Patents

Literature

399results about How to "Good anti-friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

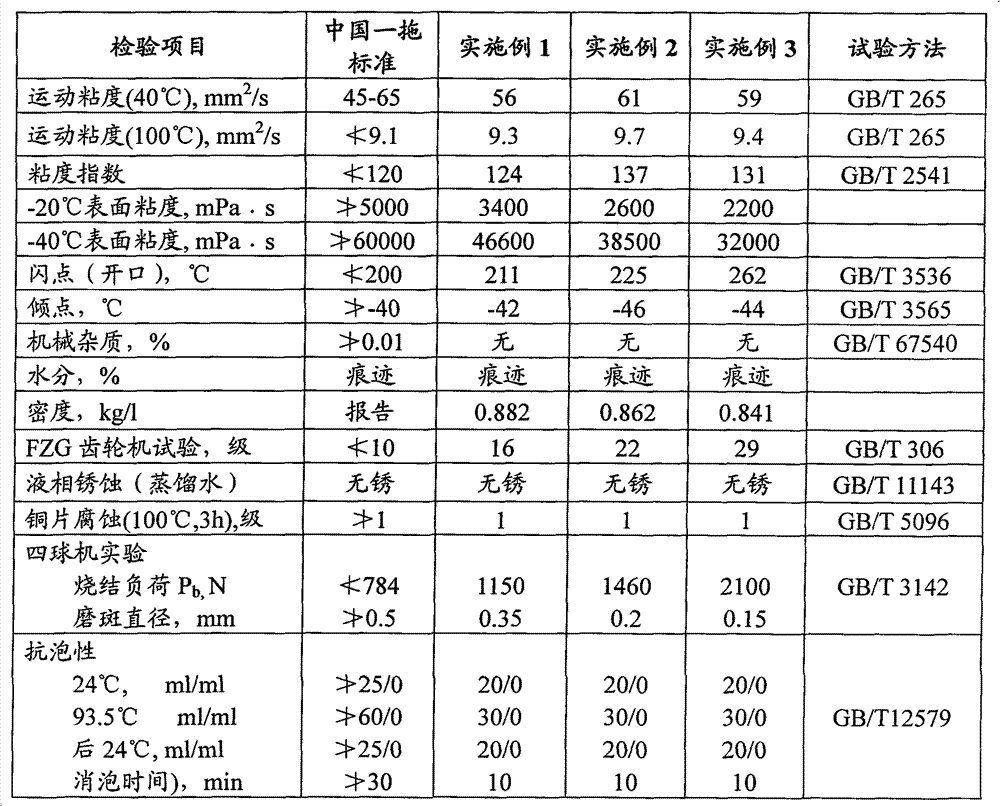

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

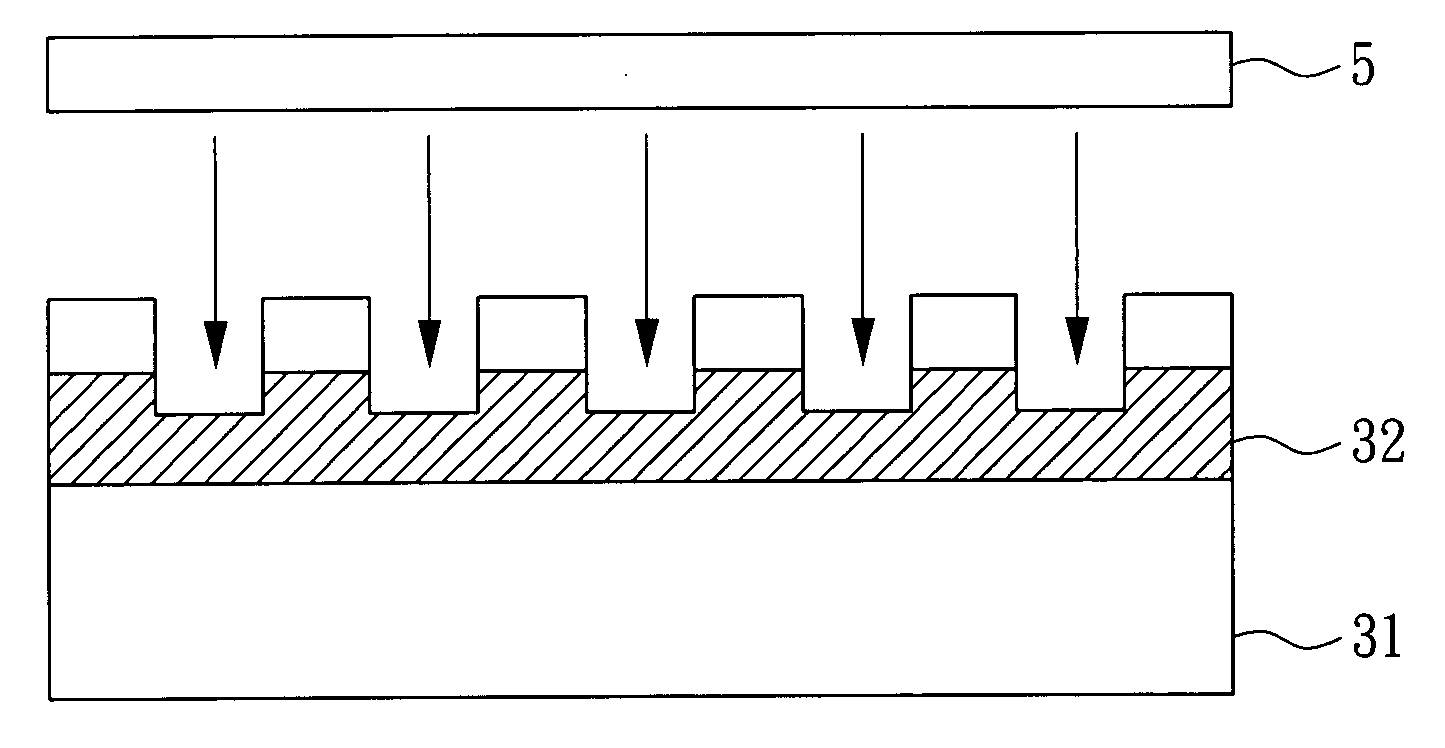

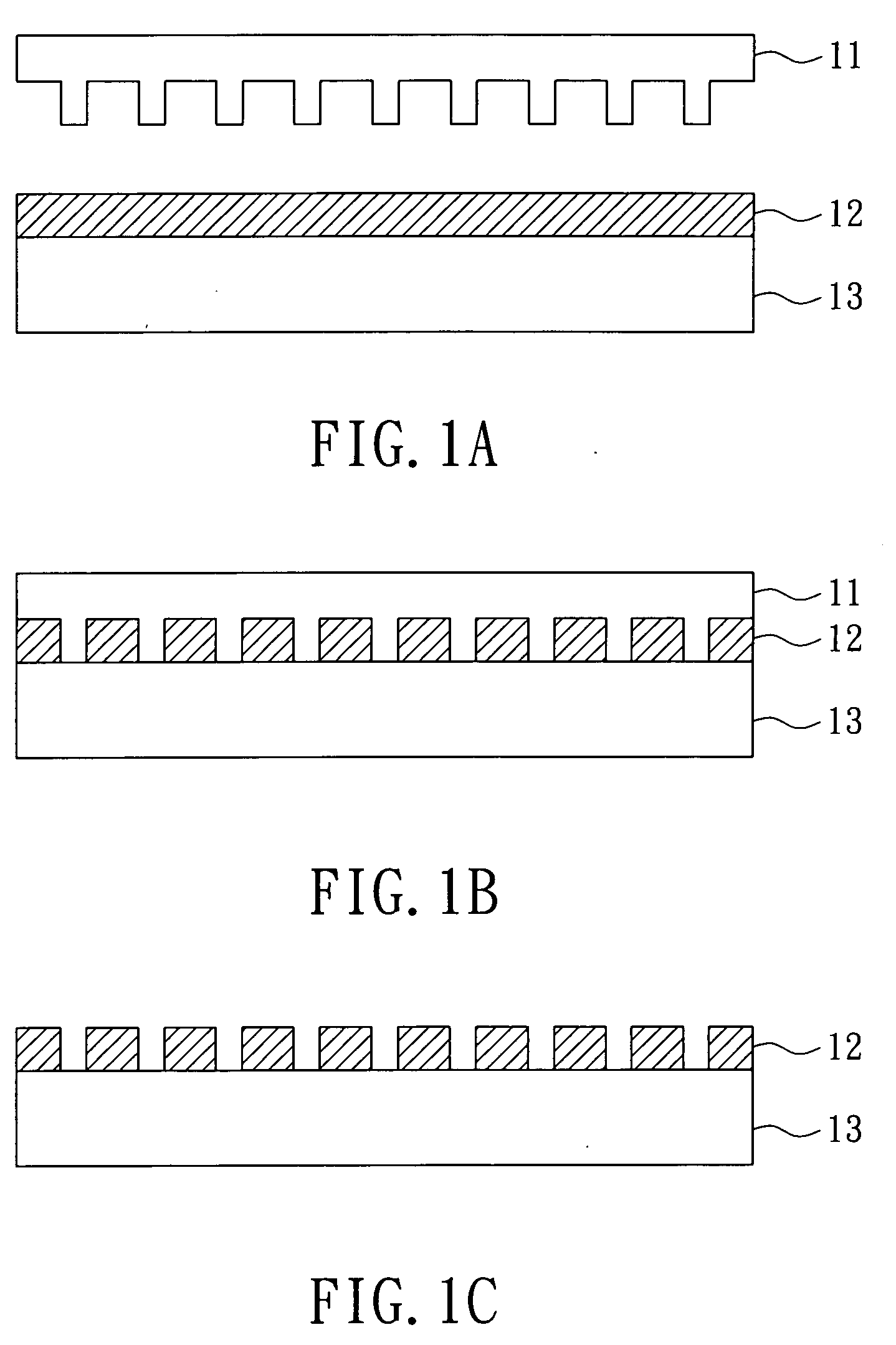

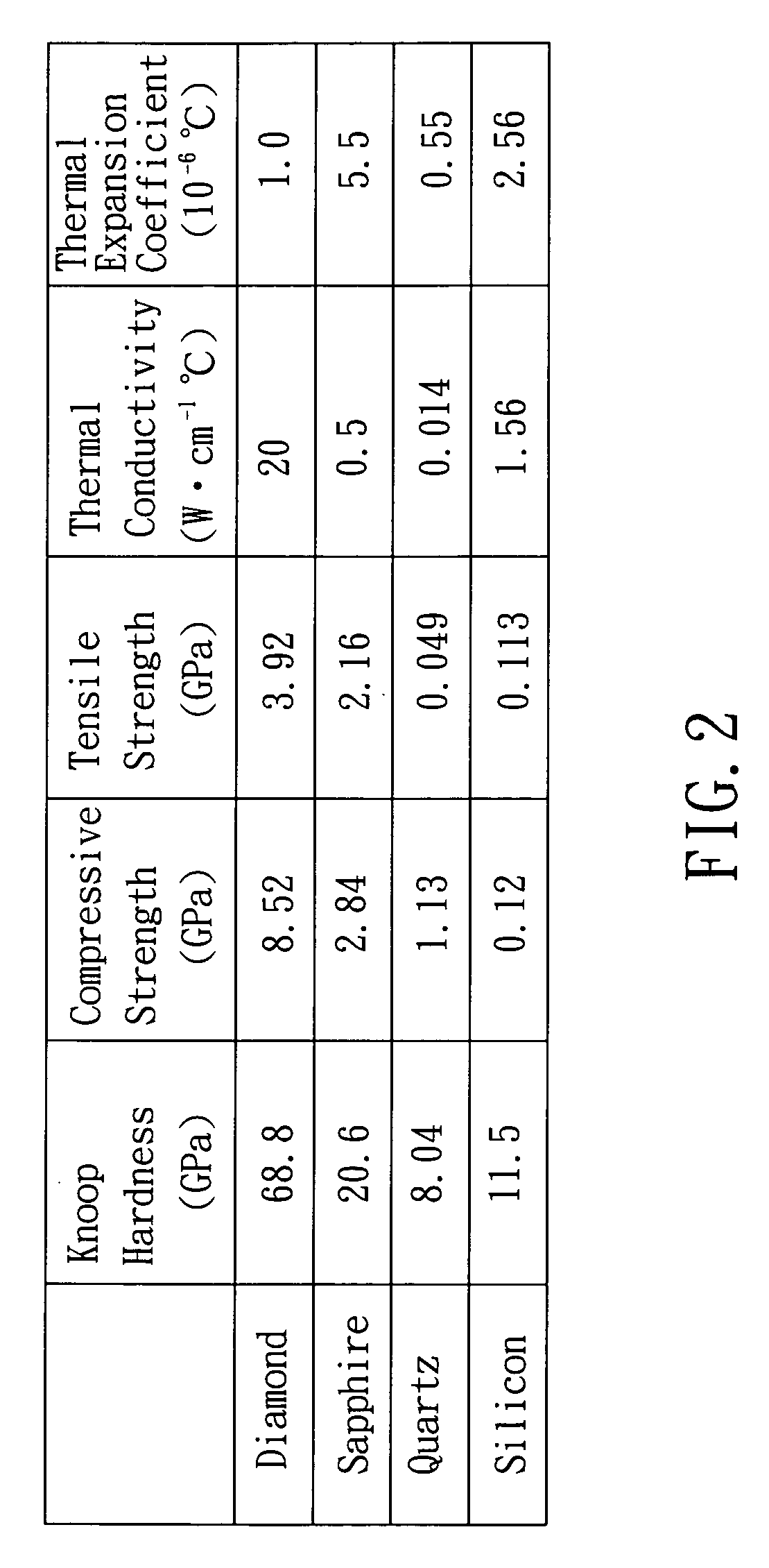

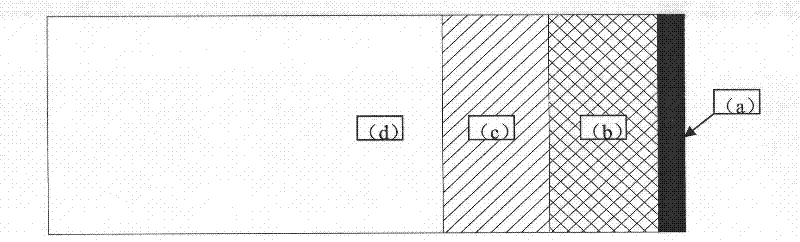

Structure of imprint mold and method for fabricating the same

InactiveUS20050170292A1Easy to carryGood anti-frictionLayered productsDecorative surface effectsLithographic artistNanoimprint lithography

The present invention is related to a structure of an imprint mold and a method for fabricating the same, which can be used in the field of nano-imprint lithography. Firstly, a diamond film and a photoresist film are successively formed onto a substrate; wherein the photoresist film is more capable of anticorrosion than the diamond film. Then an energy beam lithography system is provided to make the photoresist film form a photoresist mask with particularly arranged patterns. Because of the etching selectivity between the diamond film and the photoresist film, on the surface of the diamond film can be easily formed a pattern with recessions and protrusions according to the photoresist mask by dry etching method. Thus an imprint mold characterized as better antifriction and easily taking off from imprinted materials is completed.

