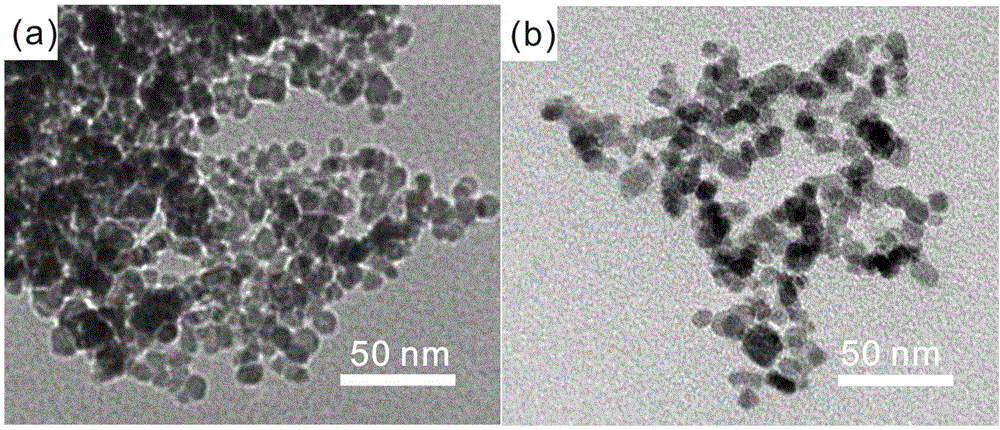

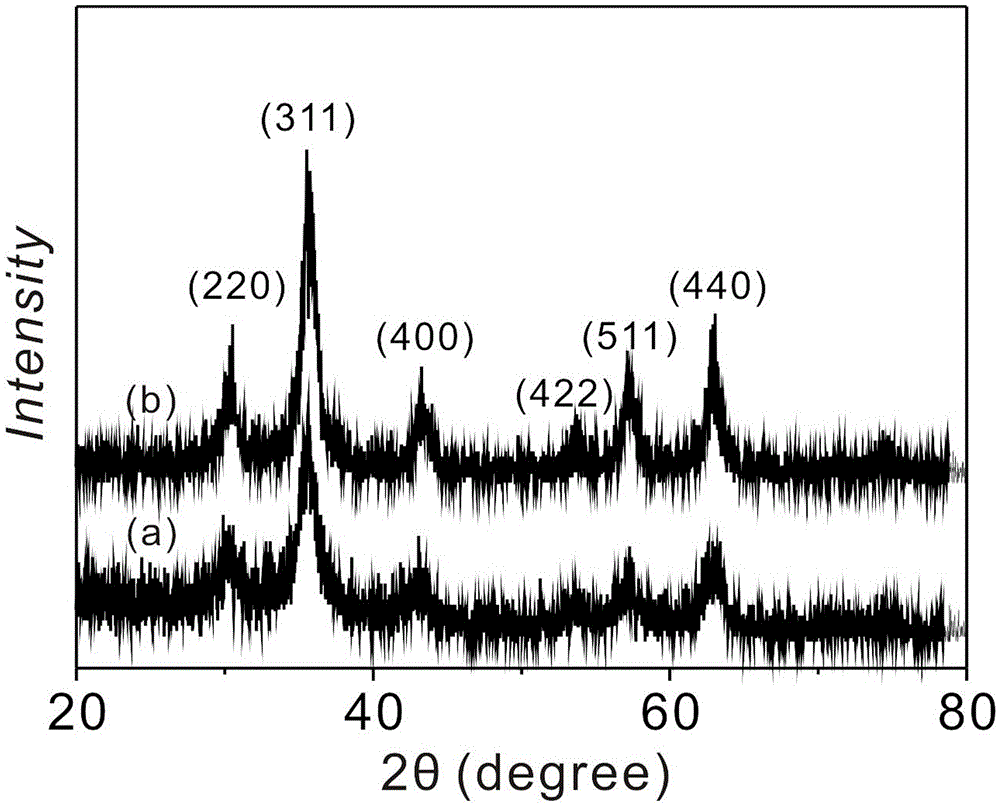

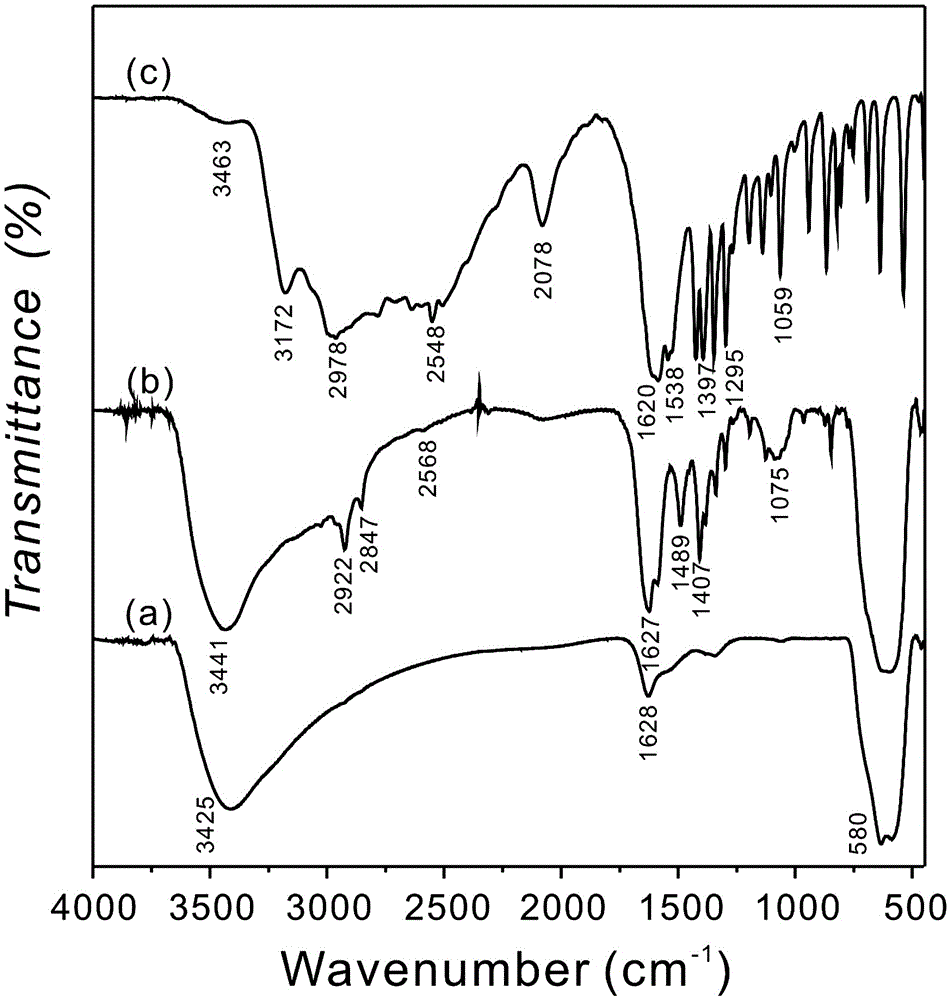

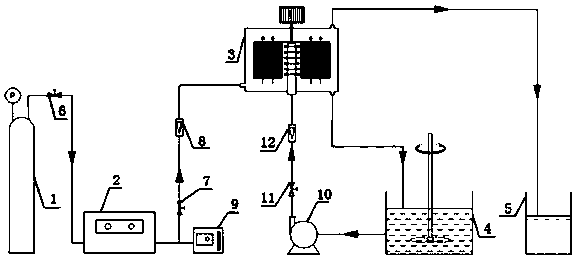

Supergravity preparation method for chitosan-supported nanoscale zero-valent iron and bimetal composite material thereof

InactiveCN108262489AUniform particle size distributionSmall particle sizeMaterial nanotechnologyTransportation and packagingDispersityMaterials science

The invention discloses a supergravity preparation method for chitosan-supported nanoscale zero-valent iron and a bimetal composite material thereof, and belongs to the technical field of nanometer materials. The invention aims at providing a method for continuously preparing chitosan-supported nanoscale zero-valent iron and a bimetal composite material thereof. The method comprises the followingsteps: conveying the mixed solution of chitosan and metal salt, and a reducing agent into a supergravity reactor simultaneously, and reacting; magnetically separating reaction products after the reaction is concluded; repeatedly cleaning the reaction products through deionized water and absolute ethyl alcohol until the reaction products are neutral; and carrying out vacuum drying on the reaction products to obtain the chitosan-supported nanoscale zero-valent iron and nano-iron bimetal composite particles. According to the method, the chitosan-supported nanoscale zero-valent iron or the nano-iron bimetal composite particles are prepared in one step, and the method is simple in process, short in reaction time, low in cost, and capable of realizing large-scale production; and meanwhile, the prepared chitosan-supported nanoscale zero-valent iron or nano-iron bimetal composite particles are small in particle size, and high in dispersity, stability and reactivity, and have an industrializedapplication prospect.

Owner:ZHONGBEI UNIV

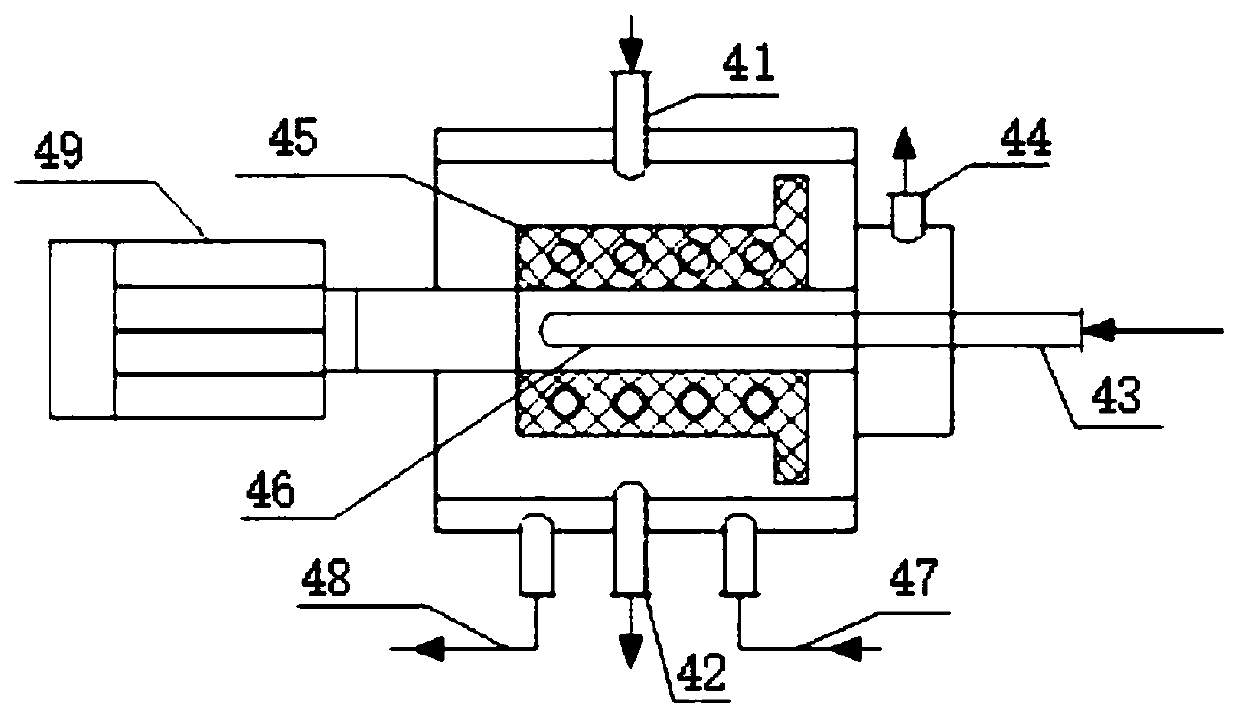

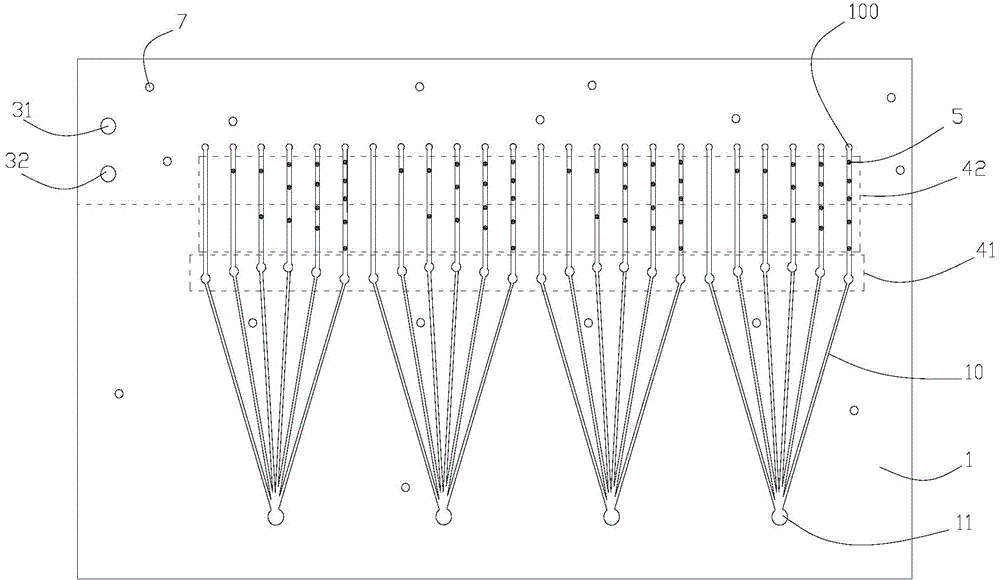

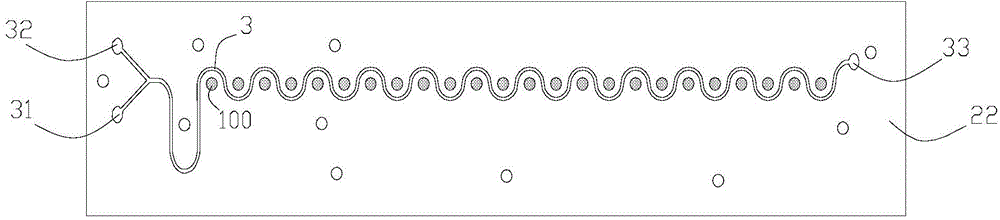

Supergravity-continuous micro impinging stream reactor based on eight-trigram diagram principle

