Patents

Literature

34results about How to "Improve the crystallization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultralow thermal expansion devitrified glass

The present invention discloses one kind of ultralow thermal expansion devitrified glass used for reflector, planar mirror, template and other precise optical elements. It has the material composition of: SiO2 47.2-49.1(in wt%, the same as below),Al2O3 27.6-29.0,Sb2O3 0.78-0.82,As2O3 0.30-0.35,BaO 2.98-3.05,ZnO 2.00-2.05, CaO 2.28-2.33,MgO 0.5-1.0,Li2O 7.1-7.5,P2O5 4.0-4.4,ZrO2 1.2-1.7 and TiO2 1.4-1.5 . The technological process includes the following steps: mixing the components, high temperature smelting in high temperature quartz-ceramic crucible at 1580-1630 deg.c, tapping at 1450 deg.c, forming, inspection, nucleating at 660-690 deg.c, crystallizing at 690-720 deg.c, precise annealing at 640-540 deg.c.

Owner:上海新沪玻璃有限公司

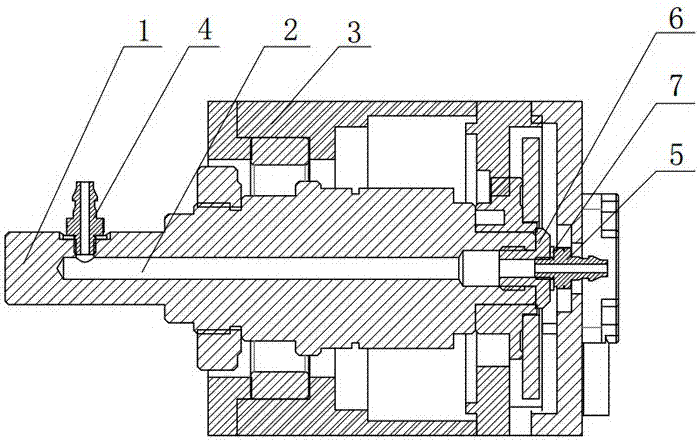

Production method for grinding-free and polishing-free black transparent microcrystalline glass plate

ActiveCN102603193ALower melting temperatureImprove the crystallization effectGlass rolling apparatusGlass productionWater flowCrystallization temperature

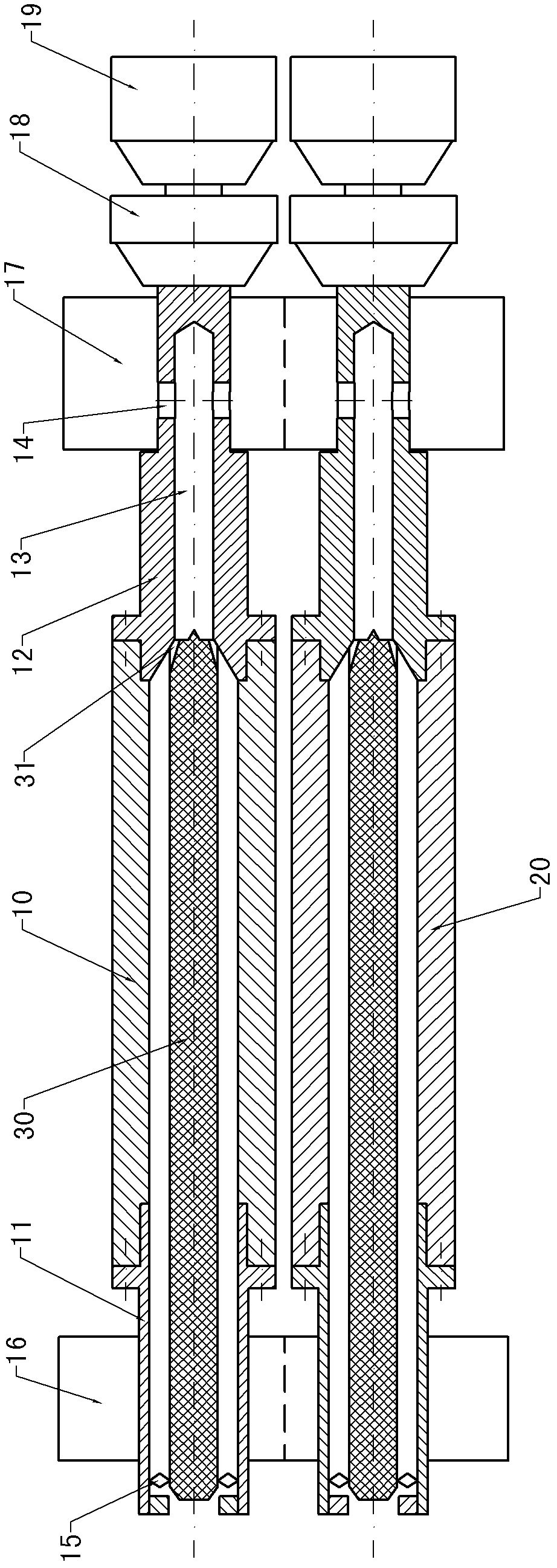

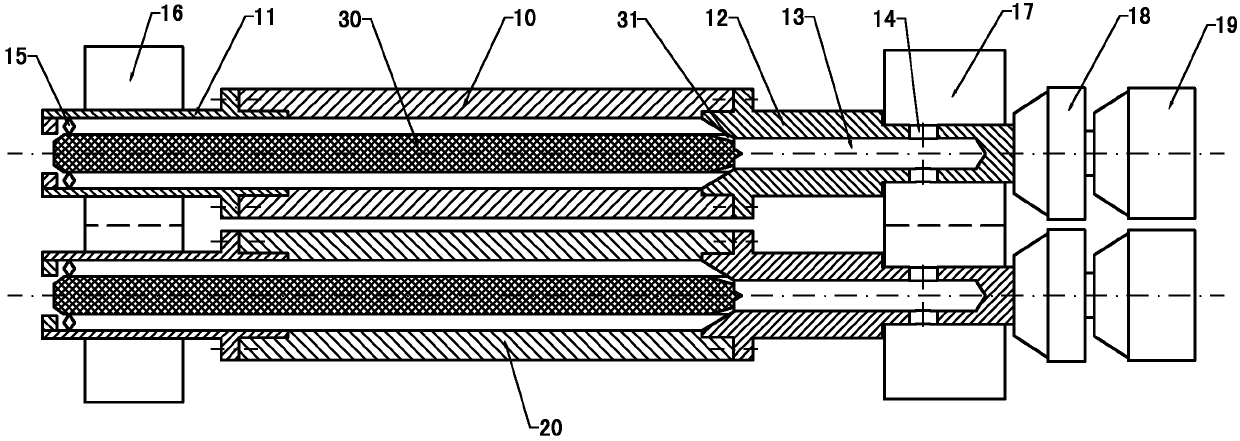

The invention relates to a production method for a Li2O-A2O3-SiO2-series grinding-free and polishing-free black transparent microcrystalline glass plate. Because modified component niobium oxide is added into a formula, the fusing temperature of the glass can be lowered by adding the niobium oxide. The modified component niobium oxide has good crystallization performance and also has the physical properties that the crystallization temperature is lowered, the coefficient of expansion is lowered, and the like. In the calendaring molding equipment, because the traditional solid molded roll is changed into a hollow roller structure and an inner core rod is arranged in the hollow roller structure, circulating cooling water is introduced into the hollow roller during production; the temperature of a molded roll body can be accurately controlled by controlling the water inlet temperature, the water outlet temperature and the flow speed, and in addition, the roller can be evenly cooled; the microcrystalline glass plate calendered and molded by the roller is flat, and the obtained microcrystalline glass plate has a smooth and flat surface so as to satisfy the user requirement, and does not deform at the high temperature for a long time; because grinding treatment and polishing treatment are omitted in the product production process, two working procedures of grinding and polishing in the product process are reduced; and therefore, the product quality is improved, the production efficiency is improved, the production cost is lowered, the production environment for workers is improved, and the clean production is realized.

Owner:广东科迪微晶玻璃实业有限公司

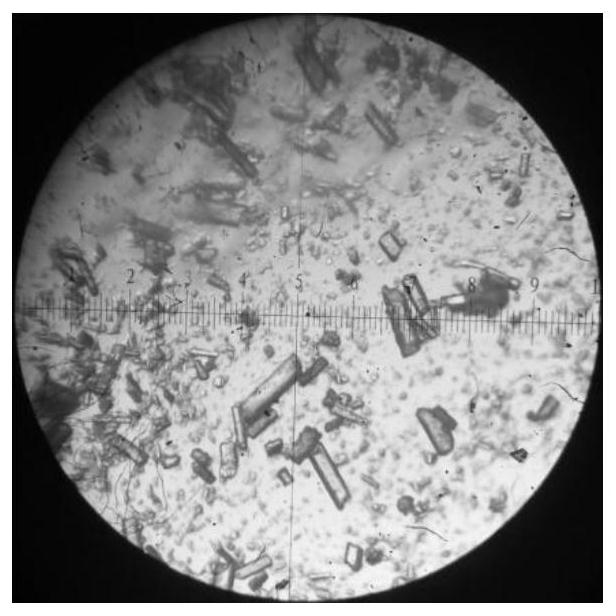

Method for synthesizing ZSM-35 molecular sieve by composite template agent

ActiveCN108147426AGood water solubilityImprove the crystallization effectFerrierite aluminosilicate zeoliteNanotechnologyMolecular sieveSodium aluminate

The invention relates to a method for synthesizing a ZSM-35 molecular sieve by a composite template agent. The method comprises the following steps: dissolving sodium metaaluminate or sodium aluminateand alkali into desalted water to prepare a sodium metaaluminate-alkali aqueous solution or a sodium aluminate-alkali aqueous solution; adding hexamethylene imine into cyclohexane to prepare a composite template agent, adding the composite template agent into silicon sol, completely stirring, dropwise adding the sodium metaaluminate-alkali aqueous solution or the sodium aluminate-alkali aqueous solution until reaching a thick point, increasing the stirring speed, opening gel and slowly adding the residual sodium metaaluminate-alkali aqueous solution or the sodium aluminate-alkali aqueous solution; adding the ZSM-35 molecular sieve, stirring, gelatinizing and crystallizing, and synthesizing a high-nanoscale ZSM-35 molecular sieve.