Owner:IND TECH RES INST

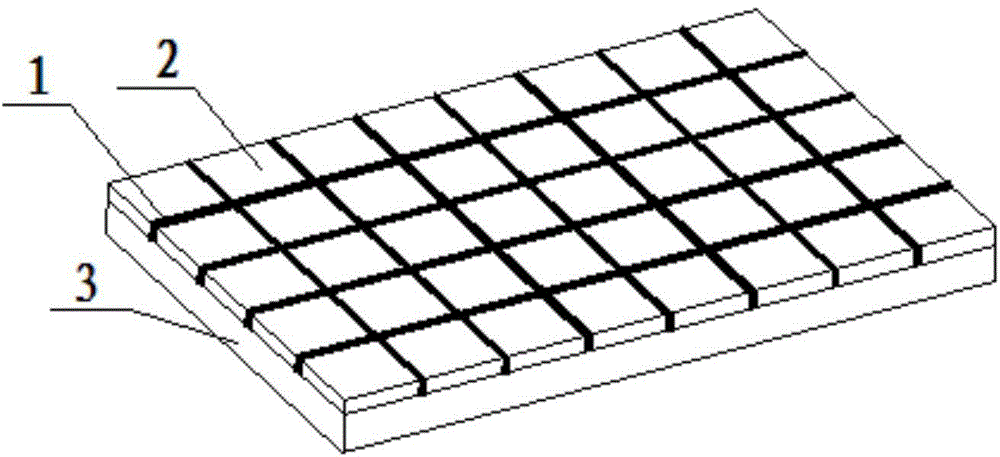

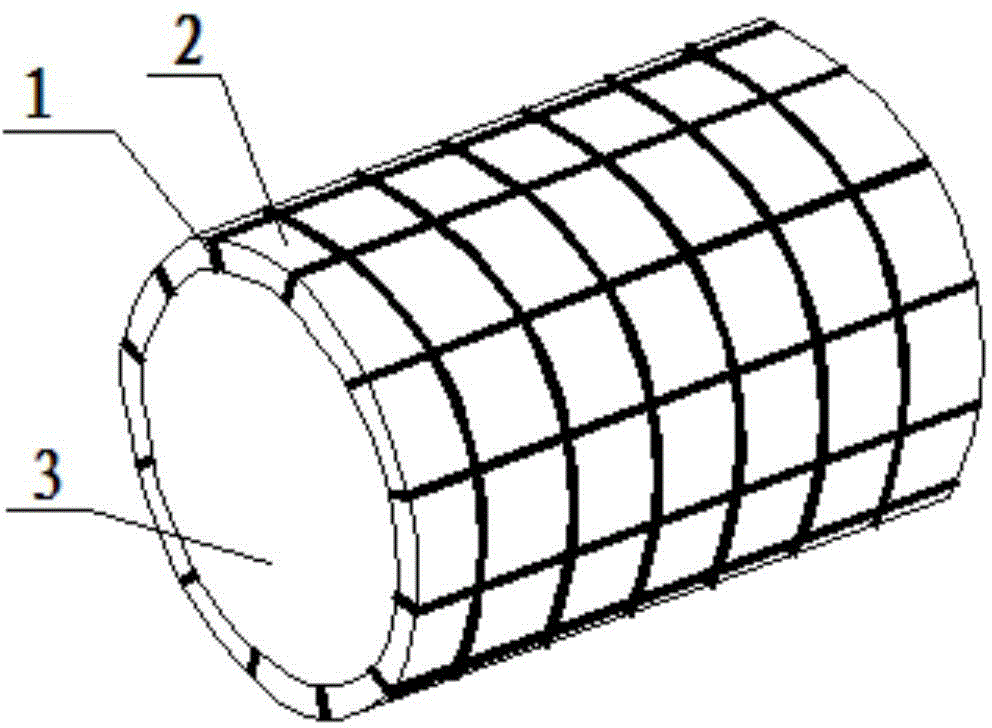

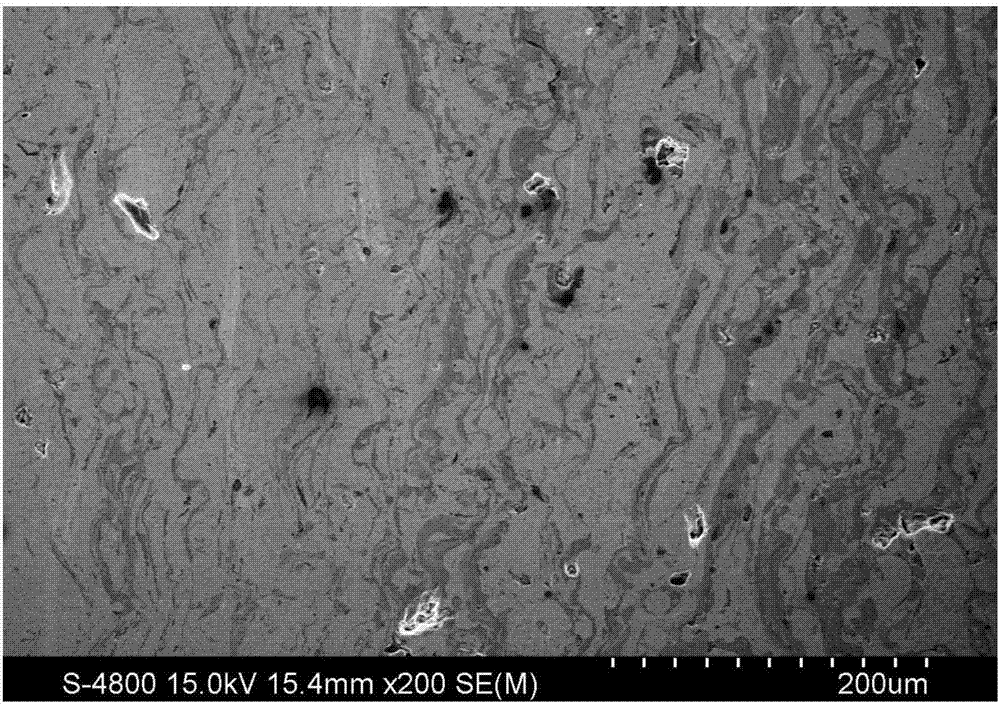

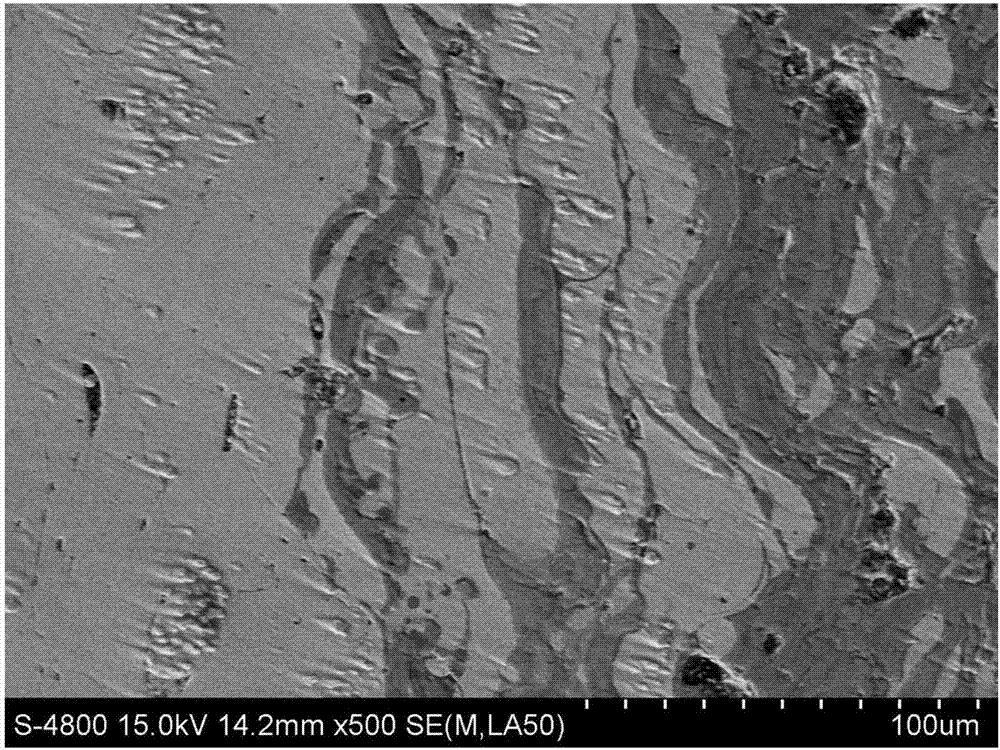

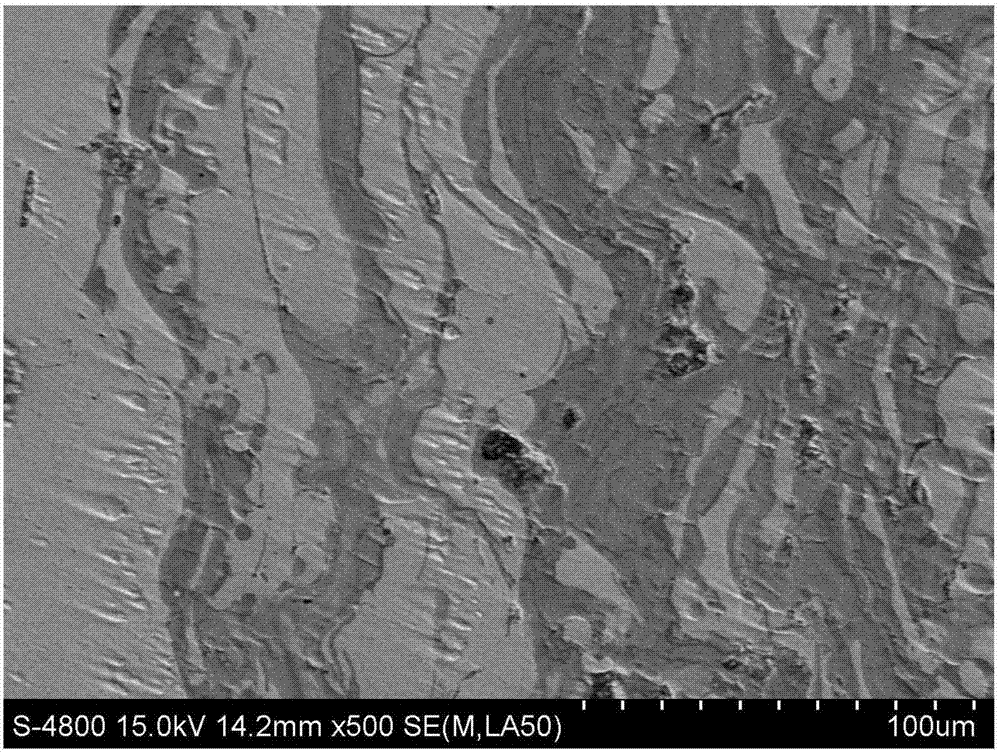

Method for preparing antifriction wear-resistant coating on metal matrix surface

ActiveCN104962909APrevents the accumulation of plastic deformationHigh hardness valueLiquid surface applicatorsMolten spray coatingWear resistantHardness

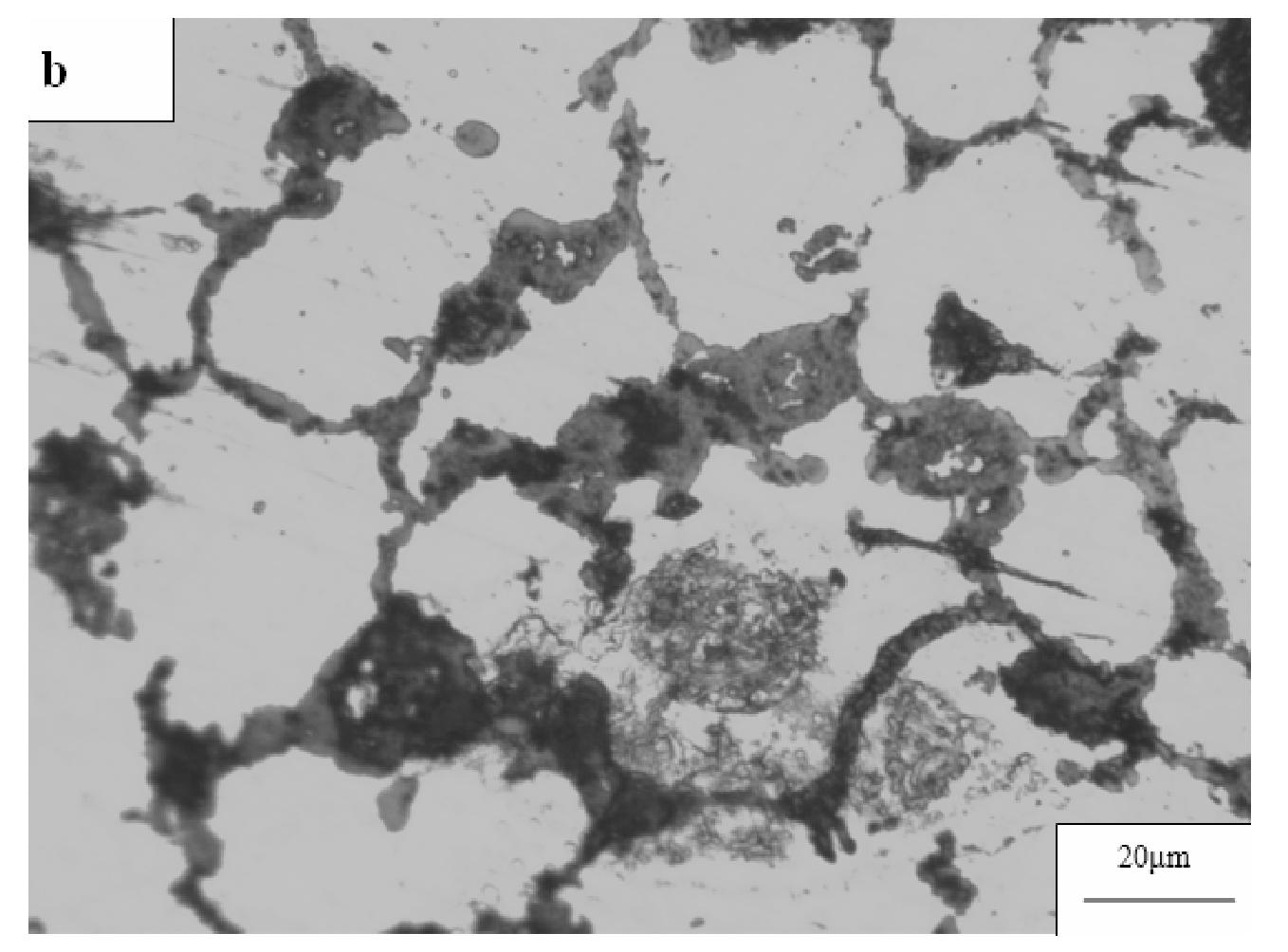

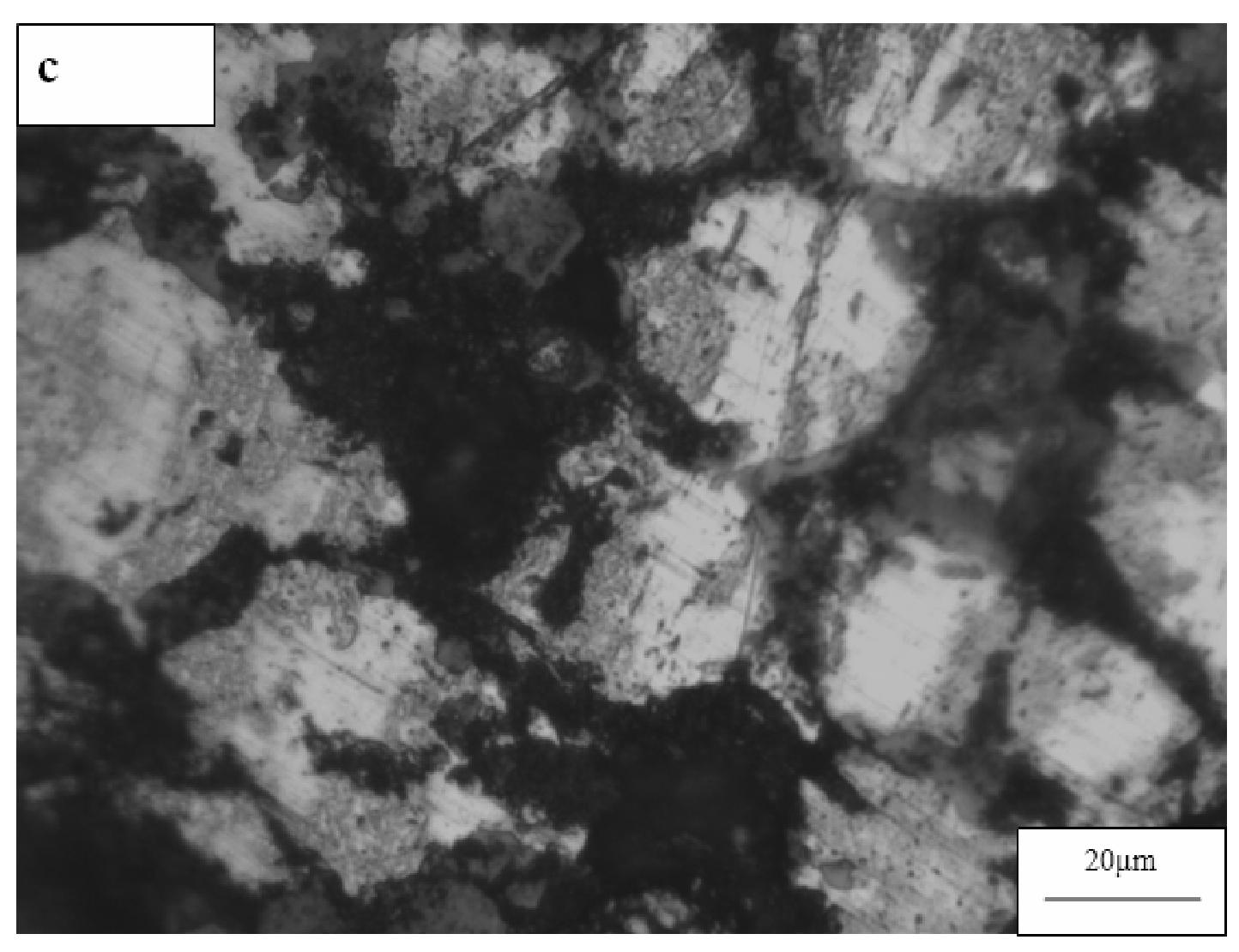

The invention discloses a method for preparing an antifriction wear-resistant coating on a metal matrix surface. The method comprises the following steps: (I) uniformly mixing wear-resistant powder with metal powder to obtain cladding powder; (II) performing laser cladding on the metal matrix surface by use of the cladding powder to form multiple cladding belts in horizontal-longitudinal crossing, wherein the cladding belts in horizontal-longitudinal crossing form a cladding skeleton of a mesh structure; and (III) filling the metal matrix surface with a lubricating phase, and polishing to obtain the antifriction wear-resistant coating on the metal matrix surface. According to the method disclosed by the invention, the cladding skeleton prepared on the metal matrix surface through the laser cladding process has a remarkably high hardness value; the cladding skeleton can realize a load dispersing function in a wear process to effectively prevent accumulation of plastic deformation on the metal matrix surface; and meanwhile, the mesh structure of the cladding skeleton realizes a support effect on the follow-up film forming process of the lubricating phase.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for preparing titanium-alloy surface micro-arc oxidation antifriction compound film layer

InactiveCN102021629AGood anti-frictionReduce pollutionSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

The invention relates to a method for preparing a titanium-alloy surface micro-arc oxidation antifriction compound film layer, which is characterized by comprising the following steps of: (1) micro-arc oxidation of an electrolyte; and (2) preparation of a compound film. The invention has the technical effects that: 1. the method provided by the invention is used for preparing the micro-arc oxidation compound film layer with an antifriction effect by introducing a solid lubricant and experimenting on a one-step method in the titanium-alloy micro-arc oxidation process on the premise of not destroying a micro-arc oxidation film layer, and the antifriction effect is remarkable; and 2. the composition raw materials of a sodium-silicate system electrolyte adopted by the invention are simply and easily obtained, a solution is neutral or weakly alkaline, the solution does not contain heavy metal ions, such as chromium ions and the like or environment-friendly constraint elements and does not contain substances harmful to human bodies and environments, the environmental pollution is small, and the requirements of high-quality clean production are satisfied.

