Method for preparing nanometer perovskite material on water base and product thereof

A nano-material and perovskite technology, which is applied in the field of water-based preparation of perovskite nano-materials, can solve the problems of unsuitable micro-nano devices, low electron transmission efficiency, unfriendly environment, etc., and achieve good stability and photoelectric performance, The effect of reducing health risks and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

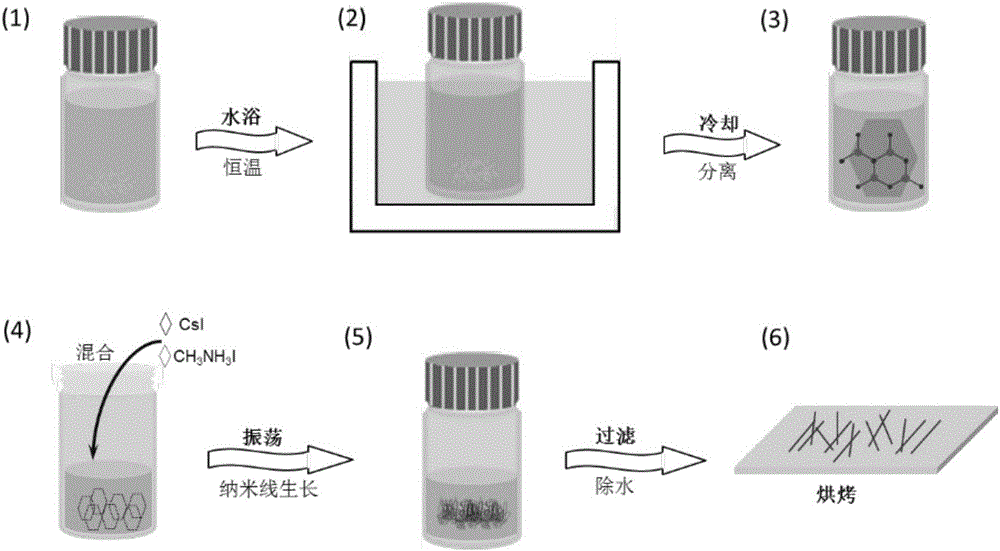

[0034] The preparation method of above-mentioned perovskite nano-material comprises the following steps:

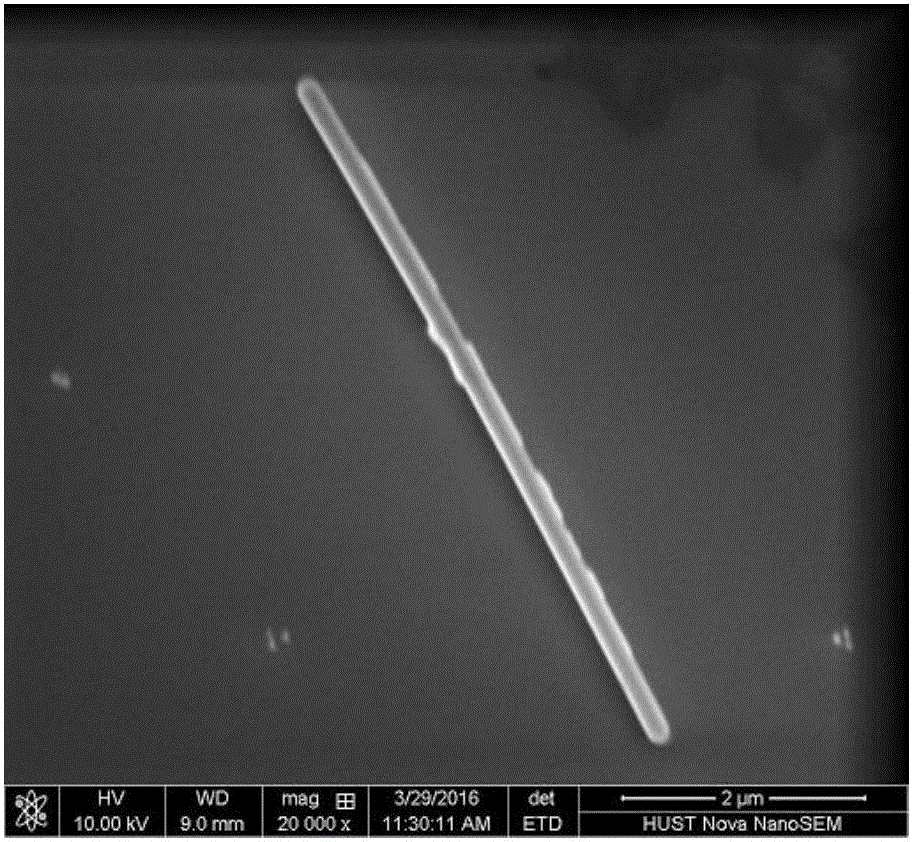

[0035] S1. Add the solid reactants to the supersaturated lead halide aqueous solution, and at the same time shake for 2s~10s until A is fully generated x B (1-x) BYZGR 3 Floc; wherein, the solid reactant includes AY and BY with a molar ratio of x:(1-x);

[0036] Usually, both AY and BY use powdery reaction raw materials in order to mix them into solid reactants with uniform composition, so as to ensure that when added to supersaturated lead halide aqueous solution, the generated products also have uniform chemical composition; AY and BY are mixed with lead halide. The halide ions can be the same or different;

[0037] S2. Drop-coat the floc on the substrate, and heat it at 75°C to 120°C for 2min to 15min to fully dry it to obtain the molecular formula A x B (1-x) BYZGR 3 perovskite nanomaterials.

