Lubricating oil additive containing ultrafine rare-earth powder

A technology of lubricating oil additive and rare earth powder, applied in lubricating composition, petroleum industry and other directions, can solve the problems of self-healing film shedding failure, complicated preparation process, poor dispersion stability, etc., and achieve reduced friction coefficient, significant corrosion resistance, The effect of improving the output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

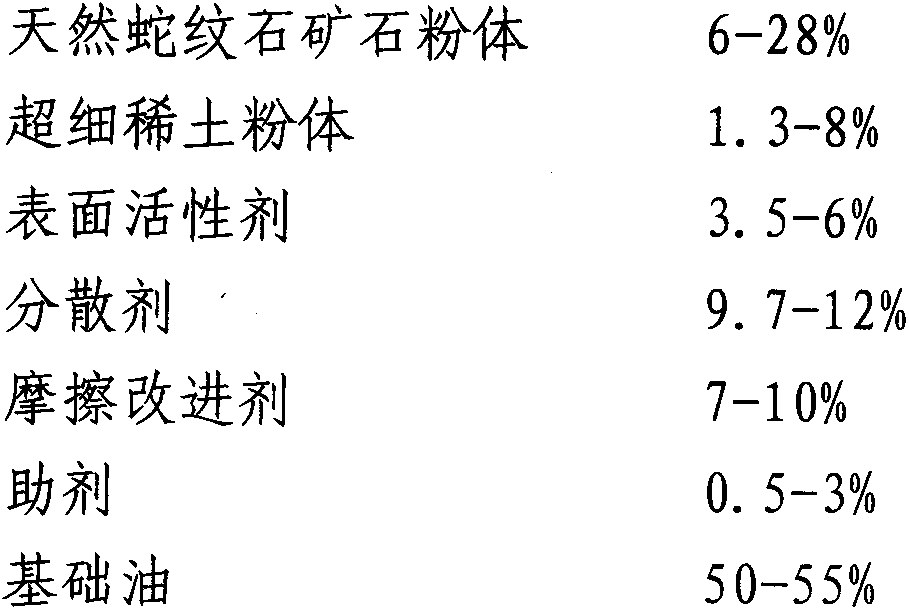

[0023] Formula components are calculated by mass percentage:

[0024]

[0025] Surfactant composition: borate 35%; Siben-60 35%; oleic acid 30%;

[0026] Auxiliary components: sulfurized dialkyl molybdenum dithiophosphate 72%; polytetradecyl methacrylate 18%; ethylene-propylene copolymer 10%.