Owner:NANCHANG HANGKONG UNIVERSITY

Pantograph sliding plate of assorted fibre reinforced composite material and preparing method thereof

InactiveCN1719549AImprove lubricating propertiesImprove conductivityNon-insulated conductorsMetal/alloy conductorsSlide plateFiber-reinforced composite

This invention relates to a hybrid fiber reinforcement compound material pantograph slide plate with lamination used in railway electric locomotives and its preparation method, which takes a metal net and hybrid fiber reinforcement compound material as the backing of said slide plate and makes them distribute in lamination, among which, phenolic resin is taken as the matrix, hybrid fiber as the reinforcement agent, rubber, graphite, copper powder, baritite and at least three kinds in SiO2 as the friction performance modifiers of the compound material to be mixed fully to be hot-pressed with the metal net to form a pantograph slide plate.

Owner:SHANDONG UNIV

Lubricant for drilling fluid

InactiveCN105368410AImprove the lubrication effectImprove wear resistanceDrilling compositionAdjuvantVegetable oil

The invention discloses a lubricant for drilling fluid and belongs to the technical field of chemical agents for petroleum drilling engineering. The lubricant for the drilling fluid contains the following ingredients in parts by weight: 35-90 parts of vegetable oil, 10-25 parts of synthesized ester type oily agent, 9-21 parts of emulsifier, 3-8 parts of extreme-pressure antiwear agent, 6-18 parts of organic molybdenum compound, 10-12 parts of nano metal powder, 7-15 parts of dispersant, 5-9 parts of graphite powder, 3-8 parts of antifoamer, 4-7 parts of surfactant and 4-8 parts of antioxidant. According to the lubricant for the drilling fluid, disclosed by the invention, the vegetable oil serves as a main raw material, and other additives are added as adjuvants, so that the lubricating property of the drilling fluid can be remarkably improved after the lubricant is added into the drilling fluid; and meanwhile, the lubricant has high-temperature and high-pressure resisting characteristics and antiwear and antifriction properties and is free of a mineral oil ingredient, and the additives are also free of sulfur and phosphorus, so that the lubricant is environment-friendly.

Owner:CHONGQING YANJIN ENVIRONMENTAL PROTECTION TECH CO LTD

Method for laser preparation of titanium nitride gradient coating on surface of titanium and titanium alloy

InactiveCN102676981AAvoid crackingSolve large surface roughnessSolid state diffusion coatingSurface cleaningTitanium nitride

The invention provides a method for a laser preparation of a titanium nitride gradient coating on a surface of titanium and titanium alloy. The method comprises the steps of performing surface cleaning treatment, surface blackening treatment and preheating treatment for a workpiece subatrate; and then carrying out laser nitriding treatment. The method is characterized in that the laser nitriding treatment is performed in a condition of filling reaction gas, and simultaneously laser scanning treatment and ultrasonic oscillating treatment for the surface of the workpiece subatrate are carried out. The titanium nitride gradient coating with a thickness of 50-200 [mu]m is obtained on the surface of the titanium and titanium alloy. The titanium nitride gradient coating is mainly composed of a nitride layer and a nitrogen diffusion layer, and has uniform transition of the coating microstructure. The surface hardness, wear resistance and corrosion resistance of the titanium nitride gradient coating are improved significantly than those of the matrix. Also, problems that crack are easy to produce, surface roughness is large, and the crystal grains of dendrite crystals of a nitride layer are coarse, in ordinary laser gas nitriding processes, are solved.

Owner:山东万丰煤化工设备制造有限公司 +1

Aluminium nitride and copper mixed nanometer lubricating grease additive and application thereof

The invention relates to preparation of an aluminium nitride and copper mixed nanometer lubricating grease additive and an application thereof, and belongs to the technical field of lubrication. The nanometer lubricating grease additive disclosed by the invention is prepared from nanometer AIN and nanometer Cu in a mixing manner, wherein the particle size ranges of the AIN powder and the Cu powder are 50-200nm. The obtained additive is added to base lubricating grease, so that not only can the anti-wear antifriction performance of the base lubricating grease be improved, but also the base lubricating grease can act on the surface of a friction pair, the roughness of the surface of the friction pair is improved, and a polishing scratch on the surface is repaired, so that the abrasion loss of the friction pair is reduced, the friction pair and the accuracy are effectively ensured, meanwhile, accumulation of heat on the friction surface is reduced, and the service life of the friction pair is prolonged. The test data show that compared with the lubricating grease to which the additive disclosed by the invention is not added, the friction coefficient of the lubricating grease to which the additive disclosed by the invention is added is reduced by 23.6-15.8%, and the friction durability is prolonged by 6-7 times.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Flux-cored welding wire for overlaying welding and application thereof

InactiveCN101537548AScientific and reasonable hardnessReasonable hardnessWelding/cutting media/materialsSoldering mediaHardnessWear resistance

Aiming at the disadvantages and market demands of the prior art, the invention discloses a flux-cored welding wire for overlaying welding, which consists of a low-carbon steel strip and a flux core; the weight percentage composition of the flux core comprises: 1 to 3 percent of Mo, 2 to 6 percent of B, 1 to 4 percent of Si, 1 to 4 percent of Mn, 0.5 to 4 percent of C, 3 to 7 percent of Nb, 10 to 40 percent of Cr, 1 to 4 percent of Re and the balance of Fe. The filling amount of the flux core is 30 percent of the total weight of the flux-cored welding wire. The flux-cored welding wire for overlaying welding can be used for the overlaying welding of a wearproof belt of a drill rod of an oil field. Compared with the prior art, the flux-cored welding wire has excellent welding manufacturability, small splashing, good compatibility and good repeated overlaying weldability; and as the wearing resistance and antifriction performance of the wearproof belt of the welded drill rod are improved, the hardness of the wearproof belt reaches HRC 59-61.

Owner:高智海

Preparation method for metal carbide coating

InactiveCN103820761APrecise content controlExtended service lifeVacuum evaporation coatingSputtering coatingCarbide coatingGraphite

The invention discloses a preparation method for a metal carbide coating. The metal carbide coating is prepared by adopting a multi-target magnetron sputtering equipment, taking pure metals (titanium, chromium and the like) and graphite as target materials, and performing the processes of vacuumizing, introducing argon, coating and the like. The preparation method for the metal carbide coating disclosed by the invention has the characteristics that the process is simple and stable, the coating components are controlled accurately, the processes are few, and the industrial production is easy to realize. The prepared metal carbide coating has the performance of high hardness, low friction coefficient and the like, and is suitable for performing deposition on the surfaces of a high-speed operating tool, a precise tool, a mold and the like; a workpiece can be endowed with high performance; the service life of a product can be prolonged.

Owner:西安金唐材料应用科技有限公司

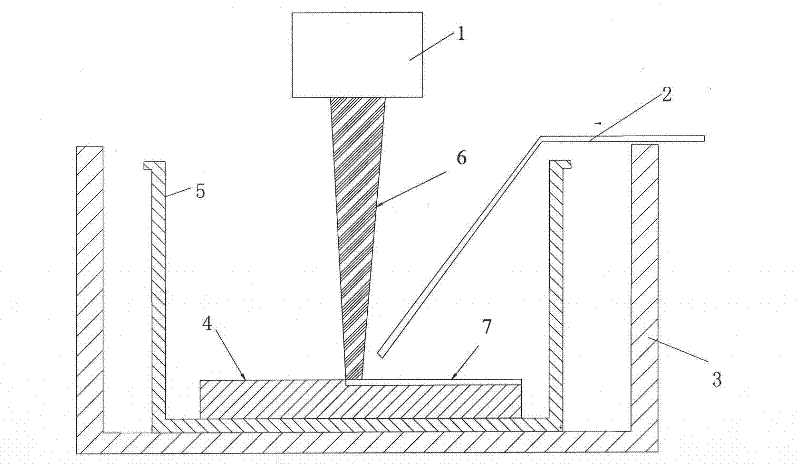

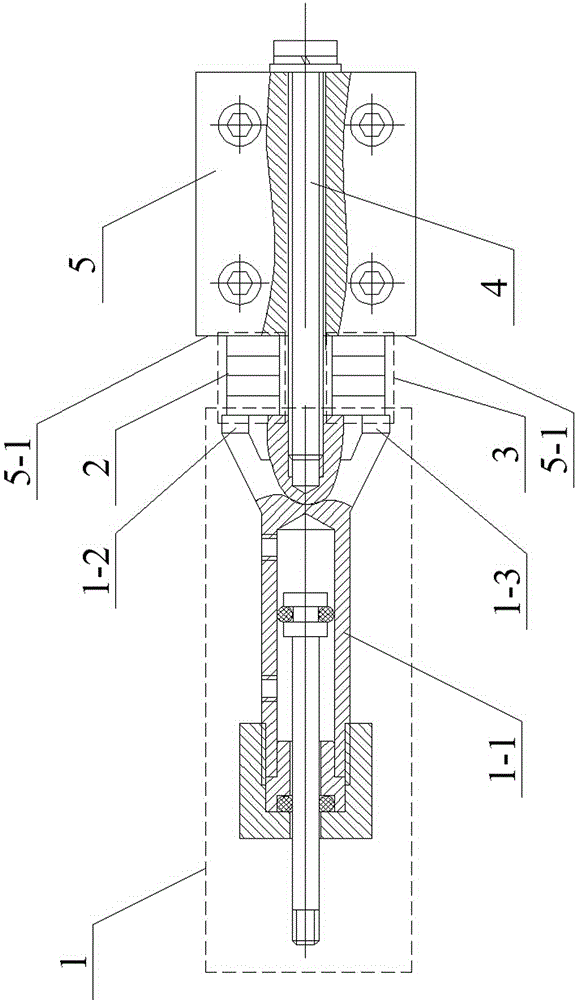

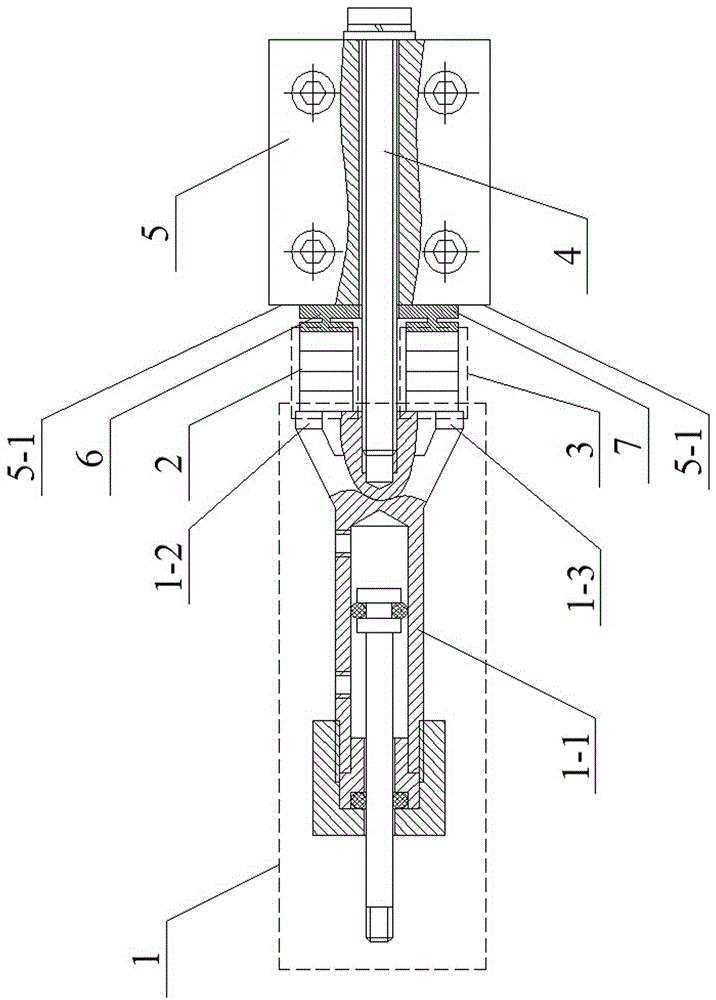

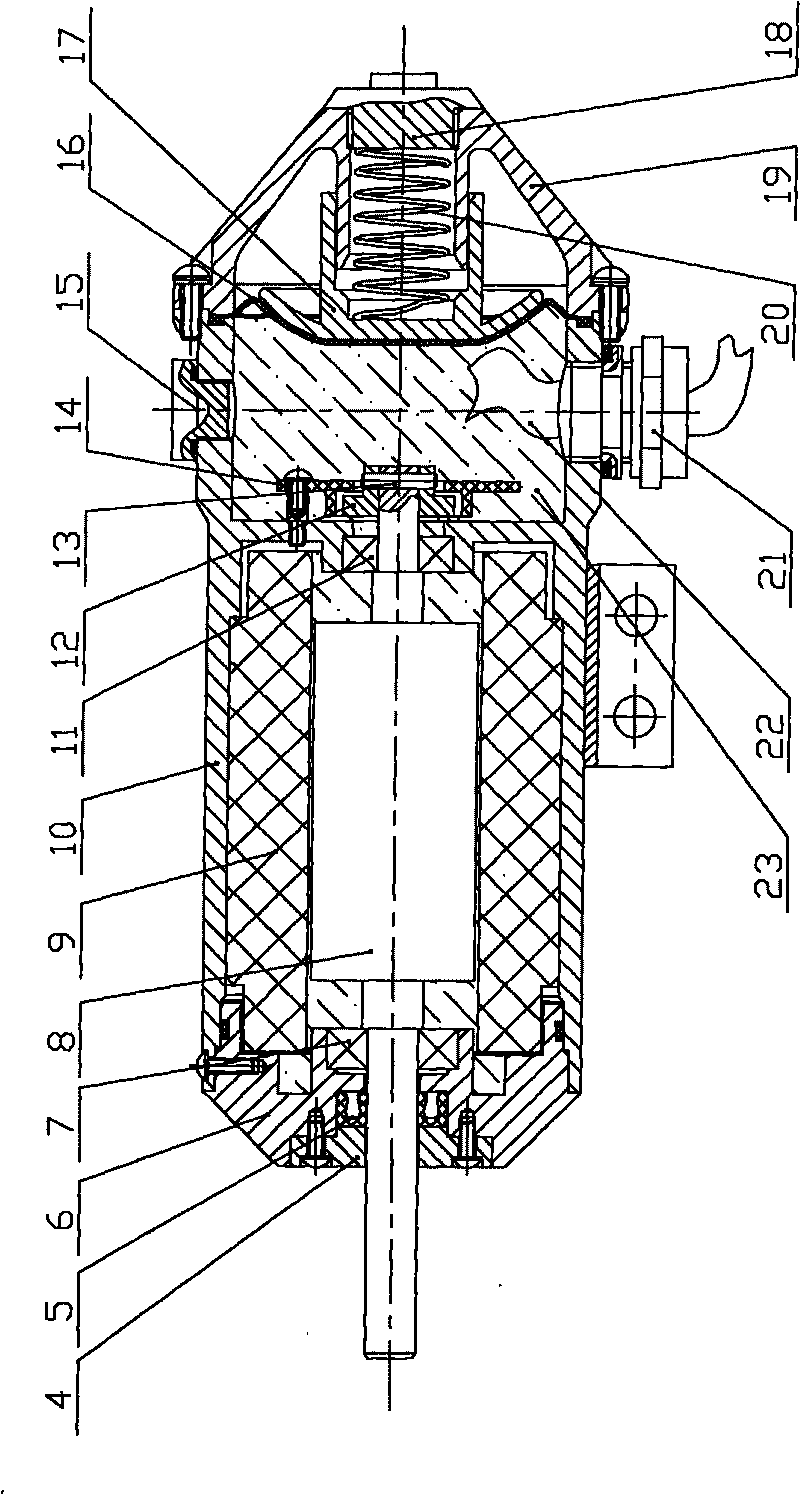

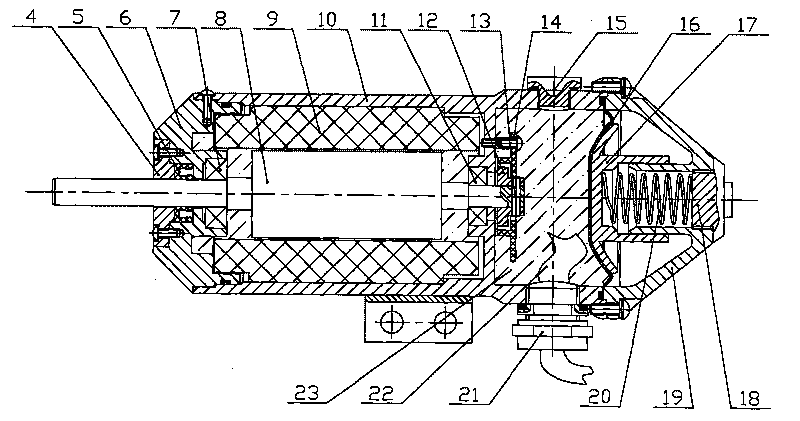

Two-end pre-tightening type low-friction-characteristic cylinder with cylinder body in multi-mode vibration caused by piezoelectric stacks

