Patents

Literature

68results about How to "Particle size and" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-sized particles, processes of making, compositions and uses thereof

InactiveUS20070140951A1Economical and efficientQuality improvementMaterial nanotechnologyToilet preparationsSolventPharmaceutical formulation

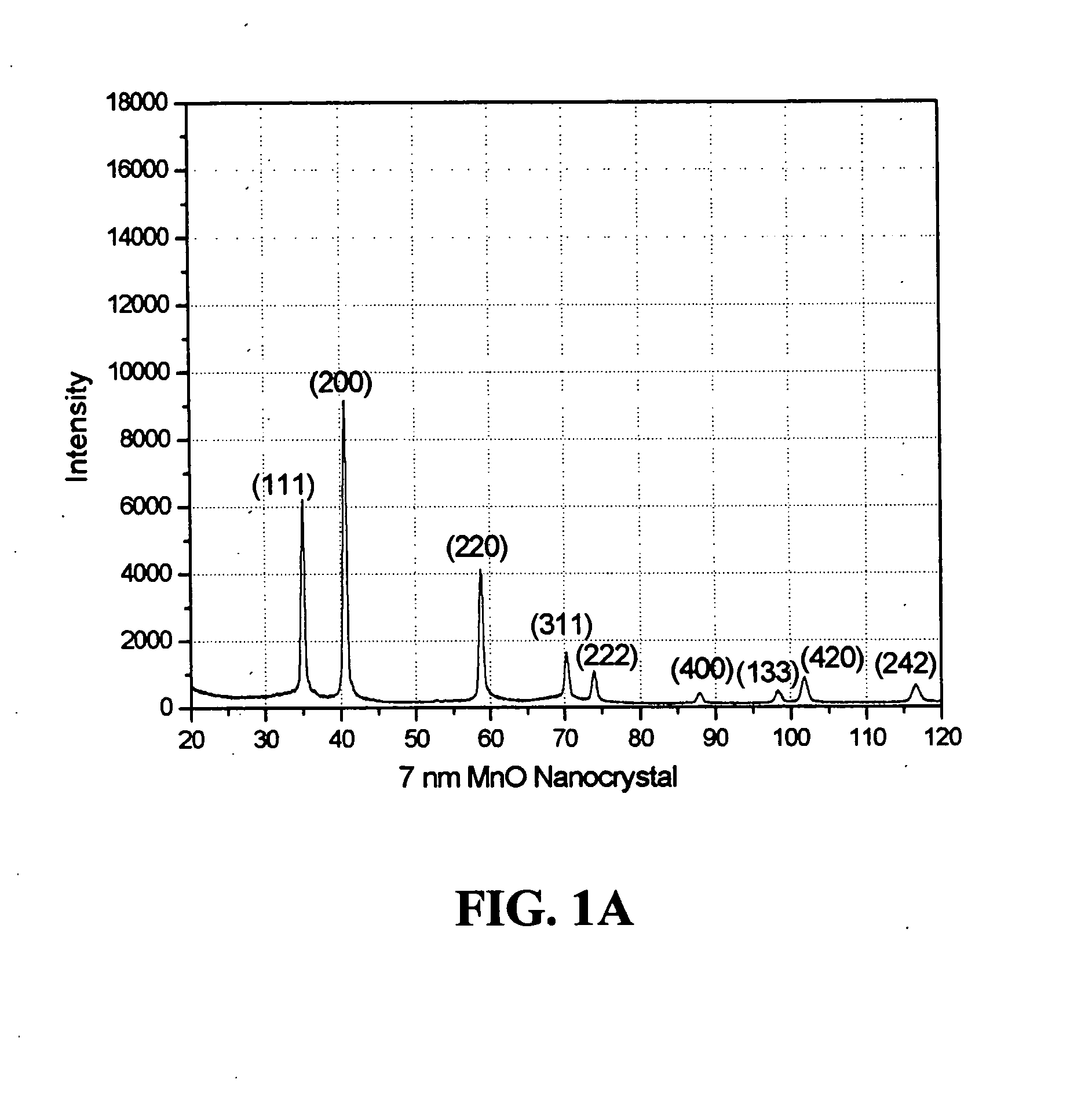

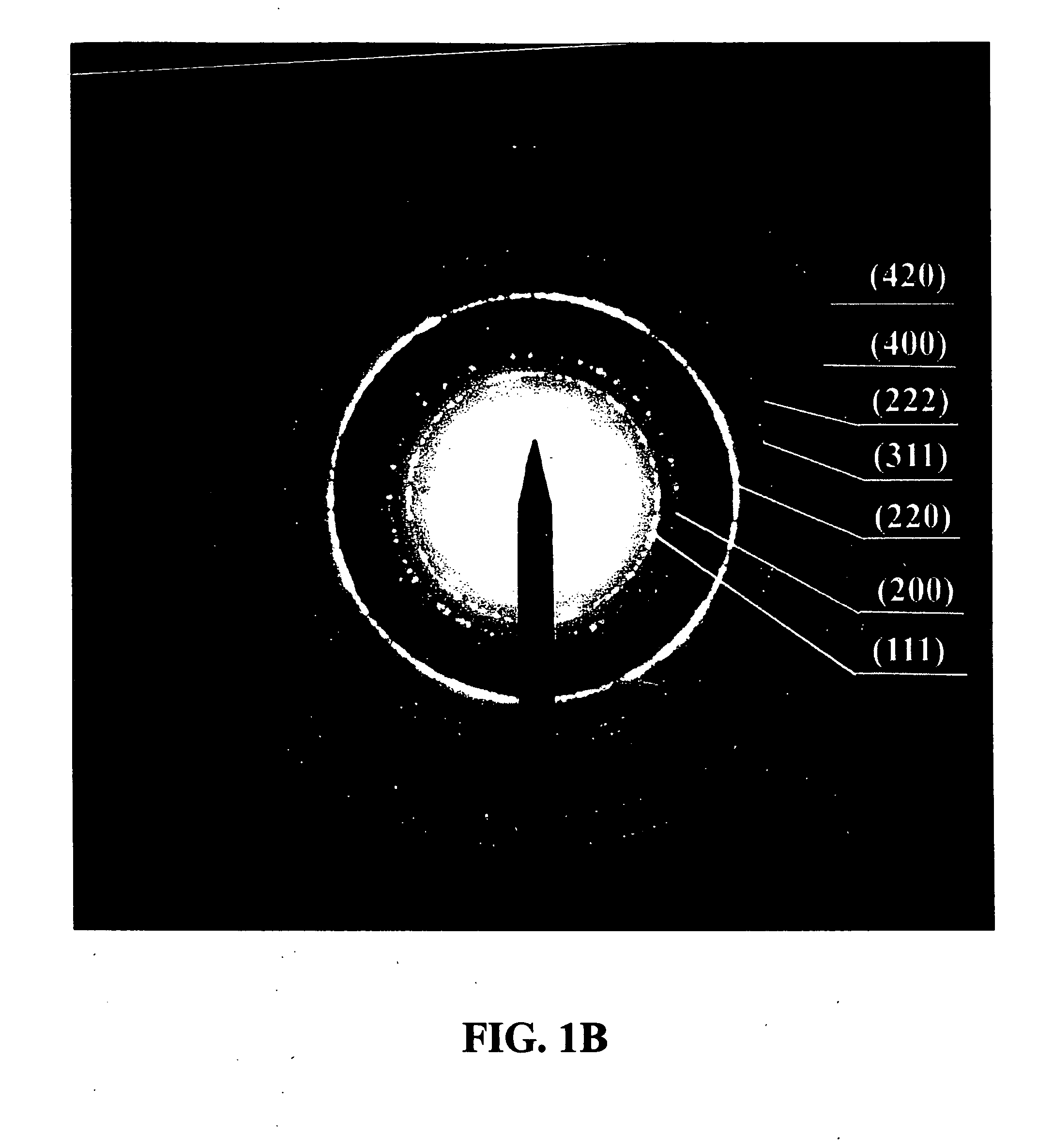

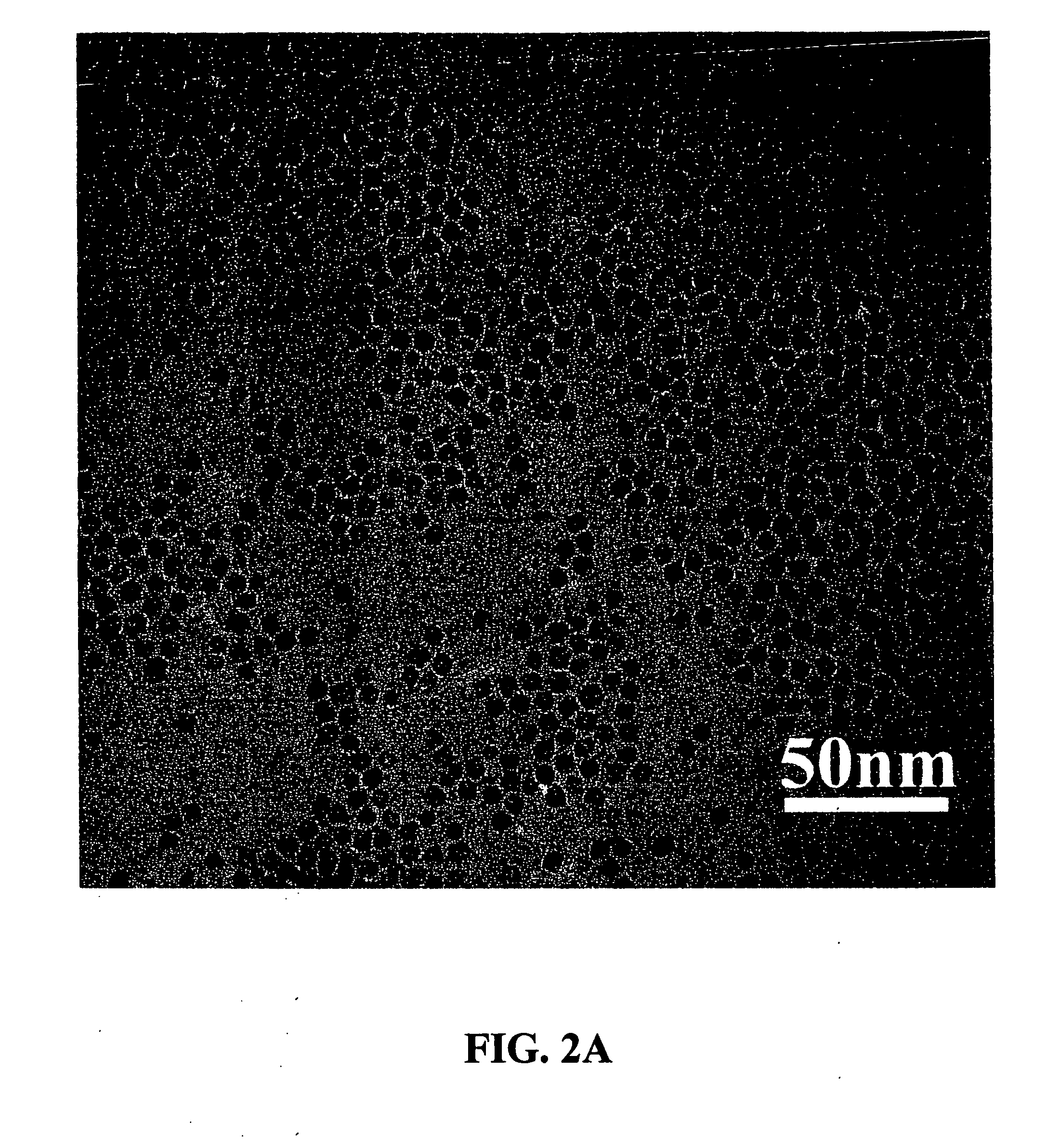

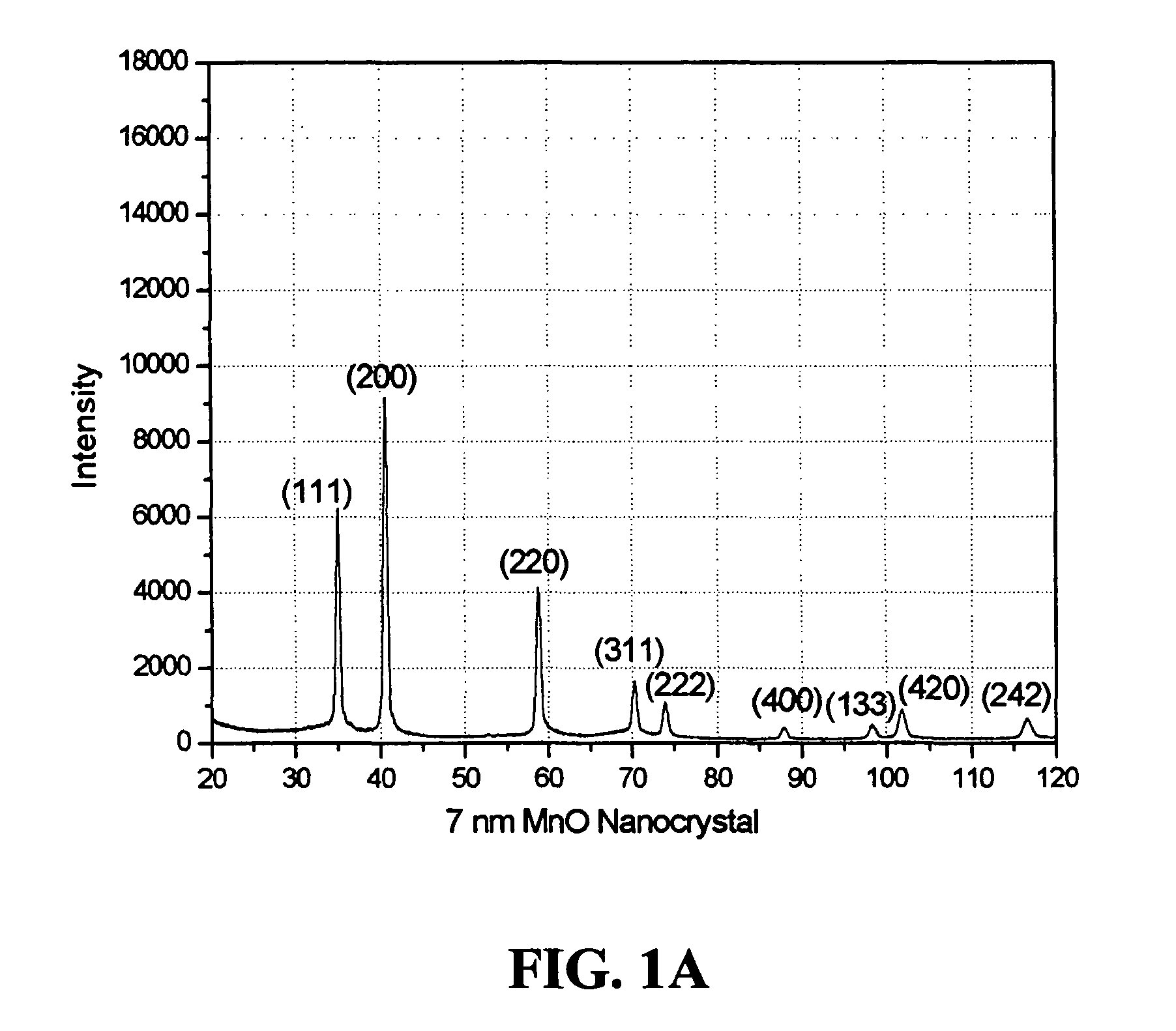

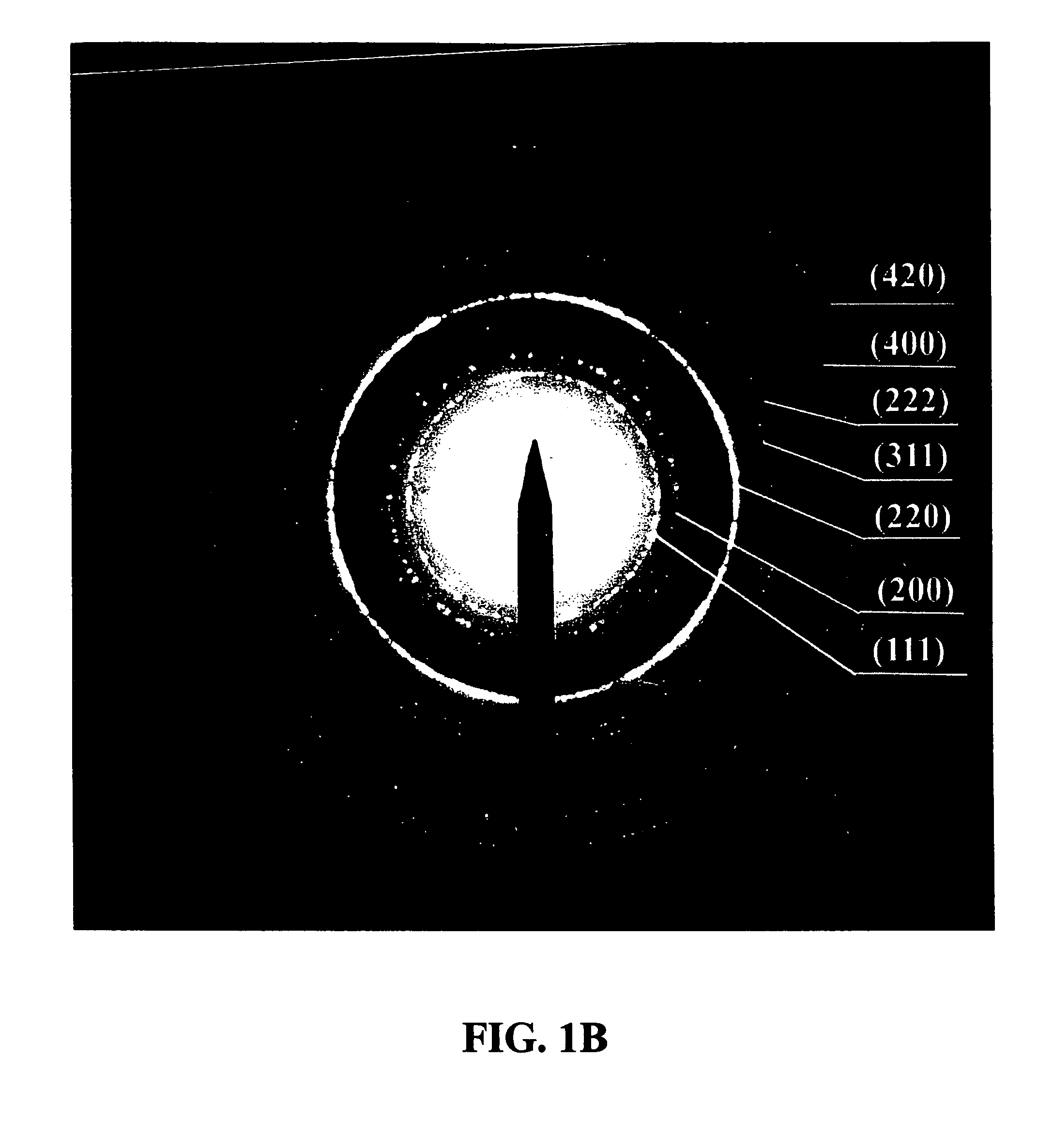

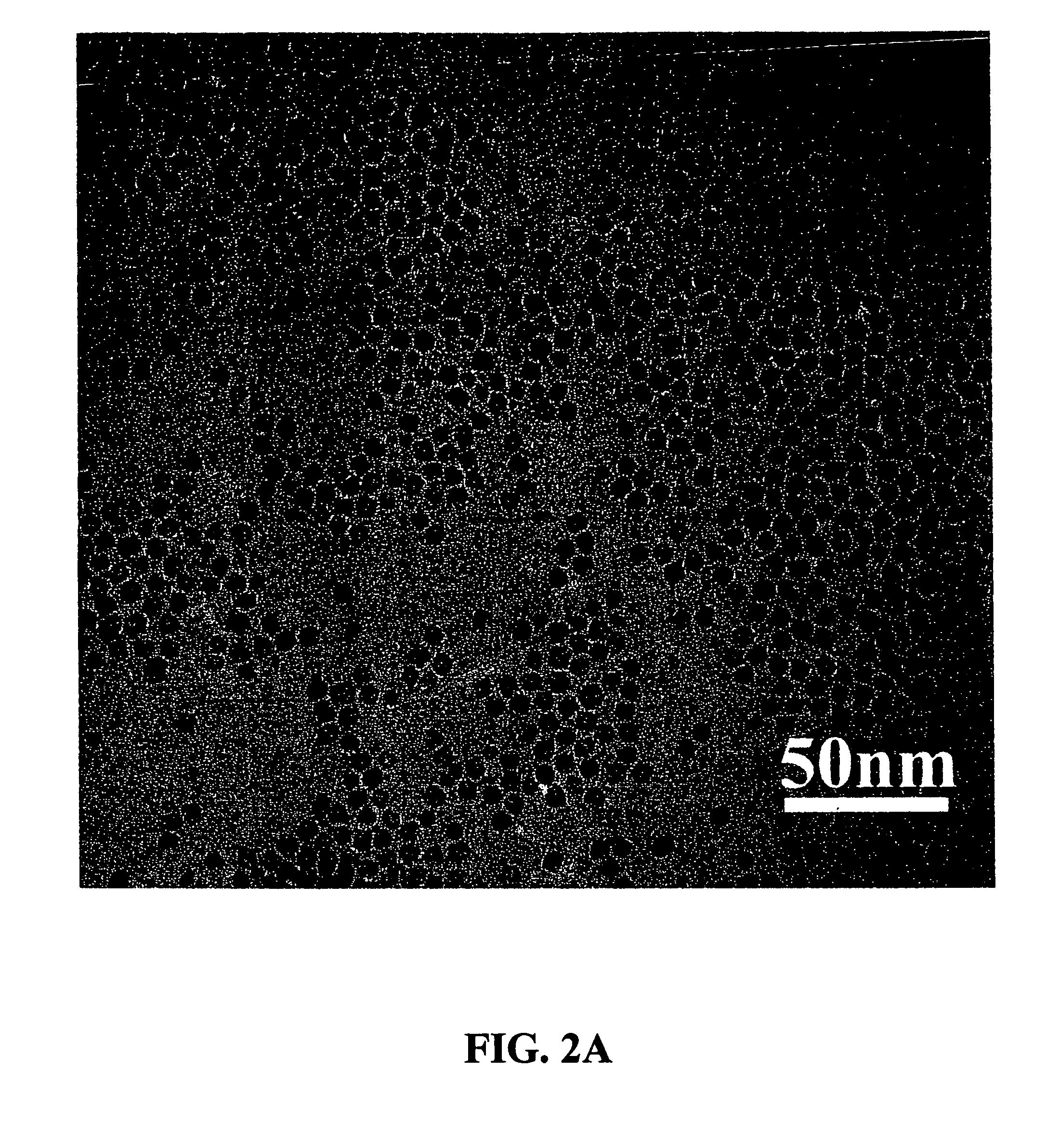

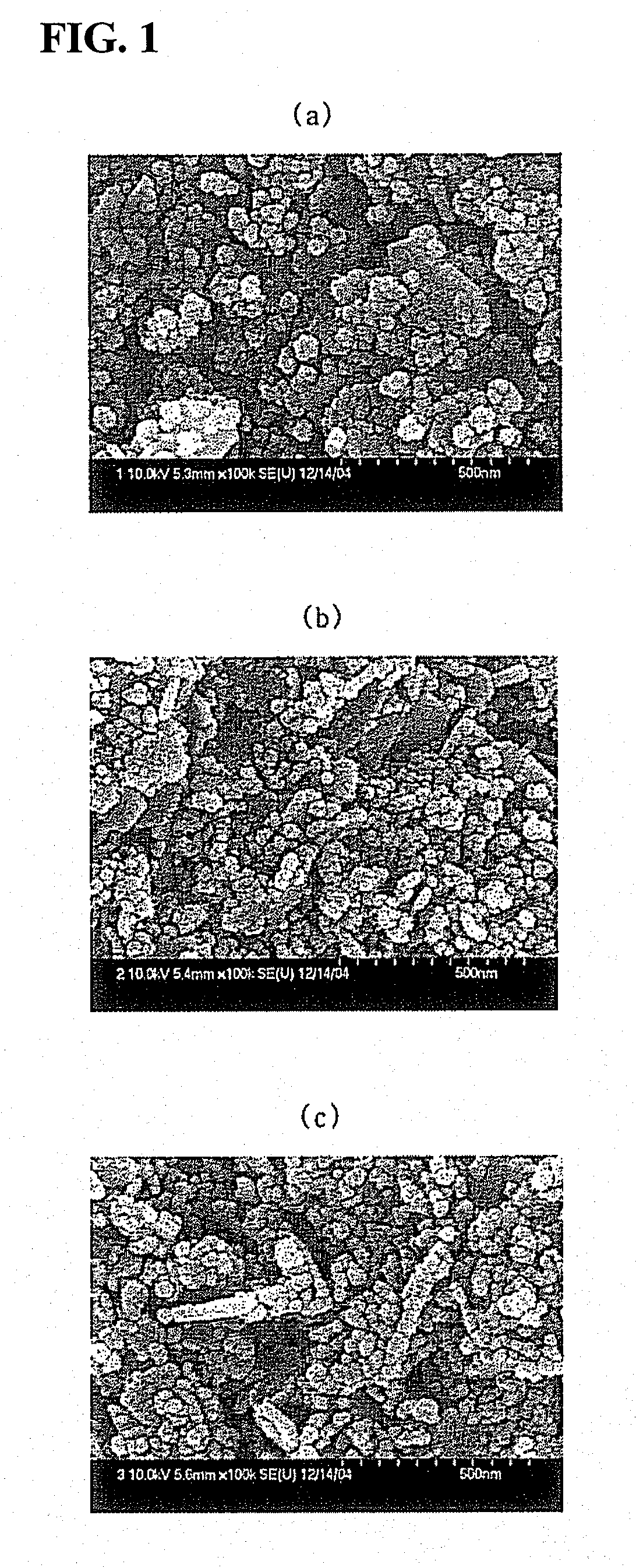

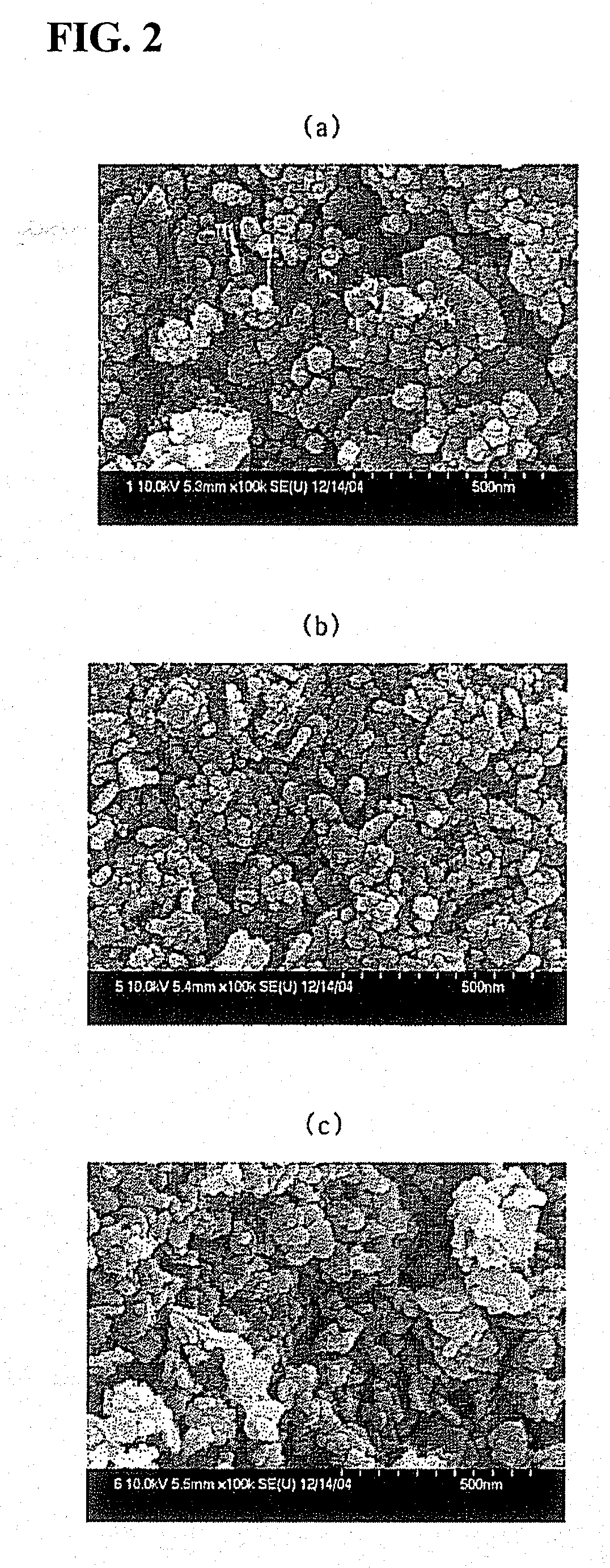

The present invention describes methods for preparing high quality nanoparticles, i.e., metal oxide based nanoparticles of uniform size and monodispersity. The nanoparticles advantageously comprise organic alkyl chain capping groups and are stable in air and in nonpolar solvents. The methods of the invention provide a simple and reproducible procedure for forming transition metal oxide nanocrystals, with yields over 80%. The highly crystalline and monodisperse nanocrystals are obtained directly without further size selection; particle size can be easily and fractionally increased by the methods. The resulting nanoparticles can exhibit magnetic and / or optical properties. These properties result from the methods used to prepare them. Also advantageously, the nanoparticles of this invention are well suited for use in a variety of industrial applications, including cosmetic and pharmaceutical formulations and compositions.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Nano-sized particles, processes of making, compositions and uses thereof

