Method for preparing cement mixture from sand washing sludge

A technology of mixing materials and mixing materials, applied in cement production and other directions, can solve the problems of sludge environment, occupation of land resources, etc., and achieve the effects of good economic benefits, alleviation of environmental pollution, and good 28d flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

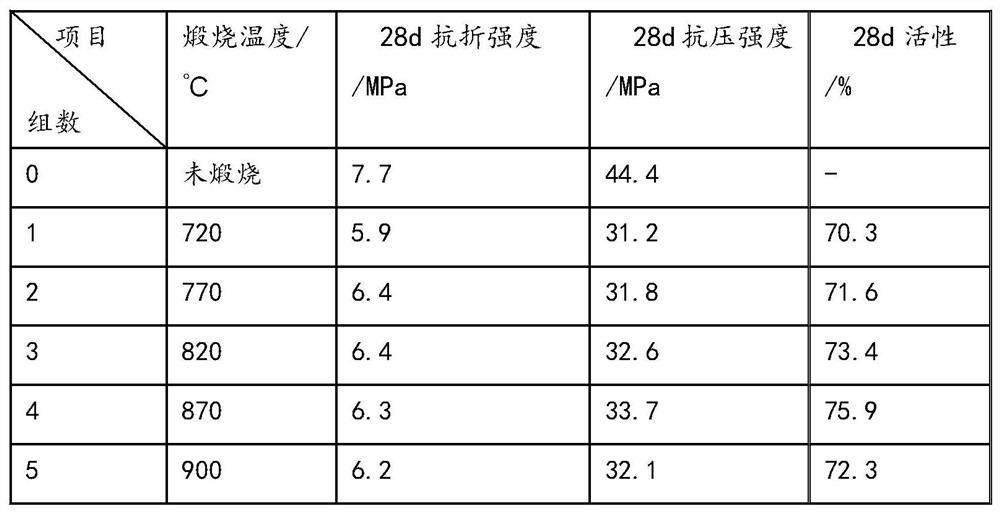

Embodiment 1

[0023] A method for preparing cement mixture from sand washing sludge, comprising the following steps:

[0024] S1. Dry the sand washing sludge

[0025] Dry the lumpy sand washing sludge with a rotary dryer until the water content is less than 10%;

[0026] S2, batching the dried sand washing sludge and quicklime according to a mass ratio of 100:5 and mixing them uniformly to obtain a mixed material;

[0027] S3. Calcining the mixed material in the calcination equipment, the calcination system is: the heating rate is 8°C / min, the temperature is raised to 400°C, then the heat is kept for 15min, and the temperature is raised to 720°C for 30min, and it is used after natural cooling; Add 0.05% alcohol amine grinding aid and 2% activator of powder mass;

[0028] S4. Send the calcined sand washing sludge into the ball mill, and use a 45-micron square hole sieve to screen powdery materials with a specific surface area greater than 400%, and the sieve residue is less than 20%;

[0...

Embodiment 2

[0034] A method for preparing cement mixture from sand washing sludge, characterized in that: comprising the following steps:

[0035] S1. Dry the sand washing sludge

[0036] Use a dryer to dry the massive sand washing sludge until the water content is less than 10%;

[0037] S2, batching the dried sand washing sludge and quicklime according to a mass ratio of 100:10 and mixing them uniformly to obtain a mixed material;

[0038] S3. Calcining the mixed material in the calcination equipment, the calcination system is: the heating rate is 10°C / min, the temperature is raised to 400°C, and then kept for 15min, and then heated to 870°C for 30min, and it is used after natural cooling; Add 0.08% alcohol amine grinding aid and 3.5% activator of powder mass;

[0039] S4. Send the calcined sand washing sludge into the ball mill, and use a 45-micron square hole sieve to screen powdery materials with a specific surface area greater than 400%, and the sieve residue is less than 20%;

...

Embodiment 3

[0042] A method for preparing cement mixture from sand washing sludge, comprising the following steps:

[0043] S1. Dry the sand washing sludge

[0044] Use a dryer to dry the massive sand washing sludge until the water content is less than 10%;

[0045] S2, batching the dried sand washing sludge and quicklime according to a mass ratio of 100:15 and mixing them evenly to obtain a mixed material;

[0046] S3. Calcining the mixed material in the calcination equipment, the calcination system is: the heating rate is 12°C / min, the temperature is raised to 400°C, and then kept for 15min, and then heated to 900°C for 30min, and it is used after natural cooling; Add 0.1% alcohol amine grinding aid and 5% activator of powder mass;

[0047] S4. Send the calcined sand washing sludge into the ball mill, and use a 45-micron square hole sieve to screen powdery materials with a specific surface area greater than 400%, and the sieve residue is less than 20%;

[0048] S5. The powdery materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com