Owner:PETROCHINA CO LTD

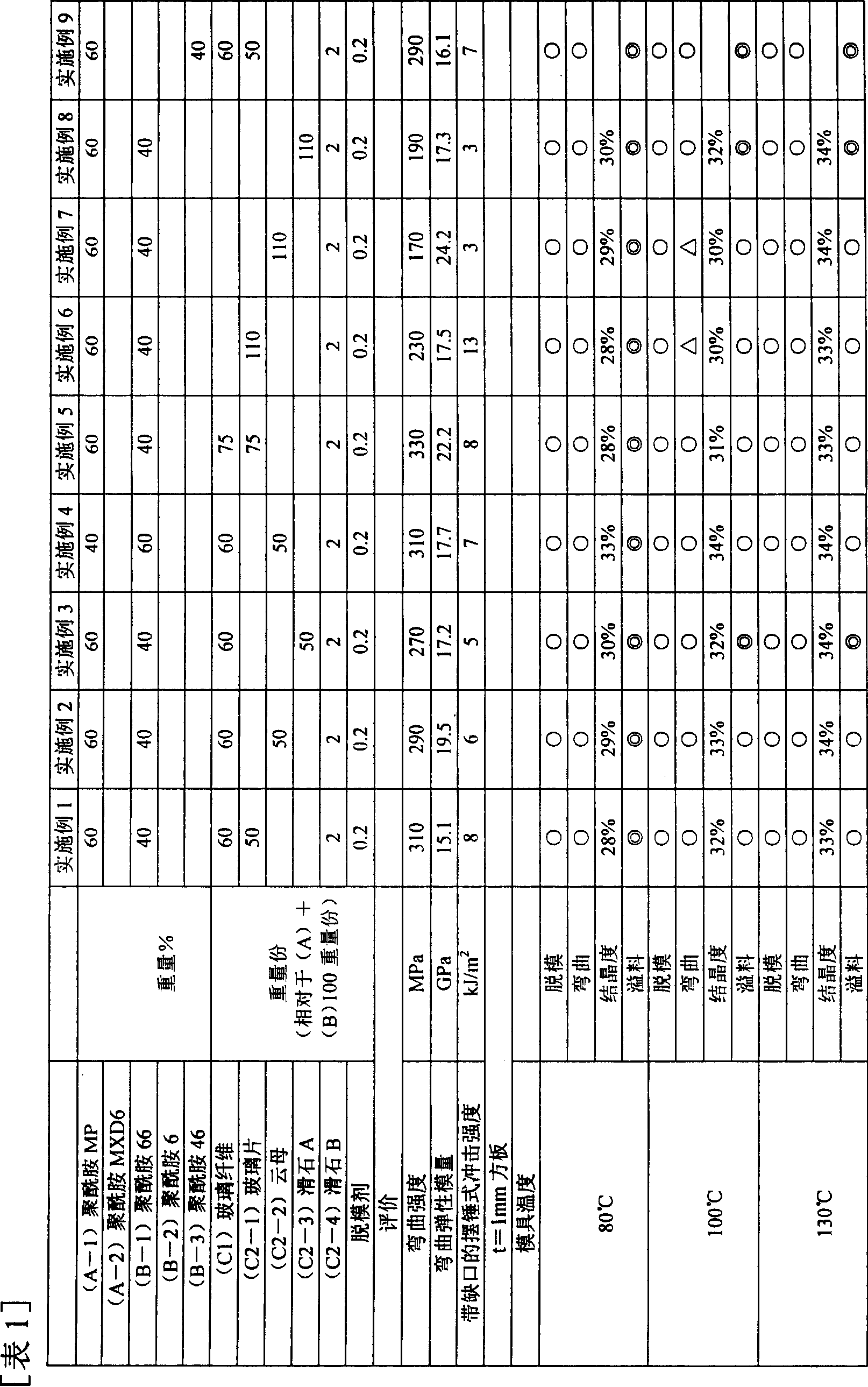

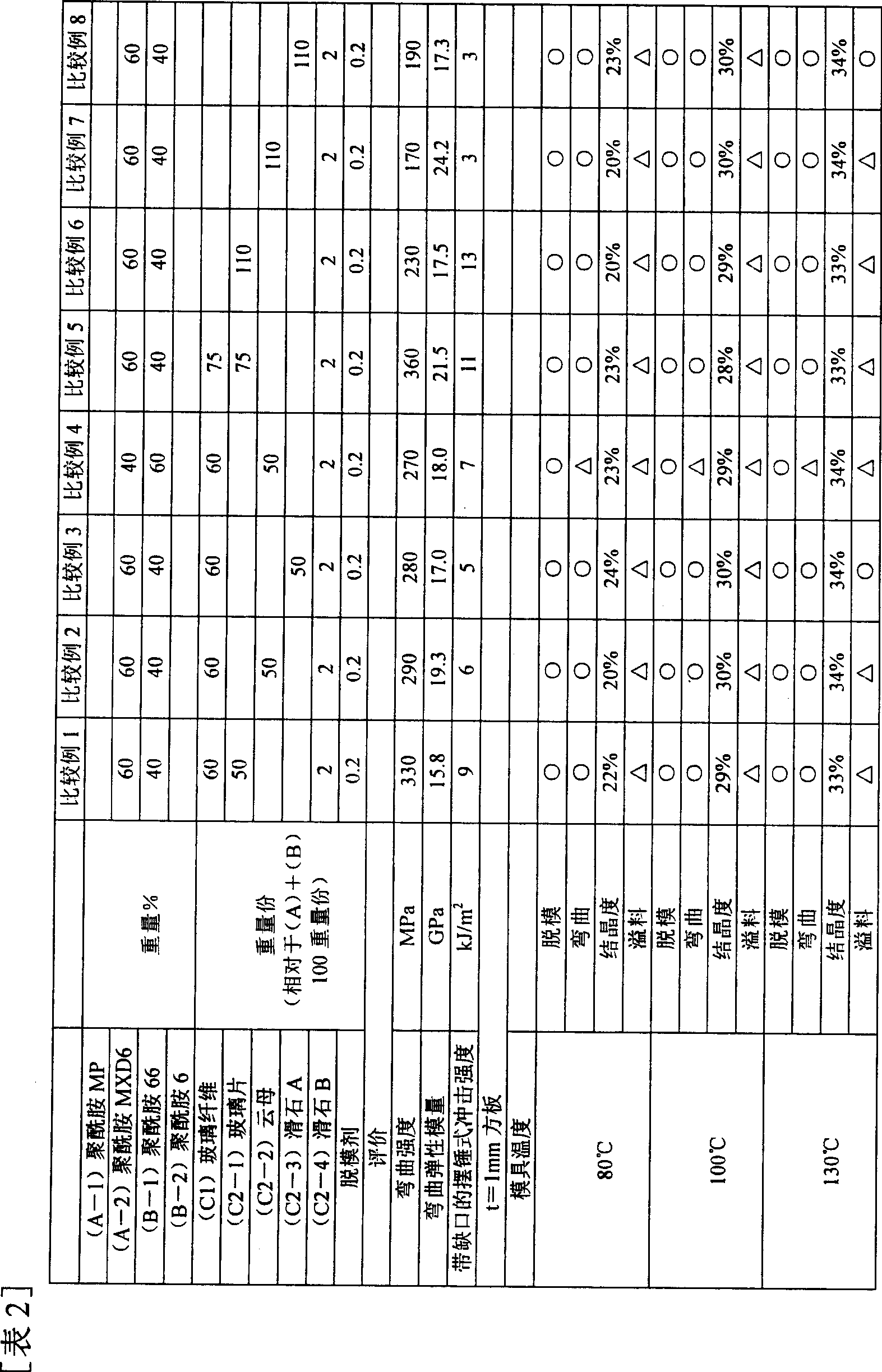

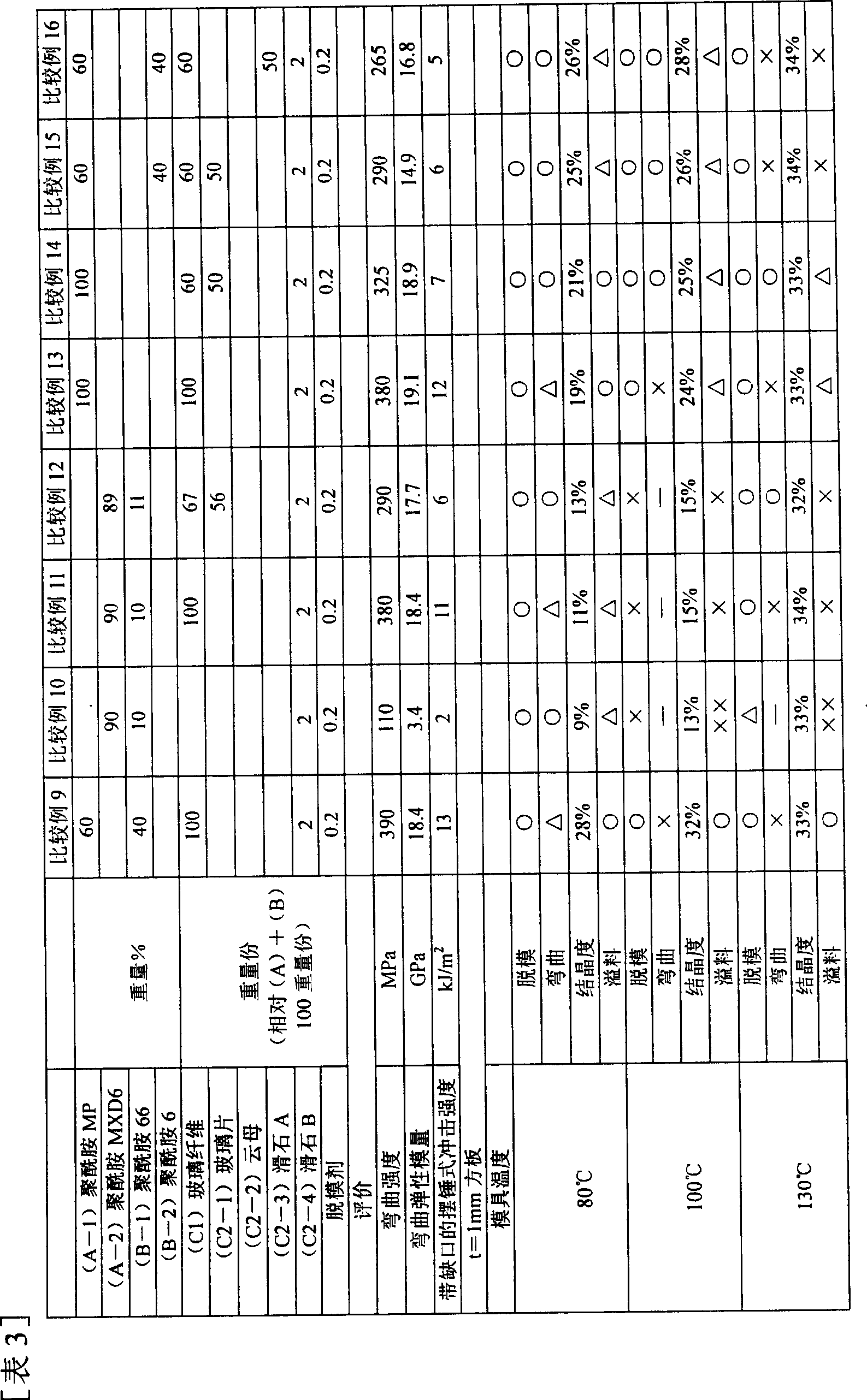

Polyamide resin composition and molded article

ActiveCN101432364AFast crystallizationImproved thin-wall formabilityFlat articlesPolyamideCrystallinity

Disclosed is a polyamide resin composition for portable electronic devices, which is excellent in mechanical strength, thin shape formability, crystallinity and warping property. Specifically disclosed is a polyamide resin composition containing 30-80% by weight of a polyamide MP (A) and 20-70% by weight of a polyamide resin (B) having a melting point not less than 245 DEG C (with the total amount of them being 100% by weight). The polyamide resin composition further contains, as a filler (C), a fibrous filler (C1) as an optional component and a plate-like filler (C2) as an essential component, and the content ratio (C1):(C2) is from 0:10 to 9:1. The total amount of the filler (C) is 30-250 parts by weight relative to 100 parts by weight of the total of the polyamide MP (A) and the polyamide resin (B). The polyamide MP (A) is a polyamide resin obtained by a polycondensation reaction between a mixed diamine, which contains 90-50% by mole of meta-xylylenediamine and 10-50% by mole of para-xylylenediamine, and an alpha, omega-linear aliphatic dibasic acid and / or an aromatic dibasic acid.

Owner:MITSUBISHI ENG PLASTICS CORP

Method for producing semi-conductor device

InactiveCN1361551AControl and reduce concentrationImprove the crystallization effectTransistorPolycrystalline material growthAmorphous siliconMetal silicide

A method of manufacturing a semiconductor device which has a crystalline silicon film comprises the steps of forming crystal nuclei in a surface region of an amorphous silicon film and then growing the crystals from the nuclei by a laser light. Typically the crystal nuclei are silicon crystals or metal suicides having an equivalent structure as silicon crystal.

Owner:SEMICON ENERGY LAB CO LTD

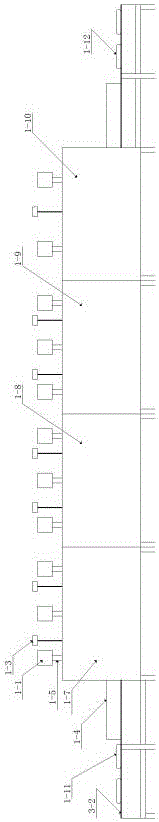

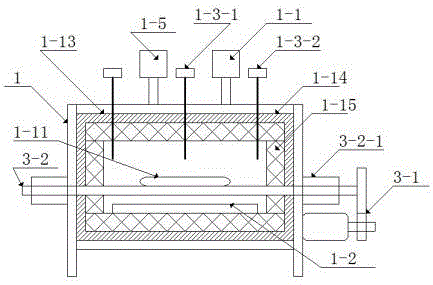

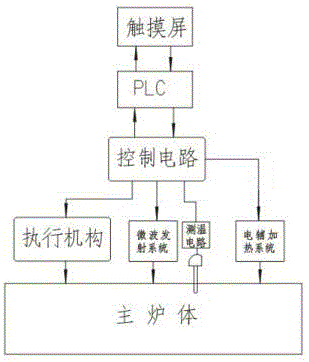

Microwave heating glass ceramic crystallization technology and device

The invention relates to a glass ceramic crystallization technology. In heating, crystallization and cooling processes, microwave heating systems and electric auxiliary heating systems carry out crystallization treatment on a glass ceramic product, temperatures of sections of a furnace are controlled through adjusting output power of the microwave heating system, and the balance of the product temperature and the temperature of a corresponding section of the furnace is realized through adjusting output power of the electric auxiliary heating system so that cracking of the glass ceramic product in crystallization is avoided. The main furnace body of a microwave heating glass ceramic crystallization device is orderly provided with a heating section, a crystallization section, a temperature reduction section and a cooling section from front to back. The sections are seal-connected. The tops of the heating section, the crystallization section and the temperature reduction section of the main furnace body are provided with microwave emission systems. The bottoms of the heating section, the crystallization section and the temperature reduction section are provided with the electric auxiliary heating systems. Temperature detection sensors are arranged in the sections of the main furnace body. An output signal is connected to a control system. The control system respectively controls and is connected to the microwave emission systems, the electric auxiliary heating systems and auxiliary systems.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

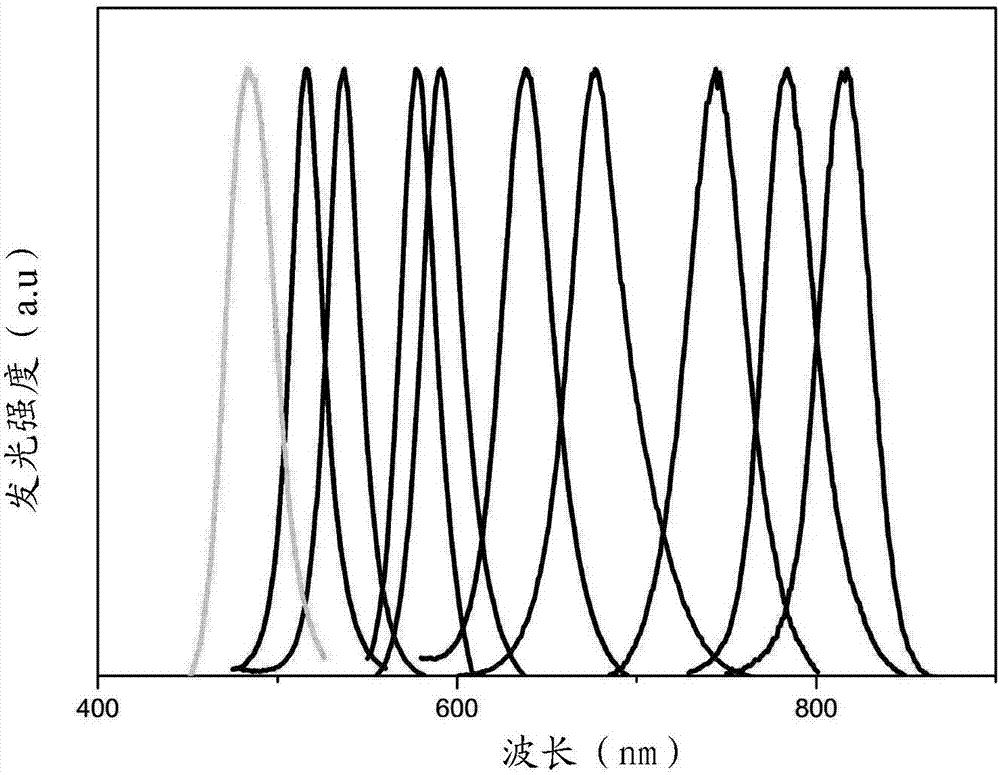

Preparation method of multilayered shell structure nanorod and preparation method of white light LED

InactiveCN108034425AImprove the crystallization effectImprove stabilityMaterial nanotechnologyNanoopticsFluorescenceLuminescence

The invention provides a multilayered shell structure nanorod and a preparation method of the multilayered shell structure nanorod, and a preparation method of a white light LED. A multilayered core-shell structure quantum dot is prepared by a step-by-step inorganic shell layer coating method of an anion-cation alternative filling method, and the method is helpful to avoid corresponding ion side products with different valence states for adding excessive anion or cation ions in one time, avoid excessive independent core formation, realize the control of the quantum dot dimension, and improve the uniformity of the grain diameter. The multilayered shell structure nanorod has good crystal forming effect and good stability. The quantum dot prepared by the invention has the advantages of narrowhalf-peak width, symmetrical luminescence spectrum, stable optical property, and high yield of the quantum dot; the quantum dot is applied to prepare the white light LED, and the white light LED is high in color purity, good in stability, and nearly free from light attenuation. The result of the embodiment indicates that the prepared quantum dot is narrow in half-peak width and symmetrical in spectrum; the fluorescence yield is over 80%; the white light LED is good in stability and high in color purity, and its CIR is more than 90.

Owner:NANCHANG HANGKONG UNIVERSITY

Salt gypsum crystal transformation activator as well as preparation method and application thereof

The invention relates to a salt gypsum crystal transformation activator. A preparation method of the salt gypsum crystal transformation activator comprises the step of grafting maleic acid triethanolamine ester on acidified starch; and the method specifically comprises the following steps: performing acidolysis on starch; synthesizing maleic acid triethanolamine ester; and grafting the acidified starch to the maleic acid triethanolamine ester by adopting a semi-dry method to prepare the salt gypsum crystal transformation activator. The invention also relates to a method for realizing salt gypsum crystal transformation by utilizing the activator. The activator provided by the invention can directly hydrothermally transform salt gypsum into alpha-type high-strength semi-hydrated gypsum in one step, thereby greatly improving the competitive advantage of salt gypsum series of products, and realizing large-scale and high-valued resource utilization of a by-product salt gypsum.

Owner:HOHAI UNIV +1

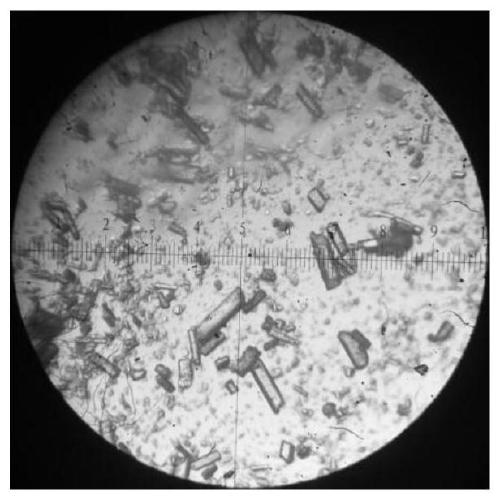

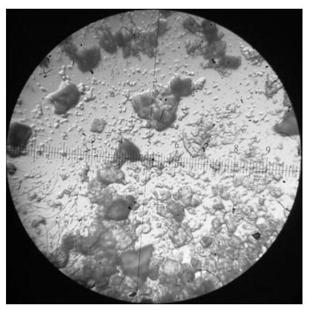

Preparation method of refined sulfanilamide

InactiveCN107311892AHigh viscosityLow viscosityOrganic compound preparationSulfonic acid amide preparationCuprous chlorideAmination

The invention discloses a preparation method of refined sulfonamide, which is characterized in that it comprises the following steps: (1) chlorosulfonation reaction; (2) deicing; (3) rejection filtration on a centrifuge; (4) amination reaction; (5) refining decolorization. The preparation method of a kind of fine sulfonamide of the present invention, adds cuprous chloride catalyst in chlorosulfonation reaction, and optimizes existing process step, effectively reduces raw material feeding ratio, reduces the generation of by-product and post-treatment, and through improving amine Compound dissolution decolorization and crystallization purification process greatly improves the purity of the produced product, and its main component content can reach more than 99.5%.

Owner:HUZHOU ZHIWEI TECHNICAL SERVICE CO LTD

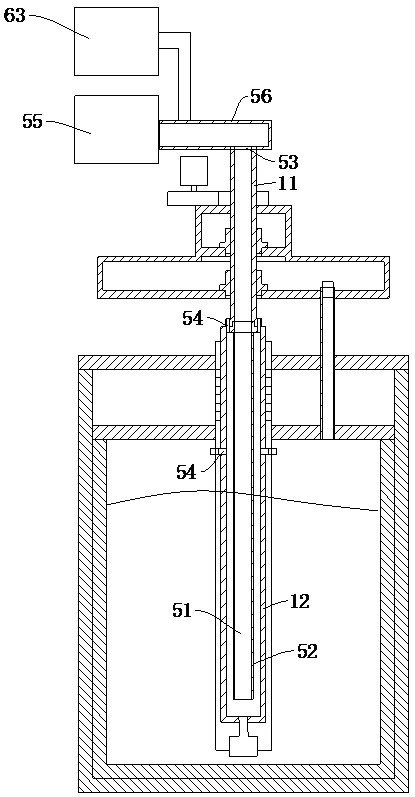

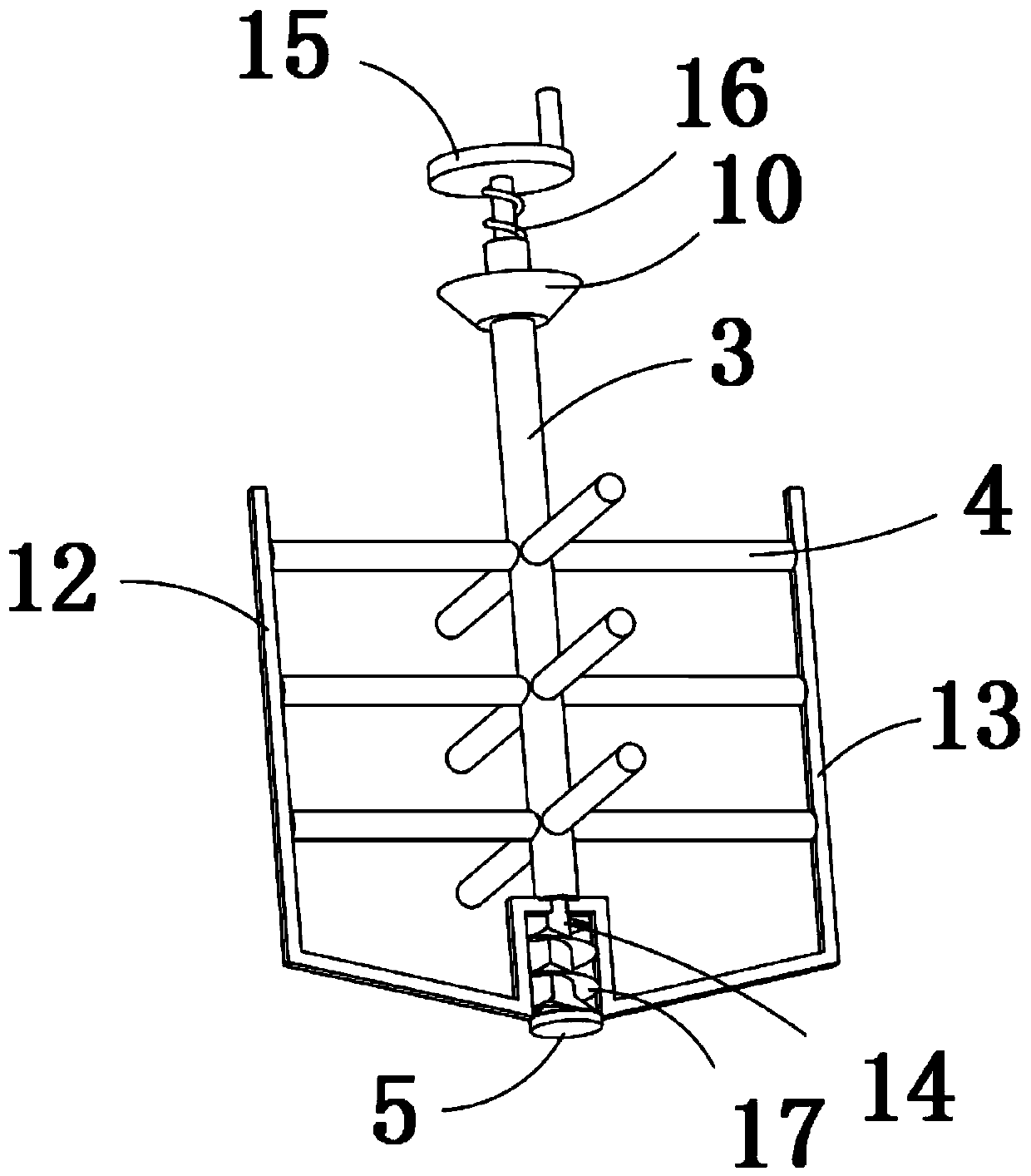

Ultrahigh-purity aluminum crystallization method

ActiveCN113106267AHigh purityAchieve purificationProcess efficiency improvementPhysical chemistryMaterials science

