Patents

Literature

30results about How to "Reduce friction load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

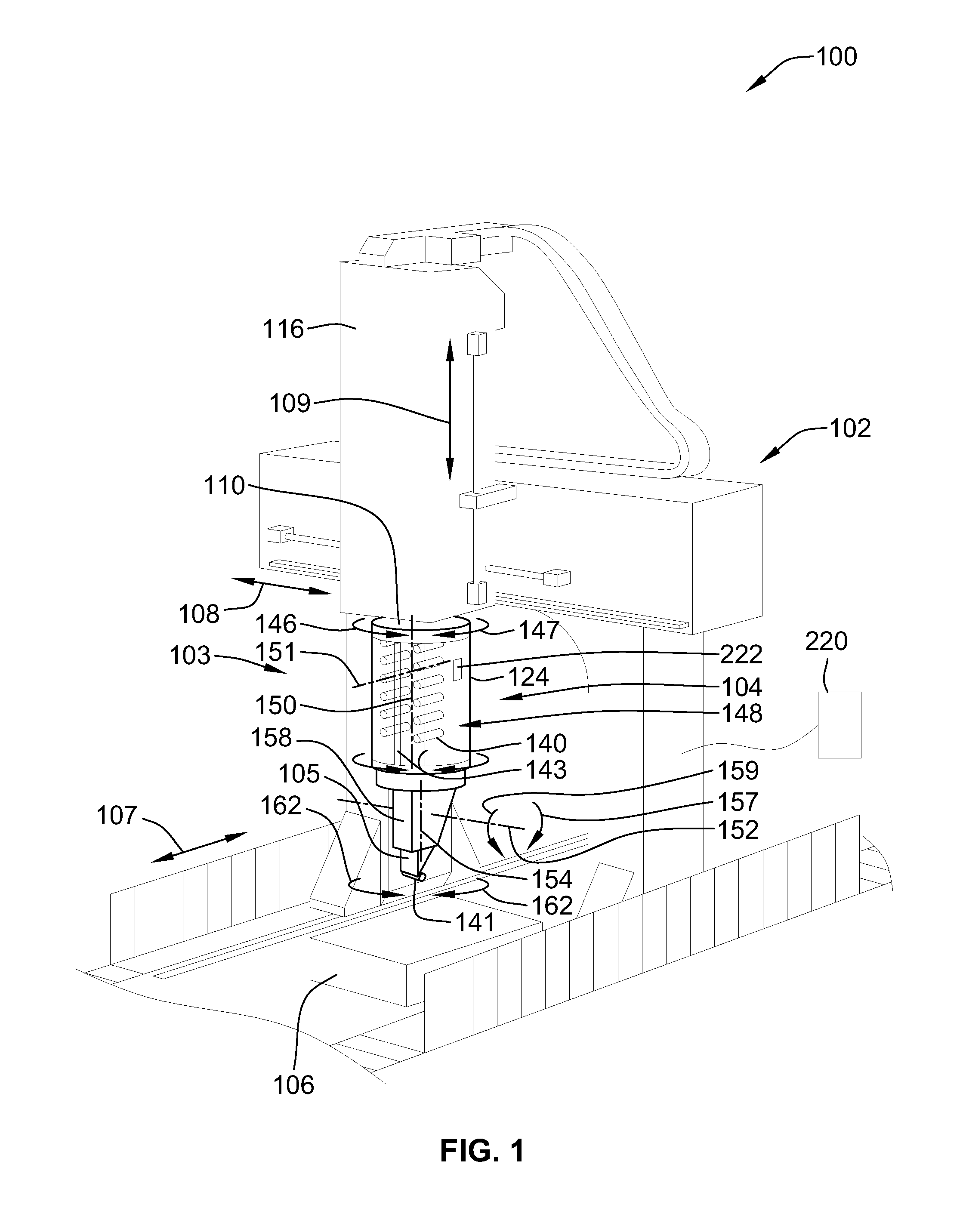

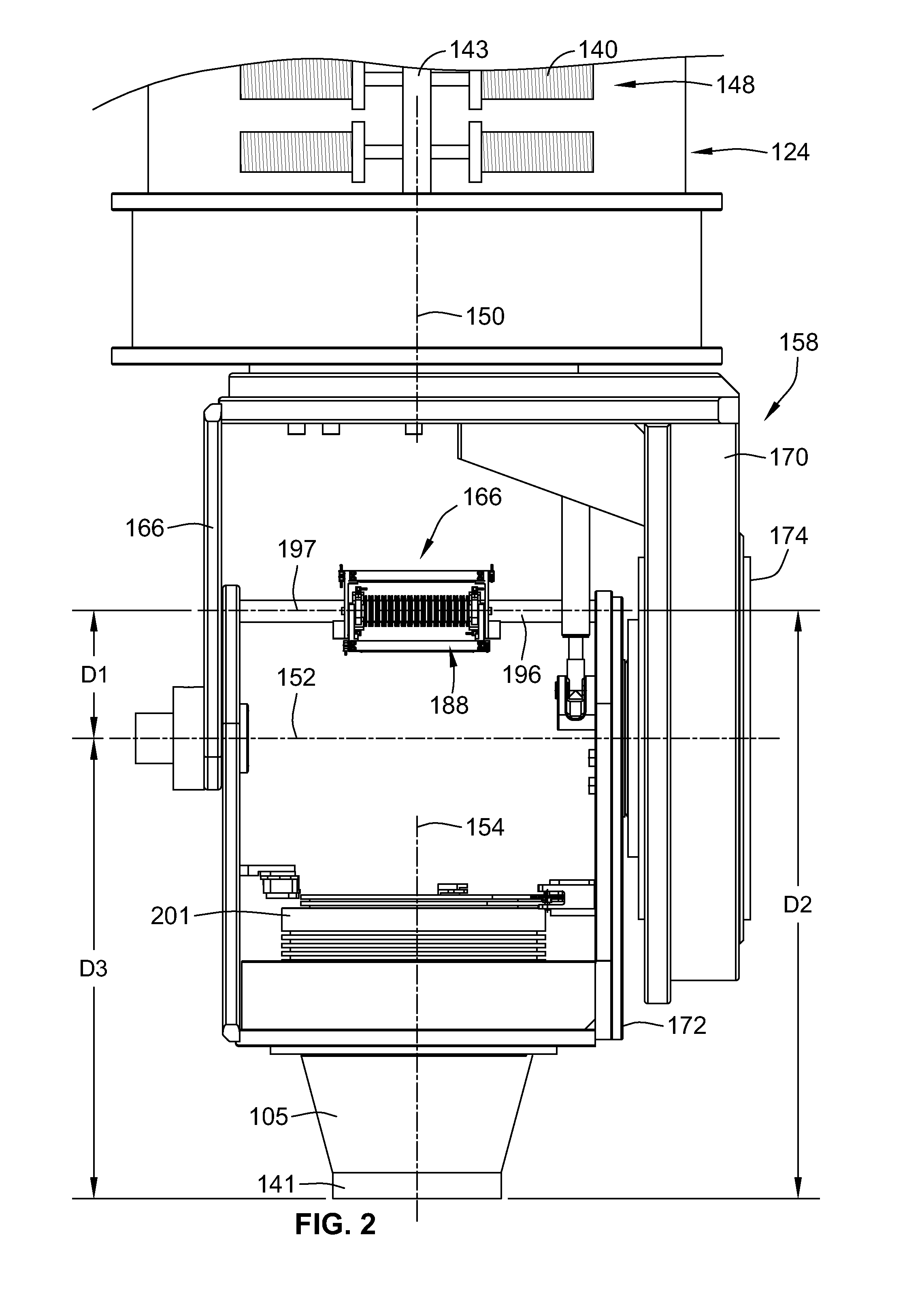

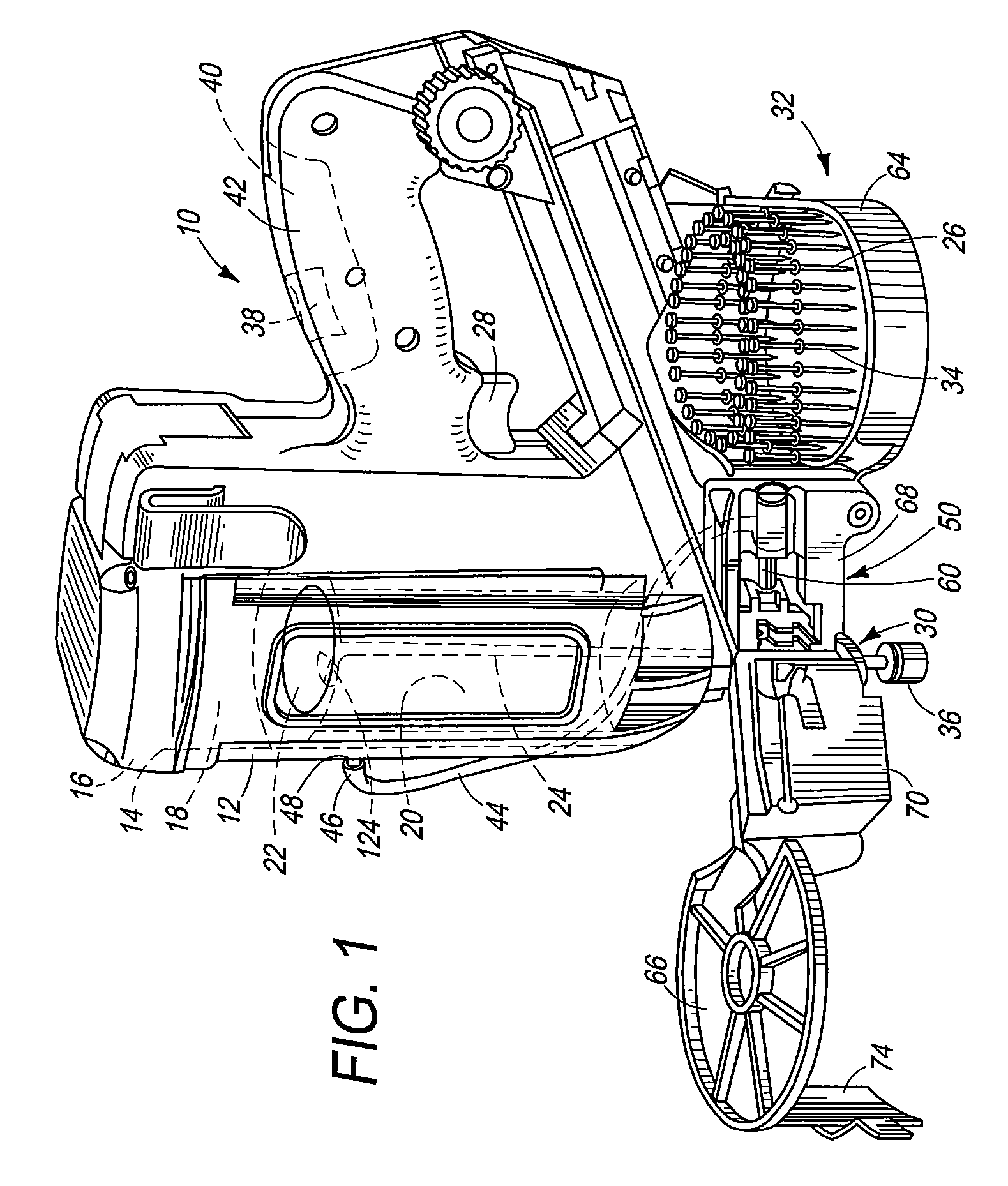

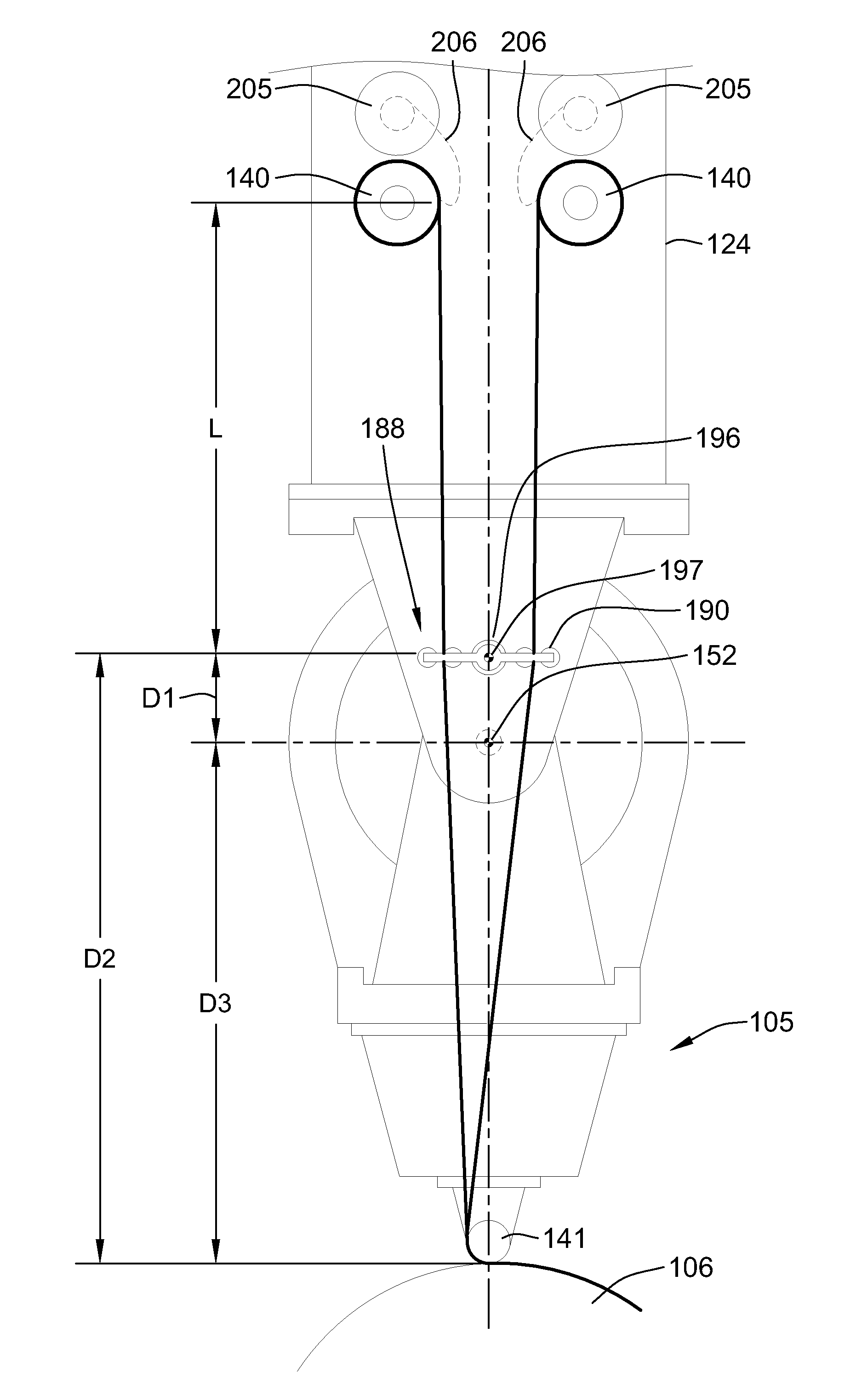

