Bearing bush and process thereof for spraying MoS2 on alloy layer

A technology of alloy layer and bearing bush, applied in the direction of coating, bearing components, shaft and bearing, etc., can solve the problems of bearing bush alloy layer or coating peeling off, and achieve the effect of improving service life, reducing pollution and good anti-dry wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

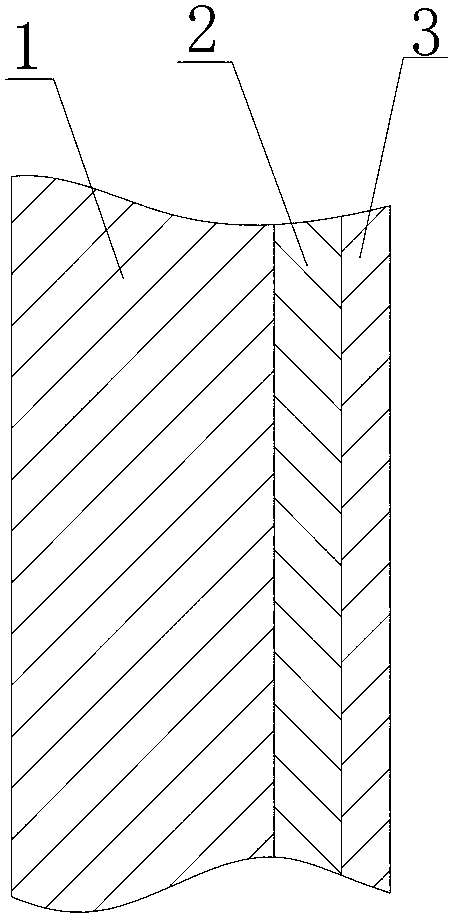

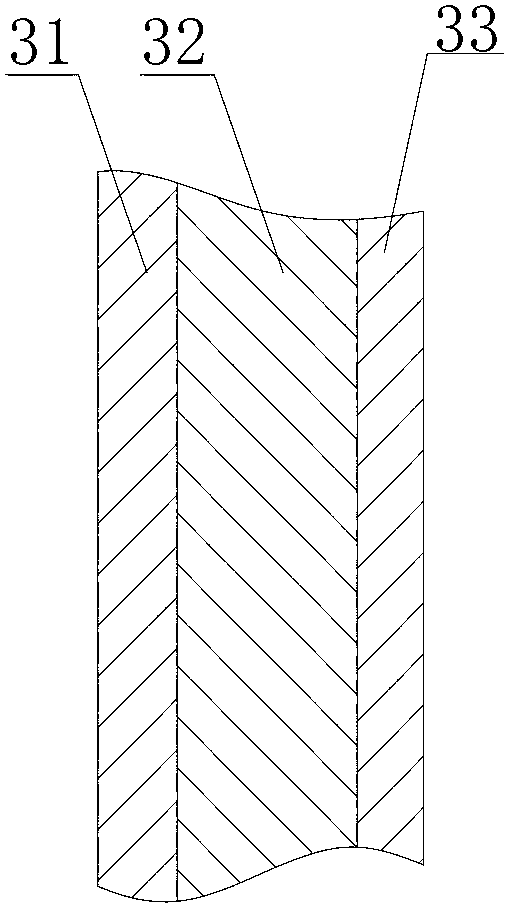

Image

Examples

Embodiment 1

[0039] When the alloy layer 2 is an aluminum alloy layer, the production process of the bearing bush includes the following steps:

[0040] 1) Cleaning: place the fine-bored aluminum alloy bearing bush (including the fixedly connected steel back layer 1 and the aluminum alloy layer) in an ultrasonic cleaning machine filled with a neutral cleaning agent for cleaning, at a temperature of 60-70°C and for a time of 2 -8 minutes;

[0041] 2) Activation: Clean the above parts in an acidic aluminum activator at a temperature of 45-60°C for 1-5 minutes;

[0042] 3) Washing with water; put the above parts in tap water, wash at least once at room temperature, each time for 1 minute, until the acidic aluminum activator on the parts is cleaned;

[0043] 4) Aluminum phosphating; put the above parts in the aluminum phosphating agent at a temperature of 35-55°C for 2-9 minutes;

[0044] 5) Rinse in cold water; place the above parts in deionized water at room temperature for 1 minute;

[004...

Embodiment 2

[0052] When the alloy layer 2 is a copper-lead alloy layer, the production process of the bearing pad includes the following steps:

[0053] 1) Cleaning: place the copper-lead bearing bush after fine boring in an ultrasonic cleaning machine filled with a neutral detergent for cleaning at a temperature of 60-70°C for 2-8 minutes;

[0054] 2) Activation: Clean the above parts in copper activator at a temperature of 30-75°C for 2-5 minutes;

[0055] 3) Washing with water; place the above parts in tap water and wash at least once at room temperature for 1 minute each time until the copper activator on the parts is cleaned;

[0056] 4) Copper passivation; place the above parts in molybdenum chromate at a temperature of 50-85°C for 2-8 minutes;

[0057] 5) Rinse in cold water; place the above parts in deionized water at room temperature for 1 minute;

[0058] 6) Rinse with hot water; place the above parts in deionized water at a temperature above 65°C for 1 minute;

[0059] 7) Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com