The invention discloses a two-end pre-tightening type low-friction-characteristic cylinder with a cylinder body in multi-mode vibration caused by piezoelectric stacks, relates to the technical field of pneumatic control, and aims at solving the problems that an existing friction reducing structure is large in noise, short in service life, high in manufacturing difficulty, large in size, prone to oil liquid pollution, low in output and low in reliability. A first supporting leg and a second supporting leg are arranged on two sides of the tail end of a cylinder barrel of a general cylinder assembly respectively; the bottom end surface of the first supporting leg is propped against one end surface of a first piezoelectric stack; the bottom end surface of the second supporting leg is propped against one end surface of a second piezoelectric stack; the other end surface of the first piezoelectric stack and the other end surface of the second piezoelectric stack are propped against the end surface of a mounting seat; a fastening bolt penetrates through the mounting seat and then is in threaded connection with the bottom of the tail end of the cylinder barrel, so that the axis of the fastening bolt coincides with that of the cylinder barrel of the general cylinder assembly. According to the cylinder, more than 50 percent of friction between a piston (a piston rod) and the cylinder body can be reduced under a supersonic vibration resonance state, and the friction reducing effect is good.

Owner:HARBIN INST OF TECH

Manufacturing method of carbon fiber-reinforced copper-based pantograph slide plate material

The invention discloses a manufacturing method of a carbon fiber-reinforced copper-based pantograph slide plate material. The carbon fiber-reinforced copper-based pantograph slide plate material comprises copper, graphite and carbon fibers. The manufacturing method is characterized by comprising the following steps of preparing graphite and electrolytic copper powder into composite powder as a base material having a nano-structure by a mechanical alloying method, carrying out alloying treatment on carbon fiber surfaces so that copper planting layers having the thickness of 30-40 microns are covered on the carbon fiber surfaces, cutting the carbon fibers plated with copper into segments, and carrying out sintering to compound the segments and the base material. A pantograph slide plate prepared from the carbon fiber-reinforced copper-based pantograph slide plate material has the characteristics of good antifriction, good wear resistance, good conductivity and low arc sensitivity. The carbon fiber-reinforced copper-based pantograph slide plate material can be used for railway trains, subway trains and urban railway trains, can also be used for similar products of related industries such as motor brush and moving contact industries, and opens a new path for slide electric contact materials.

Owner:CHANGCHUN UNIV OF TECH

Self-lubricating heat-resistnat and wear-resistant materials

InactiveCN1818117AHigh temperature strength and hardnessIncreased high temperature strength and hardnessBearing componentsOxidation resistantWear resistant

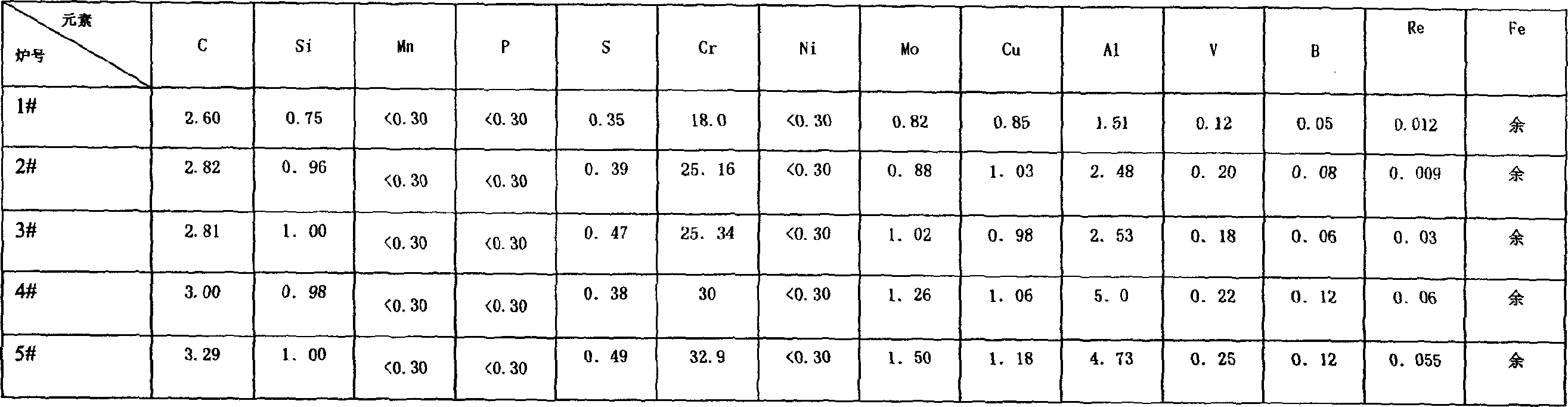

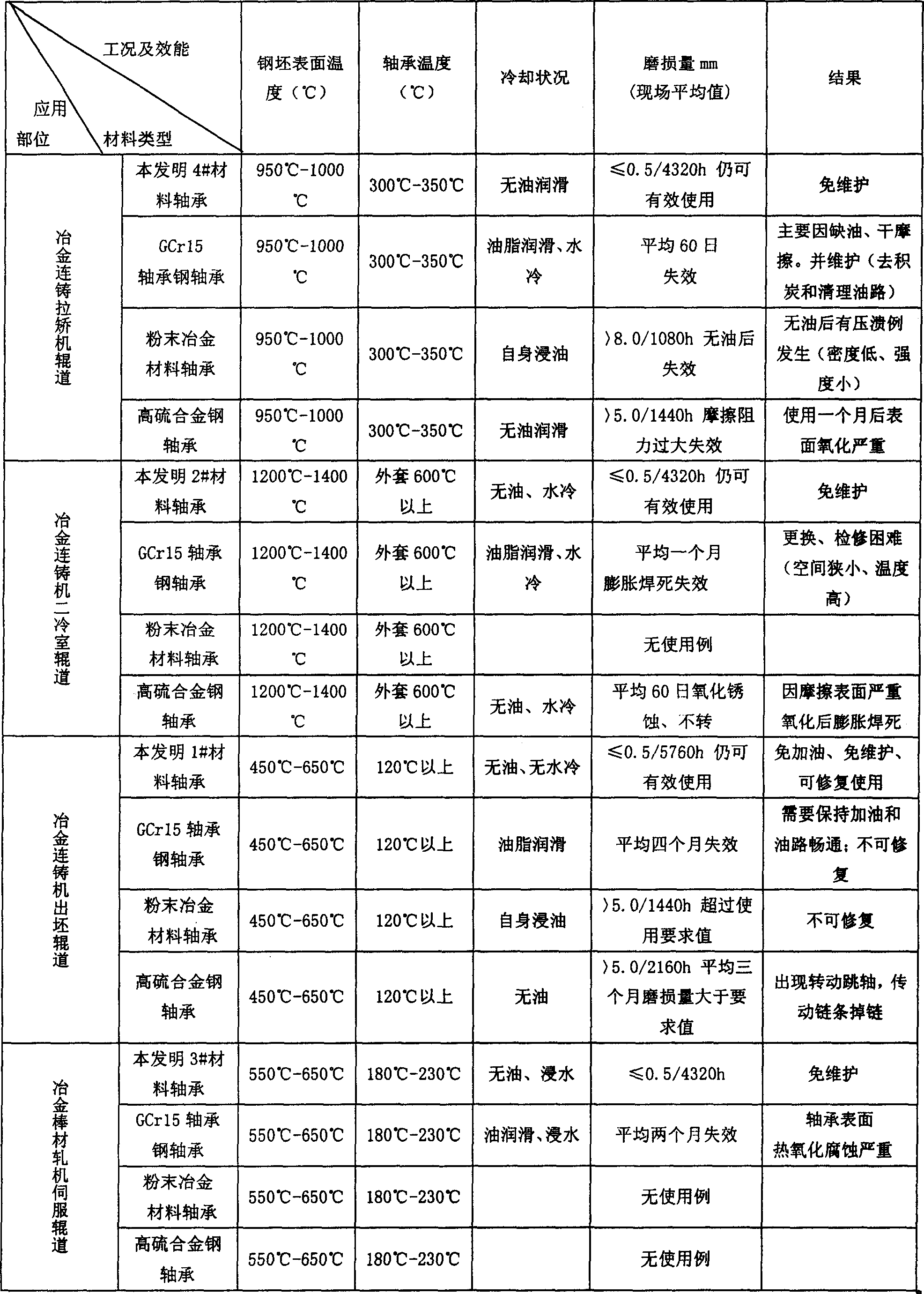

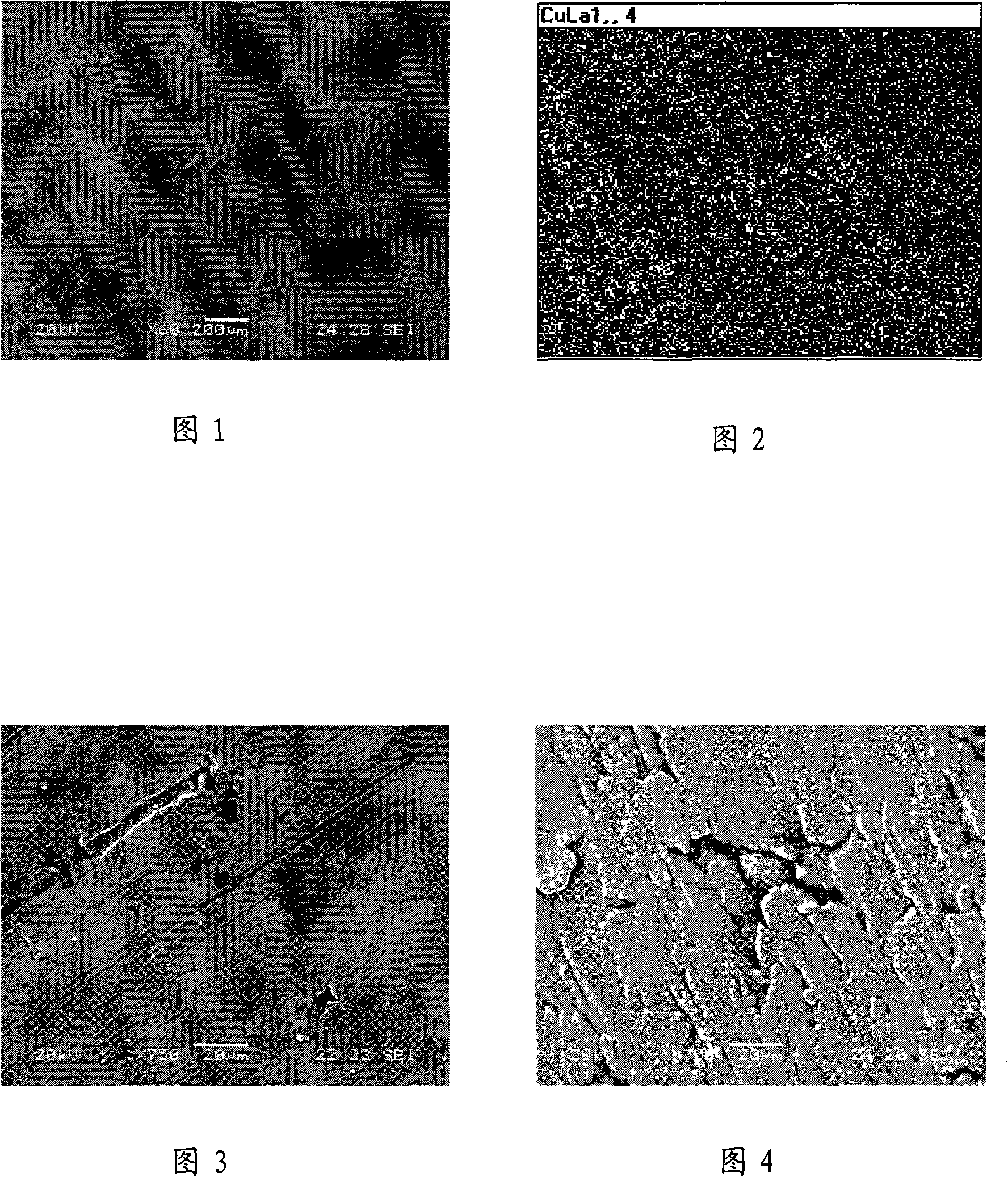

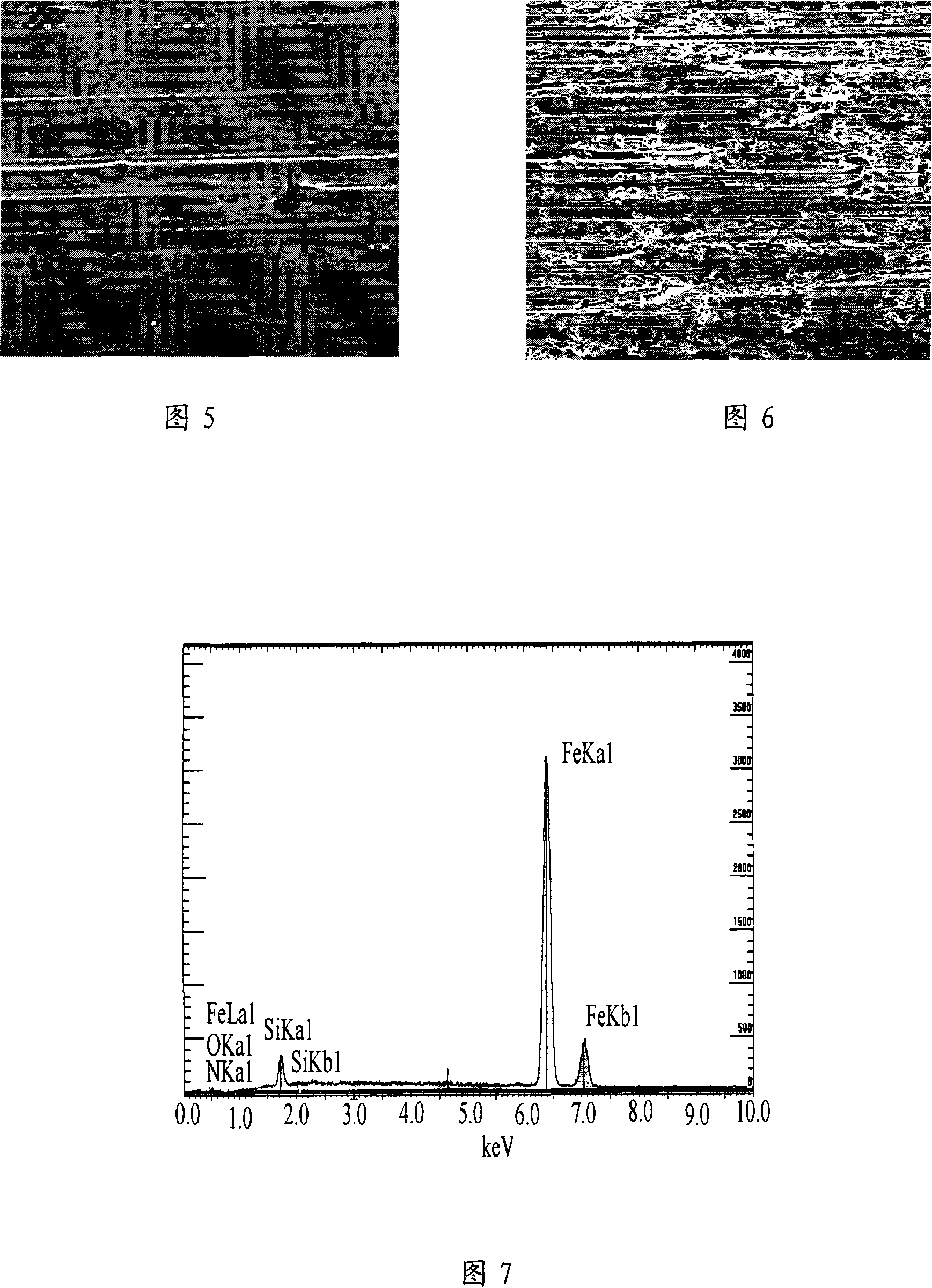

The invention opened a heat-proof and wearing self-lubricating material. It can be used to the shafting bearing, bearing bush, axile bush and the other break-away friction parts of the metallurgy, mining area and machine, especially for the parts of the high temperature (350 DEG C-800 DEG C).the weight ration of the composition is C 2.6-3.%, S 0.35-0.49%, Si 0.5-1.0%, Cr 18-35%, Mo 0.8-1.5%, Cu 0.8-1.2%, Al 1.5-5.0%, V 0.1-0.25%, B 0.05-0.15%, RE 0.008-0.08%, P<=0.3%, Ni<=0.3%, Mn<=0.3%, the residue is Fe. The weight ratio of Cr / C is 5.5-10. The material has the good resistance to heat and wearing character, also it can resist the corrosion of the CO2 and SO2.

