Supergravity preparation method of cysteine modified magnetic nano-material

A cysteine, magnetic nanotechnology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of lack of low-cost macro-engineering amplification, and achieve low preparation cost, small particle size, and preparation method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

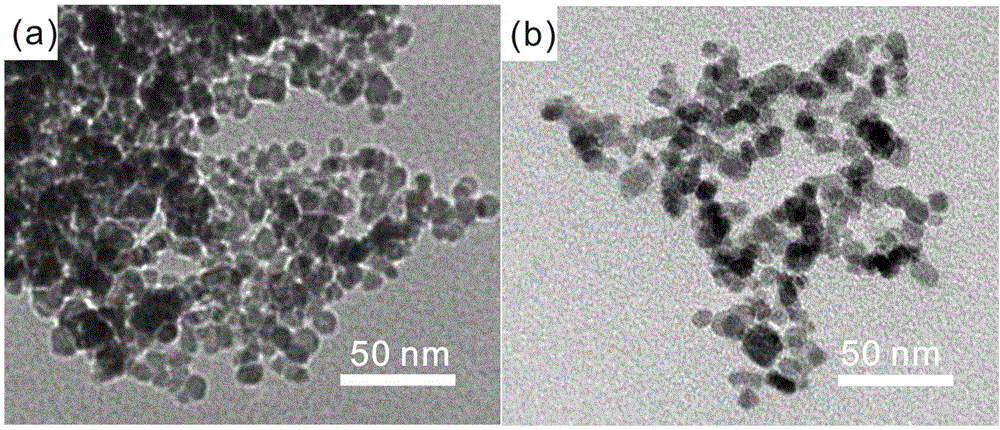

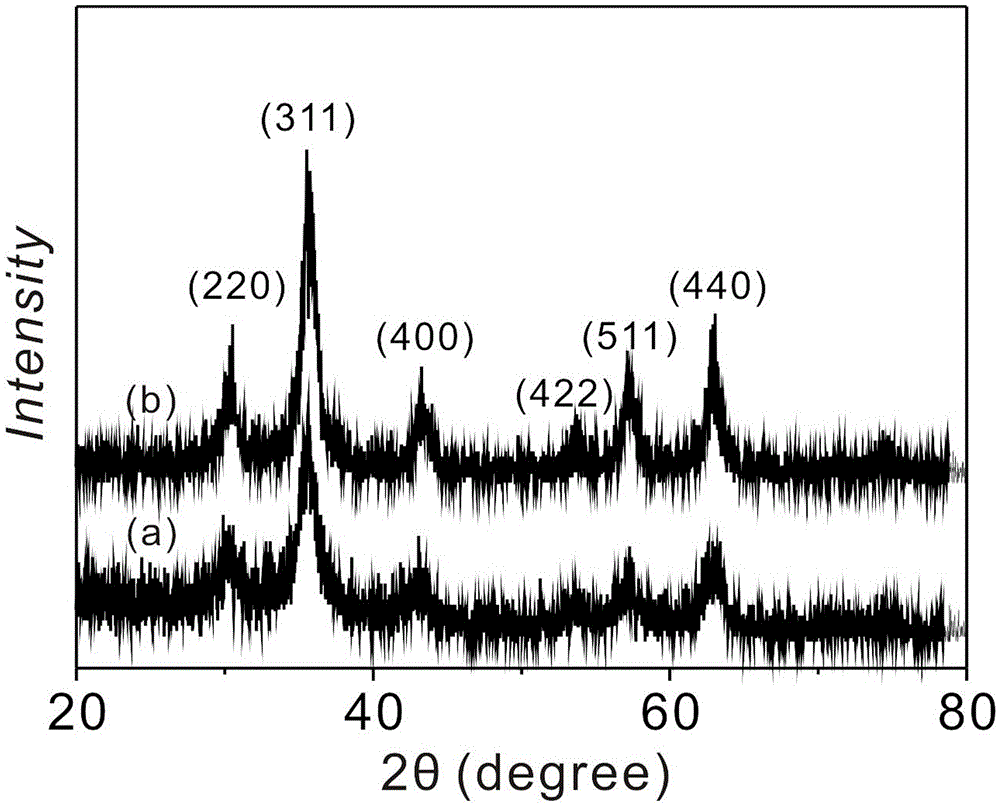

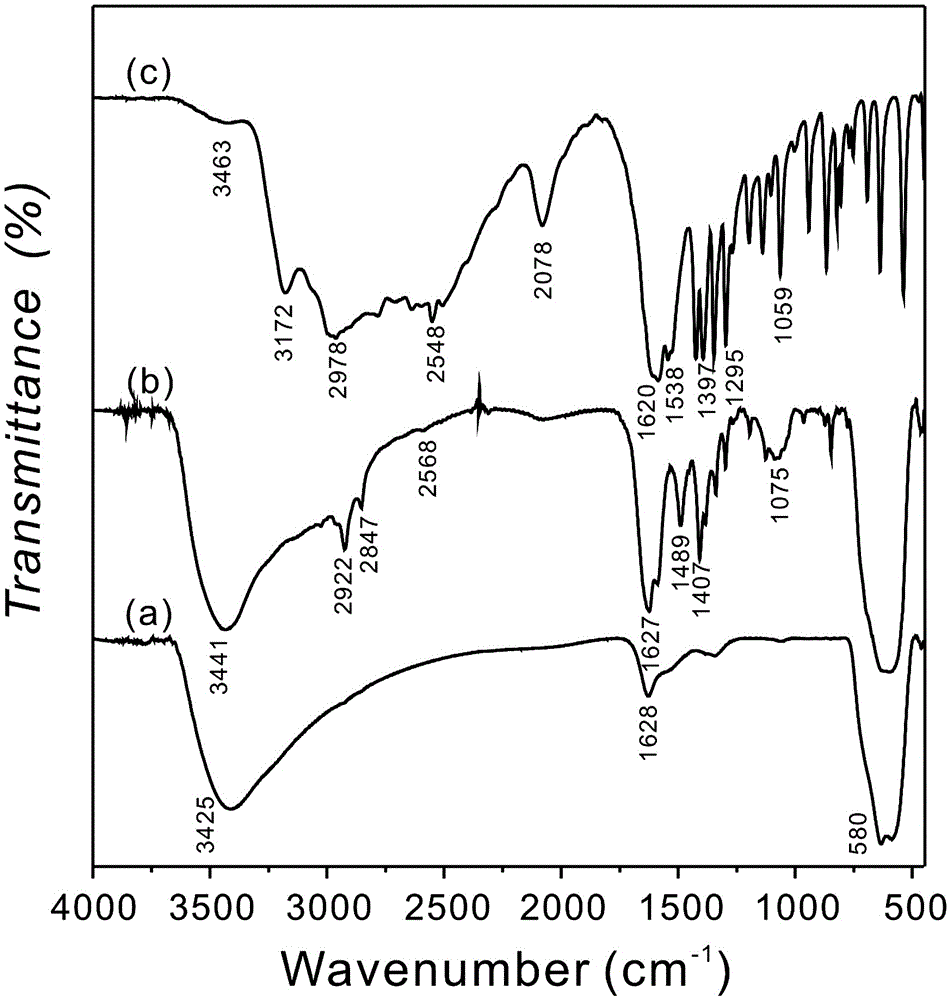

[0021] A hypergravity preparation method for cysteine-modified magnetic nanomaterials, comprising the steps of:

[0022] (1) FeCl 2 4H 2 O and FeCl 3 ·6H 2 O, according to the molar ratio of 1:1.9, the iron salt solution with a cation concentration of 0.5mol / L was prepared; in addition, according to Fe 3+ and OH - The molar ratio is 1:6 to prepare sodium hydroxide aqueous solution; preheat the above-mentioned iron salt mixed solution and lye to 80°C, adjust the volume flow rate of the two raw material liquids to 60L / h through the flowmeter, and pump the The two raw material liquids enter the impinging flow-rotating packed bed from the liquid distributor at the same time, and react in the supergravity field to obtain Fe 3 o 4 Magnetic nanoparticles, control the rotation speed of the hypergravity reactor to be 1000rpm. (2) the Fe prepared by the above (1) 3 o 4 The suspension of magnetic nanoparticles is collected in a stirred tank, the pH value of the solution is adjus...

Embodiment 2

[0025] A hypergravity preparation method for cysteine-modified magnetic nanomaterials, comprising the steps of:

[0026] (1) Mn(NO 3 ) 2 , Fe 2 (SO 4 ) 3 According to the molar ratio of 1:1.5, a metal salt solution with a cation concentration of 0.05mol / L is prepared; in addition, according to Fe 3+ and OH - The molar ratio is 1:8 to prepare ammonia solution; preheat the above metal salt mixed solution and lye to 25°C, adjust the volume flow rate of the two raw material liquids to 20L / h through the flowmeter, and pump the two kinds of raw materials respectively The raw material liquid enters the rotating packed bed from the liquid distributor at the same time, and reacts in the supergravity field to obtain MnFe 2 o 4 Magnetic nanoparticles, control the rotation speed of the hypergravity reactor to be 100rpm. (2) the MnFe prepared by the above (1) 2 o 4 The suspension of magnetic nanoparticles is collected in a stirred tank, the pH value of the solution is adjusted to...

Embodiment 3

[0028] A hypergravity preparation method for cysteine-modified magnetic nanomaterials, comprising the steps of:

[0029] (1) Ni(PO 4 ) 2 , Fe(NO 3 ) 3 According to the molar ratio of 1:2, a metal salt solution with a cation concentration of 0.75mol / L is prepared; in addition, according to Fe 3+ and OH - The molar ratio is 1:4 to prepare sodium hydroxide aqueous solution; preheat the above metal salt mixed solution and lye to 40°C, adjust the volume flow rate of the two raw material solutions to 80L / h through the flow meter, and pump the The two raw material liquids enter the spiral channel type rotating bed from the liquid distributor at the same time, and react in the supergravity field to obtain NiFe 2 o 4 Magnetic nanoparticles, control the rotation speed of the hypergravity reactor to be 2500rpm. (2) NiFe prepared by the above (1) 2 o 4 The suspension of magnetic nanoparticles is collected in a stirred tank, the pH value of the solution is adjusted to 4.0~5.0, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com