InactiveUS8182786B2Economical and efficientEfficiently tailoredMaterial nanotechnologyToilet preparationsSolventPharmaceutical formulation

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

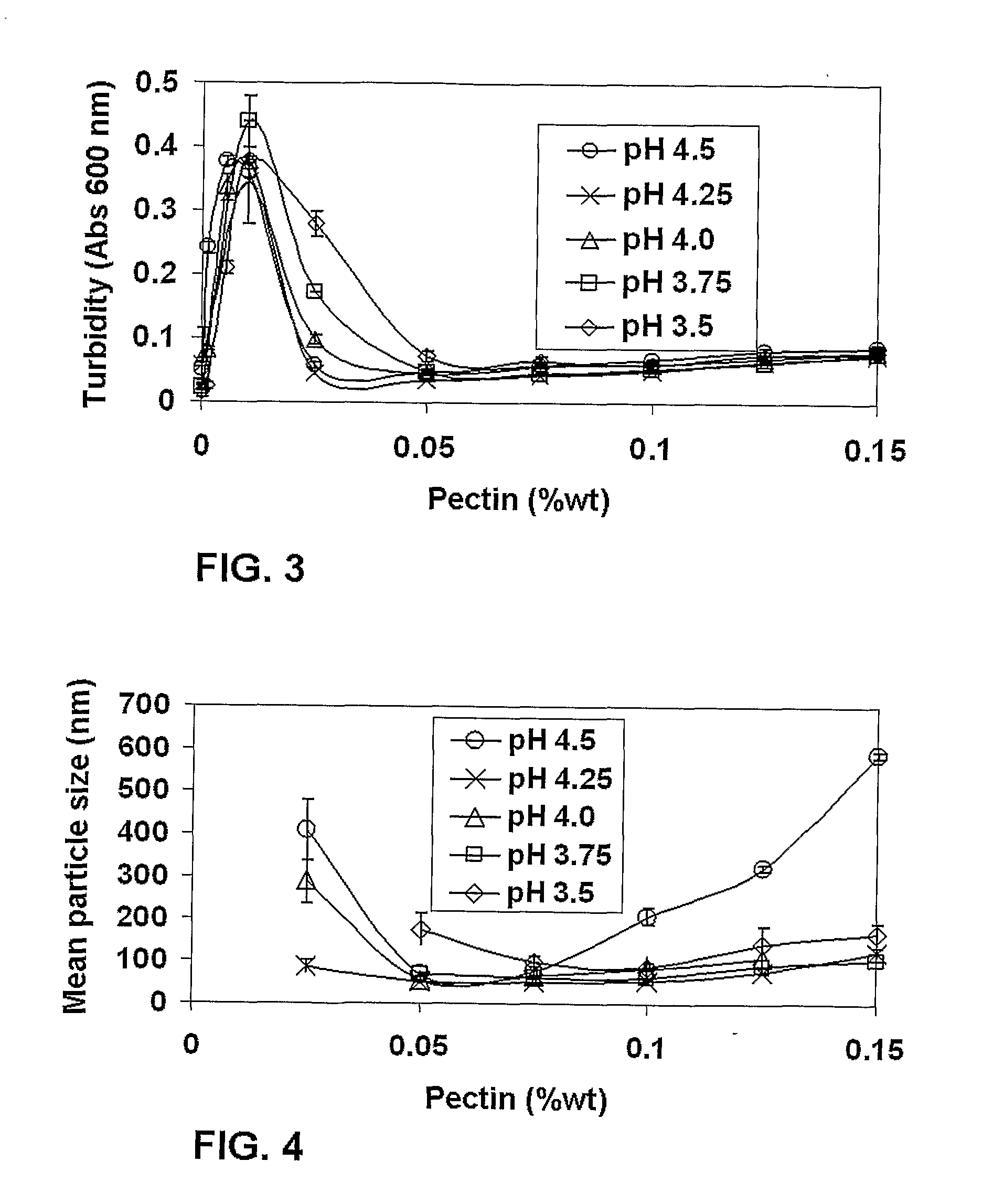

Beta-lactoglobulin-polysaccharide nanoparticles for hydrophobic bioactive compounds

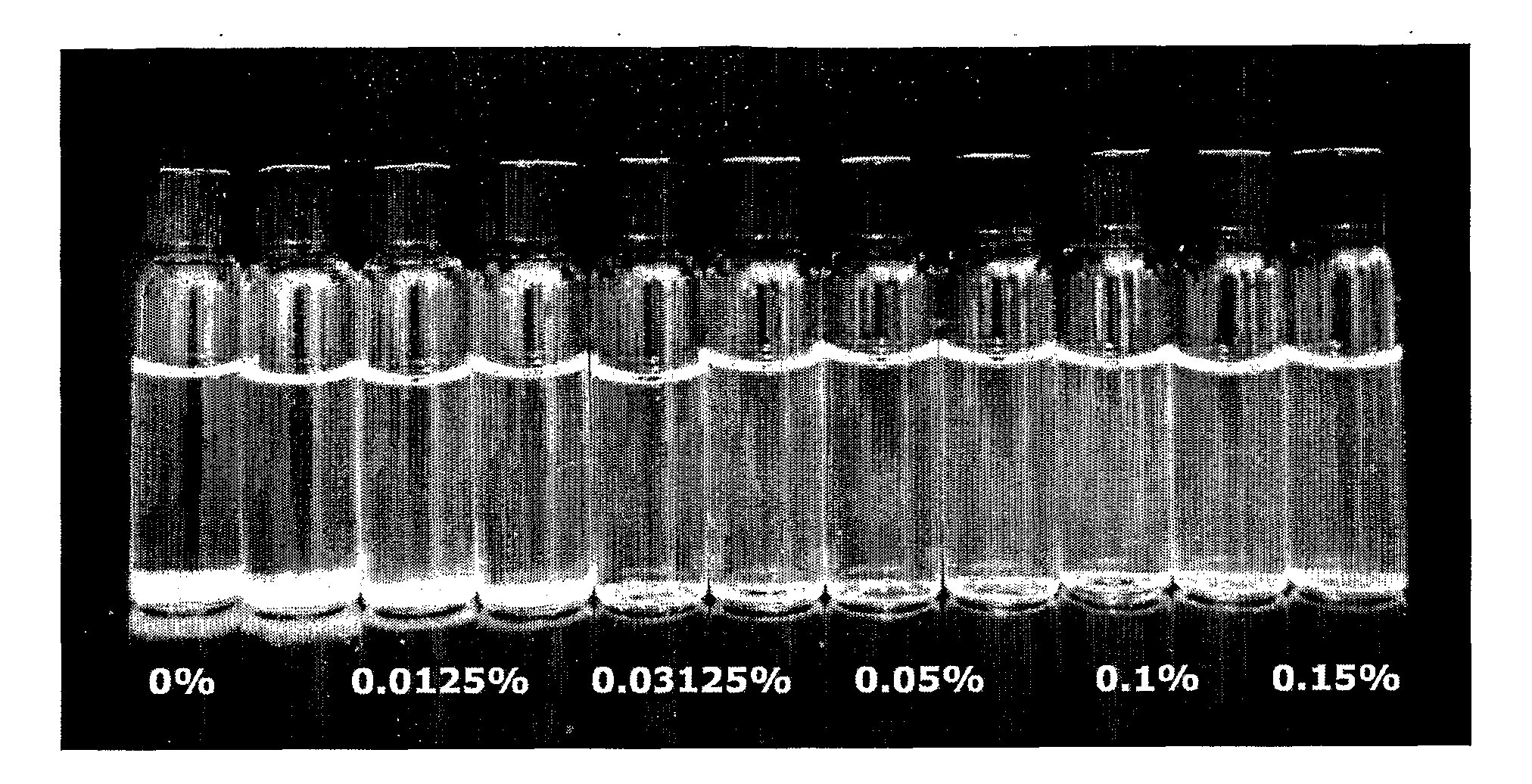

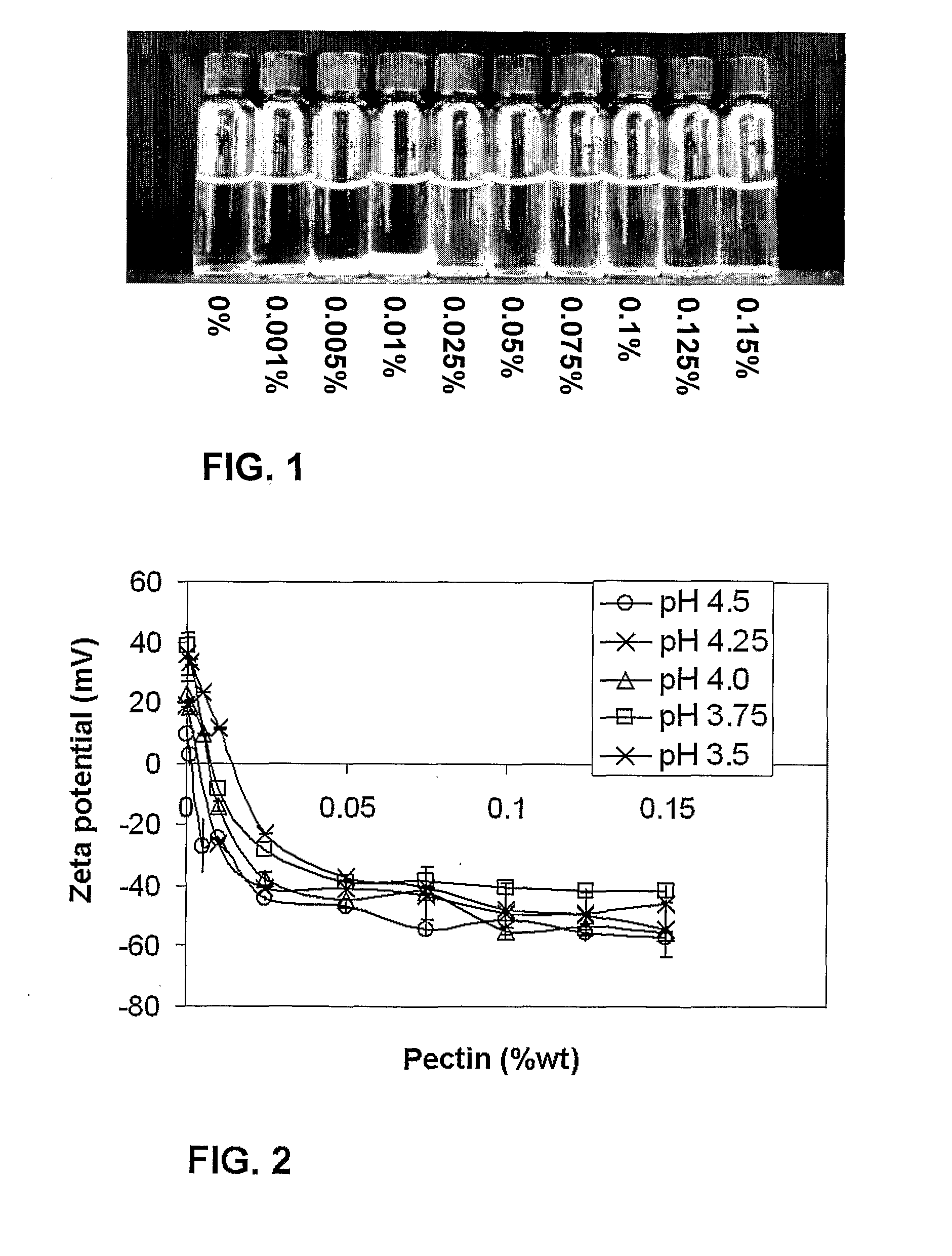

InactiveUS20110038942A1Not to compromise transparencyReduce oxidationBiocidePowder deliveryDelivery vehicleColloid

The present invention provides colloidally stable dispersions of nanoparticles comprising beta-lactoglobulin and a polysaccharide which are transparent when diluted in aqueous media. In particular these colloidally stable dispersions of nanoparticles are useful as delivery vehicles of hydrophobic nutraceuticals and fat-soluble vitamins, for enrichment of food products, especially of transparent beverages and other non-fat or low fat foods and drinks. The present invention further provides methods for the preparation of said colloidally stable dispersions.

Owner:TECHNION RES & DEV FOUND LTD

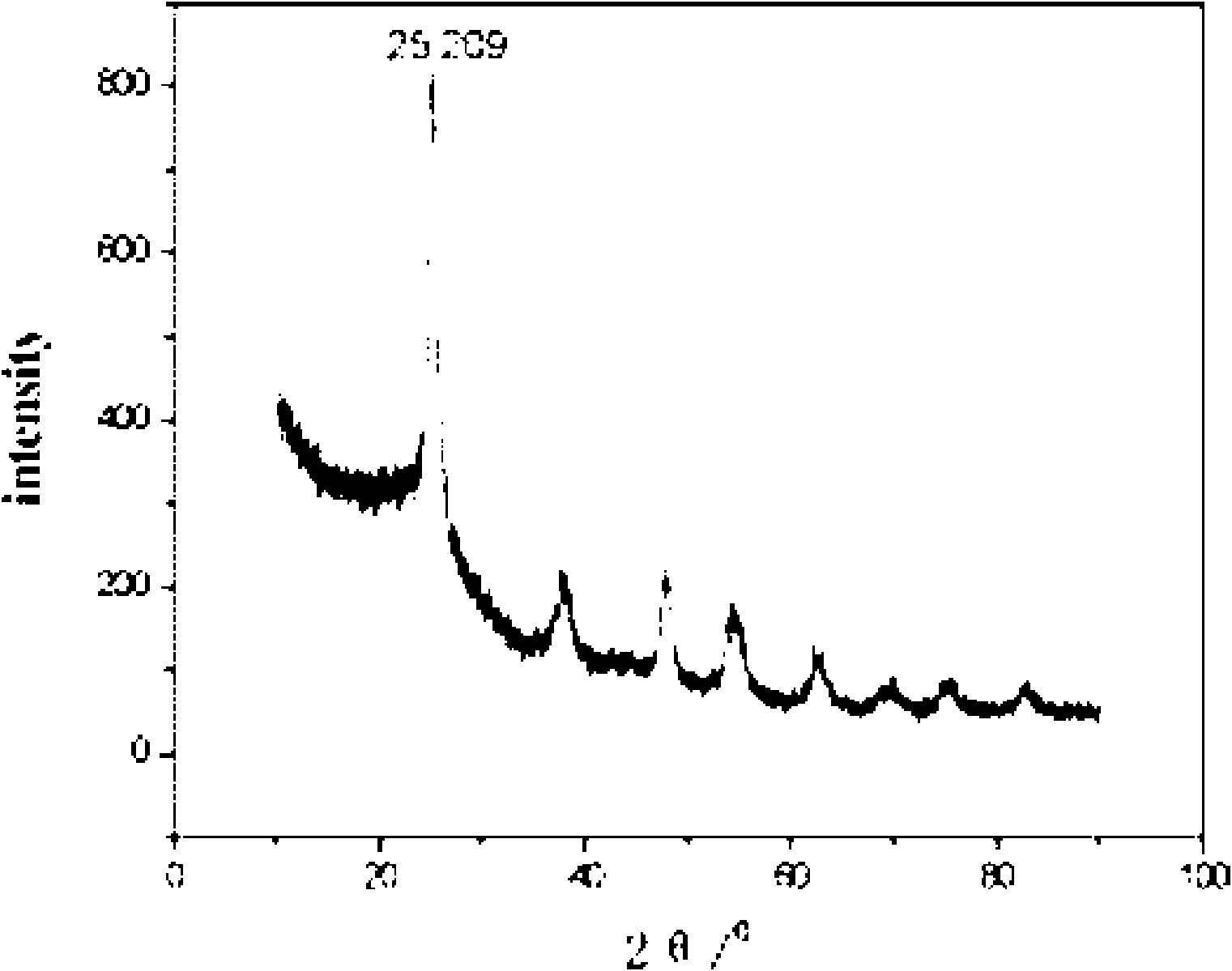

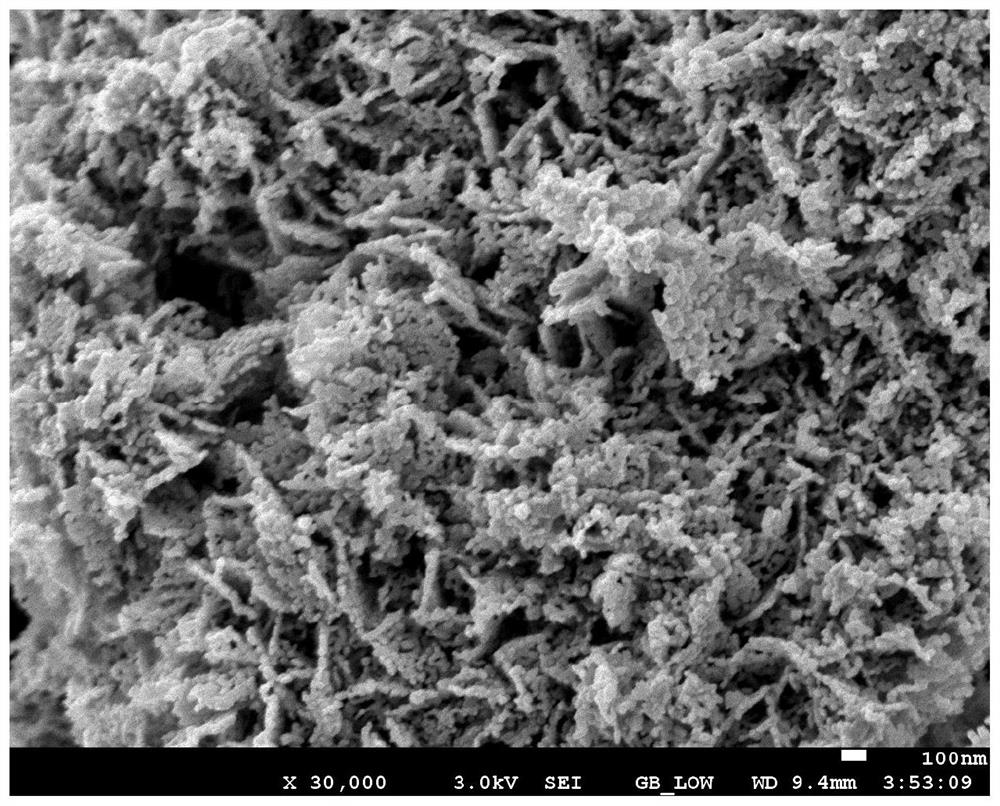

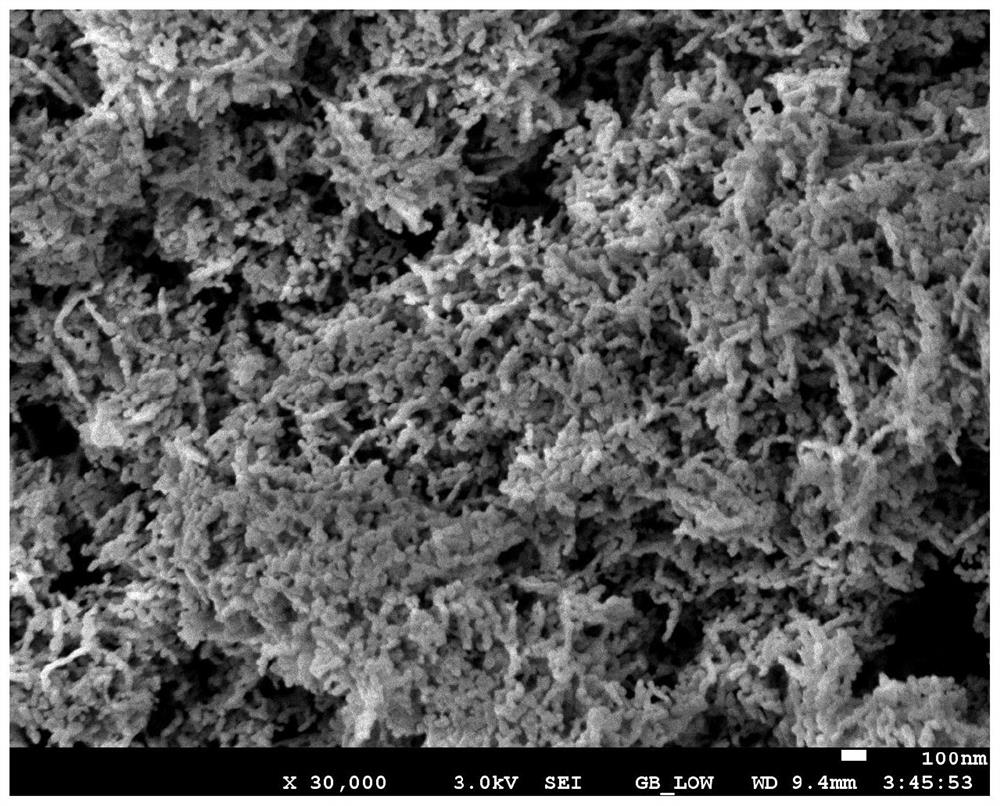

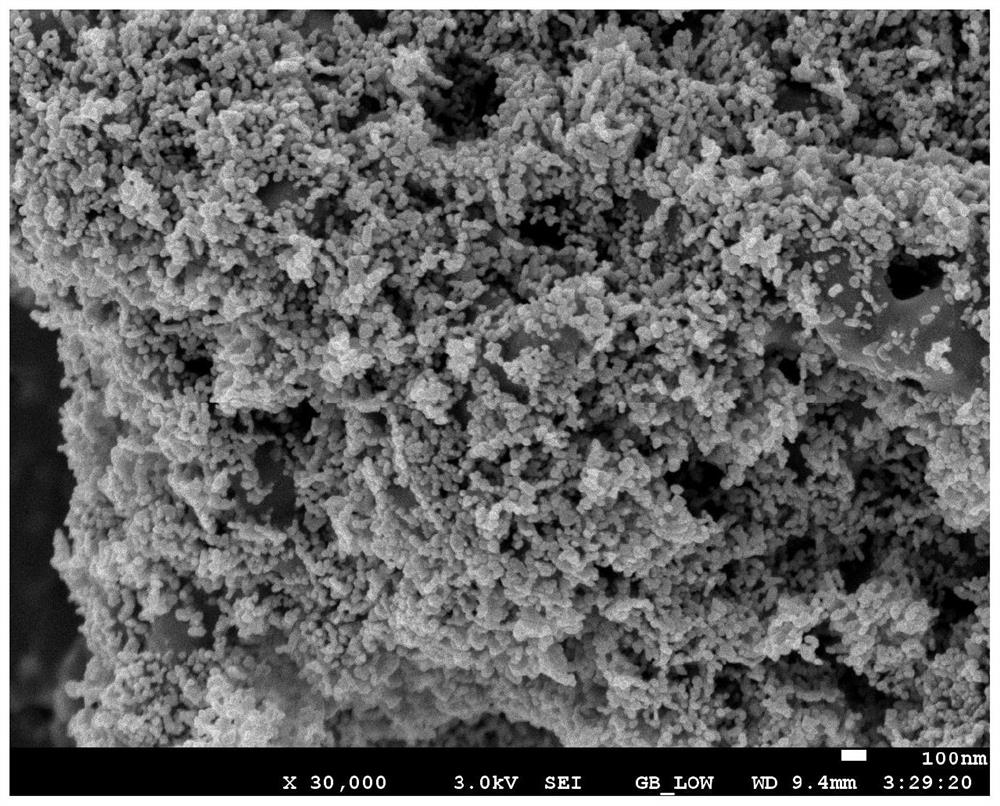

Method for preparing titanium dioxide/bamboo charcoal composite material

InactiveCN101632920AAccelerateMild conditionsWater/sewage treatment by irradiationCatalyst activation/preparationMicrostructureSewage treatment