Owner:BEIJING CISRI GAONA TECH

Self-lubricating abrasion-proof graphite//TiC gradient composite thin film

InactiveCN101209606AExcellent wear resistance and anti-friction performanceGood chemical stabilityVacuum evaporation coatingSputtering coatingTotal thicknessLubrication

The invention discloses a self-lubrication and wearing-resistant graphite-like / TiC grads compound film. The invention has the technical proposal that a TiC layer with a thickness of 50 to 250nm and a graphite-like with a thickness of 100 to 500mm thickness are sequentially plated on an alloy surface: a TiC compound transition layer and a graphite-like layer with a thickness of 300 to 1250nm form the graphite-like / TiC grads compound film. The content weight percentages of the grads compound film are: 54 to 75 percent of graphite-like and 25 to 46 percent of TiC. A total thickness of the grads compound film is between 0.45 to 2.0 Mum. The grads compound film is provided with a high wearing-resistant capability, an excellent interface joining capability and load bearing capability, and has a low friction coefficient and excellent friction environment stability in both vacuum and atmosphere, etc. The invention can be applied to manufacturing self-lubrication and wearing-resistant films, universally used in the vacuum and atmosphere, etc., of surfaces of mechanical parts such as bearings, gyroscopes and mini-type rotary shafts, etc.

Owner:ZHEJIANG UNIV

Nano lubricating oil additive

InactiveCN101148628AReduce fuel consumptionReduce fuel consumption by 5-15%, reduce noiseAdditivesOil additiveOxidation stability

The present invention discloses one kind of nanometer lubricating oil additive, which consists of liposoluble nanometer copper or copper alloy and liposoluble nanometer silica. The nanometer lubricating oil additive of the present invention can realize the self repair of the worn part, and possesses the functions of saving oil, resisting abrasion, reducing noise, decreasing carbon deposit, raising power performance, etc. It has high dispersivity in lubricating oil, high oxidation stability and long term stability, and is favorable to solving different friction and wear problems in different work conditions.