Embodiment 2

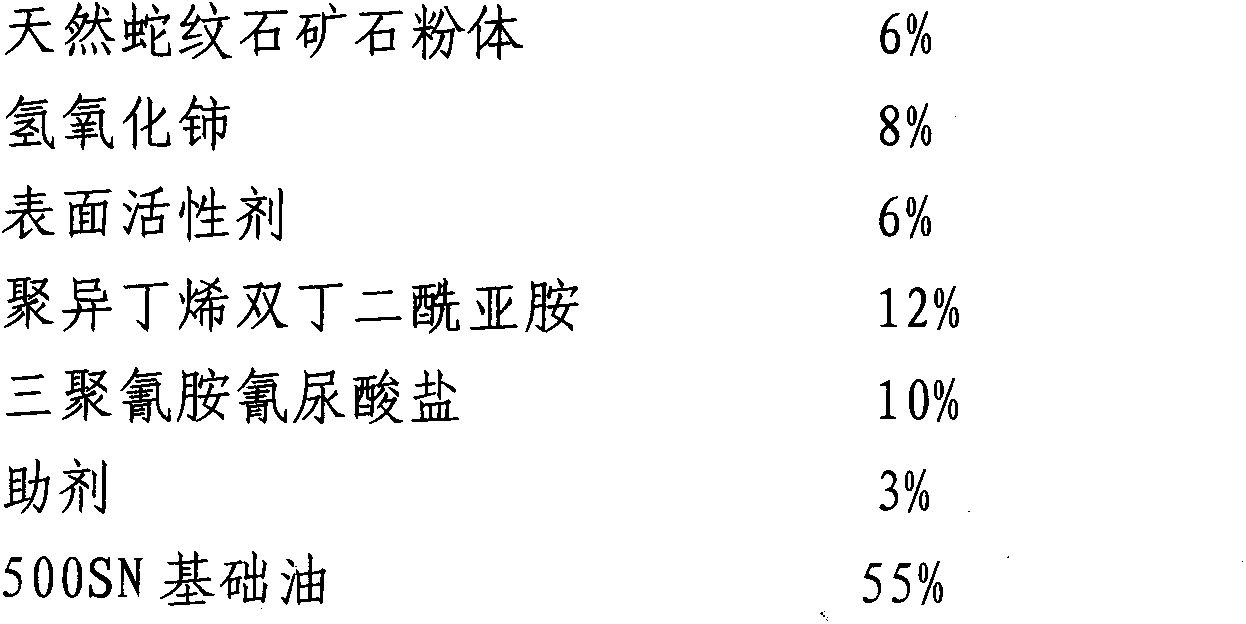

[0028] Formula components are calculated by mass percentage:

[0029]

[0030] Surfactant composition: borate 35%; Siben-60 35%; oleic acid 30%;

[0031] Auxiliary components: sulfurized dialkyl molybdenum dithiophosphate 72%; polytetradecyl methacrylate 18%; ethylene-propylene copolymer 10%.

Embodiment 3

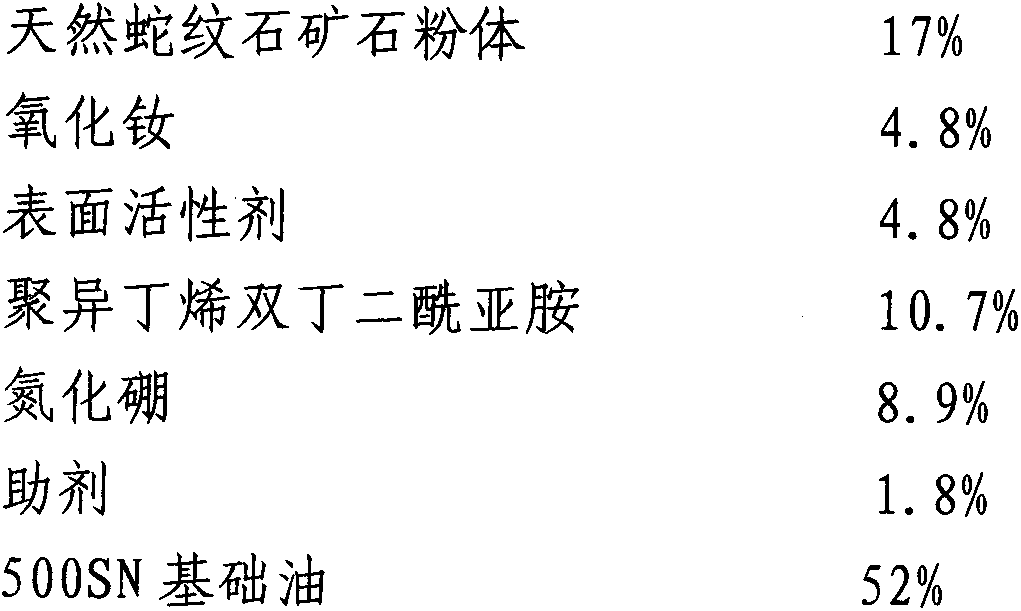

[0033] Formula components are calculated by mass percentage:

[0034]

[0035] Surfactant composition: borate 45%; Siben-60 45%; polyoxyethylene lauryl ether 10%;

[0036] Auxiliary components: sulfurized dialkyl molybdenum dithiophosphate 72%; polytetradecyl methacrylate 18%; ethylene-propylene copolymer 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com