Patents

Literature

246results about How to "No sticking phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

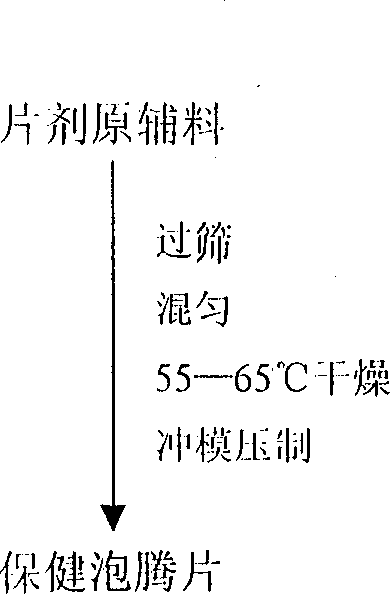

Healthy effervescent tablet and its prepn

InactiveCN1344516AImprove liquidityGood compressibilityFood scienceBifidobacteriumEffervescent tablet

The effervescent health beverage table is featured by that it contains functional oligosaccharide, such as oligo-xylose, oligo-fructose, oligo-galactose, oligo-isomaltose, etc., with bifidobacterium proleferating function and may contain medicine, vitamins, minerals, soluble chitin and other functional factors. The tablet is produced through sieving, mixing, drying at 55-65 deg.c and tableting. The effervescent health beverage tablet, when being thrown into water, will be dissolved instantly into homogeneous beverage, health liquid, medicated tea, etc. while producing bubbles and turning up and down.

Owner:卢济台

Water-based aluminized transfer glue and preparation method thereof

The invention discloses water-based acrylic aluminized transfer glue and a preparation method thereof, and belongs to the field of adhesive preparation. The transfer glue with 45 to 55 percent of solid content is prepared from monomers, composite emulsifier, initiator, buffering agent, pH regulator, water-based aid and deionized water serving as raw materials by pre-emulsifying, seed reaction, polymerization reaction and compounding; the monomers comprise hard monomer, soft monomer and functional monomer, wherein the hard monomer consists of styrene and methyl methacrylate; the soft monomer consists of ethyl acrylate and butyl acrylate; and the functional monomer consists of any one of acrylic acid and methacrylic acid, any one of hydroxyethyl acrylate and hydroxypropyl acrylate, and N-hydroxymethyl acrylamide. The transfer glue has high bonding force and peeling strength, does not drop, has good coating property, is more convenient for operation, and does not stick rollers.

Owner:NANTONG GAOMENG NEW MATERIAL

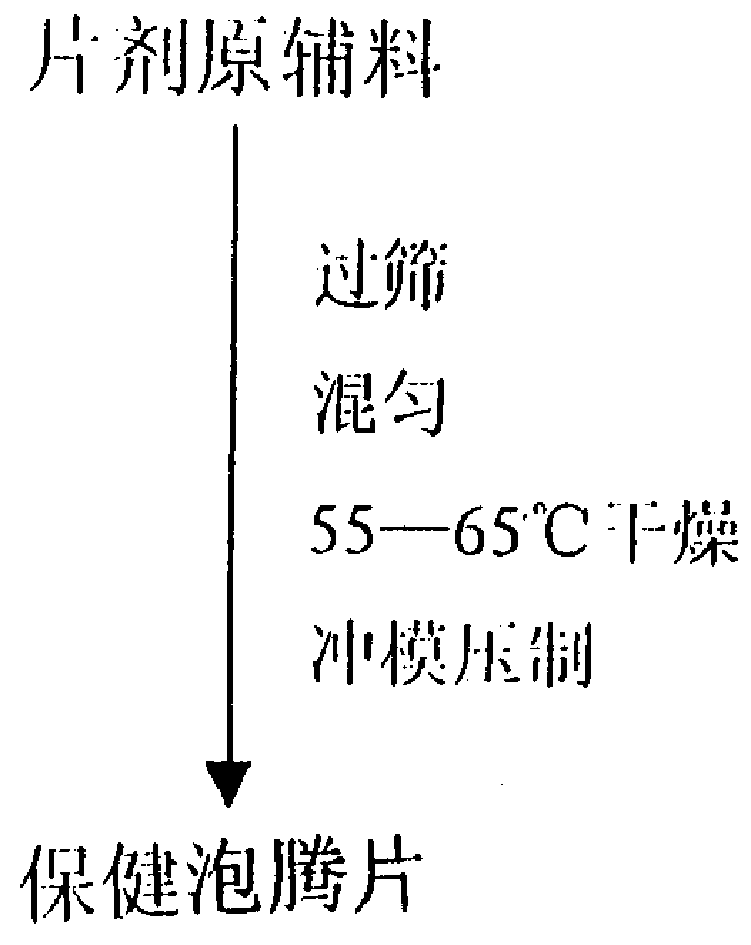

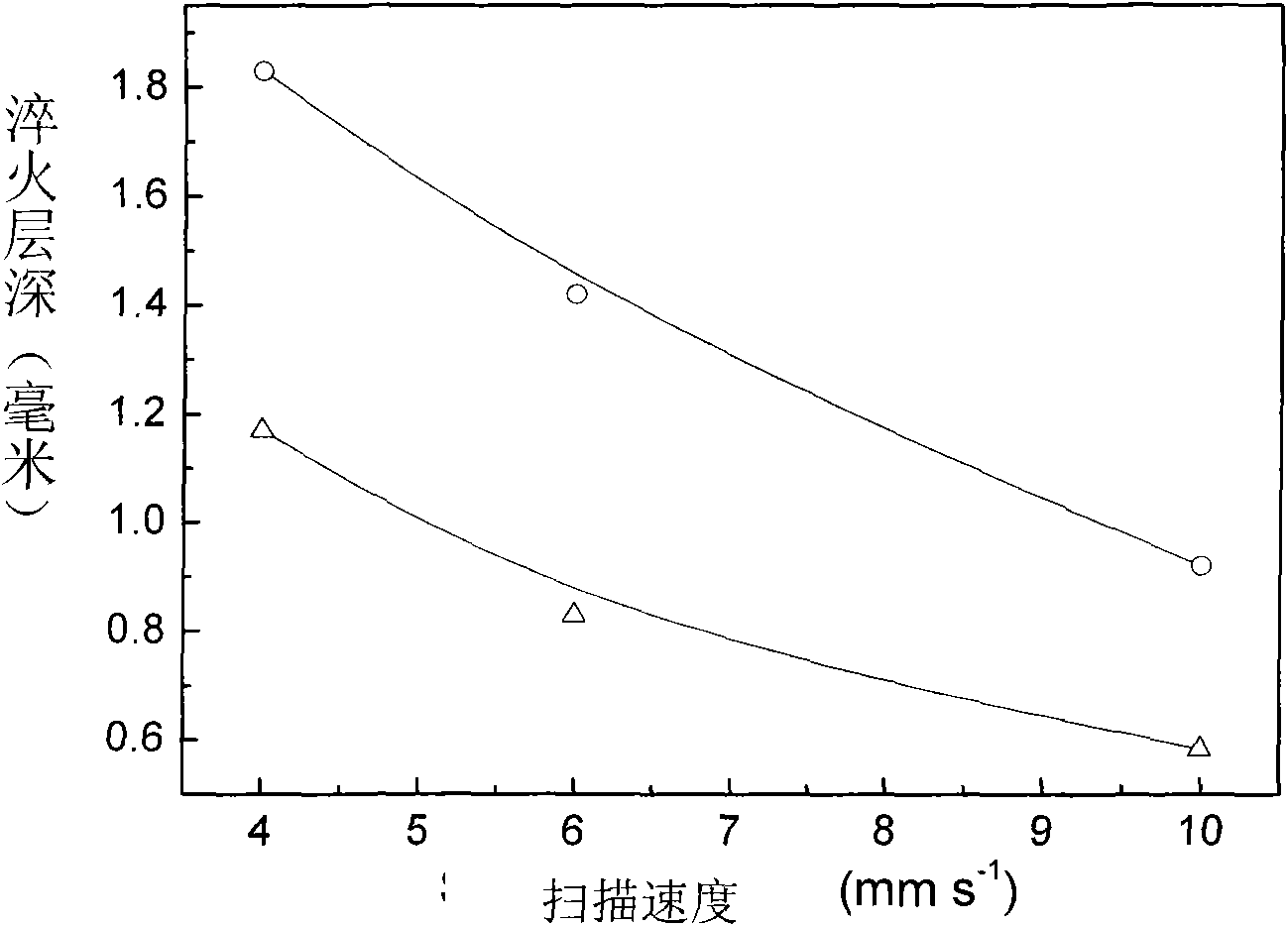

Surface laser quenching process of car panel die

InactiveCN101665862AExtend your lifeTo achieve the purpose of quenchingFurnace typesHeat treatment furnacesChemical industryLaser quenching

A laser quenching process of a car panel die surface comprises the steps of: firstly coating a coating on the surface of a die; then utilizing the laser emitted by a CO2 laser device to scan the surface of the die coated with the coating; and finally eliminating the coating on the surface of the die. The laser quenching process of the car panel die surface is characterized in that the painting ofthe coating comprises 60-70% by weight of Al2O3 particles, 10-22% by weight of ZrO2 particles and 12-20% by weight of SiO2 particles, which are then evenly dispersed by water with 20-50 percent of thepainting weight and finally coated on the surface of the die. The laser quenching process can replace processes such as the traditional high-frequency / medium-frequency quenching, flame surface quenching and the like, obtains a hardening layer with the depth of a millimeter level, has high and even hardness for the hardening layer and good process repeatability, leads the workpiece to keep a highpressure stress state, can be widely applied in the fields of metallurgy, chemical industry and heavy machinery equipment and the like, and significantly prolongs the service life of the workpiece.

Owner:武汉武钢华工激光大型装备有限公司

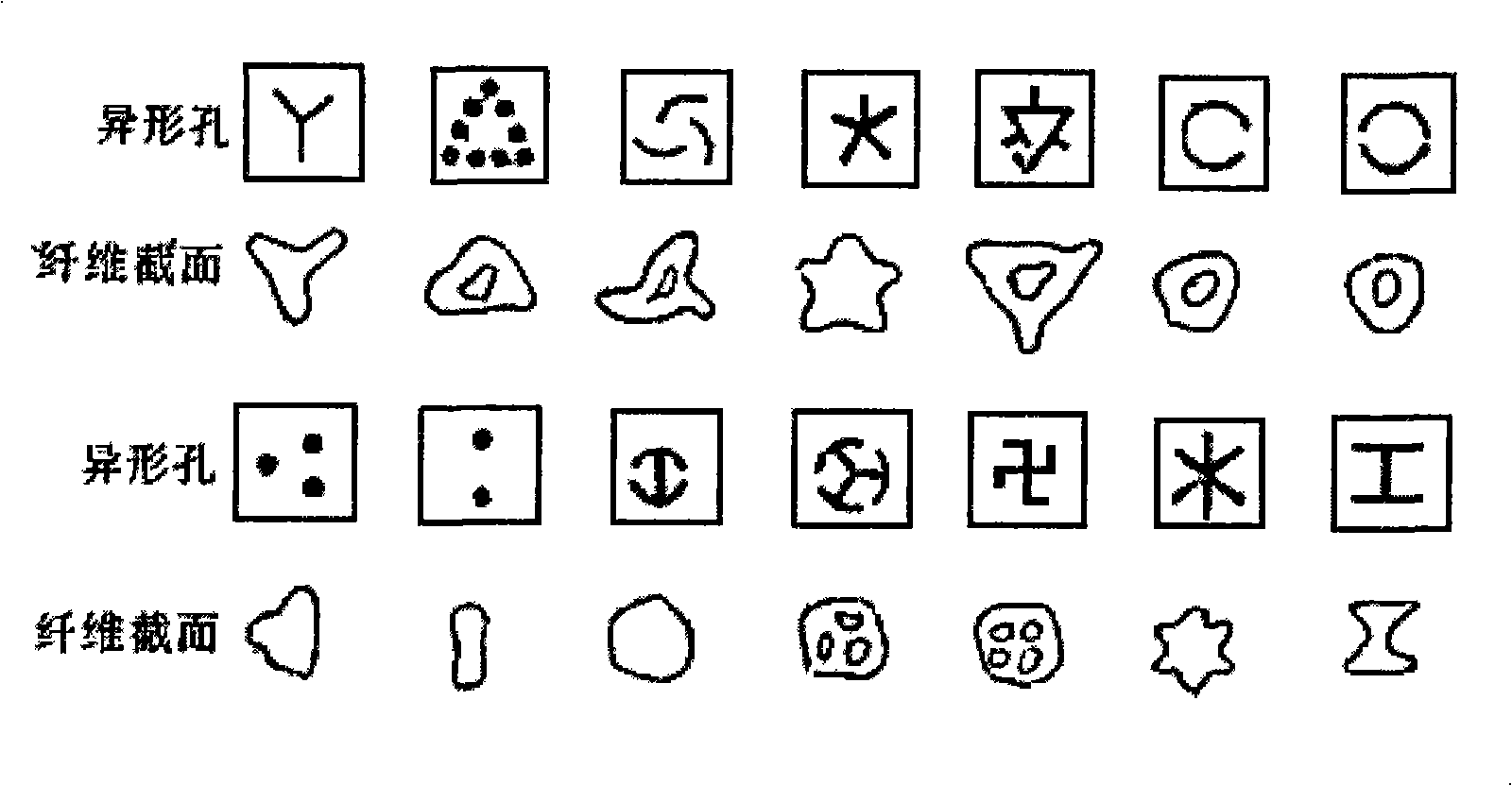

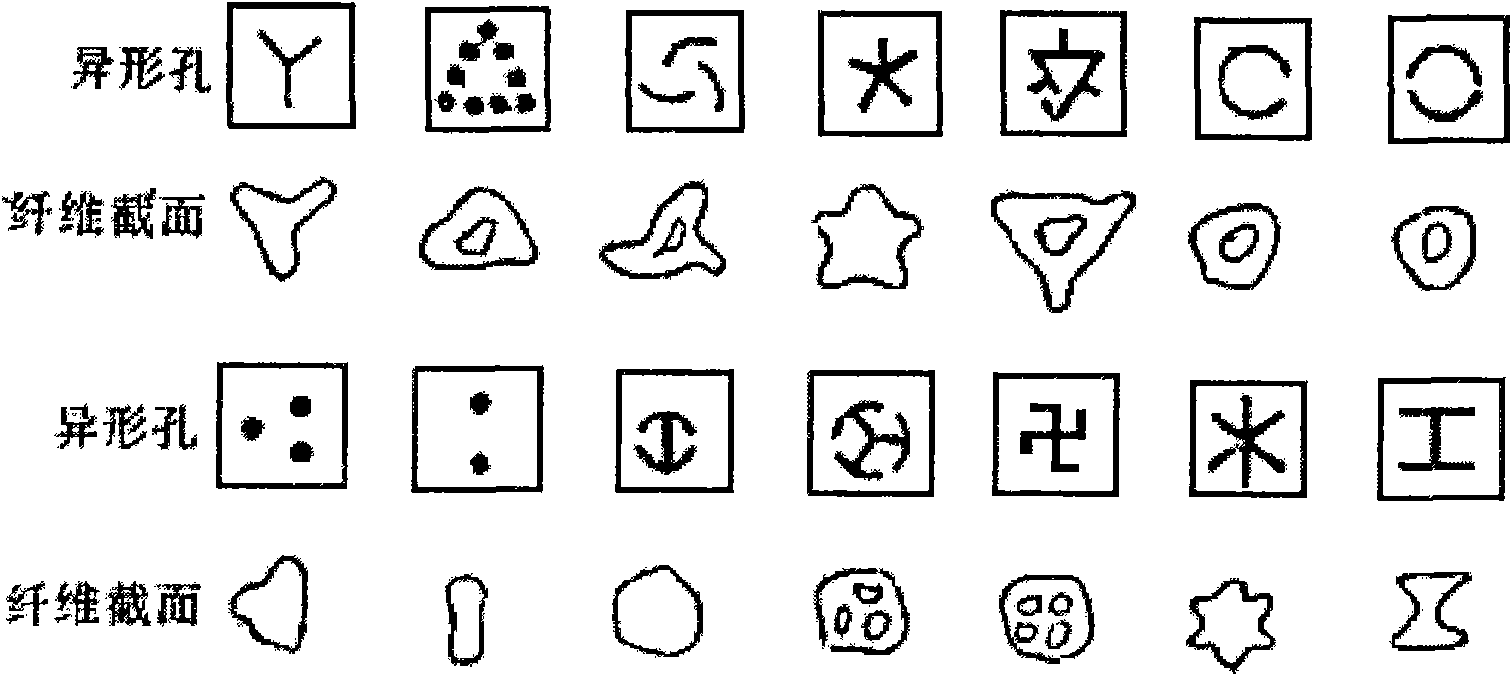

Colored profiled polyester multifilament fiber with stable dimension and preparation method thereof

ActiveCN101525786AFine and uniform meshGeometrically stableMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterYarn

The invention relates to a colored profiled polyester multifilament fiber with stable dimension and a preparation method thereof. The preparation method comprises the following steps: adjusting contents of polyester, pigment masterbatch and an additive in a fusant according to a certain proportion, drying and dehydrating, forming after melting, extrusion, spinning and cooling, and obtaining finished filament after oiling, coiling, heating, tensioning, heat setting, inspection and grading. The fiber can be prepared with conventional spinning equipment, has even multifilament bundle yarn and even color distribution, can be widely applied to fields of clothing, decoration and industry. Fabric is smooth, is characterized by soft luster, high breaking strength and low breaking elongation, can ensure stable geometric dimension of the fabric without easy deformation; and the fiber has the advantages of good fabric elastic resilience, less creep and relaxation and low boiling water shrinkage, and can improve the stability due to hard deformation at high temperature.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

