Preparation method of adriamycin nano-drug particles

A nano-drug, doxorubicin technology, applied in the direction of medical formula, drug combination, making the drug into a special physical or taking form of the device, etc., can solve the problem of poor stability of nano-powder, wide particle size distribution range, preparation process, etc. Complicated problems, to achieve the effect of narrow particle size distribution, improved dissolution rate, and avoiding local supersaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

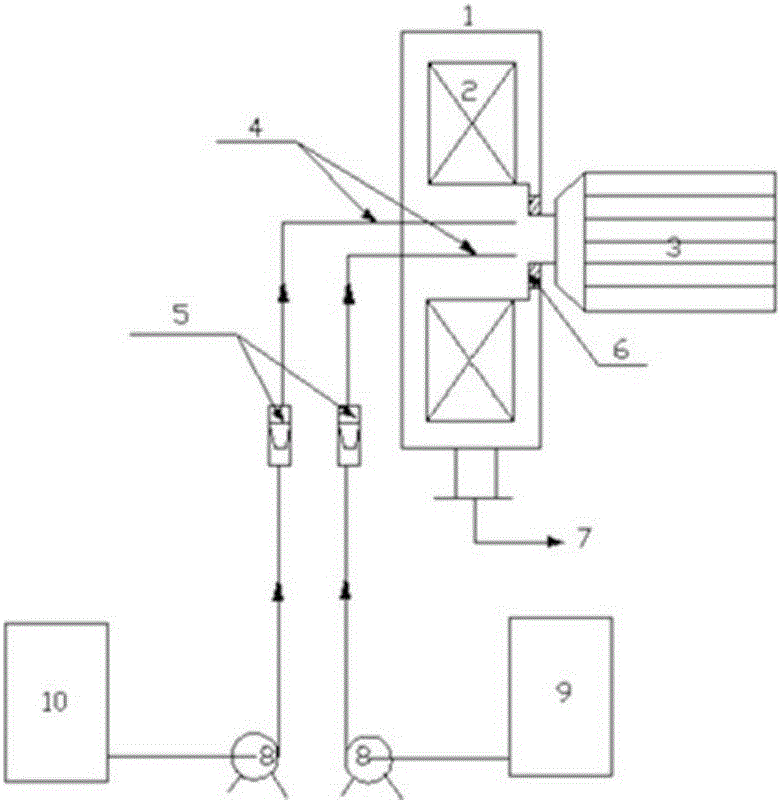

[0042] The reaction apparatus used is as figure 1 As shown, the filler layer 2 is an ordinary wire mesh.