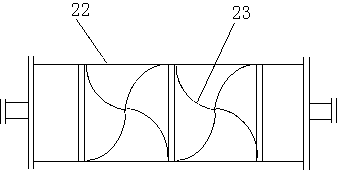

ActiveCN104437334ALow costGood dispersionChemical/physical/physico-chemical nozzle-type rreactorsFeed devicesPrinciple of orthogonal designEngineering

The invention provides a supergravity-continuous micro impinging stream reactor based on the eight-trigram diagram principle. The supergravity-continuous micro impinging stream reactor comprises a main flow channel and 24 branch flow channel outlets corresponding to 24 branch flow channels; the main flow channel comprises 24 semicircular flow channels which butt joint sequentially and are arranged along the straight line direction and the radiuses of which are equal or change from small to large; the 24 branch flow channel outlets are respectively positioned in the inner sides of the 24 semicircular flow channels, and the circulation cross sections of the 24 branch flow channel outlets are circles with equal radiuses and the circle centers of the circles are coincided with the respective corresponding semicircular flow channels; the branch flow channel outlets and the corresponding semicircular flow channels are communicated via fan-shaped slits; the circle centers of the fan-shaped slits are coincided with the circle centers of the branch flow channel outlets; the widths of the fan-shaped slits are determined by guaranteeing that the initial velocity is greater than 1m / s when branch streams run into the main stream. According to the invention, the multi-scale mixing in the liquid-liquid reaction process can be intensified by utilizing the impinging of the high-frequency reversed supergravity field and a continuous ultrathin liquid membrane.

Owner:ZHEJIANG OCEAN UNIV

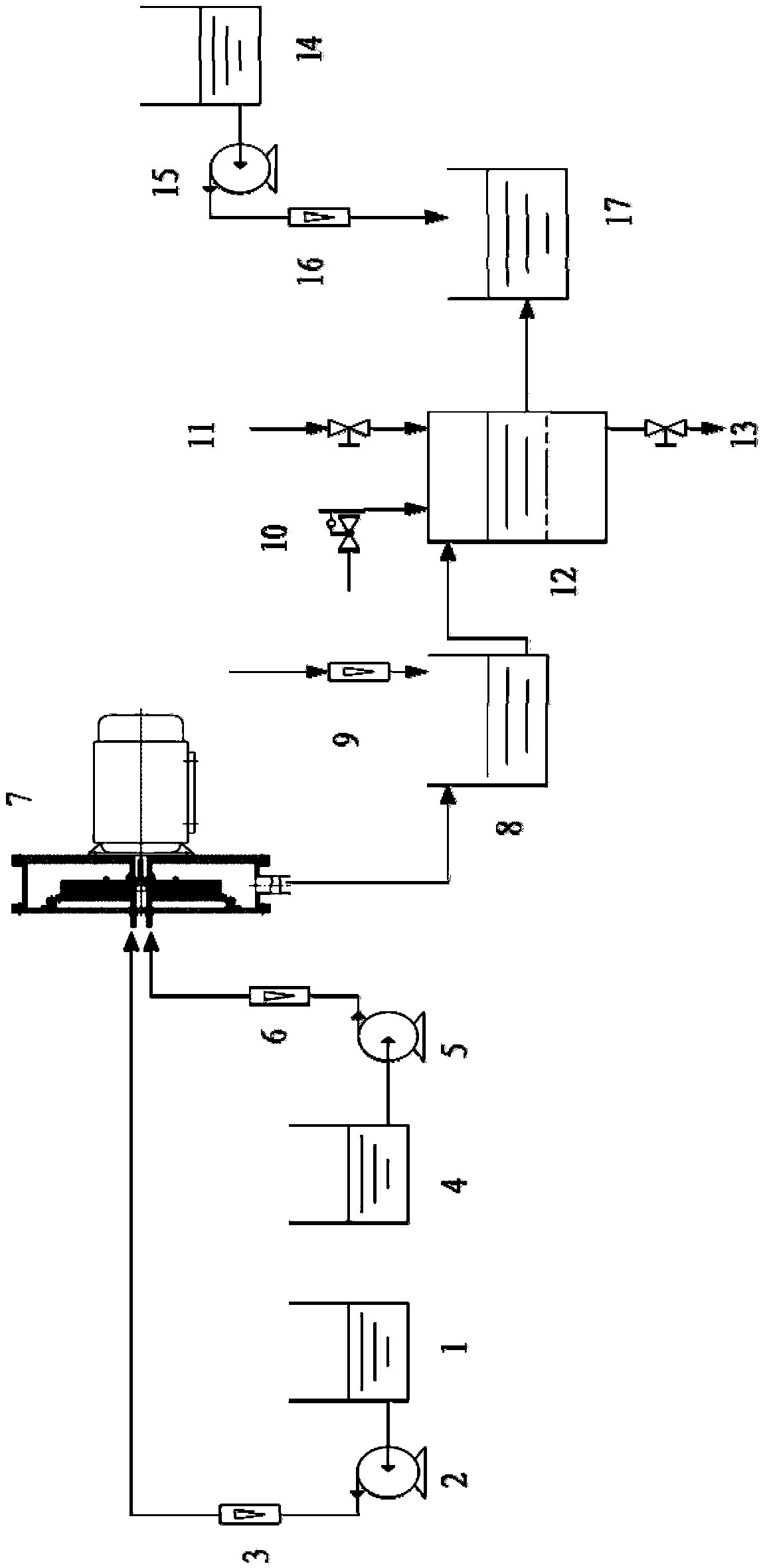

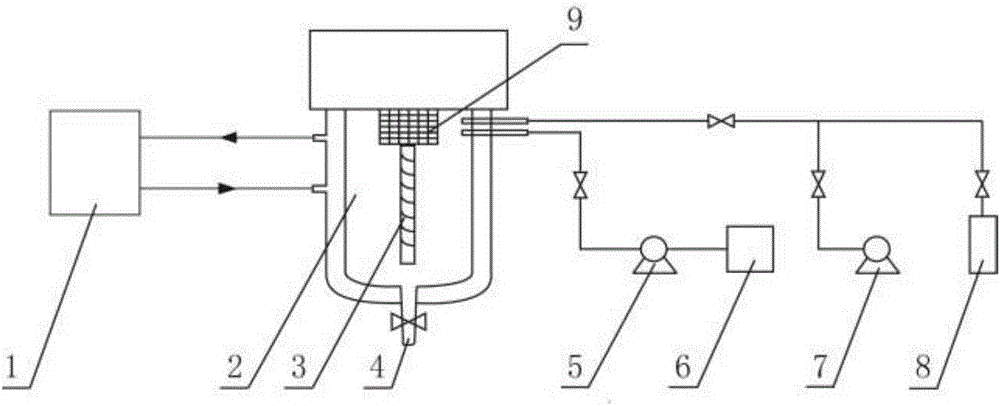

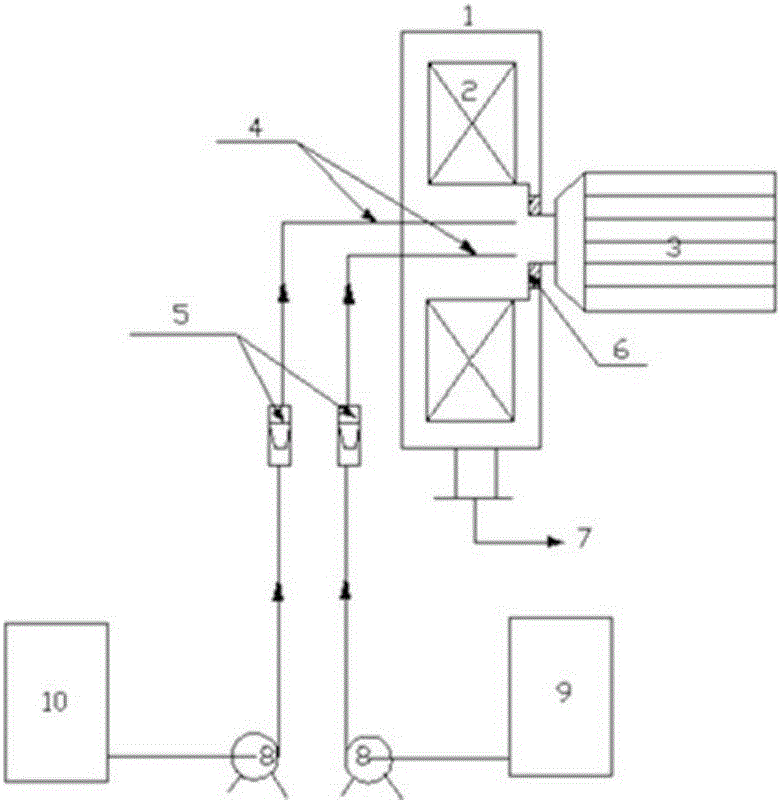

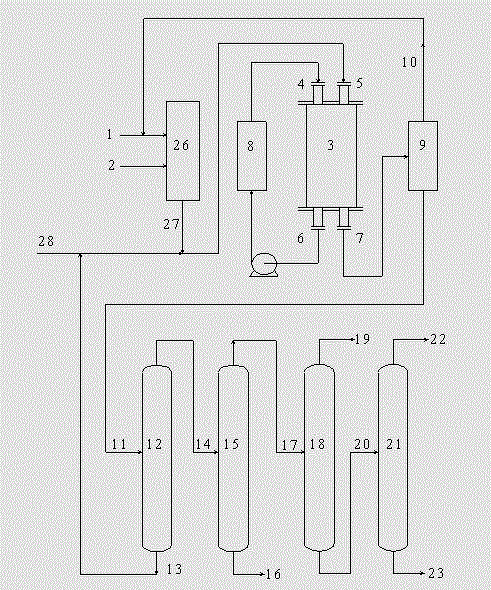

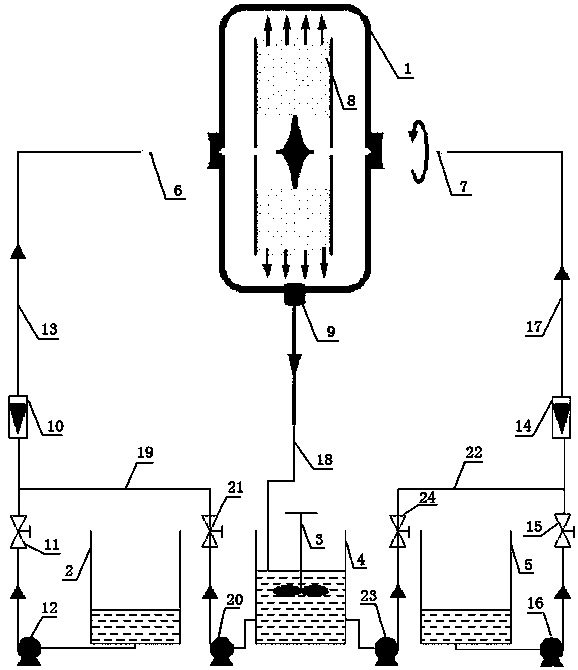

Preparation method of adriamycin nano-drug particles

InactiveCN106265542AOvercome uniformity issuesOvercoming inadequaciesPowder deliveryOrganic active ingredientsDrugs solutionFreeze-drying

The invention discloses a preparation method of adriamycin nano-drug particles, belongs to the field of drug preparation and provides an adriamycin containing solution and a proper anti-solvent. The adriamycin containing solution and the anti-solvent are put in a first storage tank for a drug solution and a second storage tank for the anti-solvent; the two kinds of liquid are conveyed out through a pump, flow through a flowmeter, enter a supergravity reactor at the same time and are sprayed to the rotating inner edge of a packing layer, so that adriamycin is recrystallized out through an anti-solvent precipitation crystallization method; adriamycin suspension liquid is collected, and adriamycin nano-drug powder is obtained after dialysis and freeze-drying. By the adoption of the method, the nanoscale adriamycin drug particles with a controllable average particle size and narrow particle size distribution can be obtained by using different surfactants, regulating the volume flow ratio of the two kinds of liquid, changing motor frequency and the like.