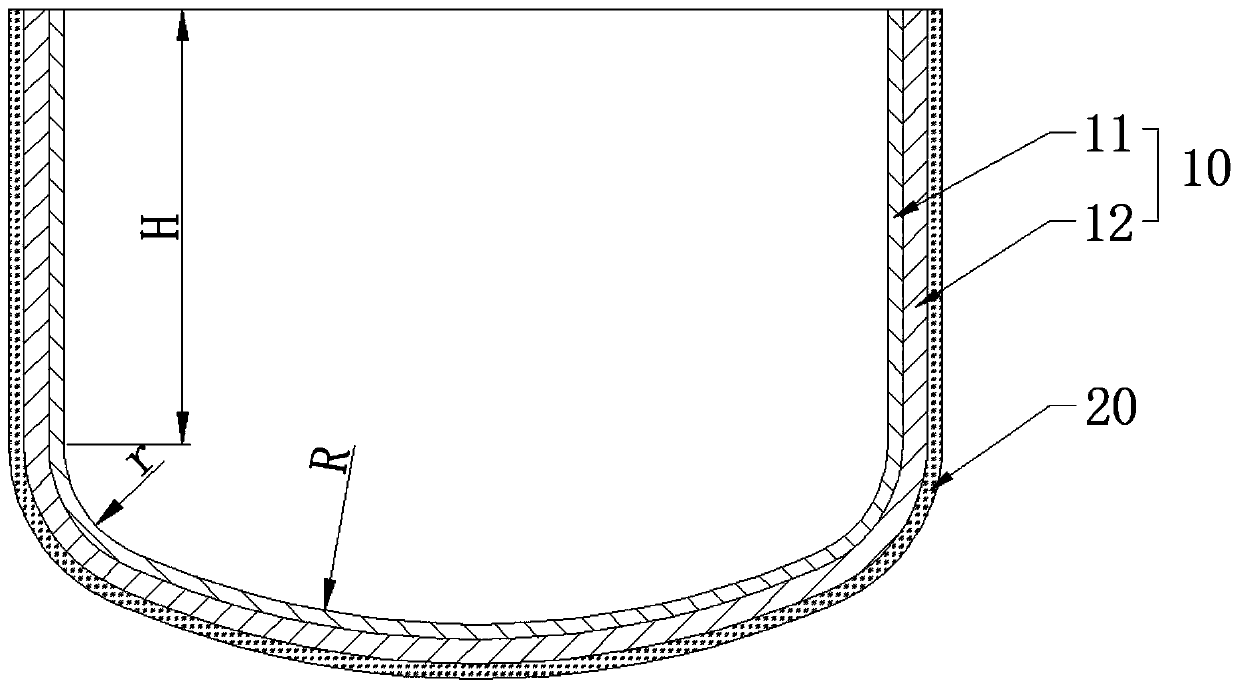

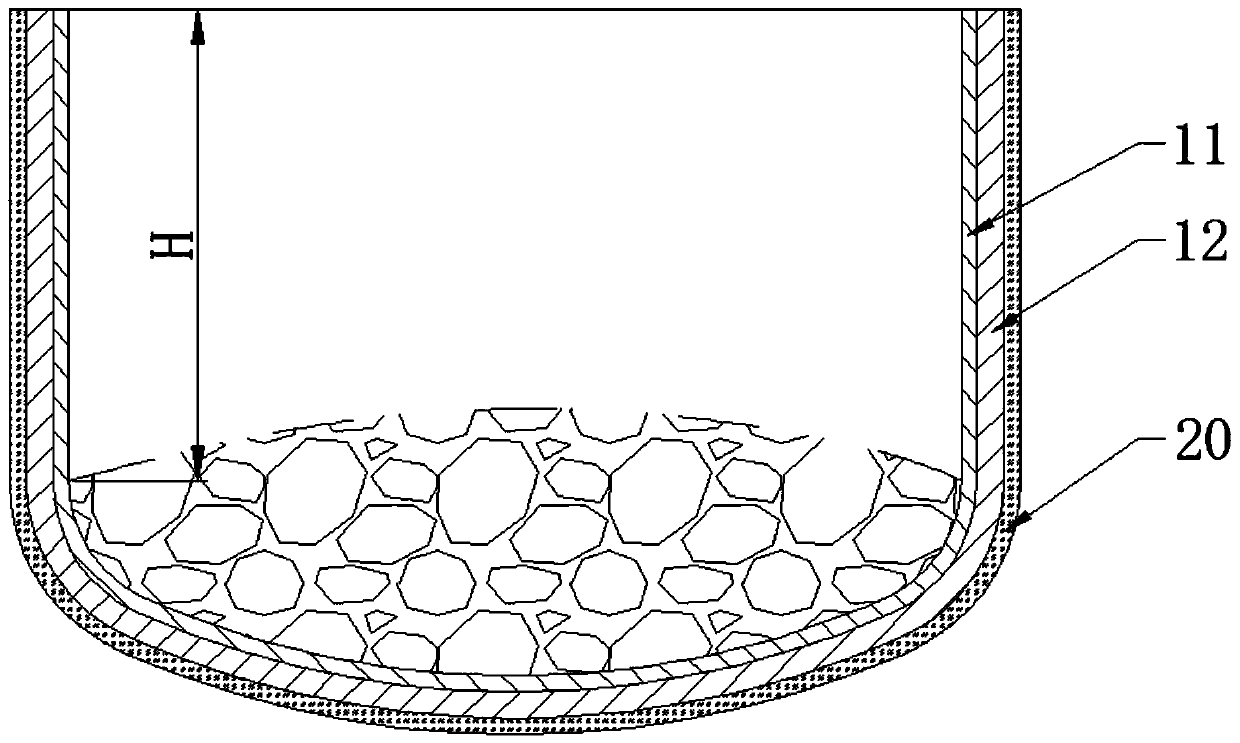

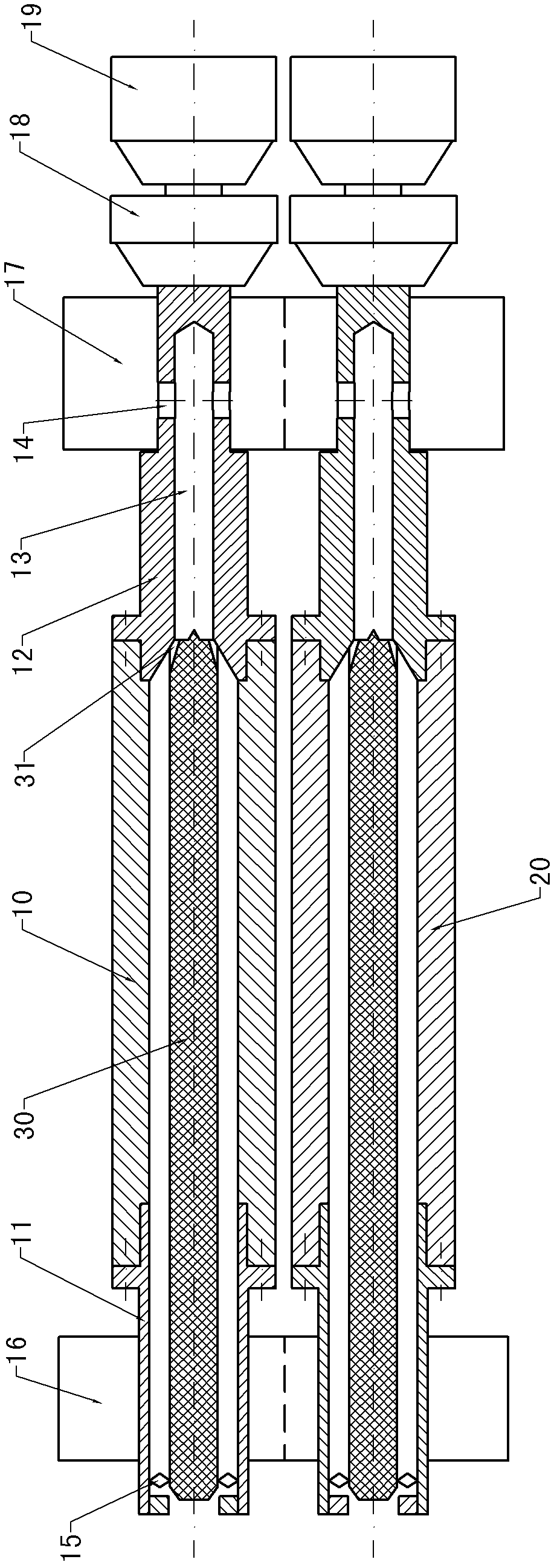

The invention discloses an ultrahigh-purity aluminum crystallization method. The ultrahigh-purity aluminum crystallization method comprises the following steps of: selecting a high-purity aluminum raw material and melting the high-purity aluminum raw material into aluminum liquid in a graphite crucible; inserting a crystallization device into the graphite crucible; driving a graphite pipe sleeve to rotate synchronously by a rotary device; continuously introducing cooling gas into a gas cooling system in the graphite pipe sleeve to start crystallization; keeping a constant rotary speed of a crystallization machine in a crystallization process; adjusting the flowing direction of the cooling gas in a cooling gas path so that the surface of the graphite pipe sleeve, which is in contact with the aluminum liquid, is directionally solidified and an inverted mushroom type high-purity crystal substance with a certain thickness is separated out; when crystallization set time is reached, stopping the crystallization device from rotating and then stopping introducing the cooling gas into a rotary body; lifting the crystallization device out from the graphite crucible and picking off the crystal substance on the graphite pipe sleeve below the crystallization machine to obtain the high-purity crystal substance; and pouring out the residual aluminum liquid in the crucible and putting the high-purity crystal substance into the crucible again to be repeatedly crystallized to obtain the crystal substance with higher purity. By adopting the method disclosed by the invention, the problems in the prior art that the purification cost is high and the purification effect is not good are solved.