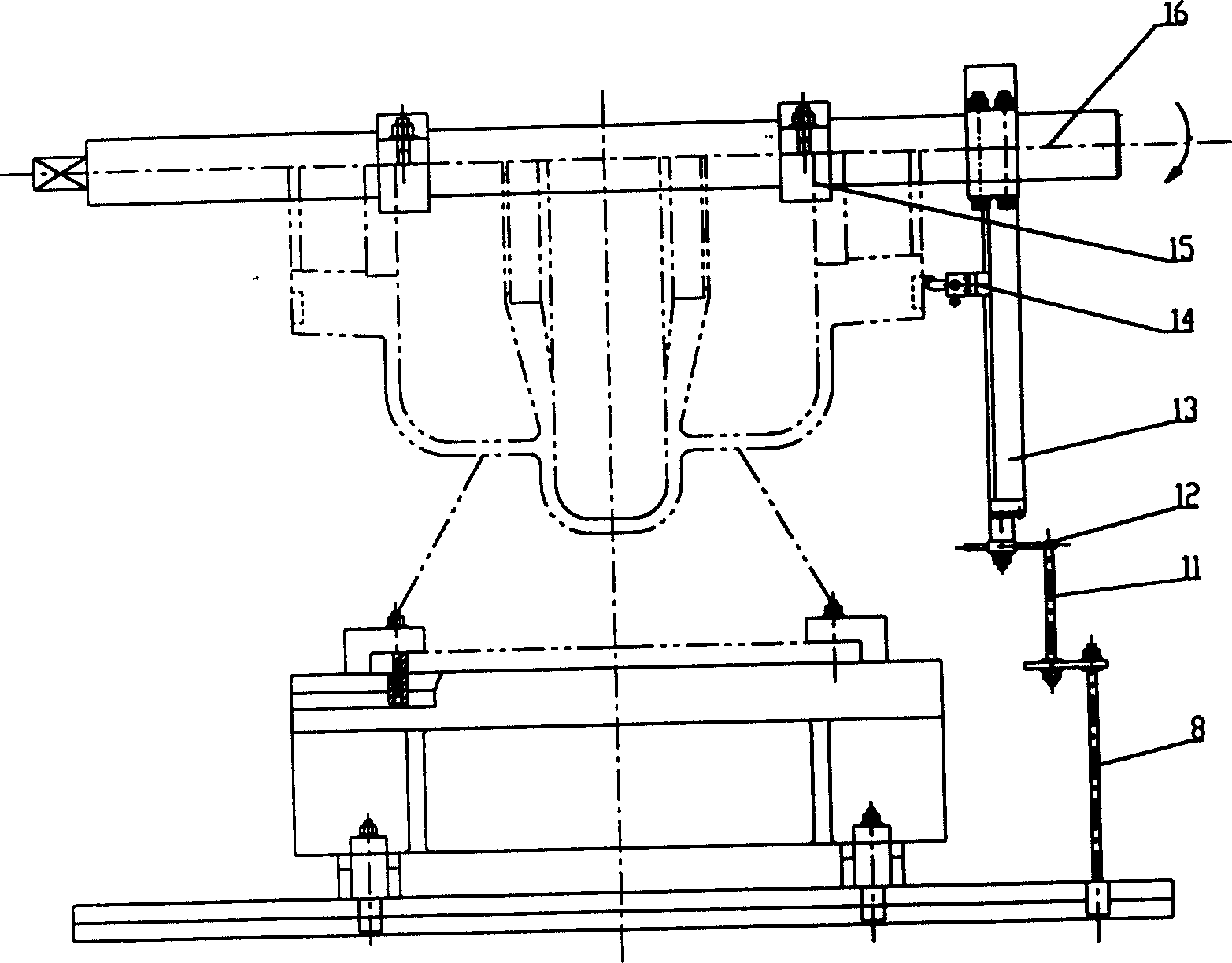

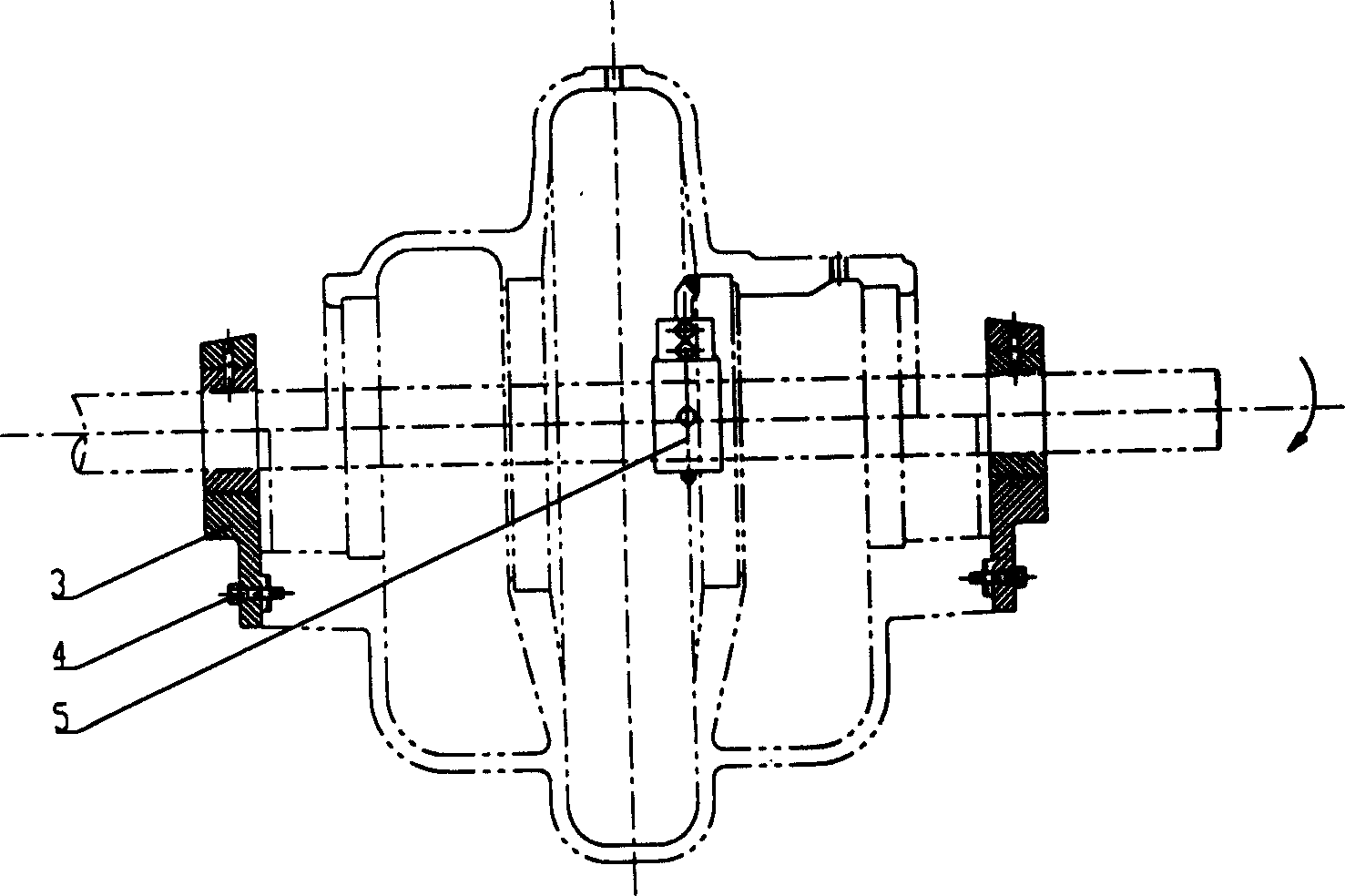

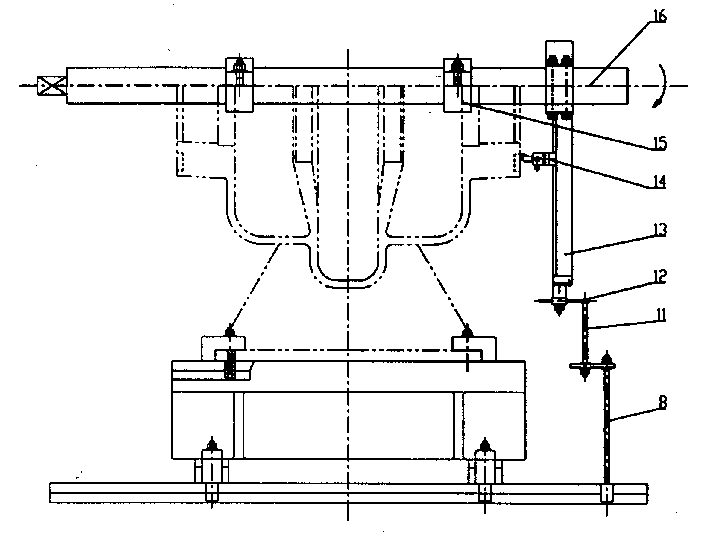

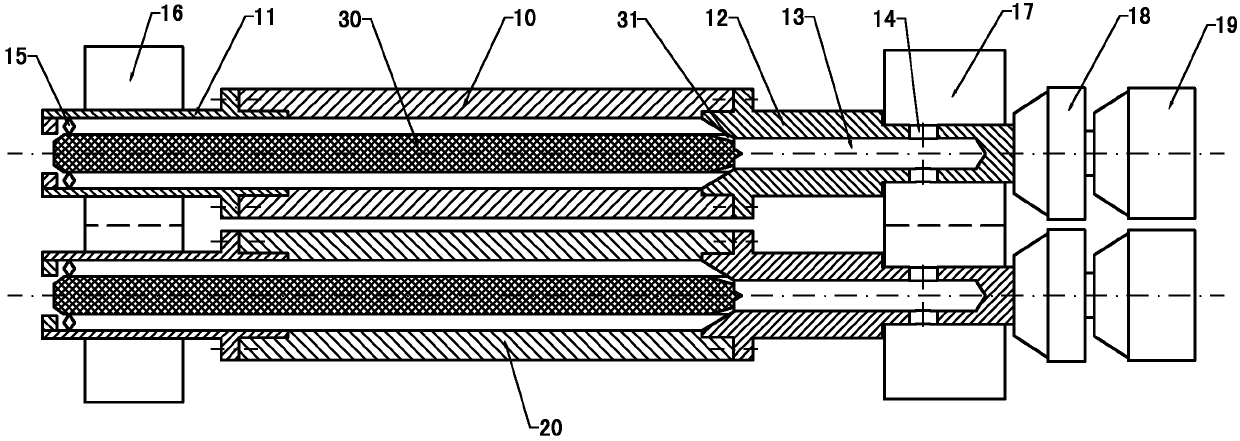

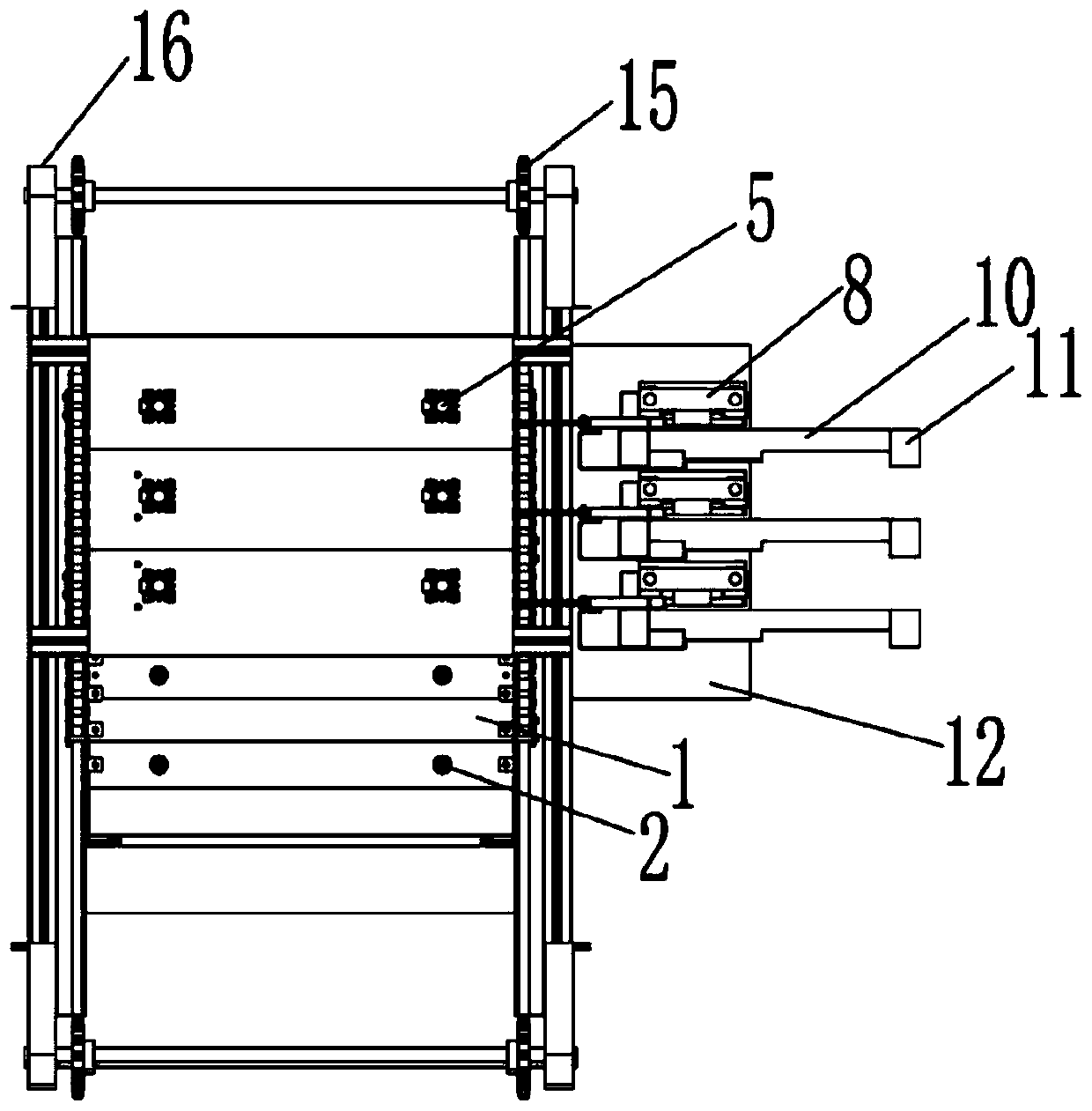

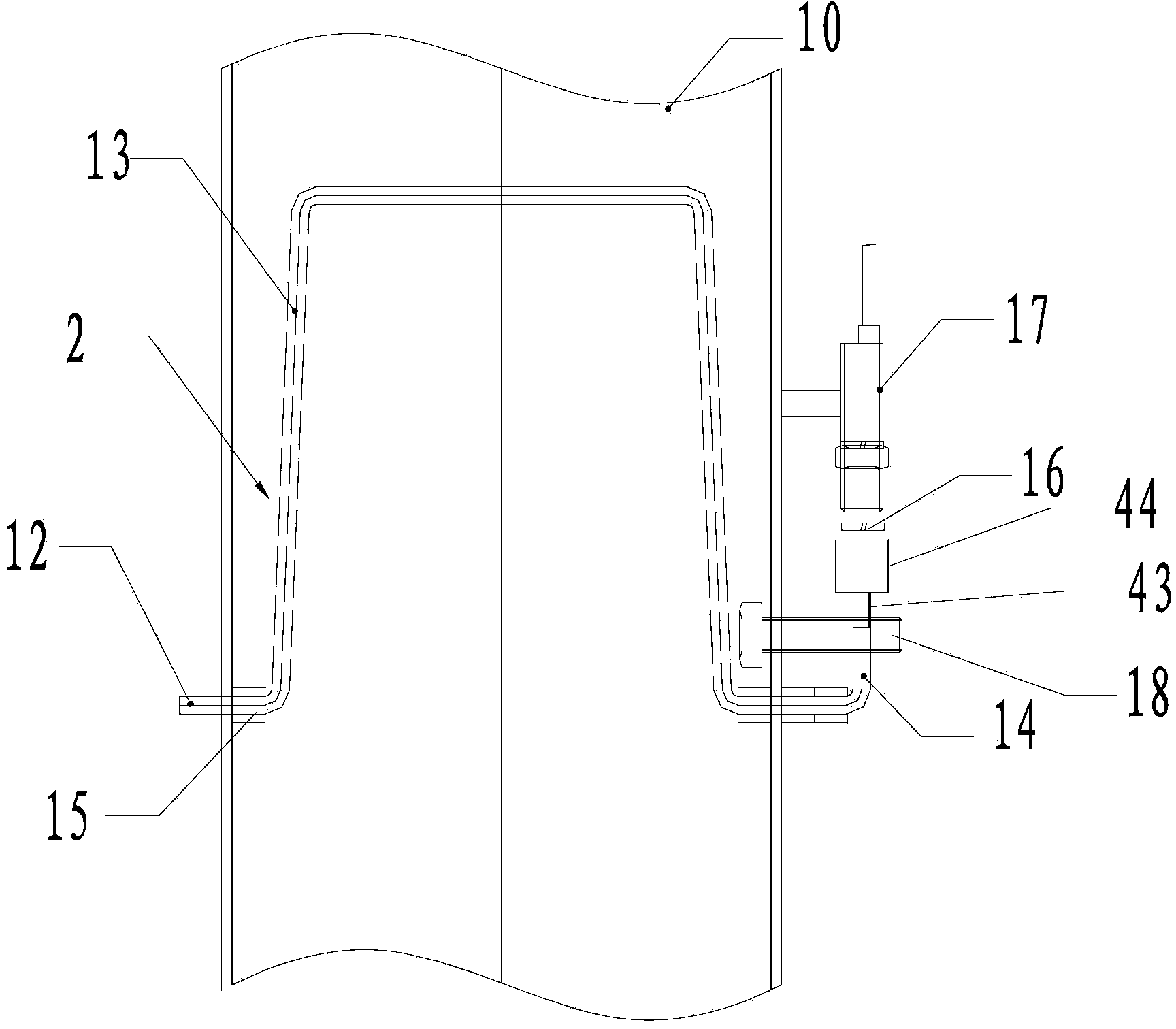

Pressing tool for assembling truck body

ActiveCN102744547AHigh strengthOpen smoothlyWelding/cutting auxillary devicesAuxillary welding devicesTruckPiston rod

The invention discloses a pressing tool for assembling a truck body. The pressing tool comprises an upright device, a pressing hook, a jack device and a workpiece locating device, wherein the upright device comprises uprights and bases, which are positioned on the two sides; the top ends of the uprights are provided with anti-rebound devices; guide devices and lug seats are arranged on the inner sides of the uprights; cylinders are arranged on the outer sides of the uprights; connecting devices matched with the guide devices are arranged on the inner sides of the guide devices; upper ends of the connecting devices are hinged with pressing hooks; pin holes and pin shafts I are arranged on the lug seats; the pin holes are matched with the pin shafts I; force amplifying levers, which rotate relative to the pin shafts I, are arranged on the pin shafts I; upper long circular holes and lower long circular holes are respectively formed in two ends of the force amplifying levers, wherein the upper long circular holes are hinged with connecting holes at lower ends of the connecting devices by pin shafts II; the lower long circular holes are hinged with connecting holes on end part joints of cylinder piston rods by pin shafts III; jack devices and workpiece locating devices are arranged on the inner sides of lower ends of the uprights; and the bases of the uprights, bottom surfaces of the jack devices and bottom surfaces of the workpiece locating devices are respectively connected with foundation embedded plates.

Owner:CRRC SHANDONG CO LTD

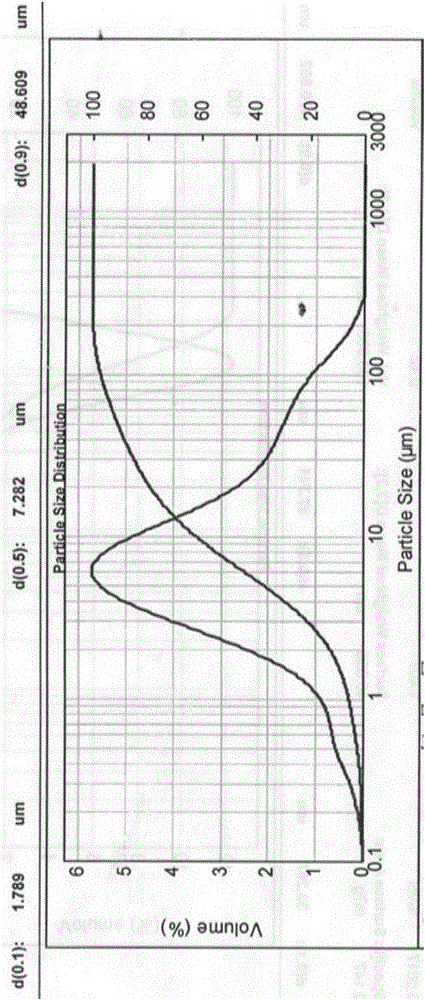

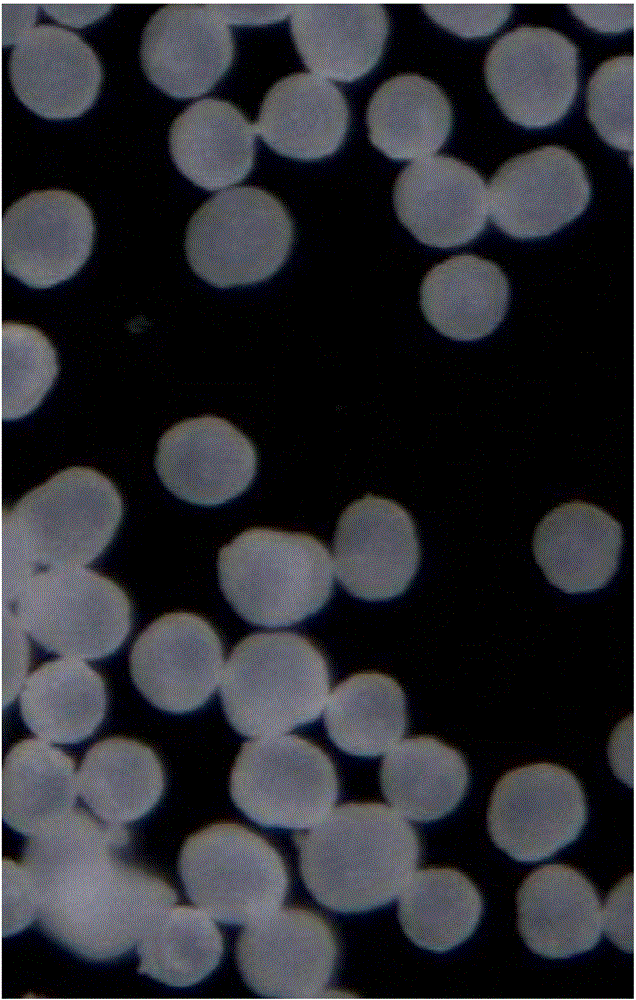

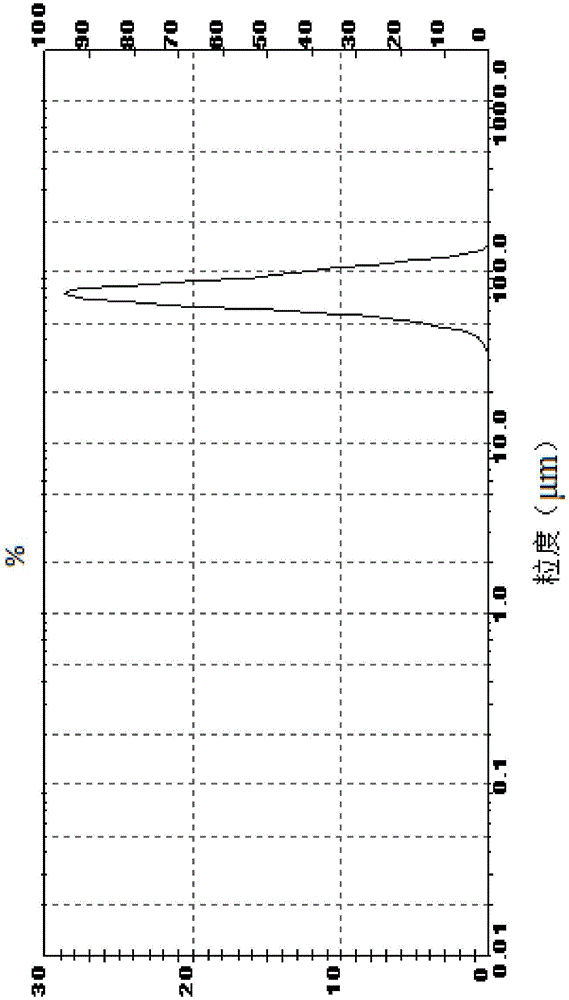

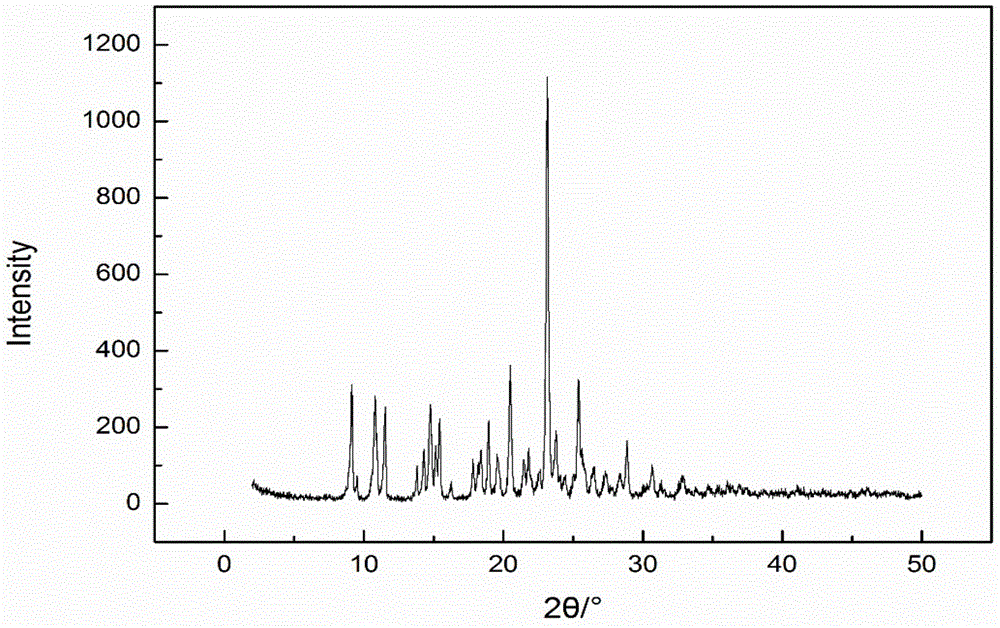

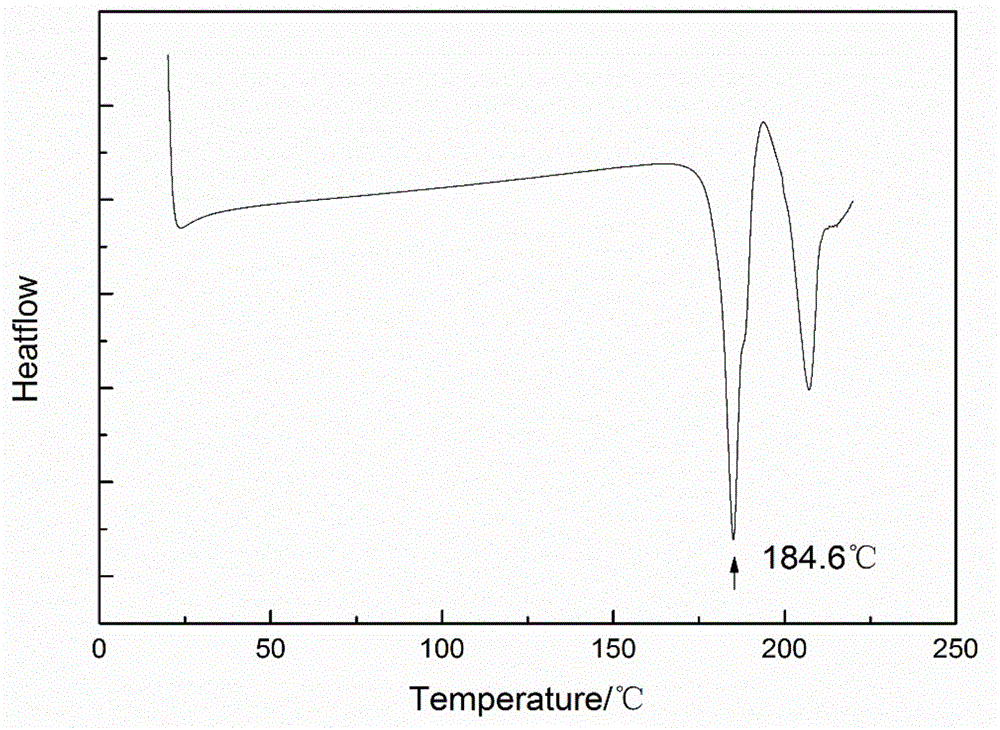

Preparation method of clopidogrel hydrogen sulfate I crystal form spherical crystal