Owner:BEIJING UNIV OF CHEM TECH

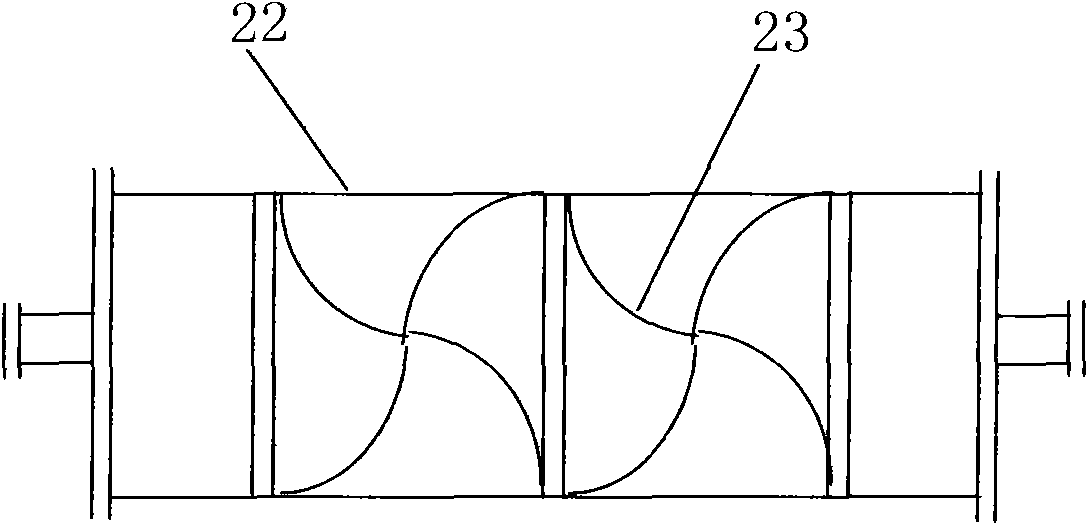

Method for preparing sec-butyl acetate by using acetic acid and butane

ActiveCN102911043ARealize continuous productionGood radial blending effectOrganic compound preparationCarboxylic acid esters preparationButeneAcetic acid ear

The present invention discloses a method for preparing sec-butyl acetate by using acetic acid and butane. The acetic acid and n-butene are sufficiently mixed by continuously passing through a static mixer, and are fed into a reactor filled with a strongly acidic cation-exchange resin catalyst for an addition reaction; the materials after the reaction are fed into a phase separator for a gas-liquid separation; and a fractional distillation of the liquid phase obtained by the gas-liquid separation is performed in a fractionation column to obtain the sec-butyl acetate. Compared with the prior art, the process of the present invention has the advantages of a simple process, high conversion of acetic acid, high selectivity of sec-butyl acetate, less byproducts, and low energy consumption, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

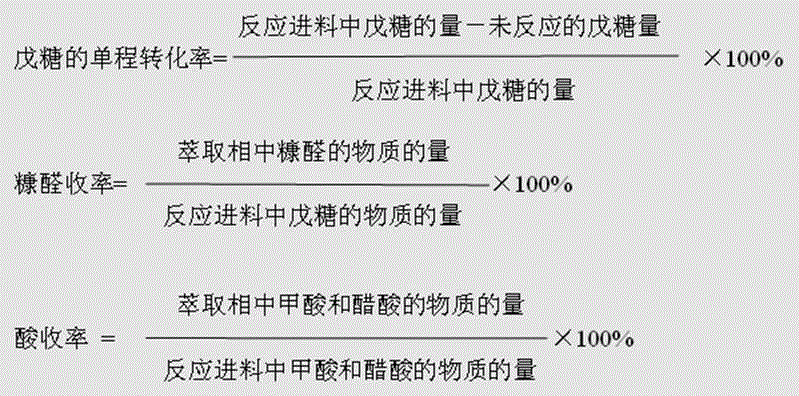

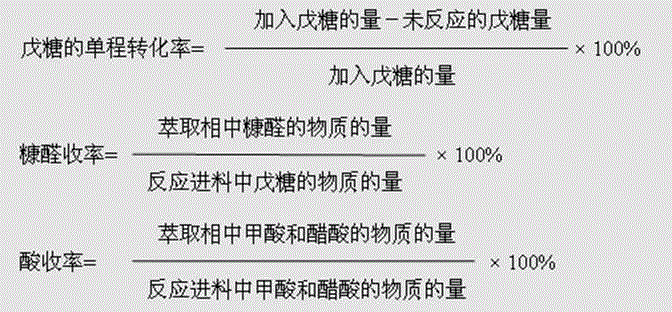

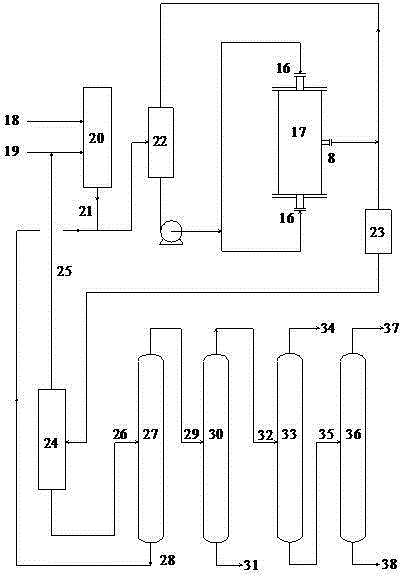

Method for producing furfural from biomass

InactiveCN104557812AIncrease mass transfer rateHigh yieldOrganic compound preparationCarboxylic compound separation/purificationAcetic acidTower

The invention provides a method for producing furfural from biomass serving as a raw material. The method comprises the steps: hydrolyzing the biomass and water, so as to obtain a mixed solution of pentose, acetic acid and formic acid; introducing the mixed solution and an extractant into a static mixer for reaction, enabling a reaction effluent to be subjected to cooling, standing and layering, so as to obtain a water phase and an extracted phase, and enabling the extracted phase to enter an extractant regeneration tower for separation, so as to obtain a mixture, containing a trace volume of water, of furfural, acetic acid and formic acid from the tower top and obtain a regenerated extractant from the tower bottom; enabling the tower top product to enter a furfural refining tower for separation, so as to obtain acetic acid and formic acid, containing a trace volume of water, from the tower top and obtain furfural from a tower reactor; enabling the tower top product to enter an azeotropic rectifying tower, so as to extract the water phase from the tower top and obtain acetic acid and formic acid from a tower reactor; enabling the tower reactor product to enter a finishing column for separation, thereby obtaining formic acid and acetic acid. According to the method provided by the invention, the static mixer is adopted as a reaction vessel, and furfural is enabled to instantly achieve a balance in two phases, namely the extractant and the water, so that the yield of furfural is increased; the process flow is simple, meanwhile, furfural, acetic acid and formic acid are recovered, and no waste liquid is discharged, so that the method is an environment-friendly process.

Owner:CHINA PETROLEUM & CHEM CORP +1

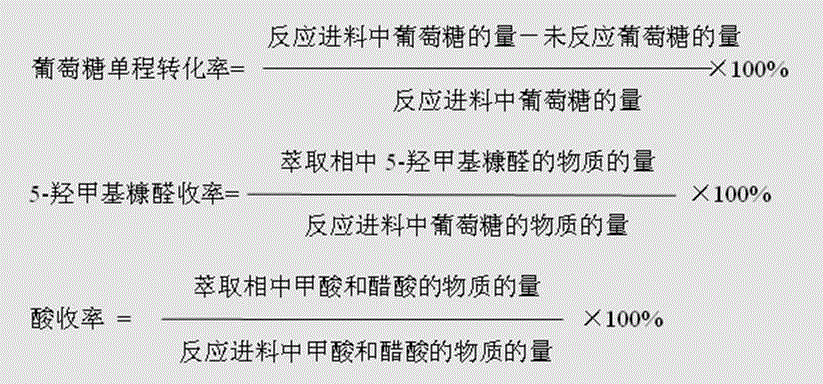

Production process of 5-hydroxymethyl furfural

InactiveCN104557807AHigh yieldNo emissionsOrganic compound preparationCarboxylic compound separation/purificationLiquid wasteHydroxymethylfurfural

The invention relates to a method for producing 5-hydroxymethyl furfural. The method comprises the following steps: hydrolyzing a biomass material from which hemicellulose is removed to obtain a mixed liquid of glucose, acetic acid and formic acid; feeding the mixed liquid to an ultrasonic reactor, and reacting with an extracting agent and a catalyst in a contact manner; cooling and layering a reaction effluent to obtain an upper-layer water phase and a lower-layer extracting phase, feeding the lower-layer extracting phase to an extracting agent regeneration tower to separate; obtaining regenerated extracting agent and a little of water from an overhead product in a phase splitting manner; feeding a tower kettle product to a product tower, and separating to obtaining 5-hydroxymethyl furfural; feeding an acetic acid and formic acid mixture obtained from the tower top into an acetic acid refining tower, and separating to obtain formic acid and acetic acid. According to the method, 5-hydroxymethyl furfural instantly reaches balance between the extracting agent and water phases by virtue of the ultrasonic reactor; the yield of 5-hydroxymethyl furfural is increased; the technological process is simple; meanwhile, 5-hydroxymethyl furfural, acetic acid and formic acid are recycled; no liquid waste is discharged; and the production process is a green environment-friendly process.

Owner:CHINA PETROLEUM & CHEM CORP +1

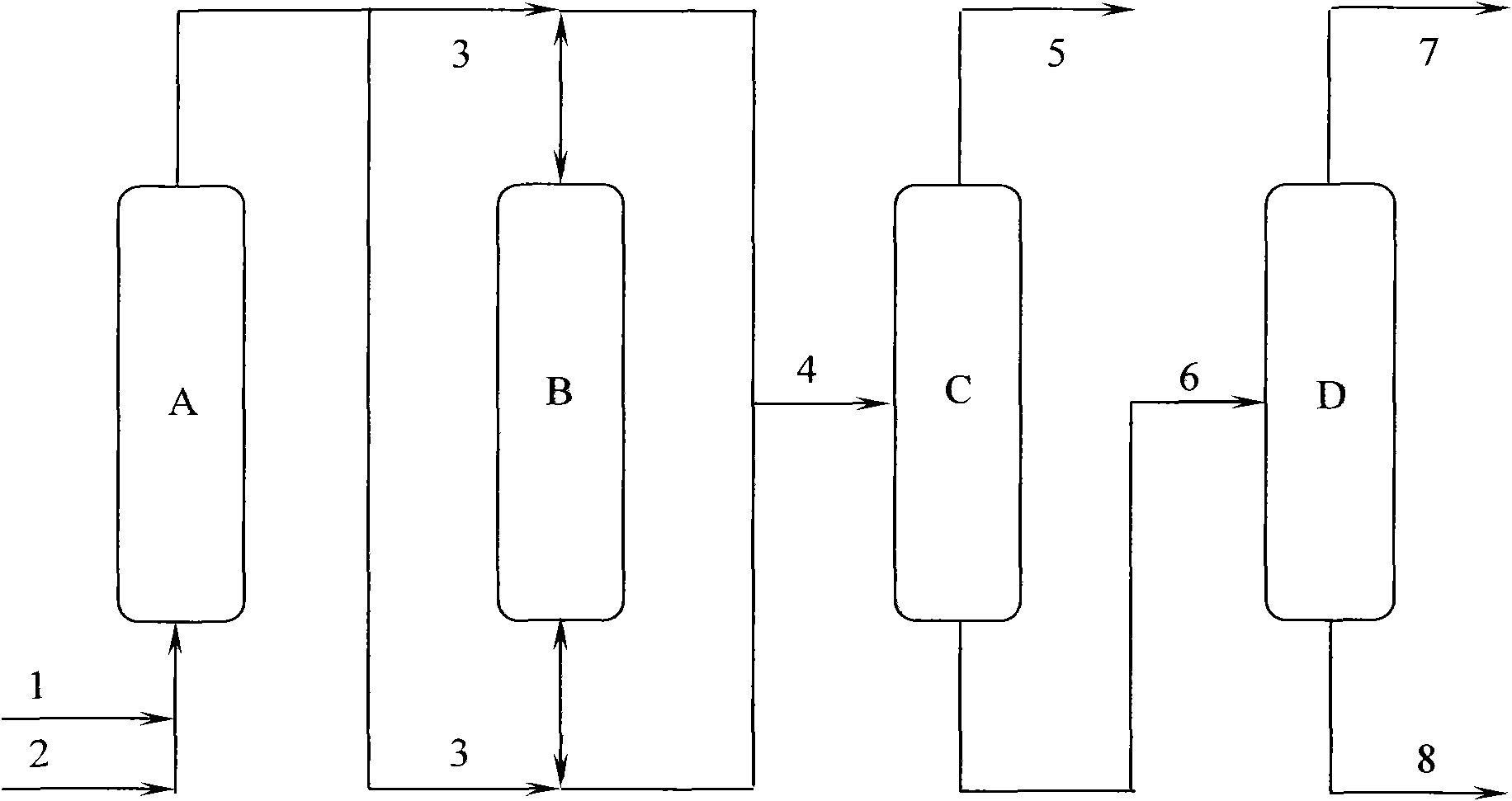

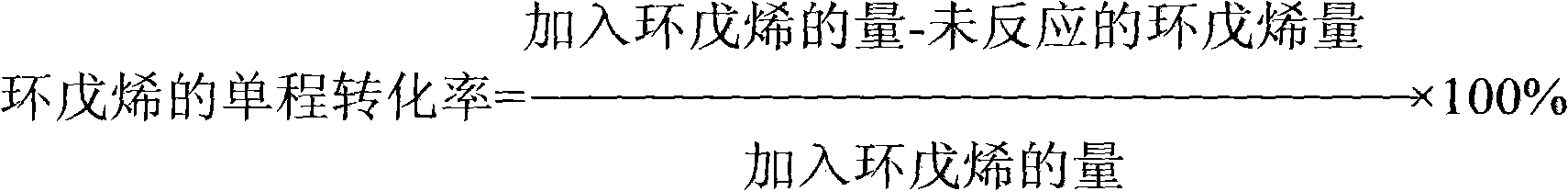

Method for preparing cyclopentanol through hydratation of cyclopentene

ActiveCN102311316AAvoid separationImprove conversion ratePreparation by hydroxy group additionCyclopenteneWater insoluble