Owner:宁波锦越新材料有限公司

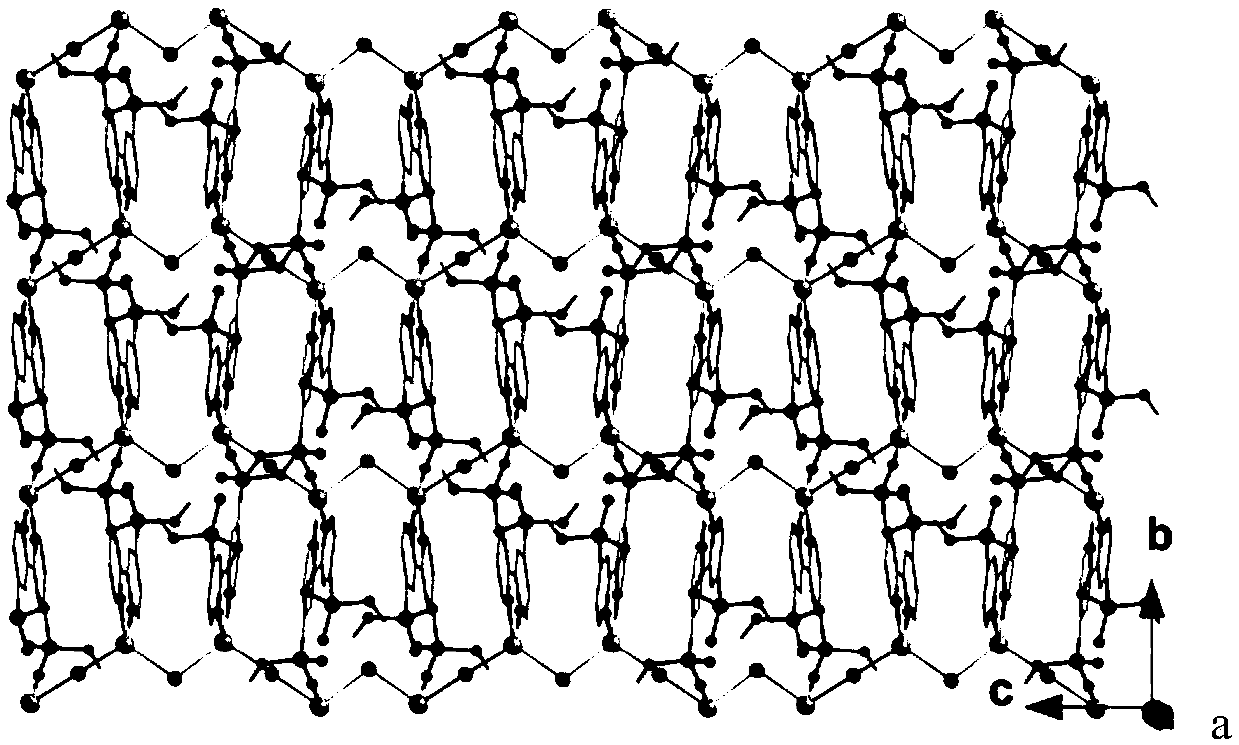

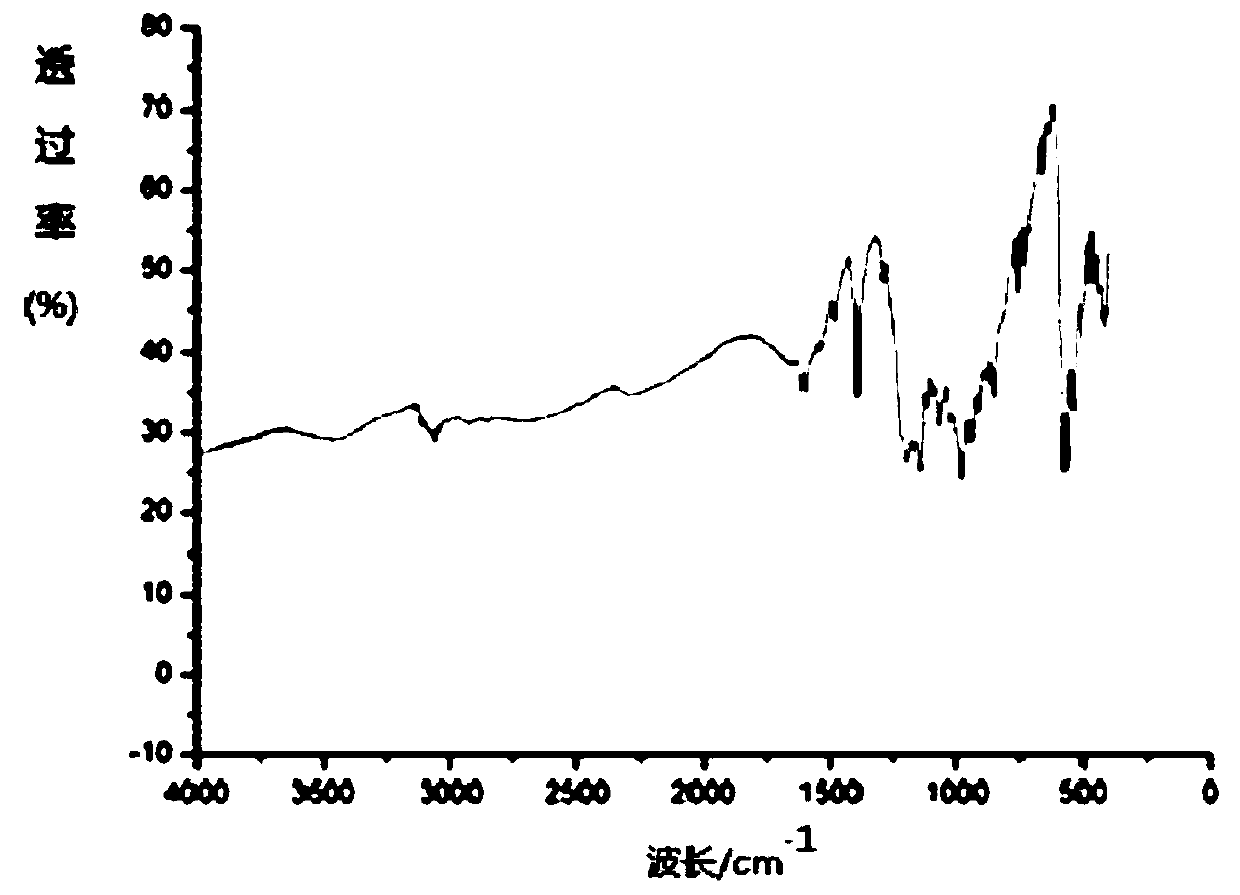

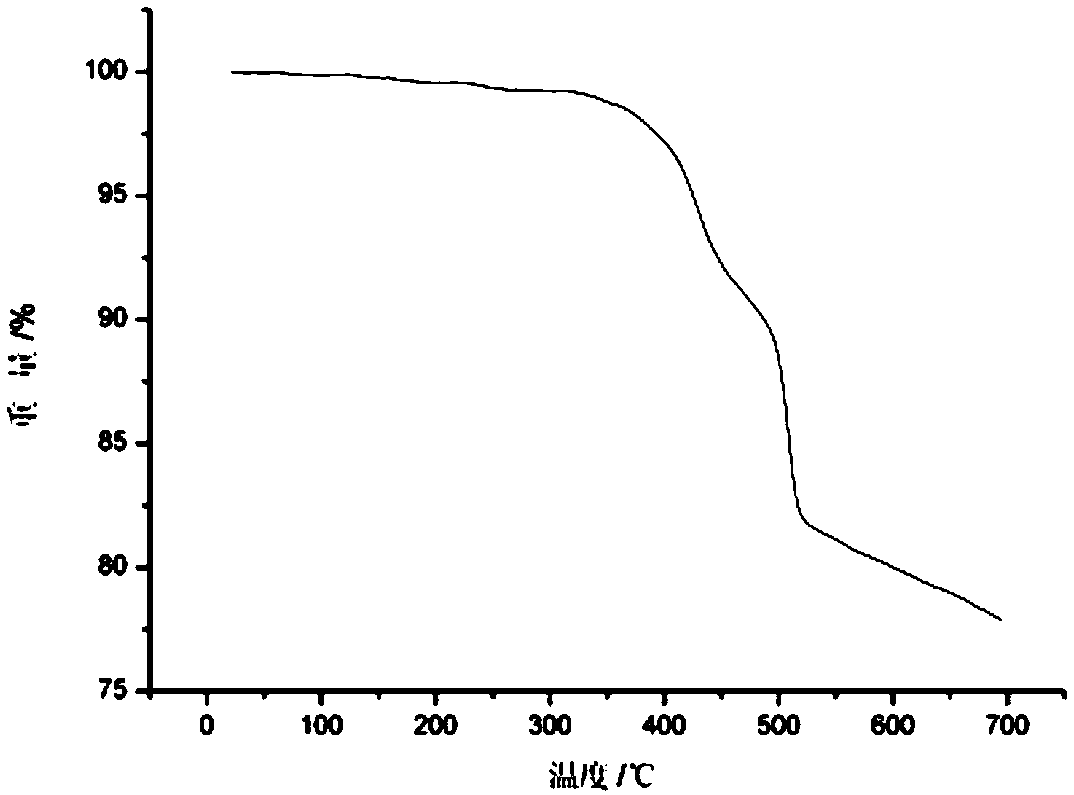

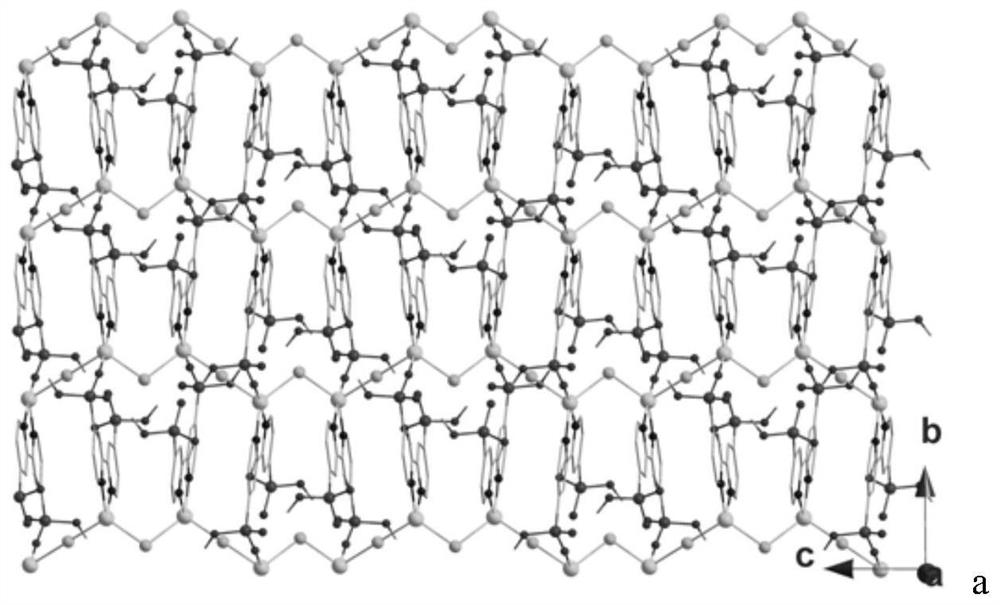

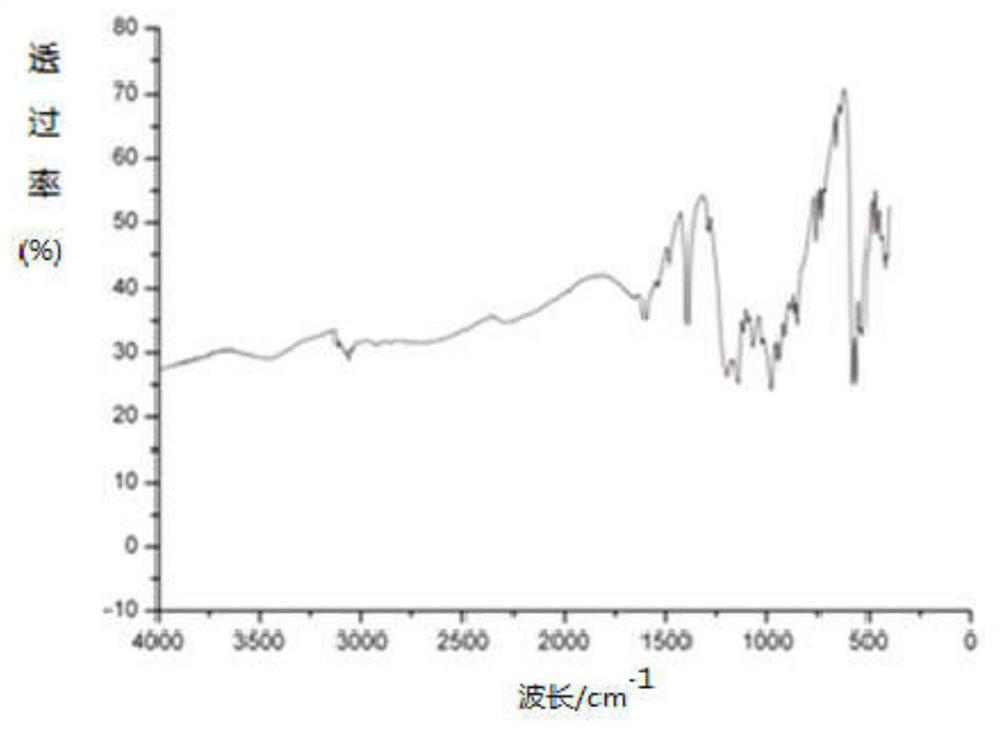

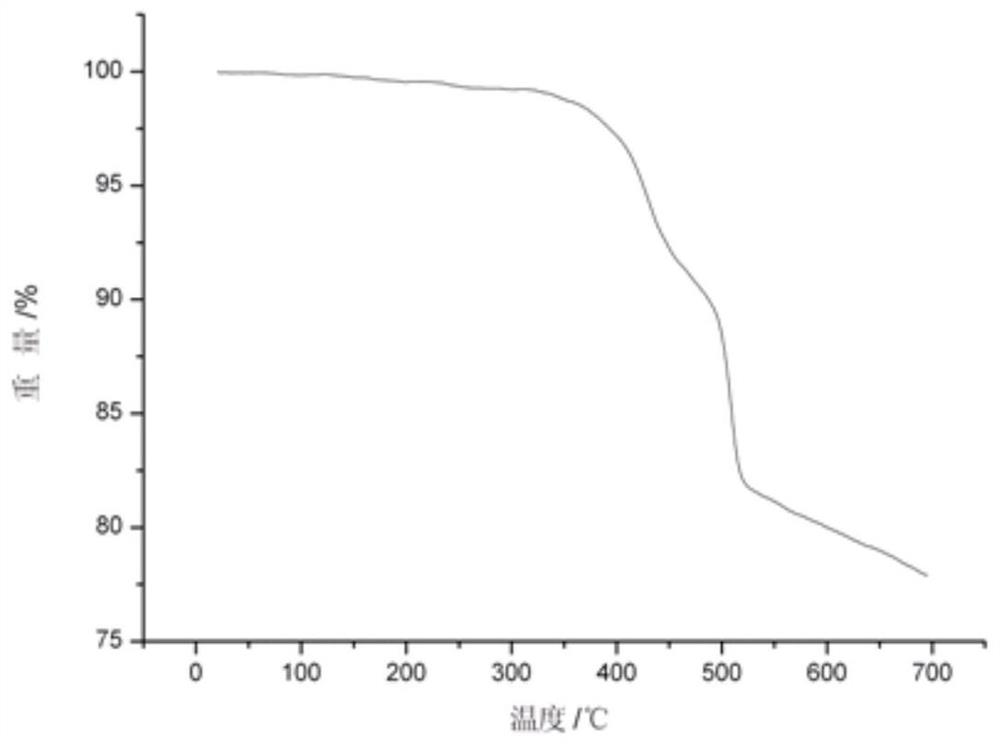

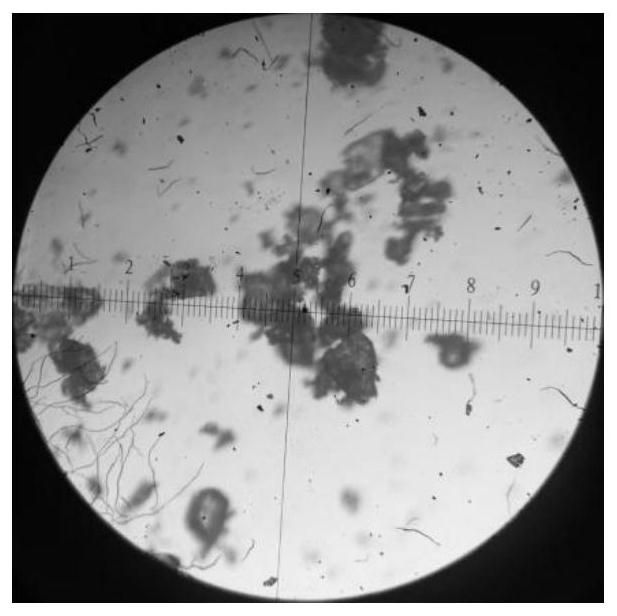

Two-dimensional MOFs (Metal Organic Frameworks) material with proton conductivity and preparation method thereof

ActiveCN109593207AImprove the crystallization effectImprove thermal stabilityMetal-organic frameworkProton

The invention relates to the field of proton conductive materials and discloses an MOFs (Metal Organic Frameworks) material with excellent proton conductivity and a preparation method thereof. According to the method, a two-dimensional layer target material is prepared through heating by taking H4L as a linking ligand and taking Cu<2+> and Cl<-> as connection points. The material disclosed by theinvention has the advantages that the proton conductivity is good; the preparation method is simple and easy to operate; the yield is high; the thermodynamic and chemical properties are stable; and the material is easy to popularize and apply in a large area.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