InactiveCN105061459AReduce claddingSimple removal processOrganic active ingredientsOrganic chemistry methodsSolvent2-Butanol

The invention overcomes the technological difficulty that a single solvent is different to prepare a spherical crystal. The single solvent 2-butanol is adopted, and the amount and grain diameters of added clopidogrel hydrogen sulfate I crystal form spherical crystal are controlled, so that clopidogrel hydrogen sulfate is stably separated out from a solution system in a spherical crystal form in a specific powder form range, the obtained clopidogrel hydrogen sulfate spherical crystal has the characteristics of specific powder and has superior state in the aspects of solvent residue, bulk density and mobility, and the preparation method is beneficial for the realization of powder vertical compression preparation technology. The invention also further discloses a medicine composition containing the clopidogrel hydrogen sulfate I crystal form spherical crystal prepared and obtained through the technology.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD +2

Colored non-conventional type polyester monofilament with stable size and preparing method thereof

ActiveCN101586266AFine and uniform meshGeometrically stableMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberPolyester

The invention relates to a colored non-conventional type polyester monofilament with stable size and preparing method thereof. The method comprises drying, de-watering, melting, squeezing, spinning, cooling to form, oiling, rolling, heating to extend and heat forming the polyester slice cospun master batch slice, checking to form product filament. Advantages of the invention lie in that preparation process is simple; filaments are even; leveling shade is even; fiber thickness is even, which can be widely applied in fiber window screen preparation and industrial field. The fabric is flat, which is lucidus and flexible, high is rupture strength, low rupture extension to ensure stable size of the fabric. It is not easy to deform. Fabric rebound resilience is great. Creep deformation and relaxation phenomenon are fewer. Waste water has low volume shrinkage ratio. The invention is not easy to deform at high temperature, which improves stable performance. Surface of fabric is clean with no polyester nonomer deposit builder.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

Process for machining ends, positioning ports and holes of central opened pump by special boring apparatus

InactiveCN1583335AFlexible rotationSolve bottlenecksBoring/drilling machinesEngineeringMechanical engineering

A technology for machining the end face, locating stop and holes of centrally splitting pump by special boring machine includes such steps as fixing the boring unit to the screwed hole on the centrally splitted surface of pump body, driving boring rod while rotating feeding gear, rotating the dial, turning the dial by 1 / 5 of a turn by a turning rod, turning the leading screw by 1 / 5 of a turn, and driving the nut under tool carrier to advance by 1 / 5 of a pitch to complete a feeding. Said locating stop is machined in same way. Said holes are machined by using said end face and locating stop as reference.

Owner:SHANGHAI LIANCHENG GRP SUZHOU

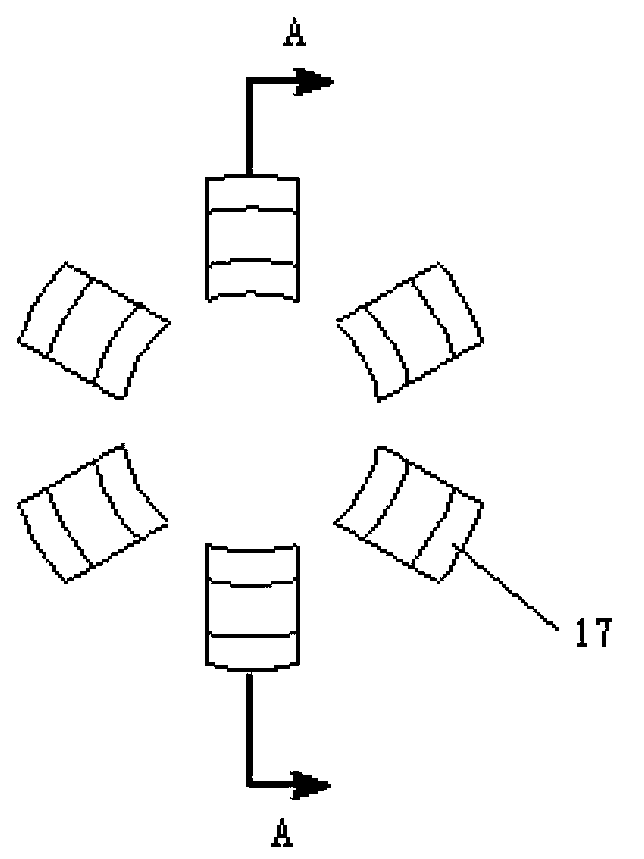

Electroplating process for annular neodymium iron boron sheet products

The invention discloses an electroplating process for annular neodymium iron boron sheet products. Each annular neodymium iron boron sheet product is bundled by a circle of binding band; the binding band is made from a non-electrical-conductivity material capable of resisting acid, base, high temperature and pressure; the width of the binding band is 1-3mm; a 2-20mm gap is formed between the binding band and each annular neodymium iron boron sheet product; the binding band winds by one circle along the inner surface, the upper end surface, the outer side surface and the lower end surface of each annular neodymium iron boron sheet product; end surfaces of the two adjacent annular neodymium iron boron sheet products can not be clung to each other due to blocking action of the binding bands of the annular neodymium iron boron sheet products in a drum; electroplating liquid enters from gaps formed by the binding bands between the end surfaces of the two adjacent annular neodymium iron boron sheet products and can be used for separating the two annular neodymium iron boron sheet products; a uniform electroplating layer is formed on the surface of each annular neodymium iron boron sheet products. The process has the advantages that the aim being 200 sheet / drum in the drum electroplating can be realized, so that the working efficiency is greatly improved; as the sheet sticking phenomenon is overcome, the percent of pass of products is obviously increased and can be up to more than 98%.

Owner:NINGBO YUNSHENG +2

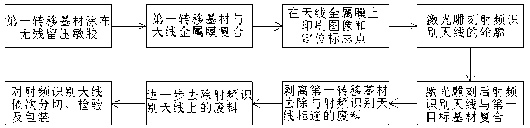

Laser production process of radio frequency identification antenna

The invention discloses a laser production process of a radio frequency identification antenna. The laser production process includes the following steps: (a) providing a first base material; (b) coating adhesives on the first base material; (c) compositing the first base material and an antenna metal film through the adhesives; (d) printing images and a plurality of positioning mark points on the antenna metal film through tacky ink, wherein the position of each positioning mark point is determined with the contour of the radio frequency identification antenna as reference; (e) using laser to grave the contour of the radio frequency identification antenna with the positioning mark points serving as positioning standards; (f) compositing the antenna metal film portion with images after laser graving and a second base material; (g) stripping the second base material and the antenna metal film portion composited with the second base material to form the radio frequency identification antenna and removing waste materials; (h) further removing waste materials on the radio frequency identification antenna; and (i) slitting, detecting and packing the radio frequency identification antenna. The laser production process is environment-friendly, simple in process, low in energy consumption, high in yield and good in stability and safety, and products can be stored easily.

Owner:SUZHOU ZUENS IOT TECH CO LTD

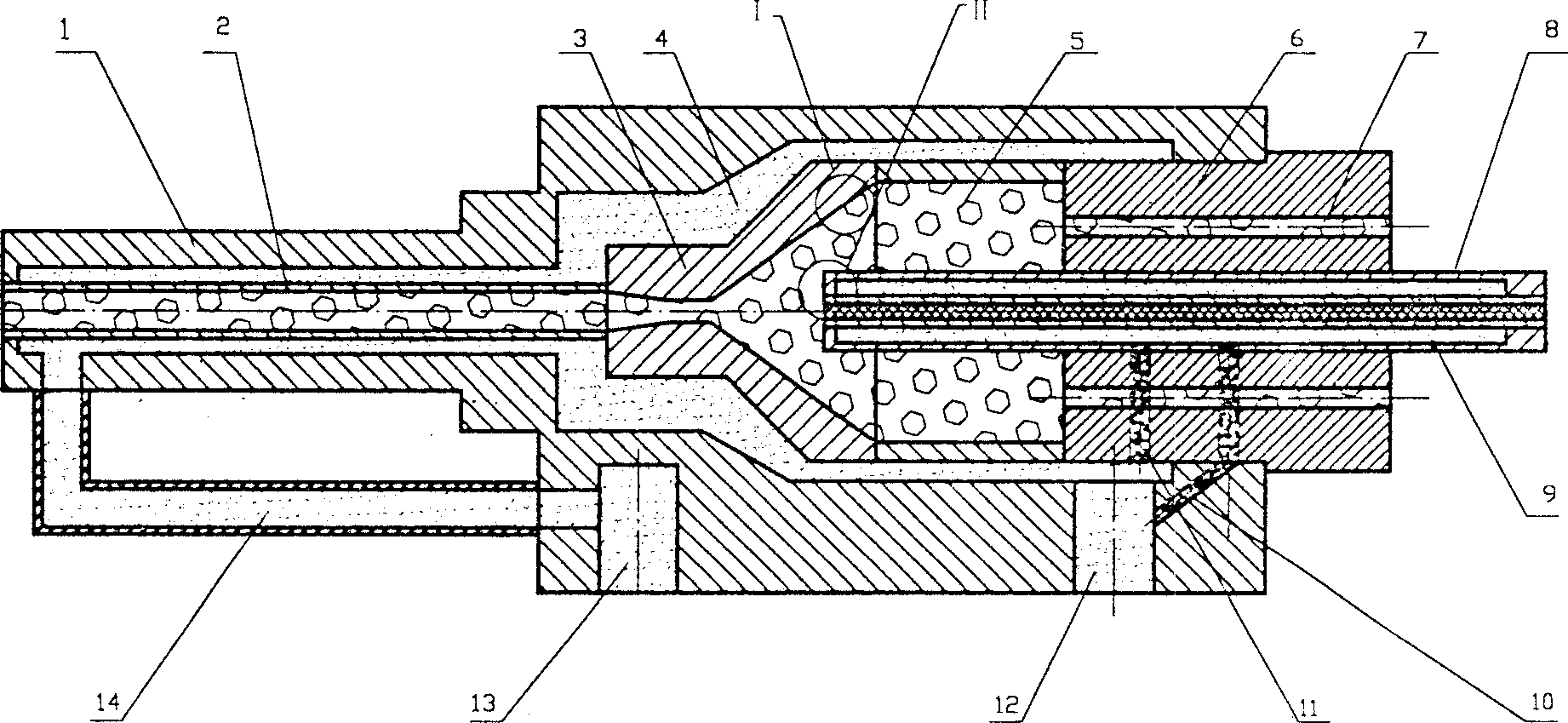

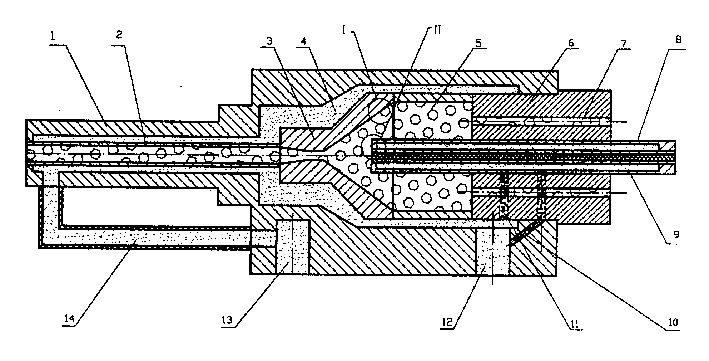

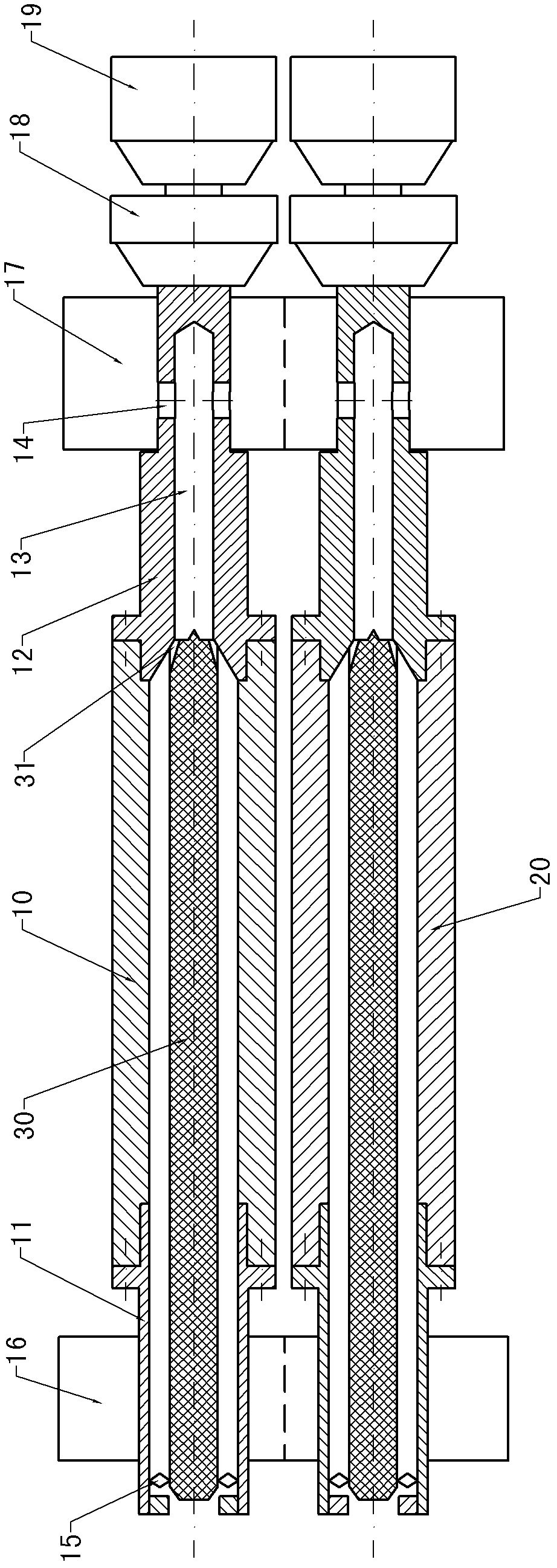

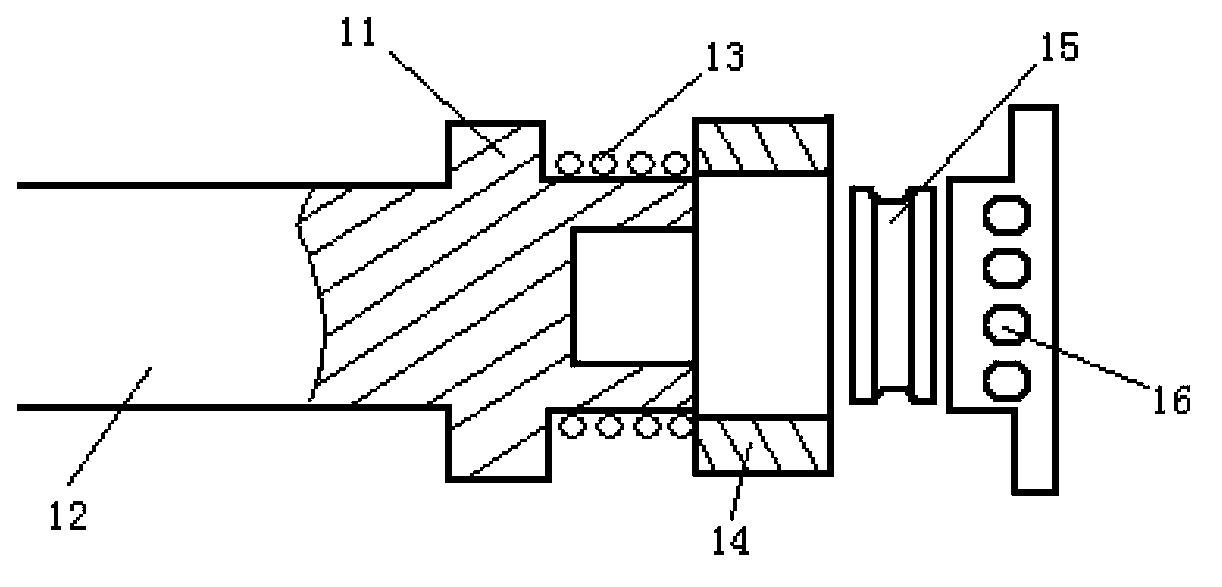

Axial sending-off powder type flame gun in supersonic speed using liquid fuel as energy sources

InactiveCN1519057AImprove powder feeding efficiencyIncrease flow rateLiquid surface applicatorsLiquid spraying apparatusCombustion chamberEngineering

An axially feeding powder type supersonic flame spraying gun using liquid fuel as energy source is composed of a casing and the serially connected gum tube, convergent divergent nozzle, combustion chamber and tail unit. A main water cooling channel is formed between said casing and the serially connected units. In said tail unit, their is a water cooled powder feeding tube surrounded by 2-12 liquid fuel spraying tubes. Its advantages are high flowing speed of powder, fully smelting of powder, and high quality of coated layer.

Owner:王泰兴

High-temperature demolding protection lubricant for producing copper alloy finished piece by hot extrusion method

ActiveCN102250674ANo internal defectsFlat surfaceLubricant compositionVegetable oilSuspending Agents

The invention relates to a high-temperature demolding protection lubricant for producing a copper alloy finished piece by a hot extrusion method, belonging to the technical field of lubricants. The high-temperature demolding protection lubricant is prepared from the following raw materials: 50-75% of vegetable oil, 10-25% of lithium-based grease, 5-20% of lithium carbonate, 5-20% of graphite powder, 0.5-5% of ammonium salt, 1-10% of alkyl sulfonate and 0.5-5% of suspending agent. The high-temperature demolding protection lubricant provided by the invention has the following advantages: 1) a pressure gauge copper joint produced by using the hot extrusion method and using the lubricant provided by the invention has the characteristics of no internal defects, smooth surface and no material adhesion and carbon deposition phenomena; 2) the wear of a mold cavity is reduced, and the service life of the mold cavity is prolonged by more than one time; 3) no adhesion phenomenon is generated, the normal demolding of a hot-extrusion finished piece is guaranteed, and the production efficiency is increased by more than 30%; 4) no obvious oil smoke, dust or toxic and harmful gases are generated in the processing site, thereby the environmental pollution is eliminated; and 5) the raw materials are conveniently available and are relatively low in price, and the production cost is lowered by more than 20%.

Owner:杭州丰源铜业有限公司

Medicinal effervescent tablet and preparation method thereof

ActiveCN104434864AReduced ambient humidity requirementsReduce manufacturing costOrganic active ingredientsPharmaceutical delivery mechanismParticulatesOrganic acid

The invention provides a medicinal effervescent tablet and a preparation method thereof. The preparation method comprises the following steps: (A) grinding a carbon dioxide source and filler for later use, and mixing an adhesive and a wetting agent to prepare an adhesive solution for later use; (B) mixing main components, organic acid, a disintegrating agent and a sweetening agent, and treating to obtain a first particulate mixture; (C) melting a parting agent, adding the molten parting agent into the carbon dioxide source, treating, adding the filter for stirring, mixing with remained adhesive solution, and treating to obtain a second particulate mixture; (D) grinding 1-2 percent of the total mass of the second particulate mixture into powder, adding essence for mixing, and dispersing to the remained second particulate mixture to form a third particulate mixture; and (E) tabletting the first particulate mixture and the third particulate mixture, packaging and detecting to obtain a finished product. The medicinal effervescent tablet is easy to preserve, and has the advantages of no sack expansion or sticky tablet in the storing process.

