Synthesis method and application of titanium dioxide coated metal nano material

A metal nano, titanium dioxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, nanotechnology, etc., can solve problems such as difficulty in forming composite nanomaterial structures, and difficulty in controlling the hydrolysis reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 100mg AgNO 3 1. Add 0.02 mL of tetrabutyl titanate into 20 g of glycerol, and stir evenly. Then the solution was transferred to a sealed pressure-resistant autoclave, and reacted at 160° C. for 10 h. After heating and reacting, the reaction kettle was left to cool down to room temperature, and the products generated in the reaction were washed with absolute ethanol, dilute hydrochloric acid, and distilled water respectively to obtain a silver nanorod material coated with a thin layer of titanium dioxide on the surface.

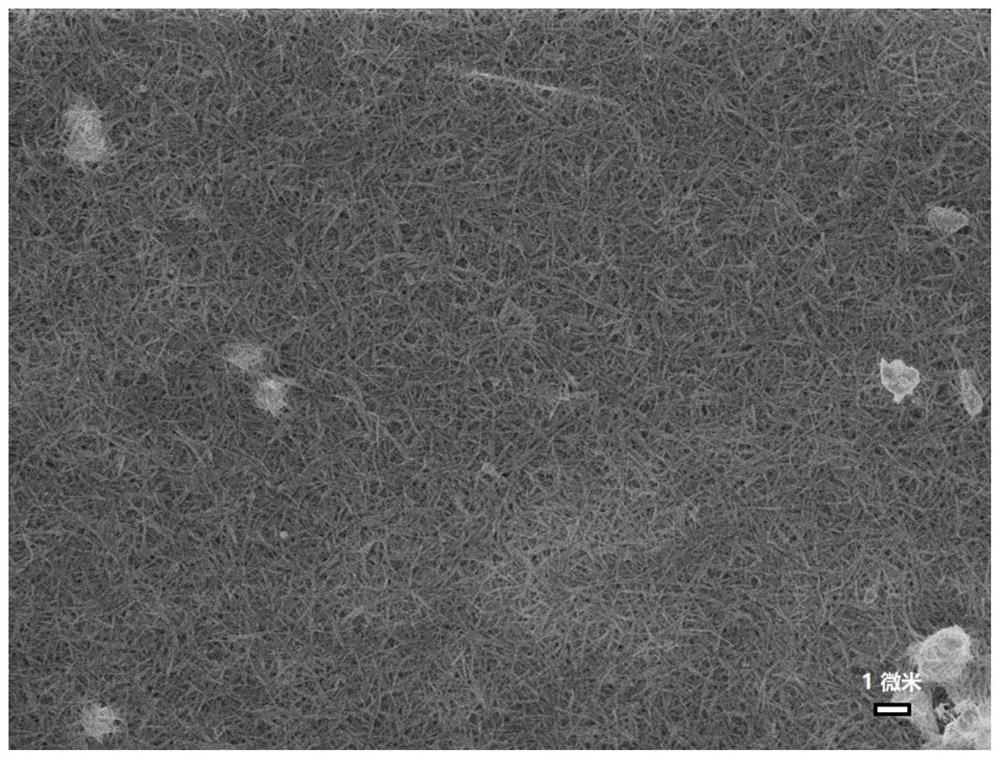

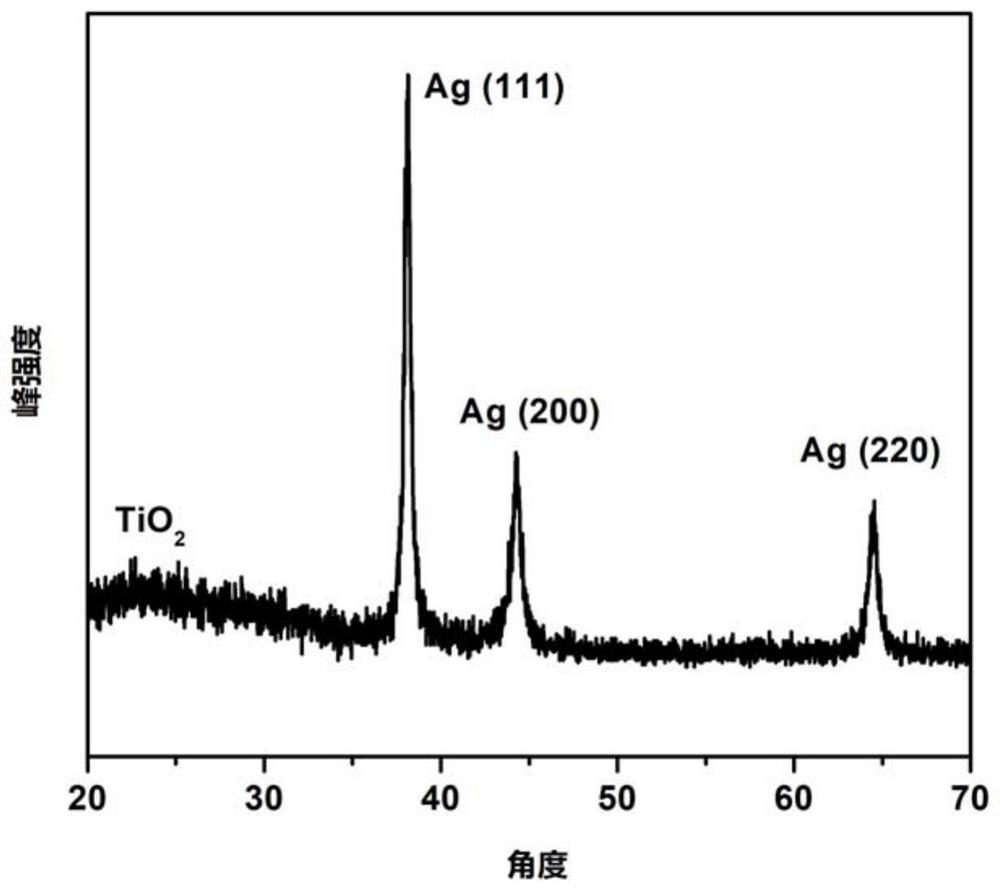

[0040] Such as figure 1 As shown, the Ag-coated TiO was tested by scanning electron microscopy 2 , it was found that a uniform nanorod structure product was generated, and Ag-coated TiO was tested by X-ray diffraction 2, it was found that the material exhibited a strong Ag crystal peak, due to the interface modified TiO 2 The amount is small, no obvious TiO 2 crystallization peak.