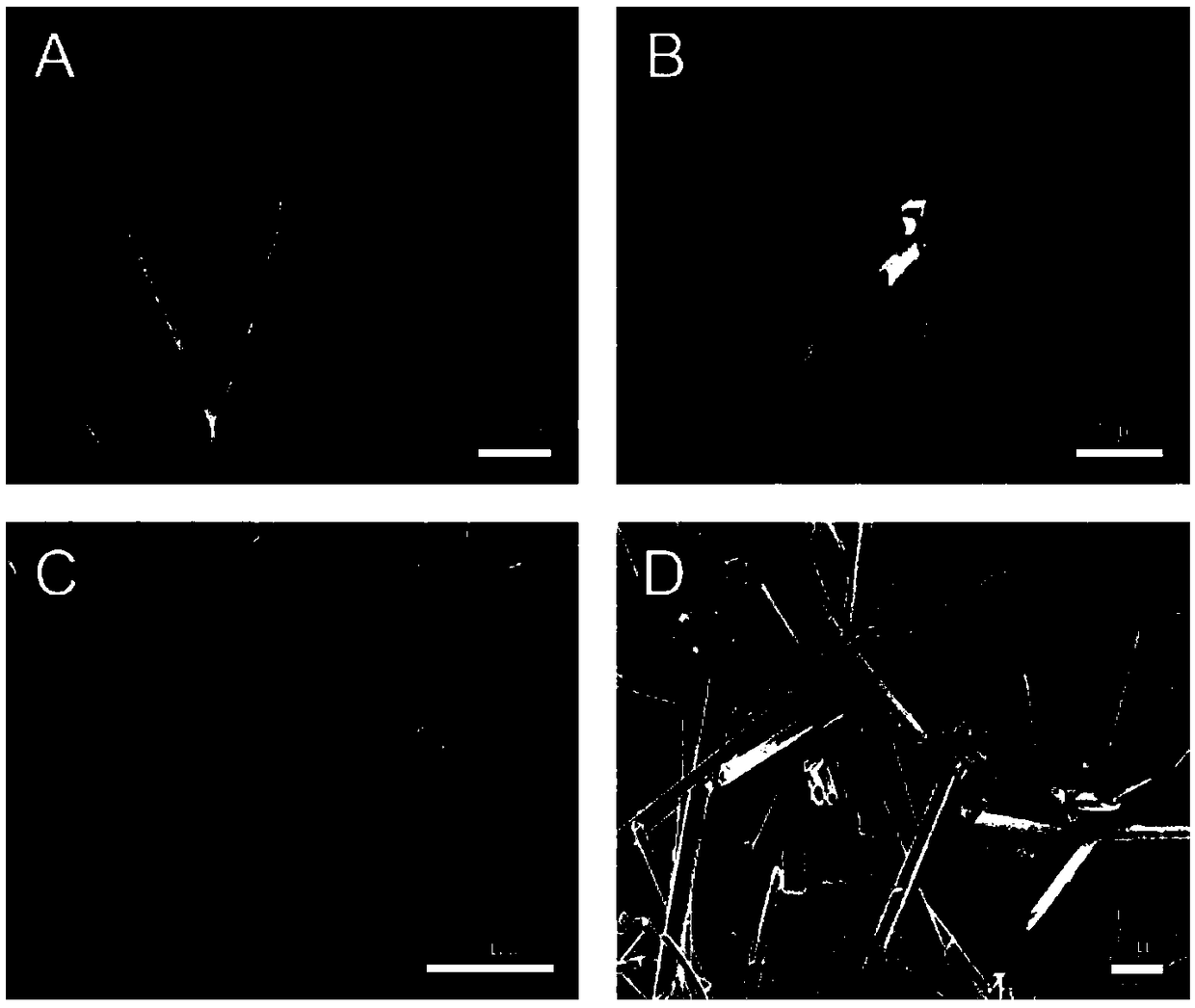

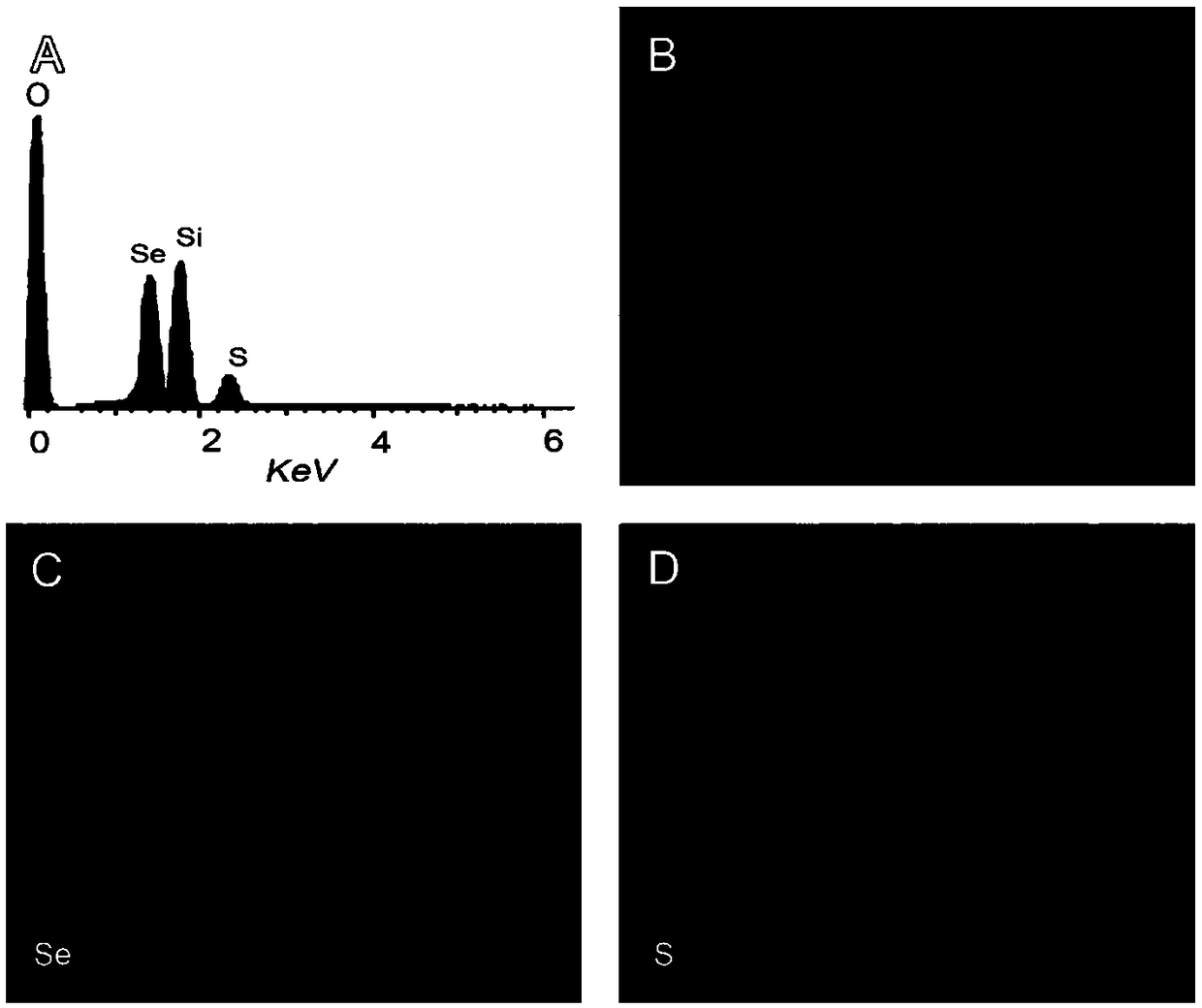

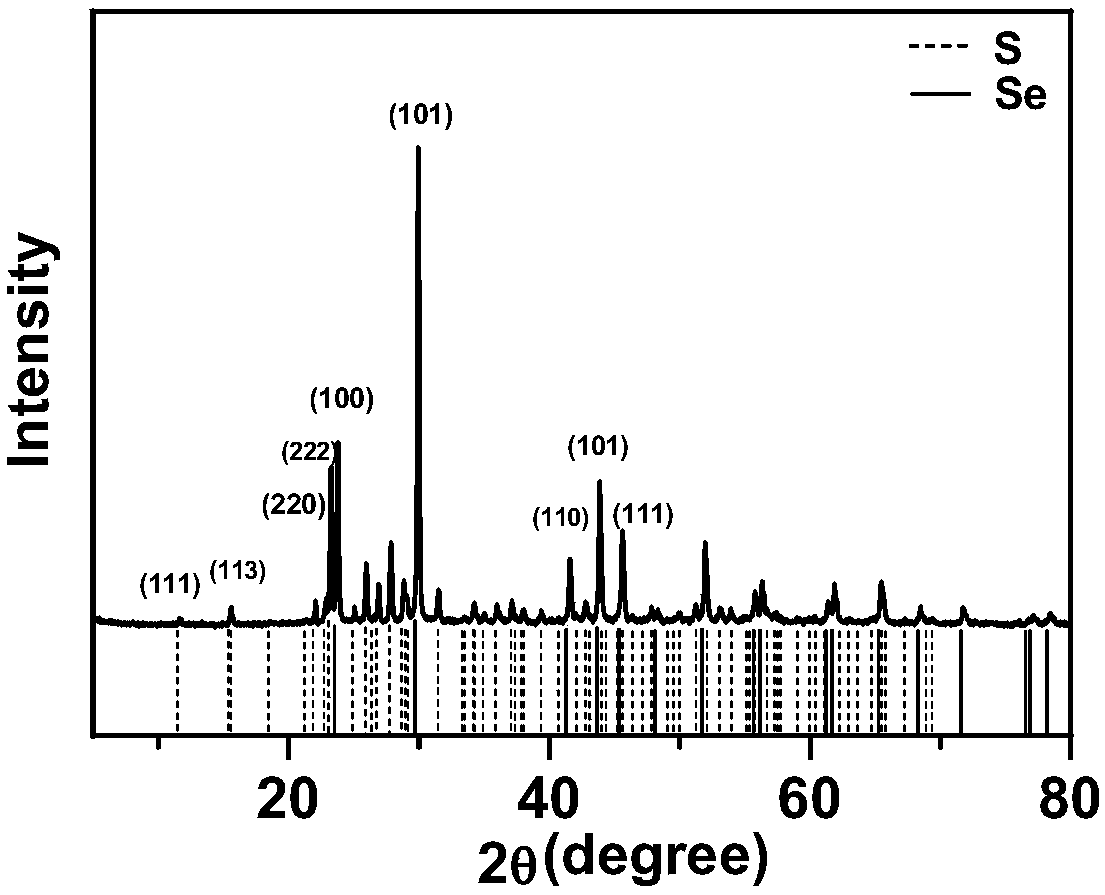

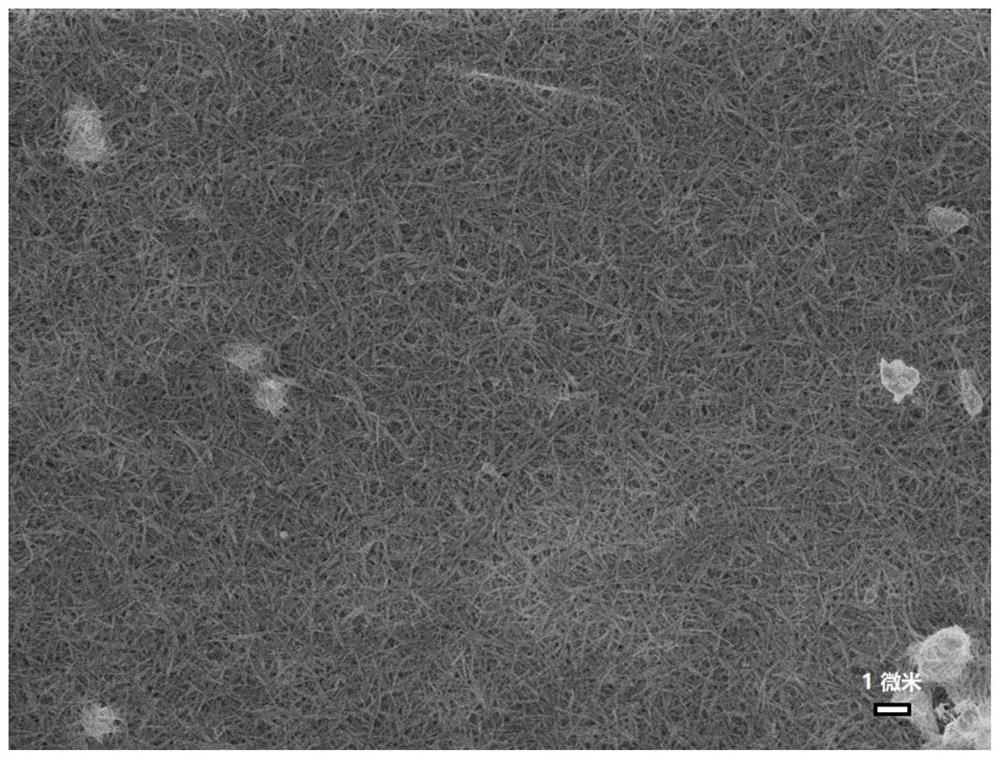

Method for preparing sulfur coated selenium hollow nanotube

InactiveCN108807877AEasy to prepareGood crystallization and repeatabilityCell electrodesNanotechnologyDiamineChemistry

The invention relates to a method for preparing a sulfur coated selenium hollow nanotube. The method comprises the following steps: dissolving selenium powder and sodium sulfite into water, controlling the temperature, stirring so as to obtain a uniform seleno-sodium sulfite solution, putting into a solution with a nonionic surfactant, carrying out ultrasonic treatment, aging, carrying out centrifugal washing so as to obtain selenium nanotubes of a hexagonal system, dissolving the selenium nanotubes into diluted hydrochloric acid, carrying out ultrasonic treatment, dissolving sublimed sulfur into ethidene diamine so as to obtain a sulfuric amino solution, slowly dropping the sulfuric amino solution into the solution, violently stirring under a sealed condition, filtering, washing with water and ethanol, and drying in a drying tank, thereby obtaining a product. Compared with the prior art, the method is capable of preparing the sulfur coated selenium hollow nanotube which has a diameterof about 500 nanometers and a length of about 5-10 micrometers, is good in crystallization and repeatability, can be applied to energy storage such as lithium-sulfur batteries, and is an excellent energy storage material.

Owner:TONGJI UNIV

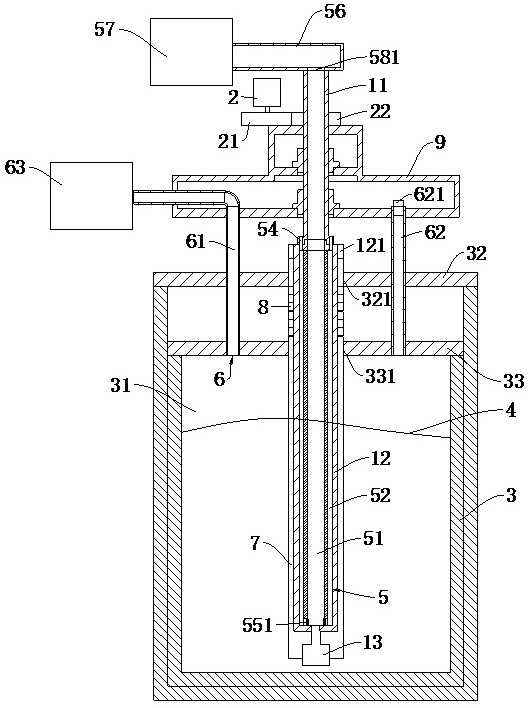

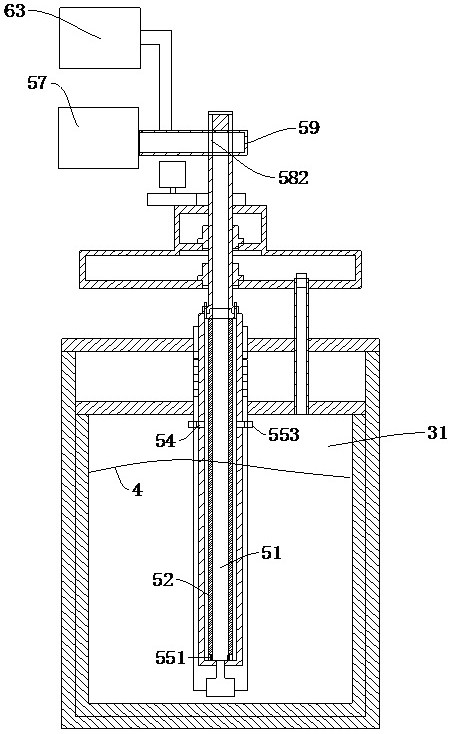

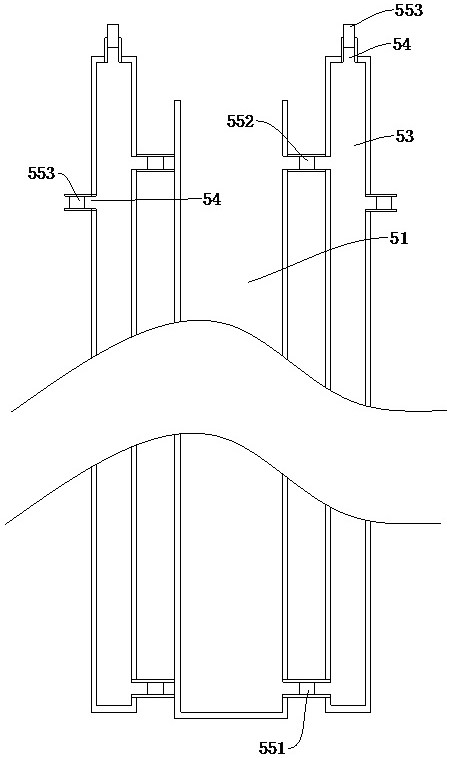

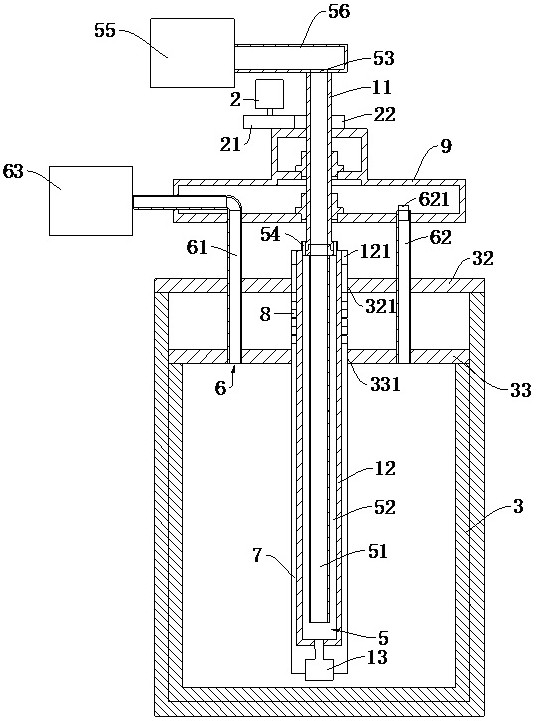

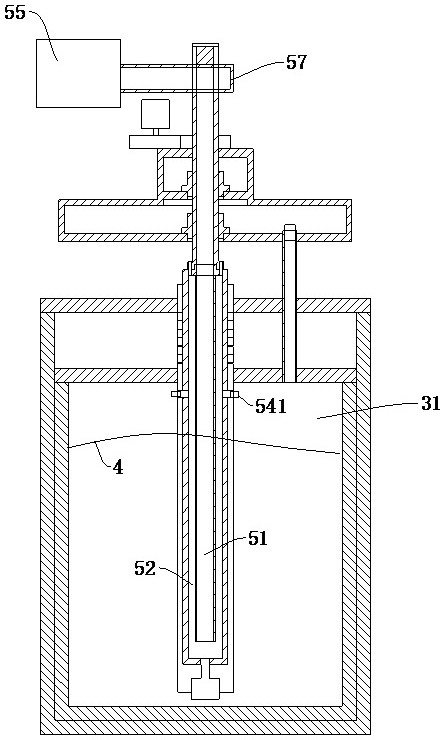

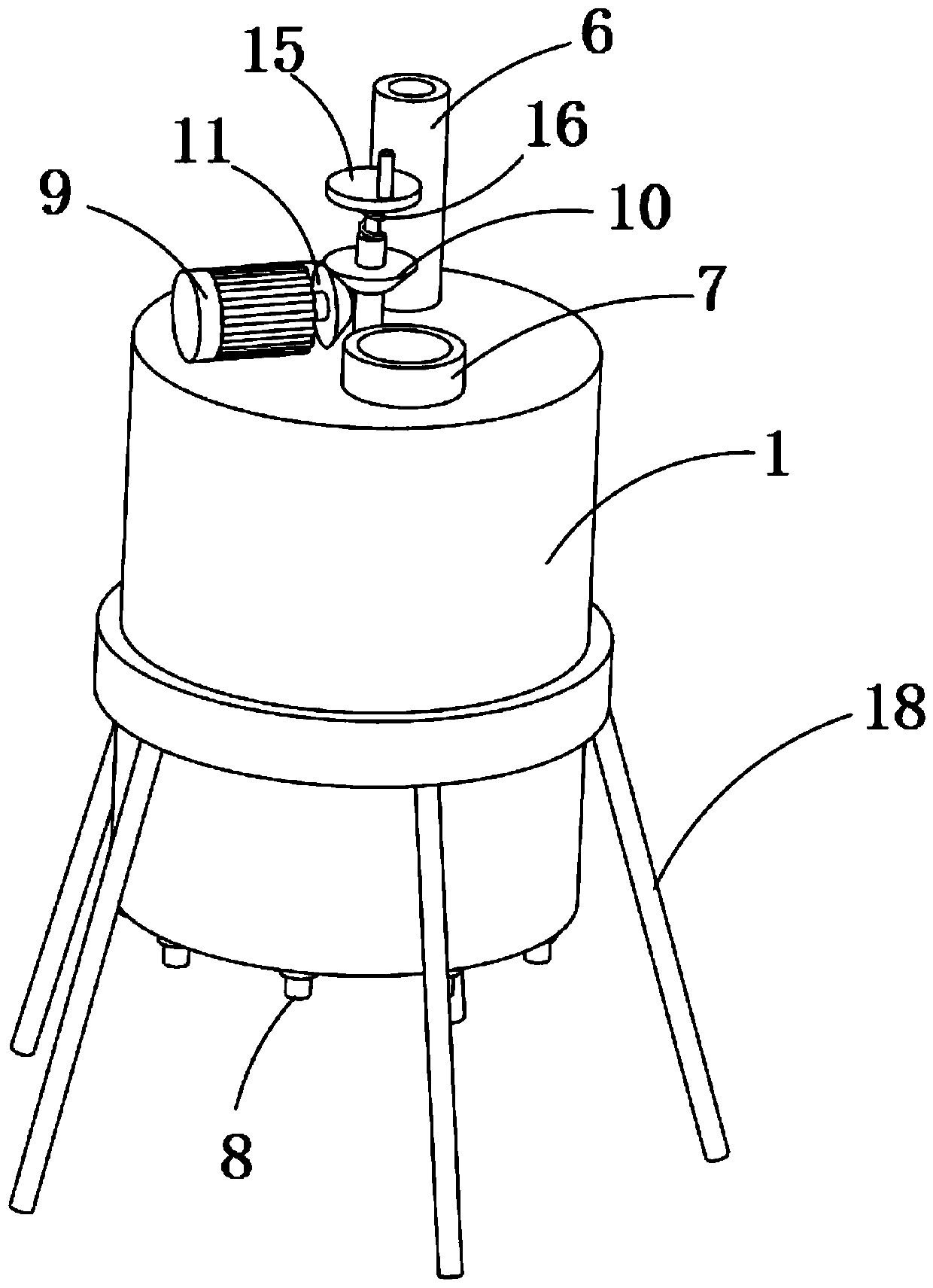

Electronic-grade ultra-high-purity aluminum crystallization device

ActiveCN112708778AHigh purityAchieve purificationProcess efficiency improvementMaterials scienceAluminium

The invention discloses an electronic-grade ultra-high-purity aluminum crystallization device. The electronic-grade ultra-high-purity aluminum crystallization device comprises a rotating body and a driving device; the rotating body is installed above a crucible; the lower end of the rotating body extends into the position below the liquid level of molten aluminum in the crucible; the driving device is connected with the rotating body and is used for driving the rotating body to rotate; a cooling gas circuit is arranged in the rotating body and is filled with cooling gas to cool the rotating body, and then high-purity aluminum crystals are formed at the lower end of the rotating body through solidification and accumulation. The electronic-grade ultra-high-purity aluminum crystallization device solves the problems of high purification cost and poor purification effect in the prior art.