Owner:峨眉山通惠制药有限公司

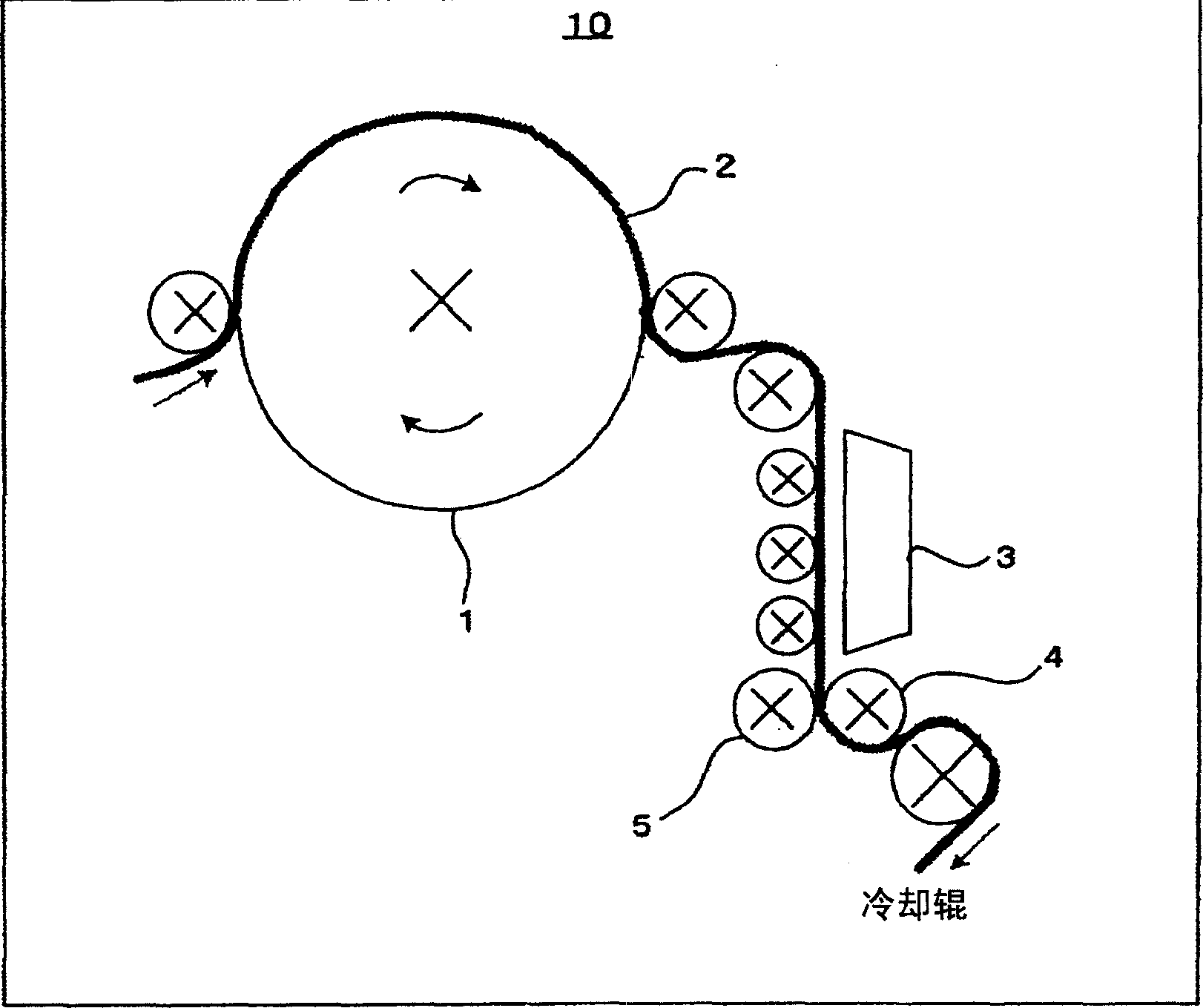

Production method for grinding-free and polishing-free black transparent microcrystalline glass plate

ActiveCN102603193ALower melting temperatureImprove the crystallization effectGlass rolling apparatusGlass productionWater flowCrystallization temperature

The invention relates to a production method for a Li2O-A2O3-SiO2-series grinding-free and polishing-free black transparent microcrystalline glass plate. Because modified component niobium oxide is added into a formula, the fusing temperature of the glass can be lowered by adding the niobium oxide. The modified component niobium oxide has good crystallization performance and also has the physical properties that the crystallization temperature is lowered, the coefficient of expansion is lowered, and the like. In the calendaring molding equipment, because the traditional solid molded roll is changed into a hollow roller structure and an inner core rod is arranged in the hollow roller structure, circulating cooling water is introduced into the hollow roller during production; the temperature of a molded roll body can be accurately controlled by controlling the water inlet temperature, the water outlet temperature and the flow speed, and in addition, the roller can be evenly cooled; the microcrystalline glass plate calendered and molded by the roller is flat, and the obtained microcrystalline glass plate has a smooth and flat surface so as to satisfy the user requirement, and does not deform at the high temperature for a long time; because grinding treatment and polishing treatment are omitted in the product production process, two working procedures of grinding and polishing in the product process are reduced; and therefore, the product quality is improved, the production efficiency is improved, the production cost is lowered, the production environment for workers is improved, and the clean production is realized.

Owner:广东科迪微晶玻璃实业有限公司

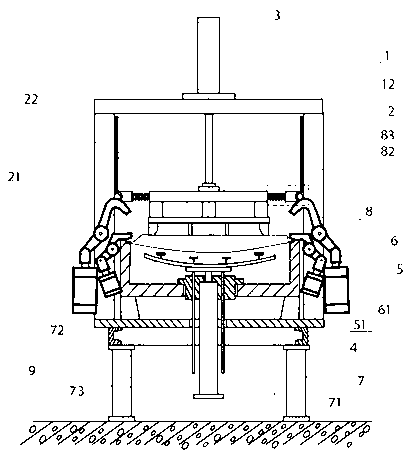

Automobile door taping machine

InactiveCN103157711ASmooth hemmingReduce noiseShaping toolsMetal-working feeding devicesEngineeringCar door

The invention discloses an automobile door taping machine. A pre-taping module and a taping module of the automobile door taping machine are provided with working faces which are matched with automobile door pre-taping molded surfaces. Two ends of the pre-taping module and two ends of the taping module are provided with rotary shafts respectively. The rotary shafts are arranged on bearing blocks which are arranged at two ends of each edge of a die block. The pre-taping module and the taping module are respectively driven by a first actuating device and a second actuating device and rotate around the rotary shafts of the pre-taping module and the taping module. The pre-taping module and the taping module are arranged in a separating mode and are controlled by independent actuating devices, so that the whole structure is reasonable, dismantling becomes convenient, and mold repairing quantity of the pre-taping module and the taping module is greatly reduced. Due to the fact that a rolling mechanism which guides a clamping device to move up and down and can adjust gaps automatically is arranged on the clamping device, work of the clamping device is stable and reliable, a chattering phenomenon generated when the clamping device works is restrained effectively, and positioning error is reduced.

Owner:戴崇强

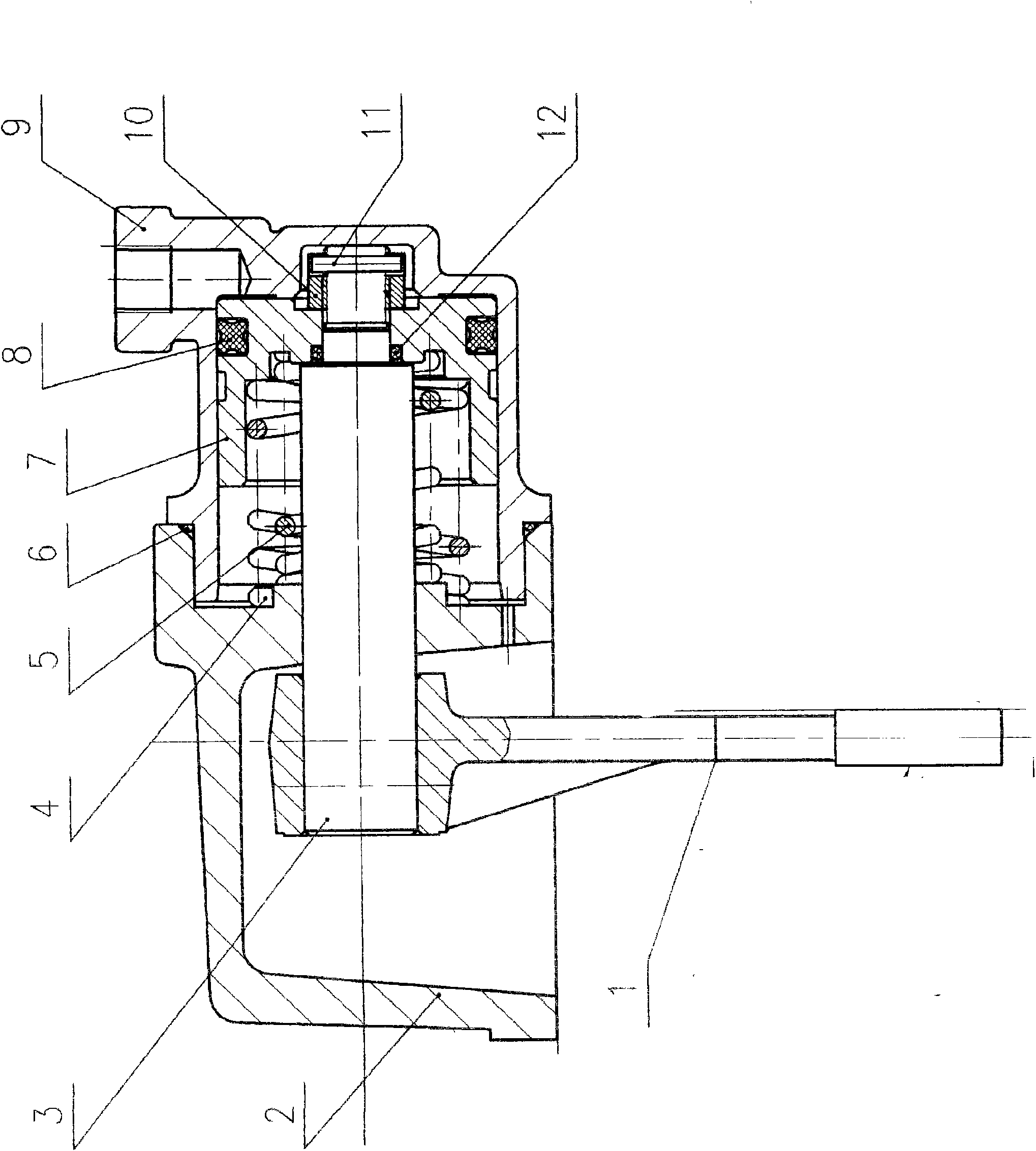

Differential lock assembly

InactiveCN101634358ANo air leakageNo sticking phenomenonDifferential gearingsControl devicesEngineeringPiston

The invention discloses a differential lock assembly, which consists of a shifting fork, a shifting fork shaft, an air cylinder and a piston. A small end of the shifting fork shaft is provided with an O-shaped sealing ring, passes through the piston, is locked by a small hexangular groove-shaped flat nut, and is fixed by an elastic cylindrical pin; the shifting fork shaft in an inner cavity of the piston is provided with two return springs; the inside of a cylindrical groove at the right end of the piston is provided with a leather cup; the left end of the shifting fork shaft passes through a base and is sleeved with the shifting fork; the air cylinder sleeves the piston in the inner cavity; and a connecting position of the cylindrical surface at the left end of the air cylinder and the base is provided with an O-shaped sealing ring. When performing gas tightness check under 0.35-0.8MPa, the differential lock assembly has no gas leakage; the shifting fork has flexible action and return, no blockage phenomenon, and working effective stroke more than 20; and the differential lock assembly meets various technical indexes, and ensures product quality.

Owner:鞠小平

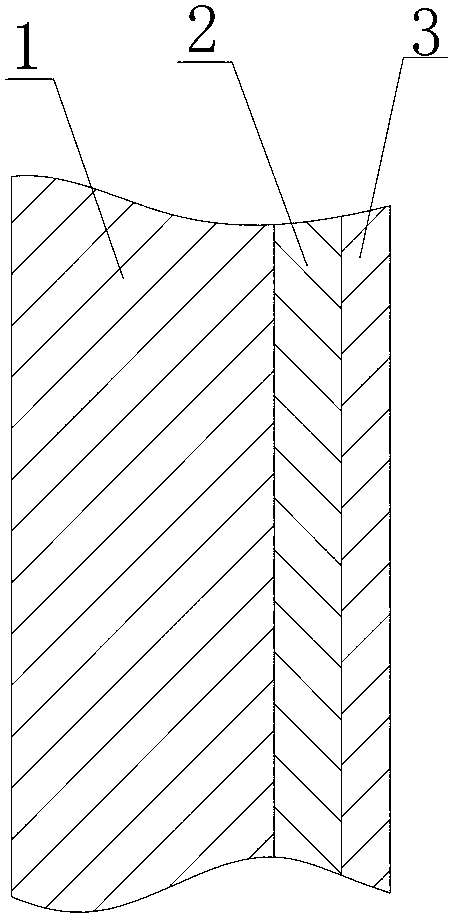

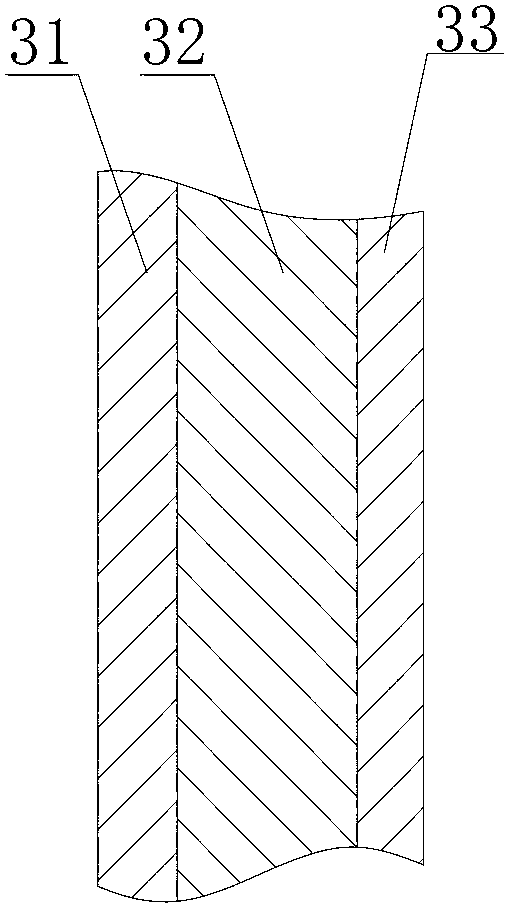

Bearing bush and process thereof for spraying MoS2 on alloy layer

ActiveCN103122937AGood bite resistanceReduce coefficient of frictionPretreated surfacesBearing componentsEnvironmental resistanceParylene

The invention provides a bearing bush and a process thereof for spraying MoS2 on an alloy layer for solving the problem that the alloy layer or the plated layer of the bearing bush peels off frequently. The bearing bush comprises a steel backing layer and the alloy layer fixedly arranged. The alloy layer is provided with a spraying layer fixed with the alloy layer. The alloy layer is one of an aluminum alloy layer or a copper-lead alloy. The spraying layer comprises a PI (Polyimide) resin layer, a MoS2 layer and a PAR (Parylene) lubricating coating sequentially arranged. The PI resin layer is contacted with the alloy layer. The bearing bush can effectively improve the dry grinding resistance, the anti-occlusion performance, the corrosion resistance and the wear resistance through the MoS2 layer by arranging the spraying layer on the alloy layer, the problem that the inner surface of the bearing bush in the installation and use process is scratched is solved, and the service lives of the bearing bush and lubricating oil in the bearing bush are prolonged. The bearing bush is good in practicality, and the whole manufacturing process of the bearing bush is safe and environment-friendly, so that the environmental pollution can be reduced.

Owner:YANTAI CHUNSHENG SLIDING BEARING

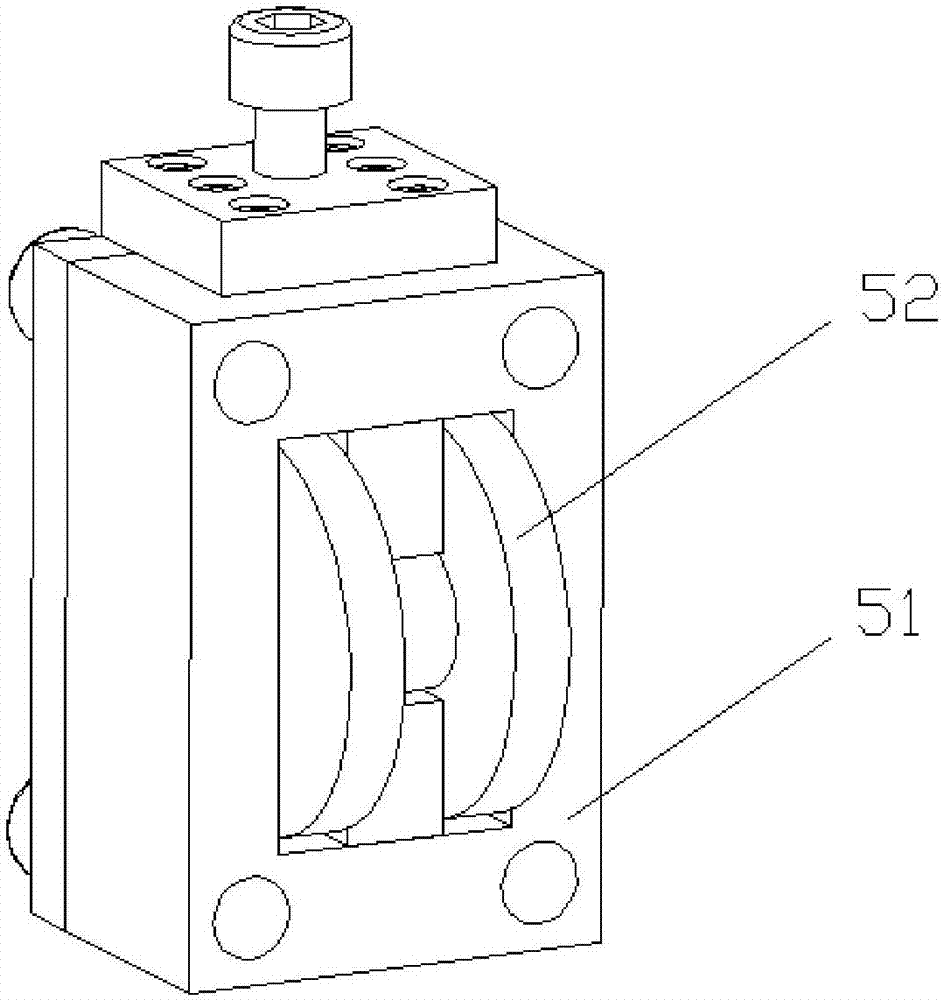

Colored special-shaped size-stabilized type polyester monofilament and preparation method thereof

InactiveCN104532388AImprove heat resistanceGood dimensional stabilityArtificial thread manufacturing machinesFilament/thread formingPolyesterPolyethylene terephthalate glycol

The invention relates to a colored special-shaped size-stabilized type polyester monofilament and a preparation method thereof. The colored special-shaped size-stabilized type polyester monofilament is composed of, by weight, 84.5 parts to 99.75 parts of polyethylene terephthalate (PET), 0.2 part to 5 parts of color master batches, 0.1 part to 10 parts of poly(ethylene 2,6-naphthalate) (PEN) and 0.05 part to 1 part of barium sulfate powder. By adding the PEN, the thermal resistance of fiber is improved, and no roller sticking phenomenon can occur even when the heat setting temperature is above 245 DEG C; nanometer barium sulfate plays a role of plasticizer, the slippage among high polymers is improved, the drawing ratio is increased, the fiber contraction rate is decreased, and meanwhile the colored fiber can be more uniform and brighter in color and luster; the high drawing ratio is achieved in the fiber drawing process, induced crystallization produced in the fiber drawing process is improved, and the boiling water shrinkage is decreased; the fiber preparing process is simple, dry strands are uniform, fiber is uniform in thickness, woven fabric is smooth, grids are exquisite and uniform, and a colored special-shaped filament is softer and richer in color so that stylized reflection can be facilitated.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD +1