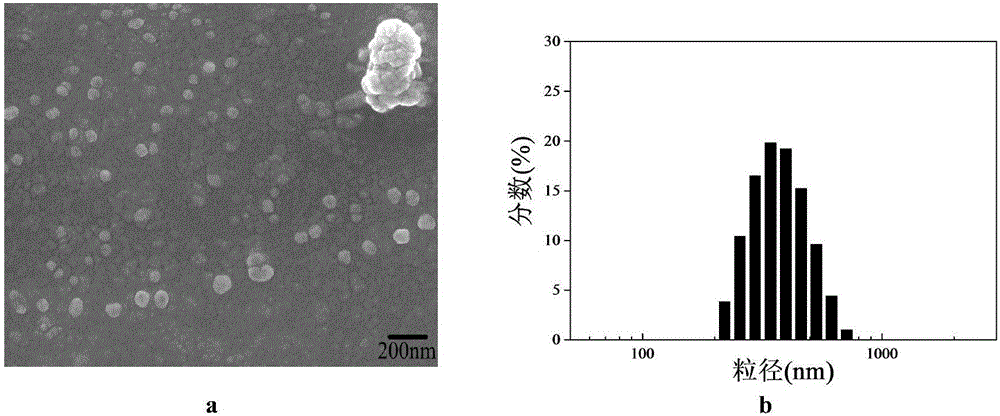

[0043] Weigh 100 mg of doxorubicin hydrochloride, dissolve it in 40 mL of dimethyl sulfoxide at room temperature, add 40 μL of triethylamine to remove hydrochloric acid, react for 5 min, and add 100 mg of Poloxamer 188, stirred to make it fully dissolved, and placed in the storage tank 9 as the solvent phase. Measure 400 mL of pure water and place it in the storage tank 10 as the anti-solvent phase. Turn on the digital display frequency regulator controlling the motor 3 to 20Hz (1150rpm). Adjust the flow meter 5, set the flow rate of the solvent phase to 30mL / min, and the flow rate of the anti-solvent phase to 300mL / min, that is, the ratio of the solvent to the anti-solvent is 1:10. Start the motor 3, and when the number displayed on the frequency regulator rises from 0 to 20Hz and displays stably for 10s, the two feed liquids are sent out by the pump 8, and sprayed on...

Embodiment 2

[0046] The reaction apparatus that adopts is identical with embodiment 1.

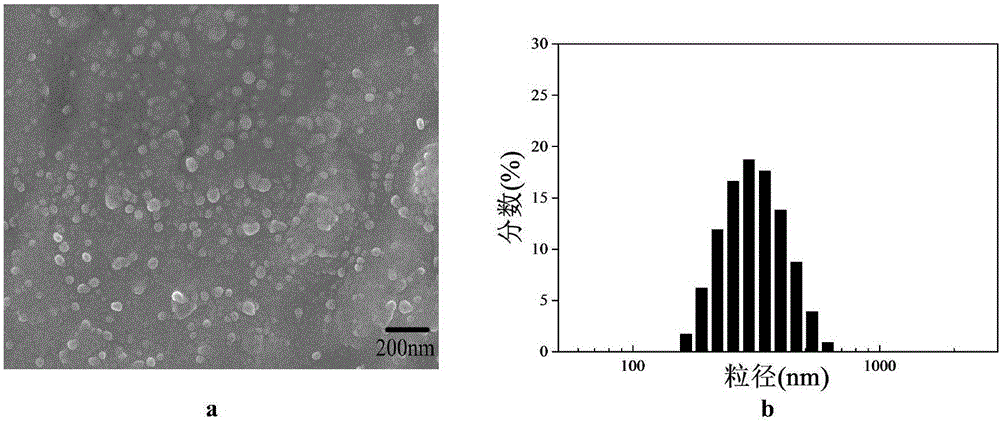

[0047] Weigh 100 mg of doxorubicin hydrochloride, dissolve it in 40 mL of dimethyl sulfoxide at room temperature, add 40 μL of triethylamine to remove hydrochloric acid, react for 5 min, and add 100 mg of Poloxamer 188 , stirred to make it fully dissolved, and placed in the storage tank 9 as the solvent phase. Measure 400 mL of pure water and place it in the storage tank 10 as the anti-solvent phase. Turn on the digital display frequency regulator controlling the motor 3 to 30Hz (1730rpm). Adjust the flow meter 5, set the flow rate of the solvent phase to 30mL / min, and the flow rate of the anti-solvent phase to 300mL / min, that is, the ratio of the solvent to the anti-solvent is 1:10. Start the motor 3, and when the number displayed on the frequency regulator rises from 0 to 30Hz and displays stably for 10s, the two feed liquids are sent out by the pump 8, and sprayed on the inner edge of the rotating...

Embodiment 3

[0050] The reaction apparatus that adopts is identical with embodiment 1.

[0051] Weigh 100 mg of doxorubicin hydrochloride, dissolve it in 40 mL of dimethyl sulfoxide at room temperature, add 40 μL of triethylamine to remove hydrochloric acid, react for 5 min, and add 100 mg of Poloxamer 188 , stirred to make it fully dissolved, and placed in the storage tank 9 as the solvent phase. Measure 400 mL of pure water and place it in the storage tank 10 as the anti-solvent phase. Turn on the digital display frequency regulator controlling the motor 3 to 40Hz (2300rpm). Adjust the flow meter 5, set the flow rate of the solvent phase to 30mL / min, and the flow rate of the anti-solvent phase to 300mL / min, that is, the ratio of the solvent to the anti-solvent is 1:10. Start the motor 3, and when the number displayed on the frequency regulator rises from 0 to 40Hz and displays stably for 10s, the two feed liquids are sent out by the pump 8, and sprayed on the inner edge of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com