Owner:宁波锦越新材料有限公司

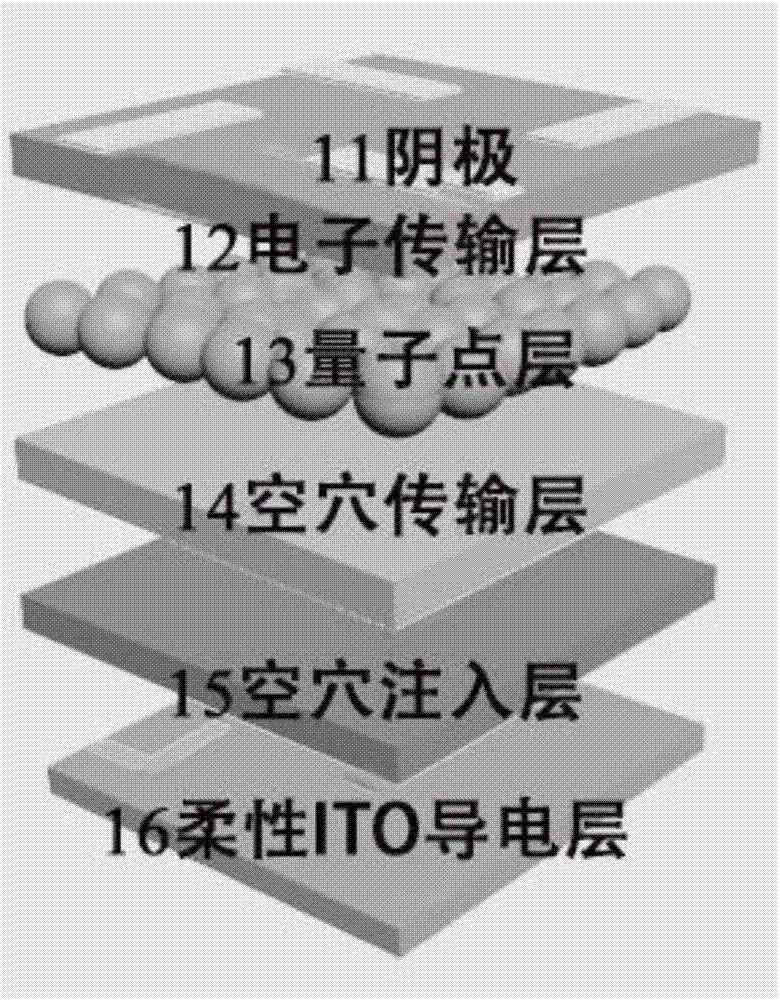

Multiplex quantum dot, preparing method thereof and flexible display device

InactiveCN107083238AHigh Quantum Dot YieldLuminescence Spectrum SymmetrySolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceQuantum dot

The invention provides a multiplex quantum dot, a preparing method thereof and a flexible display device. A two-step method is adopted to prepare the multiplex quantum dot through the mode of adding zinc sources, which is beneficial to avoiding the generation of a by-product of zinc caused when the zinc sources are added with an excessive quantity at one time, avoiding independent nucleations of excessive zinc, achieving control over the size of the multiplex quantum dot, and improving the evenness of particle diameters; the multiplex quantum dot is good in crystalizing effect and good in stability. The prepared multiplex quantum dot has the advantages of being half-peak in width, symmetric in luminescent spectrum, long in fluorescence lifetime, and high in quantum dot yield, and is beneficial to prolonging the service life of the display device when applied to the flexible display device. A result of the embodiment shows that the prepared the multiplex quantum dot is long in fluorescence lifetime, half-peak in width and symmetric in luminescent spectrum, and the fluorescence yield reaches 80% or above.

Owner:广州琉芯光电科技有限公司

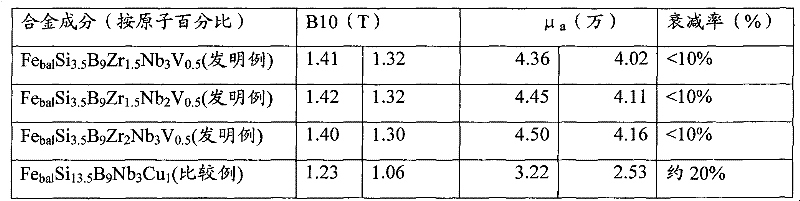

A kind of iron-based nanocrystalline thin ribbon and its manufacturing method

InactiveCN101787499BImprove magnetic propertiesImprove temperature stabilityChemical compositionNanocrystalline silicon

The invention discloses an iron-based nanocrystalline thin strip, wherein, the composition of the iron-based nanocrystalline thin strip is calculated according to the atomic number percentage, and its chemical composition expression is: FeaSibZrcNbdBeMx, wherein, 76≤a≤85, 0≤b+ c+d≤10, 3≤e≤15, 0<x≤4, and a+b+c+d+e+x=100. M is any one or more of Cu, Cr, V, Al. The composition of the iron-based nanocrystalline ribbon is preferably FebalSi3.5B9Zr1.5Nb3V0.5 or FebalSi3.5B9Zr1.5Nb1.5Cr1 or FebalSi3B9Zr1Nb3Al2 or FebalSi13.5B9Nb3Cu1. The high saturation magnetic induction Bs of the iron-based nanocrystalline ribbon is not less than 1.3T. The thickness of the iron-based nano crystal strip is 20-30 microns, and the width is 5-12 mm. The present invention has the characteristics of excellent comprehensive magnetic properties and good temperature stability. In addition, the iron-based nanocrystalline thin strip produced by the manufacturing method of the present invention has good crystallization effect.

Owner:青岛高斯磁通材料有限公司

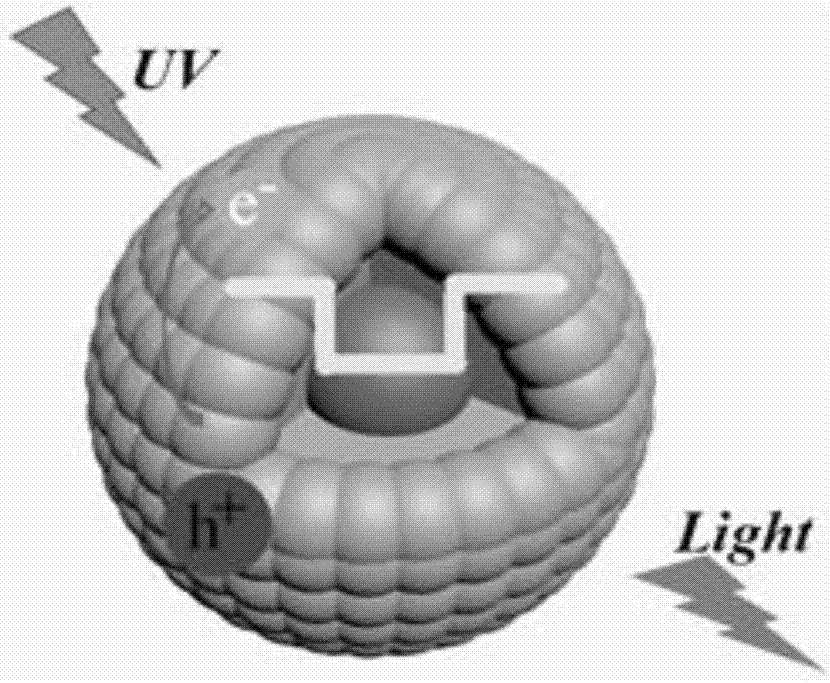

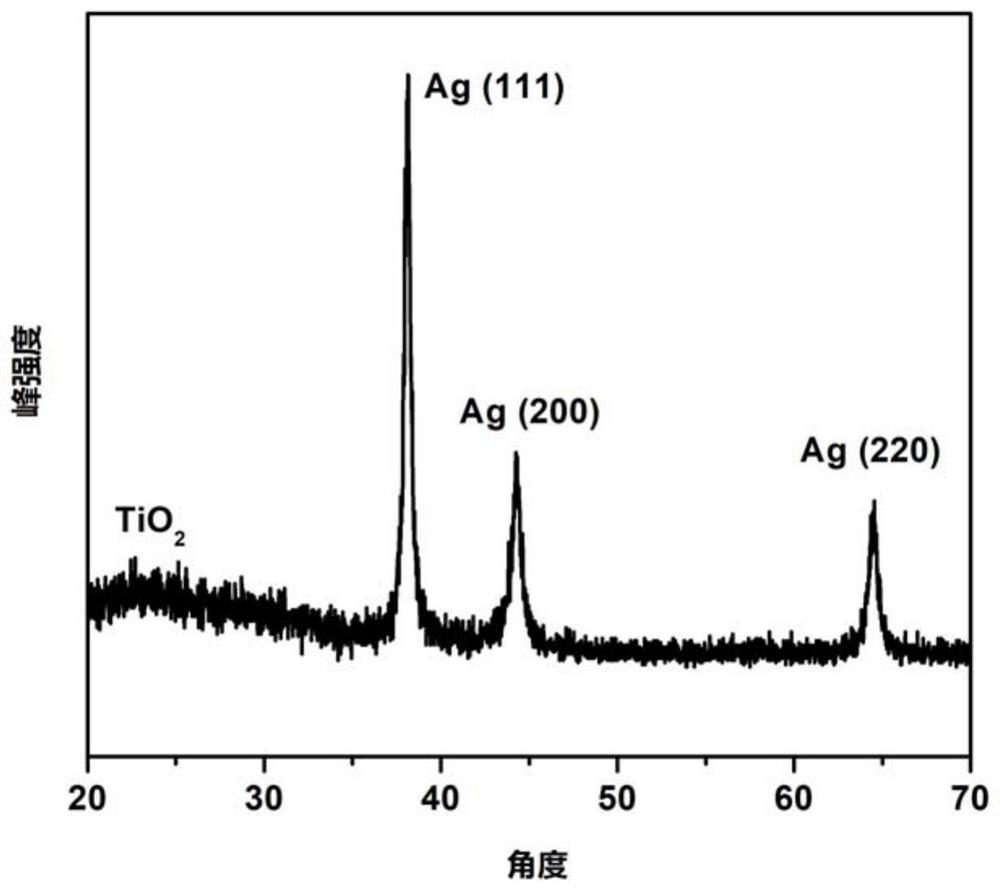

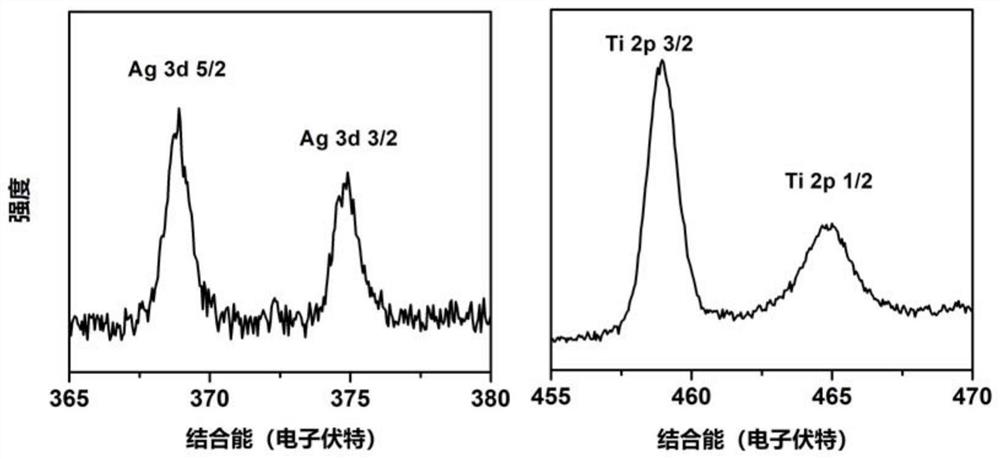

Synthesis method and application of titanium dioxide coated metal nano material

PendingCN113600184AThe overall thickness is thinHydrolysis reaction improvement and optimizationMaterial nanotechnologyHydrogen productionPhotocatalytic reactionPtru catalyst

The invention belongs to the technical field of preparation of metal and titanium dioxide composite nano materials, and discloses a synthesis method and application of a titanium dioxide coated metal nano material. According to the method, metal nanoparticles are generated through reaction between metal salt and organic alcohol, water generated through redox reaction of the metal salt and the organic alcohol provides water needed for generating titanium dioxide, titanium dioxide layers generated on the surfaces of the metal nanoparticles through hydrolysis reaction can be improved and optimized, and the thickness of the generated titanium dioxide layers is small and is 1-5 nanometers. X-ray crystallography characterization shows that according to the synthesized metal titanium dioxide composite structure, metal is crystallized, and the amount of generated titanium dioxide is small. According to the synthesis method, the metal surface can be coated with a thin layer of titanium dioxide, the structure can be used as a photocatalytic active component for a photocatalytic reaction, and in addition, the corrosion resistance of the metal can be improved. Meanwhile, the thickness of a modification layer of titanium dioxide is small, so that metal keeps catalytic reaction activity and can still serve as a catalyst.

Owner:曹洋

Preparation method of high-purity sulfanilamide

InactiveCN108250108AGood hygroscopicityHighly corrosiveOrganic compound preparationSulfonic acid amide preparationM-chloroanilineSulfanilamide

The invention discloses a preparation method of high-purity sulfanilamide. The preparation method specifically comprises the following steps that (1) a chlorosulfonation reaction is conducted, specifically, m-chloroaniline, chlorosulfonic acid and phosphorus trichloride are mixed at the molar ratio of 1:(2.8-3.6):(1-1.8), chlorosulfonic acid is added dropwise within 1.5-2 hours in m-chloroanilinewith the temperature being 35-55 DEG C, after dripping is ended, the mixed liquid is maintained for 10-30 minutes, and first mixed liquid is obtained; phosphorus trichloride is added dropwise into thefirst mixed liquid; and heating is conducted to make the temperature of the mixed product rise to 100-115 DEG C, and heat preservation is conducted for 1.5-3.5 hours at the temperature of 100-115 DEGC; (2) standing is conducted; (3) a chlorosulfonated substance is obtained; (4) an ammoniation reaction is conducted; and (5) refining is conducted, specifically, the obtained amide is subjected to dissolution decoloration and crystallization and purification. By controlling the adding sequence, frequency and amount requirements of the reactants, the reaction can be conducted more sufficiently and safer, the generated by-products are less, obtaining of high-purity sulfanilamide can be ensured, and the main component (4-amino-chloro-1,3-benzendisulfonamide) of high-purity sulfanilamide can beas high as 99.9% or above.

Owner:安徽新世纪药业有限公司

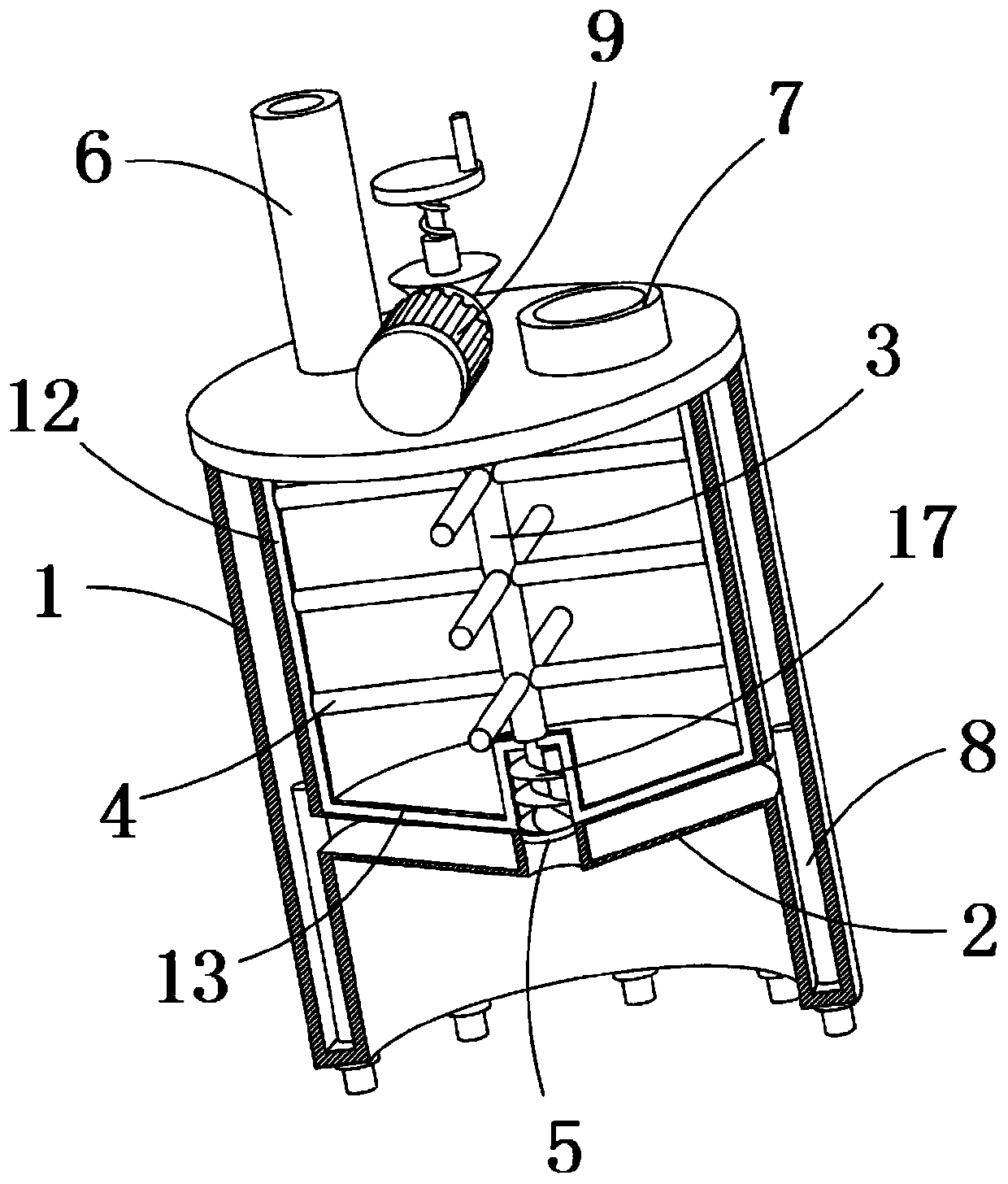

Crystallizer for lithium hydroxide purification product

InactiveCN111167150AGuaranteed uniformityImprove the crystallization effectSolution crystallizationHeat exchange cooling cystallizationPhysicsHeating effect

The invention discloses a crystallizer for a lithium hydroxide purification product. The crystallizer comprises a shell provided with a support frame, wherein a crystallization plate is arranged in the shell; the section of the crystallization plate is in a downward cone shape; a leakage port is formed in the center of the crystallization plate; a cavity is formed in the inner wall of the shell; asecond cavity communicating with a first cavity is formed in the crystallization plate; the first cavity and the second cavity are both filled with water; a heating mechanism for heating the water inthe first cavity and the second cavity is arranged on the shell; a rotating rod is arranged in the shell in a rotating manner; a plurality of stirring rods are fixedly connected to the periphery of the rotating rod; a driving mechanism for driving the rotating rod to rotate is arranged on the shell; and a cleaning and scraping structure is arranged in the shell. The crystallizer of the inventionis reasonable in structure; crystal substances can be conveniently guided out after crystallization, and the phenomena of adhesion and blockage are avoided; and heating effect is stable, so a temperature is constant, and crystallization effect is guaranteed.