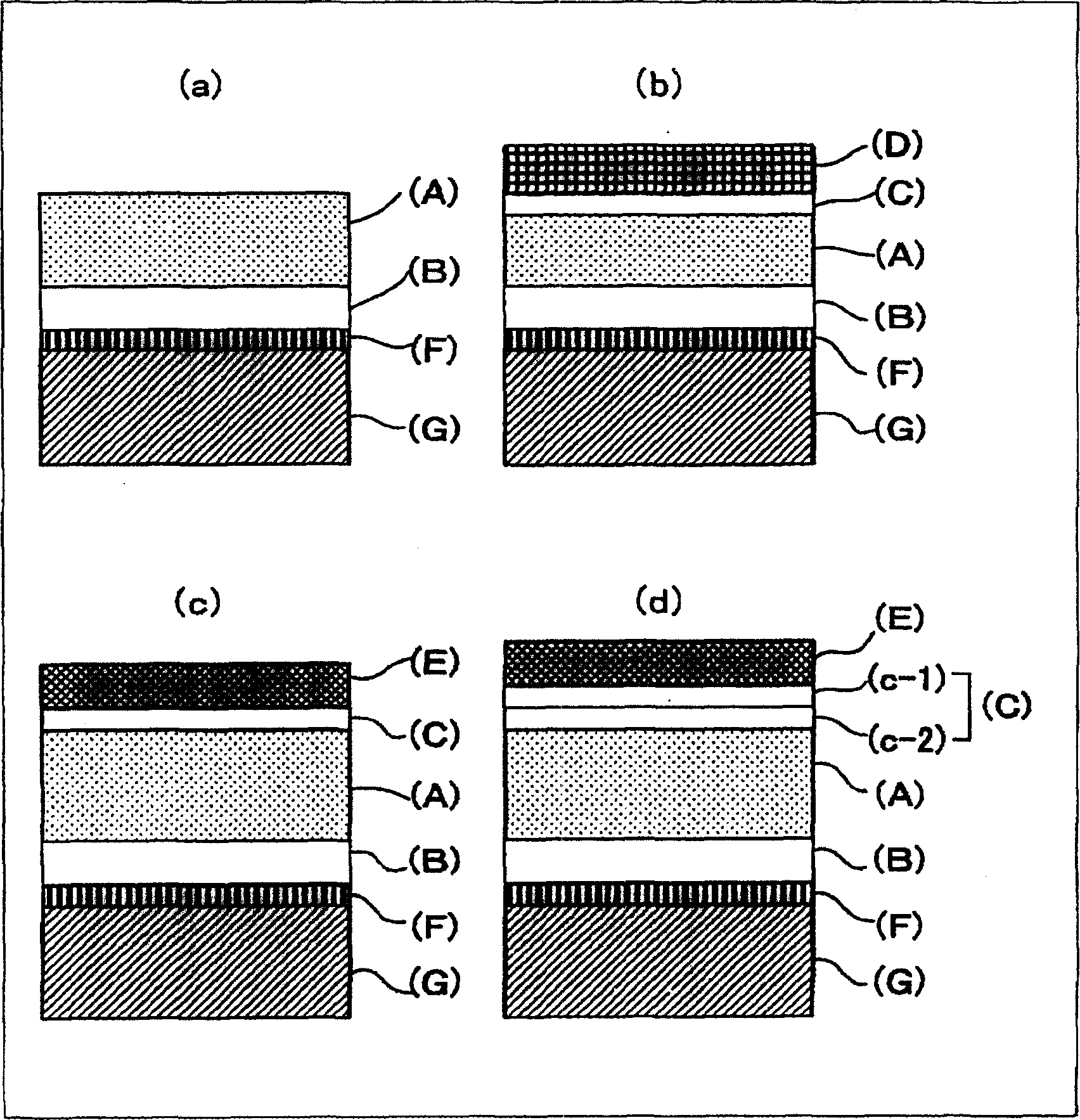

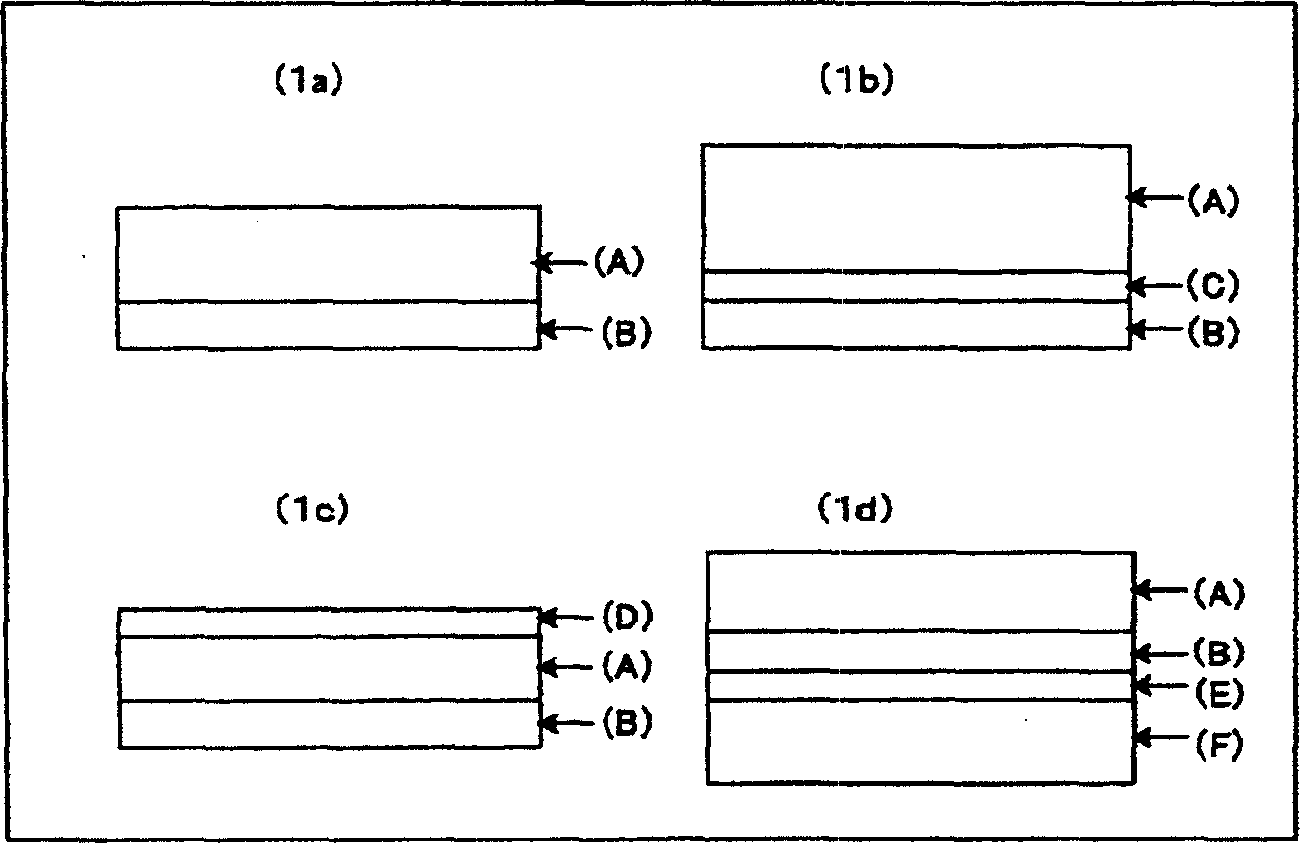

Resin-covered metal sheet, pattern sheet for resin -covered metal sheet, and process for the production of resin-covered metal sheet

InactiveCN1692015AMaintain physical propertiesSuppresses the phenomenon of molecular weight decreaseLayered productsAdhesivePolyester resin

A resin-covered metal sheet excellent in durability (resistance to moist heat) which is obtained by laminating a metal sheet with a laminated sheet consisting of at least two unstretched layers (layers A and B) made mainly of a polyester resin via an adhesive with the layer B side employed as the adhesive surface, wherein the laminated sheet has a total thickness of 65 to 300mum and a pigment for coloring and hiding is incorporated mainly into the layer A, with the layers A and B having thicknesses of 50 to 250mum and 15 to 80mum respectively and with the amount of the pigment component contained in the layer B being limited to at most 10 parts by weight per 100 parts by weight of the resin component. Further, resin-covered metal sheets having good embossed appearance can be provided by the use of a current embossing machine used in embossing flexible PVC sheets.

Owner:MITSUBISHI PLASTICS INC

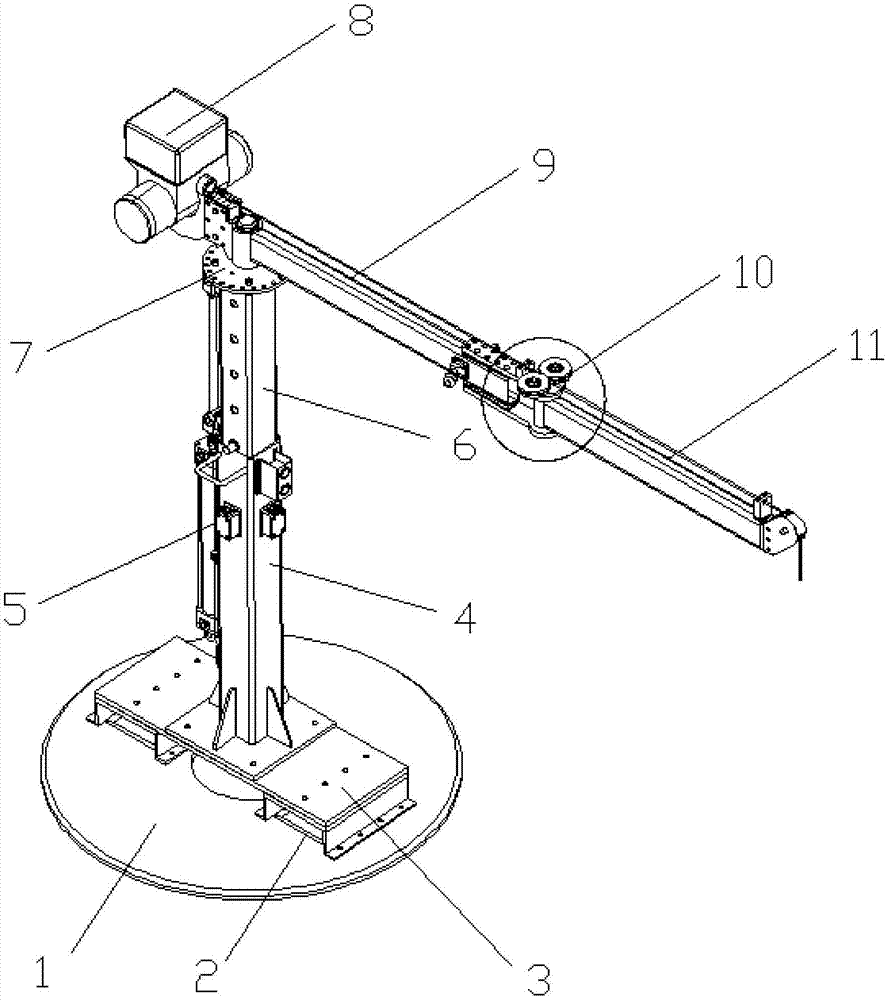

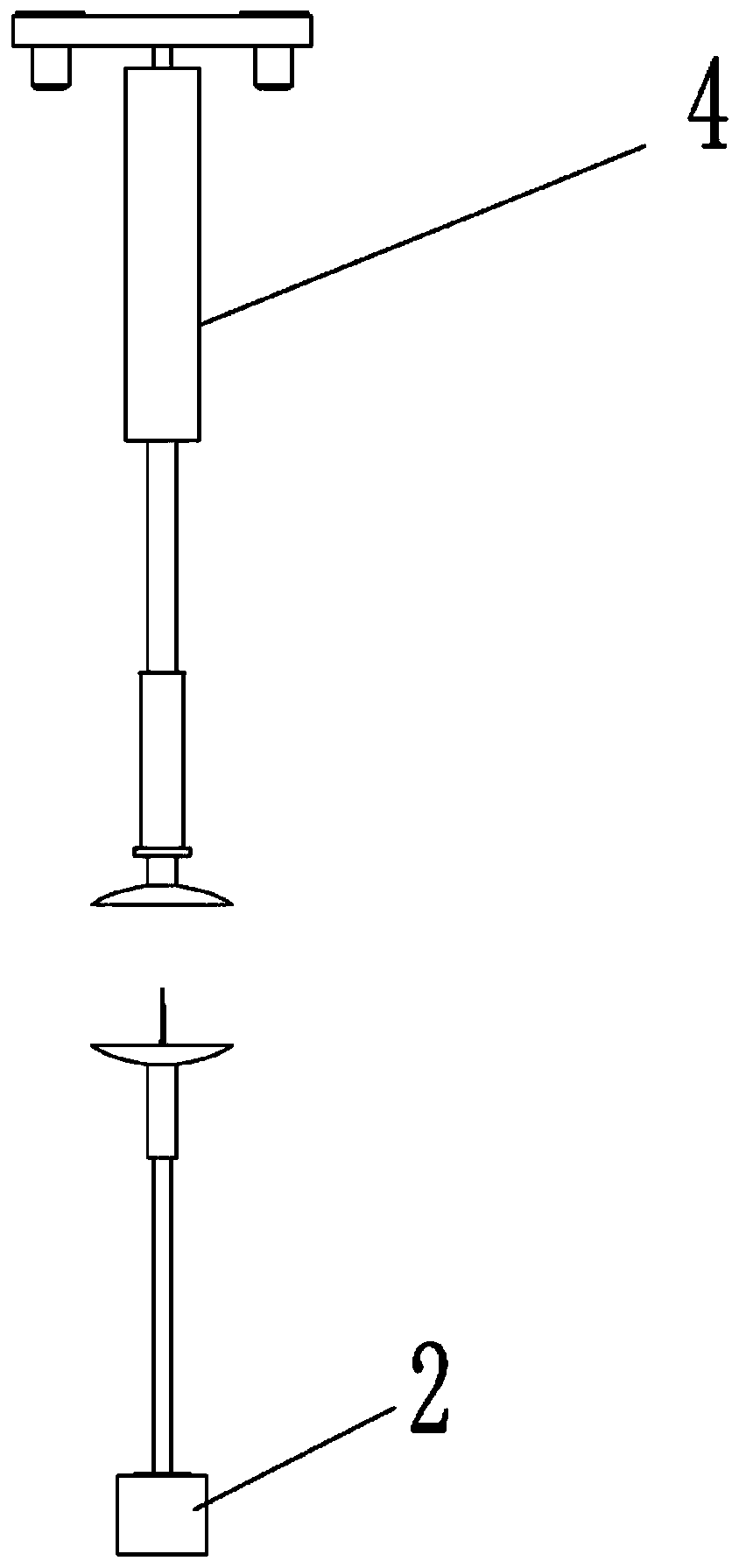

Flexibility pneumatic elevation-type transfer machine and using method thereof

The invention discloses a flexible pneumatic lift-type transfer machine and a use method thereof, which belong to the technical field of mobile handling equipment and solve the problem that the lifting coverage area of the existing transfer equipment is small. The transfer machine of the present invention includes a base, a column and a cantilever, and the column is fixed on the base; the cantilever is rotatably arranged on the top of the column, and also includes a pneumatic balance hoist; the The cantilever includes a long section and a short section; the division point of the long section and the short section is the point where the cantilever is rotatably connected to the column; the pneumatic balance hoist is set on the short section At the end, the steel wire rope in the pneumatic balance hoist protrudes toward the end of the long section along the upper surface of the cantilever. The invention can be easily moved and transported, has high stability, and has the effect of increasing the hoisting coverage area compared with the prior art.

Owner:铮孚智能工程(上海)有限公司

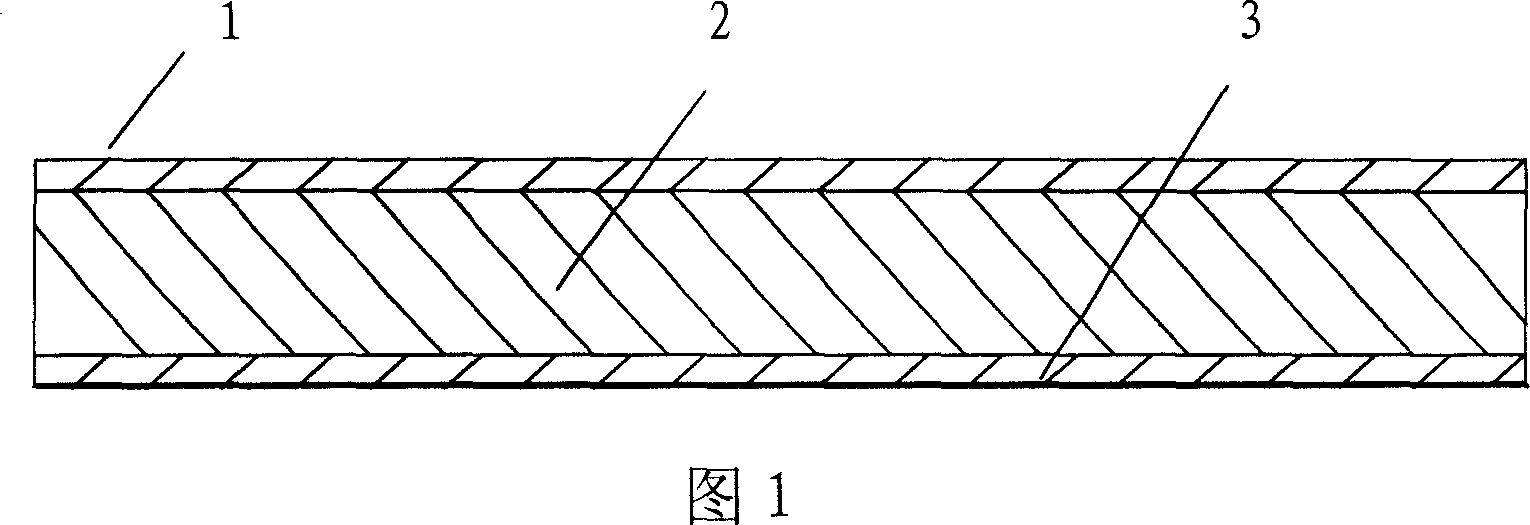

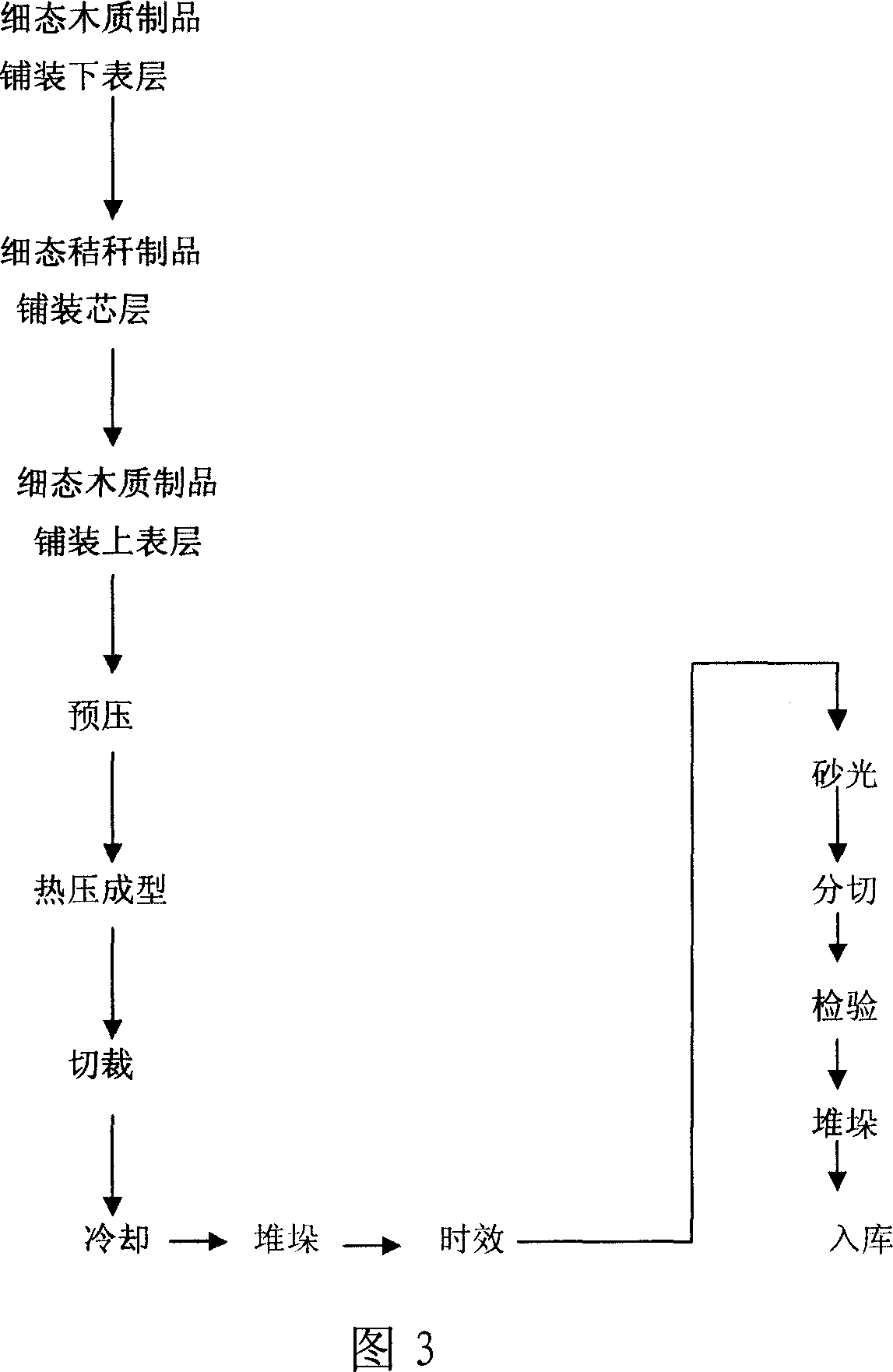

Composite artificial board and its preparing method

InactiveCN1944007AAvoid disadvantagesReduce dosageWood veneer joiningDomestic articlesWood shavingsFiber

The present invention is composite artificial board and its making process, and belongs to the field of composite artificial board making technology. The composite artificial board is made with stalks, wood material and shavings as material, and organic adhesive, and through mixing, spreading, pressurizing and other steps. The composite artificial board has stalk material in the core layer and wood material in the surface layers, and is superior to pure stalk board. The composite artificial board of the present invention has the advantages of low cost, high performance and environment friendship, and may be used widely in building decoration, reinforced floor and furniture.