The invention discloses a method for preparing a titanium dioxide / bamboo charcoal composite material. The titanium dioxide / bamboo charcoal composite material is prepared by using bamboo charcoal as the carrier and n-tetrabutyl titanate as the titanium source and through assisting by a microwave process. During microwave heating, large and small particles in the material are simultaneously and fast heated, thereby reducing thermal stress and further avoiding the breakage of the material, improving the microstructure of the material, uniformly loading active components on the carrier and improving the photocatalysis property of the material used in the field of sewage disposal with photocatalysis oxidization process. According to the detection of X-ray diffraction, the TiO2 loaded in the composite material is mainly of anatase type. The method solves the problems that the preparation of the titanium dioxide / bamboo charcoal composite material is time-consuming and costy, uniform titanium dioxide / bamboo charcoal composite material is difficult to prepare and carbon pollution is easily caused during the sintering.

Owner:LONGYAN UNIV

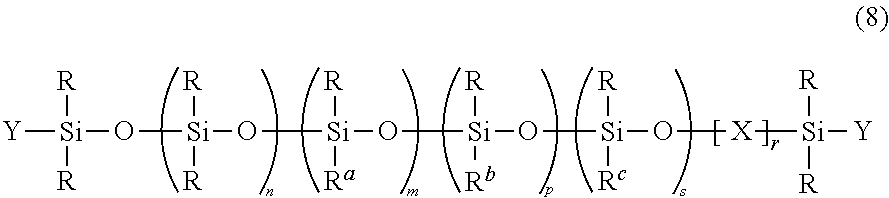

Oil-in-water organopolysiloxane emulsion composition, cosmetic ingredient comprising this composition, and method of producing a hair cosmetic using this composition

ActiveUS8546483B2Large particle sizeParticle size andCosmetic preparationsHair cosmeticsPolymer scienceCosmetic ingredient

Owner:DOW TORAY CO LTD

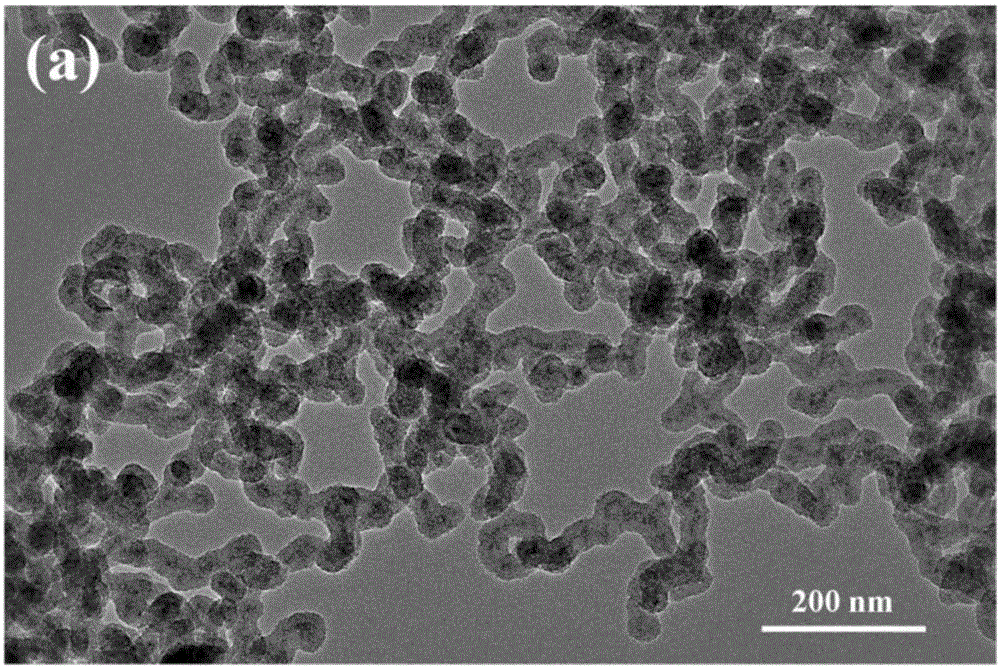

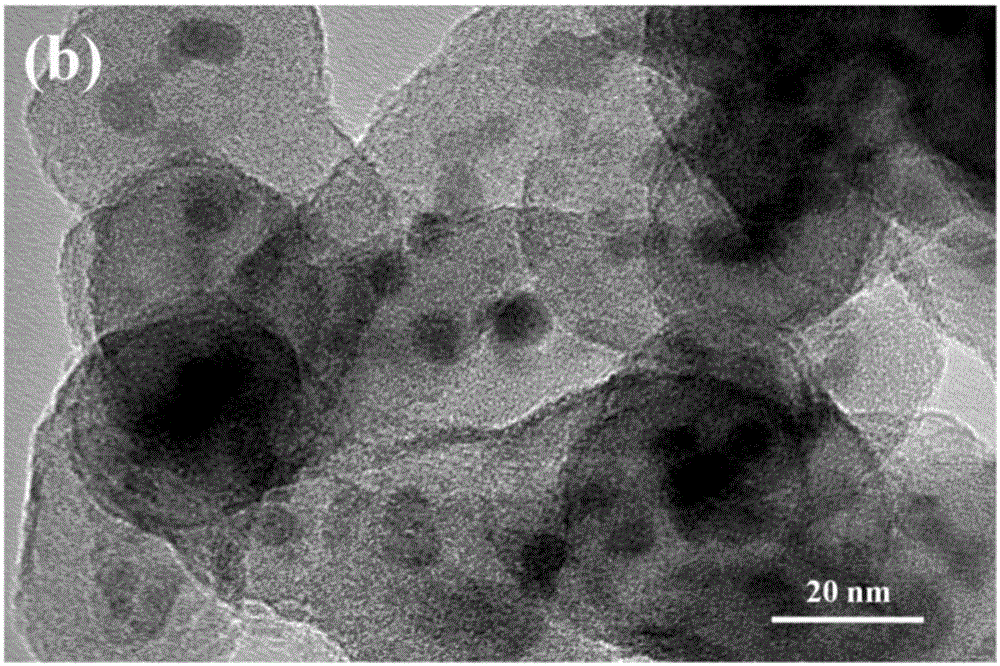

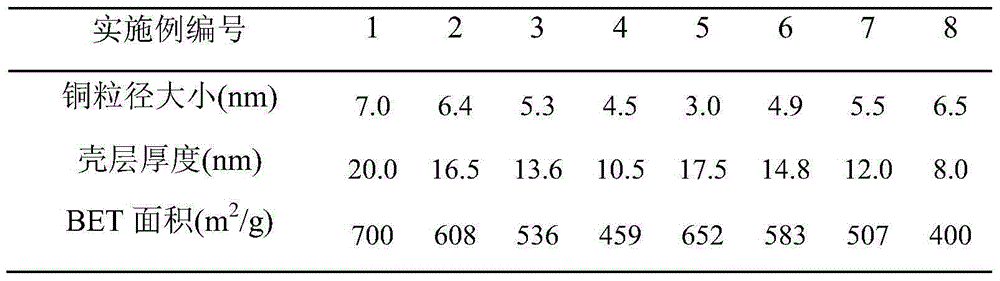

Core-shell structure type copper-based catalyst as well as preparation method and application thereof

ActiveCN105170151AUniform particle size distributionGood dispersionOrganic compound preparationHydroxy compound preparationHydrogenation reactionCopper

The invention provides a core-shell structure type copper-based catalyst as well as a preparation method and application thereof. The catalyst takes Cu as a core and takes mesoporous SiO2 as a shell layer material, the weight percentage of Cu is 8-25%, and the weight percentage of SiO2 is 75-92%. The core-shell structure type nano-composite catalyst material is uniform in grain distribution, adjustable in size, good in dispersibility, small in inner core copper grain, large in specific surface area, good in stability performance, and long in service life; in CO2 hydrogenation reaction operation, the catalyst is stable in performance, and high in activity, and can be operated at a high temperature (240-300 DEG C); the high CO2 conversion per pass can be still kept after long period evaluation, and the core-shell structure type copper-based catalyst has the advantages of being low in cost, easy to operate, easy to enlarge in industry and the like.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

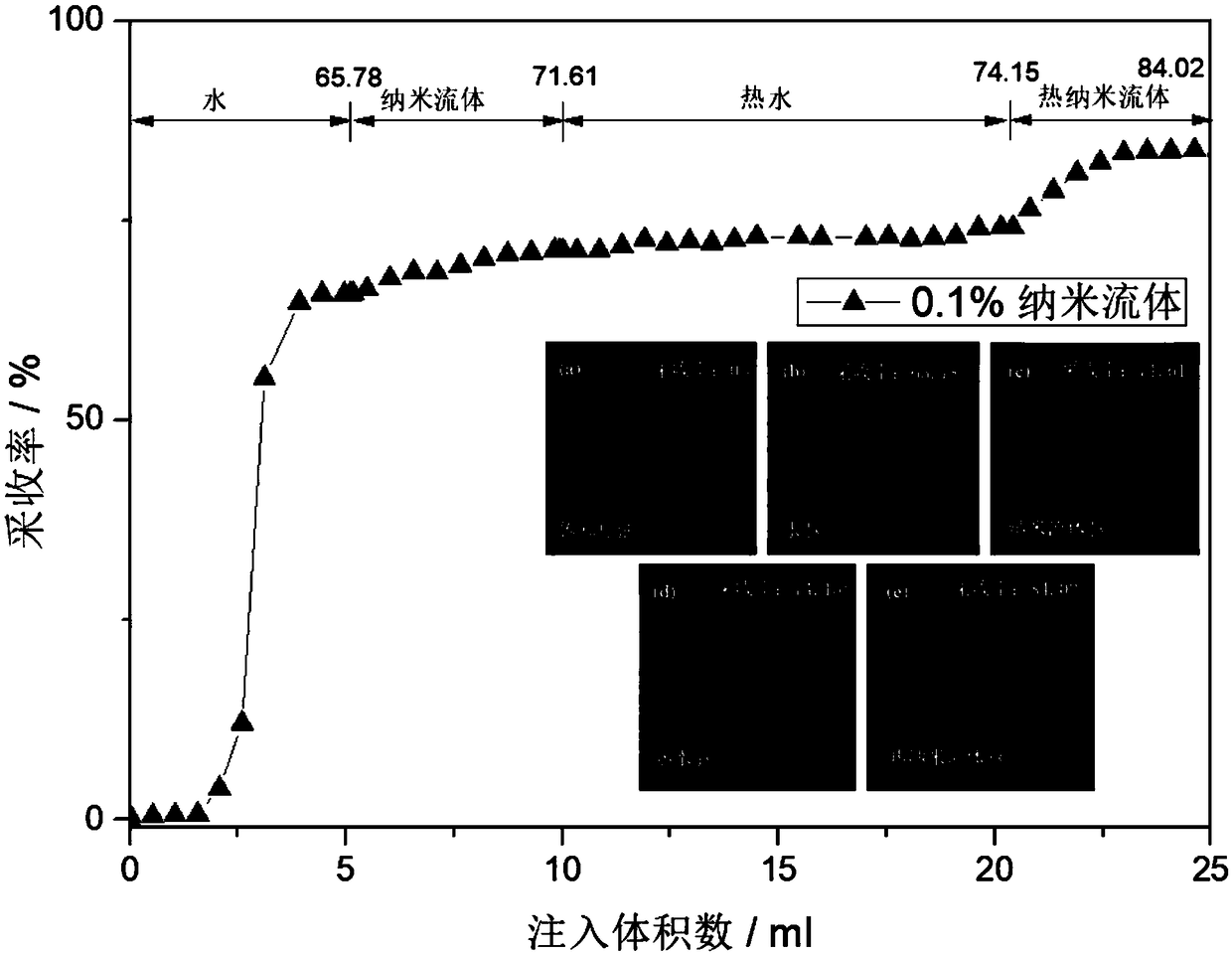

Preparation method of intelligent nano-foam oil-displacing agent

ActiveCN108659807AReduced stabilityIncrease the spread areaDrilling compositionNanoparticleOil water

The invention discloses a preparation method of an intelligent nano-foam oil-displacing agent. By grafting a temperature-sensitive polymer onto magnetic nano particle surfaces, compound nano particleswith the temperature-sensitive property and magnetic response are prepared, and the nano particles have the property of stabilizing foam. The oil-displacing agent has the characteristics that the hydrophilia and lipophilicity of the oil-displacing agent can be adjusted and controlled; when the formation temperature is high, the nano particles show the lipophilicity, and when the foam meets crudeoil, the foam bursts, which is beneficial to peeling the crude oil off a rock stratum surface and improving the recovery ratio; when the temperature is low, the nano particles show the hydrophilia, which is beneficial to separation of oil and water, and through an applied magnetic field, recovery of the nano particles can be fast achieved; moreover, the foam-displacing liquid can respond to the magnetic field, so that through the applied magnetic field, flow of the displacing liquid can be controlled.

Owner:XI AN JIAOTONG UNIV

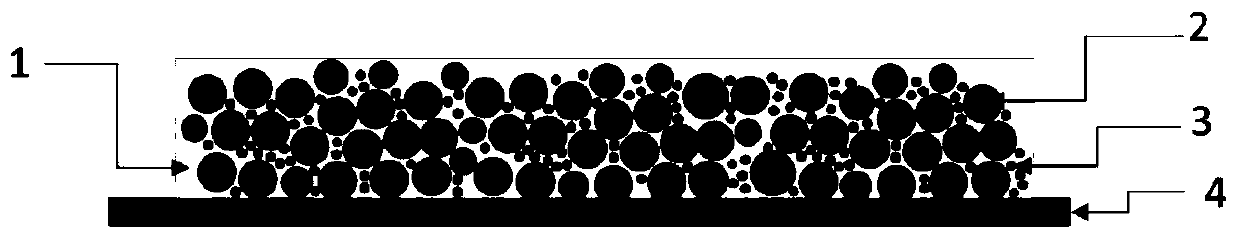

Multi-size nanoparticle hybrid metal film and preparation method thereof

ActiveCN109979904ALow costReduce operational complexitySemiconductor/solid-state device detailsSolid-state devicesPorosityNanoparticle

The invention provides a multi-size nanoparticle hybrid metal film and a preparation method thereof. The multi-size nanoparticle hybrid metal film comprises an organic medium material which forms an organic coating layer, wherein the organic medium material is configured with nano-metal particles with at least two sizes; the small-size nano-metal particles are driven into gaps of the large-size nano-metal particles by means of physical impact so as to realize gap filling of the large-size nano-copper particles, and the nano-metal particles preferably use a nano-copper material, thereby avoiding the problems such as high porosity, low thermal conductivity, high cost, thermal mismatch with Si, SiC-based chips and high electric mobility of the existing composite silver films, and improving the overall reliability of power devices. Meanwhile, the multi-size nanoparticle hybrid metal film has the characteristic of easy assembly and can effectively reduce the cost.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

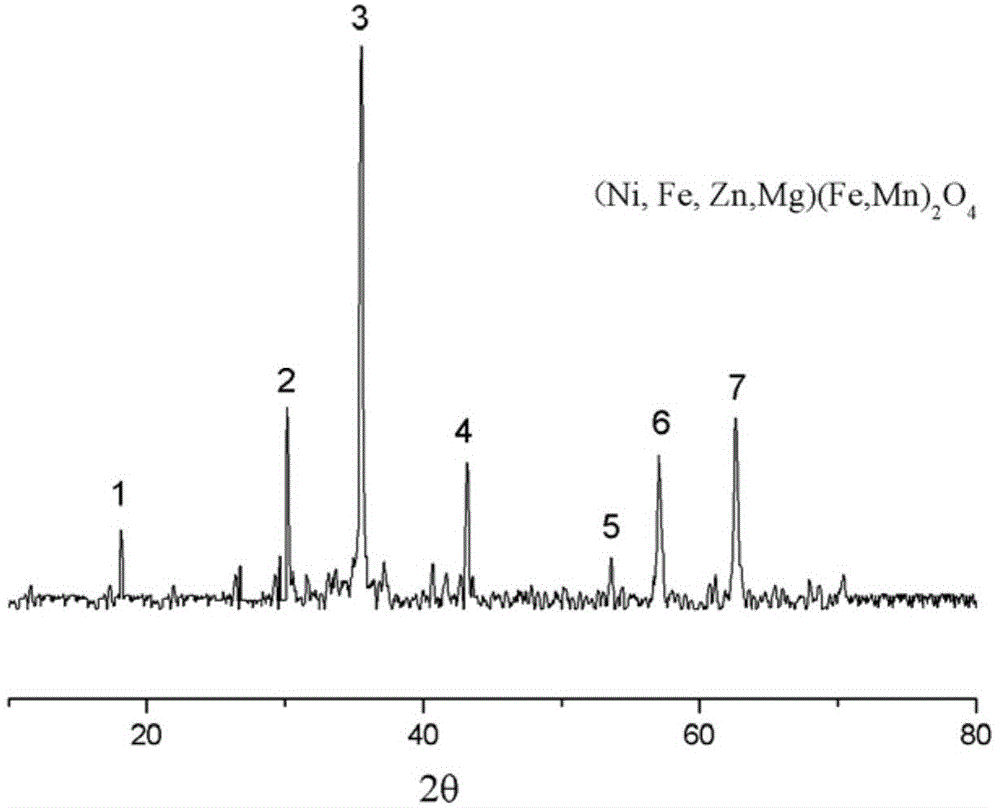

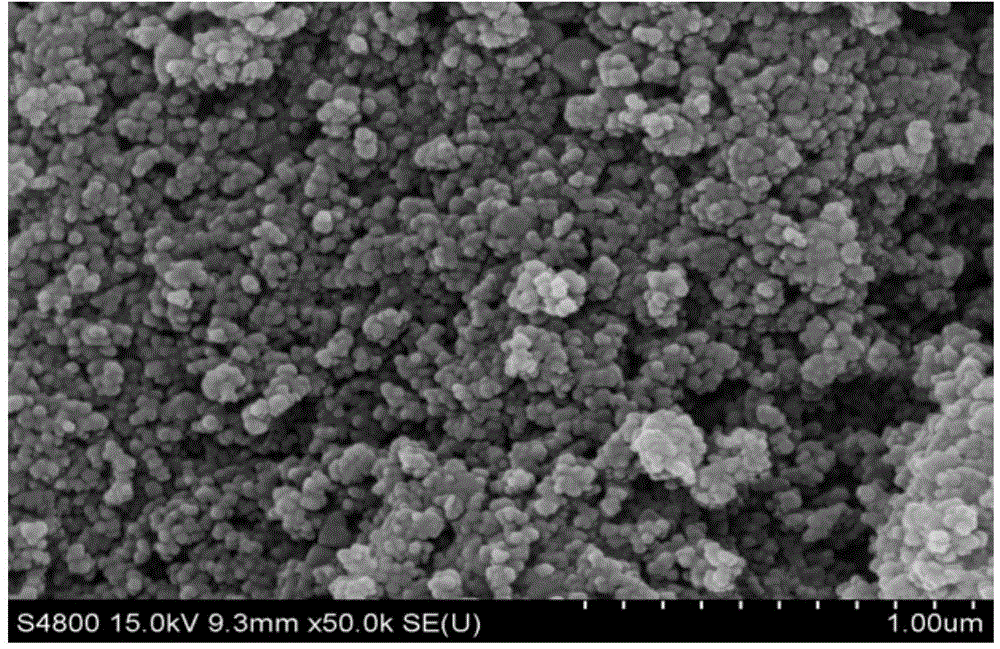

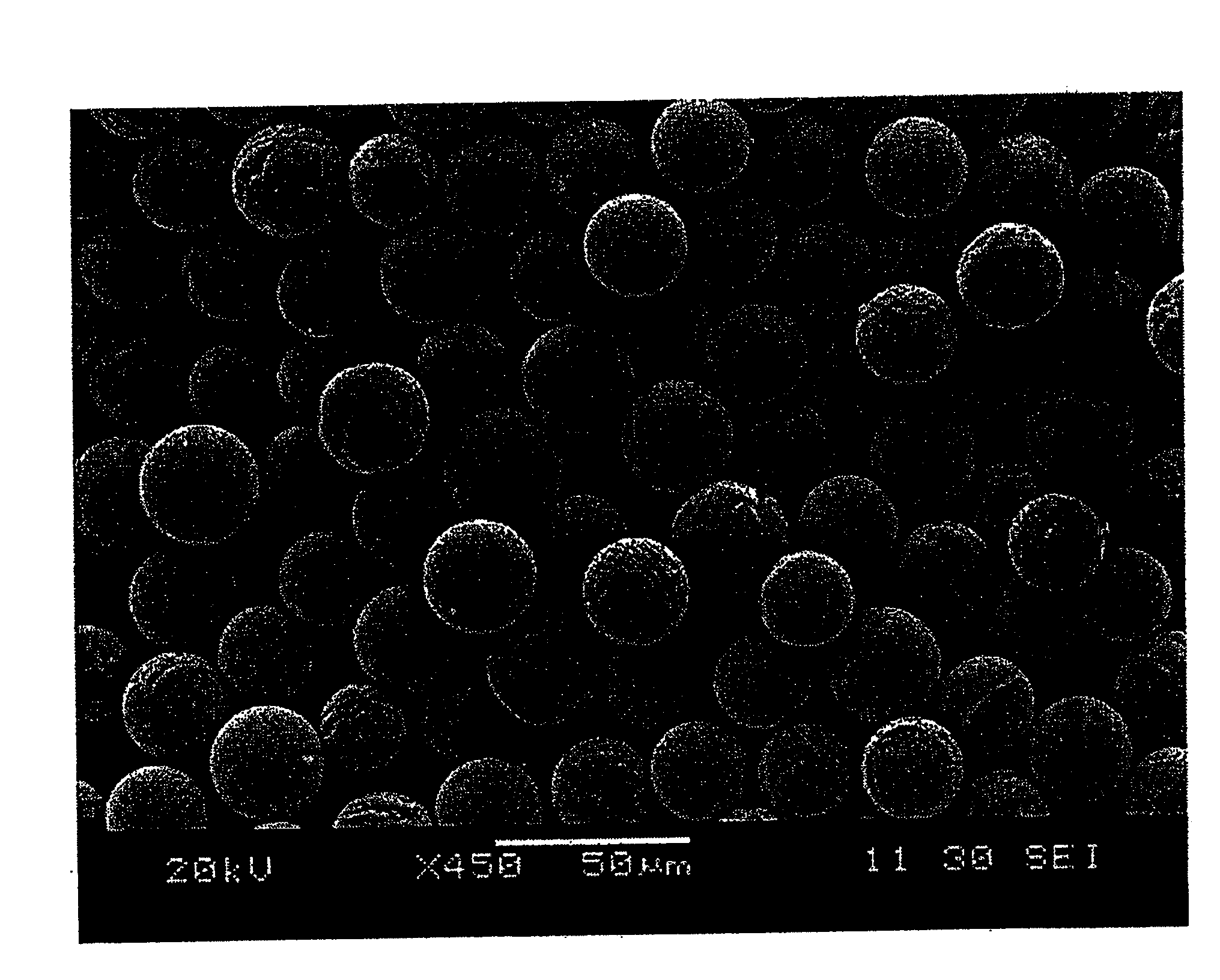

Recycling method of pickling sludge

InactiveCN103950987AAlleviate environmental pollutionConducive to environmental protectionIron compoundsSolventAmmonium hydroxide

The invention discloses a recycling method of pickling sludge, and belongs to the solid waste material utilization technology of environmental engineering. According to the recycling method, a pickling sludge solid waste material is taken as raw material; an appropriate amount of an iron source is replenished; water is taken as a solvent; ammonium hydroxide is taken as a pH conditioning agent; a foaming agent is added; and a corresponding heavy metal hydroxide is obtained at a certain temperature under a certain pressure; the heavy metal hydroxide is taken as a precursor, and is delivered into a special physical and chemical environment which can not be realized at normal temperature under normal pressure, so that the precursor is dissolved completely, different growth units are formed, nucleation growth according to a certain combination manner is realized, stable ferrite with low leaching toxicity and high saturation magnetization degree is obtained via crystallization. The recycling method is suitable for environmental protection, and is capable of realizing recycling of pickling sludge resources, and increasing additional value of the pickling sludge resources. Particle size of the ferrite obtained via the recycling method ranges from 200 to 400nm; the ferrite is spherical particle particles, and possesses excellent crystal form and organic waste water adsorption capacity.