The invention discloses a method for preparing cyclopentanol through hydratation of cyclopentene. The method comprises the following steps of: continuously mixing the cyclopentene and water uniformly by using a static mixer; performing hydratation in a reactor loaded with a strong acid cation exchange resin catalyst; allowing materials obtained through reaction to enter a phase separator for gas-liquid separation; returning unreacted gas phase cyclopentene to the static mixer, and ensuring that the obtained liquid phase contains cyclopentanol and water; and separating products to obtain the cyclopentanol. Compared with the prior art, the method has the advantages that: a reaction system is not added with any solvent or aid, so the technological process is simple, the per pass conversion of the cyclopentene is high, the selectivity of the cyclopentanol is high, a few byproducts are generated, the products are more easy to separate, energy consumption is low, and the method can be applied to the hydratation for water-insoluble C2-C5 hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

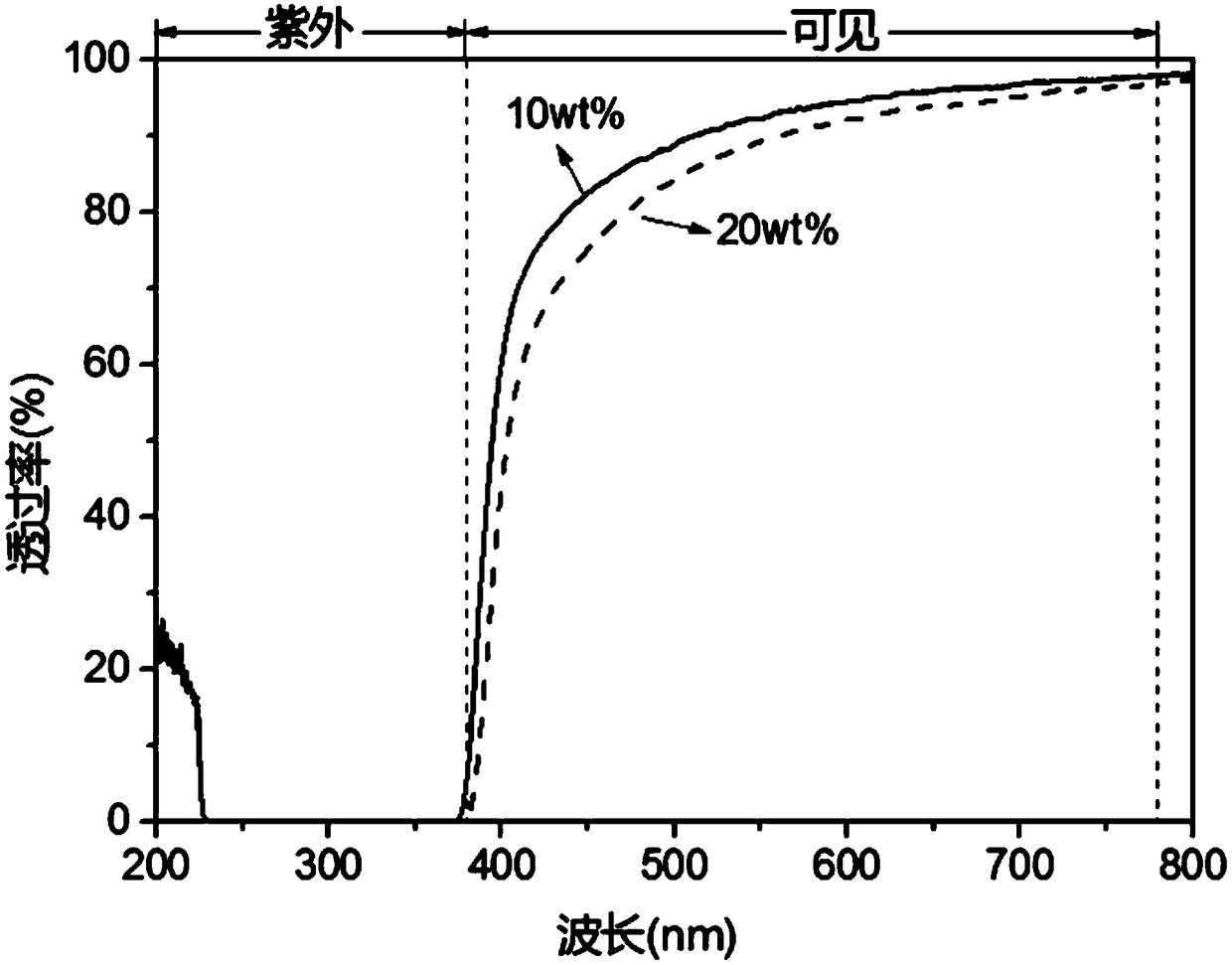

Transparent zinc oxide liquid phase dispersion preparing method

ActiveCN108793226AEnhanced mass transferEnhanced MicromixingZinc oxides/hydroxidesNanotechnologyChemistryMass transfer

The invention discloses a transparent zinc oxide liquid phase dispersion preparing method. The transparent zinc oxide liquid phase dispersion preparing method comprises the following steps of 1) dissolving salt into a liquid phase medium A to obtain a salt solution, and dissolving alkali into a liquid phase medium B to obtain an alkaline solution, wherein the salt is zinc salt of mixed zinc salt,specifically, the mixed zinc salt is obtained by mixing zinc salt and doping elements at a molar ratio of 10-100:1; 2) filling the salt solution and the alkaline solution into a supergravity rotatingpacked bed reactor for reaction at a certain temperature to obtain a zinc oxide suspension; 3) adding surface coating agent into the zinc oxide suspension for modifying coating at a certain temperature for a period of time; 4) settling, centrifuging, washing and then dispersing the stood modified solution into a liquid phase medium C to obtain a transparent zinc oxide liquid phase dispersion. Thetransparent zinc oxide liquid phase dispersion preparing method is completed inside the supergravity rotating packed bed reactor to greatly strengthen mass transfer and micro-mixing; the prepared transparent zinc oxide liquid phase dispersion is transparent and good in dispersibility and stability and has no precipitation when being stood for more than 12 months.