Owner:王春鸣

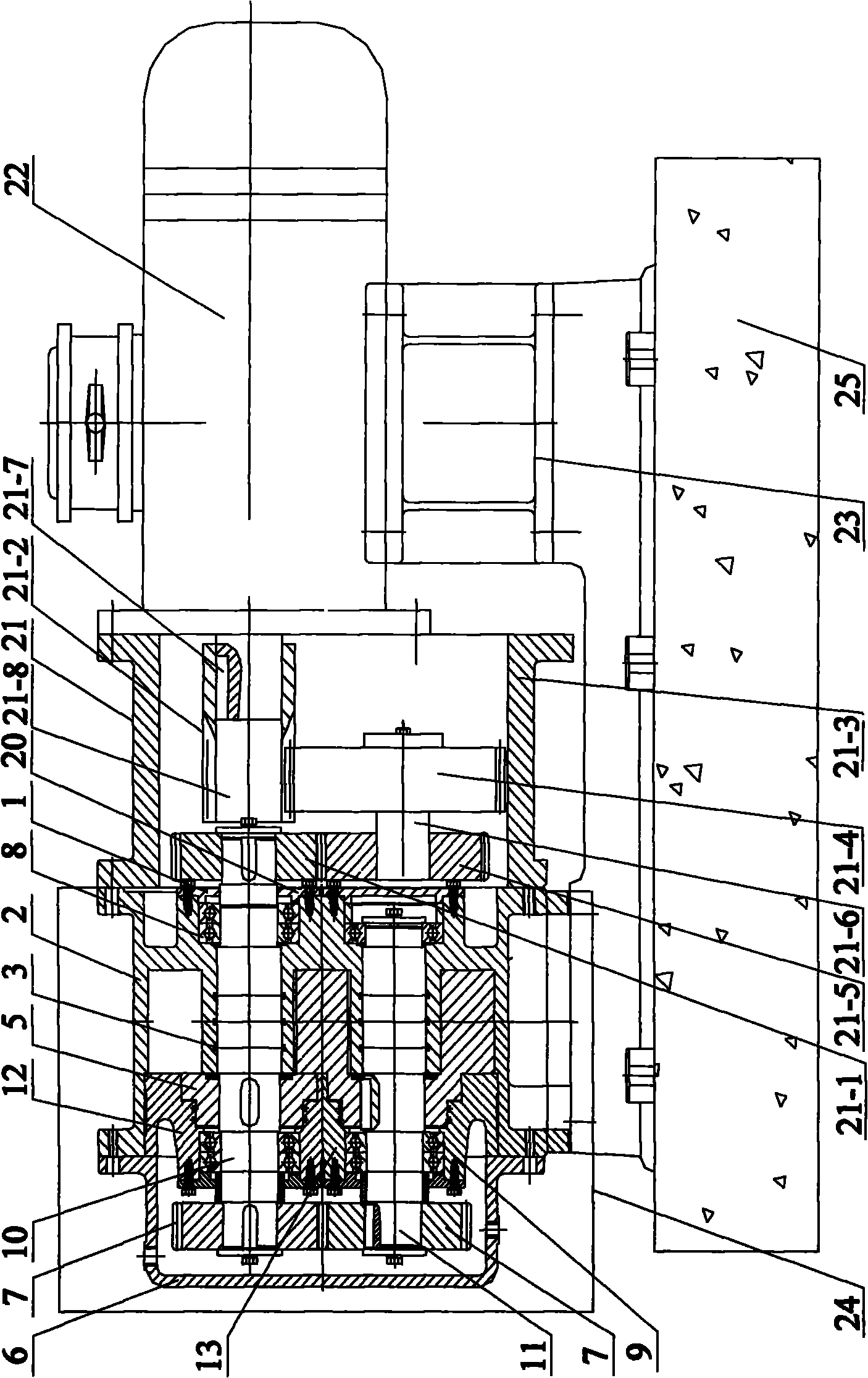

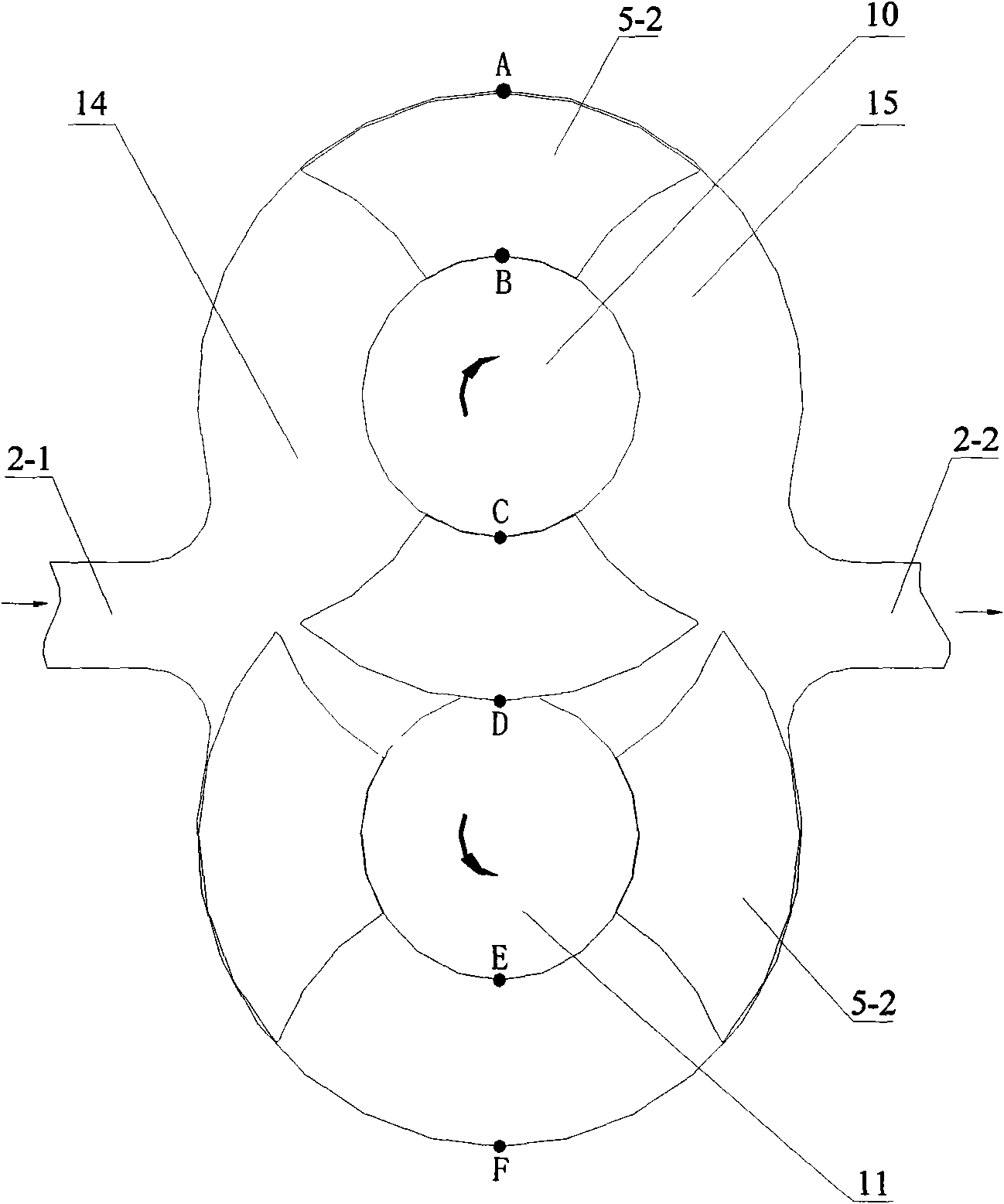

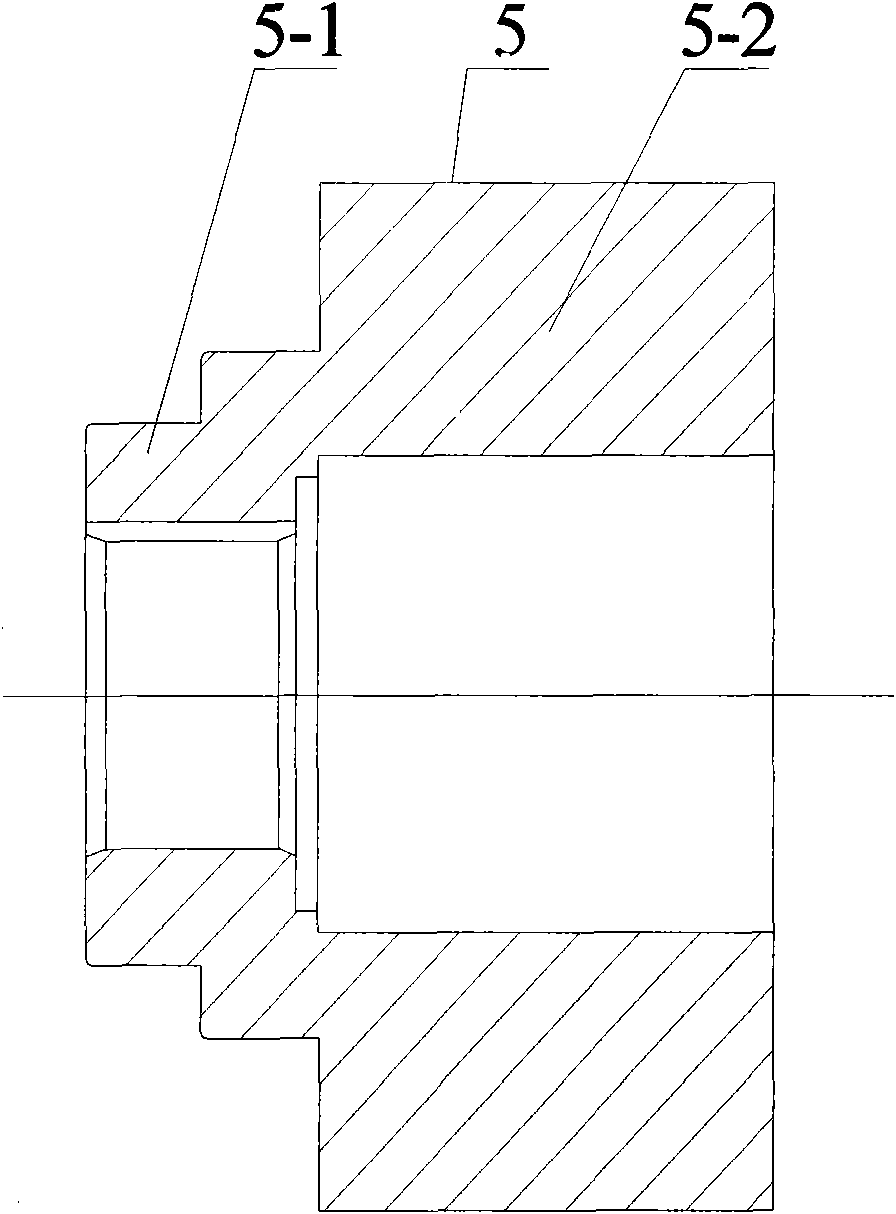

Gather and delivery pump set for thick oil containing sand

InactiveCN102011728AGuaranteed not to deformFlexible rotationRotary piston pumpsRotary piston liquid enginesDrive shaftReducer

The invention provides a gather and delivery pump set for thick oil containing sand, which relates to a gather and delivery pump set. The invention aims to solve the problem that the traditional common pump has the disadvantages of low efficiency, high power consumption, poor abrasion resistance, short service life and high oil extraction production cost when used for delivering thick oil containing sand. One side of a pump casing is provided with an oil inlet, and the other side is provided with an oil outlet; a driving shaft and a driven shaft are arranged in the pump casing and a gear cover; the driving shaft and the driven shaft are respectively and fixedly provided with a synchronizer gear, and the two synchronizer gears are meshed with each other; the driving shaft and the driven shaft are provide with a first bearing pedestal and a second bearing pedestal, and are also respectively provided with a rotor; sector vanes on the two rotors are perpendicular to each other; the rotating clearance between the rotors and the pump casing is 0.36mm; an output gear of a speed reducer is fixedly arranged on an input shaft of the driving shaft; an input gear of the speed reducer is connected with an output shaft of a motor in a driving manner; and the motor is fixedly arranged on a motor base. The invention has the characteristics of good sealing effect, good abrasion resistance, high efficiency, low power consumption, long service life and low oil extraction cost. The gather and delivery pump set is mainly used for storage, gather and delivery in an oil project.

Owner:HARBIN JIANCHENG GRP

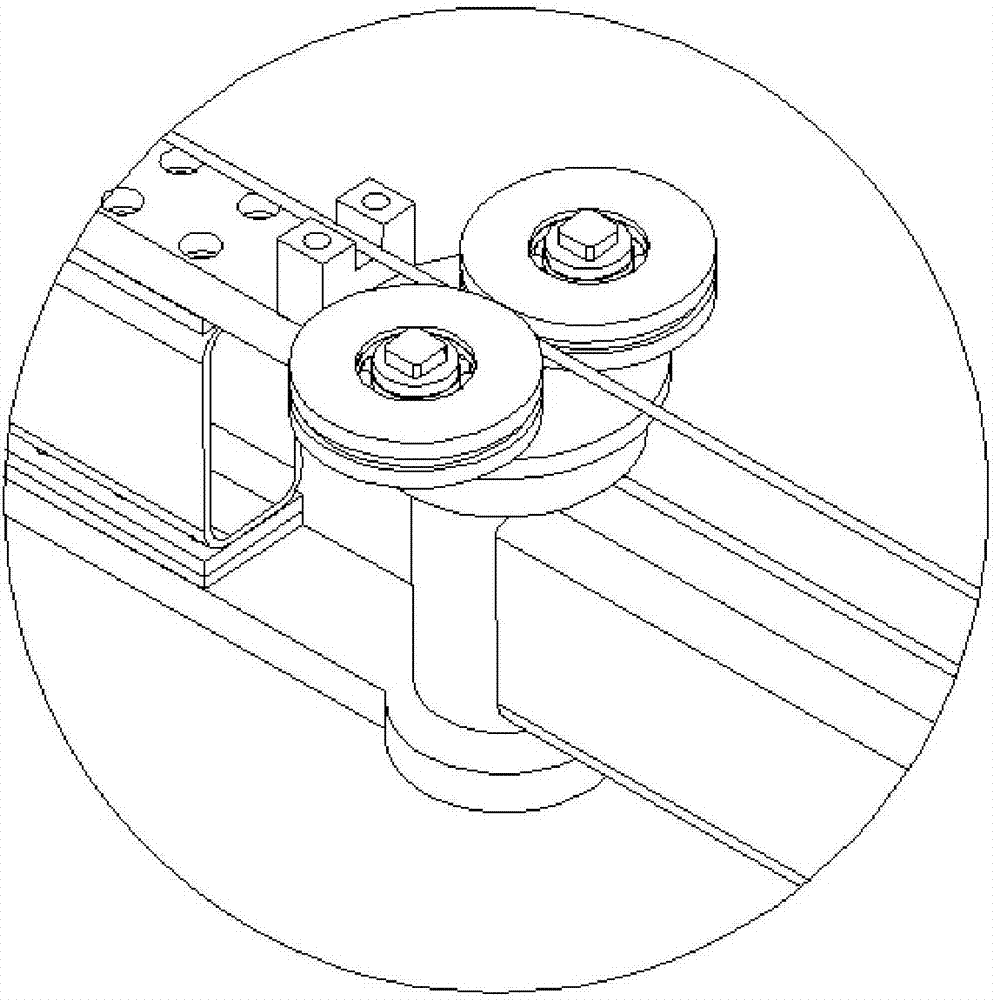

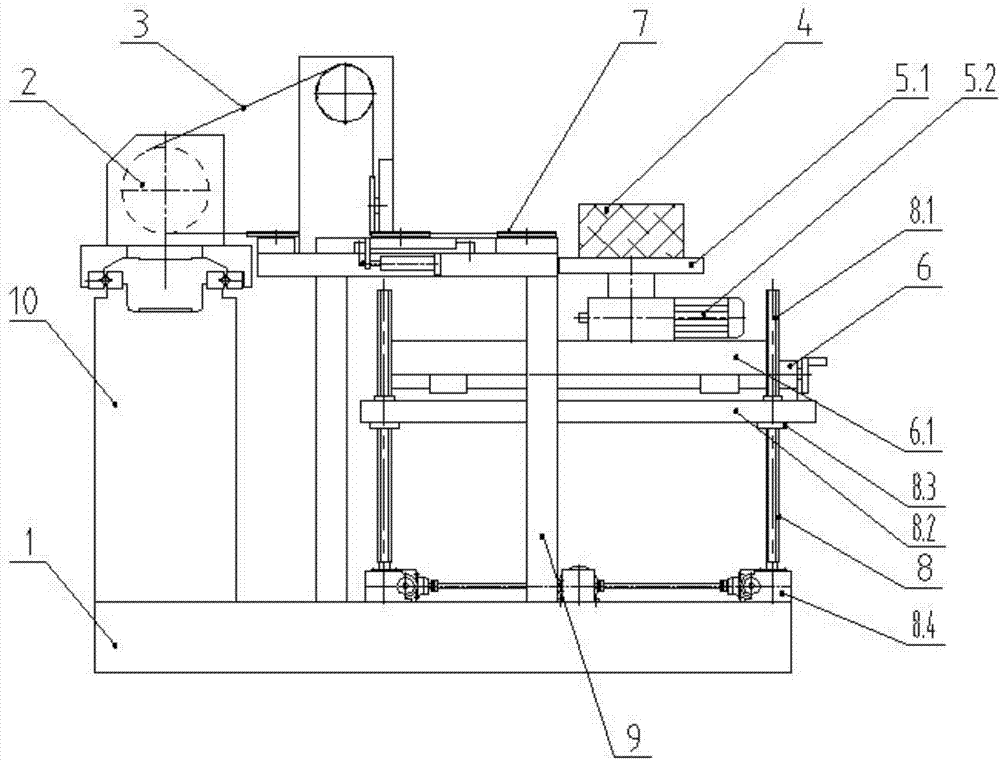

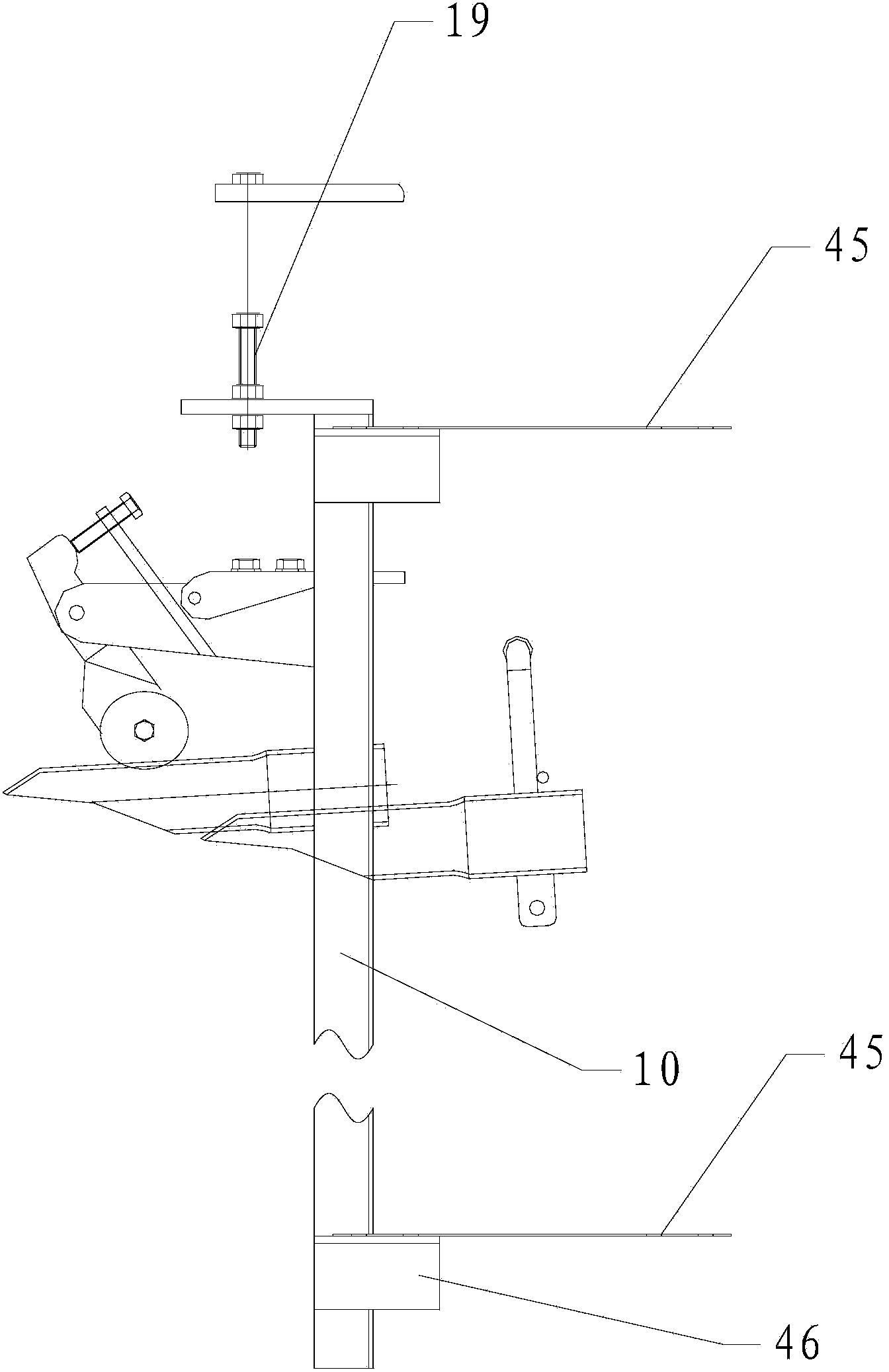

Cutting machine tool horizontally cutting sand line

InactiveCN106881773AEasy to installAchieve horizontal cuttingWorking accessoriesGrinding machinesMetallic materialsLarge size

The invention discloses a cutting machine tool horizontally cutting a sand line. The cutting machine tool comprises a base, a line storage cylinder, a line storage cylinder moving part, a sand line, a worktable assembly, a guide wheel assembly, a lifting mechanism and a guide wheel supporting frame. The central axis of the line storage cylinder is arranged levelly, and the line storage cylinder is driven by the line storage cylinder moving part to achieve transverse moving. The guide wheel assembly is arranged on the guide wheel supporting frame. The lifting mechanism is supported on the base and comprises a top plate arranged levelly above the base. The worktable assembly is supported on the upper end face of the top plate of the lifting mechanism and comprises a worktable which is located on the upper portion of the worktable assembly and can longitudinally move. The guide wheel assembly can achieve sand line horizontal cutting. Further improvement lies in that the lifting mechanism is an electric lifting mechanism. A rotating disc assembly is arranged on the upper end face of the worktable. A nylon or resin layer is arranged on the outer surface of a line storage cylinder body. Non-metallic materials with large sizes and high weights can be cut conveniently and quickly, the production efficiency is high, no stripe cutting can be achieved, and cutting precision is high.

Owner:泰州市江洲数控机床制造有限公司

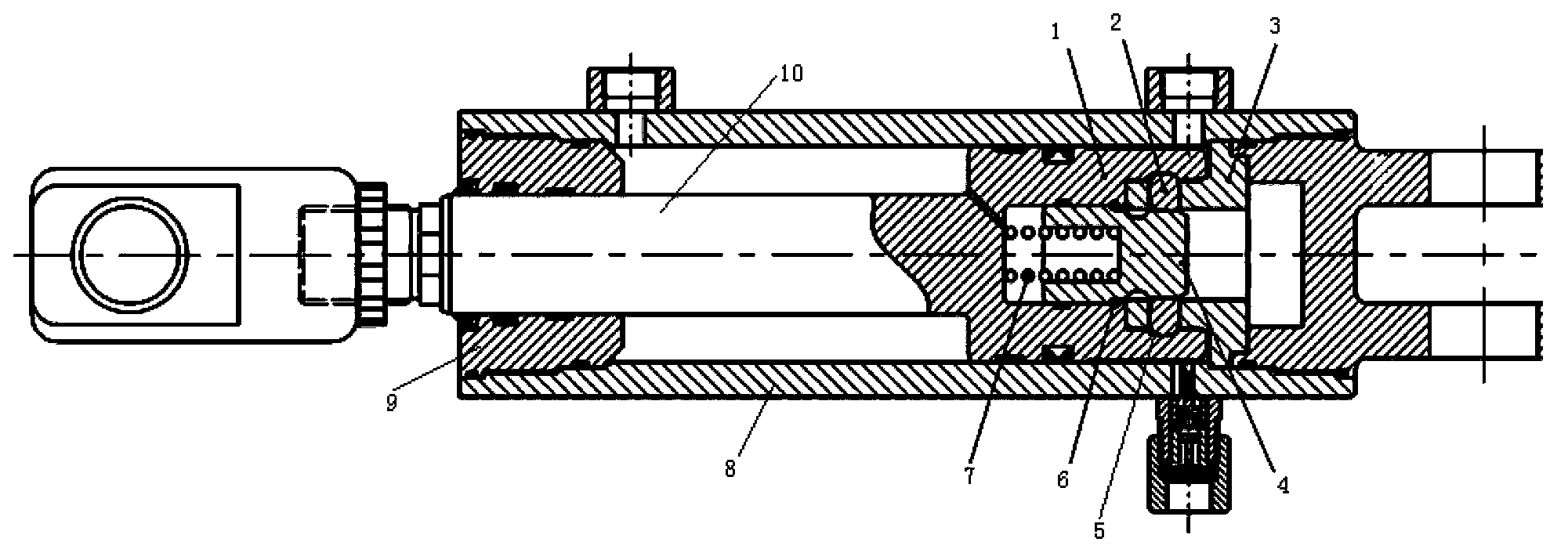

Hydraulic cylinder provided with mechanical lock

InactiveCN103352899AEasy to lockNo sticking phenomenonFluid-pressure actuatorsHydraulic cylinderMechanical engineering

The invention provides a hydraulic cylinder provided with a mechanical lock. The hydraulic cylinder comprises a cylinder barrel, a piston rod, a piston, a plunger piston, a clamping key and a clamping key seat, wherein a piston hole is formed in the piston; the plunger piston is arranged in the piston hole; a reset spring is arranged between the plunger piston and the piston; the clamping key seat is arranged at the bottom of the cylinder barrel and is a tube body with a cavity formed inside; a clamping key hole is formed in the side wall of the tube body; the clamping key comprises a circular ring and a raised key fixed on the outer spherical surface of the circular ring; the raised key is arranged in the clamping key hole; a clamp spring is arranged between the clamping key and the plunger piston; and a clamping key groove for partially accommodating the raised key is formed in the inner wall of the piston. According to the hydraulic cylinder provided with the mechanical lock, the locking effect is good, no clamping stagnation phenomenon exists in an action process, the hydraulic cylinder can be accurately locked and opened, unlocking and locking processes are guaranteed to be normal, larger tension can be borne in a locking state, and the hydraulic cylinder is not easy to damage and long in service life.