Owner:NANJING UNIV OF SCI & TECH

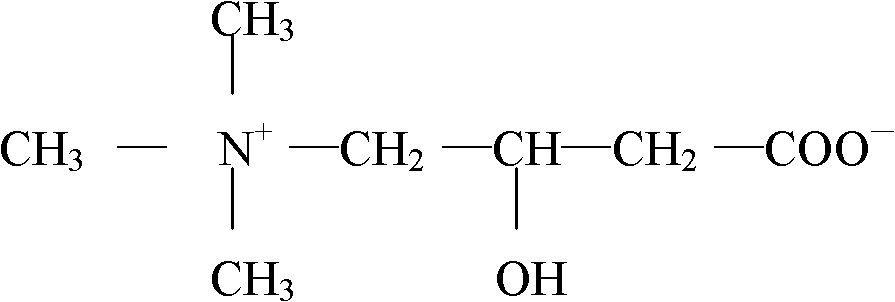

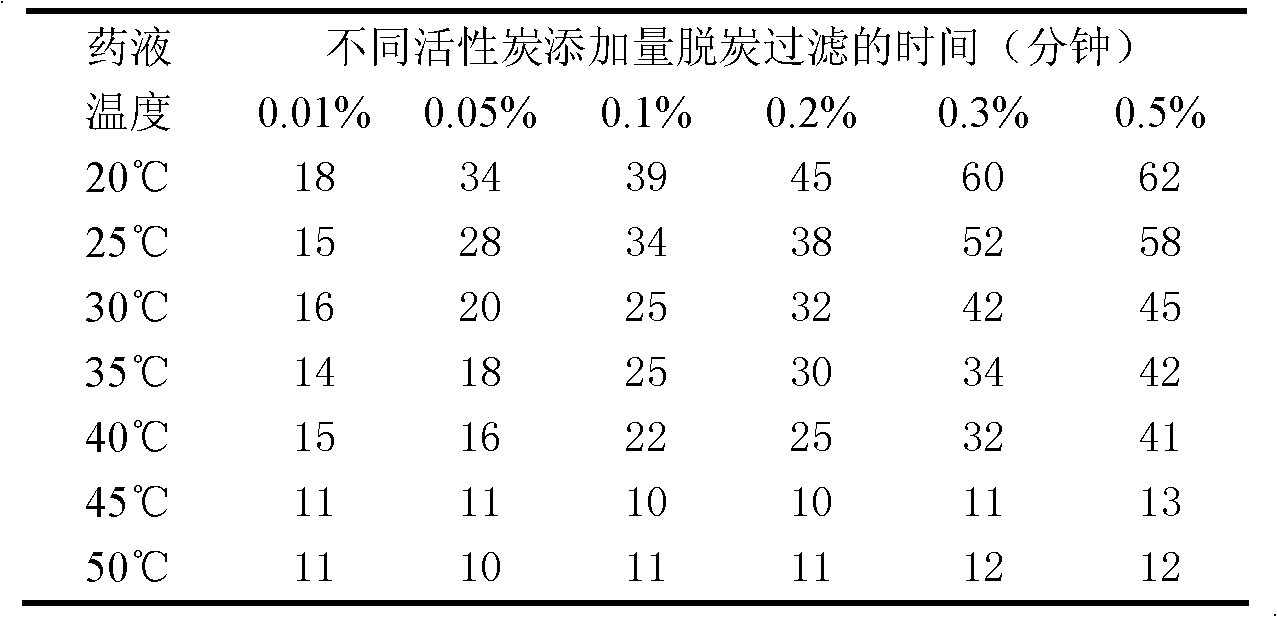

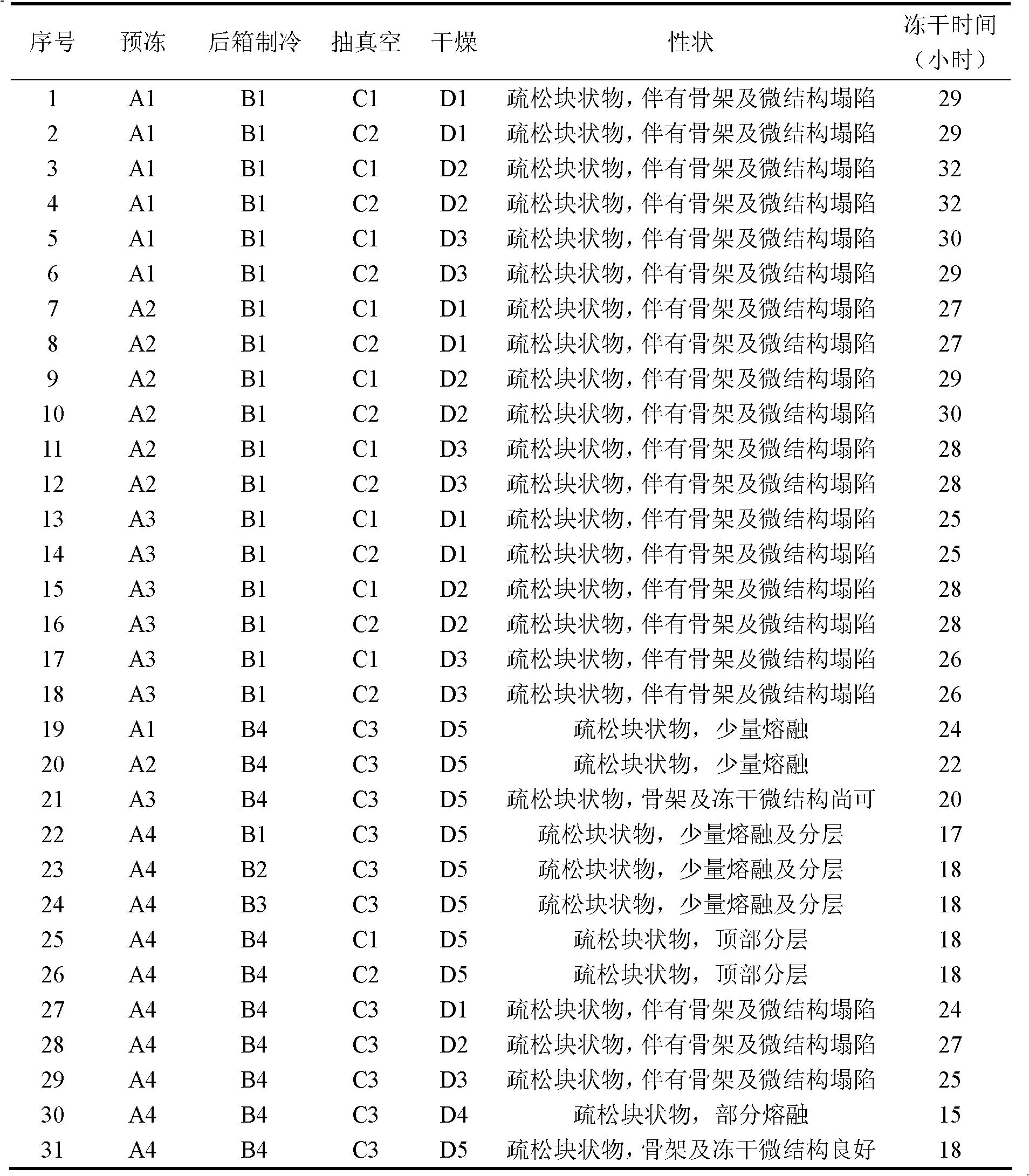

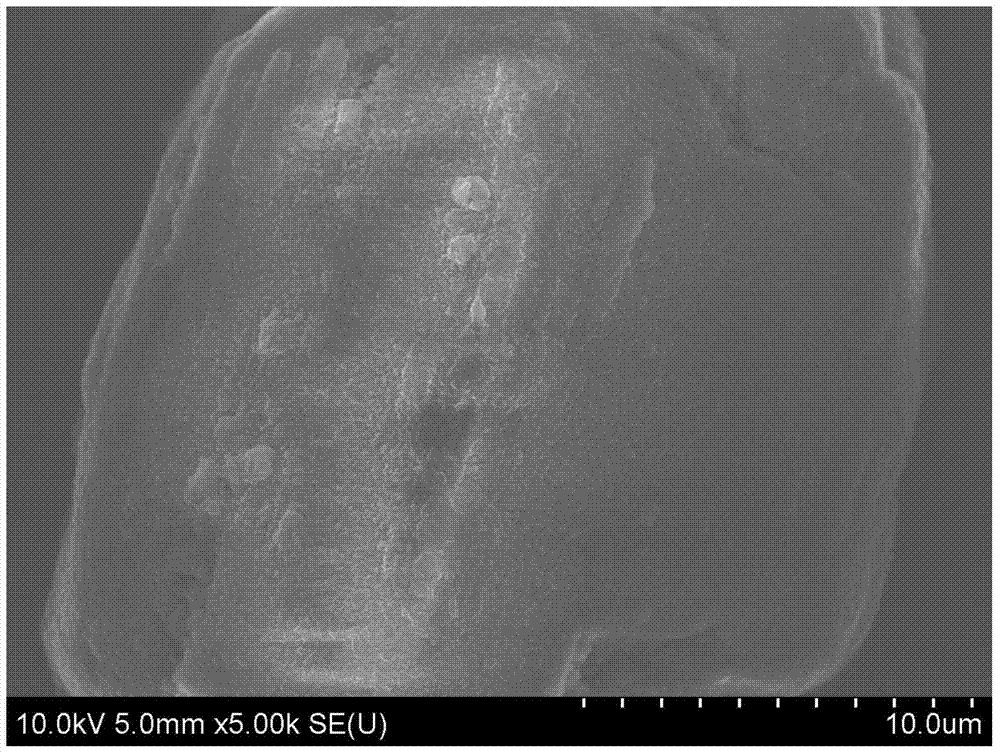

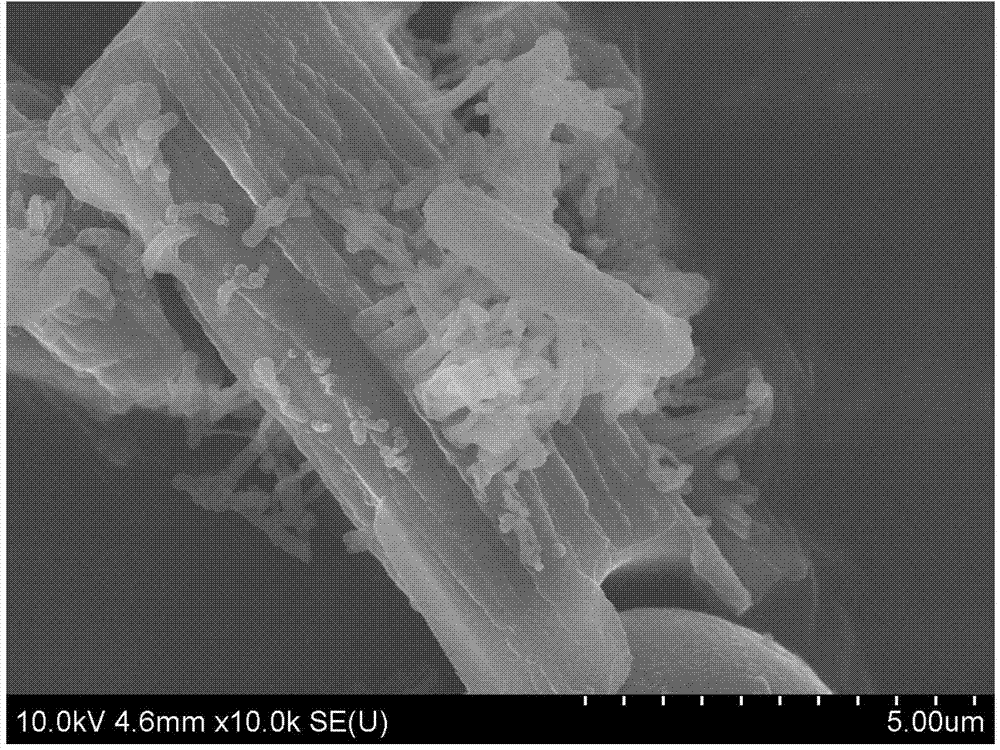

Levocarnitine composition for injection and preparation method of levocarnitine composition

ActiveCN102327238AReduce dosageReduce skeletonOrganic active ingredientsPowder deliveryPorosityFreeze-drying

The invention relates to a levocarnitine composition for injection and a preparation method of the levocarnitine composition; the levocarnitine composition is lyophilized powder containing levocarnitine and mannitol, wherein the weight ratio of the levocarnitine to the mannitol is 1:(0.75-1.25); the average particle diameter of the lyophilized powder is 90-130 nm, and the porosity is 94-98%. The preparation method comprises the steps of: 1) preparing: weighing levocarnitine and mannitol, putting the levocarnitine and the mannitol in a preparing tank, adding injection water, agitating to enable the levocarnitine and the mannitol to be completely dissolved and uniformly mixing, regulating the pH to 5.7-6.3 through a 0.1mol / L hydrochloric acid solution; 2) decarburizing and sterile filtering; 3) sterile packaging; 4) vacuum freeze drying to obtain the levocarnitine composition . The levocarnitine composition has the advantages of simple preparation, advanced technique, uniform quality, excellent stability, better redissolution capability and clinic medicine application safety.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

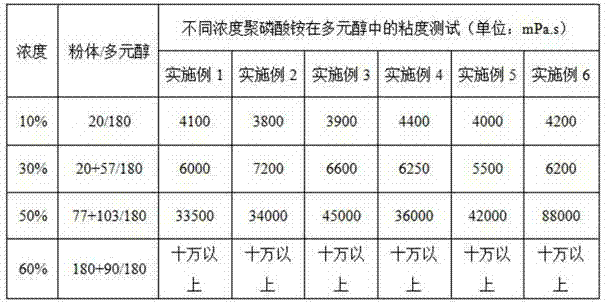

Preparation method of low-viscosity microcapsule-wrapped APP (ammonium polyphosphate)

ActiveCN103483873ALow viscosityExcellent fluidity and compatibilityPigment treatment with macromolecular organic compoundsPolyolefinAqueous solubility

The invention discloses a preparation method of low-viscosity microcapsule-wrapped APP. The method comprises the steps as follows: in a reaction kettle, a melamine formaldehyde resin pre-polymer and APP are dispersed in a solvent; a curing agent solution is dripped; after dripping, a backflow reaction is performed for 0.5-5 h; the temperature is decreased to 40-50 DEG C; an end-sealing agent is dripped; after dripping, a heat preservation reaction is performed for 0.5-3 h; the mixture is cooled to a room temperature; then the mixture is filtered, washed with a solved and pumped; a rake type drier is used; and the mixture is dried for 6-24 h under a pressure reduction condition, so that microcapsule-wrapped APP powder is obtained. Compared with un-wrapped APP, the microcapsule-wrapped polyphosphate powder has the characteristics of low viscosity and water solubility, excellent flowing property and compatibility, high-temperature soaking resistance, precipitation resistance, excellent electrical property and the like. The APP can be applied to high polymer materials such as polyolefin and the like and can also be applied to fabrics, epoxy and coatings.