Owner:BEIJING SIBNANO TECH

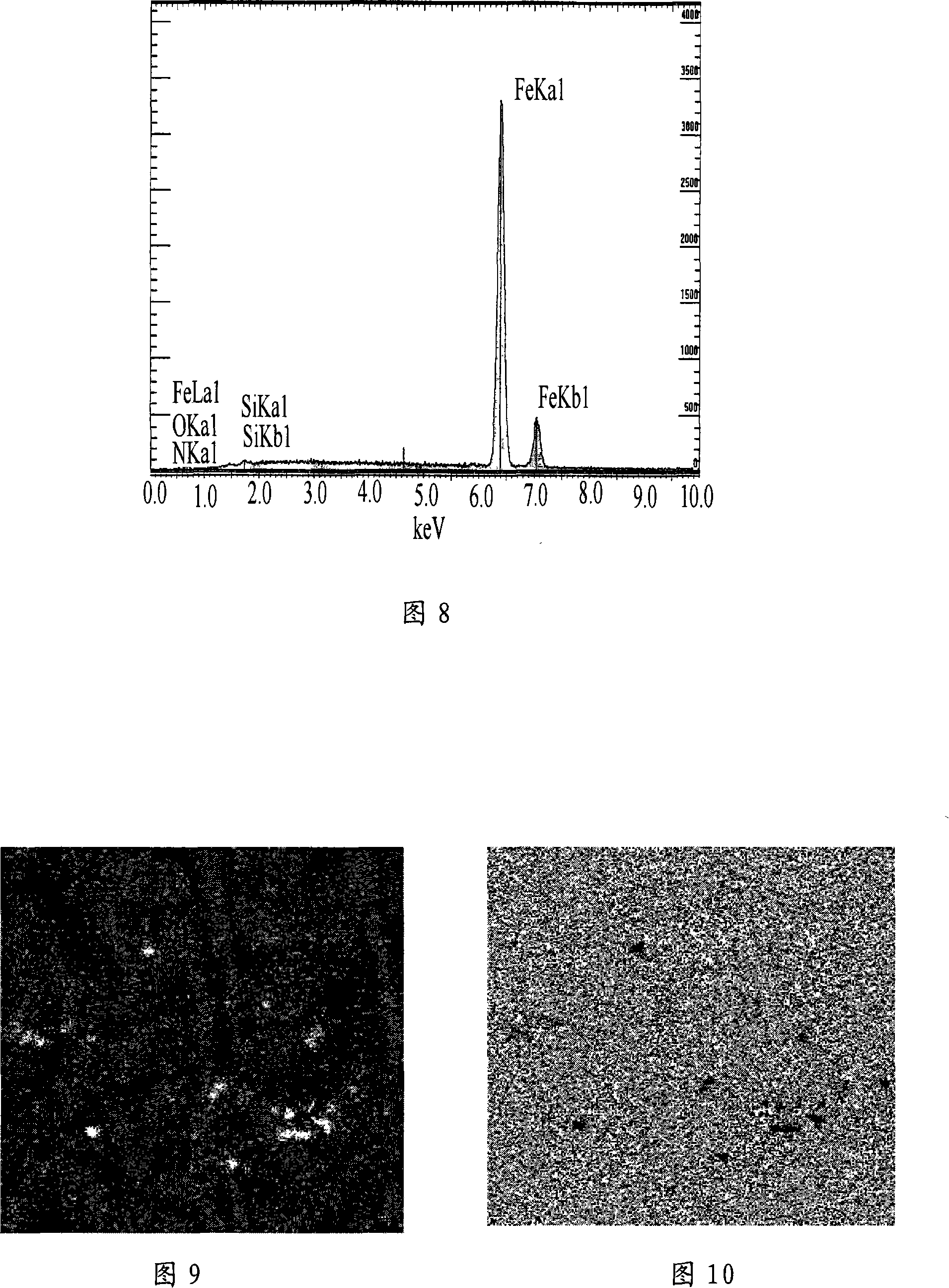

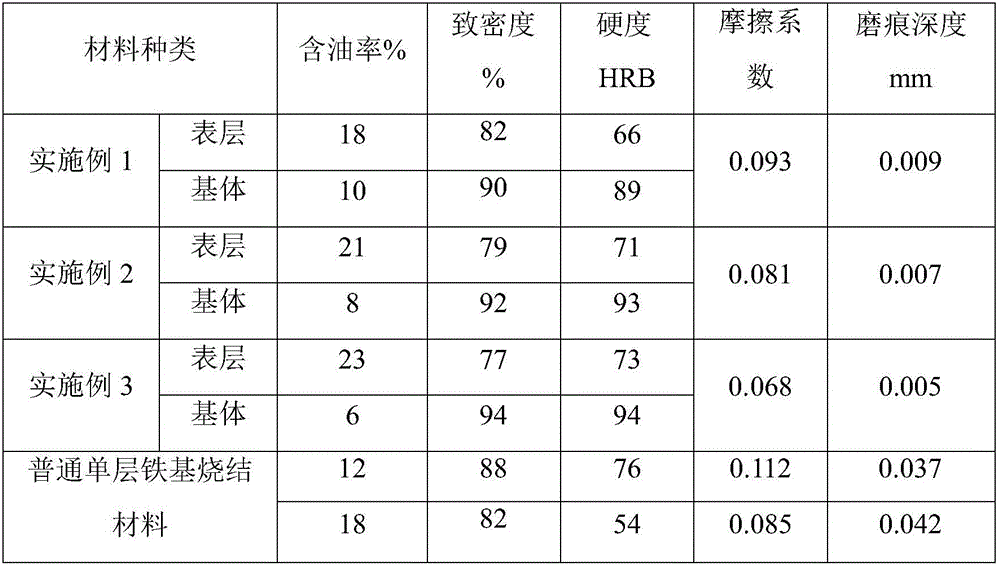

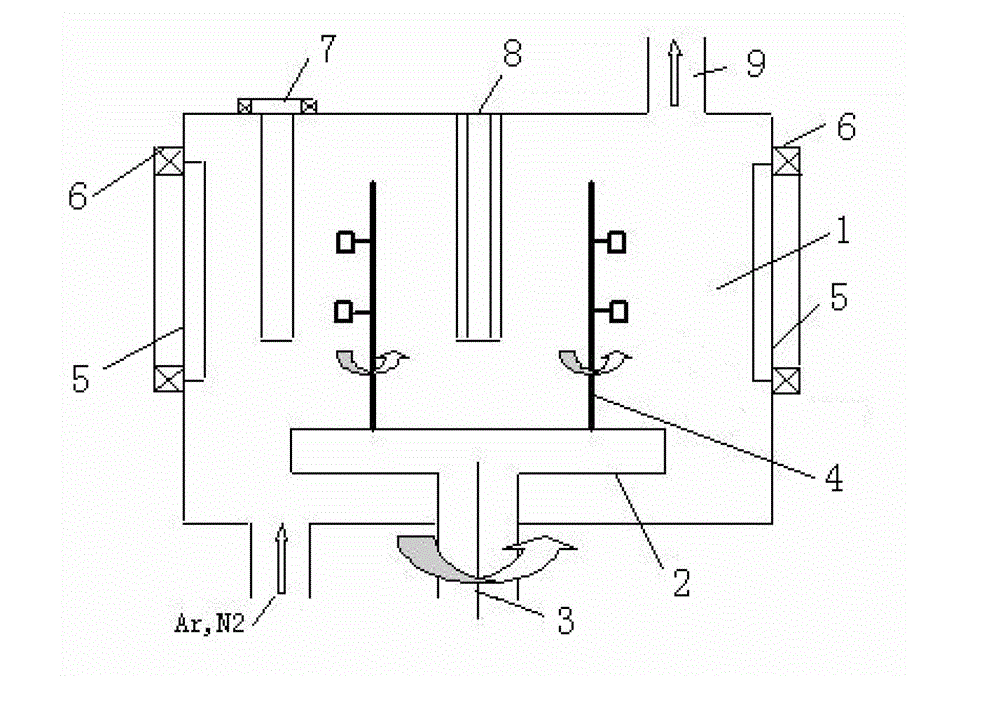

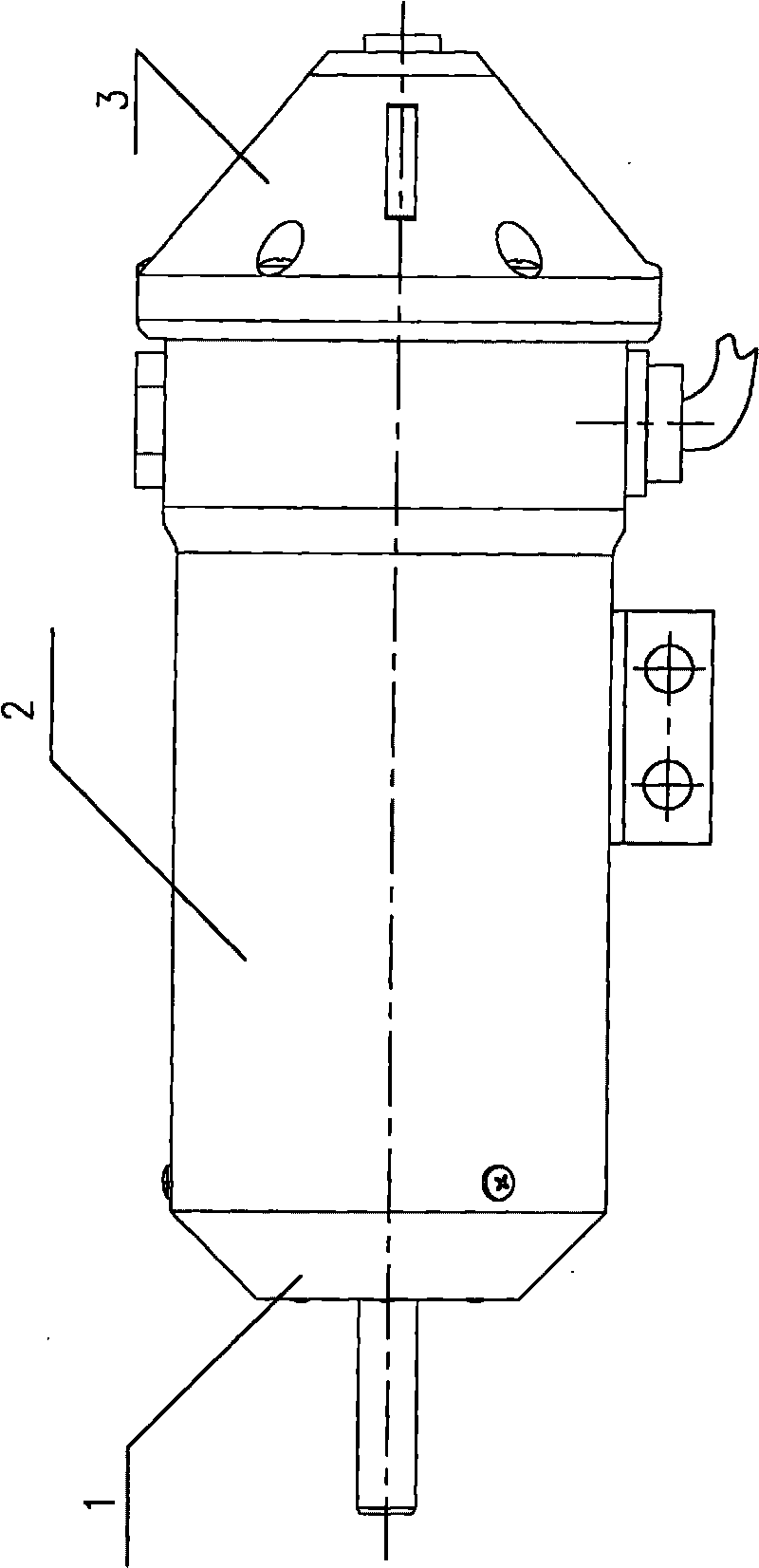

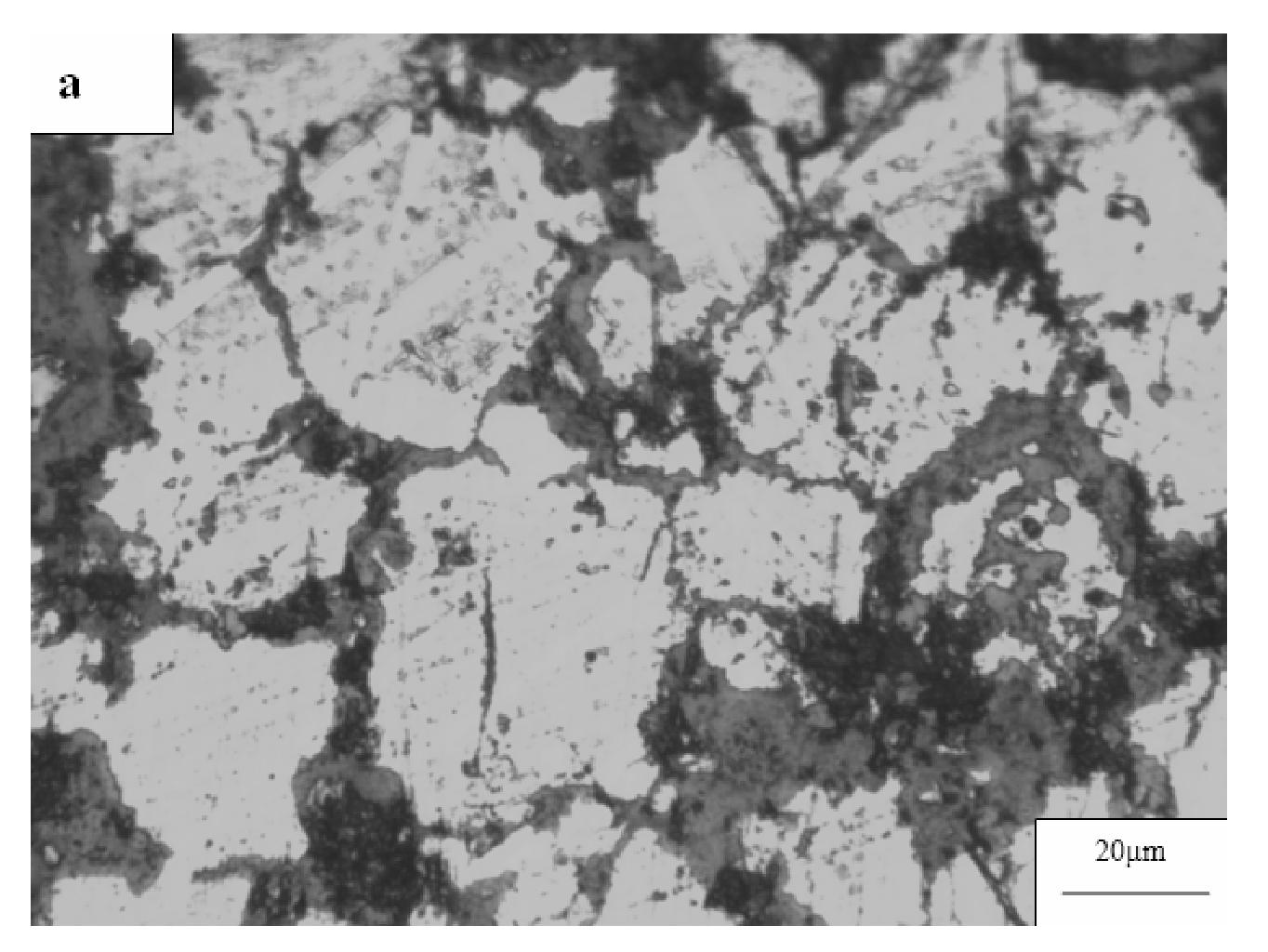

High-strength antifriction double-layered iron base powder metallurgy material and preparation method thereof

ActiveCN106041099AImprove carrying capacitySpeed up the flowTransportation and packagingMetal-working apparatusSurface layerHardness

The invention discloses a high-strength antifriction double-layered iron base powder metallurgy material and a preparation method thereof. The preparation method comprises the following steps that a densification enhancer is mixed in a matrix, so that a matrix material is dense and high in strength; a compound pore-forming agent is mixed in a surface layer to enable a surface layer material to be porous and oil-bearing, and besides, the requirements on the hardness and the wear resistance of the surface layer are met, and the contact interface and the lubricating condition of a friction pair are kept stable, so that the novel high-strength antifriction double-layered iron base powder metallurgy material is prepared. The bearing property, the wear resistance and the antifriction anti-seizing property of the iron base powder metallurgy material are improved remarkably, and high strength and a high lubricating property are effectively combined.

Owner:HEFEI UNIV OF TECH

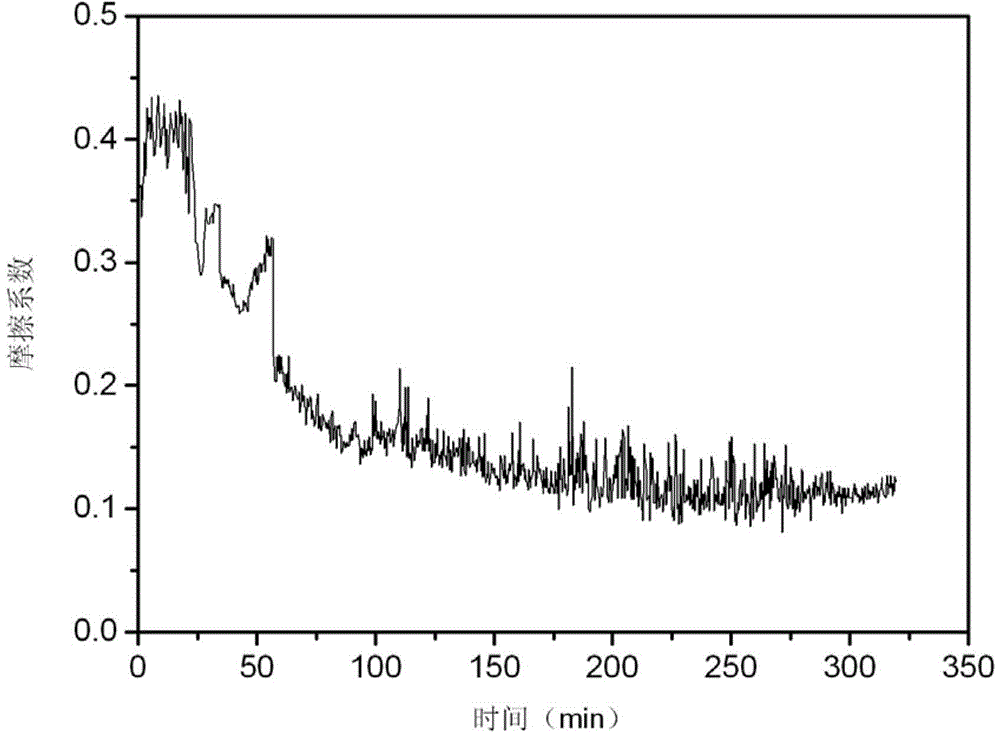

Wide-temperature-range self-lubricating coat material and its preparation method

InactiveCN103074561AImprove bindingGood anti-frictionMolten spray coatingFriction reductionThermal spraying

The invention belongs to the technical field of thermal spraying, and especially relates to a wide-temperature-range self-lubricating coat material and its preparation method. The coat material is a uniform mixture material composed of a bonding phase, a hard phase and a lubrication phase. The wide-temperature-range self-lubricating coat material is prepared through mixing coated NiMoAl used as the bonding phase, spherical Cr3C2 or Cr2O3 used as a wear resistant phase which is the hard phase, and Ag and CaF2.BaF2 used as the lubrication phase. Polymerized NiMoAl undergoes a reaction in the spray process and promotes the bonding of a coat, and the simple substance state of a part of metallic Mo in NiMoAl is reserved after the spraying, so the friction reduction effect is realized, the lubrication component distribution uniformity is improved, and it is helpful for the rapid formation of a self-lubricating coat in the initial friction stage. Simultaneously the adoption of the spherical hard phase can reduce the wear of a friction mating plate by the hard phase. After the adoption of the wide-temperature-range self-lubricating coat material, the initial-stage friction coefficient stably decreases to below 0.2 from 0.4, and the bonding strength increases to above 40MPa from below 30MPa.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

Cr-doped DLC (diamond-like carbon) coating with anticorrosion and antifriction properties and preparation method

InactiveCN102912298AImprove bindingSmooth and dense surfaceVacuum evaporation coatingSputtering coatingDlc coatingSputtering

The invention discloses a method for preparing a corrosion-resistant antifriction Cr-doped DLC (diamond-like carbon) coating. The method comprises the steps of placing a pretreated substrate on a rotating stand rod of arc and magnetron sputtering composite deposition equipment, taking a post arc Cr target as a Cr source and three pairs of flat targets C targets as C sources, and installing the three pairs of flat targets C on the inner wall of a furnace body in an opposite manner; adopting high-purity Ar as a main ionization gas to guarantee an effective glow discharge process; and adopting high-purity N2 as a reacting gas, ionizing the reacting gas and combining the reacting gas with Cr and C elements to deposit on the surface of the substrate so as to form the Cr-doped DLC coating. The prepared Cr-doped DLC coating has a smooth and compact surface, hardness of 20 GPa, binding force with the substrate of 80N, coating thickness of 2.0 micrometers, and excellent corrosion resistance and antifriction performance.

Owner:XIAN HAOYUAN COATING TECH

Compensated underwater brushless DC motor structure and assembly method thereof

InactiveCN101752937AImprove reconfigurabilityEasy maintenanceStructural associationSupports/enclosures/casingsUnderwaterEngineering

The invention relates to a compensated underwater brushless DC motor structure and an assembly method thereof. The motor structure comprises a motor end cover subassembly (1), a motor main body (2) and a compensator device (3), wherein the motor end cover subassembly (1) is positioned at the front end of the motor main body (2) and is fixedly connected with the motor main body (2) via bolts, the compensator device (3) is positioned at the tail of the motor main body (2) and connected with the motor main body (2) via bolts, and the compensator device (3) comprises a compensator skin (16), a compensator gland bush (17), a motor tail hood (19), a compensator spring (20) and a compensator screw cap (18). The motor structure has modularized design characteristic, the compensator device and the motor main body can be separated, and different compensator devices can be correspondingly adjusted or replaced for meeting different work environmental requirements so that the motor structure has the advantages of simple and compact structure, convenient assembly and debugging, and safe and reliable working and easy maintenance.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

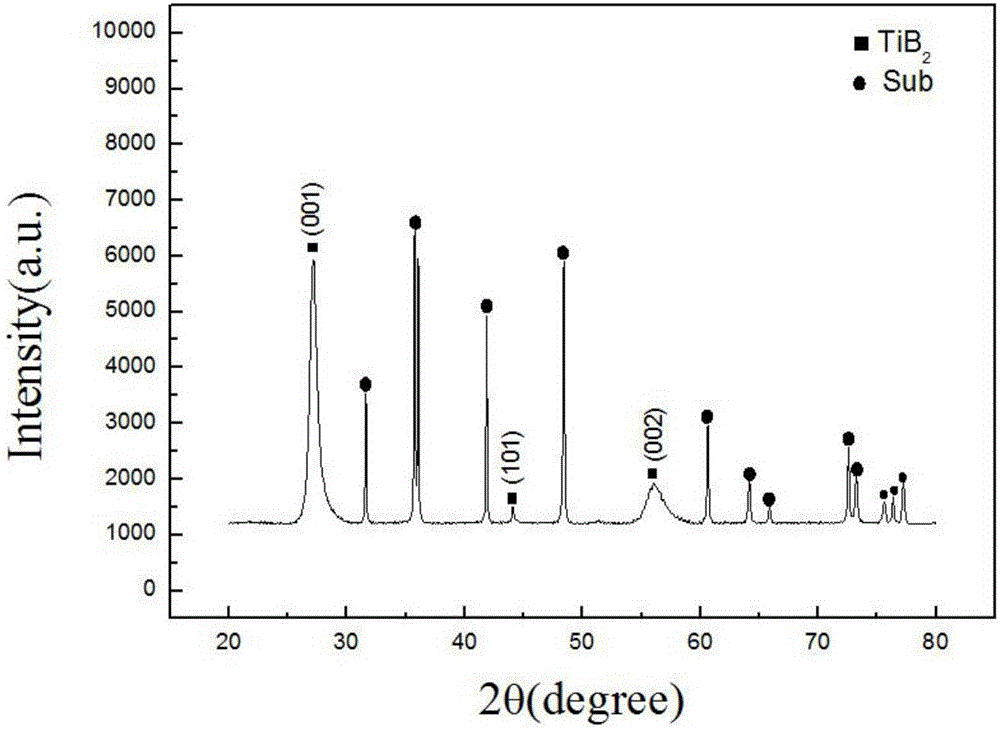

Preparation method of h-BN added titanium boride-based self-lubricating ceramic cutter material

The invention relates to a preparation method of an h-BN (hexagonal Boron Nitride) added titanium boride-based self-lubricating ceramic cutter material. According to the method, the material is formed in such a way that TiB2 as a base body, added micron WC (Wolfram Carbide) as a reinforced phase, the micron h-BN as a solid lubricant, and micron Mo and micron Ni as sintering additives are sintered. The preparation method comprises the following steps: respectively dispersing the micron TiB2 powder, the micron WC powder and the micron h-BN powder, and carrying out ball milling and drying so as to obtain powders, and finally, sintering the powders through a hot pressing method. The method has the advantages of simplicity, convenience in operation and the like. The self-lubricating ceramic cutter material has an excellent comprehensive mechanical property and an anti-friction wear-resisting property, and can be used for fabricating cutting tools, dies and other friction-resistant corrosion-resistant parts.