Owner:TIANJIN HUARONG PNEUMATIC & HYDRAULIC COMPLETE SYST

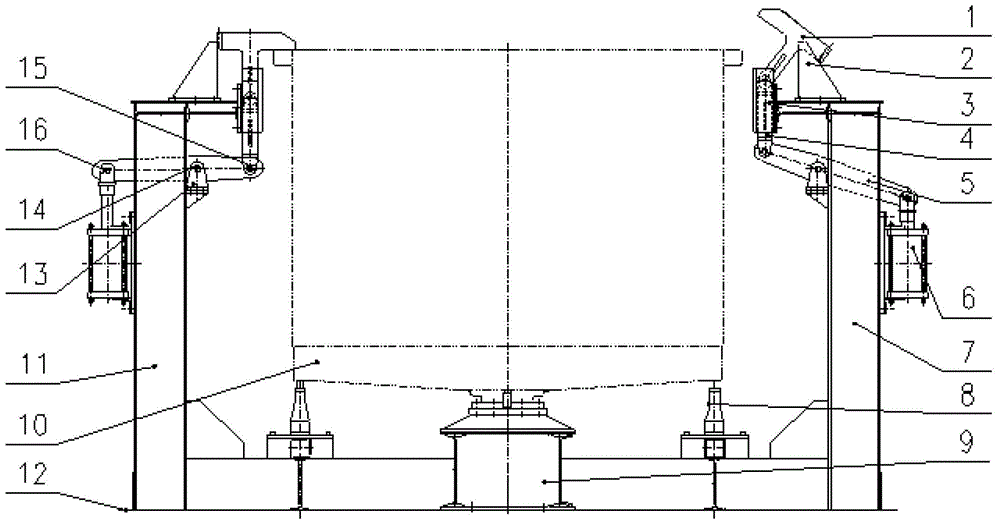

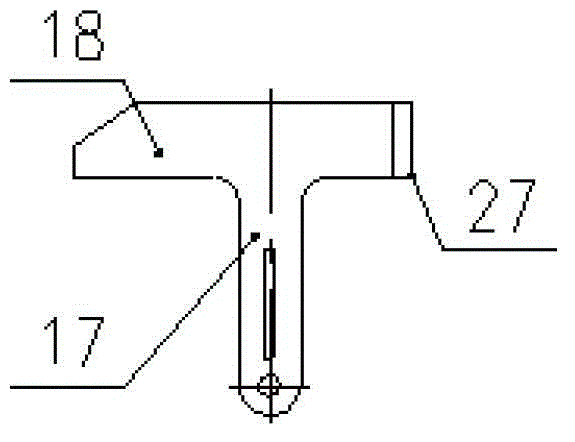

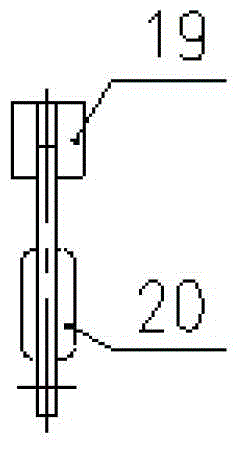

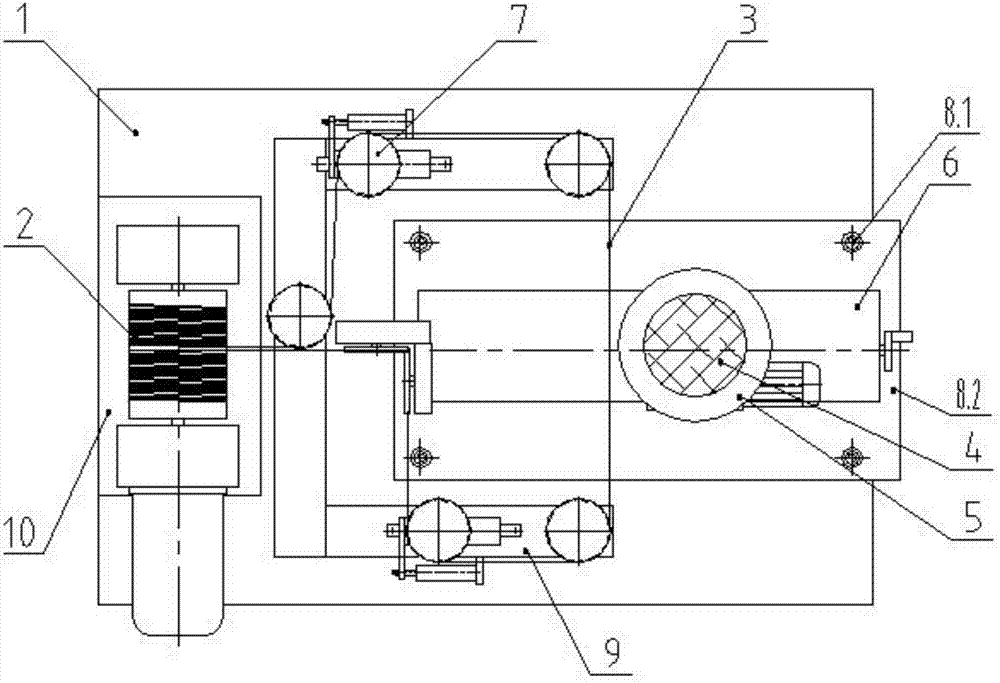

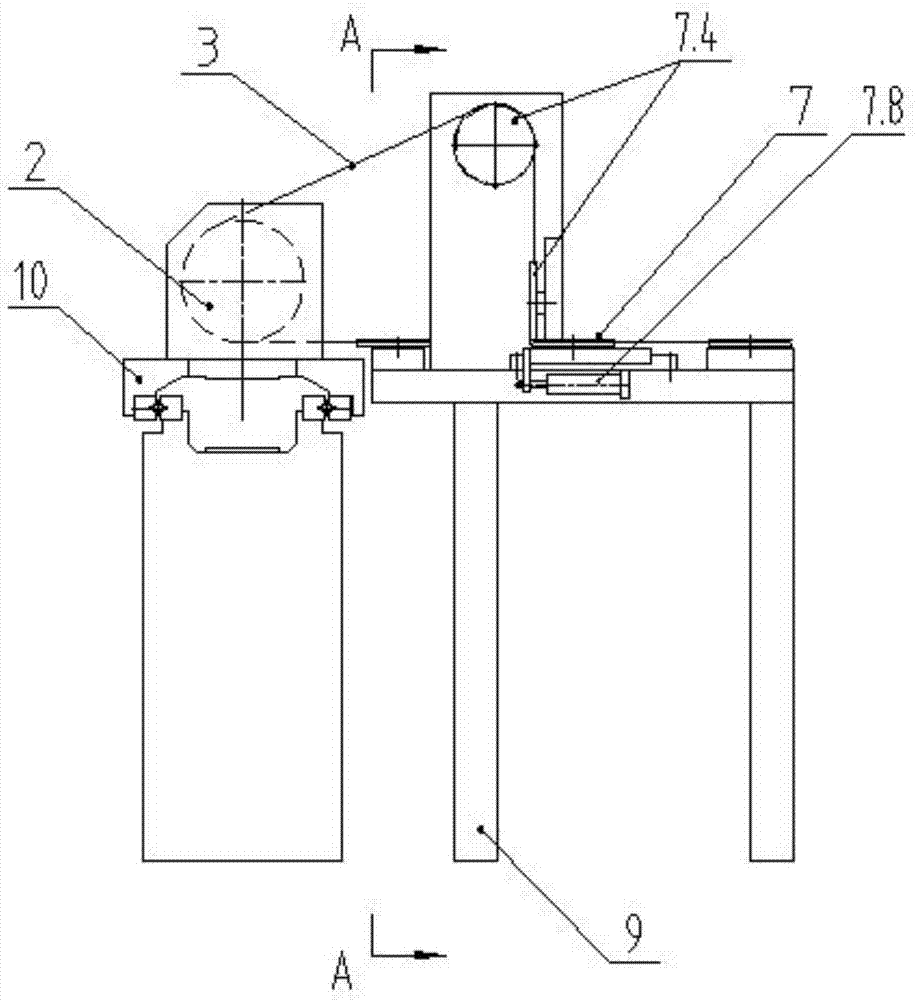

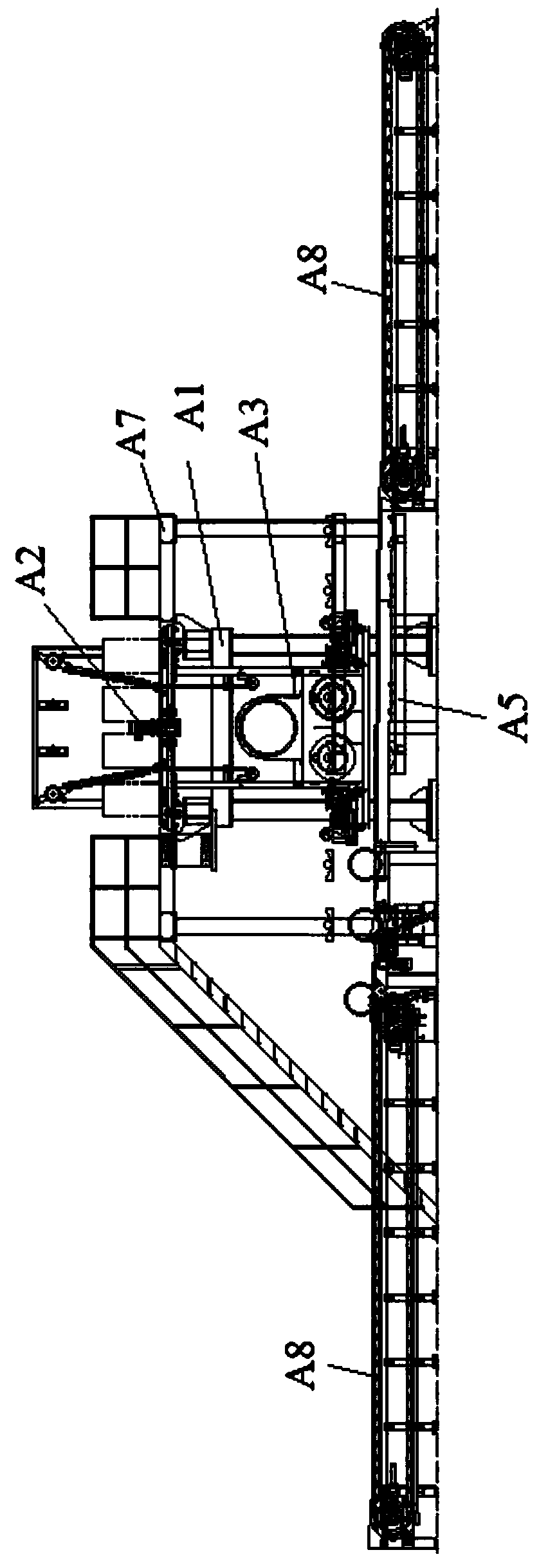

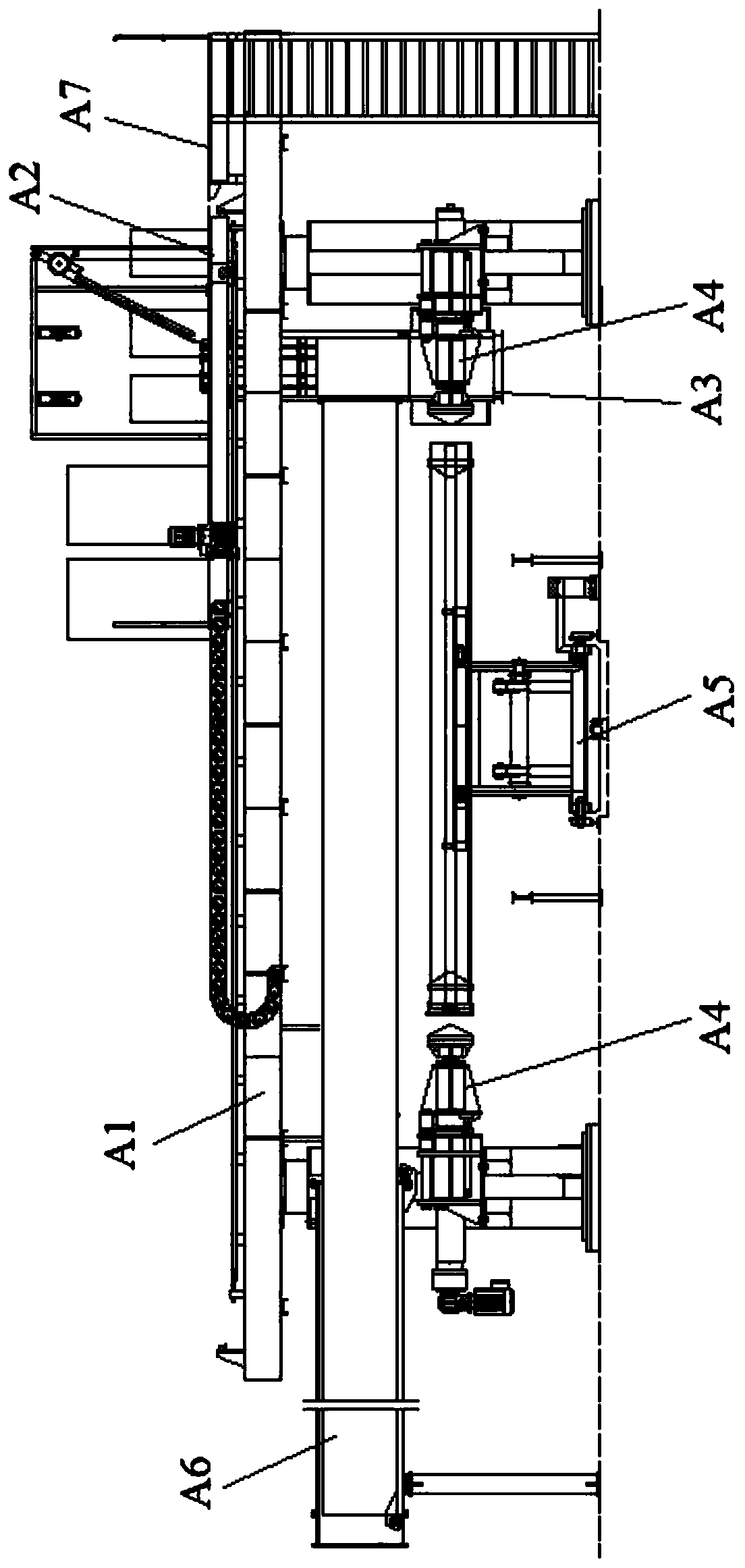

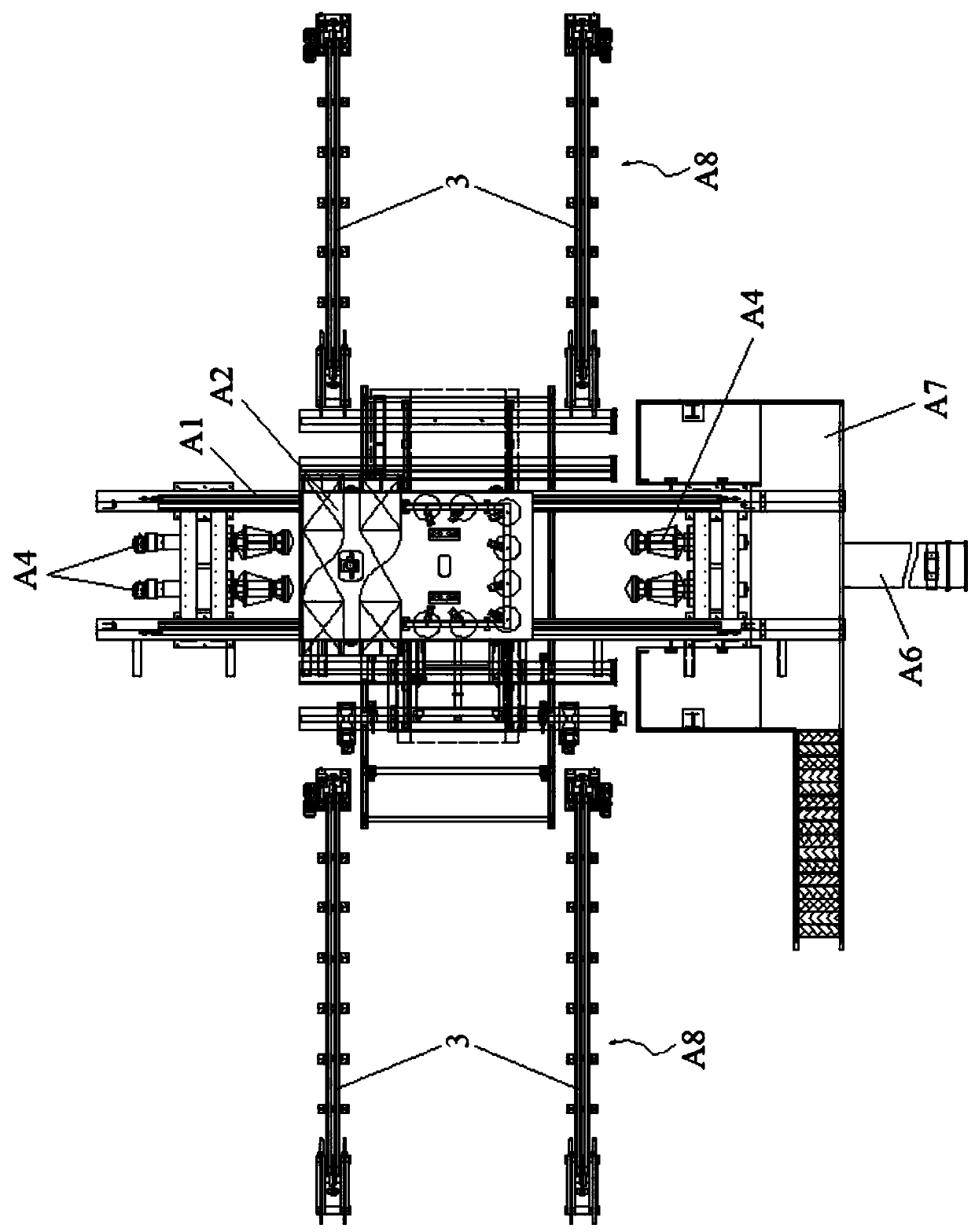

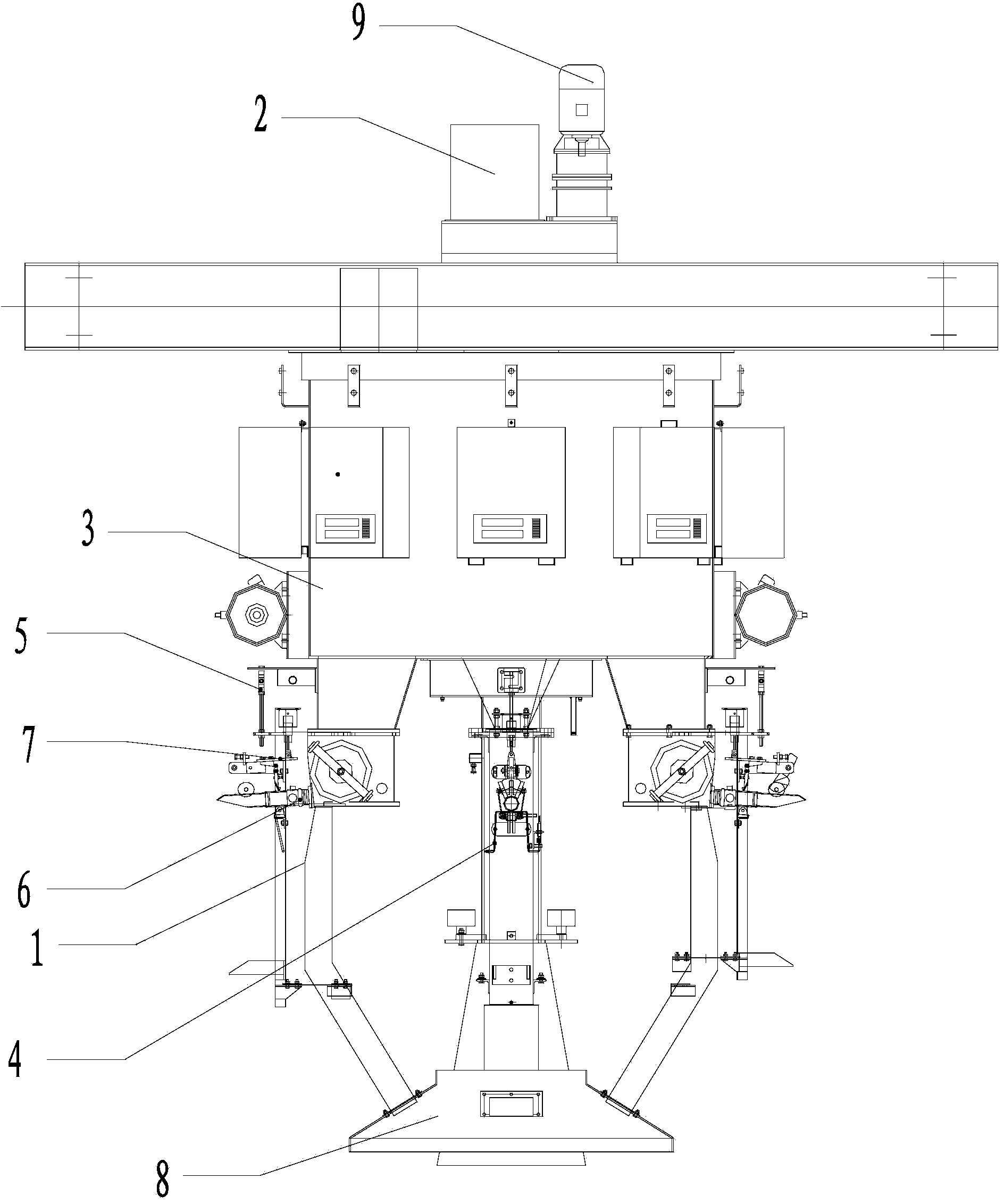

Double-station cast tube surface zinc spraying machine

The invention relates to a double-station cast tube surface zinc spraying machine. The machine is characterized in that a zinc spraying trolley is arranged on a rack and transversely moves along the rack, wherein a wire feeding adjusting device is arranged on the lower surface of the zinc spraying trolley and connected with the zinc spraying trolley, and spray gun assemblies for spraying zinc on the surface of a cast pipe are arranged on two sides of the wire feeding adjusting device; two pushing and rotating mechanism sets are arranged at the lower part of the rack and are used for clamping two casting pipes and driving the casting pipes to rotate; the wire feeding adjusting device is driven by the zinc spraying trolley to transversely move along the axial direction of the casting pipes in the rotating process of the casting pipes; the spray gun assemblies are capable of spraying zinc on the surfaces of the casting pipes in the transversely moving process; a cast tube feeding and discharging mechanism is arranged at the lower part of the rack and used for feeding the cast tubes to a pushing and rotating mechanism and taking the cast tubes subjected to zinc spraying down from the pushing and rotating mechanism; and a dust removal device is arranged at the upper part of the pushing and rotating mechanism and used for treating zinc mist generated in the zinc spraying processing process. The double-station zinc spraying machine is capable of spraying zinc to two casting tubes at one time, and has the characteristics of wide application range, stable operation, simple operationand the like.