Owner:PRESAFER QINGYUAN PHOSPHOR CHEM

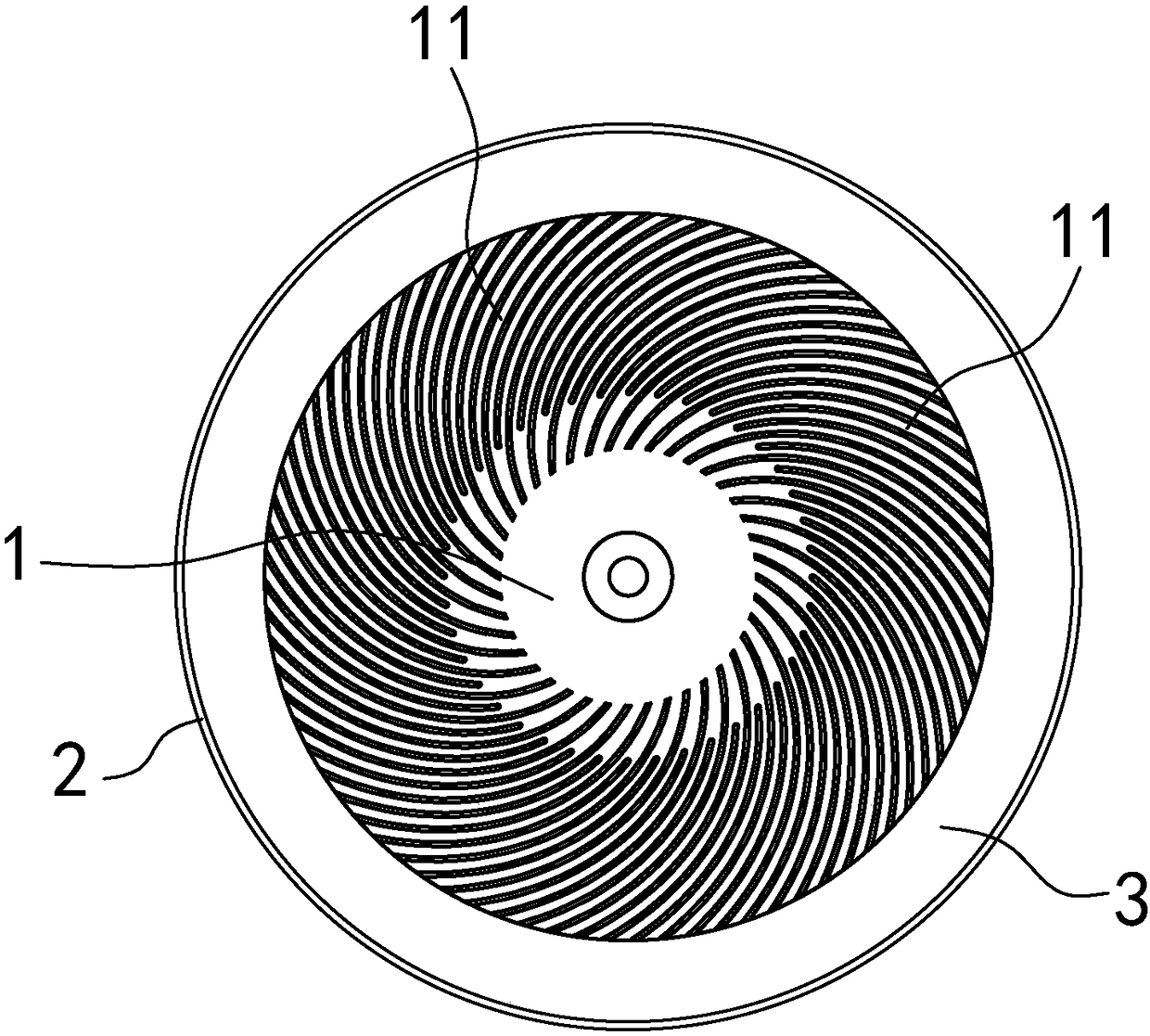

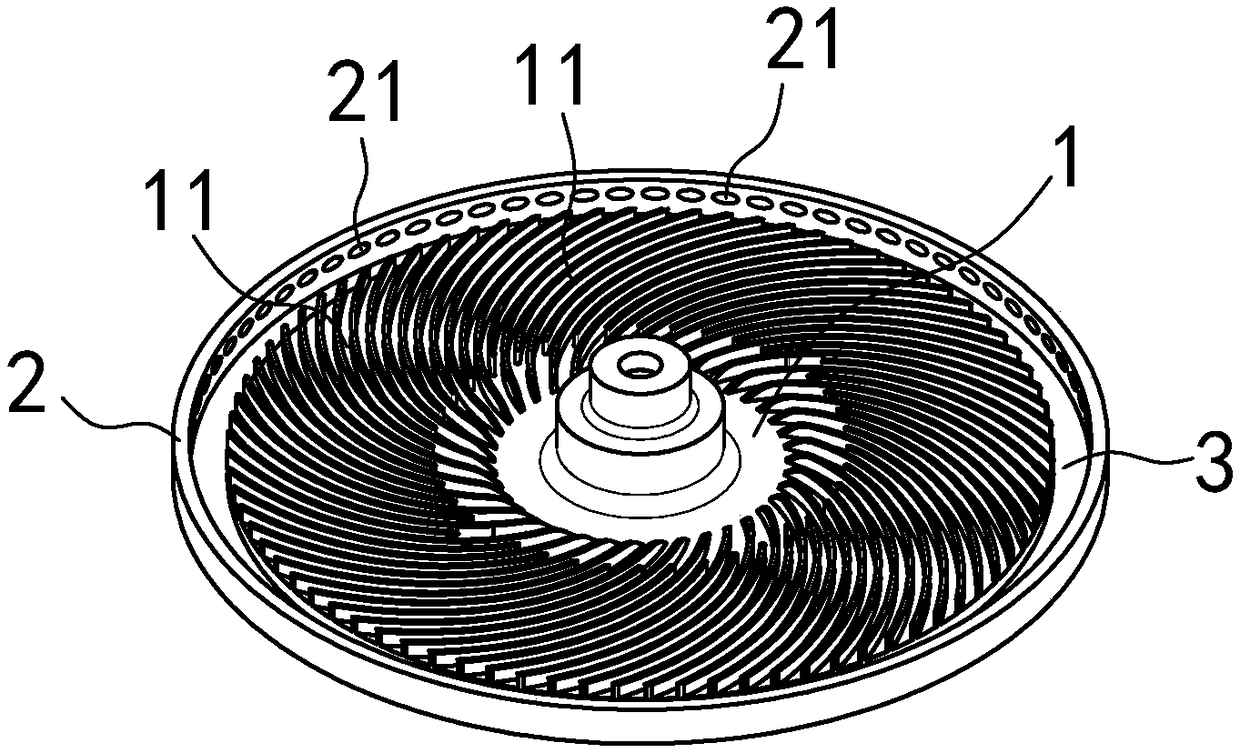

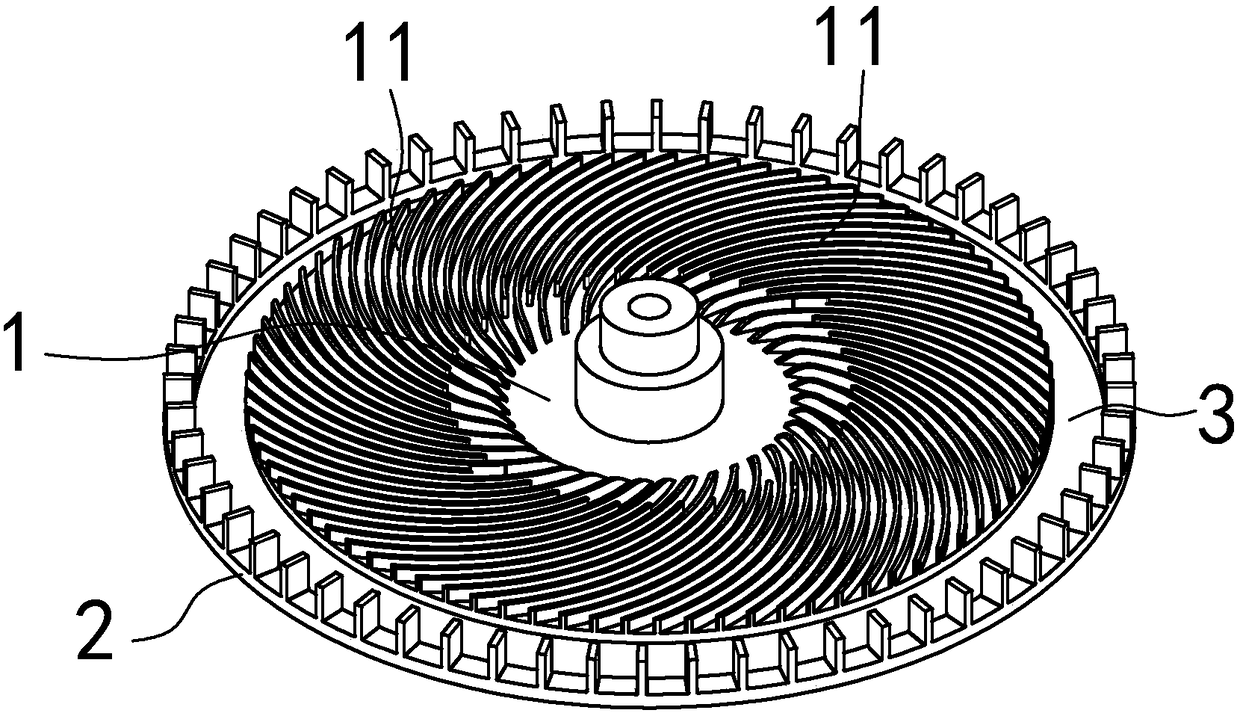

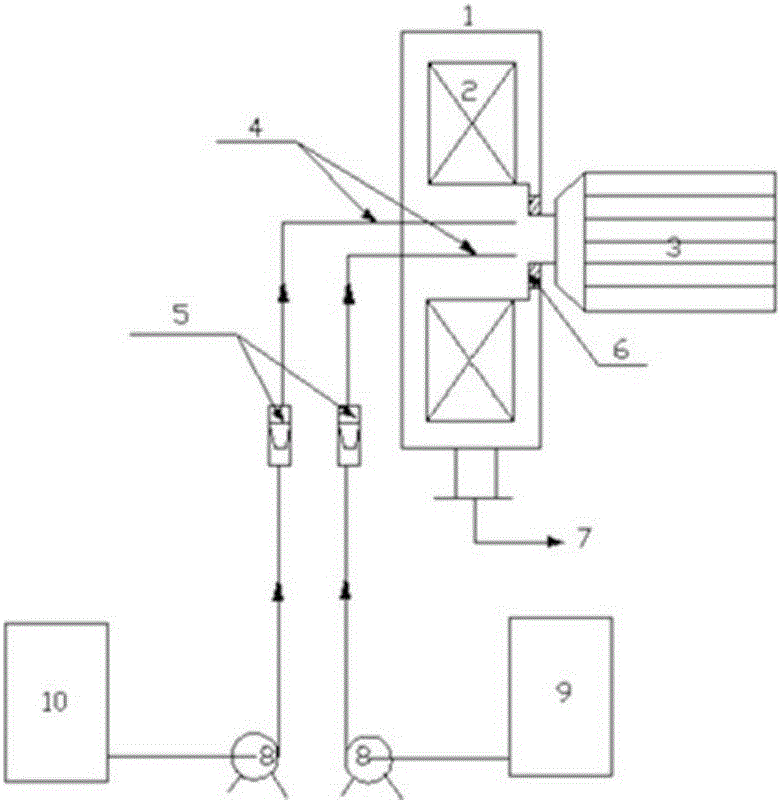

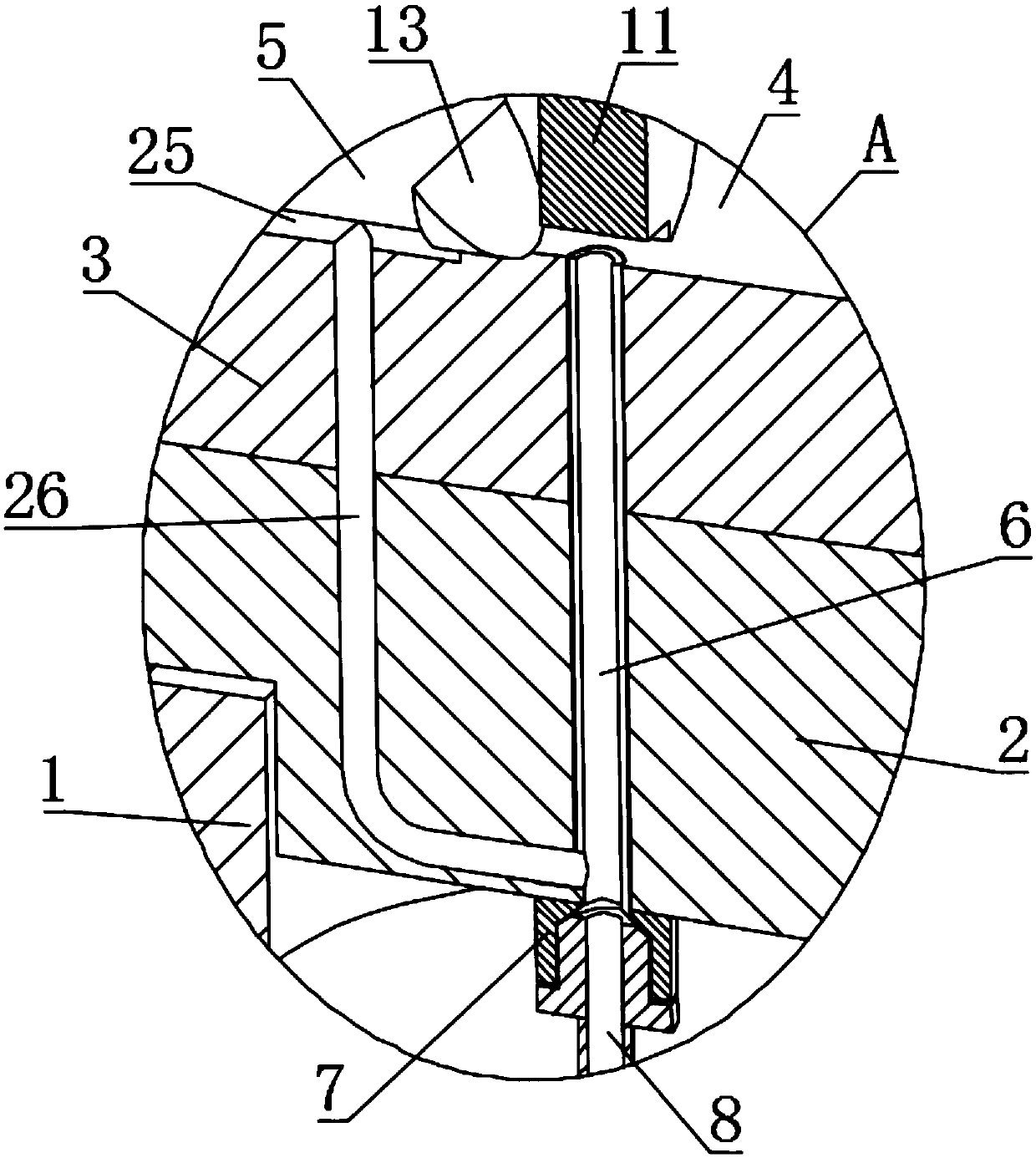

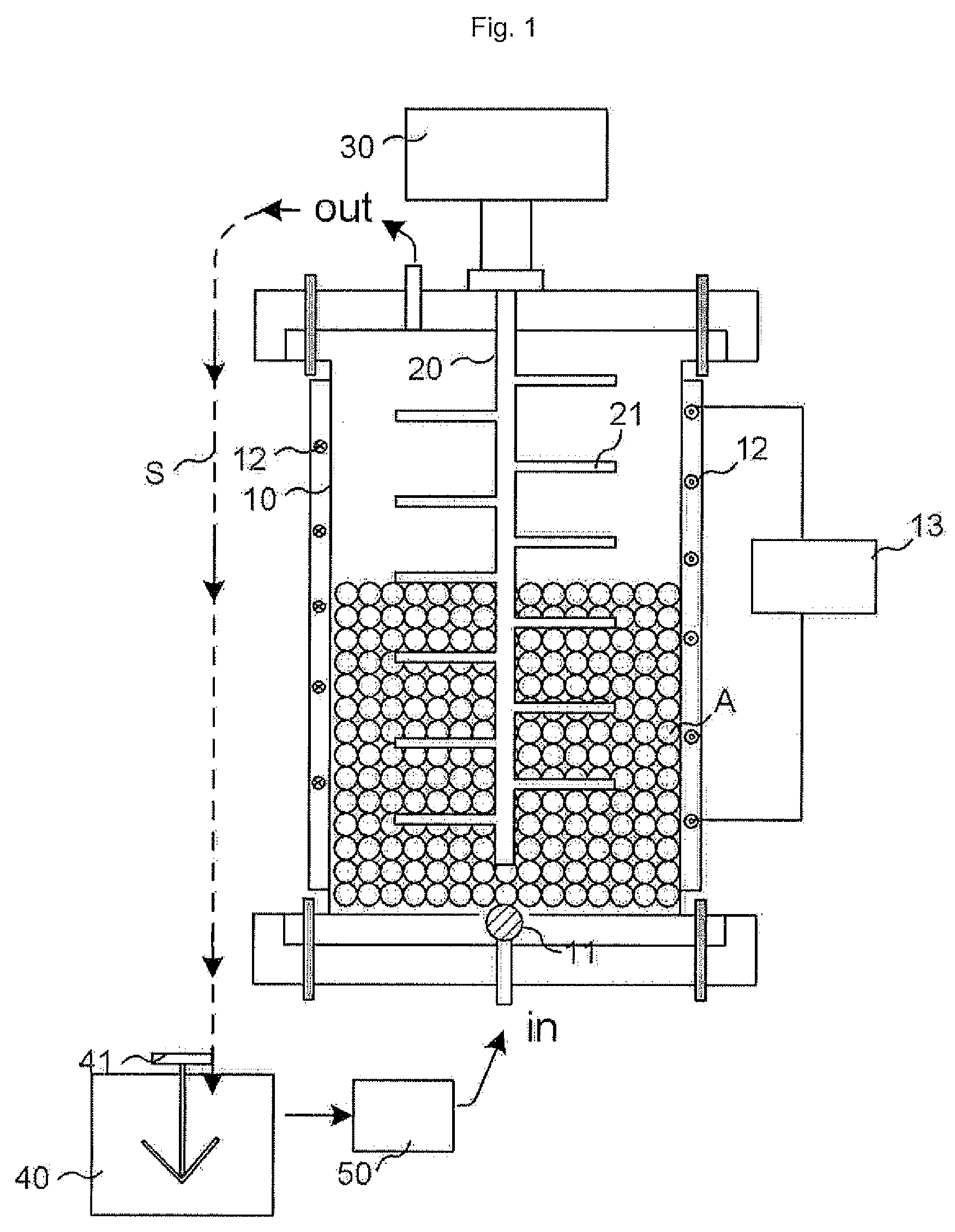

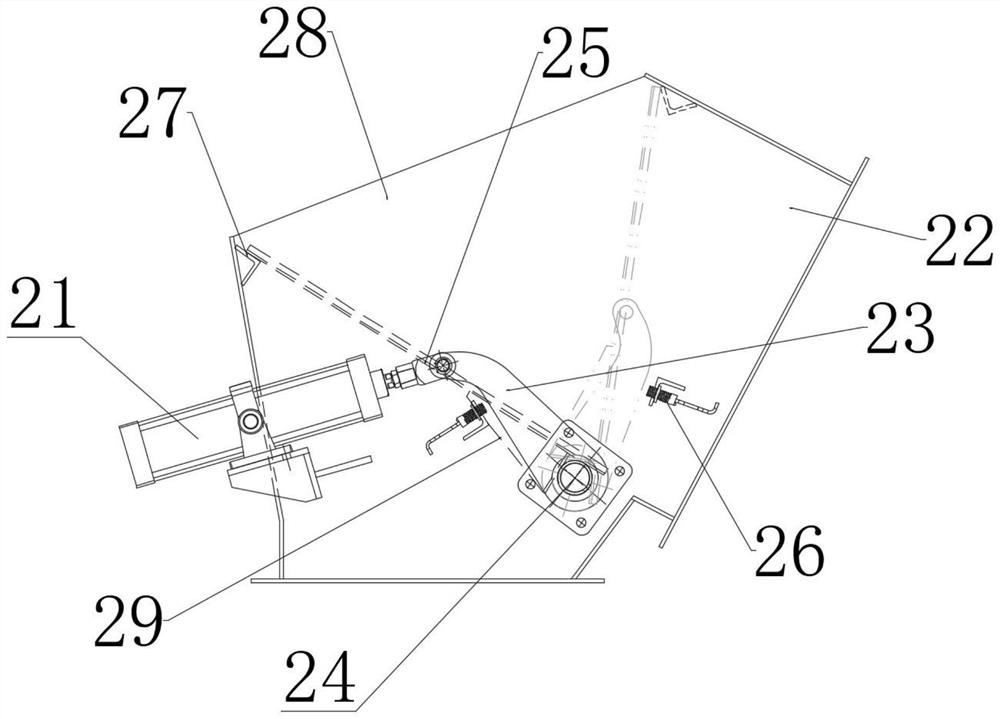

Centrifugal atomizing device

PendingCN108568358AIncrease speedSpeed does not need to be increasedMovable spraying apparatusWind fieldEngineering

The invention discloses a centrifugal atomizing device which comprises a centrifugal atomizing disc, wherein multiple diversion trenches are formed in the centrifugal atomizing disc. The centrifugal atomizing device is characterized in that a ring body is arranged on the outer side of the centrifugal atomizing disc; the ring body and the centrifugal atomizing disc are coaxial with each other and are rotationally arranged relative to each other; a spacing is formed between the ring body and the centrifugal atomizing disc in a radial direction; the centrifugal atomizing disc rotates at the periphery to form a positive wind field; the positive wind field rotates clockwise and anticlockwise around the center of the centrifugal atomizing disc; the ring body provides a reverse wind field betweenthe ring body and the centrifugal atomizing disc in an operating state; and the reverse wind field weakens or reverses the positive wind field, so that an accelerated wind zone is formed between thecentrifugal atomizing disc and the ring body. Therefore, the relative velocity of liquid drops and air is increased, and the aim of multiplying the atomizing effect is achieved.

Owner:SUZHOU EAVISION ROBOTIC TECH CO LTD

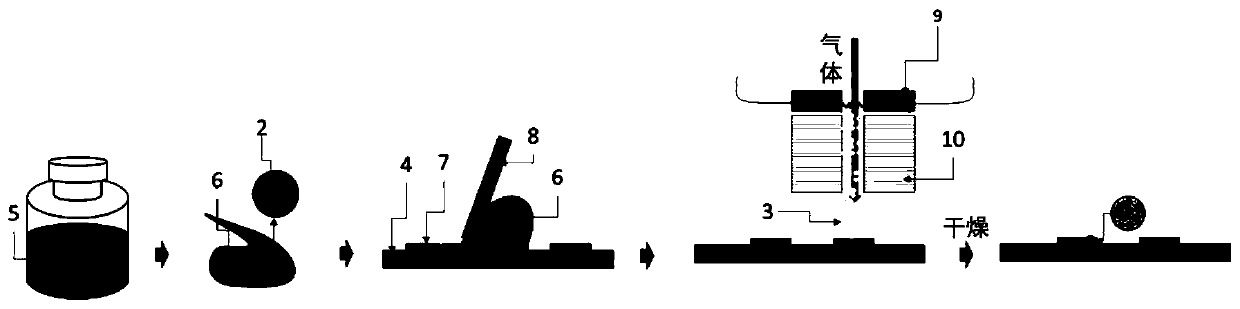

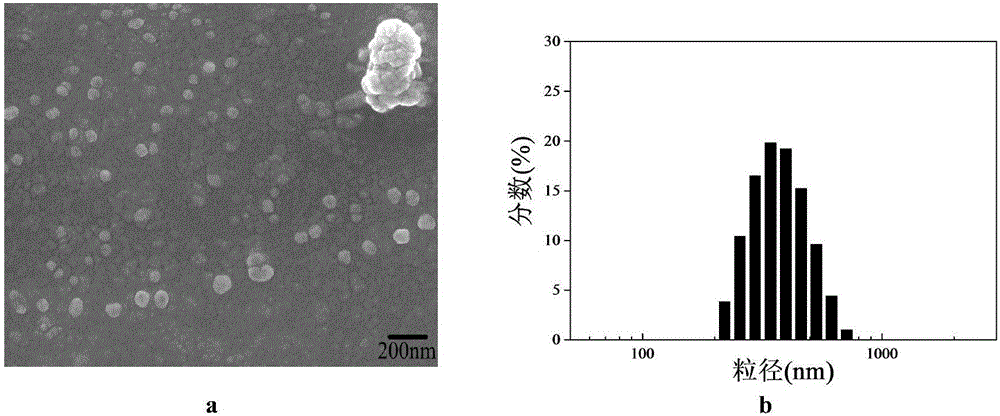

Preparation method of adriamycin nano-drug particles

InactiveCN106265542AOvercome uniformity issuesOvercoming inadequaciesPowder deliveryOrganic active ingredientsDrugs solutionFreeze-drying

The invention discloses a preparation method of adriamycin nano-drug particles, belongs to the field of drug preparation and provides an adriamycin containing solution and a proper anti-solvent. The adriamycin containing solution and the anti-solvent are put in a first storage tank for a drug solution and a second storage tank for the anti-solvent; the two kinds of liquid are conveyed out through a pump, flow through a flowmeter, enter a supergravity reactor at the same time and are sprayed to the rotating inner edge of a packing layer, so that adriamycin is recrystallized out through an anti-solvent precipitation crystallization method; adriamycin suspension liquid is collected, and adriamycin nano-drug powder is obtained after dialysis and freeze-drying. By the adoption of the method, the nanoscale adriamycin drug particles with a controllable average particle size and narrow particle size distribution can be obtained by using different surfactants, regulating the volume flow ratio of the two kinds of liquid, changing motor frequency and the like.

Owner:BEIJING UNIV OF CHEM TECH

Method for synthesizing ZSM-35 molecular sieve by composite template agent

ActiveCN108147426AGood water solubilityImprove the crystallization effectFerrierite aluminosilicate zeoliteNanotechnologyMolecular sieveSodium aluminate

The invention relates to a method for synthesizing a ZSM-35 molecular sieve by a composite template agent. The method comprises the following steps: dissolving sodium metaaluminate or sodium aluminateand alkali into desalted water to prepare a sodium metaaluminate-alkali aqueous solution or a sodium aluminate-alkali aqueous solution; adding hexamethylene imine into cyclohexane to prepare a composite template agent, adding the composite template agent into silicon sol, completely stirring, dropwise adding the sodium metaaluminate-alkali aqueous solution or the sodium aluminate-alkali aqueous solution until reaching a thick point, increasing the stirring speed, opening gel and slowly adding the residual sodium metaaluminate-alkali aqueous solution or the sodium aluminate-alkali aqueous solution; adding the ZSM-35 molecular sieve, stirring, gelatinizing and crystallizing, and synthesizing a high-nanoscale ZSM-35 molecular sieve.

Owner:PETROCHINA CO LTD

Resin-coated ferrite carrier for electrophotographic developer and electrophotographic developer using the resin-coated ferrite carrier

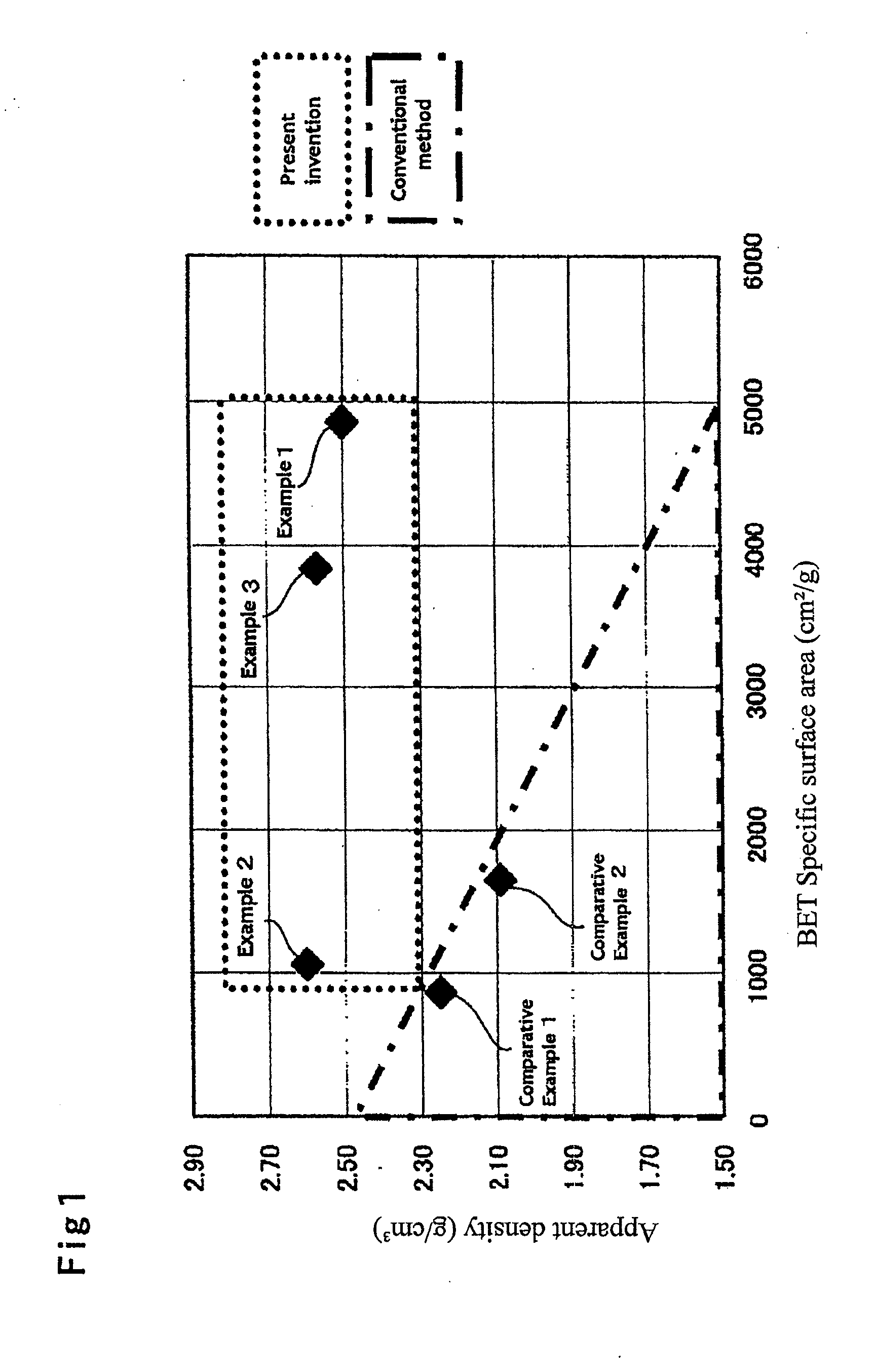

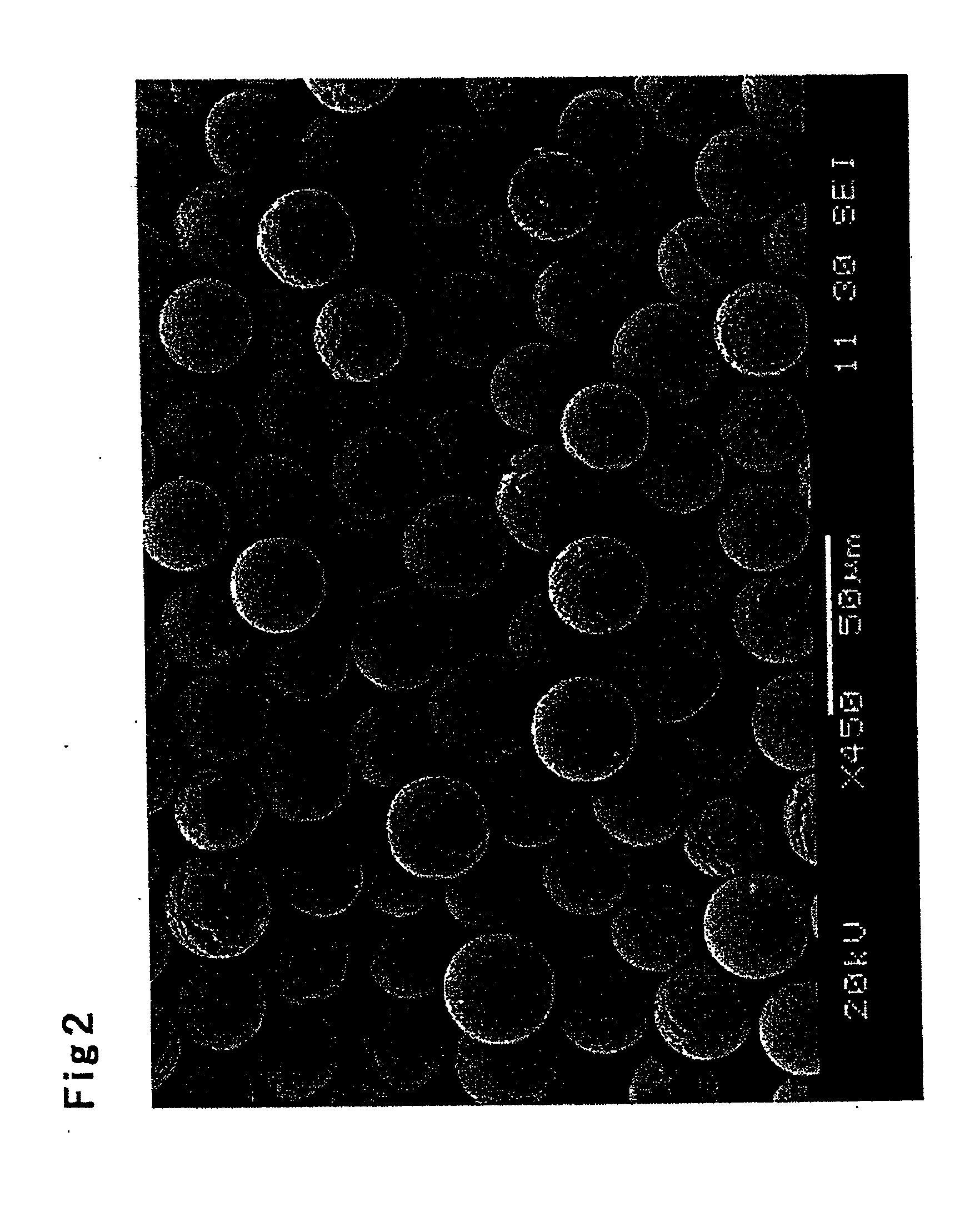

ActiveUS20080241729A1Small sizeGood sphericityPigmenting treatmentIron compoundsApparent densityEngineering

Employed are a resin-coated ferrite carrier for an electrophotographic developer including a ferrite carrier core material having a BET specific surface area of 900 to 5,000 cm2 / g and an apparent density of 2.30 to 2.80 g / cm3, and the electrophotographic developer using this resin-coated ferrite carrier.