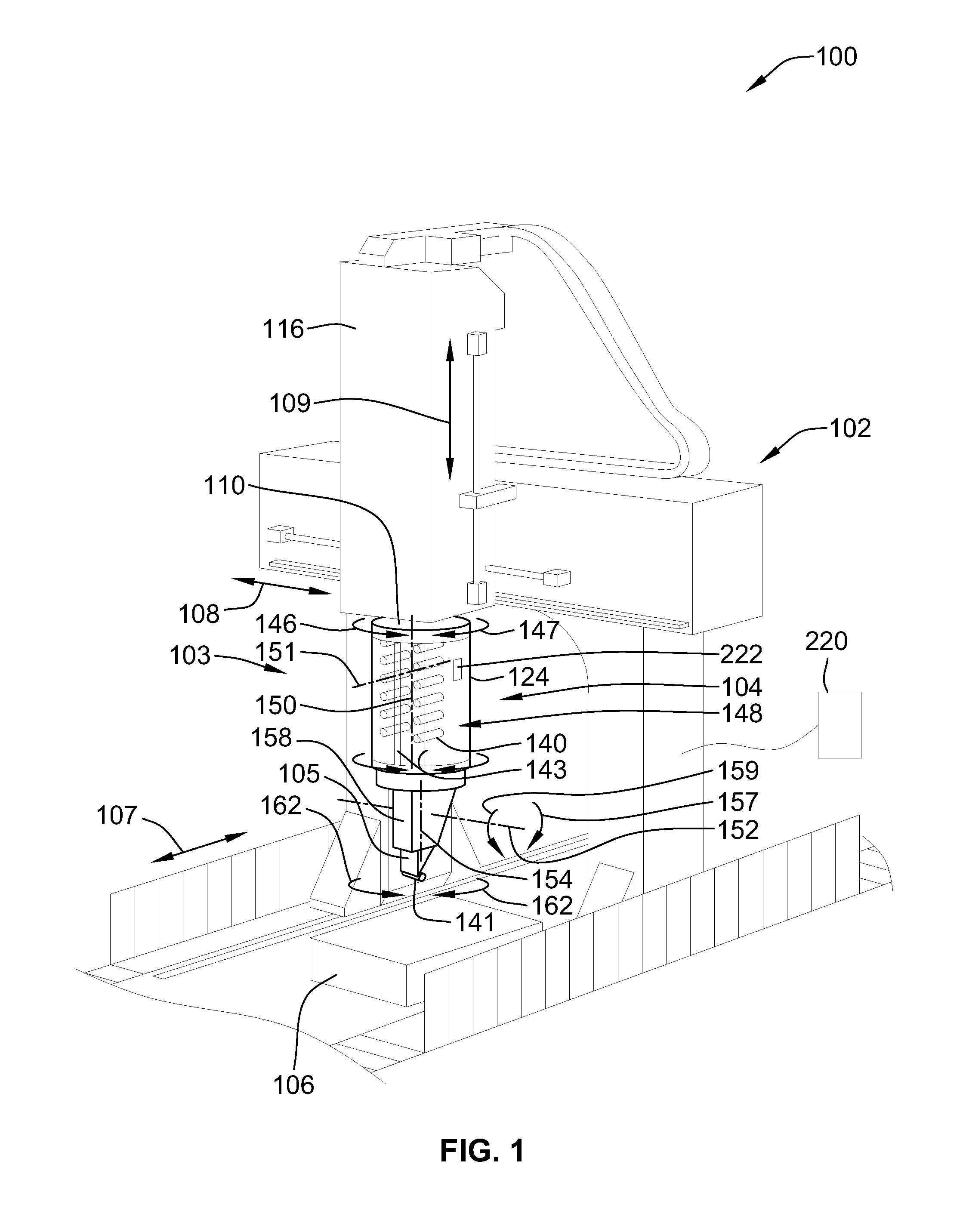

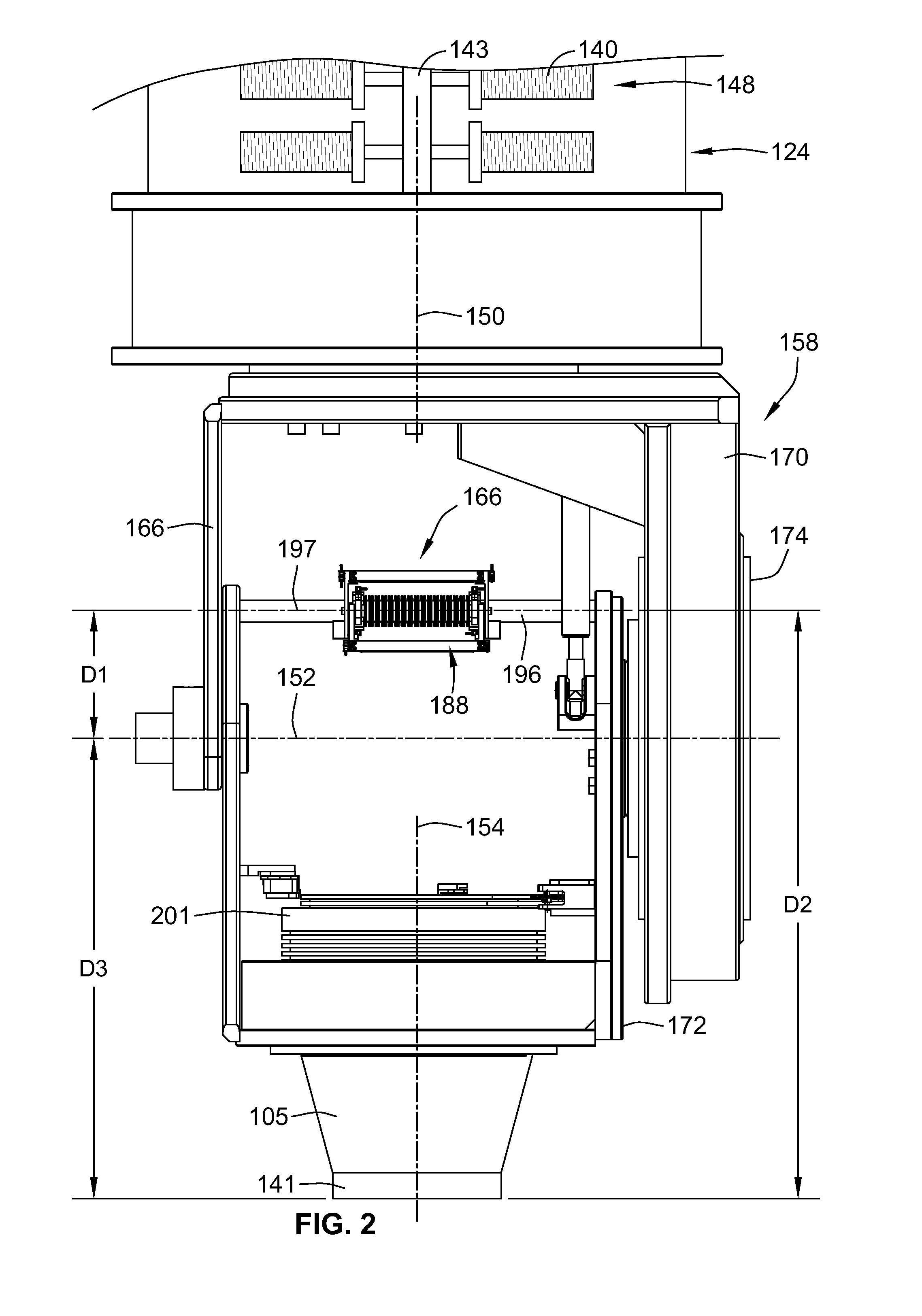

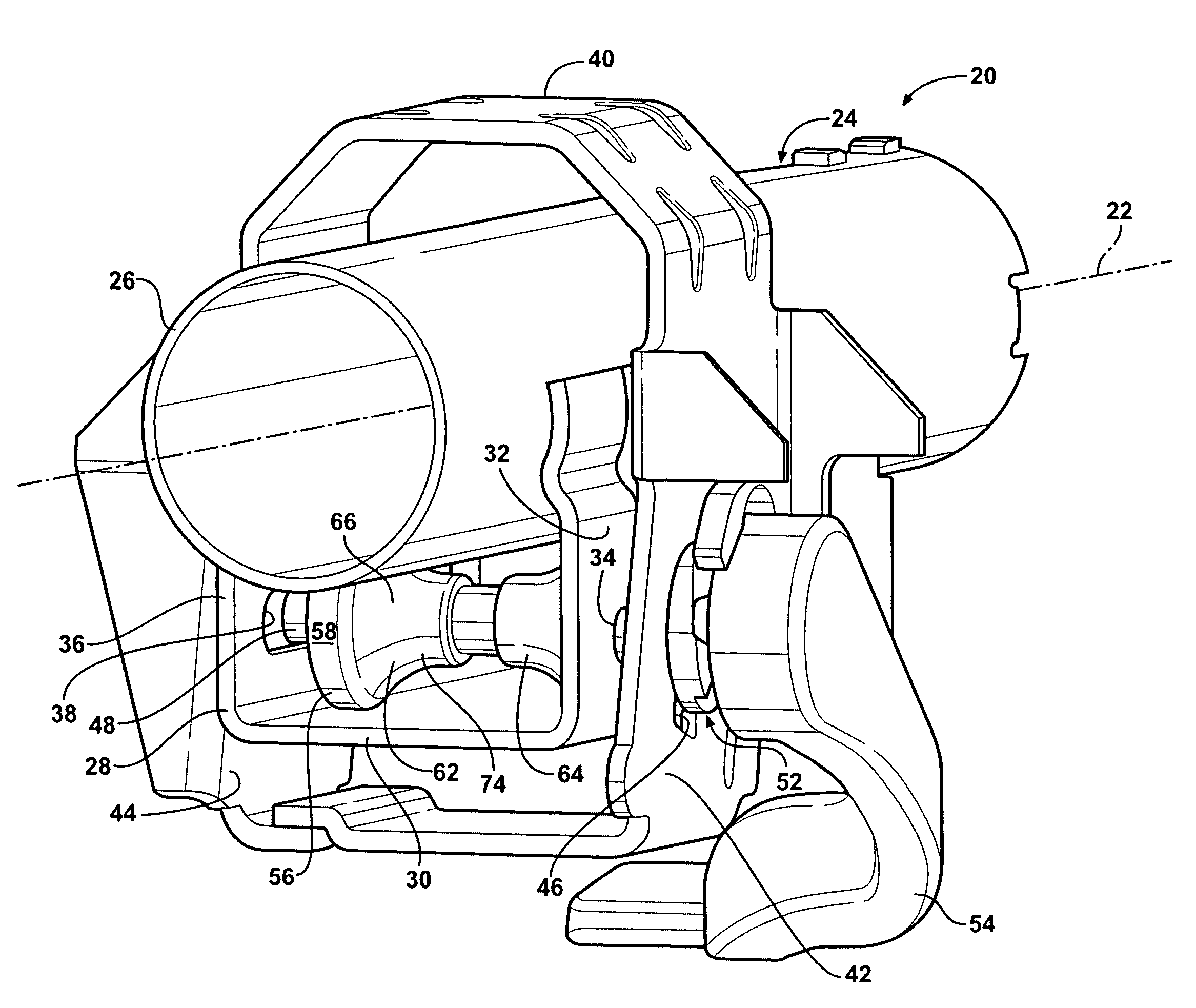

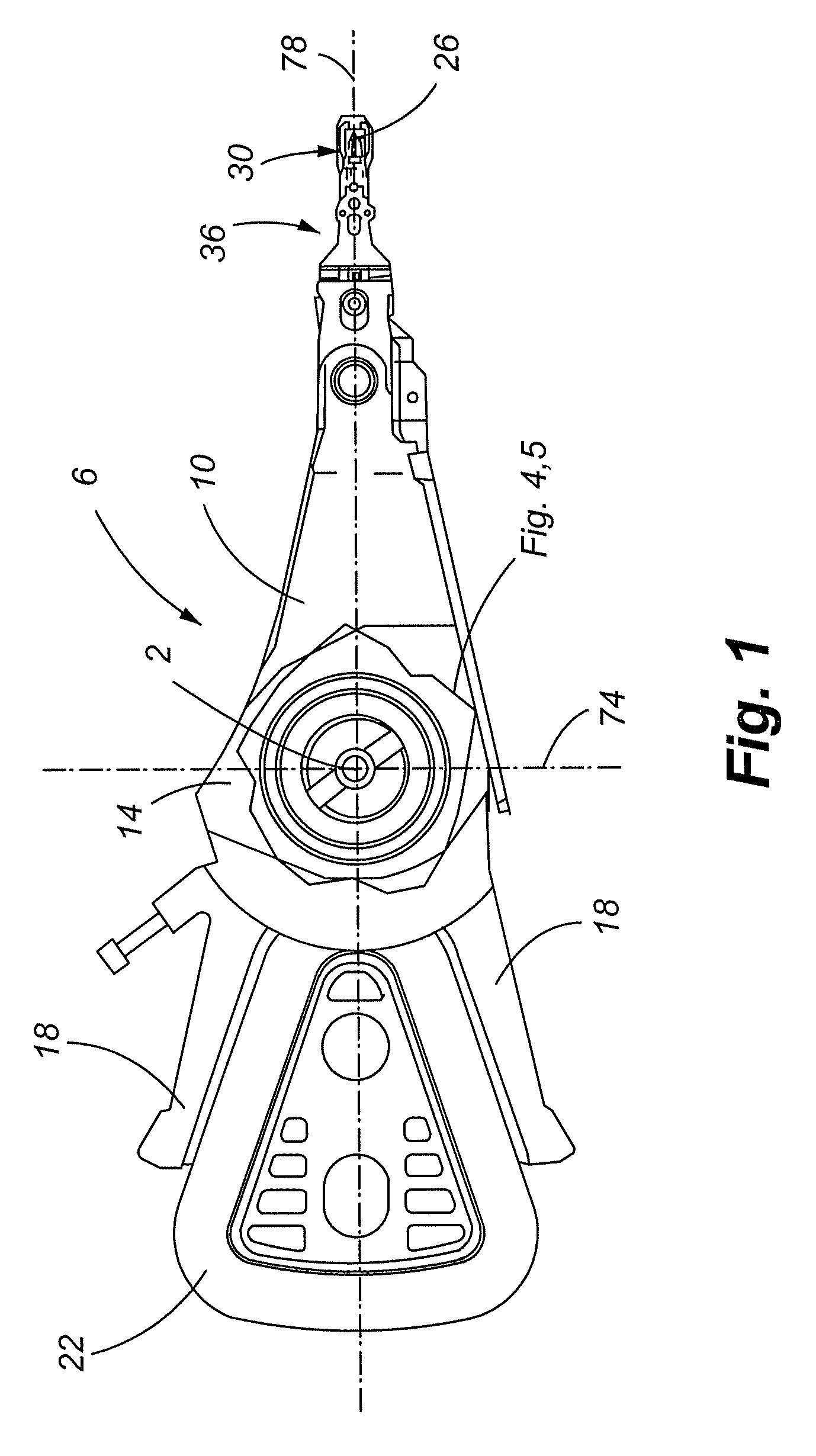

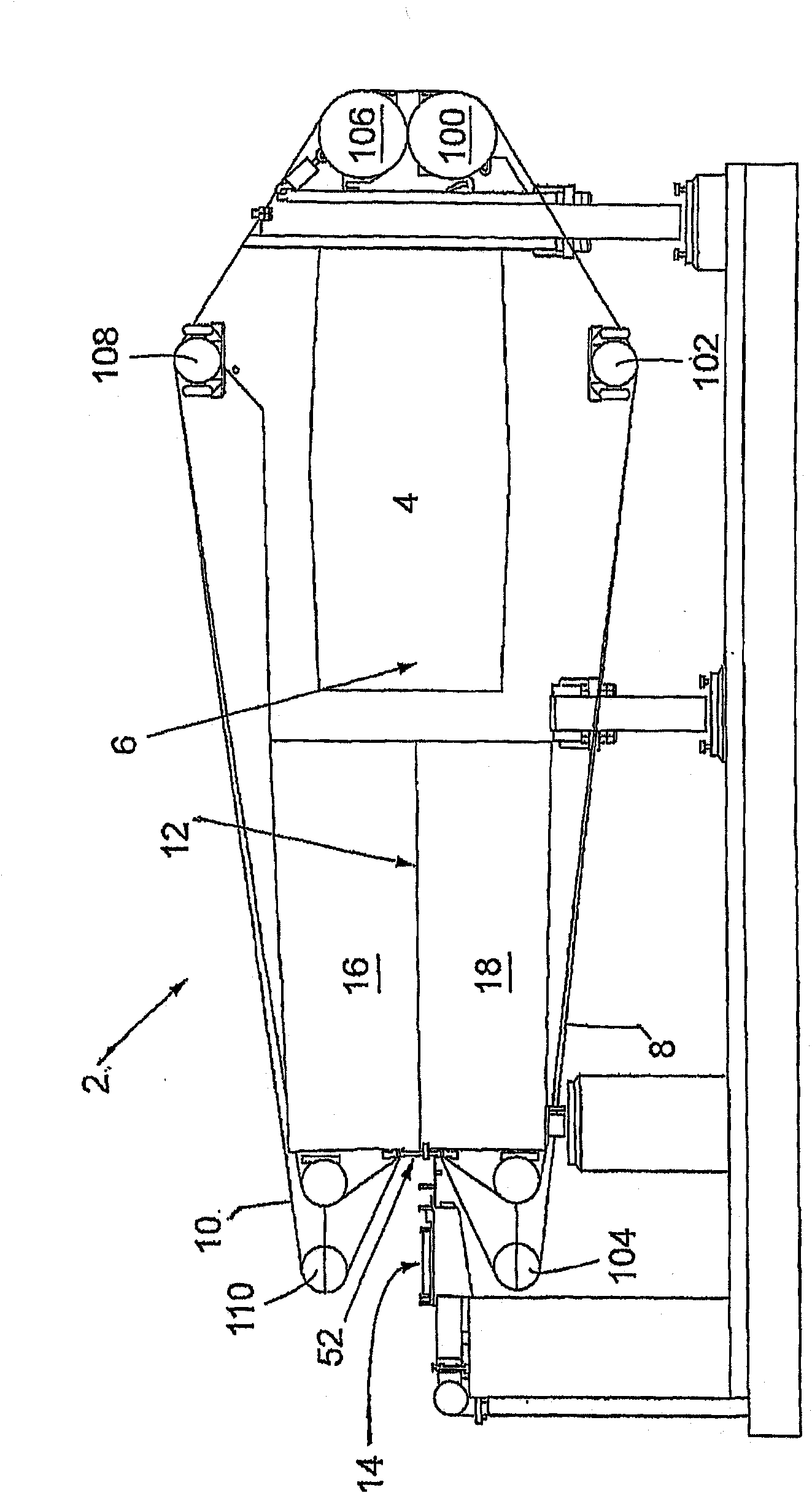

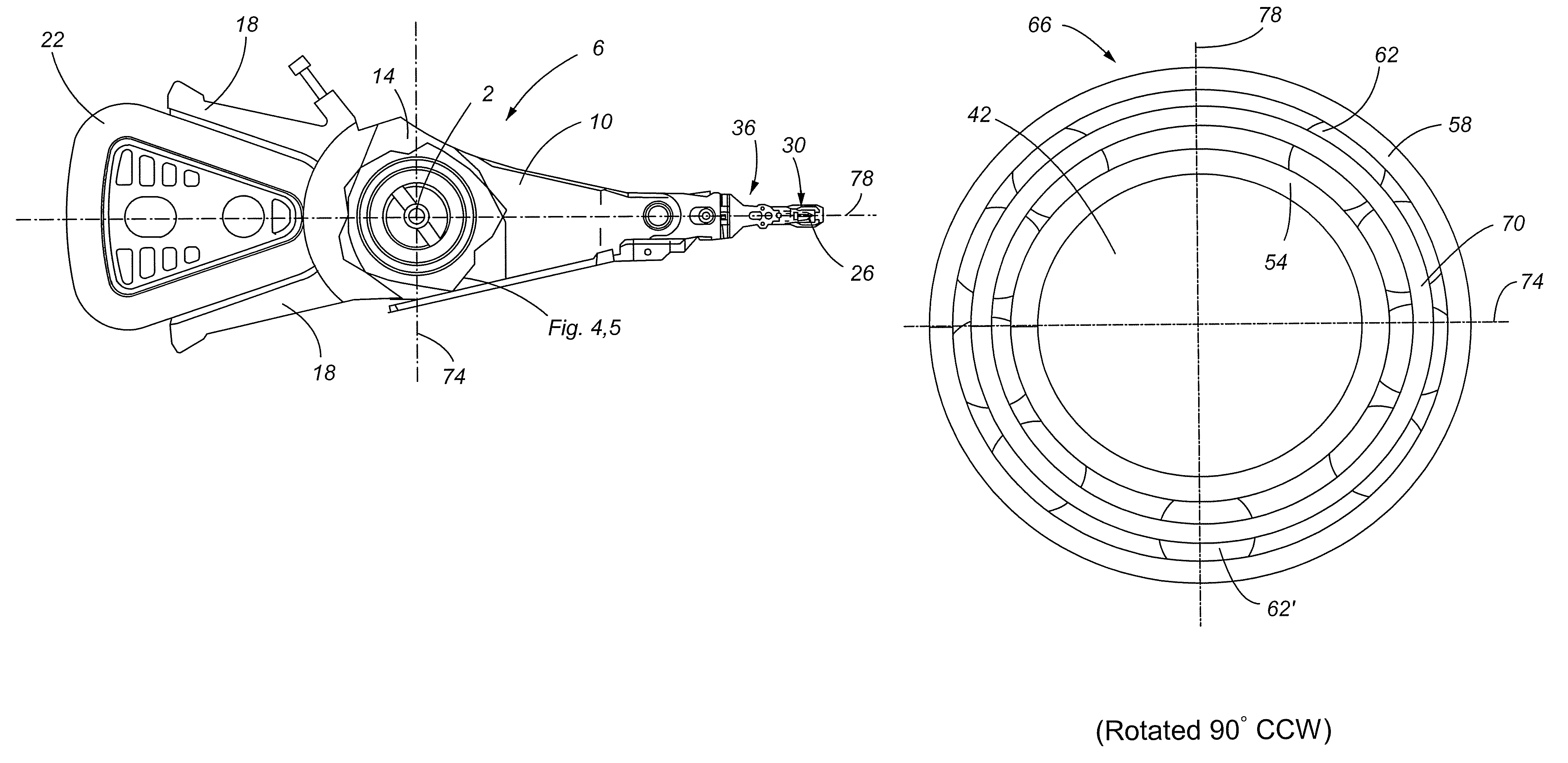

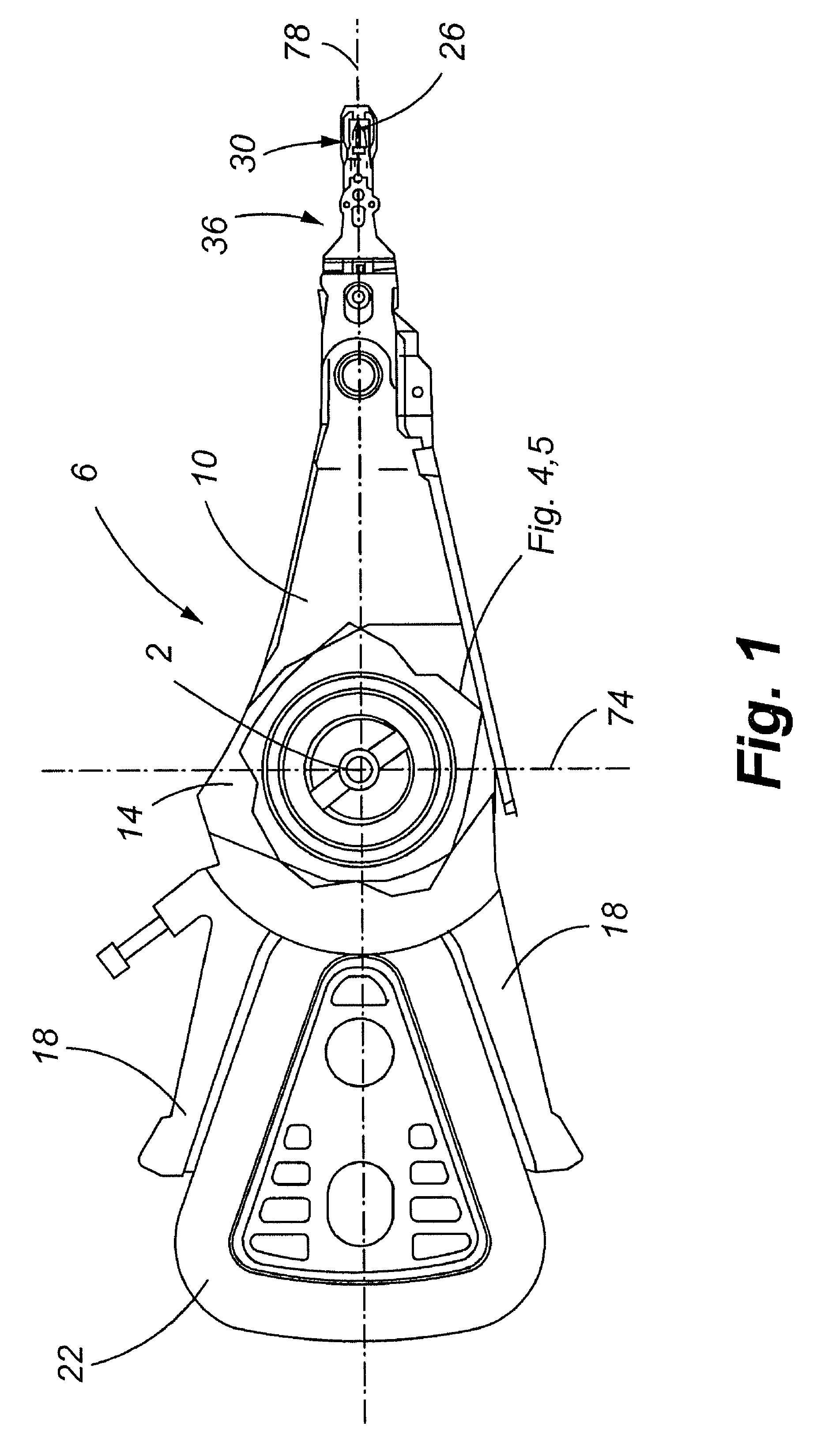

Fiber delivery apparatus and system having a creel and fiber placement head with polar axis of rotation

ActiveUS8534338B2Improve protectionReduce any negative affects on fiber towsEngine sealsLamination ancillary operationsFiberDegrees of freedom

A fiber placement system including positioner and a fiber delivery apparatus having a creel assembly and a fiber placement head is provided. The positioner moves the entire fiber delivery apparatus including the creel assembly and the fiber placement head via at least three linear degrees of freedom. The fiber delivery apparatus includes an articulating wrist for moving the fiber placement head relative to the creel assembly. The fiber placement apparatus is substantially free of linear degrees of freedom within the fiber tow paths between the spools and the fiber placement head. One or more rotational degrees of freedom may be provided along the tow path. In one embodiment, the interface between the fiber delivery apparatus and the positioner is laterally offset such that a portion of the creel axially overlaps with vertical ram of the positioner.