Owner:杭州春风机械工程股份有限公司

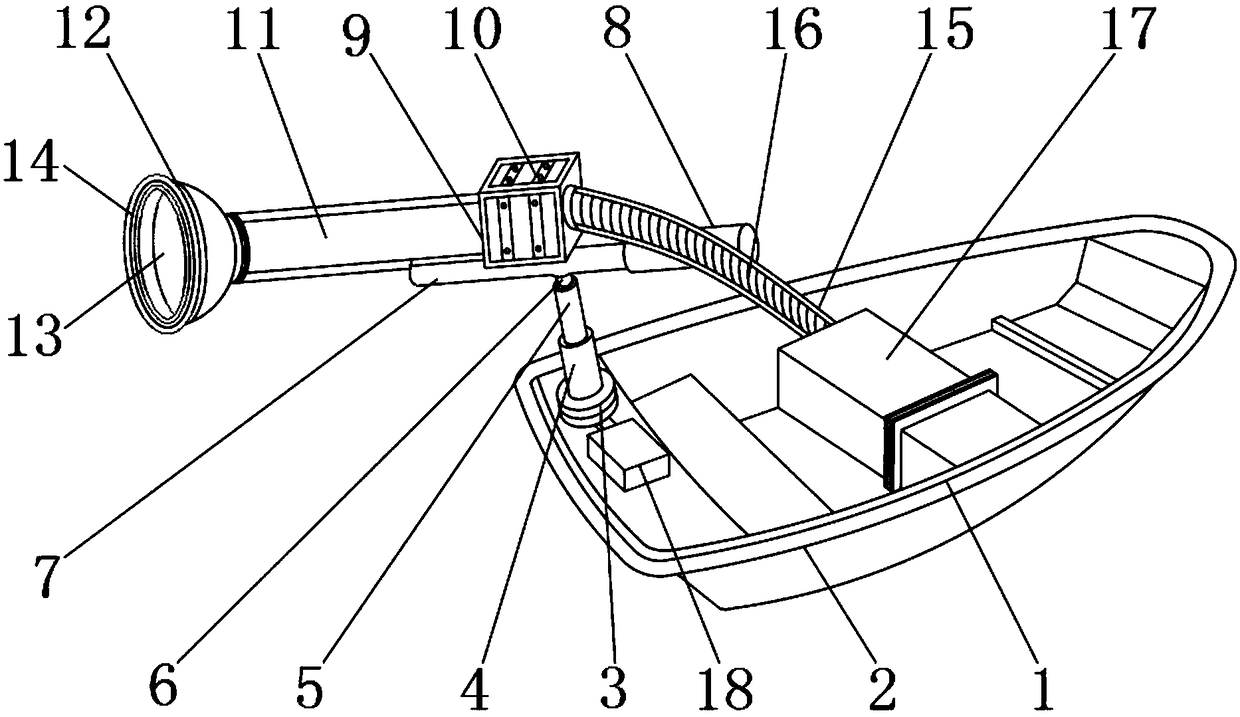

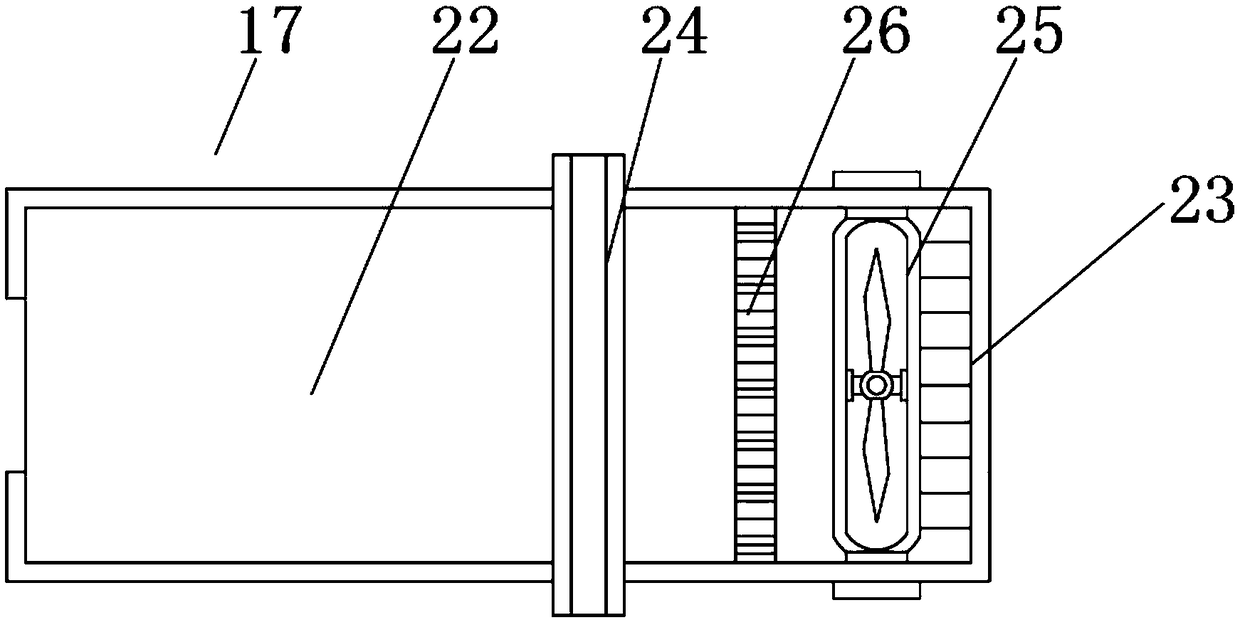

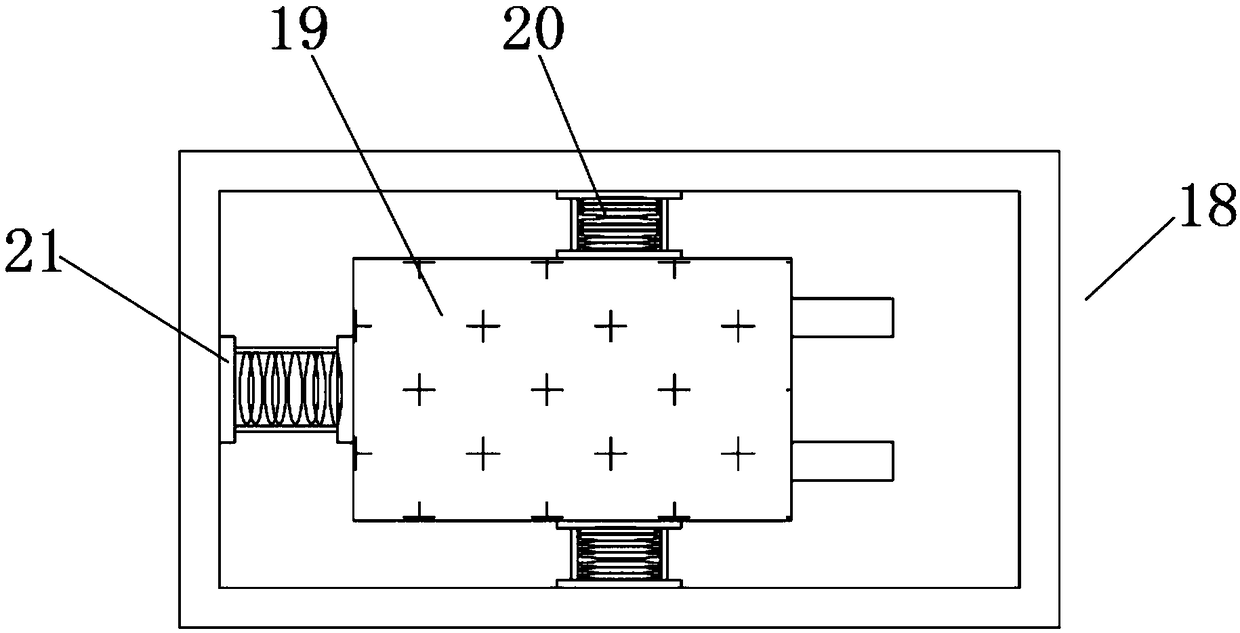

Artificial fishing device for water environment treatment

ActiveCN108708359AScientific and reasonable structureEasy to useWater cleaningWaterborne vesselsEngineeringWaste treatment

The invention discloses an artificial fishing device for water environment treatment. The artificial fishing device comprises an electric telescopic rod, a connecting rotating ball, an electric push rod, a waste treatment box, a dirt collection box and a damping spring. The connecting rotating ball is mounted at the top end of the electric telescopic rod. The waste treatment box is arranged abovethe electric push rod. The damping spring is arranged on one side of the dirt collection box. The artificial fishing device is scientific and reasonable in structure and safe and convenient to use; the electric telescopic rod, the connecting rotating ball and the electric push rod are arranged, and the dirt suction height, direction and range of a conical sucker can be changed, so that when the conical sucker of the fishing device is operated by people, the operation is easier and more convenient, the dirt suction range of the conical sucker is enlarged, and the fishing efficiency of the fishing device is improved; the waste treatment box and the dirt collection box are arranged, so that fished dirt can be treated and collected in a centralized manner, and subsequent manual centralized cleaning is facilitated; and the damping spring is provided to prevent the edge of a storage battery from being damaged due to the shaking of a ship hull during use.

Owner:安徽中疆数字科技有限公司

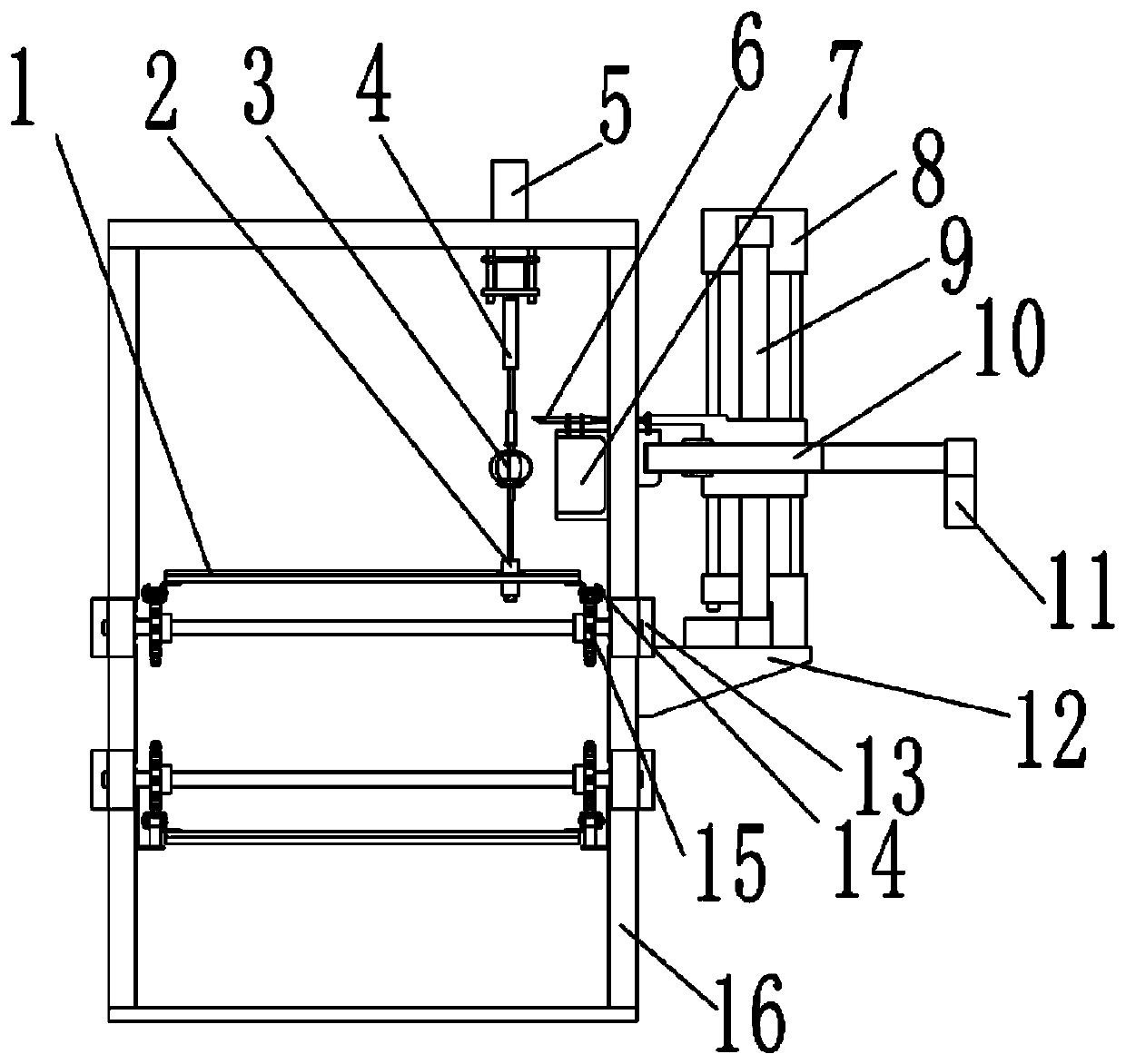

Automatic segmenting device and method for orange fruits

ActiveCN110916221AAchieve orientationImprove accuracyFood treatmentAutomatic segmentationEngineering

The invention discloses an automatic segmenting device and method for orange fruits. The device includes orange fruit positioning equipment, orange fruit segmenting equipment and a frame; the orange fruits are positioned by the orange fruit positioning equipment, image data information of orange fruit segmenting lines are collected, stored and analyzed by using an image data acquisition system toobtain the orange fruit segmenting lines, and the orange fruits are segmented by using the orange fruit segmenting equipment. According to the device and method, after the orange fruits are put into the segmenting equipment, the automatic orange segmenting operation can be realized, and multiple sets of orange fruit positioning equipment and orange fruit segmenting equipment can be arranged in parallel on the device frame, so that the labor cost investment can be reduced, and the orange segmentation is more efficient; by using the image data acquisition system to control the position of orangefruit segmentation, the device can improve the accuracy of the orange segmentation; and by using a combination of a segmentation bow and support knife equipment to segment the orange fruits, the device can automatically segment the orange fruit according to the segmenting lines, so that automatic segmentation and complete cutting of the orange fruits with different specifications can be realized,and the device does not have the phenomenon of orange segment adhesion.

Owner:CHANGZHOU MINGSHI AUTOMATION EQUIP CO LTD

Pharmaceutical composition containing spherical clopidogrel bisulfate I crystal form and preparation method of pharmaceutical composition

ActiveCN105012298AComply with clinical drug requirementsConducive to the realization of powder direct compression processOrganic active ingredientsOrganic chemistryClopidogrel BisulfateCrystal

The invention provides pharmaceutical composition containing spherical clopidogrel bisulfate I crystal form and a preparation method of the pharmaceutical composition. Direct powder compressing can be achieved favorably by the powder property of the pharmaceutical composition, and sticking during tablet compressing is avoided. The invention further provides a clopidogrel bisulfate tablet using direct powder compressing and a preparation method of the tablet. The tablet meets the requirements of clinical medication.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD +2

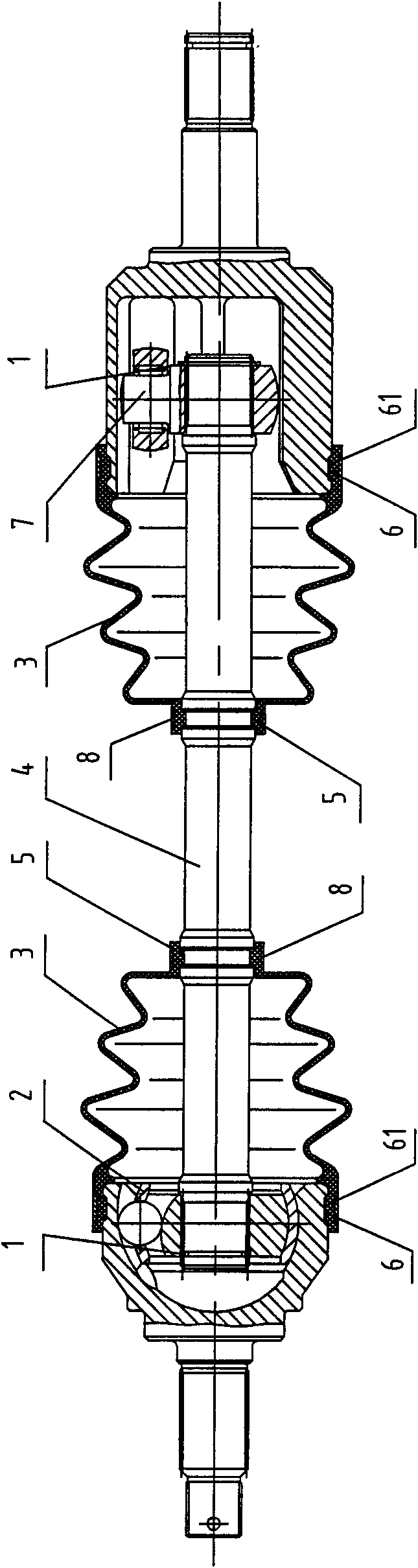

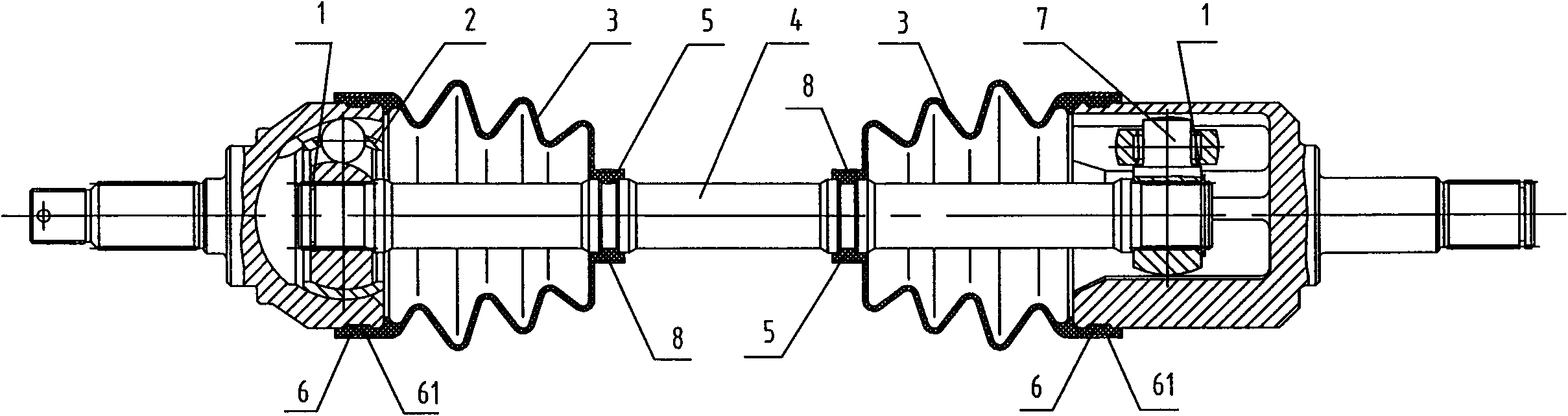

Automobile drive shaft assembly

InactiveCN101966815AImprove sealingExtended service lifeYielding couplingControl devicesAxial displacementDrive shaft

The invention relates to an automobile drive shaft assembly, comprising a rzeppa universal joint with seven raceways, a tripod constant velocity universal joint, a drive shaft with splines at the two ends, retainer rings, sealed covers and hoops, A starlike inner race of the rzeppa universal joint with seven raceways and a spider of the tripod constant velocity universal joint are respectively installed on the outer splines at the two ends of the drive shaft by inner splines and are axially fixed by the elastic retainer rings; and the dustproof covers and the hoops are arranged at the joints of the drive shaft and the universal joints. The automobile drive shaft assembly can bear axial displacement and angular displacement while transferring torque, not only can steadily, flexibly, reliably and accurately transfer motion and torque, but also is flexible in rotation, free from clamping stagnation and high in bearing capability. By integrating the universal joints by the drive shaft, sliding spline pairs are omitted, the universal joints have good sealability after adopting the dustproof covers and the service life of the drive shaft is prolonged.

Owner:石宝枢

Rotary dry powder packing machine

The invention provides a rotary dry powder packing machine which comprises a rack, wherein a rotating shaft is rotatably mounted on the rack, a rotating cylinder is fixedly mounted on the rotating shaft, a plurality of annularly distributed packing devices are arranged uniformly at the bottom of the rotating cylinder, each packing device comprises a bag insertion starting device used for starting the whole set of the packing device after bag insertion, an automatic metering device used for weighing a packing bag, a sealing device used for sealing a discharge rubber tube after the last packing bag is packed, an automatic bag dropping return device used for automatically dropping the packing bag after the packing bag is packed, and a dust collection device used for processing the raised dust leaking from a dust discharge nozzle of the automatic bag dropping return device, and the bag insertion starting device, the automatic metering device, the sealing device and the automatic bag dropping return device are all electrically connected with a control system of the rotary dry powder packing machine. The rotary dry powder packing machine achieves automated packing production, is simple in operation and accurate in metering, simplifies the operation process, and also improves the production capacity and the working efficiency.

Owner:潍坊佰固建材设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com