Owner:QILU UNIV OF TECH

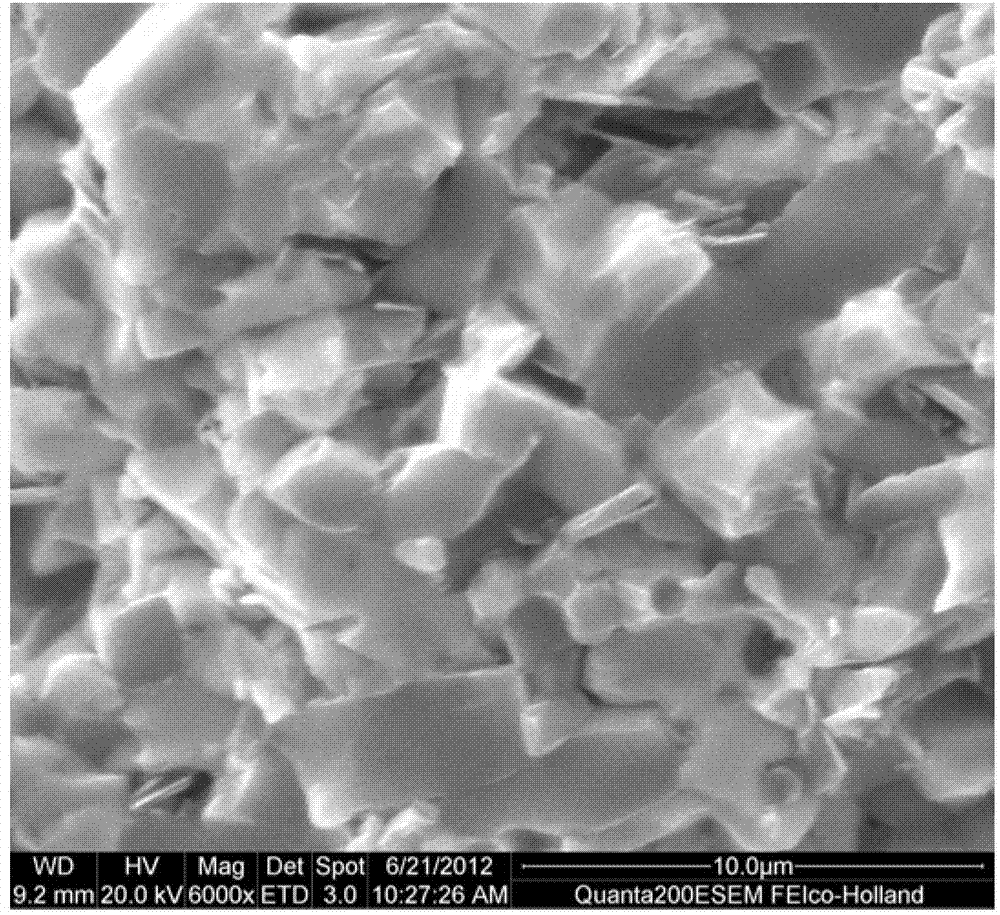

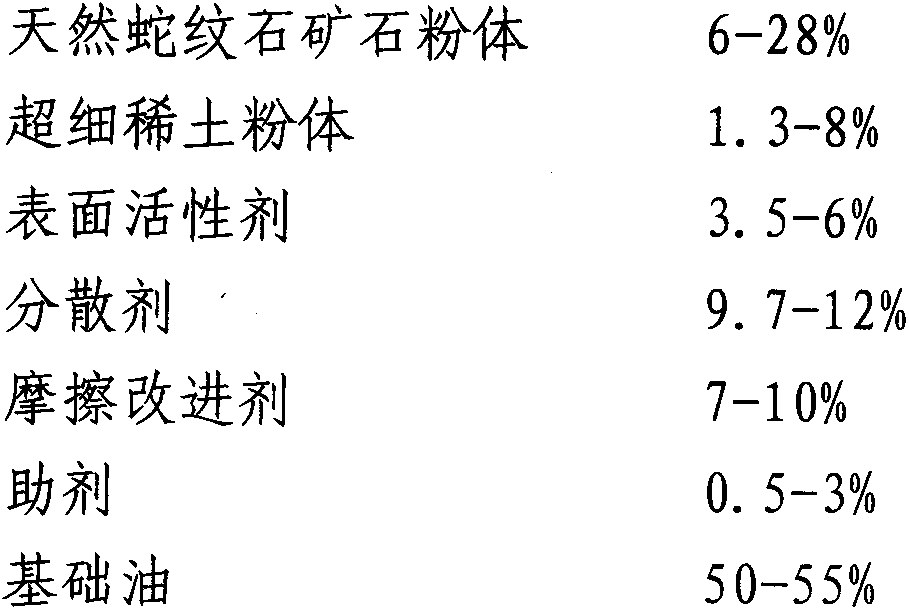

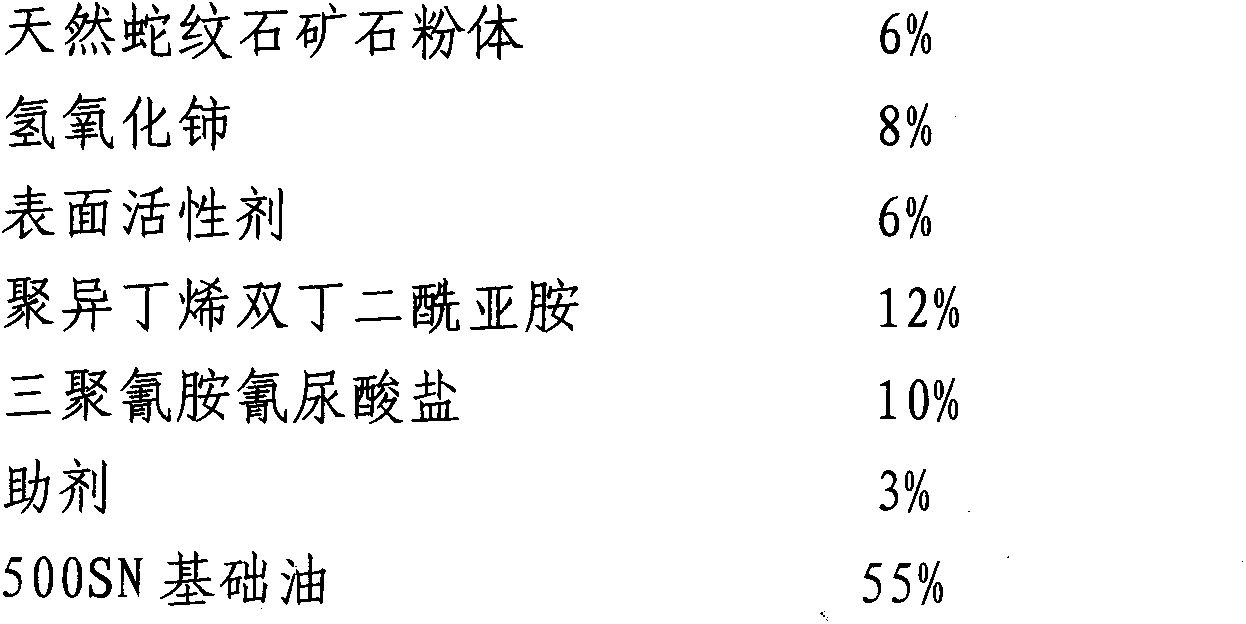

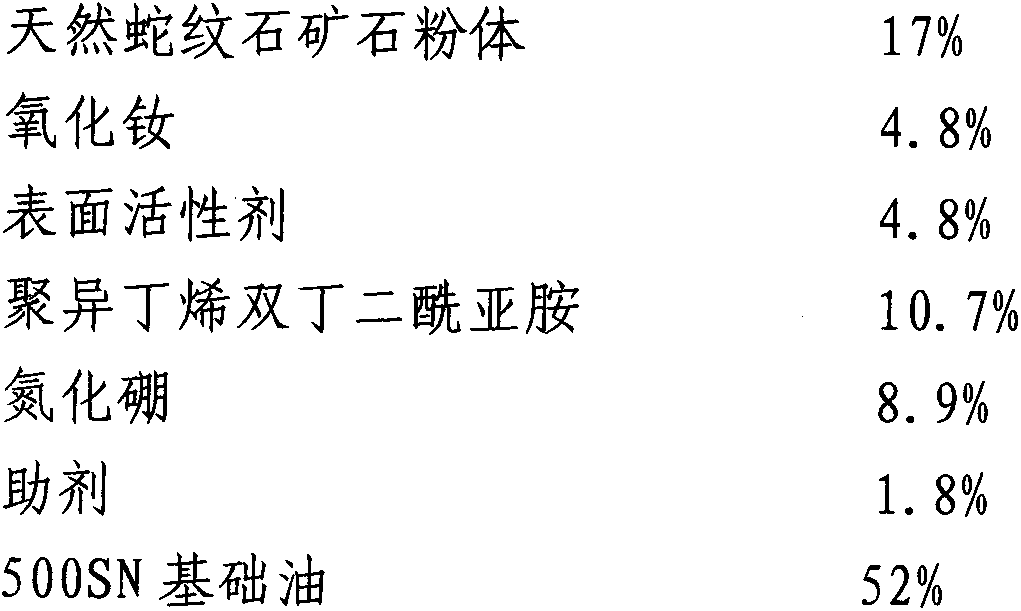

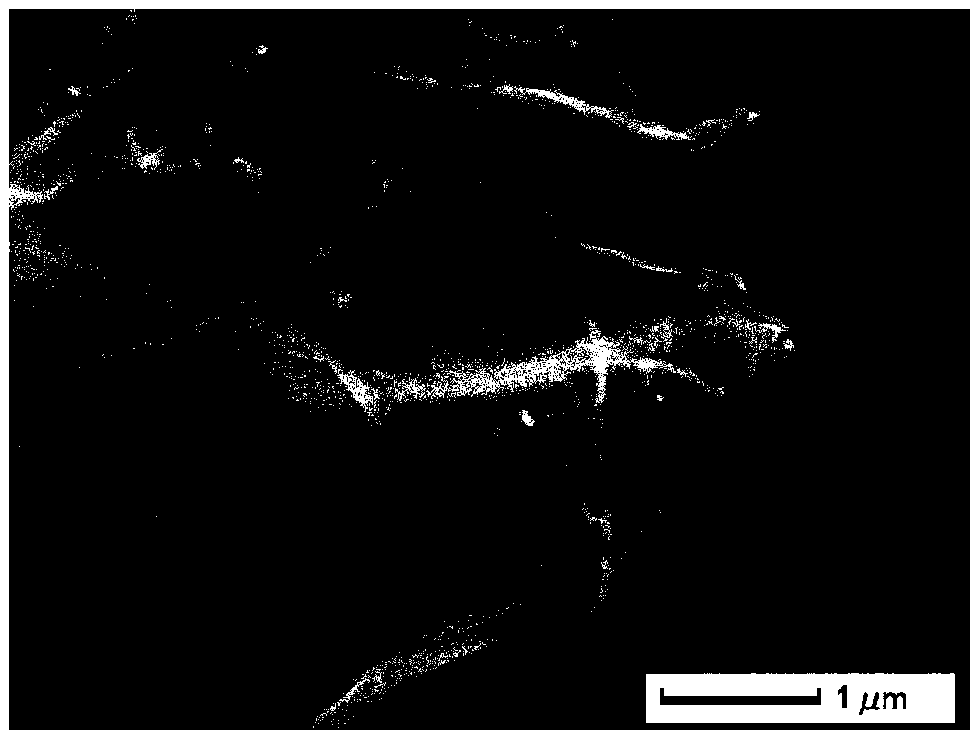

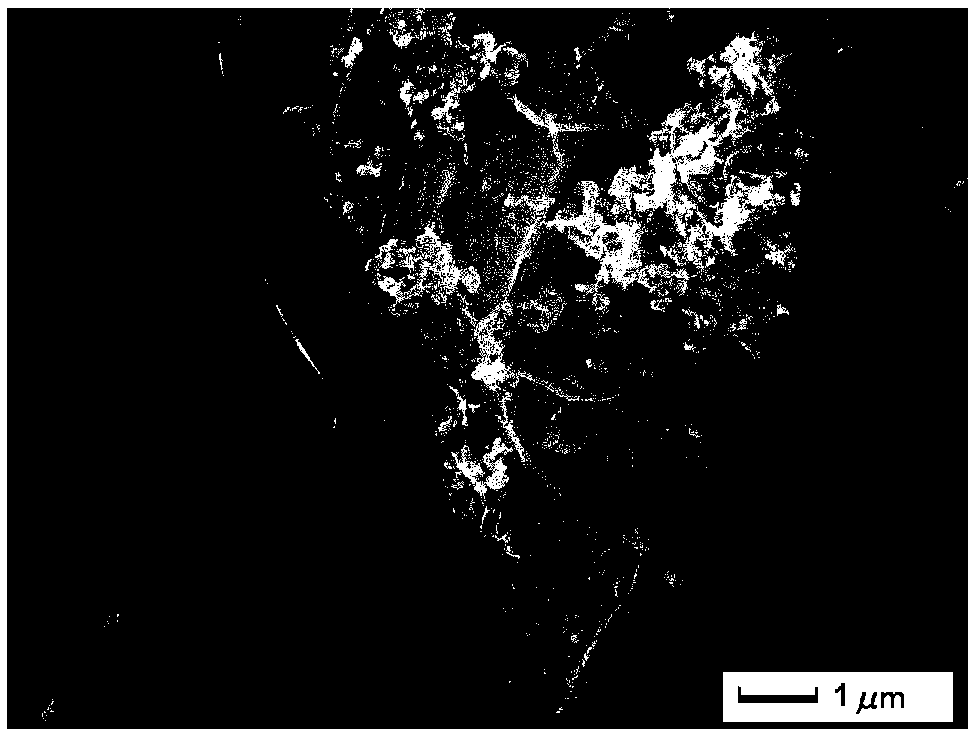

Lubricating oil additive containing ultrafine rare-earth powder

InactiveCN103642569AAvoid direct contactReduce harmful ingredientsLubricant compositionPhosphateOil additive

The invention relates to a lubricating oil additive containing ultrafine rare-earth powder. The additive consists of the following components in percentage by mass: natural serpentine mineral powder, ultrafine rare-earth powder, surfactant, a dispersing agent, a friction modifier, an auxiliary and base oil, wherein the ultrafine rare-earth powder is one of cerium hydroxide, neodymium oxide and cerium fluoride; the surfactant is borate, span-60 or oleic acid; the dispersing agent is either polyisobutene dibutyl succinimide or high molecular weight polyisobutene dibutyl succinimide; the friction modifier is one of melamine cyanurate, boron nitride and calciuym nitride; the auxiliary comprises 72% of dialkyl disulfo oxygen molybdenum phosphate sulfide, 18% of polymethyl tetradecyl acrylate and 10% of a vinyl-propylene copolymer; and the base oil is 500SN base oil. The additive has obvious corrosion resistance; and after an engine is treated technically by using the self-repairing additive, the dry friction coefficient of the machine is reduced from original 0.05 to be less than 0.005 and therefore the surface abrasion is reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

Nanometer hybrid material-modified epoxy resin self-lubricating composite coating layer and preparation method thereof

The invention provides a nanometer hybrid material-modified epoxy resin self-lubricating composite coating layer and a preparation method thereof. The preparation method comprises the following stepsof firstly, preparing a carbon nanotube / graphene oxide / molybdenum disulfide nanometer hybrid material by a hydrothermal method, and adding the carbon nanotube / graphene oxide / molybdenum disulfide nanometer hybrid material into epoxy resin, a curing agent and an organic solvent, so as to obtain a mixed solution; spraying the mixed solution onto a substrate, curing and forming, so as to obtain an epoxy resin self-lubricating composite coating layer with high abrasion-reduction property and abrasion-resistant property. The nanometer hybrid material-modified epoxy resin self-lubricating composite coating layer has the advantages that the preparation method is novel; the abrasion-reduction property and abrasion-resistant property of the epoxy resin coating layer are enhanced by preparing the carbon nanotube / graphene oxide / molybdenum disulfide nanometer hybrid material for the first time; the conditions are mild, the operation is simple, and the large-area abrasion-reduction and abrasion-resistant coating layer is easy to prepare, and is suitable for large-scale production; the obtained composite coating layer is dense and uniform, and the lower friction coefficient and higher abrasion-resistant property are realized.

Owner:名畔科技(镇江)有限公司

Self-lubricated composite plating in multiple layers and preparation method

InactiveCN1727520AGood anti-frictionReduce internal stressVacuum evaporation coatingSputtering coatingSputteringUltimate tensile strength

A self-lubricating multi-layer coated layer is composed of several Mo layers and several IF-MoS2 layers, which are alternatively prepared. Its preparing process includes providing laminar MoS2 powder, S powder and Mo sheets and alternative magnetically controlled sputterings and multi-arc ionic platings. Its advantages are high stability, low friction coefficient, high antiwear nature and high adhesion.

Owner:ZHEJIANG UNIV +1

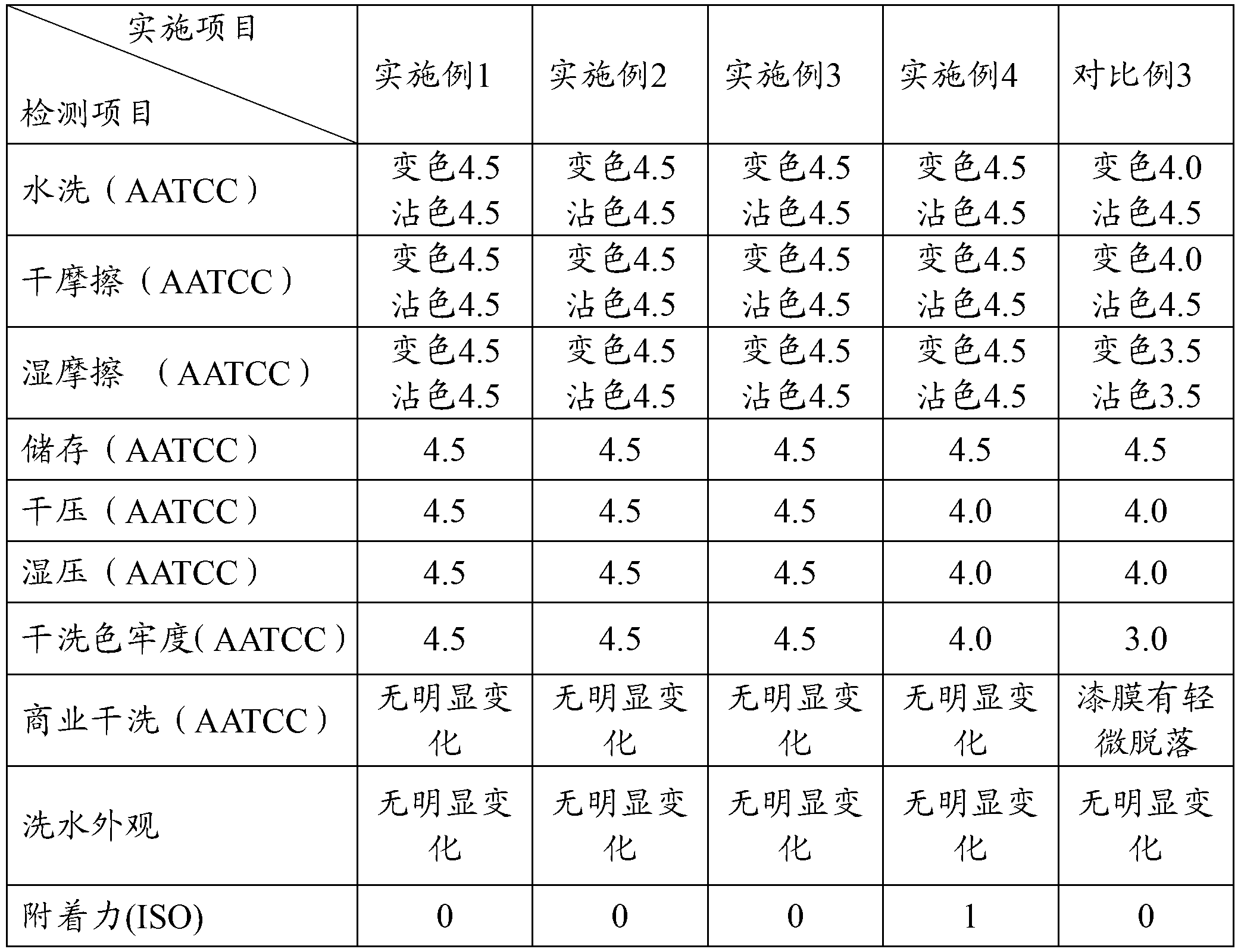

Button with hammer effect and preparation method of button

ActiveCN103194144AHas a hammer effectStrong visual impactClothes buttonsPolyurea/polyurethane coatingsDiluentShock resistance

The invention discloses a button with a hammer effect and a preparation method of the button. The button comprises a base material, and a coating with a hammer effect is sprayed onto the base material and is a mixture of hammer paint, a curing agent and a diluent with the ratio in parts by weight of 1: (0.2-0.3): 0.5. The preparation method comprises the following steps of: processing the base material: carrying out water-grinding treatment on the base material to be sprayed to guarantee that the surface of the base material is clean without pollution; spraying, wherein the viscosity of the coating is controlled for 14s-20s, and then the coating is sprayed onto the base material; and molding, namely naturally drying or stoving the base material with the coating. The button provided by the invention is strong in visual impact and decoration function, simple in preparation method and beneficial to waste reduction, and also has good performance of scratch resistance, friction resistance, shock resistance, washing durability and general chemical corrosion resistance; and the raw materials are easily available, and suitable materials are more.