Owner:BEIJING UNIV OF CHEM TECH

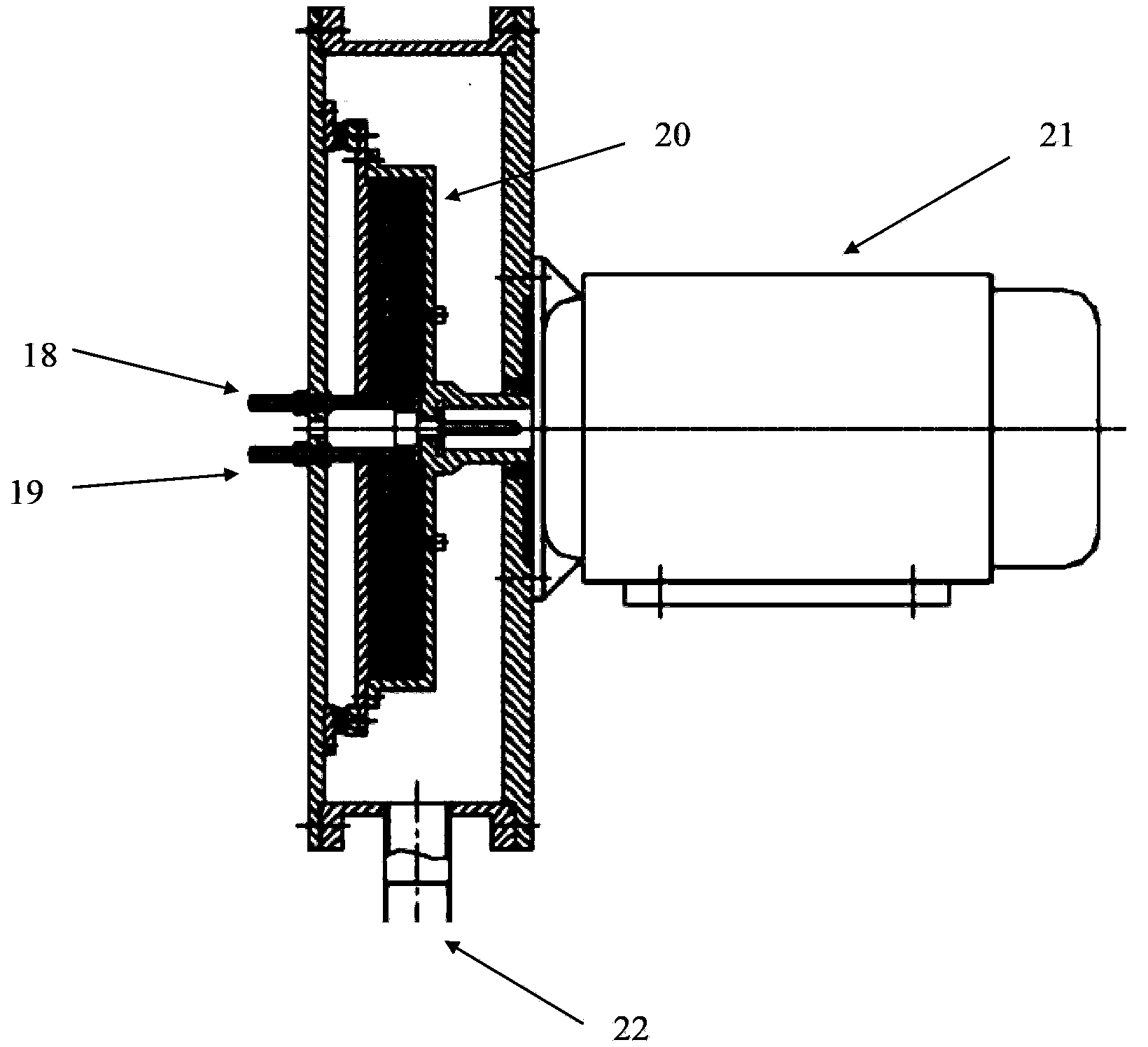

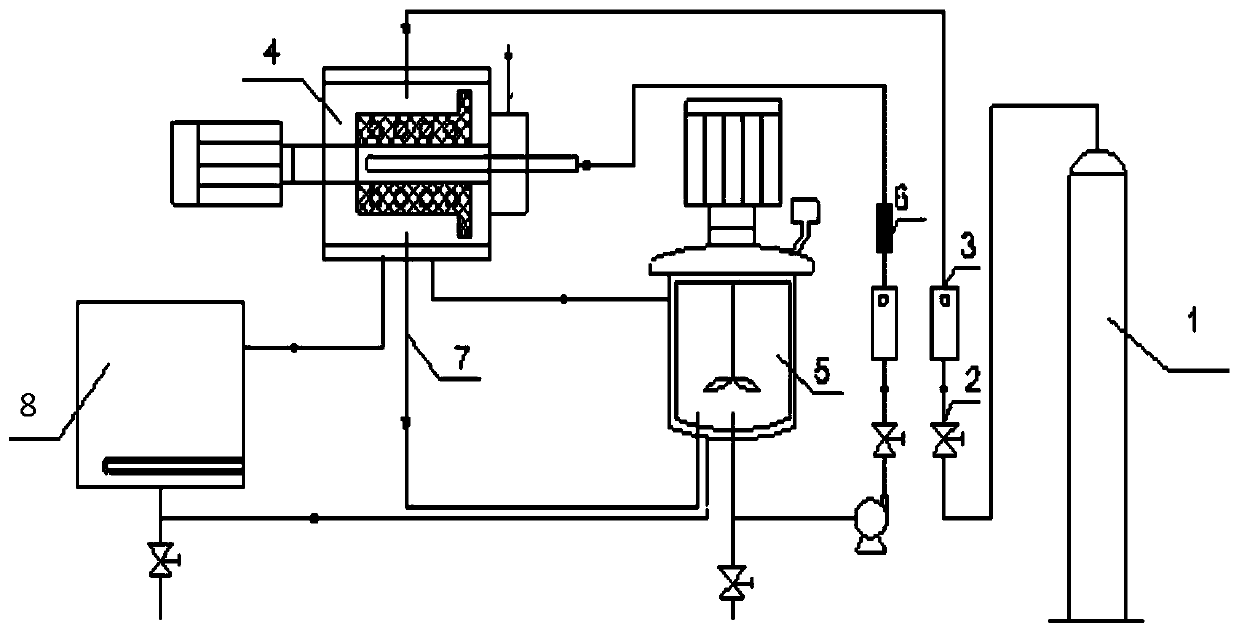

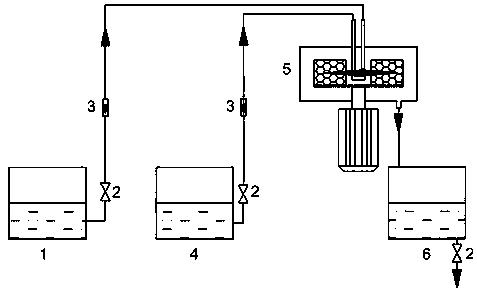

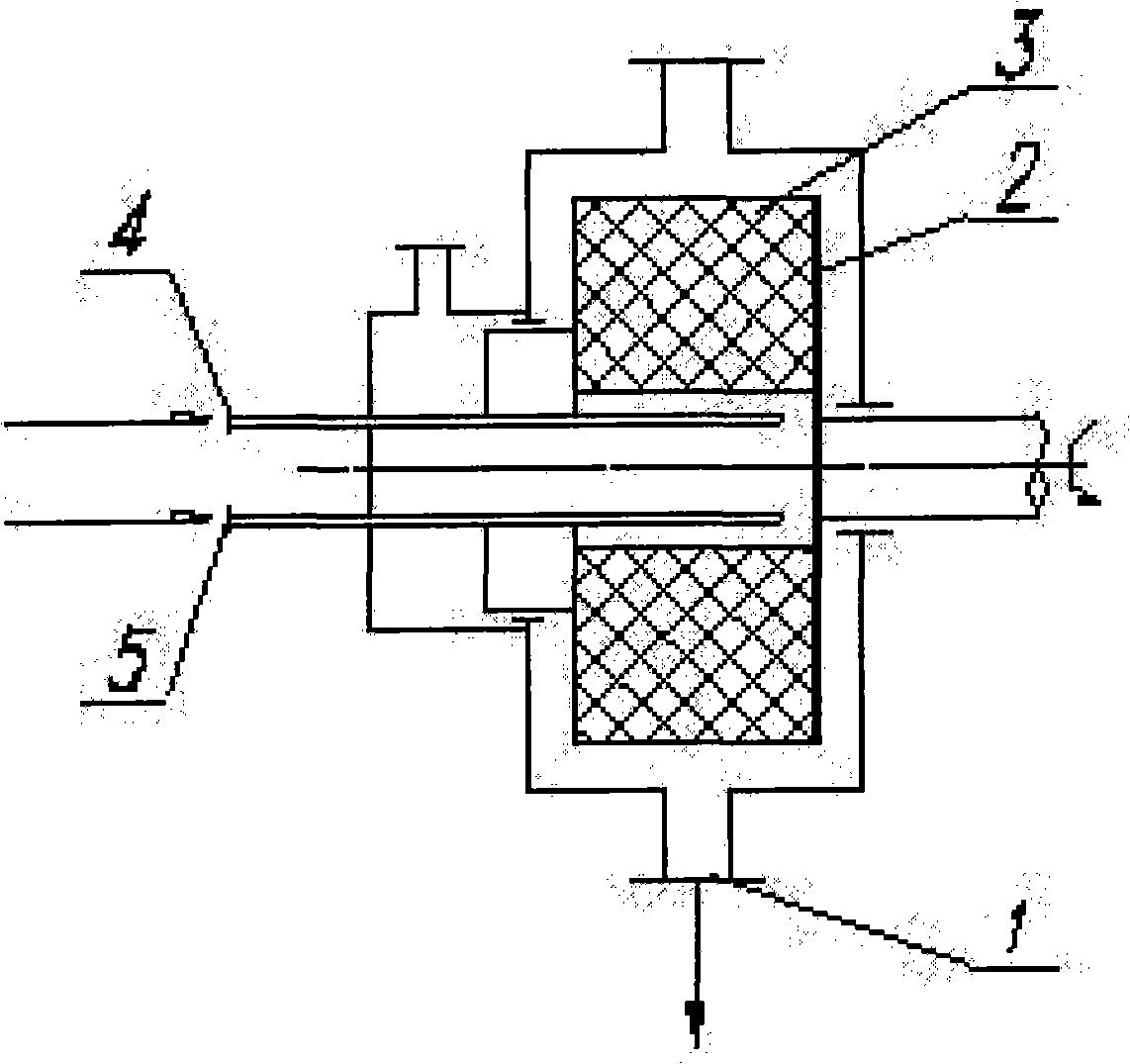

Method of preparing ultra-fine danazol powder

InactiveCN101292958AFine granularityUniform compositionPowder deliveryOrganic active ingredientsUltra fineDesolvation

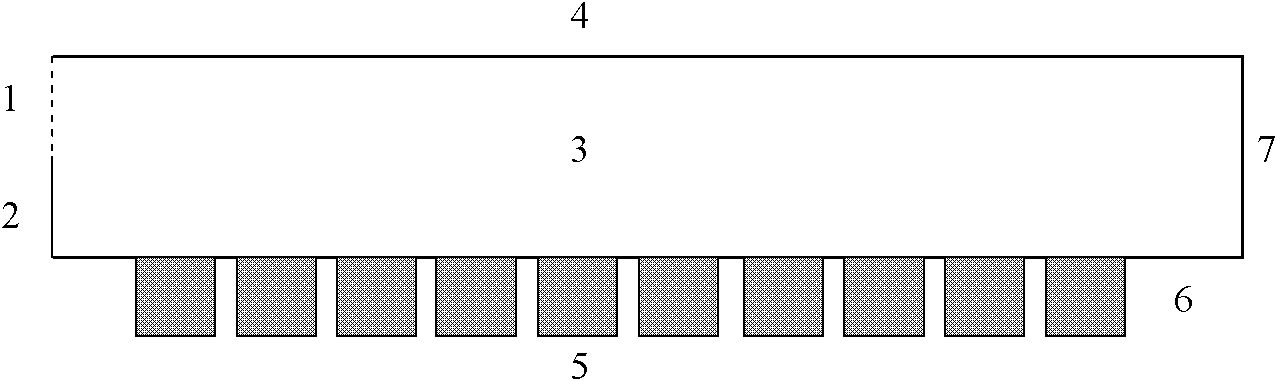

A preparation method of ultra-fine danazol powder belongs to the method of drug micronization. The method is that danazol solution and desolvation are first put into a supergravity rotating bed through a solution entrance 4 and a desolvation entrance 5 respectively at the same time, and the recrystallized danazol paste by the desolvation flows out from a discharge hole 1; the danazol paste is collected, filtered and dried to obtain the ultra-fine danazol powder. The method can obtain the ultra-fine danazol powder of controlled average grain size, controlled shape and narrow grain size distribution.

Owner:BEIJING UNIV OF CHEM TECH +1

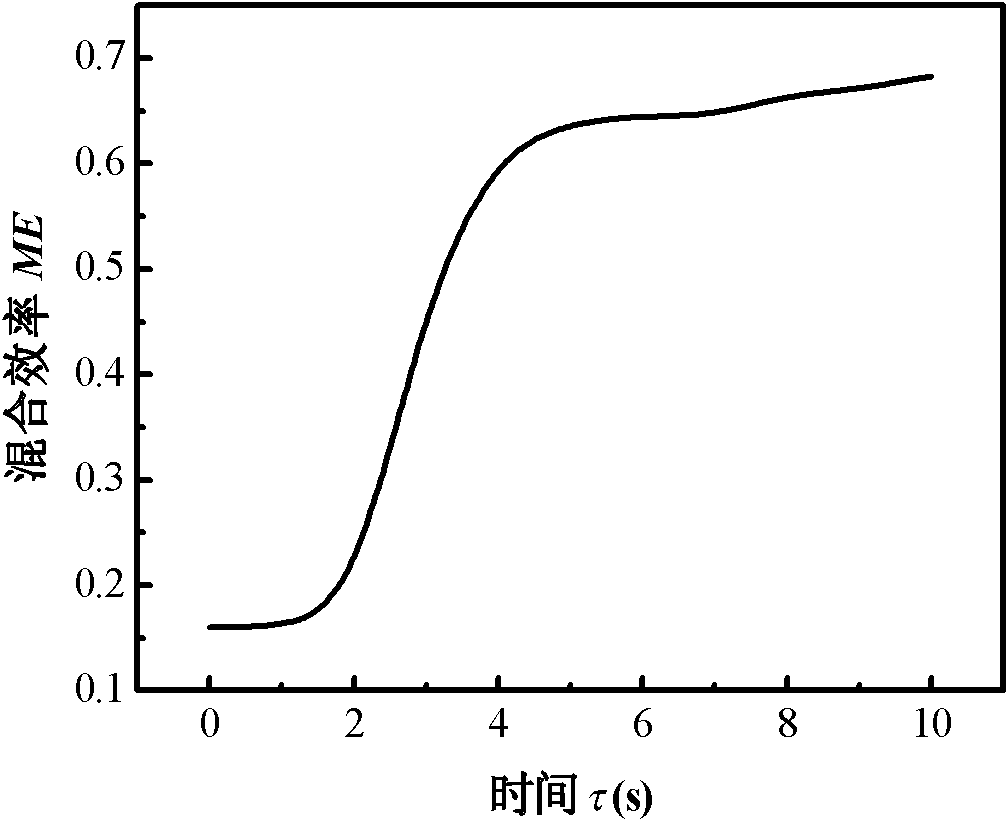

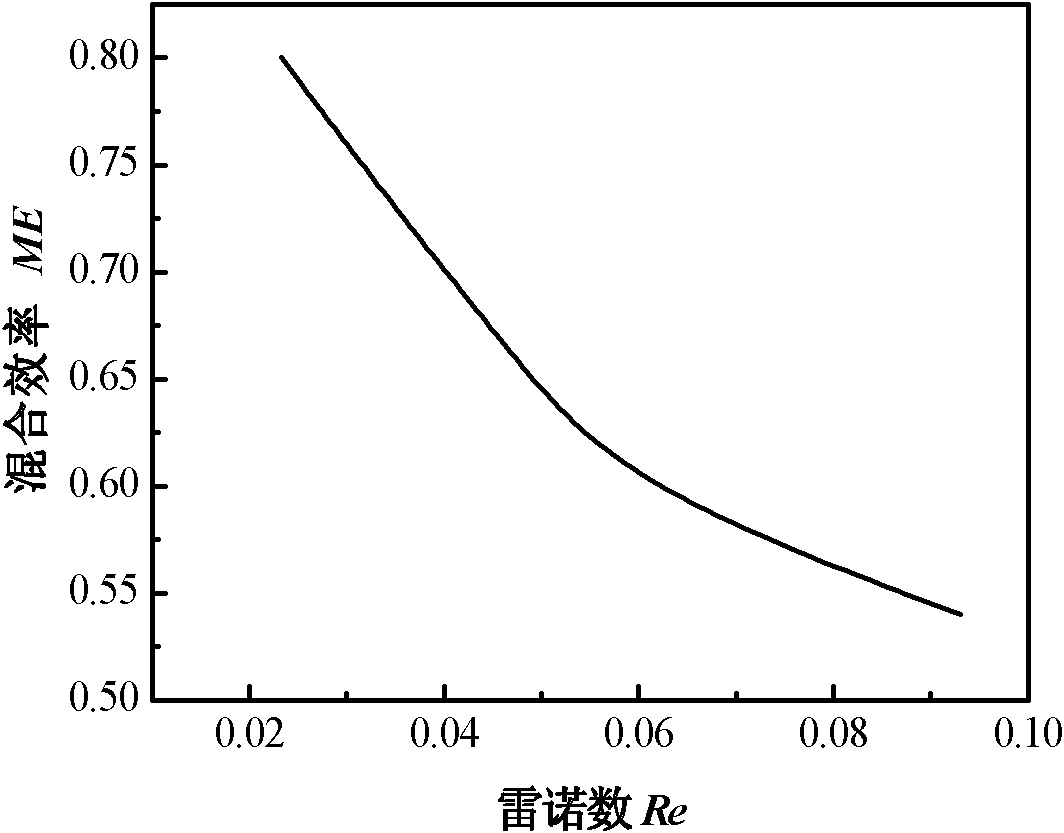

Method for strengthening micro-mixing by using low-frequency intermittent magnetic fields in microchannel

The invention discloses a method for strengthening micro-mixing by using low-frequency intermittent magnetic fields in a microchannel. The method comprises the following steps: processing a tiny soft magnet array on a side wall surface of the microchannel; injecting two strands of fluid into the microchannel, wherein the two strands of fluid are same in initial velocity and flow, and the two strands of fluid are a superparamagnetic bead containing suspension and a biochemical sample solution; exerting an intermittent uniform magnetic field on the outside of a chip, so that a soft magnet generates a new magnetic field under the excitation of the external uniform magnetic field. Because of the mutual superposition of magnetic fields generated by the magnets in the soft magnet array and the superposition of external magnetic fields, a magnetic force exerted on magnetic beads in the microchannel presents a positive-negative alternate space change along the axis direction of the microchannel, the magnetic force presenting a positive-negative alternate space change is sporadic with the external intermittent magnetic field so as to induce the magnetic beads in the microchannel to carry out a transverse motion and an axial motion which occur alternately, and the motions of the magnetic beads disturb the laminar flow in the microchannel, thereby achieving the purpose of strengthening micro-mixing.

