Recycling method of pickling sludge

A technology of pickling sludge and washing with water, which is applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of mild and weak magnetism, increase waste liquid, complex process, etc., and achieve low cost, easy operation, and high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

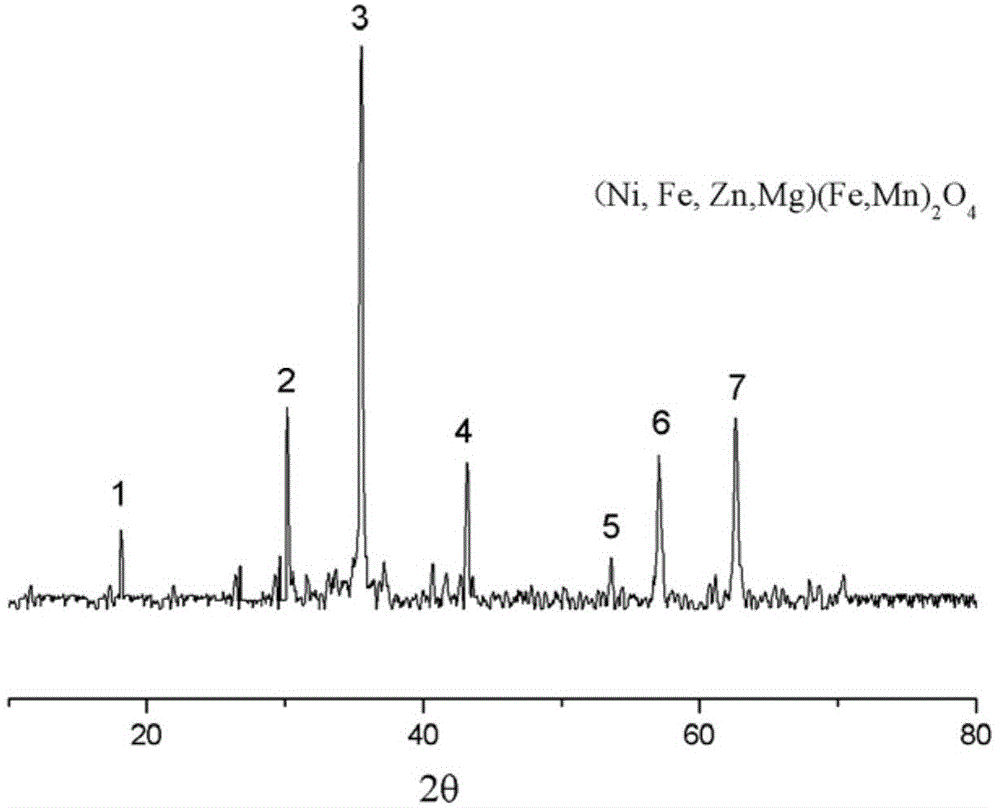

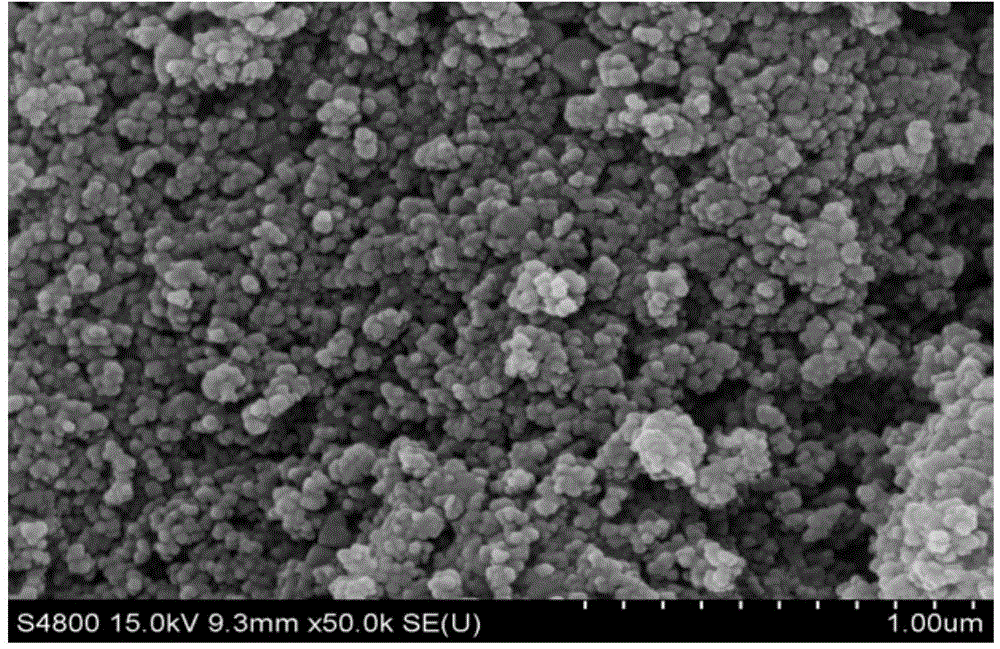

Embodiment 1

[0029] The process and steps of this embodiment are as follows:

[0030] The main heavy metal content (wt%) in the pickling sludge is shown in the following table 1:

[0031] Table 1 Main heavy metal content in pickling sludge (wt%)

[0032] the element

Fe

Cu

Ni

Cr

Zn

mn

Mg

Cd

Pb

Ag

Ca

g / 100g dry sludge

40.32

2.00

0.52

0.62

0.42

0.43

1.4

UD

UD

UD

12.93

[0033] Dry the pickling sludge at 105°C for 12 hours, grind it, and pass it through a 100-mesh sieve;

[0034] Weigh 1g of pickling sludge and 1g of ferrous chloride and put it into a conical flask, add 20ml of distilled water to form a slurry;

[0035] Then add 0.05g polyethylene glycol, stir to make a raw material slurry, then add ammonia water to adjust the pH value of the slurry to 11, put it in an autoclave, and conduct a hydrothermal reaction at a temperature of 200°C, and the reaction time is 8h; the reaction...

Embodiment 2

[0042] The main heavy metal content (wt%) in the pickling sludge is shown in the following table 2:

[0043] Table 2 Main heavy metal content in pickling sludge (wt%)

[0044] the element

Fe

Cu

Ni

Cr

Zn

mn

Mg

Cd

Pb

Ag

Ca

g / 100g dry sludge

50.12