[0038] In said step S1, the preparation method of the supersaturate...

Embodiment 1

[0043] The preparation method of embodiment 1 is as figure 1 shown, including the following steps:

[0044] S1. Put 1g of lead halide powder in a 25mL glass bottle, add 20mL of deionized water, the lead halide powder is not completely dissolved; the lead halide in this embodiment is lead iodide;

[0045]S2. Tighten the cap of the glass bottle in the first step, place the tightened glass bottle in a water bath for heating, when the temperature of the water bath reaches 100°C, start timing, keep the temperature of the water bath at 100°C for 10 minutes, and after 10 minutes, make the water bath The temperature is naturally lowered; and when the temperature of the water bath in S2 drops to 75°C, start timing to keep the temperature of the water bath at 75°C for 30 minutes. After 30 minutes, unscrew the bottle cap and draw 15 ml of the supernatant to transfer the saturated lead iodide solution In the glass bottle of new 25 milliliters, the concentration of this saturated lead iod...

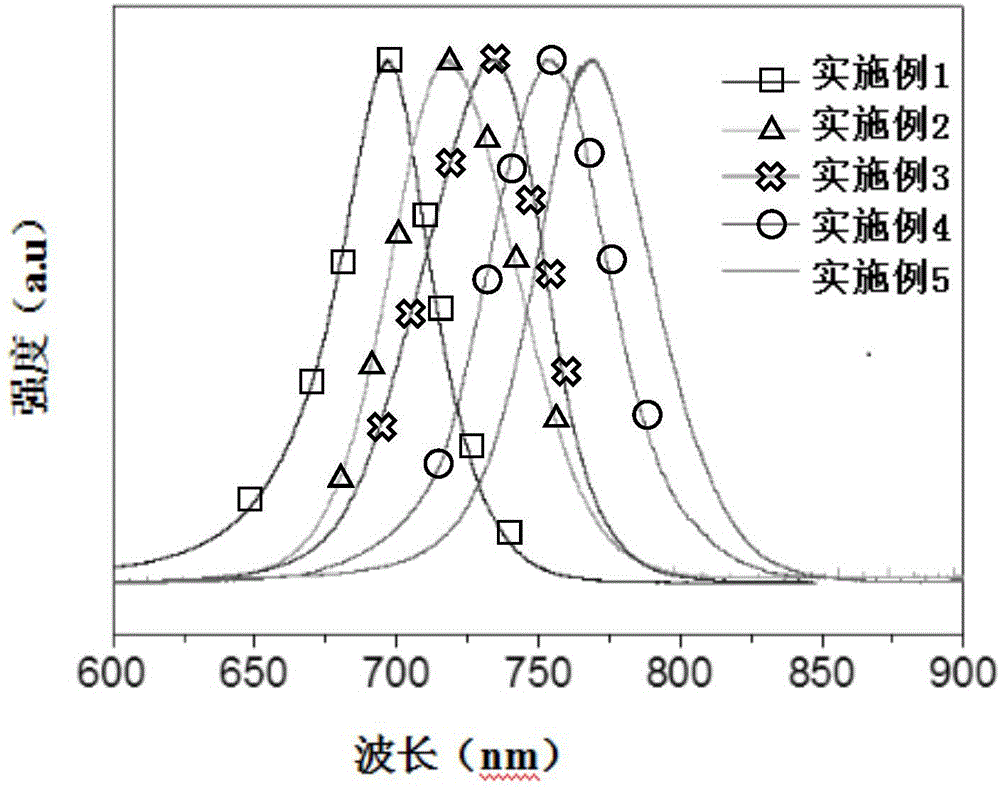

Embodiment 16

[0053] Repeat Example 1 with the same steps described above, the difference is that in the step S2, place the tightened glass bottle in a water bath for heating, and when the temperature of the water bath reaches 100°C, start timing to make the water bath temperature of 100°C Keep it for 15 minutes, then unscrew the bottle cap, draw 15 milliliters of the supernatant, that is, the saturated lead iodide solution, and transfer it to a new 25 milliliter glass bottle;

[0054] In the step S3, the saturated lead iodide solution is cooled to 30° C. to obtain a supersaturated lead iodide solution with a concentration of 0.03 mol / L;

[0055] In said step S4, oscillate for 2s;

[0056] In the step S5, heat at 75° C. for 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com