Owner:浙江华美新能源科技有限公司

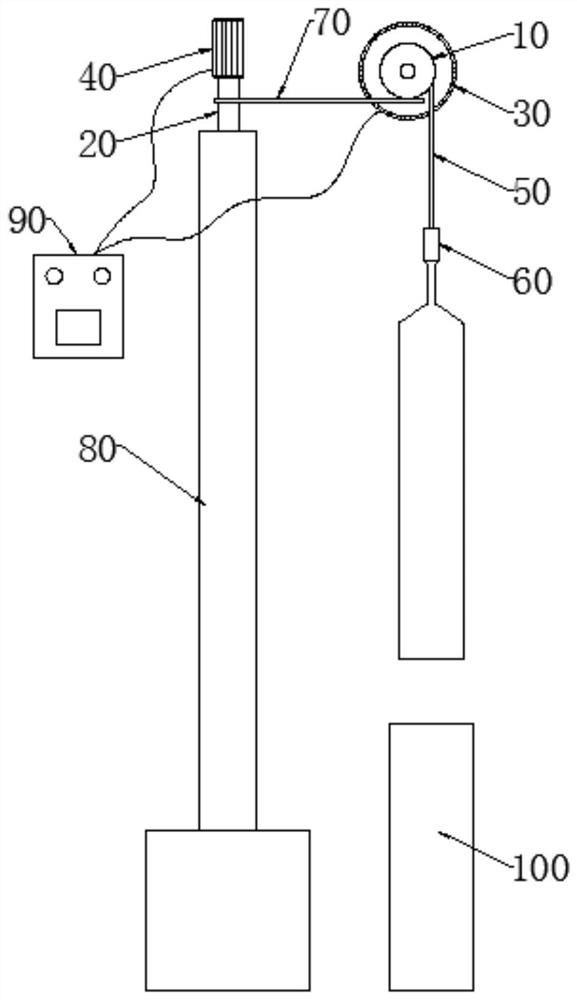

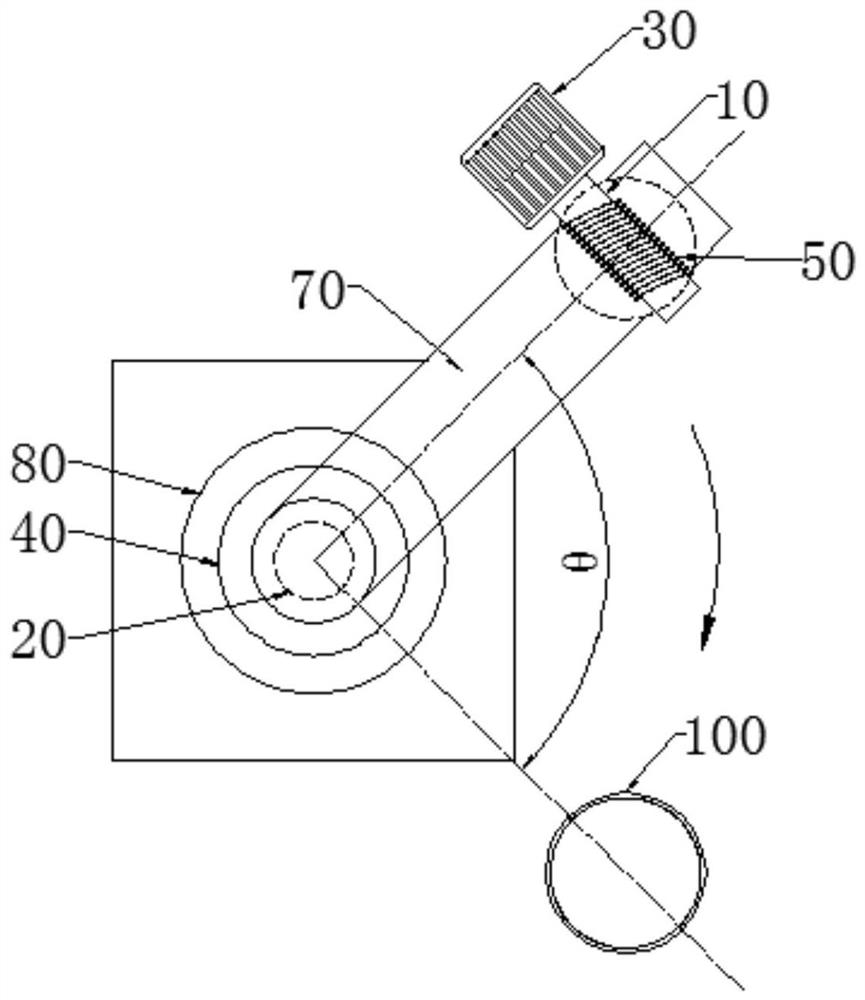

Czochralski silicon rod crystal extraction device and crystal extraction process thereof

PendingCN113549998AExtended service lifeSimple structural designPolycrystalline material growthBy pulling from meltEngineeringMonocrystalline silicon

The invention provides a Czochralski silicon rod crystal extraction device. The device comprises a first rotating shaft, a second rotating shaft, a mooring rope wound around the first rotating shaft, a first driving part used for driving the first rotating shaft to rotate, and a second driving part used for driving the second rotating shaft, one end of the mooring rope is connected with the first rotating shaft, and the other end is connected with the monocrystalline silicon rod through seed crystal; the first driving part drives the first rotating shaft to enable the silicon single crystal rod to move up and down along the axis direction of the silicon single crystal rod; and the second driving part drives the second rotating shaft to enable the single crystal silicon rod to rotate and move along the axis of the single crystal silicon rod. The invention further provides a Czochralski silicon rod crystal extraction process. The crystal extraction device provided by the invention is simple in structural design and easy to operate, the silicon single crystal rod can be safely taken out and placed in a crystal extraction cylinder, the service life of the crystal extraction device is prolonged, and the crystal extraction device is suitable for crystal extraction operation of the silicon single crystal rods with various diameters, wide in applicability, good in crystal extraction effect and high in working efficiency.

Owner:内蒙古中环晶体材料有限公司

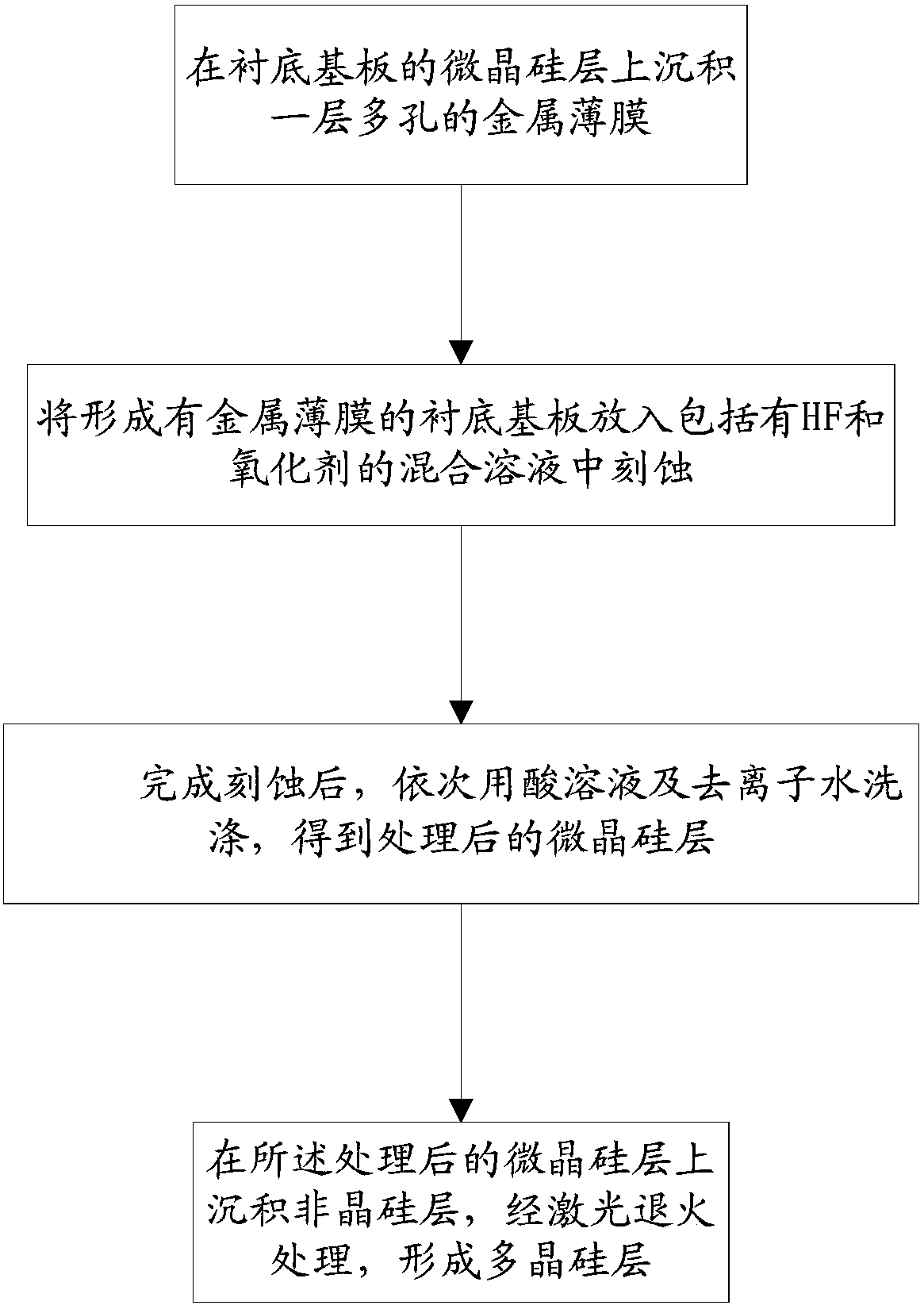

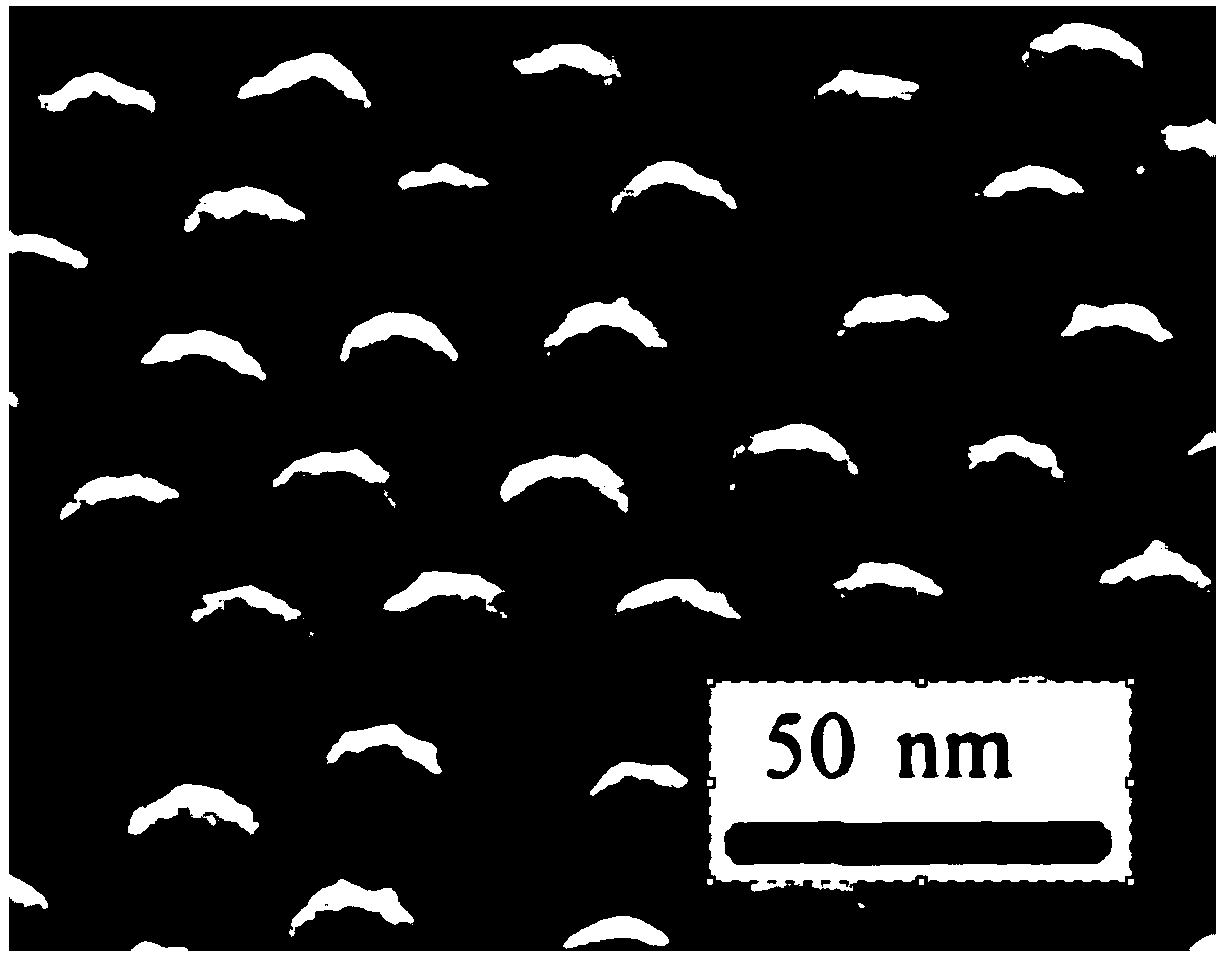

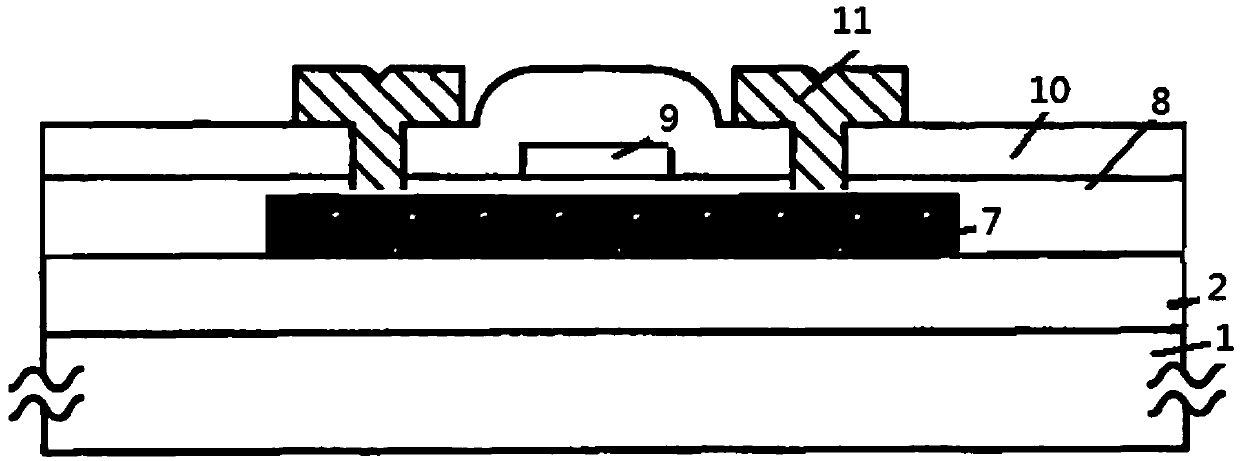

Preparation method of polysilicon layer, thin film transistor, array substrate and display device

ActiveCN106548926BSame growth directionControl areaTransistorSolid-state devicesEtchingDisplay device

Owner:BOE TECH GRP CO LTD

A kind of white light alloy quantum dot and its preparation method, electroluminescent diode and photoluminescent diode

ActiveCN106206878BHigh yieldImprove the crystallization effectSemiconductor devicesColor rendering indexPhotoluminescence

The invention provides a white-light alloy quantum dot and a preparation method therefor, an electroluminescent diode and a photoluminescence diode. The white-light alloy quantum dot is prepared by a thermal injection method in combination of jacketing for multiple times; the reaction temperature is low, the reaction time is short and the yield is high; the prepared white-light alloy quantum dot is good in crystalline forming effect and high in stability; the nanocrystal dimensions are easy to control and uniform in distribution; and the prepared electroluminescent diode and photoluminescence diode are wide in range and relatively high in color rendering index, and can achieve composite white light. The preparation method provided by the invention is simple to operate, mild in conditions, low in energy consumption, low in cost, easy to control a process, and suitable for large-scale industrial popularization.