Owner:POWDERTECH

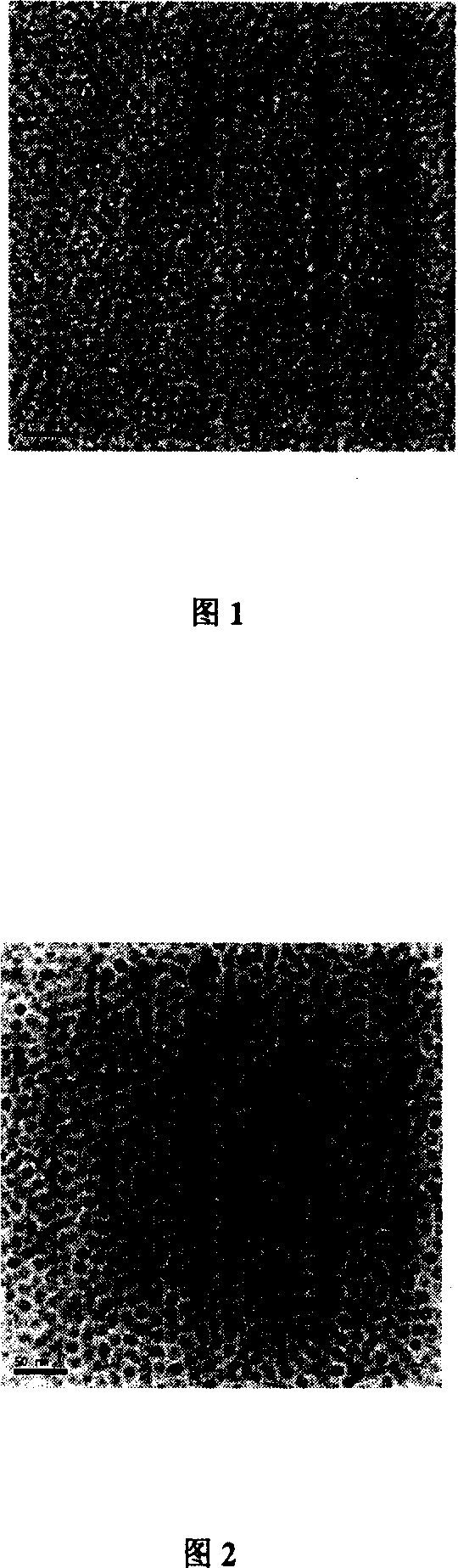

Preparing process of monodisperse nano metal oxide particle

InactiveCN1986418AParticle size controllableIncrease unit outputDispersed mediaMetal oxide nanoparticles

The process of preparing monodisperse nanometer metal oxide particle includes the following steps: 1. preparing solution with surfactant 0.25-1 weight portions and dispersing medium 2-10 weight portions, adding metal oxide to the concentration of 0.05-0.5 mol / L, and heating in the temperature raising rate of 3-6 deg.c / min to the nucleation temperature 150-300 deg.c to react for 0.5-3.5 hr; and 2. heating to the dispersing medium boiling temperature 210-370 deg.c in the temperature raising rate of 5-12 deg.c / min for controlling the growth and reflux reaction in boiling state for 0.5-5 hr to form the monodisperse nanometer metal oxide particle. The present invention realizes the preparation of monodisperse nanometer particle, and may be used in preparing different kinds of nanometer metal oxide particle.

Owner:TIANJIN UNIV

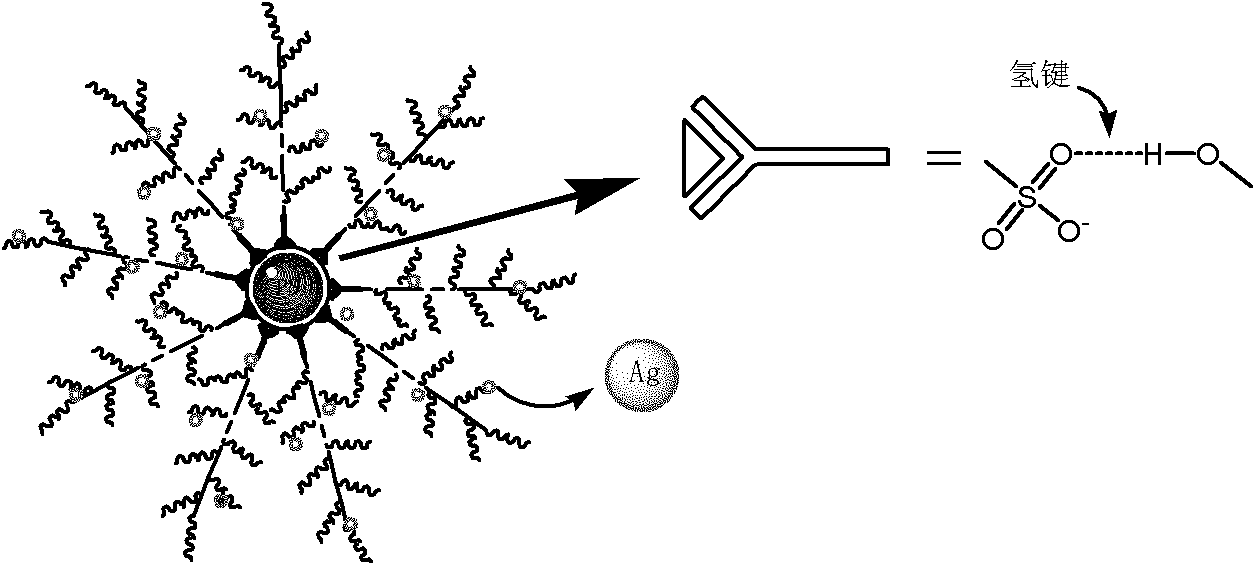

Reduced nano-grade silver antibiotic finishing agent containing spherical polymer brushes, and preparation method thereof

The invention relates to a reduced nano-grade silver antibiotic finishing agent containing spherical polymer brushes, and a preparation method thereof. The spherical colloidal particles are prepared through steps that: nano-grade polystyrene microspheres are prepared through emulsion polymerization; the polystyrene microspheres are adopted as cores, and styrene sulfonic acid (SS) is further initiated, such that transition layers are formed; a photo-initiator 2-hydroxyl-2-methyl-1-phenyl-1-acetone (HMPP) is firmly adhered onto the polystyrene sulfonic acid layers under the effect of hydrogen bonds with which the particle sizes of the colloidal particles can be controlled by temperatures; polyethylene glycol methacrylate (PEGMA) is added, ultraviolet light radiation is carried out, such that polymerization is initiated, and shells are formed. The brush-shaped shells can be used for reducing and immobilizing nano-grade silver particles. The nano-grade silver particles have a narrow particle size distribution of 710nm. More importantly, the colloidal particles have good stability, such that the nano-grade silver particles can stably exist for a long time, and the antibiotic effect is good and long-lasting.

Owner:泉州红瑞兴纺织有限公司

Preparation of environment-protective glass fibre flame-retardant nylon flame retardant

ActiveCN101376720AComply with processing conditionsParticle surface is smoothPolyesterPolymer science

The invention discloses a preparation method of a flame retardant of environment-protective fiberglass retardant nylon. At first, diammonium phosphate, phosphorus pentoxide, carbamide and a multi-amino group compound are added into a kneader according to a proportion and are reacted for 4 to 12 hours under an ammonia atmosphere to obtain modified APP; then the APP is dispersed in solvent and cation surface activator is added to carry out ion exchange reaction with cyanamide salt for 1 to 10 hours under the situations of micro-boiling and circumfluence of the solvent; after the reaction is finished, the nitrogen-phosphor flame retardant used for nylon is obtained after the reagent is cooled, filtered, washed and dried. The flame retardant prepared by the invention has more uniform chemical components, better thermal stability, more excellent compatibility with nylon as well as more excellent flame retardant performance and more reasonable price. No corrosive and poisonous compounds are generated during the use process of the flame retardant. The product prepared by the invention is mainly used as the flame retardant of fiberglass reinforced retardant nylon and fiberglass reinforced retardant polyester.

Owner:GUANGDONG JUSHI CHEM CO LTD

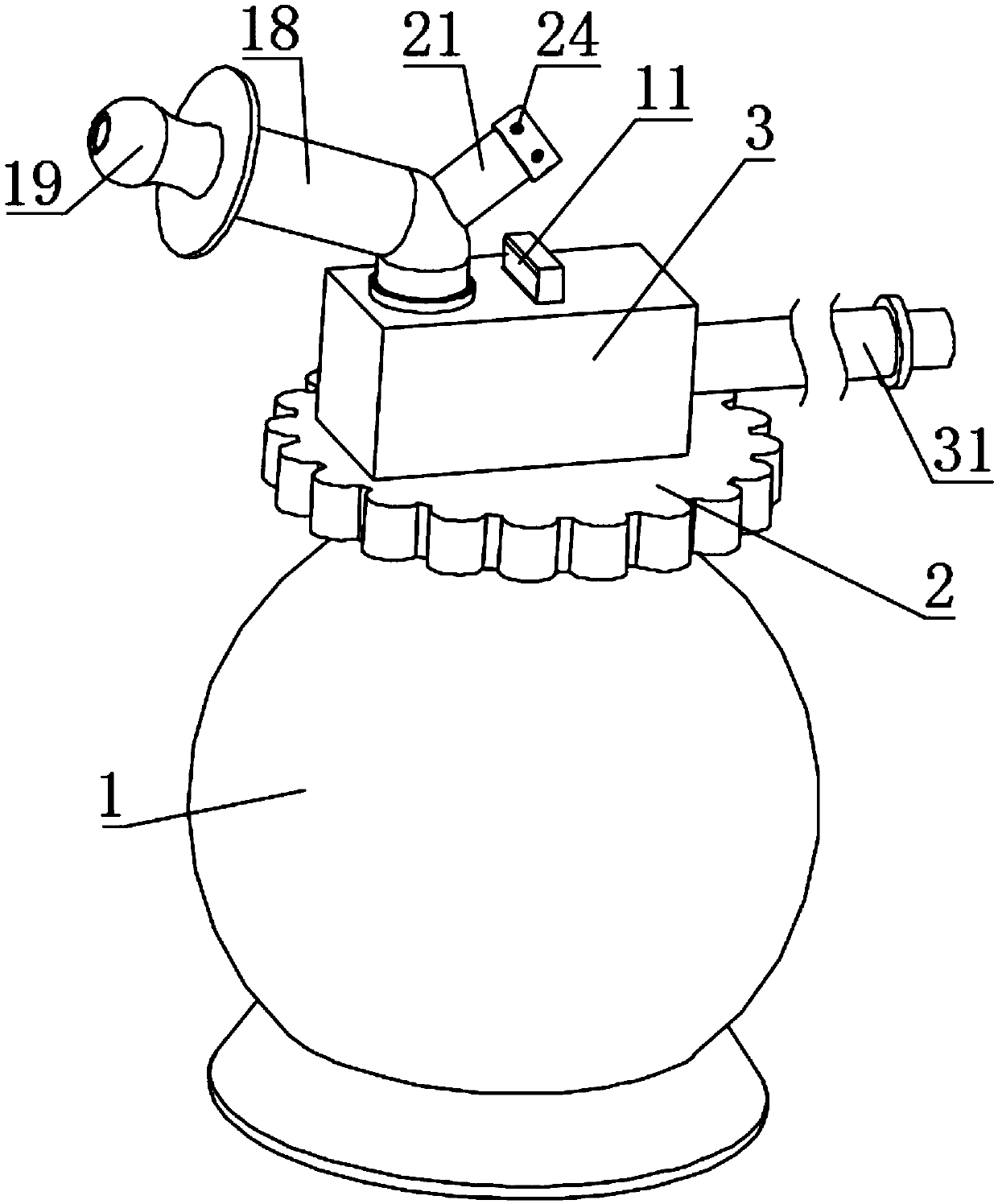

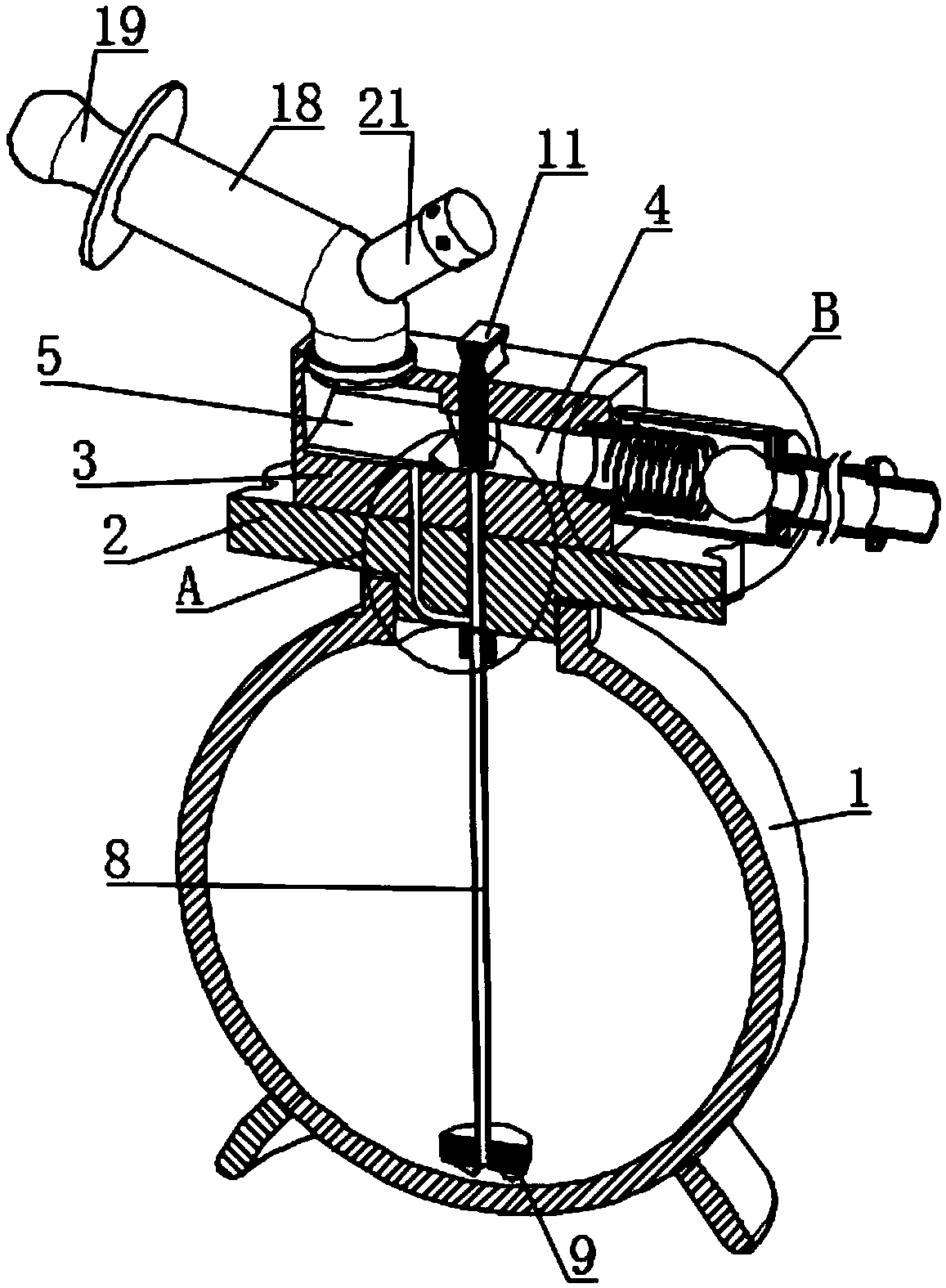

Novel nebulizer with reflux structure

InactiveCN109513076ALarge particle sizeParticle size andMedical devicesMedical atomisersRefluxNebulizer

The invention discloses a novel nebulizer with a reflux structure. The novel nebulizer comprises a bottle body for holding liquid medicine, the upper side of the bottle body is connected to a seal cover and a fixed block, the fixed block is internally provided with an airflow channel and a nebulizing chamber, a liquid accumulating slot is disposed at a bottom middle part of the nebulizing chamber,a reflux pipe is disposed under the liquid accumulating slot, a connecting pipe is movably inserted on the nebulizing chamber, the seal cover is internally equipped with a drain pipe, the upper end of the drain pipe is communicated with the airflow channel, one side of the drain pipe is equipped with an impact plate, and the lower end of a regulation block is provided with a flow velocity port. The novel nebulizer provided by the invention regulates the nebulization effect through up-and-down sliding of the regulation block, also is equipped with the reflux structure and the like, so that nolarge amount of liquid accumulates in the nebulizing chamber, connecting pipe and other cavities communicated with the mouth, the risk of mis-suction of liquid cannot be caused, and while the drug application precision is improved, the waste of liquid medicine is also reduced.

Owner:黄梅

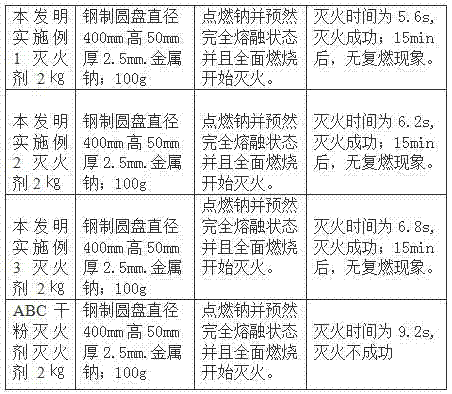

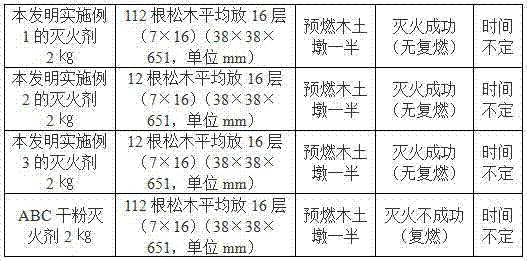

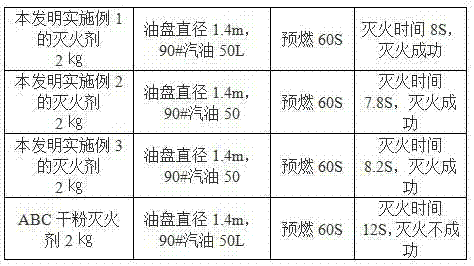

Organic/inorganic composite microcapsule fire-extinguishing agent and preparation method thereof

The invention discloses an organic / inorganic composite microcapsule fire-extinguishing agent, and belongs to the field of fire-fighting materials. The organic / inorganic composite microcapsule fire-extinguishing agent comprises the following components in percentage by weight: 15 to 25 percent of monoammonium phosphate, 60 to 75 percent of ammonium sulfate, 0.5 to 1.5 percent of urea, 1 to 2.5 percent of potassium chloride, 4 to 9 percent of sodium silicate, 0.1 to 0.5 percent of fatty acid zinc, 0.2 to 0.5 percent of fatty acid magnesium and 1.5 to 2 percent of methyl silicane, wherein the sum of the components is 100 percent. According to the organic / inorganic composite microcapsule fire-extinguishing agent, grain diameters of the components are controlled, and the components are microencapsulated by a special process to prepare the fire-extinguishing agent, so that the fire-extinguishing agent cannot deteriorate after being used for 7 years and is inert at the temperature of less than 60 DEG C, and the standard of a product is applicable to international standard organization (ISO), European norm (EN) 615 and national standard (GB) 4066.2-2004; and the fire-extinguishing agent contains nutrient elements such as N, P, K and B which are required by plants and is absolutely harmless to human and animals, and microbes can be degraded within three days, so the organic / inorganic composite microcapsule fire-extinguishing agent is the most ideal 'reen' fire-extinguishing agent which is environment-friendly and low in cost and does not have carbon emission, is efficient in fire-extinguishing performance, wide in fire-extinguishing range and low in production cost and has high economic and social benefits.