UD

0.14

0.58

0.18

0.12

1.6

UD

UD

UD

6.14

[0045] Dry the pickling sludge at 110°C for 10 hours, grind it, and pass it through a 200-mesh sieve;

[0046] Weigh 1g of pickling sludge and 2g of ferrous chloride into a conical flask, add 30ml of distilled water to form a slurry; then add 0.35g of polyethylene glycol, stir to make a raw material slurry, then add ammonia water to adjust the pH of the slurry to 7 Finally, place it in an autoclave, and carry out a hydrothermal reaction at a temperature of 300° C., and the reaction time is 4 hours;

[0047] After the reaction is completed, the kettle body is naturally cooled to room ...

Embodiment 3

[0049] The main heavy metal content (wt%) in the pickling sludge is shown in the following table 3:

[0050] Table 3 Main heavy metal content in pickling sludge (wt%)

[0051] the element

Fe

Cu

Ni

Cr

Zn

mn

Mg

Cd

Pb

Ag

Ca

g / 100g dry sludge

18.27

3.00

0.17

0.27

1.15

0.12

1.65

0.12

UD

UD

12.93

[0052] Dry the pickling sludge at 120°C for 6 hours, grind it, and pass it through a 300-mesh sieve;

[0053] Weigh 1g of pickling sludge and 5g of ferrous chloride into a conical flask, add 40ml of distilled water to form a slurry; then add 0.5g of polyethylene glycol, stir to make a raw material slurry, and then add ammonia water to adjust the pH value of the slurry to 13 , placed in an autoclave, and subjected to a hydrothermal reaction at a temperature of 100°C, the reaction time is 12h;

[0054] After the reaction is completed, the kettle body is naturally cooled to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com