Owner:厦门世纳芯科技有限公司

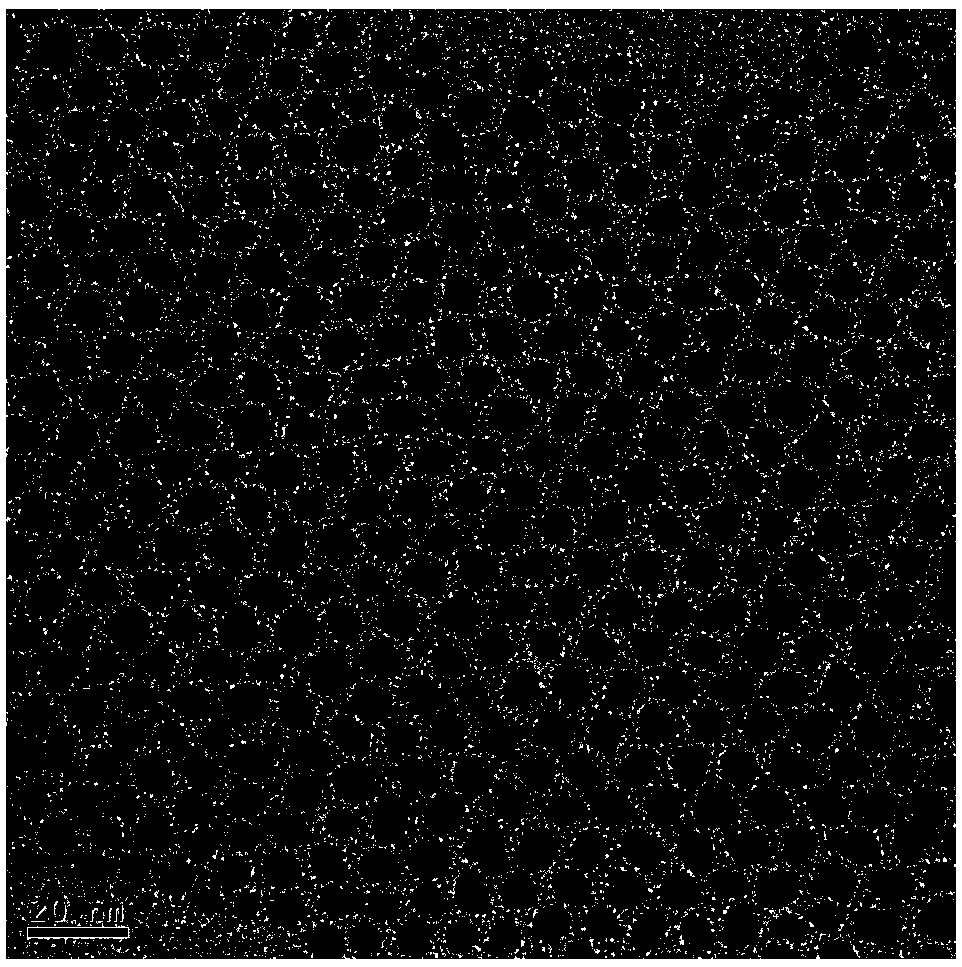

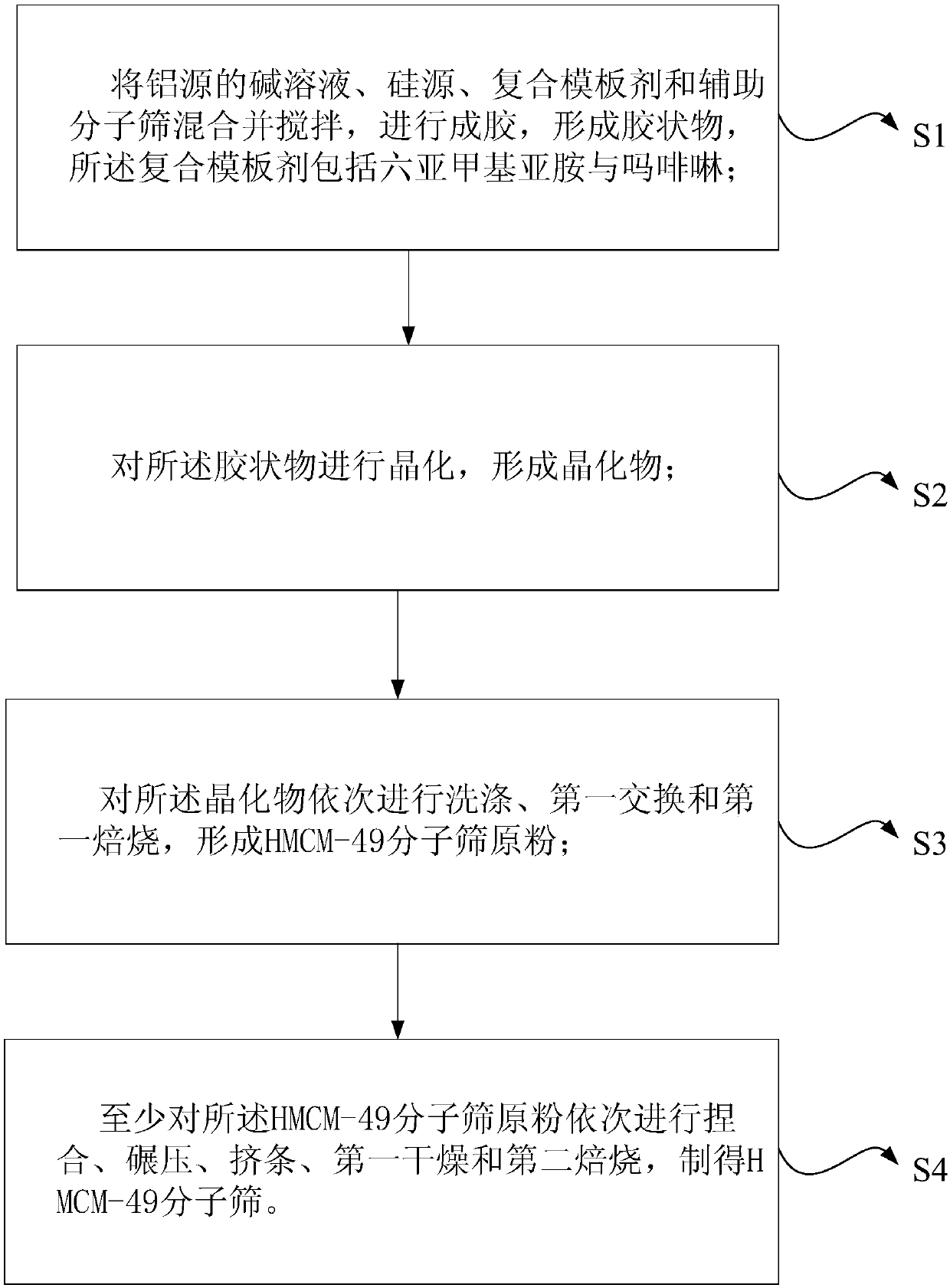

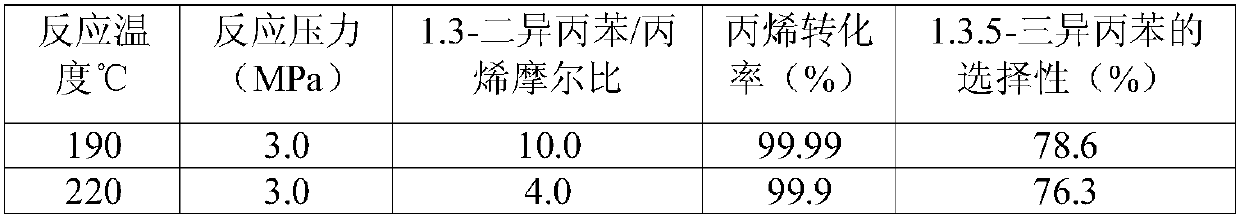

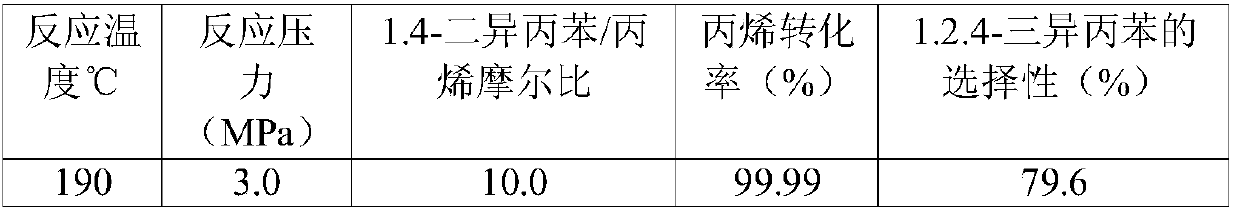

Molecular sieve catalyst for synthesizing triisopropylbenzene, and preparation method thereof, and synthesis method of triisopropylbenzene

ActiveCN111346667AGood water solubilityImprove gel performanceMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention provides a molecular sieve catalyst for synthesizing triisopropylbenzene, a preparation method of the molecular sieve catalyst, and a synthesis method of the triisopropylbenzene. The preparation method comprises the following steps: S1, mixing and stirring an alkaline solution of an aluminum source, a silicon source, a composite template agent and an auxiliary molecular sieve, and carrying out gelatinization to form a jelly, wherein the composite template agent comprises hexamethyleneimine and morpholine; S2, crystallizing the jelly to form a crystallized substance; S3, sequentially carrying out washing, first exchange and first roasting on the crystallized substance to form HMCM-49 molecular sieve raw powder; and S4, sequentially at least carrying out kneading, rolling, strip extrusion, first drying and second roasting on the HMCM-49 molecular sieve raw powder to prepare the HMCM-49 molecular sieve. According to the preparation method, a composite template agent containing hexamethyleneimine and morpholine is adopted, and the obtained HMCM-49 molecular sieve is small in grain size, wherein the grain size ranges from 50 nm to 200 nm.

Owner:PETROCHINA CO LTD

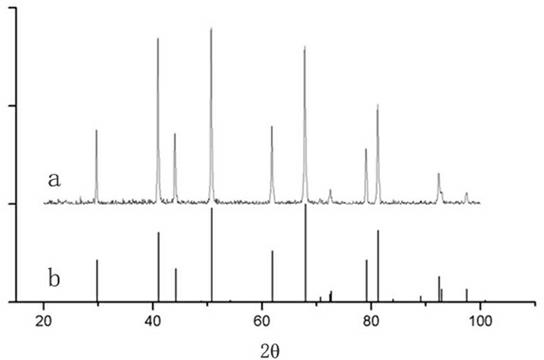

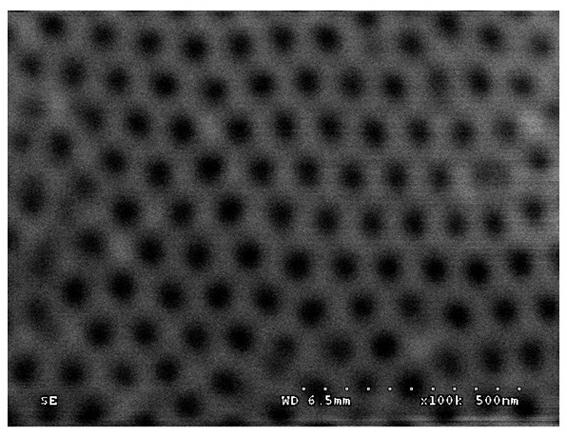

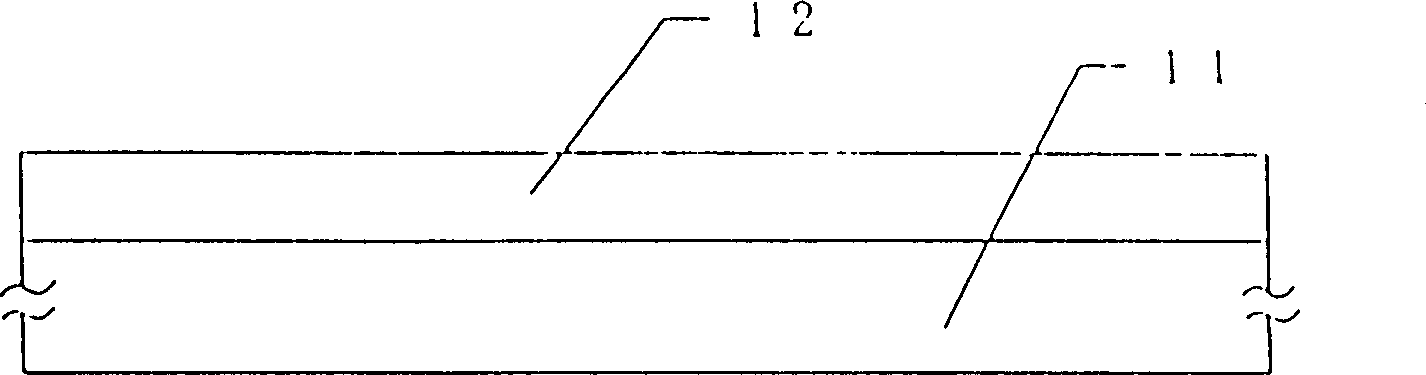

Nano micropore corundum film and preparation method thereof

InactiveCN102618904AImprove the crystallization effectImprove heat resistanceAnodisationMaterial nanotechnologyNanostructureNanometre

The invention discloses a nano micropore corundum film and a preparation method thereof. The nano micropore aperture of the corundum film is 30 to 200 nanometers, the thickness of the corundum film is 5 to 100 microns, and the corundum film contains aluminum oxide serving as a main component. The nano micropore corundum film is prepared by the steps of preparing a porous anodic aluminum oxide template and thermally treating the porous anodic aluminum oxide template at a high temperature. The nano micropore corundum film is a film with a nano structure, can be widely applied in the fields of nano material extraction, preparation, synthesis and biotechnology, has single component, regular shape and stable performance, and is easy to prepare.

Owner:FUZHOU UNIV

A kind of two-dimensional MOFs material with proton conductivity and its preparation method

ActiveCN109593207BImprove the crystallization effectImprove thermal stabilityMOSFETConductive materials

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

A salt gypsum crystal transformation activator, preparation method and application

Owner:HOHAI UNIV +1

Crystal taking device of direct drive motor

ActiveCN107403749AStable airflowGood crystallization effectSemiconductor/solid-state device manufacturingElectric machineSemiconductor package

The invention relates to the technical field of semiconductor packaging, in particular to a crystal taking device of a direct drive motor. The device comprises a power device used for blowing and absorbing air, a motor, a swinging arm arranged on a rotation shaft of the motor, an air mouth arranged in the swinging arm, and an air pipe used for communicating the power device and the air mouth. The air pipe is divided into a first air pipe and a second air pipe. A channel (2) for air circulation is arranged in a rotor (1) of the motor. One end of the first air pipe communicates with the power device and the other end of the first air pipe communicates with one end of the channel (2) in the rotor of the motor. One end of the second air pipe communicates with the other end of the channel (2) in the rotor of the motor, and the other end of the second air pipe communicates with the air mouth in the swinging arm. According to the invention, the air path is stable during work of the crystal taking device.

Owner:宁波知了智能科技有限公司

Method of manufacturing semiconductor device with crystallizing semiconductor film

InactiveCN1094652CControl and reduce concentrationImprove the crystallization effectTransistorPolycrystalline material growthMetal silicideAmorphous silicon

A method of manufacturing a semiconductor device having a crystalline silicon film consisting of two steps of forming a crystal nucleus in a surface region of an amorphous silicon film and growing a crystal from the nucleus using a laser. Typical nuclei are silicon crystals or metal silicides with the same structure as silicon crystals.

Owner:SEMICON ENERGY LAB CO LTD

The method that compound template agent synthesizes zsm-35 molecular sieve

ActiveCN108147426BGood water solubilityImprove the crystallization effectFerrierite aluminosilicate zeoliteNanotechnologyMolecular sieveSodium aluminate

The invention relates to a method for synthesizing a ZSM-35 molecular sieve by a composite template agent. The method comprises the following steps: dissolving sodium metaaluminate or sodium aluminateand alkali into desalted water to prepare a sodium metaaluminate-alkali aqueous solution or a sodium aluminate-alkali aqueous solution; adding hexamethylene imine into cyclohexane to prepare a composite template agent, adding the composite template agent into silicon sol, completely stirring, dropwise adding the sodium metaaluminate-alkali aqueous solution or the sodium aluminate-alkali aqueous solution until reaching a thick point, increasing the stirring speed, opening gel and slowly adding the residual sodium metaaluminate-alkali aqueous solution or the sodium aluminate-alkali aqueous solution; adding the ZSM-35 molecular sieve, stirring, gelatinizing and crystallizing, and synthesizing a high-nanoscale ZSM-35 molecular sieve.

Owner:PETROCHINA CO LTD

Crystallization method for improving czochralski monocrystal

InactiveCN110552056AIncrease crystallization rateImprove the crystallization effectPolycrystalline material growthBy pulling from meltBarium carbonateN type silicon

The invention provides a crystallization method for improving a czochralski monocrystal. The crystallization method comprises the step: sequentially adding a silicon raw material and a barium carbonate powder into a quartz crucible at an initial charging stage of the czochralski monocrystal. The quartz crucible comprises a body; the body comprises a transparent layer and an air bubble layer whichare sequentially arranged from inside to outside; and the outer wall of the body is provided with an outer coating. The invention provides the crystallization method suitable or pulling P-type and N-type silicon single crystal rods, the technical problem that barium carbonate powder is repeatedly added during repeated charging to increase the content of a barium element in a silicon liquid so as to result in low crystallization rate of the czochralski monocrystal is solved, not only can the crystallization rate of monocrystal pulling be increased, but also the content of the barium element inthe silicon liquid can be effectively controlled, the process is simplified, the production efficiency is increased, and the production cost is reduced.

Owner:内蒙古中环晶体材料有限公司

Production method for grinding-free and polishing-free black transparent microcrystalline glass plate

ActiveCN102603193BLower melting temperatureImprove the crystallization effectGlass rolling apparatusGlass productionWater flowCrystallization temperature

The invention relates to a production method for a Li2O-A2O3-SiO2-series grinding-free and polishing-free black transparent microcrystalline glass plate. Because modified component niobium oxide is added into a formula, the fusing temperature of the glass can be lowered by adding the niobium oxide. The modified component niobium oxide has good crystallization performance and also has the physical properties that the crystallization temperature is lowered, the coefficient of expansion is lowered, and the like. In the calendaring molding equipment, because the traditional solid molded roll is changed into a hollow roller structure and an inner core rod is arranged in the hollow roller structure, circulating cooling water is introduced into the hollow roller during production; the temperature of a molded roll body can be accurately controlled by controlling the water inlet temperature, the water outlet temperature and the flow speed, and in addition, the roller can be evenly cooled; the microcrystalline glass plate calendered and molded by the roller is flat, and the obtained microcrystalline glass plate has a smooth and flat surface so as to satisfy the user requirement, and does not deform at the high temperature for a long time; because grinding treatment and polishing treatment are omitted in the product production process, two working procedures of grinding and polishing in the product process are reduced; and therefore, the product quality is improved, the production efficiency is improved, the production cost is lowered, the production environment for workers is improved, and the clean production is realized.

Owner:广东科迪微晶玻璃实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com