Owner:广东康派环创科技有限公司

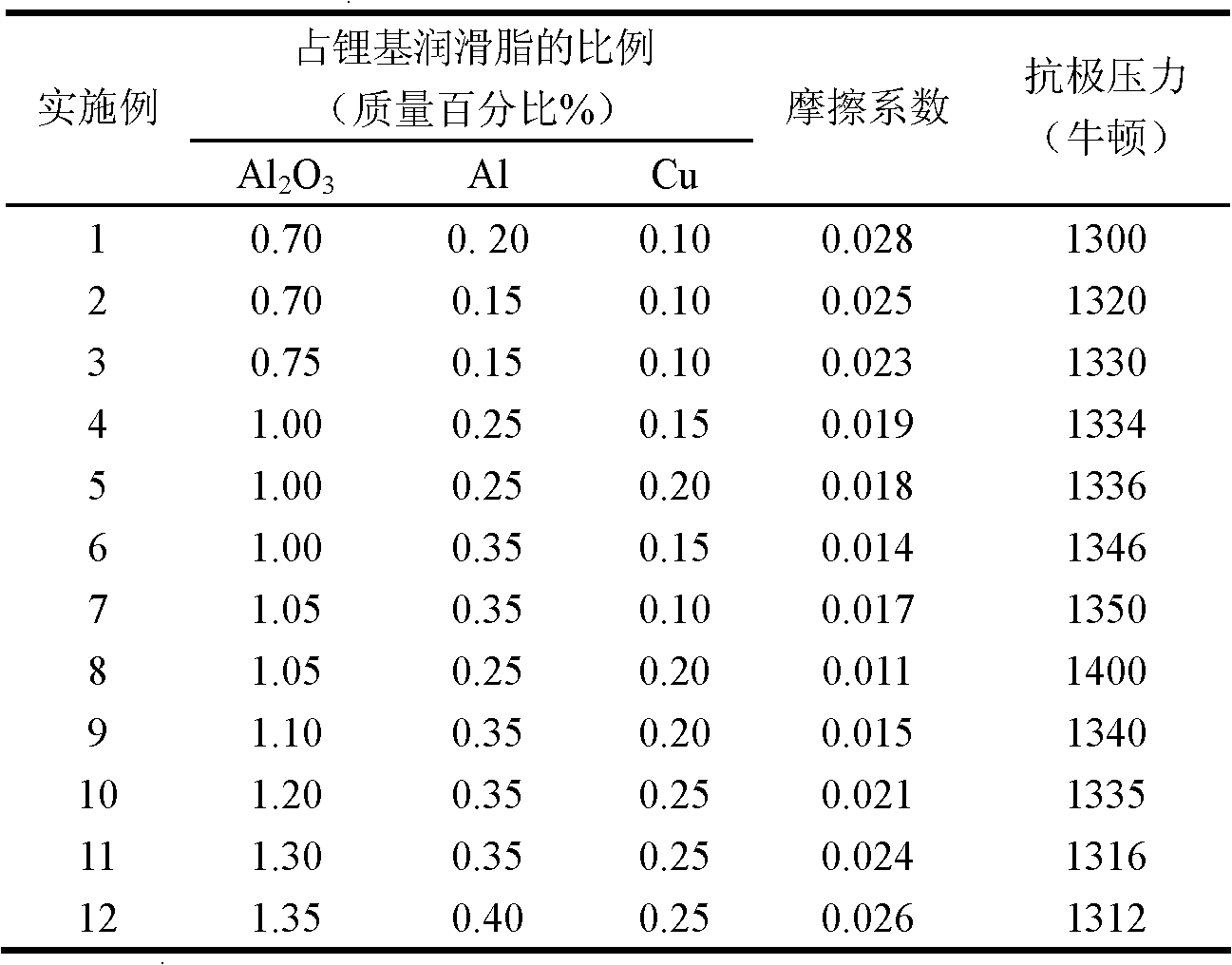

Mixed nanometer lubricating grease additive and application thereof

The invention relates to a mixed nanometer lubricating grease additive and application thereof, and belongs to the technical field of lubrication. The mixed nanometer lubricating grease additive consists of the following components in percentage by mass: 50 to 80 percent of Al2O3 powder, 5 to 15 percent of Cu powder and 15 to 35 percent of Al powder, wherein the particle sizes of the Al2O3 powder, the Cu powder and the Al powder are 20 to 60 nanometers. The prepared additive is added into base lubricating grease, so that the anti-extreme pressure, wear-resistant and antifriction performance of the base lubricating grease can be improved; and the additive can act on the surface of a friction pair to improve the roughness of the surface of the friction pair and repair the grinding cracks on the surface, so that the abrasion loss of the friction pair is reduced, the accuracy of the friction pair is ensured effectively and the service life of the friction pair is prolonged. Experimental data display that compared with the lubricating grease into which the additive is not added, the lubricating grease into which the additive is added has the advantages that the friction coefficients are reduced by 42 to 79 percent, and the anti-extreme pressure performance is improved by 36.8 to 47.4 percent.

Owner:DALIAN JIAOTONG UNIVERSITY

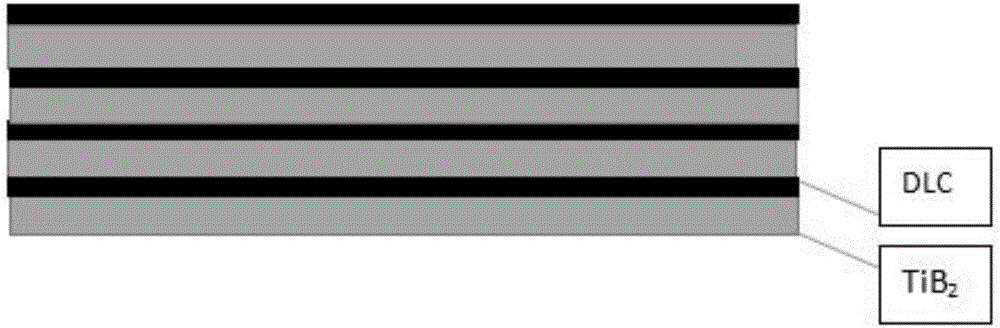

Self-lubricating titanium diboride/diamond-like carbon coating and preparing method and application thereof

ActiveCN106086886AHigh hardnessImprove toughnessSuperimposed coating processDiamond-like carbonMicrometer

The invention discloses a self-lubricating titanium diboride (TiB2) / diamond-like carbon (DLC) hard coating and a preparing method of the coating. According to the TiB2 / DLC hard coating, a bipolar pulse magneto-sputtering deposition technology is adopted to enable a TiB2 ceramic layer and a DLC layer to be periodically overlaid on a base to form the coating; the modulation period of the TiB2 / DLC hard coating ranges from 15 nm to 60 nm, and the total thickness of the coating ranges from 1.2 micrometers to 1.4 micrometers; according to the TiB2 / DLC hard coating, advantages of TiB2 and advantages of DLC are integrated, the coating has the excellent hardness and lubricating characteristics, the good conducting property is achieved, meanwhile, the pulse magneto-sputtering deposition technology is convenient to operate, the process is simple, the preparing period is short, the cost is low, large-scale industrial production is facilitated, and the coating can be widely applied to fields of cutters, molds, microelectronics, protection and the like.

Owner:GUANGDONG UNIV OF TECH

High-performance high water-based lubricant composition

The invention discloses a high-property high-water based lubricant composition, which comprises the following parts: 95-99% water and 1-5% functional additive (lubricant and alkali) and lucricating additive with nanometer silica particle and soluble phosphate, wherein the even grain size of nanometer silica particle is 10-60nm; the high-water based lubricant consists of nanometer silica particle and soluble phosphate, which improves bearing capacity (PB value) and reduces spot-abrasion diameter (D3040); the water based lubricant is fit for metal manufacturing liquid to cut and polish.

Owner:SHANGHAI UNIV

Method for preparing NiCrBSi-TiN gradient composite coating abrasion-resistant belt on the surface of drill rod joint

ActiveCN107267908AHigh strengthExtend the life cycleMolten spray coatingOxidation resistantPlasma sprayed

The invention discloses a method for preparing a NiCrBSi-TiN gradient composite coating abrasion-resistant belt on the surface of a drill rod joint. The method includes the following steps that (1) surface pre-treatment of a base material is performed; (2) a gradient coating is prepared, specifically, mixed powder of each layer is prepared according to the proportions of NiCrBSi powder and Ti powder in each layer in a composite gradient coating shown as follows, the mixed powder of each layer is put in a grinding miller to be mixed, the powder is dried for 0.7-1.2 hours at the temperature of 100 DEG C to 110 DEG C before spraying, and then plasma spraying of each layer is performed in sequence; and (3) induction remelting aftertreatment of the coating is performed, specifically, the drill rod joint is coated with a high-temperature antioxidant coating material with the thickness being 0.2-0.3 mm after being subjected to composite gradient spraying, and then induction melting treatment is performed through high-frequency induction heating equipment. According to the method, the process operation is simple, the feasibility is high, the abrasion resistance is remarkably improved, and abrasion to the abrasion-resistant material is small.

Owner:HEBEI UNIV OF TECH

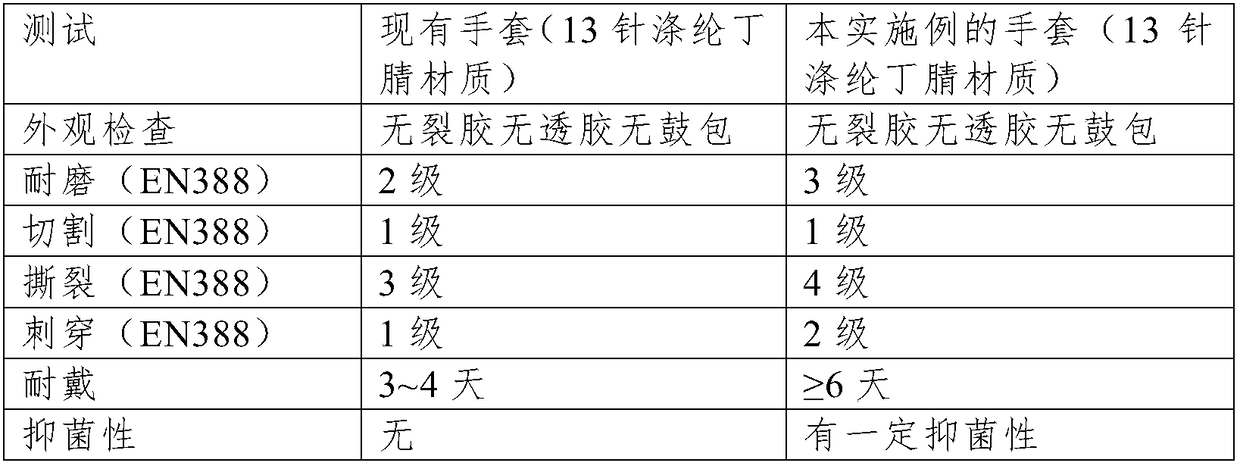

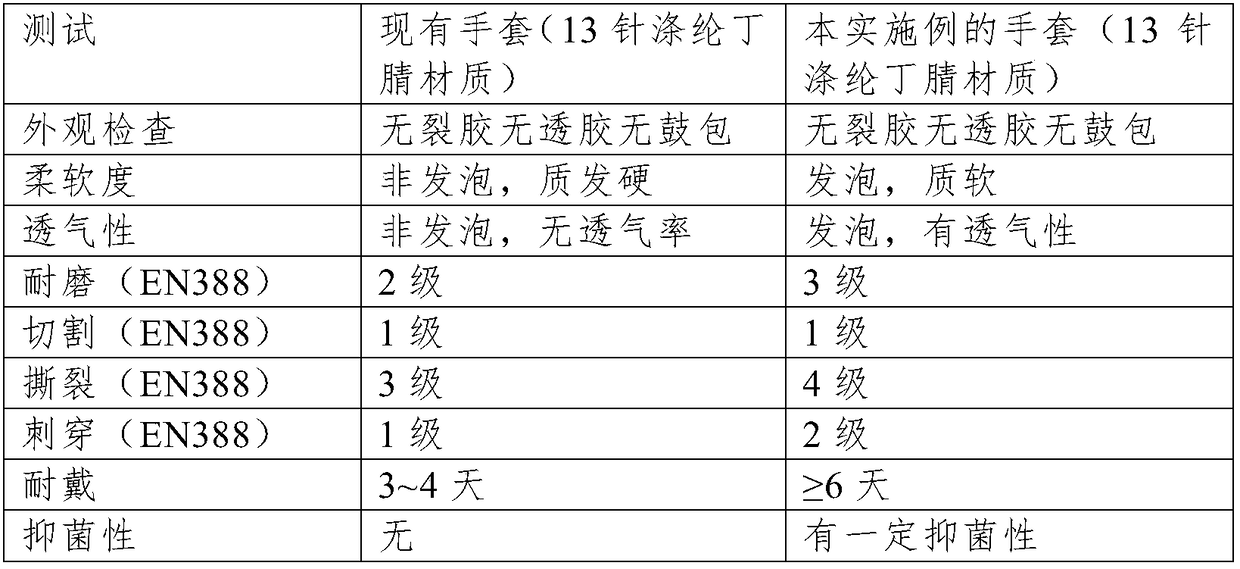

Graphene laminated rubber glove and preparation method thereof

ActiveCN108486902AImproved cut and tear resistanceBacteriostaticGlovesConjugated diene hydrocarbon coatingsPolymer scienceVulcanization

The invention relates to a graphene laminated rubber glove which comprises a glove blank, a rubber layer and a graphene membrane layer, wherein the rubber layer is adhered to the outer surface of theglove blank; the graphene membrane layer covers the outer surface of the rubber layer; the rubber layer is made of graphene-free foamed rubber or non-foamed rubber. A preparation method of the glove comprises the following steps: preparing graphene-free rubber slurry, and soaking a knitted glove blank into the rubber slurry; preparing a graphene-latex dispersion, and further soaking the glove blank soaked into the rubber slurry into the graphene-latex dispersion; performing vulcanization drying, thereby obtaining the graphene laminated rubber glove. Due to secondary soaking, the rubber slurryof primary soaking is cured to form a rubber body structure part of the glove, and then the quality of the main body structure can meet related standards (EN388) and ensure basic working protection functions of gloves; due to secondary soaking, a graphene laminated membrane can be formed, so that a rubber surface formed by primary soaking can be protected, and various overall properties of a gloveproduct can be improved.

Owner:SHANDONG XINGYU GLOVES

Novel high-speed train pantograph sliding block material

InactiveCN102618771AMeet the performance requirements of the pantograph sliderMeet performance requirementsNon-rotary current collectorContactsOperational costsPerformance index

The invention relates to a novel high-speed train pantograph sliding block material, belonging to the technical field of metallic functional materials. The novel high-speed train pantograph sliding block material is characterized in that the alloy material comprises the following compositions in mass percent: 7-13 percent of Ti3SiC2, 0.9-3.1 percent of C and the balance of Cu. A pantograph sliding block which is made of the material provided by the invention has the advantages of excellent friction antifriction performance, good self-lubricating performance, good conductive performance, good arc burning loss resistance, good weather resistance, higher strength and rigidity, simple manufacturing process, good machining performance and low cost. When the material is used for a conductive system of a high-speed train, the conductive system can adapt to severe environments such as high temperature, high speed, heavy load, large impact and poor lubrication, the performance indexes of the high-speed train sliding block are realized, and the material is of a great practical significance to guaranteeing the safety and the normal work of the train and reducing the operating cost of a high-speed railway system.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com