Owner:SHANGHAI JIAO TONG UNIV

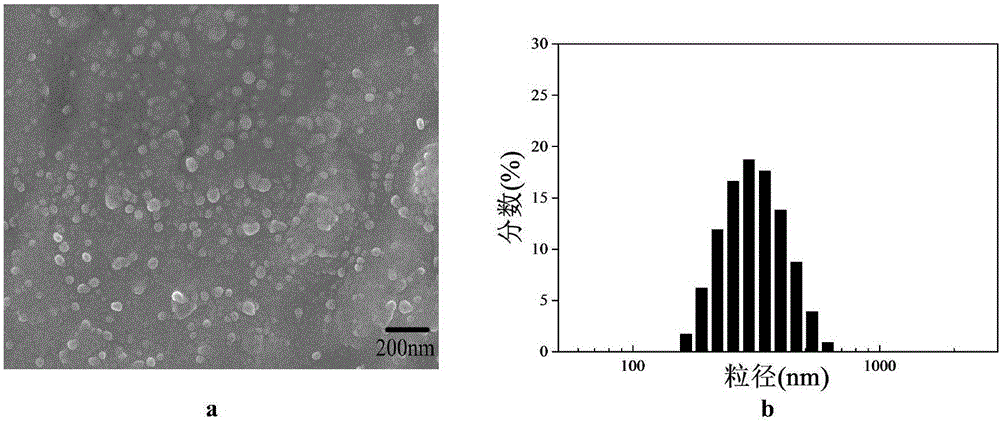

Supergravity preparation method of cysteine modified magnetic nano-material

ActiveCN105469920ASmall particle sizeEvenly distributedInorganic material magnetismFerroso-ferric oxidesVacuum dryingPrecipitation

The invention belongs to the technical field of inorganic chemical functional magnetic nano-materials, and provides a supergravity preparation method of a cysteine modified magnetic nano-material. The supergravity preparation method comprises the following steps: continuously feeding a metal salt solution and an alkali liquor into a supergravity reactor to carry out a co-precipitation reaction; after the reaction is finished, collecting the reaction product of magnetic nano-particles into a stirring kettle; dropwise adding a cysteine water solution; stirring for a reaction, and then magnetically separating the reaction product; repeatedly washing with deionized water and absolute ethyl alcohol until to neutral; and carrying out vacuum drying to obtain the cysteine modified magnetic nano-material. The material has the characteristics of simple technology, short reaction time, low cost and large-scale production; the prepared cysteine modified magnetic nano-material is small in grain diameter and uniform in dispersion, and is easy for industrial enlarged production; and compared with a conventional method, the efficiency can be improved by 4-20 times, and the application field of magnetic separation technology in water treatment is expanded. The synthetic material can be expected to be widely applied to the fields of sewage treatment, heavy metal detection, magnetic catalysis, magnetic recording, biomedicine and the like.

Owner:ZHONGBEI UNIV

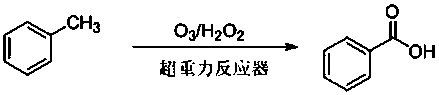

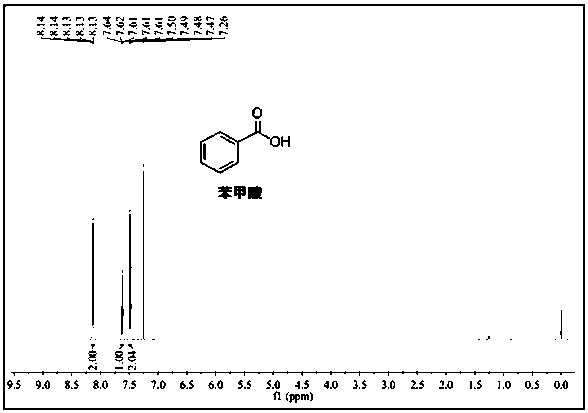

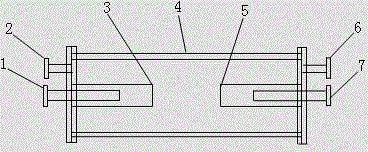

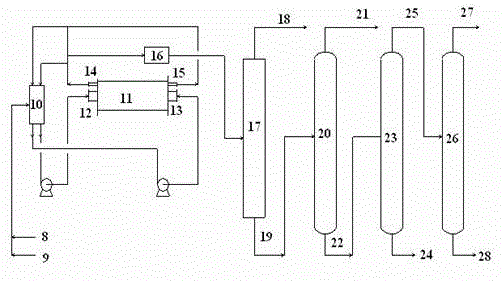

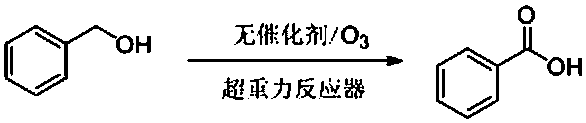

Device and method for preparing benzoic acid from toluene

ActiveCN109970544AAtom economy is highEnhanced MicromixingOrganic compound preparationCarboxylic compound preparationBenzoic acidEnvironmental resistance

The invention relates to a device and method for preparing benzoic acid from toluene, and belongs to the technical field of fine organic synthesis. In view of the problems in a current preparation method of benzoic acid, the invention provides the method. According to the method provided by the invention, a super-gravity rotating packed bed is utilized, a fluid is greatly sheared and crushed by utilizing a high-speed rotating filler to generate a huge quickly-updated phase interface, so that the micromixing and mass transfer process are greatly strengthened; ozone is selected as an oxidant, hydrogen peroxide is selected as a catalyst, so that the method has the advantages of greenness, high efficiency and no secondary pollution; low-toxicity low-boiling-point reagents such as dichloromethane and ethyl acetate are selected as a solvent, so that recovery is facilitated; and the method has the advantages of greenness, environmental protection and high atomic economy, thereby having broadindustrial application prospects.

Owner:ZHONGBEI UNIV

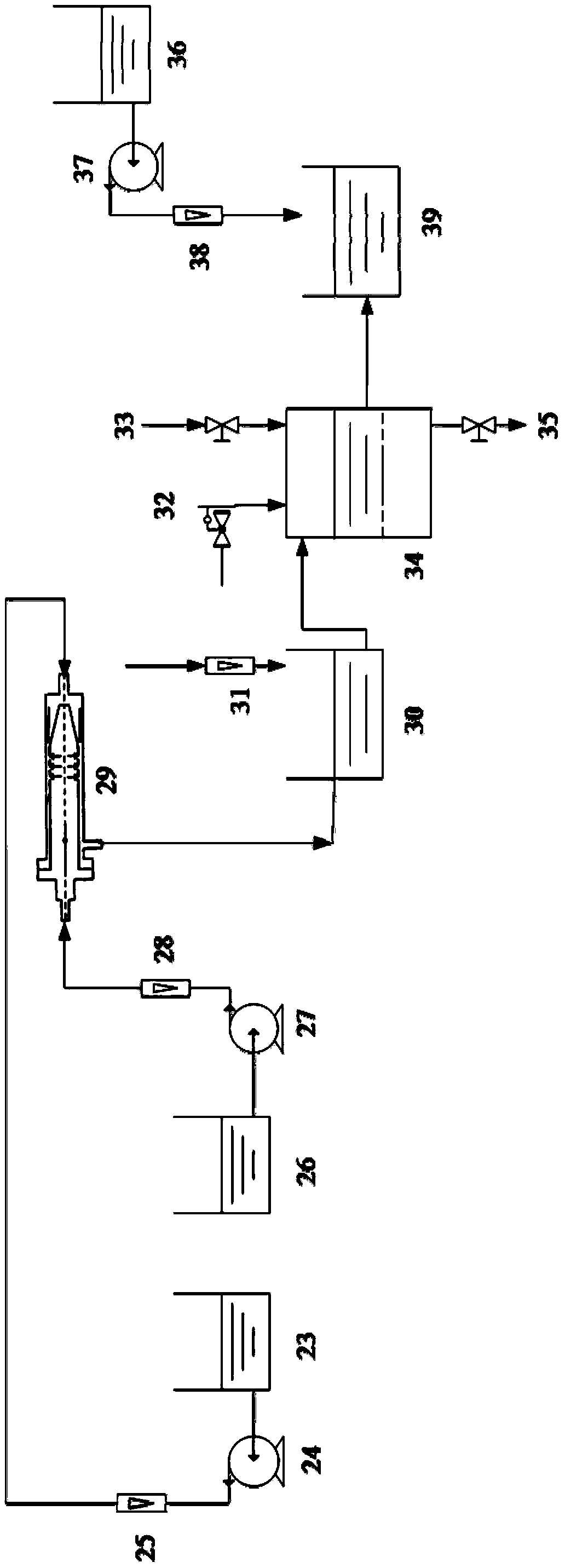

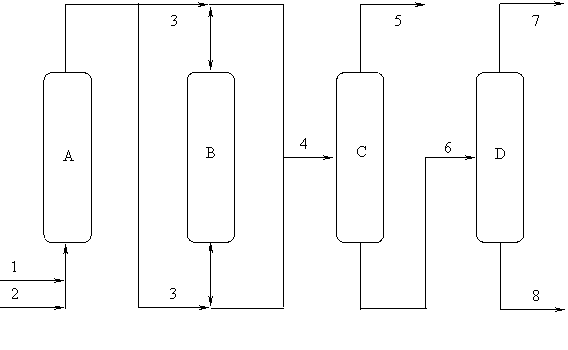

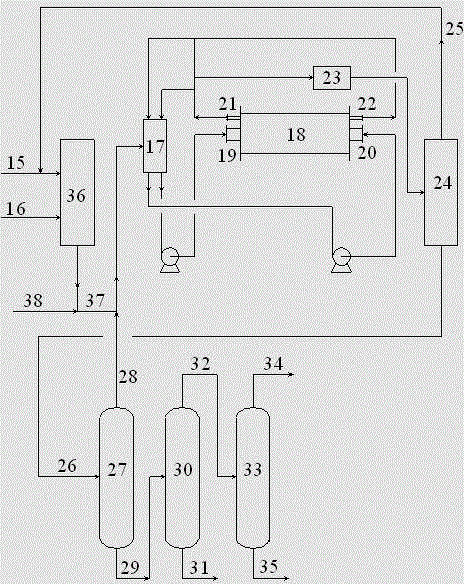

Method for producing furfuraldehyde from pentose solution by adopting impinging stream reactor

The invention provides a method for producing furfuraldehyde from pentose solution by adopting an impinging stream reactor. The method for producing furfuraldehyde from pentose solution by adopting the impinging stream reactor comprises the following steps: introducing pentose solution and an extraction agent into an impinging stream reactor, reacting under the condition that furfuraldehyde is generated by virtue of pentose, cooling reaction effluent, and layering, wherein an aqueous phase is formed at an upper layer, an extraction phase is formed at a lower layer, the aqueous phase can be recycled as water for hydrolysis of hemicellulose, the extraction phase enters an extraction agent regenerating tower to be further separated, phase splitting is carried out on products at tower top to obtain recycled extraction agent and a small amount of recycled water, the extraction agent can be recycled, products at the bottom of the regenerating tower enter a furfuraldehyde finished product tower to be further separated, acetic acid and formic acid are obtained at the top of the furfuraldehyde finished product tower, and furfuraldehyde is obtained at the bottom of the furfuraldehyde finished product tower; and acetic acid and formic acid enter an acetic acid refining tower to be further separated, formic acid is obtained at the top of the acetic acid refining tower, and acetic acid is obtained at the bottom of the acetic acid refining tower. The method for producing furfuraldehyde from pentose solution by adopting the impinging stream reactor has the advantages that the impinging stream reactor is adopted for producing furfuraldehyde, mass transfer rate is high, side reaction is hardly carried out, and yield of furfuraldehyde is increased; meanwhile, furfuraldehyde, acetic acid and formic acid are recycled, and no waste liquid is discharged, so that the method for producing furfuraldehyde from pentose solution by adopting the impinging stream reactor is an environment-friendly technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

5-hydroxymethylfurfural production technology

InactiveCN106146436AEnhanced mass transferHigh proportion of flow channel volumeCarboxylic compound separation/purificationChemistryFormic acid

The invention discloses a novel technology for producing 5-hydroxymethylfurfural and simultaneously recovering formic acid and acetic acid. The technology utilizes an impinging stream reactor especially suitable for the technology. Through multiple impinging processes, fluid mixing is realized and good microscopic mixing effects are obtained. The mixed liquid is horizontally pushed to flow outside an impinging zone so that enough staying time is supplied for materials, a stepwise reaction is realized and a desired conversion rate is realized through channel and liquid flow rate designs. The technology solves the problem that the existing impinging stream reactor cannot realize a high conversion rate through a single reactor, simplifies processes, reduces a production cost and an equipment investment and guarantees long-term equipment operation. The technology does not discharge a waste liquid in production and is a green environmental protection technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

