Crystallization method for improving czochralski monocrystal

A single crystal, straight cylinder technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of increased barium content and low crystallization rate of Czochralski single crystal, so as to improve the effect and increase the cost. The effect of crystal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

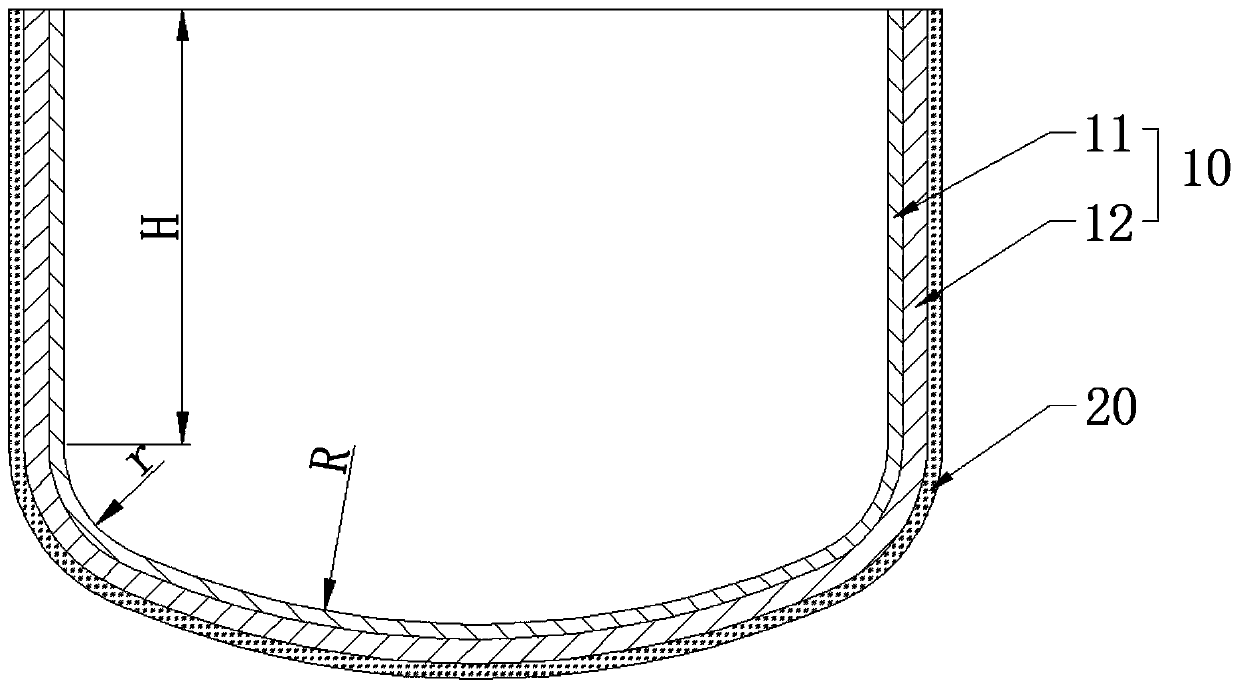

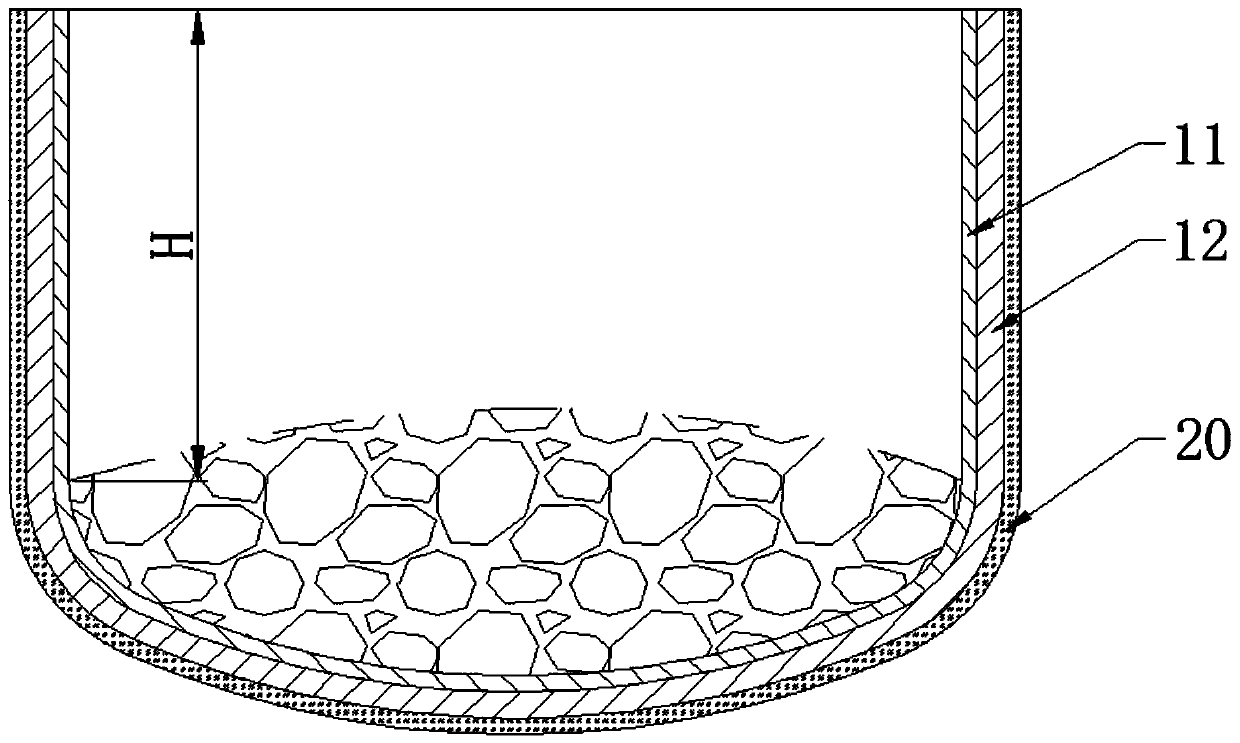

[0022] The present invention proposes a quartz crucible, such as figure 1 Shown, comprise main body 10, main body 10 comprises transparent layer 11 and air bubble layer 12, and transparent layer 11 and air bubble layer 12 are set up from inside to outside successively; It is compatible with the structure of the air bubble layer 12. Further, both the main body 10 and the outer coating 20 include a straight part and a curved part arranged below the straight part. There is a connecting part in between, and the connecting part is also an arc-shaped structure. The radius r of the connecting part is smaller than the radius R of the curved part. The thickness of the connection part, the thickness of the connection part is smaller than the thickness of the bending part. Among them, the purpose of the transparent layer 11 is to reduce the bubble de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com