Owner:姜发扬

Preparation method of antimony pentoxide composite powder

InactiveCN104355333AImprove stabilityImprove flame retardant performanceAntimony oxides/hydroxides/oxyacidsPhosphateCreatinol phosphate

The invention relates to a preparation method of an antimony pentoxide composite powder. The preparation method comprises the following steps: firstly, antimony trioxide is taken for refining; then the refined antimony trioxide dry powder is added into water, then creatinol-o-phosphate as a stabilizer and oxydol are added for oxidation reflux reaction, after the reaction, a reacting liquid is taken for dialysis for 2 to 3 times, redundant creation o-phosphate is removed, and an antimony pentoxide hydrosol is prepared; finally, the prepared antimony pentoxide hydrosol is added with zeolite powder, the mixture is stirred and then left to stand, precipitate is obtained through centrifugation, and the precipitate is filtered and dried so as to obtain the antimony pentoxide composite powder. The preparation method provided by the invention uses the creatinol-o-phosphate as the stabilizer, and the creatinol-o-phosphate contains a plurality of hydroxies and two inflaming retarding elements N and P, so that the stabilizing effect is good, the flame-retardant effect of the colloid of antimony pentoxide is improved, a zeolite powder is adopted for adsorbing the colloid of antimony pentoxide, so as to prepare the antimony pentoxide-zeolite powder composite powder, during the preparing process, the problem of much loss of antimony pentoxide dry powder during the drying process caused by relatively fine antimony pentoxide dry powder can be solved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

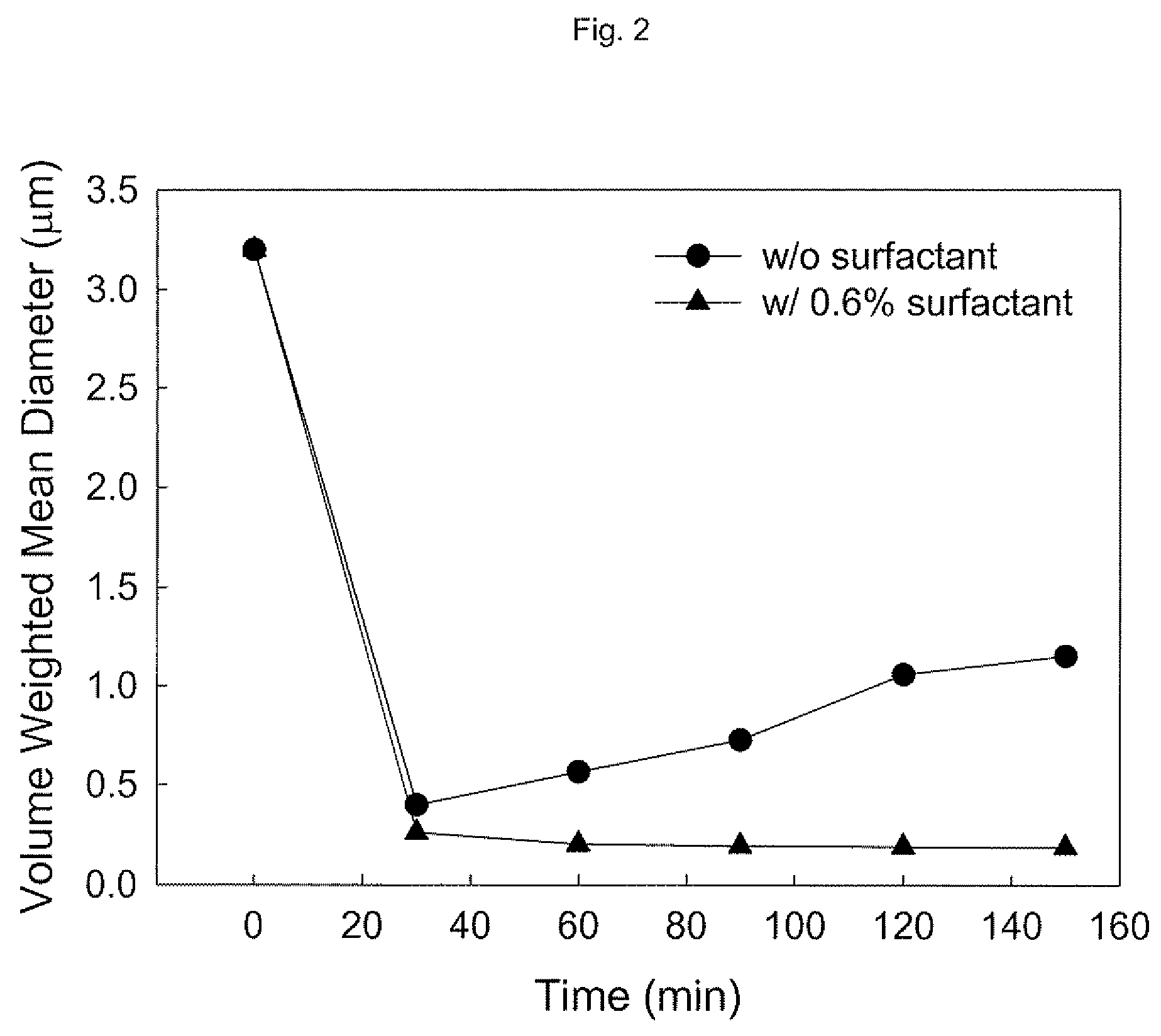

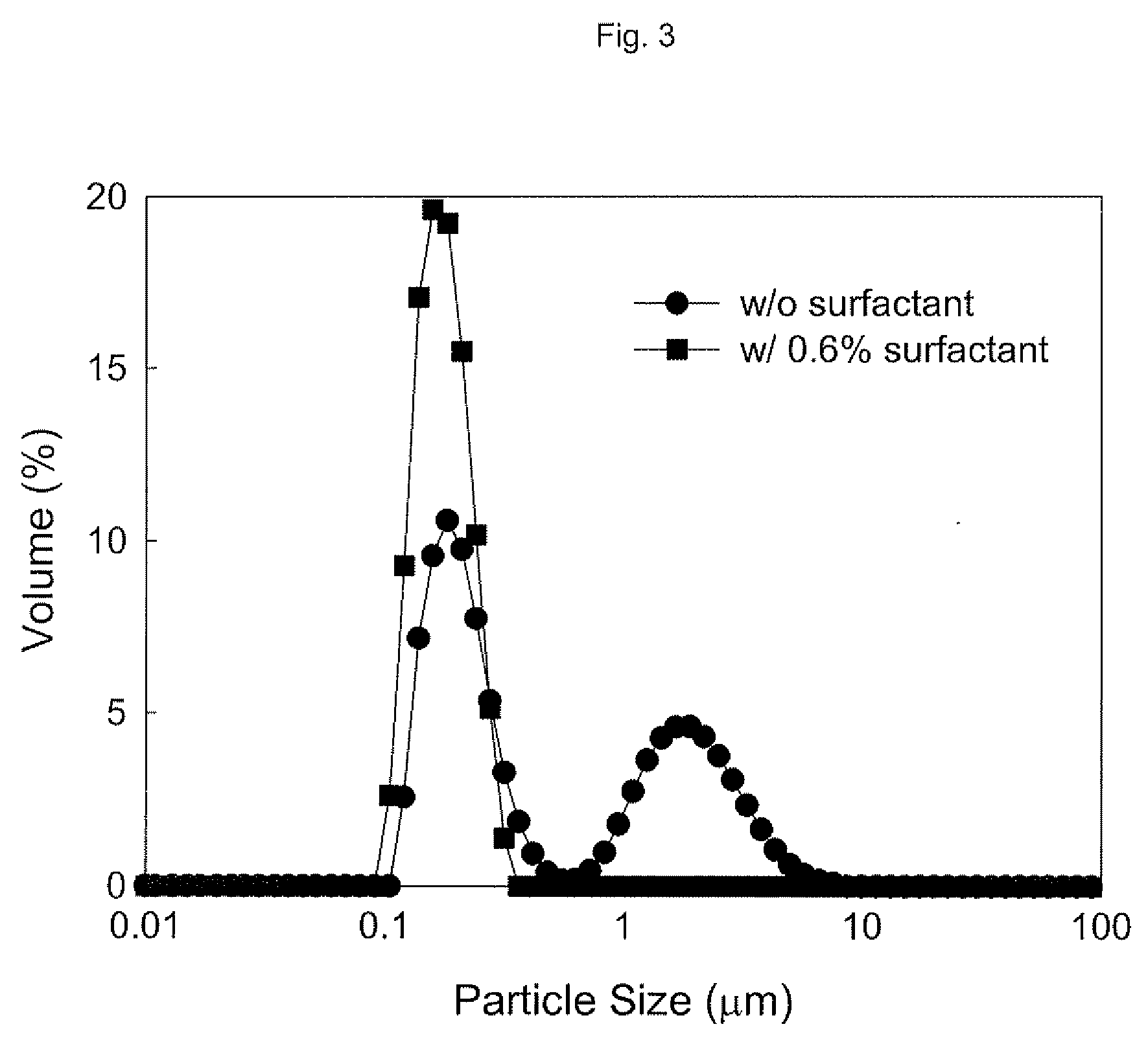

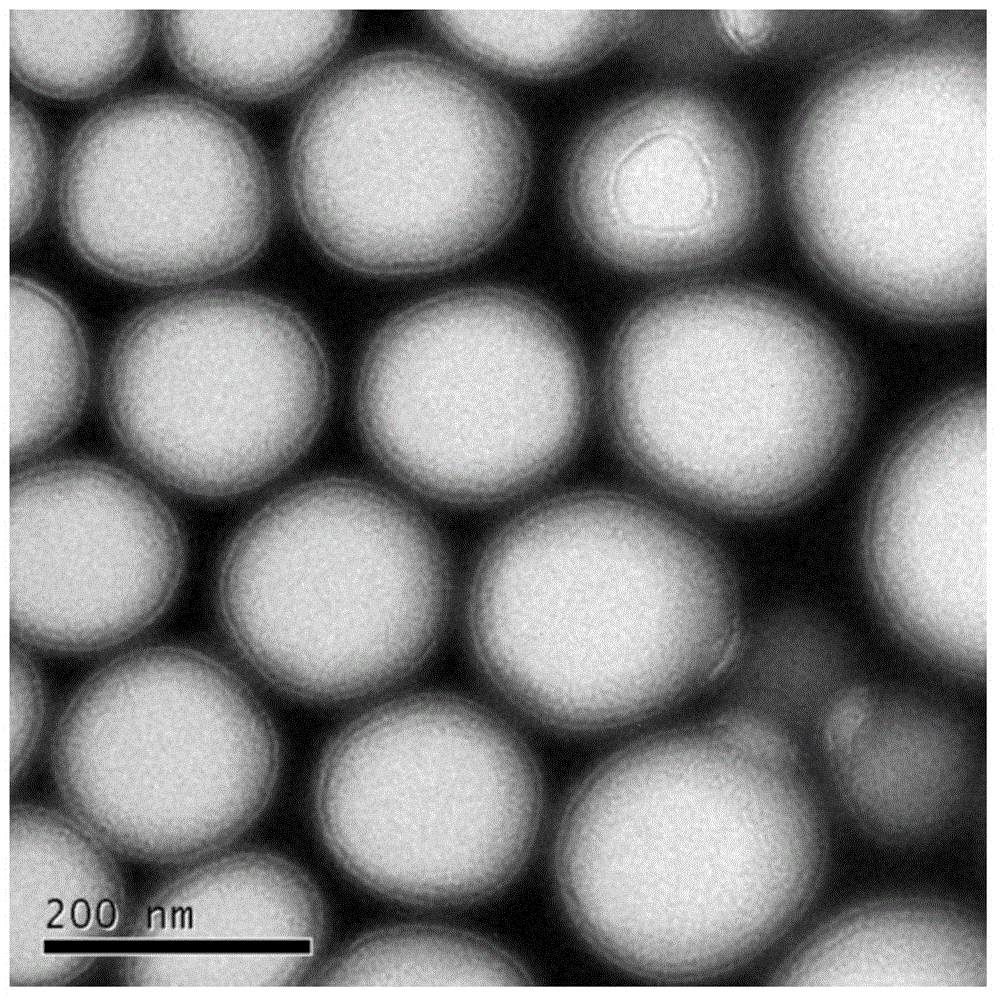

Fabrication Method of CaCO3 Nanoparticles Using Beads Milling

ActiveUS20100048741A1Simply producedLow costMaterial nanotechnologyPigmenting treatmentNanometreMicrometer

The present invention relates to a method for fabricating calcium carbonate nanoparticles dispersed in water from ground calcium carbonate of micrometer (μm) order using beads milling. More particularly, the present invention relates to a method for fabricating calcium carbonate nanoparticles dispersed in water by which a complex aqueous slurry comprising coarse ground calcium carbonate having an average particle size of several micrometers (μm) and a surfactant is subjected to beads milling, such that grinding and dispersion in water of the ground calcium carbonate occur simultaneously, and the resultant calcium carbonate nanoparticles have an average particle size of 10-100 nm and a unimodal clustering distribution.

Owner:KOREA INST OF GEOSCI & MINERAL RESOURCES

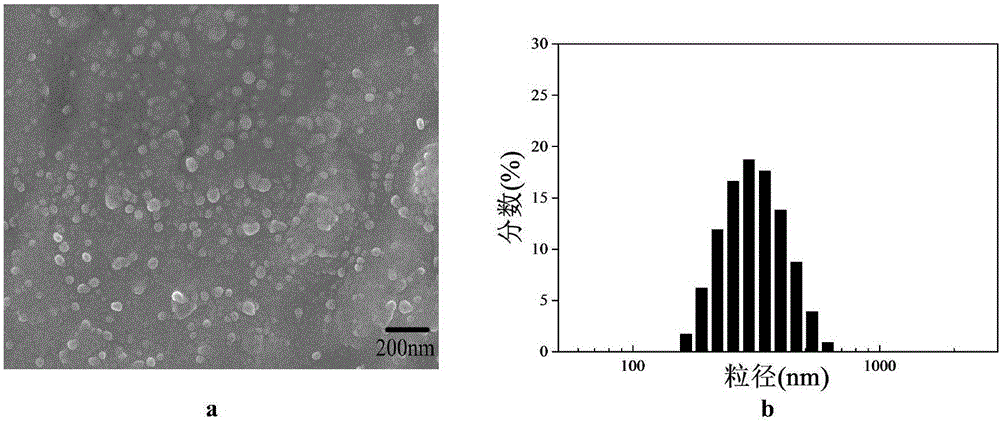

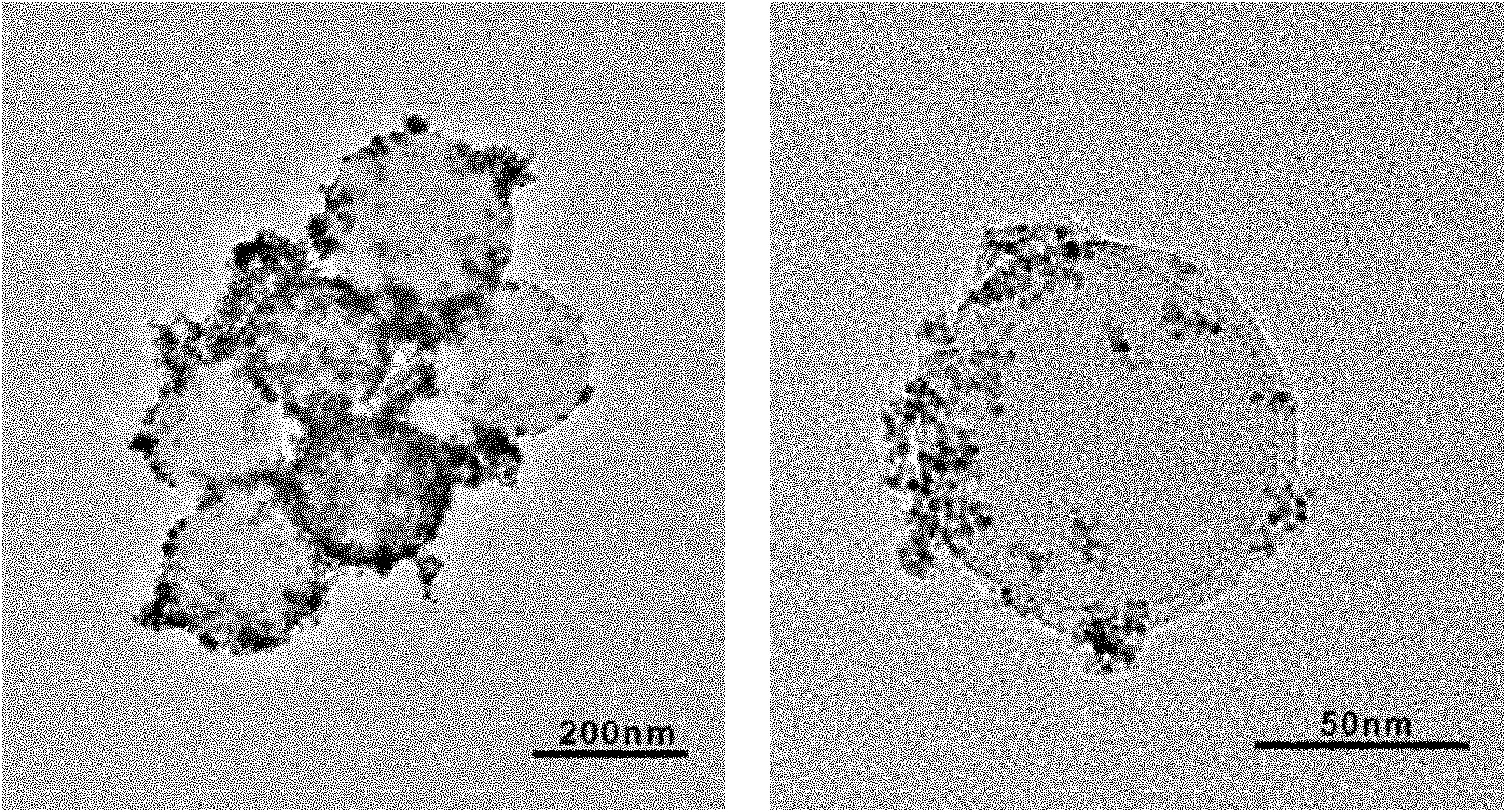

PEG-PLGA encapsulated hemoglobin

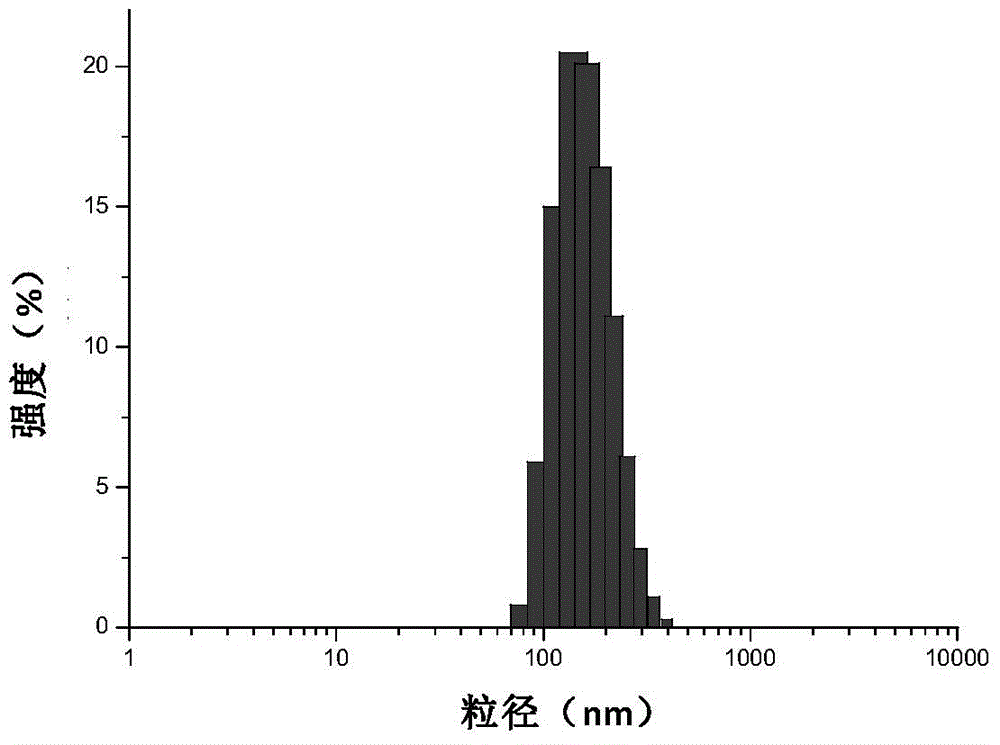

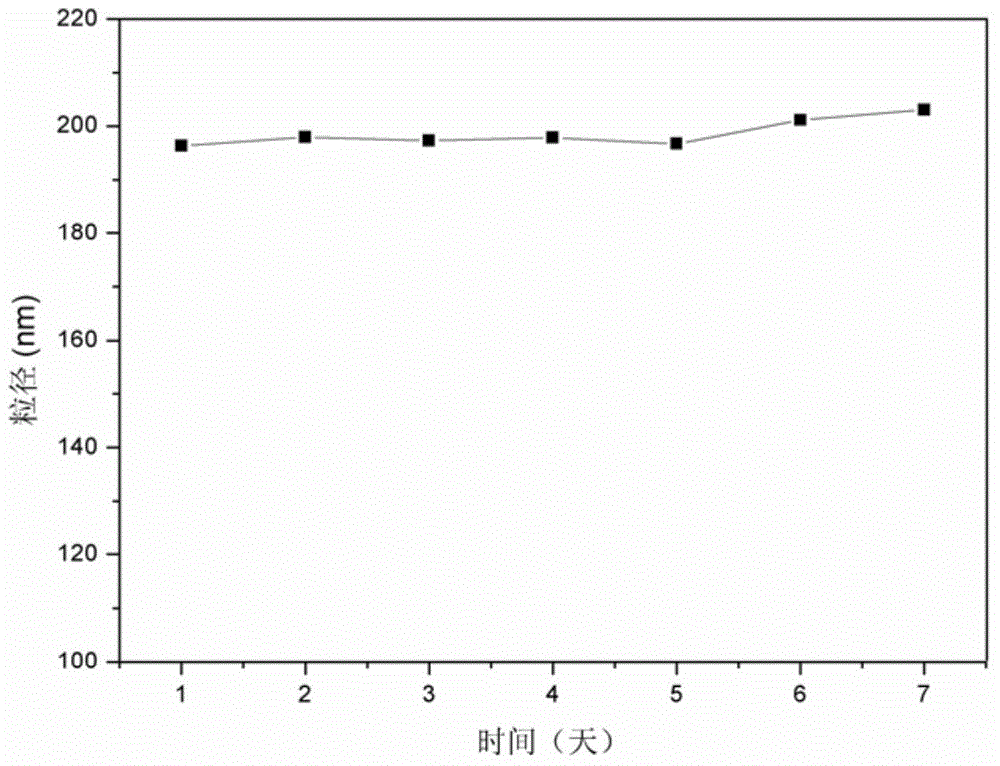

ActiveCN104644613AParticle size andUniform particle size distributionPeptide/protein ingredientsAntinoxious agentsLactideWhole body

The invention discloses hemoglobin oxygen carrier-PEG-PLGA encapsulated hemoglobin. The PEG-PLGA encapsulated hemoglobin is obtained by encapsulating the hemoglobin with polyethylene glycol-poly(lactide-co-glycolide) (PEG-PLGA) nanoparticles. The hemoglobin is uniform in particle size distribution, good in dispersibility and high in oxygen appetency and has good oxygen supply effect and can be used for the system with general or partial anoxia or the system needing in vitro oxygen supply. The hemoglobin oxygen carrier-PEG-PLGA encapsulated hemoglobin plays an important role in the medical field when serving as a blood substitute and has a broad application prospect.

Owner:ACADEMY OF MILITARY MEDICAL SCI

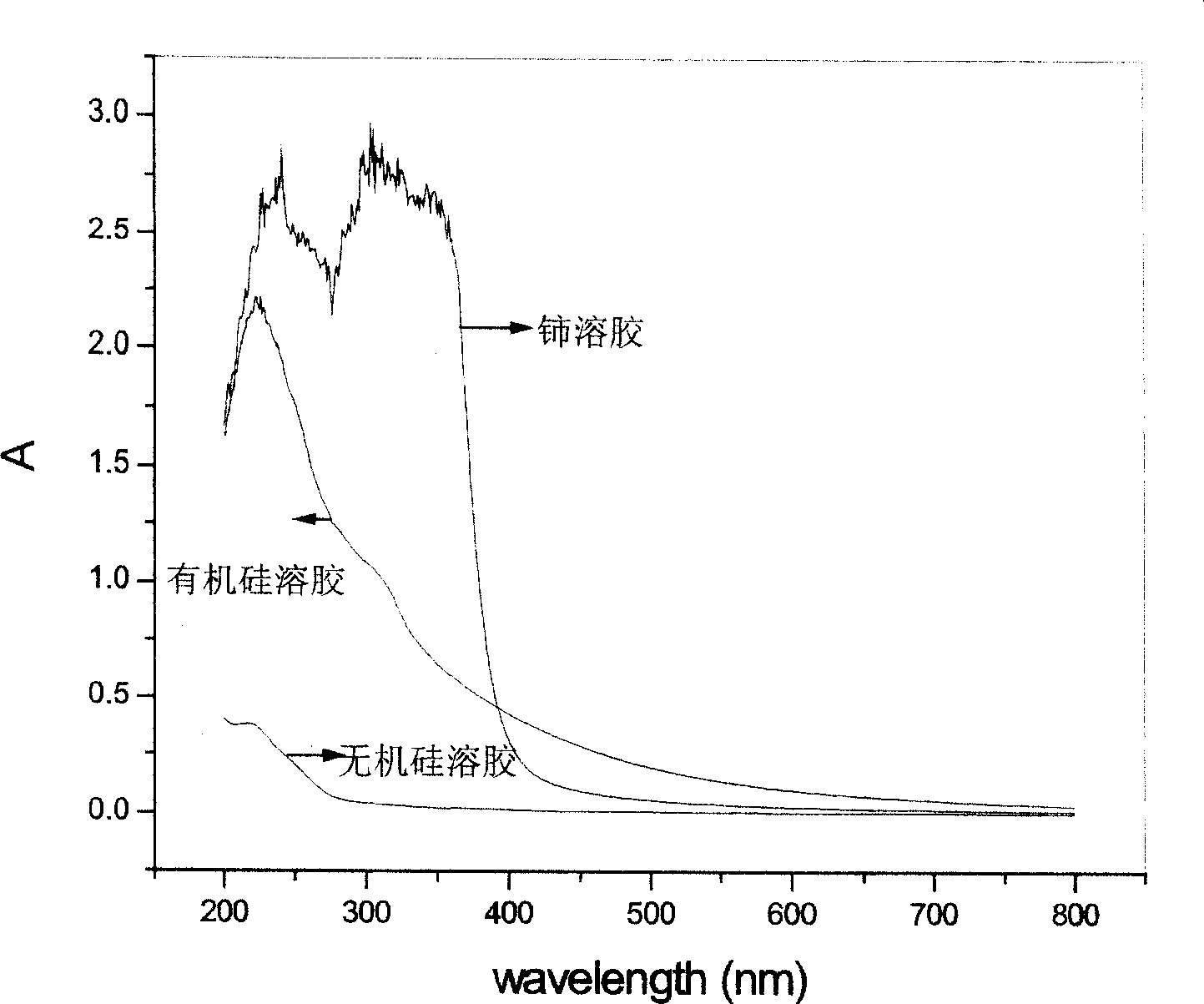

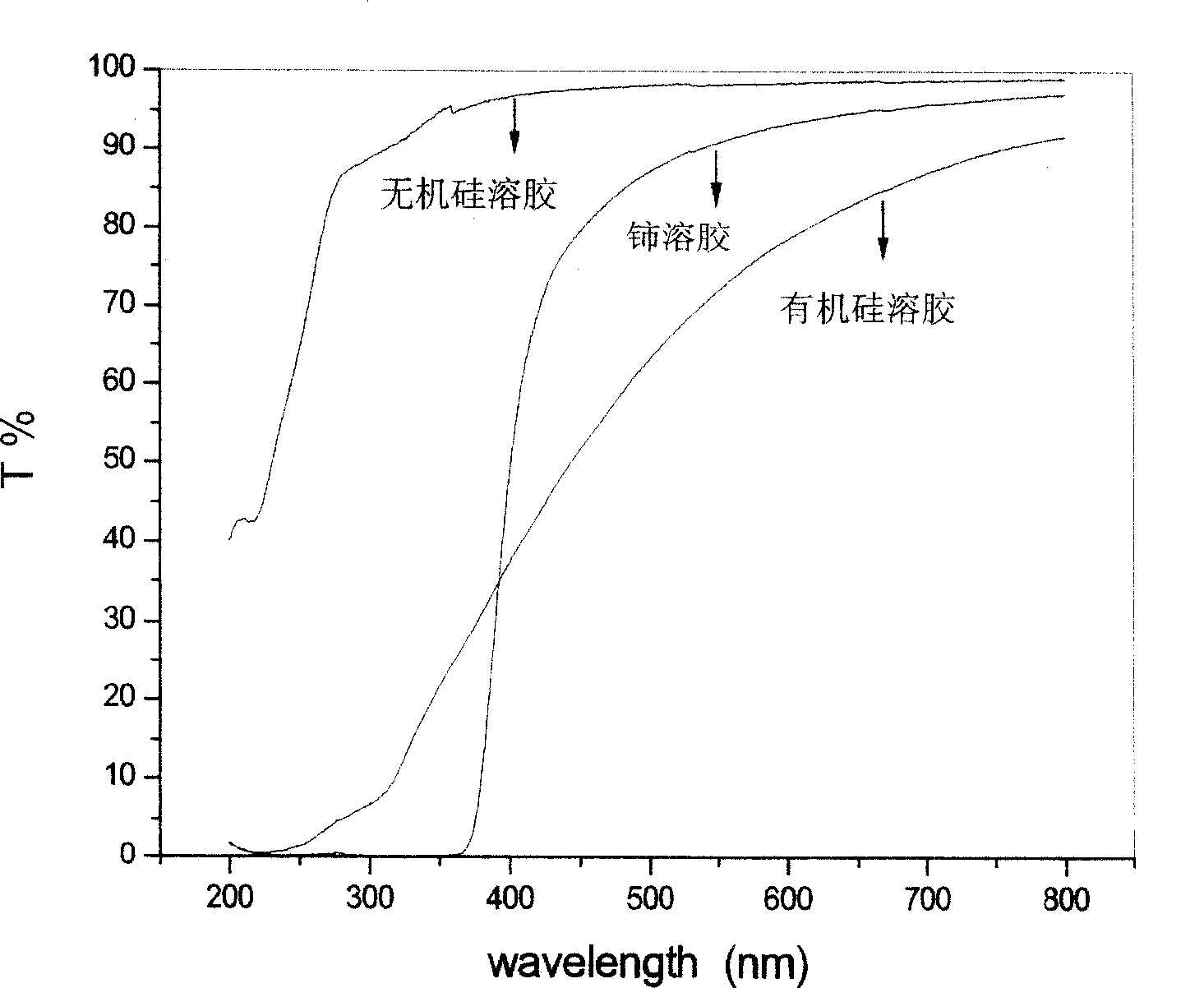

Rare earth composite silicasol capable of repressing rice absorbing heavy metal

ActiveCN100469249CIncrease concentrationImprove stabilityPlant growth regulatorsBiocideRare-earth elementNano silicon