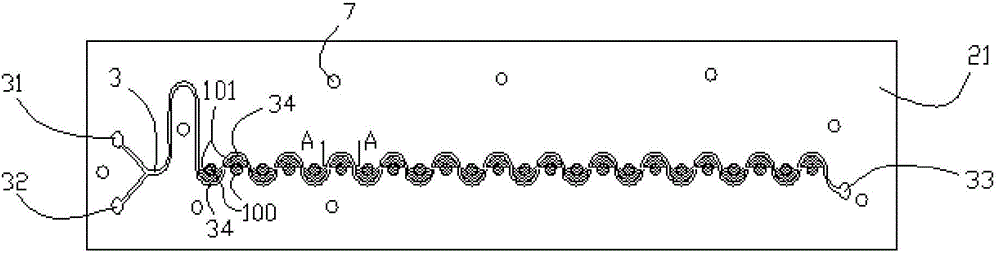

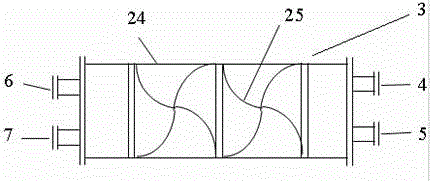

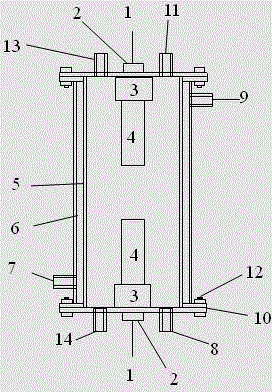

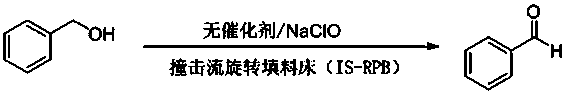

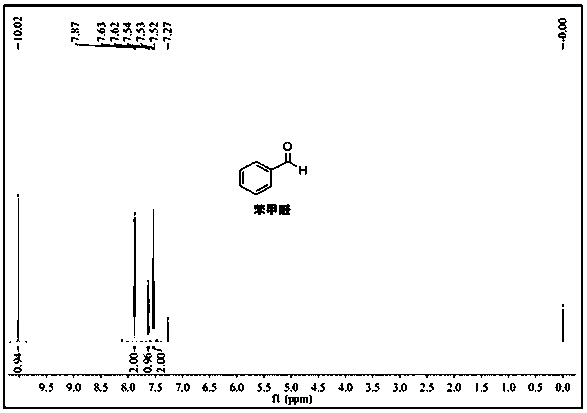

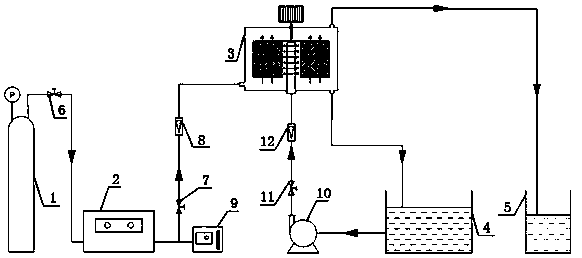

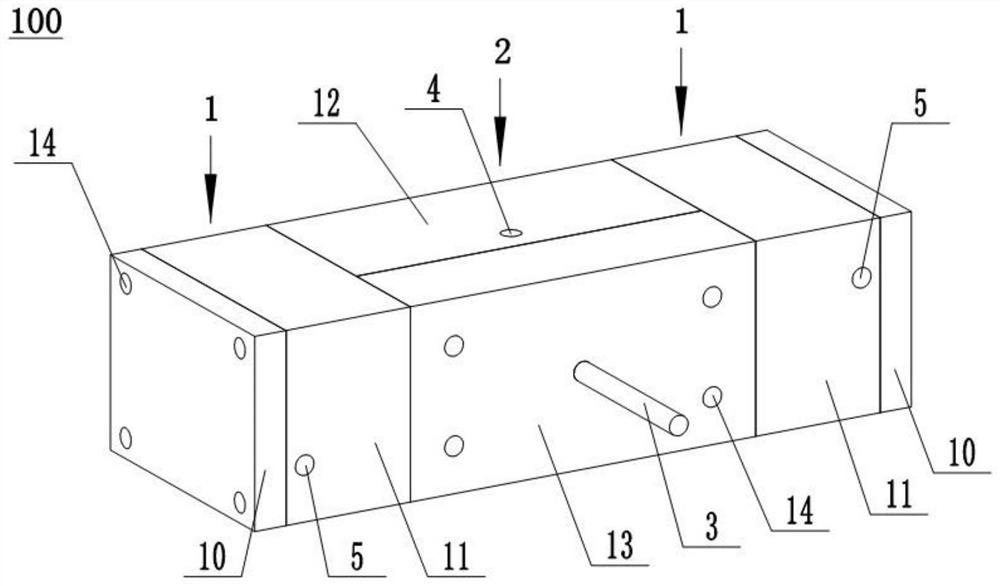

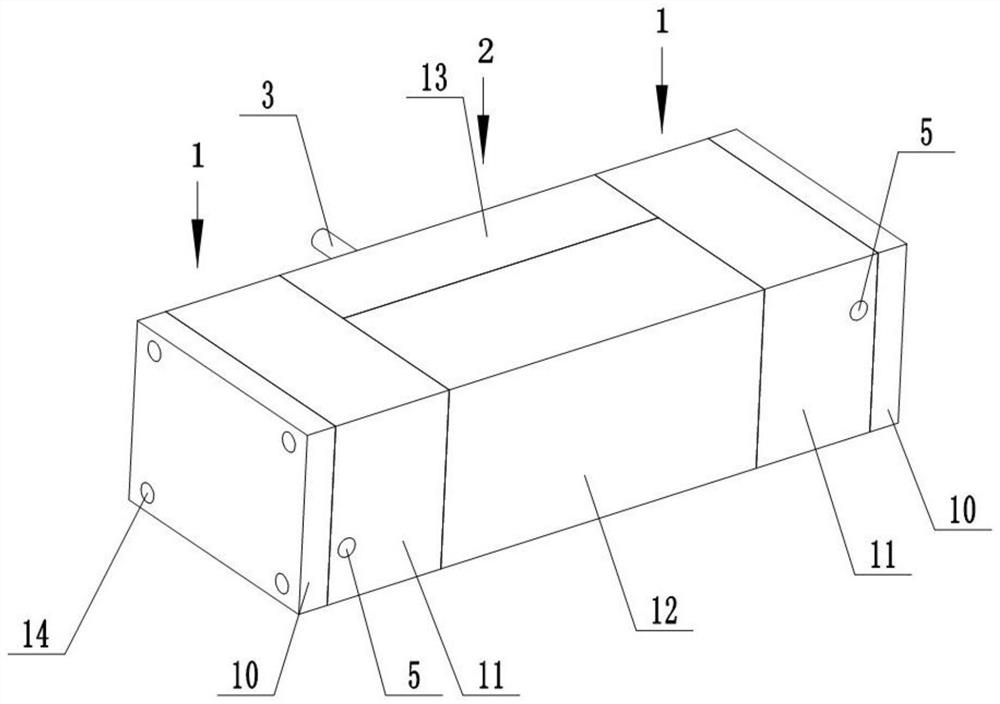

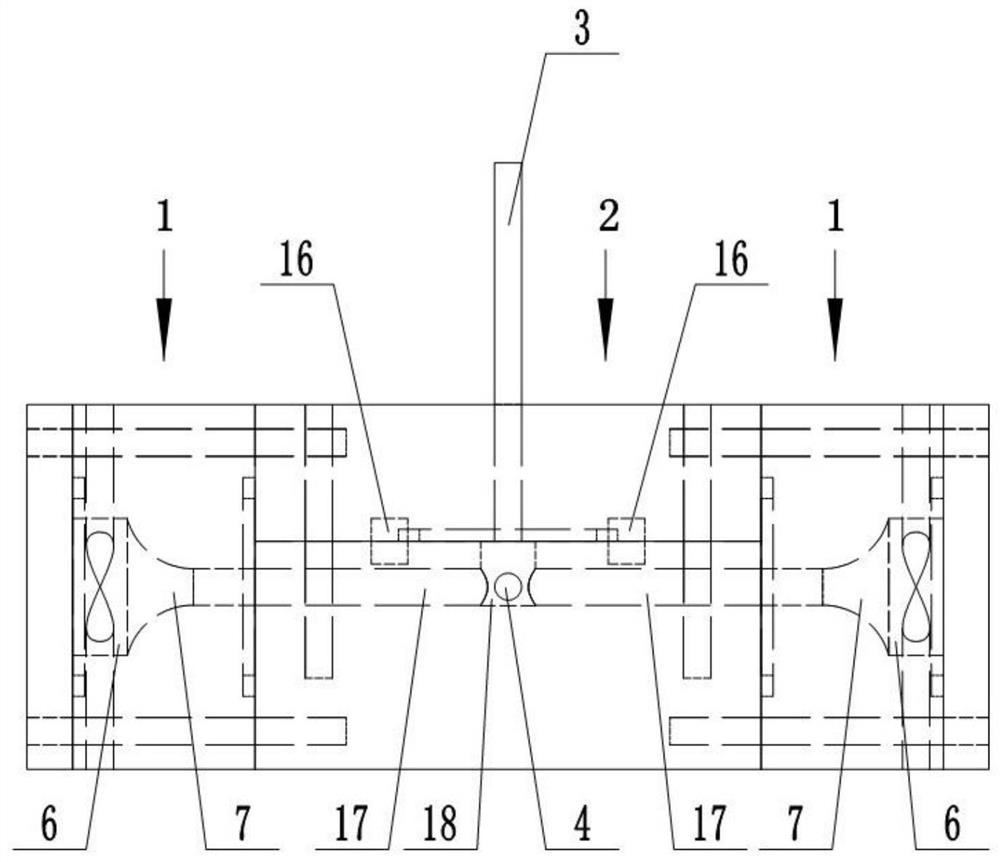

Device and method for preparing benzaldehyde by using impinging stream rotating packed bed

ActiveCN110026146AHigh yieldEnhanced MicromixingProcess control/regulationOrganic compound preparationReaction rateBenzaldehyde

The invention discloses a device and method for preparing benzaldehyde by using an impinging stream rotating packed bed, belongs to the technical field of fine chemical engineering, and can solve theproblems that in existing synthesis of benzaldehyde compounds, reaction conditions are harsh, synthetic steps, the yield is low, the energy consumption cost is higher, and the quality of benzaldehydeproducts is not high. The device comprises the impinging stream rotating packed bed, a liquid storage tank I, a liquid storage tank II provided with a stirring rod, and a liquid storage tank III. Theimpinging stream rotating packed bed is used for violently shearing and crushing fluid to generate a huge and quickly updated phase interface, so that the microscopic mixing and mass transfer processis greatly enhanced, the reaction rate is increased, and the method has the advantages of simplicity in operation, high yield, mild reaction conditions, easiness for industrialization and the like.

Owner:ZHONGBEI UNIV

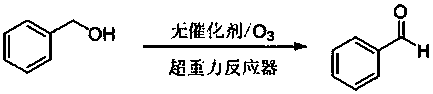

Supergravity reaction device and application thereof

ActiveCN110026145AAtom economy is highEnhanced MicromixingPreparation by ozonolysisCarboxylic preparation by ozone oxidationBenzoic acidOrganic synthesis

The invention discloses a supergravity reaction device and application thereof, belongs to the technical field of fine organic synthesis, and solves the problems existing in existing preparation processes of benzaldehyde and benzoic acid. According to the invention, fluid is greatly sheared and crushed through a supergravity rotating packed bed and a high-speed rotating packing, a huge and rapidlyupdating phase interface is generated, and the microcosmic mixing and mass transfer process is greatly enhanced. Ozone is selected as an oxidizing agent, and the device has the advantages of greenness, high efficiency, no secondary pollution and the like. Low-toxicity low-boiling-point reagents such as dichloromethane and ethyl acetate are selected as solvents, and recycling is facilitated. The method has the advantages of being environmentally friendly, high in atom economy and the like, and has wide industrial application prospects.