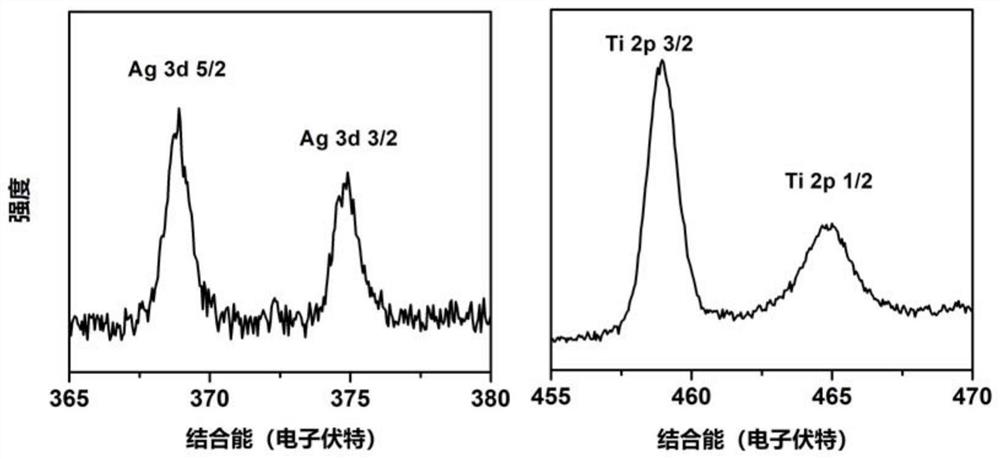

[0041] Such as figure 2 As shown, through X-ray photoelectron s...

Embodiment 2

[0044] 100mg AgNO 3 1. Add 0.05 mL of tetrabutyl titanate into 20 g of glycerol, and stir evenly. Then the solution was transferred to a sealed pressure-resistant autoclave, and reacted at 160° C. for 12 h. After heating and reacting, the reaction kettle was left to cool down to room temperature, and the products generated in the reaction were washed with absolute ethanol, dilute hydrochloric acid, and distilled water respectively to obtain a silver nanorod material coated with a thin layer of titanium dioxide on the surface.

Embodiment 3

[0046] 100mg AgNO 3 1. Add 0.01 mL of tetrabutyl titanate into 20 g of glycerol, and stir evenly. Then the solution was transferred to a sealed pressure-resistant autoclave, and reacted at 160° C. for 10 h. After heating and reacting, the reaction kettle was left to cool down to room temperature, and the products generated in the reaction were washed with absolute ethanol, dilute hydrochloric acid, and distilled water respectively to obtain a silver nanorod material coated with a thin layer of titanium dioxide on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com