A high wear-resistant shaft-free aluminum-based alloy and its preparation method

An aluminum-based alloy and alloy technology, which is applied in the field of high wear-resistant non-shaft-holding aluminum-based alloys and its preparation, can solve the problems of shaft "seizure, shaft holding, etc., prolong service life, increase density, and increase alloy size The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

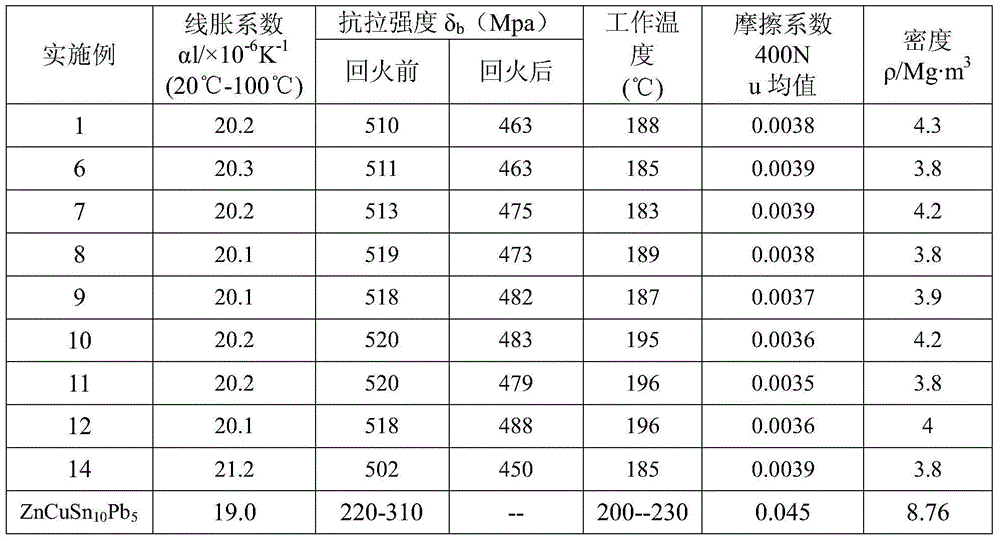

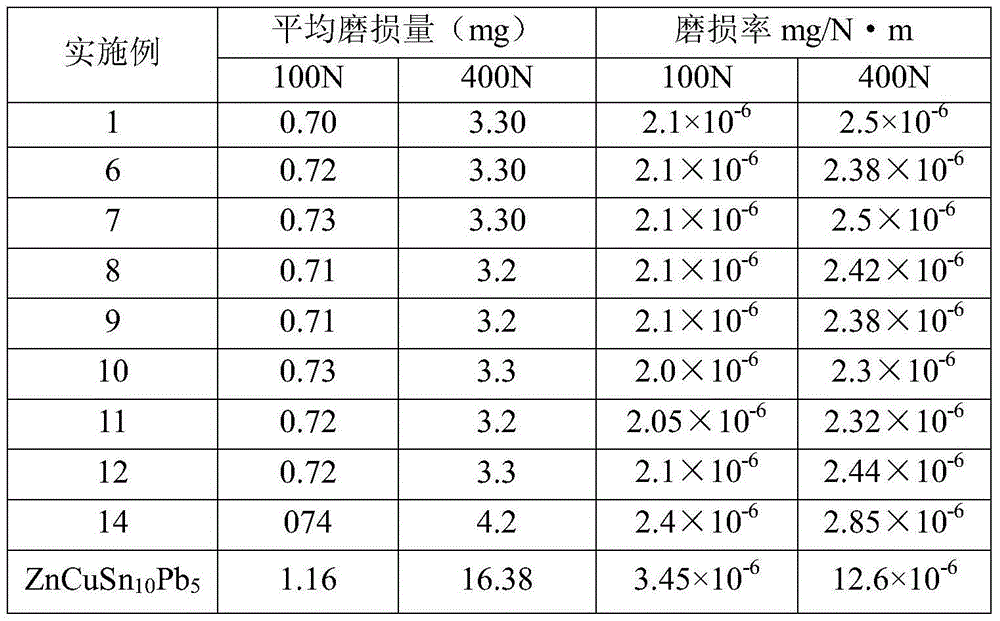

Examples

Embodiment 1

[0027] A high wear-resistant shaft-free alloy, made of the following components by weight percentage: 39 zinc, 2.5 silicon, 4.2 copper, 0.75 manganese, 0.42 chromium, 1.6 rhenium, 1.2 boron, 0.043 magnesium, 0.018 titanium, and the balance is aluminum.

Embodiment 2

[0029] Preparation of copper-aluminum master alloy. Put 300kg A00# aluminum ingot into the natural gas furnace, heat to 800℃ to melt all the aluminum ingot, then add 150kg1# electrolytic copper plate into the furnace gradually at 3~5KG / time, and stir fully after each addition, Add the next copper plate until the copper plate is completely melted. At the same time, with the addition of the copper plate, gradually increase the temperature, and finally reach 1300 ° C. Continue to melt for 3 hours, complete the melting, pour into the mold, and get 2 kg / piece of copper-aluminum intermediate alloy.

Embodiment 3

[0031] Preparation of silicon-aluminum master alloy. Put 300kg of A00# aluminum ingot into the natural gas furnace, heat to 730°C to melt the aluminum ingot, then gradually add 150kg of metal silicon into the furnace at a rate of 3-5KG / time, and stir thoroughly after each addition until the metal The silicon is all melted, and then the next metal silicon is added. At the same time, with the addition of metal silicon, the temperature was gradually increased, and finally reached 1430 ° C, and the melting was continued for 1 hour to complete the melting, pouring into the mold, and obtaining a 1.5 kg / block silicon-aluminum master alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com