The invention discloses a nano composite silicasol doped with rare-earth element, which comprises nano silicon dioxde collosol and rare-earth oxide collosol, wherein the content of the rare-earth elements is 0.01-1 wt%. The nano composite silicasol can be synthesized under rather low temperature and normal pressure.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Method for refining and grading lead powder

ActiveCN102324499AScale adjustableSingle-stage grading with high production efficiencyLead-acid accumulator electrodesAcid waterMetallurgy

The invention discloses a method for refining and grading lead powder. The method comprises the following steps of: crushing a lead pig to obtain lead powder by using a lead powder machine; refining the lead powder entering an air current classifier system through the air current classifier system and classifying the lead powder into rough lead powder and fine lead powder; allowing the rough lead powder and the fine lead powder to respectively enter different hoppers; feeding the lead powder into a paste combining machine by using the hoppers filled with the lead powder; adding an acid water anode accessory and uniformly mixing to obtain positive lead paste; feeding the lead powder into the paste combining machine by using the hoppers filled with the rough lead powder; and adding an acid water anode accessory and uniformly mixing to obtain negative lead paste. According to the method disclosed by the invention, during lead powder processing, the lead powder is fully refined as required and is classified into the rough lead power and the fine lead powder, thus the classification of proper refining and any proportion can be conveniently achieved according to the purposes and the requirements, the requirements of the anode on the mean particle size and narrower particle size of the lead powder can be fully met (the requirements of the cathode can be met simultaneously), the particle size distribution of the anode active substance lead powder and the cathode active substance lead powder is smaller, the uniformity of the active substances is improved, further the utilization rate of the active substance of the battery is improved and the service life of a battery pack is prolonged while the lead loss is reduced. Since the yield of the lead powder machine is in positive correlation with the mean particle size of the lead powder, the yield cannot be influenced while the quality of the lead powder is improved after a refining and classifying device is additionally arranged.

Owner:重庆万里电源科技有限公司

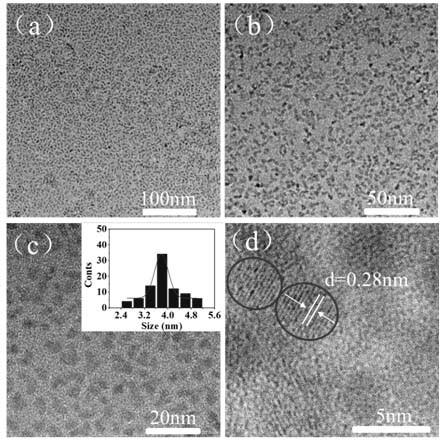

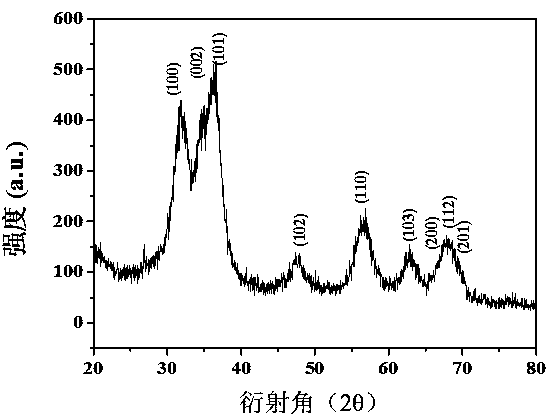

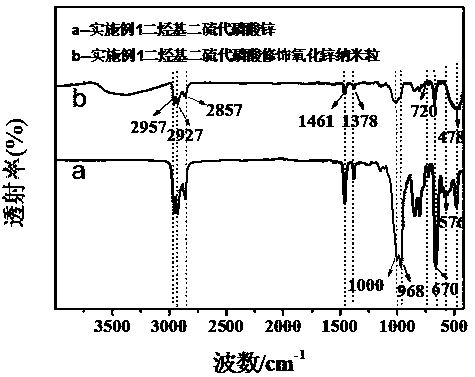

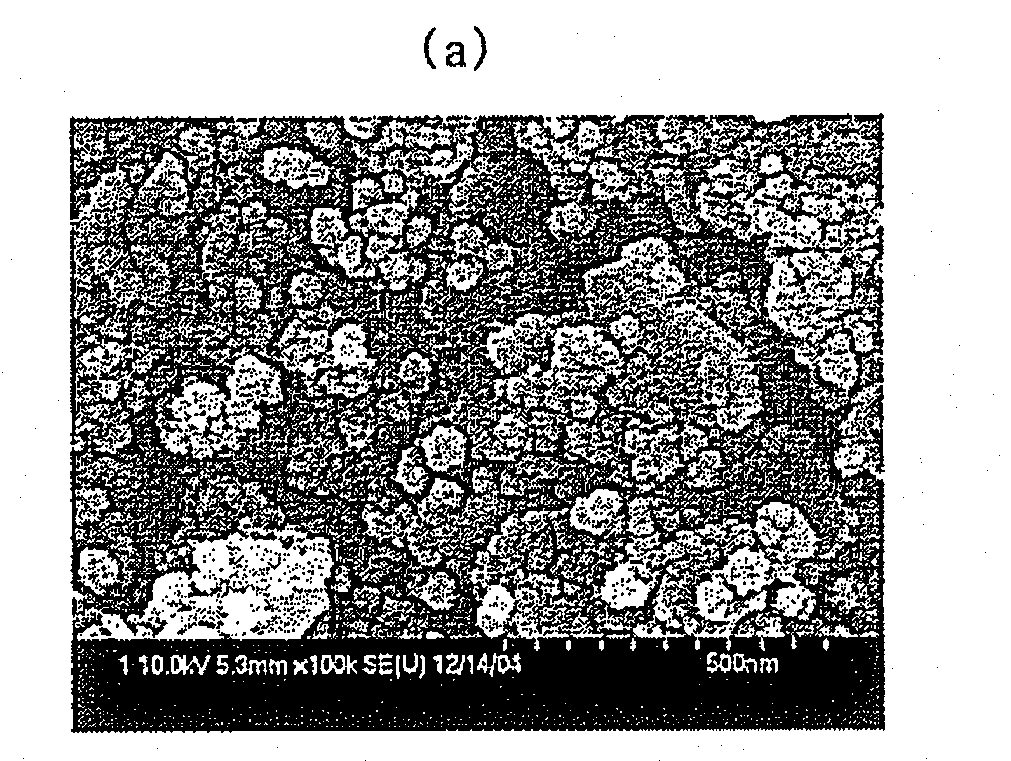

Dialkyldithiophosphoric acid modified zinc oxide nanoparticles as well as preparation method and application thereof

ActiveCN110129110AAchieving Dispersion StabilityImprove dispersion stabilityAdditivesPigment treatment with non-polymer organic compoundsDispersion stabilityAviation

The invention belongs to the technical field of lubricating oil additives, and discloses dialkyldithiophosphoric acid modified zinc oxide nanoparticles, a preparation method and application thereof. The method comprises the following steps: adding an alcohol solution of inorganic strong alkali or organic strong alkali into a polar organic solvent of zinc dialkyldithiophosphate, performing a reaction at 30-40 DEG C for 10-14 hours, removing the solvent after the reaction is finished, and washing and drying a reaction product to obtain the dialkyldithiophosphoric acid modified zinc oxide nanoparticles. The invention further discloses an application of dialkyldithiophosphoric acid modified zinc oxide nanoparticles as an antifriction and anti-wear additive in aluminum-based friction pair lubricating oil. The dialkyldithiophosphoric acid modified zinc oxide nanoparticles are small in particle size and uniform in distribution, and have excellent dispersion stability in lubricating oil. The product has outstanding antifriction and anti-wear effects on aluminum and aluminum alloy, and has a wide application prospect in the field of lubrication of automobiles, aviation and aerospace equipment.

Owner:HENAN UNIVERSITY

Metal Oxide with High Thermal Stability and Preparing Method Thereof

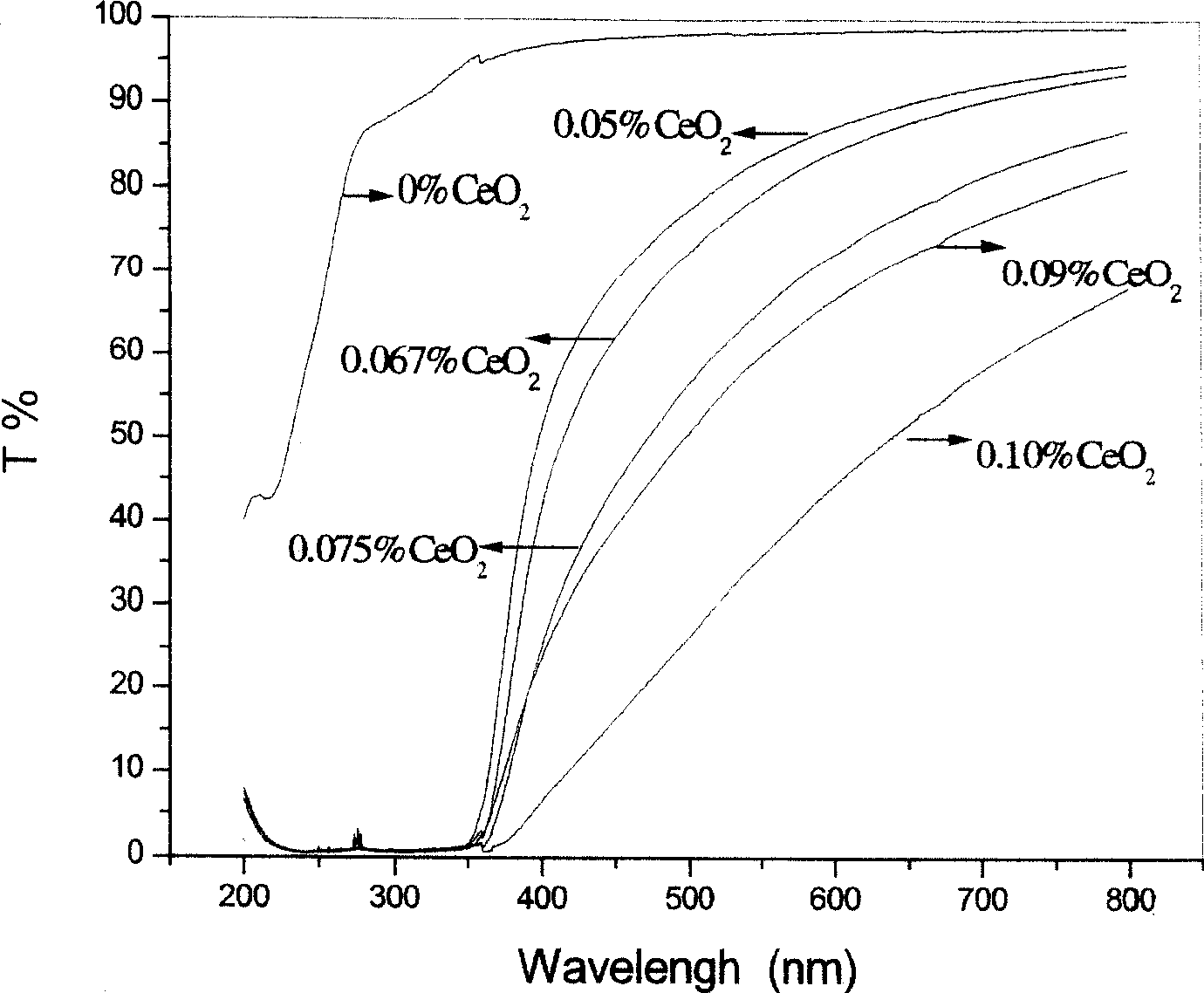

InactiveUS20080242536A1Large specific surface areaImprove thermal stabilityMaterial nanotechnologyAluminium compoundsCeriumThermal stability

Disclosed are metal oxide having high thermal stability and a preparation method thereof, specifically including continuously reacting a reaction mixture, composed of (i) water, (ii) a first metal salt including an aqueous cerium compound and (iii) a second metal salt including an aqueous aluminum compound, at 200˜700° C. under pressure of 180-550 bar, the reaction product having a molar ratio of metal, other than aluminum, to aluminum of 0.1˜10.

Owner:HANWHA CHEMICAL CORPORATION

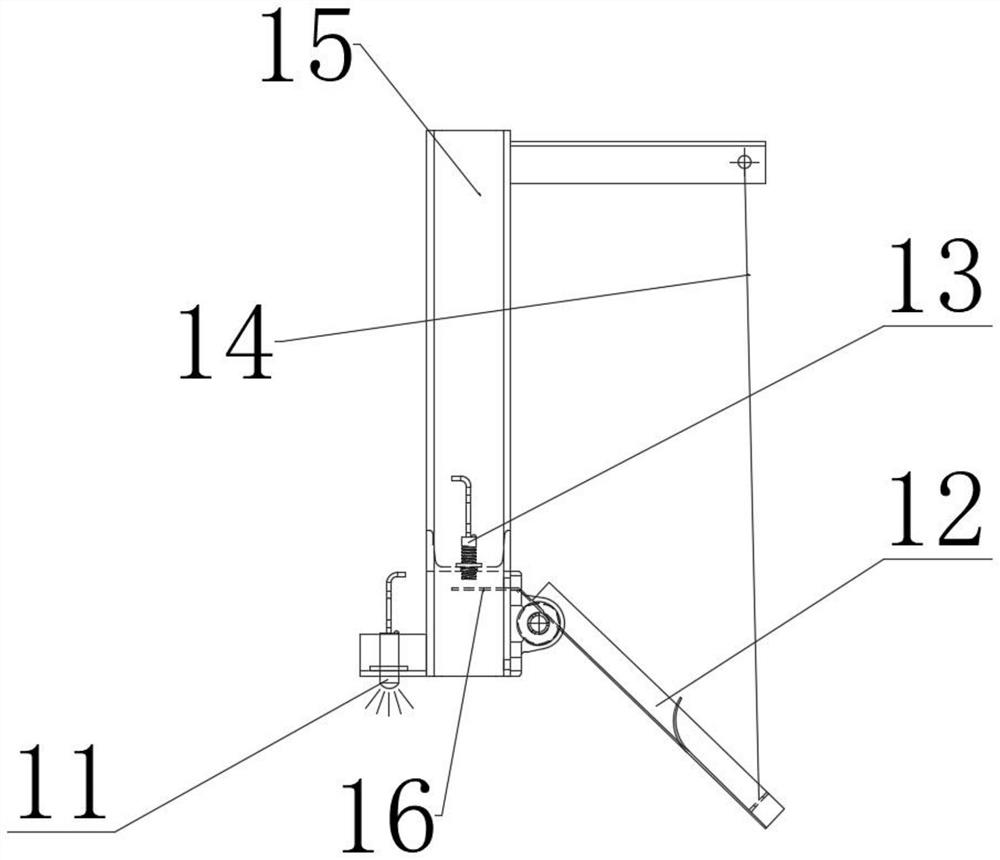

Hot-end high-temperature large glass identifying and removing device and removing method

InactiveCN112775012AAverage particle sizeParticle size andMeasurement devicesSortingProcess engineeringFishing

The invention relates to a hot-end high-temperature large glass identifying and removing device and a removing method. The hot-end high-temperature large glass identifying and removing device comprises an identifying mechanism and a removing mechanism; the identifying mechanism is located above an outlet of a material fishing machine to identify materials on the outlet of the material fishing machine; the removing mechanism is located below one side of the outlet of the material fishing machine to screen the materials on the outlet of the material fishing machine; and the identifying mechanism comprises a support, a high-temperature detection probe and a large block detection sensor, wherein the high-temperature detection probe and the large block detection sensor are installed on the support. According to the hot-end high-temperature large glass identifying and removing device and the removing method, through the arrangement of the identifying mechanism and the removing mechanism, high-temperature large glass liquid blocks can be identified; the bearable high-temperature large glass liquid blocks which are fished out by a material fishing machine and are not lowered to follow-up equipment can be identified and removed in advance and can be discharged to a designated area for follow-up special treatment; and therefore, it is guaranteed that glass liquid blocks entering subsequent conveying equipment and crushing equipment of the material fishing machine are all cooled to the temperature below the required temperature.

Owner:OUTSYS (TIANJIN) TECH DEV CO LTD

Preparation method of zinc oxide with core-shell structure and obtained zinc oxide

PendingCN114436320ALarge particle sizeParticle size andZinc oxides/hydroxidesPhysical chemistryStearic acid

The invention provides a preparation method of zinc oxide with a core-shell structure and zinc oxide obtained by the preparation method. The preparation method comprises the following steps: 1) taking a core material, adding a dispersing agent and sepiolite, stirring the dispersing agent which is a composite dispersing agent composed of stearic acid, CTAB, SDBS and KH550 according to a mass ratio of (1-2): (0.1-0.3): (0.05-0.10): (0.5-1.0) to obtain a primary mixture; 2) taking a zinc-containing solution, adding the primary mixture into the zinc-containing solution, and stirring to obtain a reaction solution; 3) adding an alkaline solution into the reaction solution, stirring for reaction, and removing water to obtain a precipitate; and 4) taking the precipitate, drying and calcining to obtain the core-shell structure zinc oxide. The core material is uniformly dispersed and suspended in the zinc-containing solution under the action of the dispersing agent and the sepiolite, insoluble substances generated in situ are strongly adsorbed on the surface of the core material, the energy consumption is low, and the carbon emission is small; the obtained zinc oxide has the advantages of small particle size, large specific surface area, high activity and high effective utilization rate.

Owner:QINGDAO UNIV OF SCI & TECH

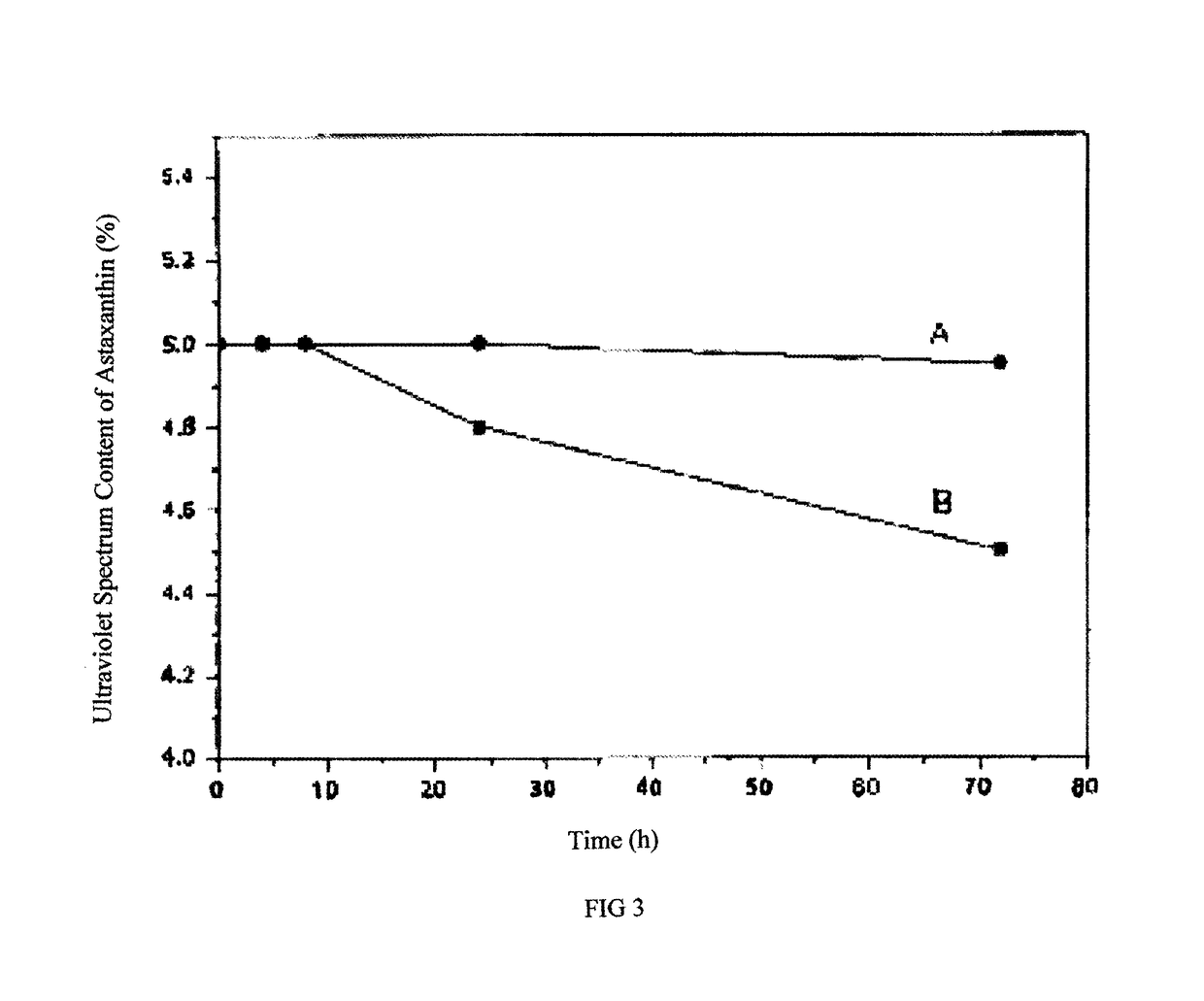

Method for preparing oil-dispersible carotenoid preparation

ActiveUS10212957B2Improve stabilityPracticalCosmetic preparationsHydrocarbon active ingredientsVegetable oilAntioxidant

Disclosed in the present invention is a method for preparing an oil-dispersible carotenoid preparation, comprising (by weight parts): mixing 100 parts of carotenoid microcapsule, 100-400 parts of vegetable oil and 0.1-1 part of oil-soluble antioxidant; and grinding the mixture in a colloid mill in a nitro—gen atmosphere and at 10-30° C. to obtain a uniform oil-dispersible carotenoid preparation, wherein the preparation contains 2%-14% carotenoid with an average particle size of up to 0.1-1 μm, and 100 parts of carotenoid microcapsule contains 10.5-35.8 parts carotenoid, 0.1-1 part of water-soluble antioxidant, and the remainder is a water-soluble colloid. The advantages of the present invention lie in that the oil-dispersible form has a high stability as the surface of the carotenoid particles is still protected with a dense water-soluble colloid, and that an oil-dispersible carotenoid preparation containing carotenoid with a content of up to 2%-14% and an average particle size of only 0.1-1 μm can be prepared.

Owner:ZHEJIANG NEW WEIPU ADDITIVE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com