Method for preparing electrode materials by using electroplating sludge and eggshell membranes

A technology for electroplating sludge and preparing electrodes, applied in chemical instruments and methods, cable/conductor manufacturing, circuits, etc., can solve the problem of high cost, and achieve the effects of improving conductivity, shortening process flow, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

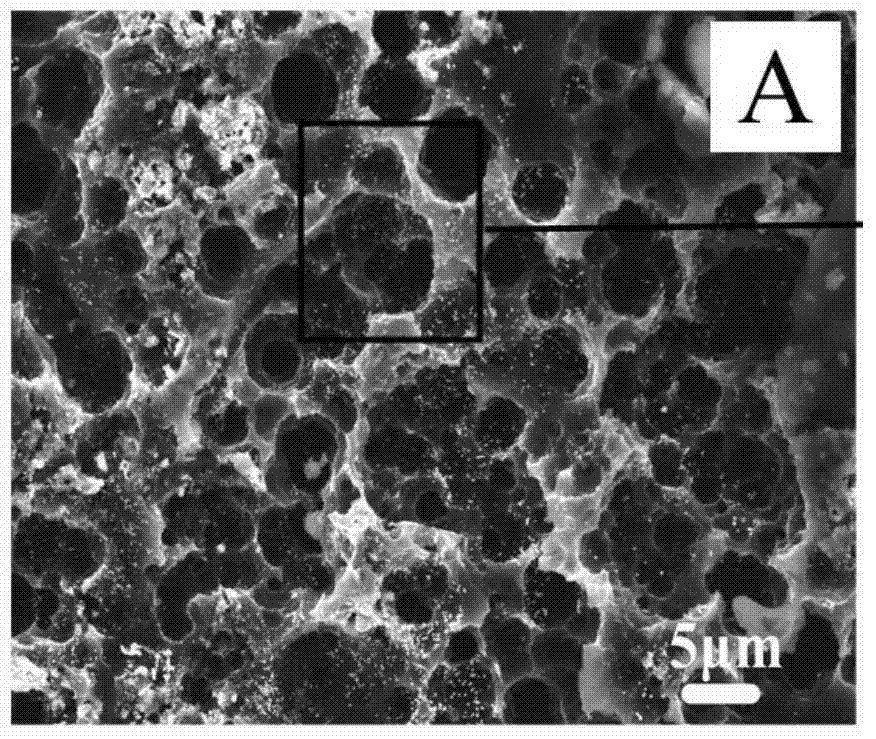

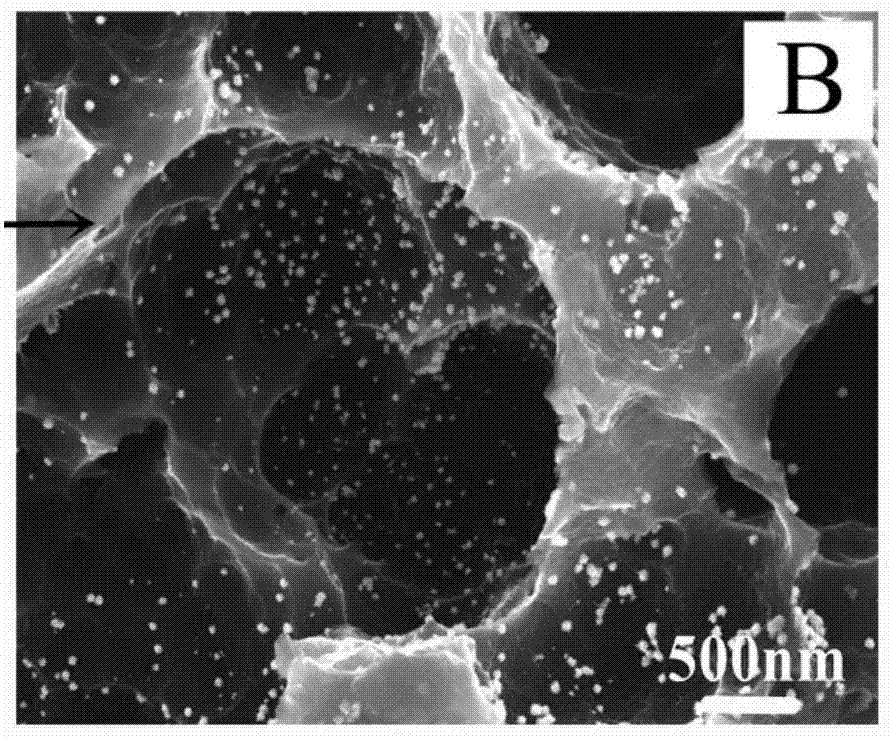

Image

Examples

Embodiment 1

[0047] (1) Choose fresh eggshells, soak the eggshells in 1mol / L hydrochloric acid solution for 0.5h, peel off the inner membrane and wash with water, and then blow dry at room temperature.

[0048] (2) Crush the electroplating sludge into small particles with a particle size of 15mm or less. According to the volume ratio of electroplating sludge to water is 1:2, add water to the electroplating sludge and stir to form electroplating sludge fluid.

[0049] (3) Sodium hydroxide solution is used for leaching treatment, and the electroplating sludge fluid is injected into the reactor. The reaction temperature is 30°C, the pressure is 1MPa, the volume ratio of electroplating sludge fluid to alkali is 1:2, and alkali is added for 5 times .

[0050] (4) Soak the eggshell membrane in multiple alkaline washing mixtures for 3 hours, and put it in an oven at room temperature to raise the temperature from room temperature to 5°C every 5 minutes to 80°C and dry for 4 hours.

[0051] (5) Pu...

Embodiment 2

[0055] (1) Choose fresh duck eggshells, soak the eggshells in 1.5mol / L hydrochloric acid solution for 0.5h, peel off the inner membrane and wash with clean water, and then blow dry at room temperature.

[0056] (2) Crush the electroplating sludge into small particles with a particle size of 15mm or less. According to the volume ratio of electroplating sludge to water is 1:2.5, add water to the electroplating sludge and stir to form electroplating sludge fluid.

[0057] (3) Hydrochloric acid solution was used for leaching treatment, and the electroplating sludge fluid was injected into the reactor. The reaction temperature was 40°C, the pressure was 1.5MPa, the volume ratio of electroplating sludge fluid to acid was 1:2, and acid was added for 5 times of leaching.

[0058] (4) Soak the eggshell membrane in multiple pickling mixtures for 5 hours, and put it in an oven at room temperature to raise the temperature from room temperature to 5°C every 5 minutes to 80°C and dry for 4 h...

Embodiment 3

[0062] (1) Choose fresh goose eggshells, soak the eggshells in 2mol / L hydrochloric acid solution for 1 hour, peel off the inner membrane and wash with clean water, and then blow dry at room temperature.

[0063] (2) Crush the electroplating sludge into small particles with a particle size of 15mm or less. According to the volume ratio of electroplating sludge to water is 1:2.5, add water to the electroplating sludge and stir to form electroplating sludge fluid.

[0064] (3) Hydrochloric acid solution was used for leaching treatment, and the electroplating sludge fluid was injected into the reactor. The reaction temperature was 35°C, the pressure was 2MPa, the volume ratio of electroplating sludge fluid to acid was 1:2.5, and acid was added for 5 times of leaching.

[0065] (4) Soak the eggshell membrane in multiple pickling mixtures for 4 hours, and put it in an oven at room temperature to raise the temperature from room temperature to 5°C every 3 minutes to 80°C and dry for 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com