Owner:ZHONGBEI UNIV

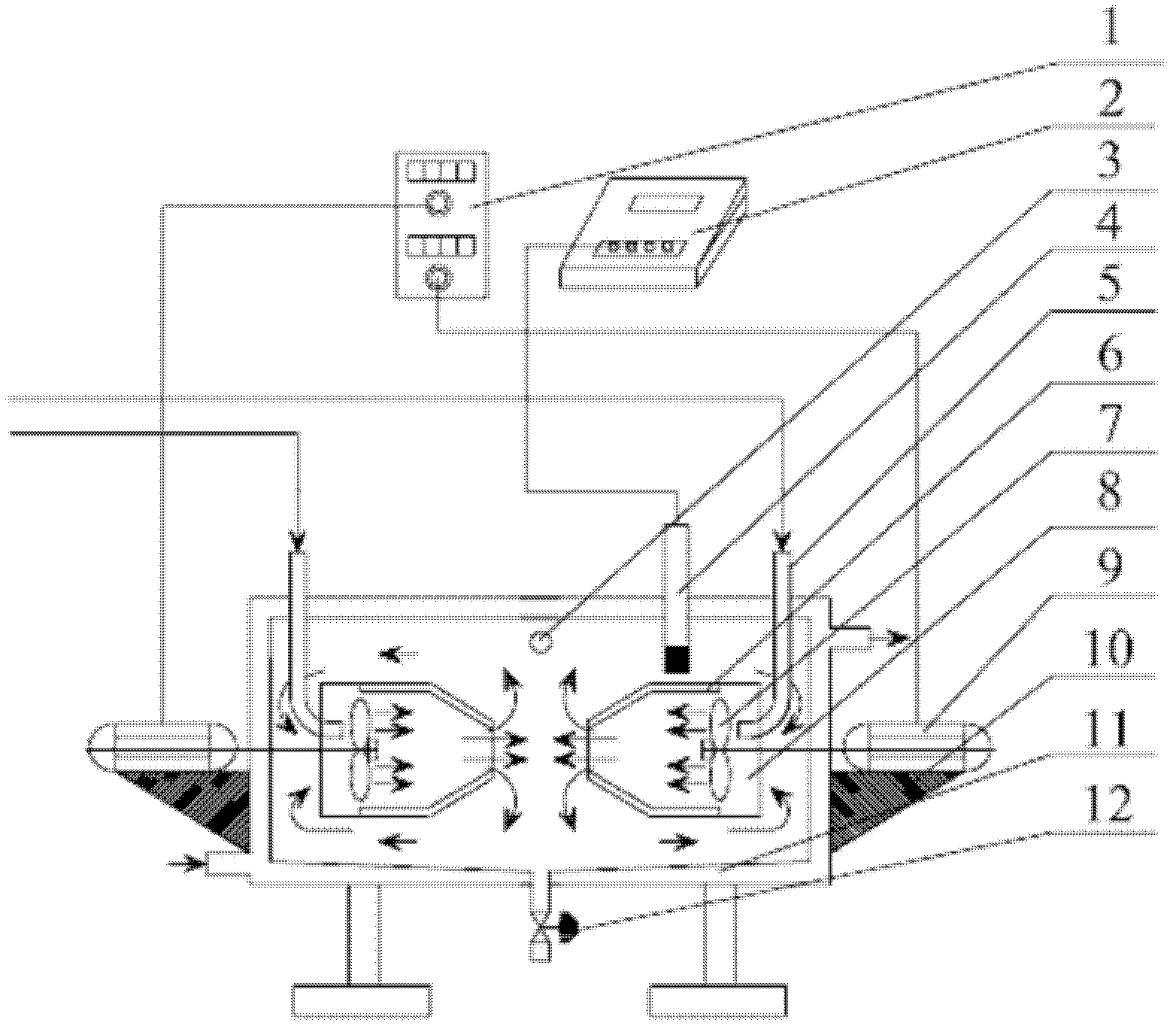

Ultrasonic enhanced reverse vortex flow and impinging stream reactor

PendingCN113413846AEnhanced mixing mass transfer performanceShorten the timeSequential/parallel process reactionsChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

The invention discloses an ultrasonic enhanced reverse vortex flow and impinging stream reactor, and relates to the technical field of chemical reaction equipment, wherein the ultrasonic enhanced reverse vortex flow and impinging stream reactor comprises at least two vortex reactors, an impinging structure and an ultrasonic amplitude-change pole; each vortex reactor is communicated with the impinging structure, and the ultrasonic amplitude-change pole extends into the impinging structure; the impinging structure is provided with a discharge port; and each vortex reactor comprises at least one feed port, the feed ports are arranged along the tangential direction of the vortex reactors, and a reaction raw material fluid enters the vortex reactors at the two sides through the double feed ports arranged at the two sides of the reactor to generate reverse axial flow vortex flow and then flows into a central impact cavity in an accelerated manner along the axial direction. The reaction raw material fluid generates broad-spectrum multi-scale turbulent vortexes in the vortex reactors, reinforced micro-scale turbulent entrainment mixing is achieved in the impact cavity through reverse vortex axial flow, a mixture is formed and a chemical reaction is carried out, and the mass transfer performance is further improved by reinforcing local turbulent shearing through the ultrasonic amplitude-change pole, and the mixed mass transfer performance of the reactor is reinforced.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

Method used for preparing transparent zinc oxide liquid phase dispersion

ActiveCN109181367AEnhanced mass transferEnhanced MicromixingMaterial nanotechnologyZinc oxides/hydroxidesHypergravityCentrifugation

The invention discloses a method used for preparing a transparent zinc oxide liquid phase dispersion. The method comprises following steps: 1, a salt is dissolved in a liquid phase medium A so as to obtain a salt solution, an alkali is dissolved in a liquid phase medium B so as to obtain an alkali solution, an adopted salt is a zinc salt or a mixed zinc salt, wherein the mixed zinc salt is prepared through mixing of a zinc salt and a doping element at a molar ratio of 10-100:1; 2, the salt solution and the alkali solution are introduced into a hypergravity rotation packed bed reactor, reactionis carried out a certain temperature so as to obtain a zinc oxide suspending liquid; 3, a surface coating agent is added into the zinc oxide suspending liquid for a certain time of modifying coatingat a certain temperature; and 4, an obtained modifying solution is allowed to stand, is subjected to precipitation, centrifugation, and washing, and is dispersed in a liquid phase medium C so as to obtain the transparent zinc oxide liquid phase dispersion. The preparation process is completed in the hypergravity rotation packed bed reactor, mass transfer and microscopic mixing are reinforced greatly; the obtained product is transparent, and excellent in dispersibility and stability; and no precipitation is caused after longer than 12 months of standing.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing ethylene carbonate by using CO gas phase method

InactiveCN102649758AHigh selectivityMild reaction conditionsOrganic compound preparationCarbonic/haloformic acid esters preparationMethyl carbonateGas phase

The invention relates to a method for preparing ethylene carbonate by using a CO gas phase method and mainly solves the technical problems of low nitric oxide or ethylene carbonate utilization rate and low selectivity existing in the prior art. With the adoption of the technical scheme that the method for preparing the ethylene carbonate by using the CO gas phase method comprises the following steps that: a), the ethylene carbonate, water, methanol and sulfuric acid or nitric acid firstly enter a reactor I, and an effluent II containing methyl nitrite is obtained after a generated effluent is separated; and b), the effluent II and CO gas enter a coupling reactor, a generated NO-contained effluent IV is reacted with the methanol and oxygen in a reactor II, and an effluent VI containing the methyl nitrite obtained after the generated effluent is separated flows back and is continuously reacted with the effluent II and the CO gas in the coupling reactor, wherein the reactor I and the reactor II are rotary super-gravity reactors, so the problems are better solved. The method can be used in the industrial production for preparing the ethylene carbonate by using the CO gas phase method.

Owner:CHINA PETROLEUM & CHEM CORP +1

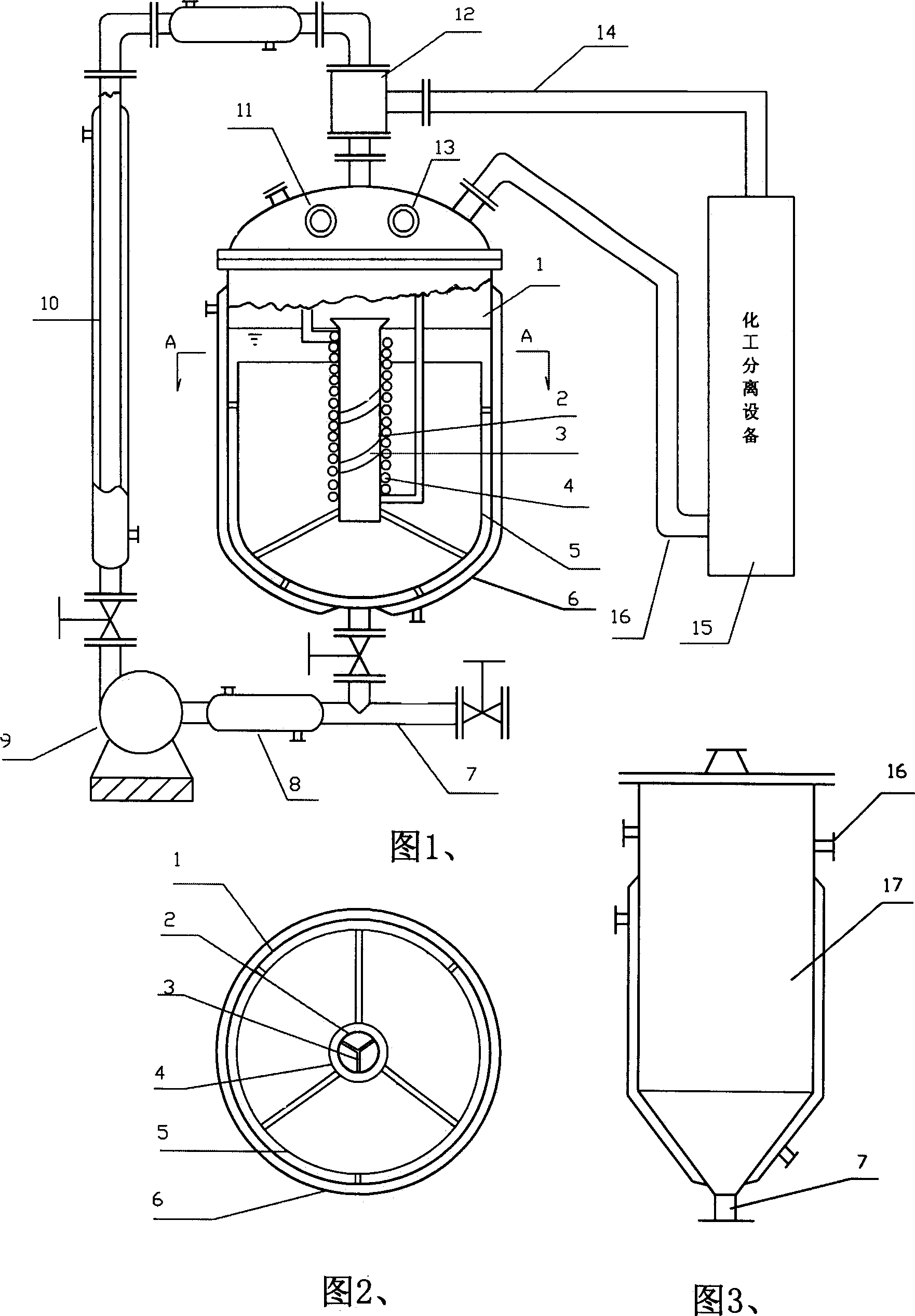

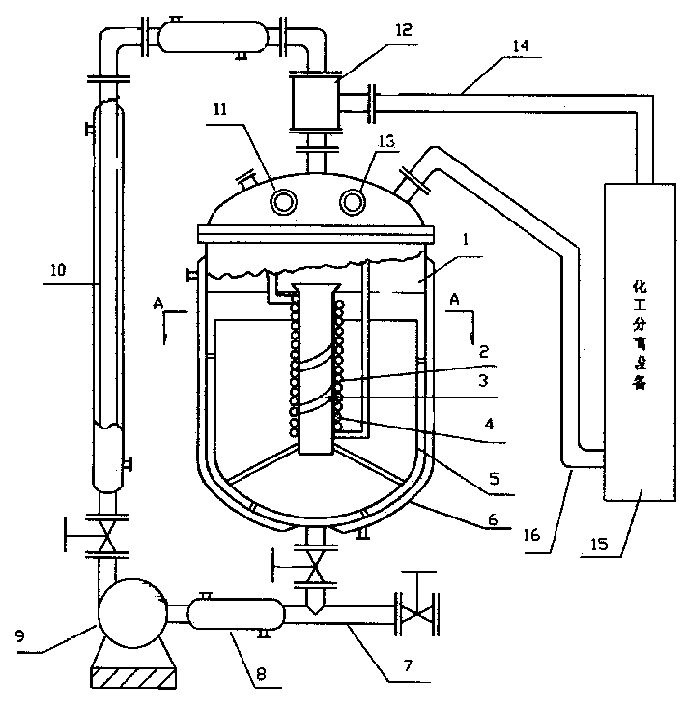

Coupling equipment of reaction and separation

InactiveCN1380135AImprove conversion rateIncrease reaction rateChemical/physical/physico-chemical processesInjectorProcess engineering

The reaction-separation coupling equipment incldues reactor, circulating pump and sprayer which are connected with the reactor and liquid phase circulating pipeline as chemical reaction circulation and gas phase circulating pipeline for separation circulation which is connected with chemical separation equipment and reactor. Its operation process includes the following steps: the raw material heated in the reactor is pumped out by circulating pump, passed through the liquid phase circulating pipeline and sprayer, and high-speed sprayed into the interior of reactor so as to form liquid phase circulation, at the same time the gas in the reactor is passed through the gas phase circulating pipeline and chemical separation equipment and sprayed into the reactor so as to from gas phase circulation.

Owner:WUHAN CHEM COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com