Owner:INGERSOLL MACHINE TOOLS

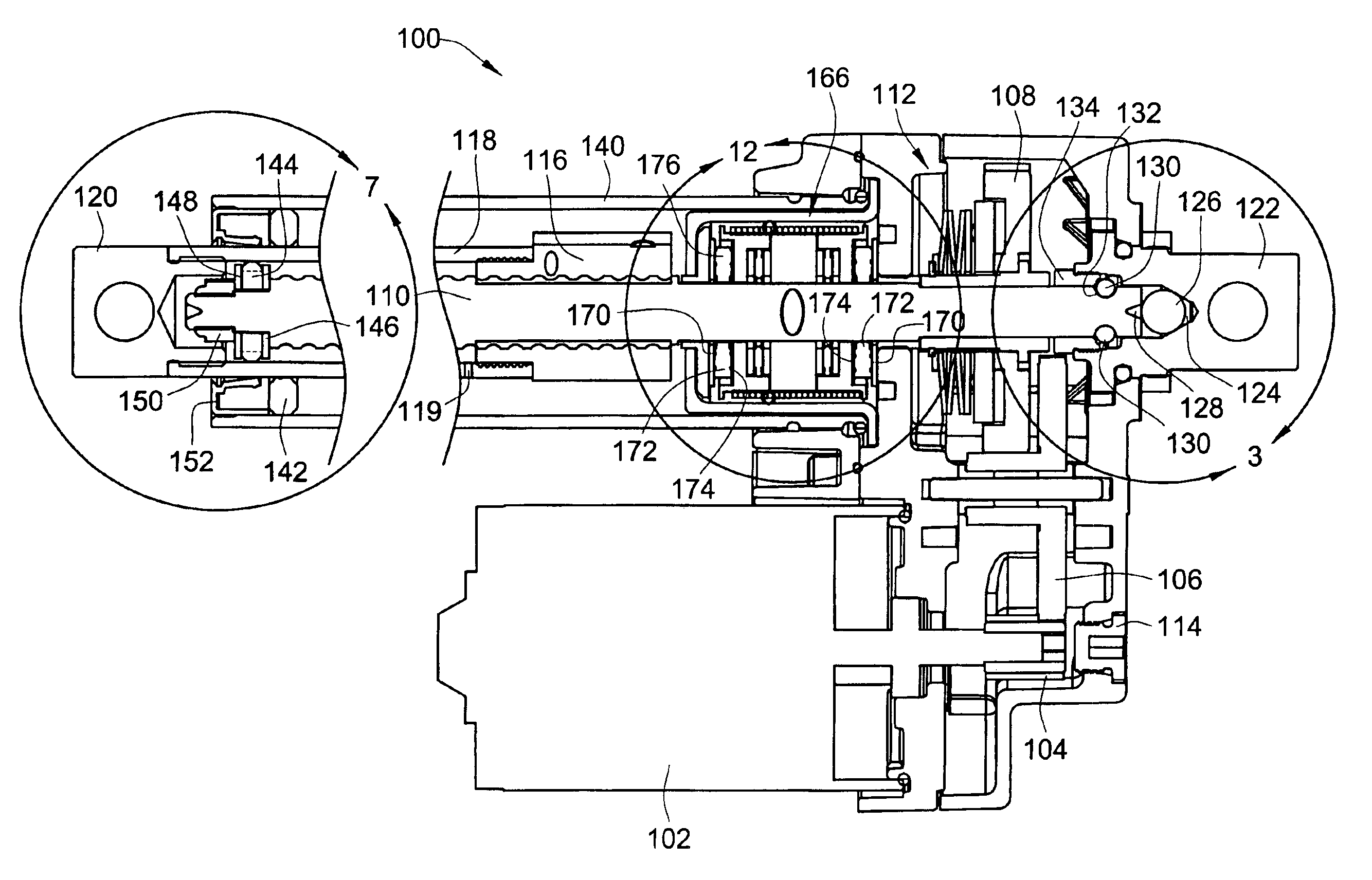

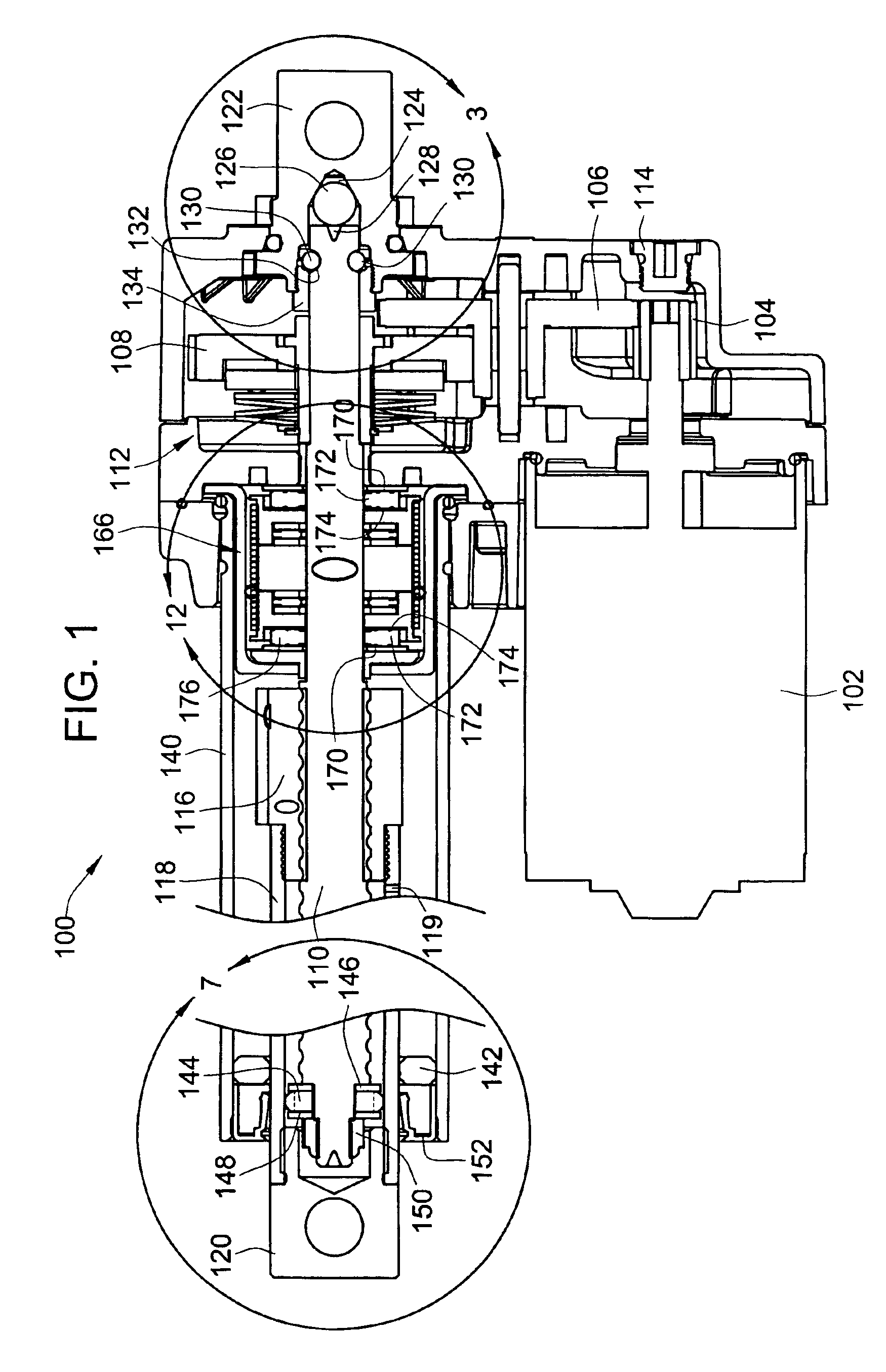

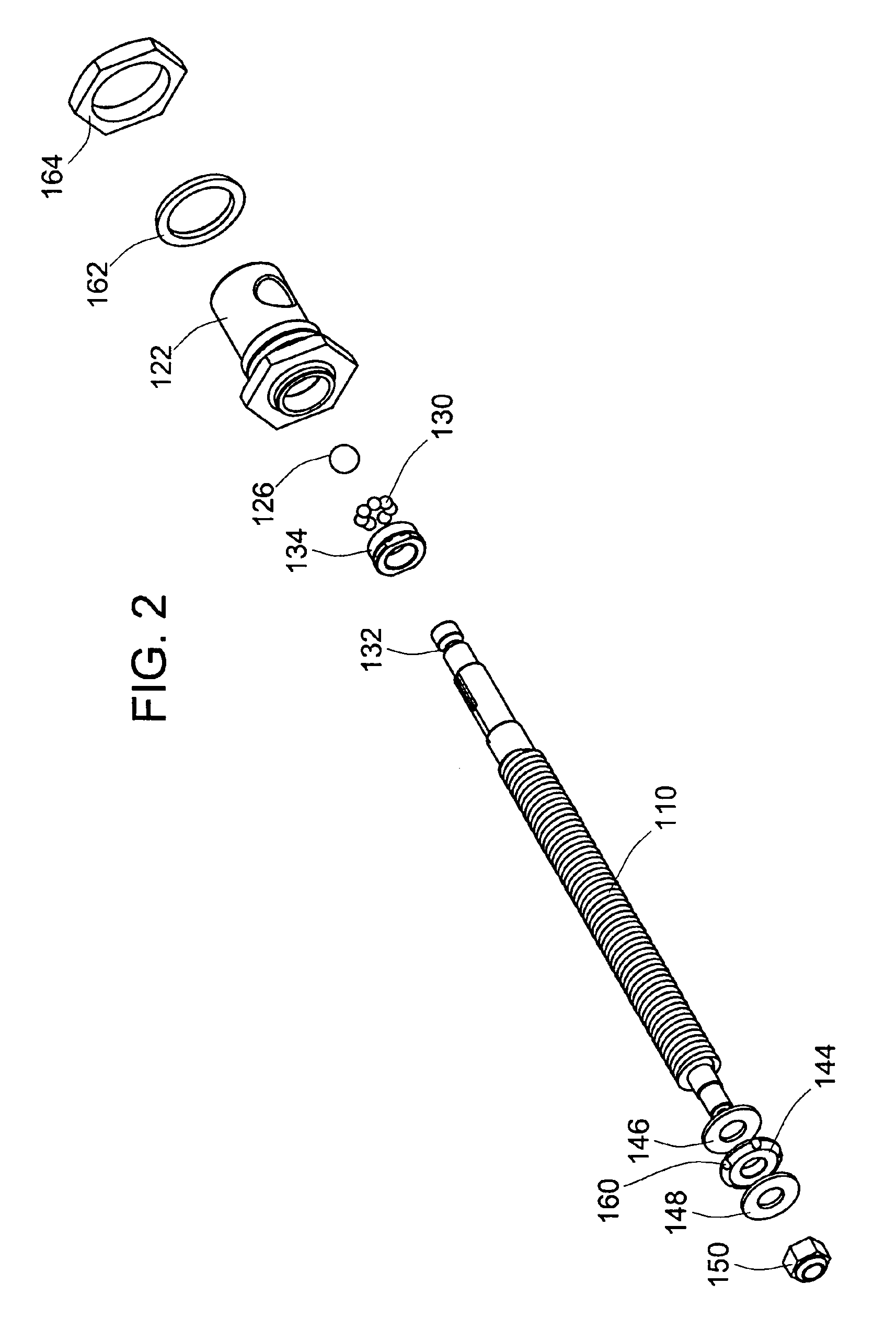

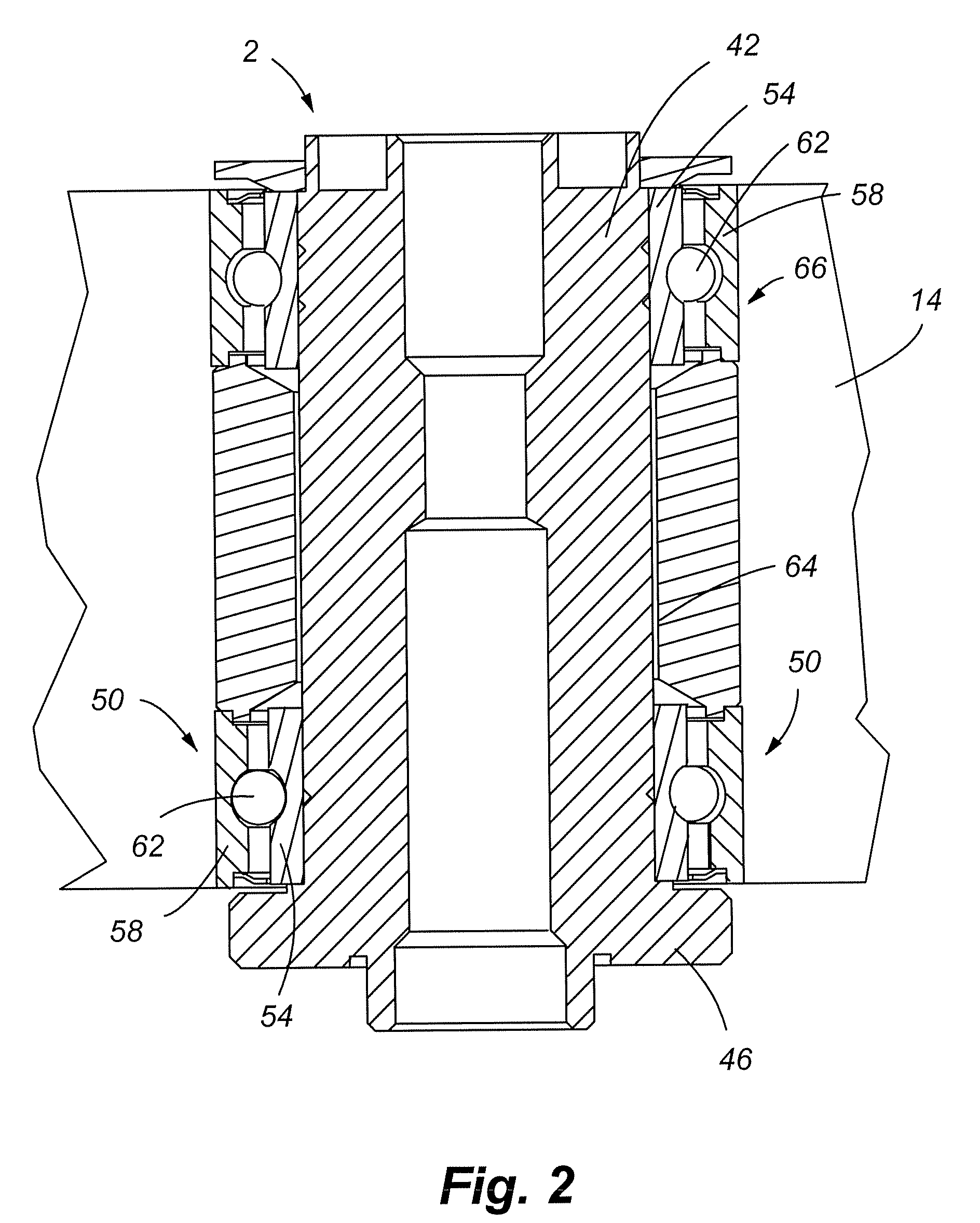

Electromechanical screw drive actuator

ActiveUS6927513B2Efficient load transferLarge load capabilityToothed gearingsMechanical energy handlingLubricationLinear actuator

An electromechanical linear actuator assembly having in-line axial load support of its screw drive shaft is provided. The bearing support structure provides a single in-line ball bearing accommodated within a hardened end fitting and a screw pivot recess in the axial screw drive shaft. For axial loading in an opposite direction, a number of smaller ball bearings are provided around the outer periphery of the screw shaft in a groove, and are retained within the hardened end fitting by a bearing retainer. End rod support bearings providing heat compensation and lubrication fluid transfer are also provided. A braking mechanism having increased life and more consistent load engagement is also provided. Further, integrated electronics may be provided for position sensing and power efficiency control.

Owner:WARNER ELECTRIC

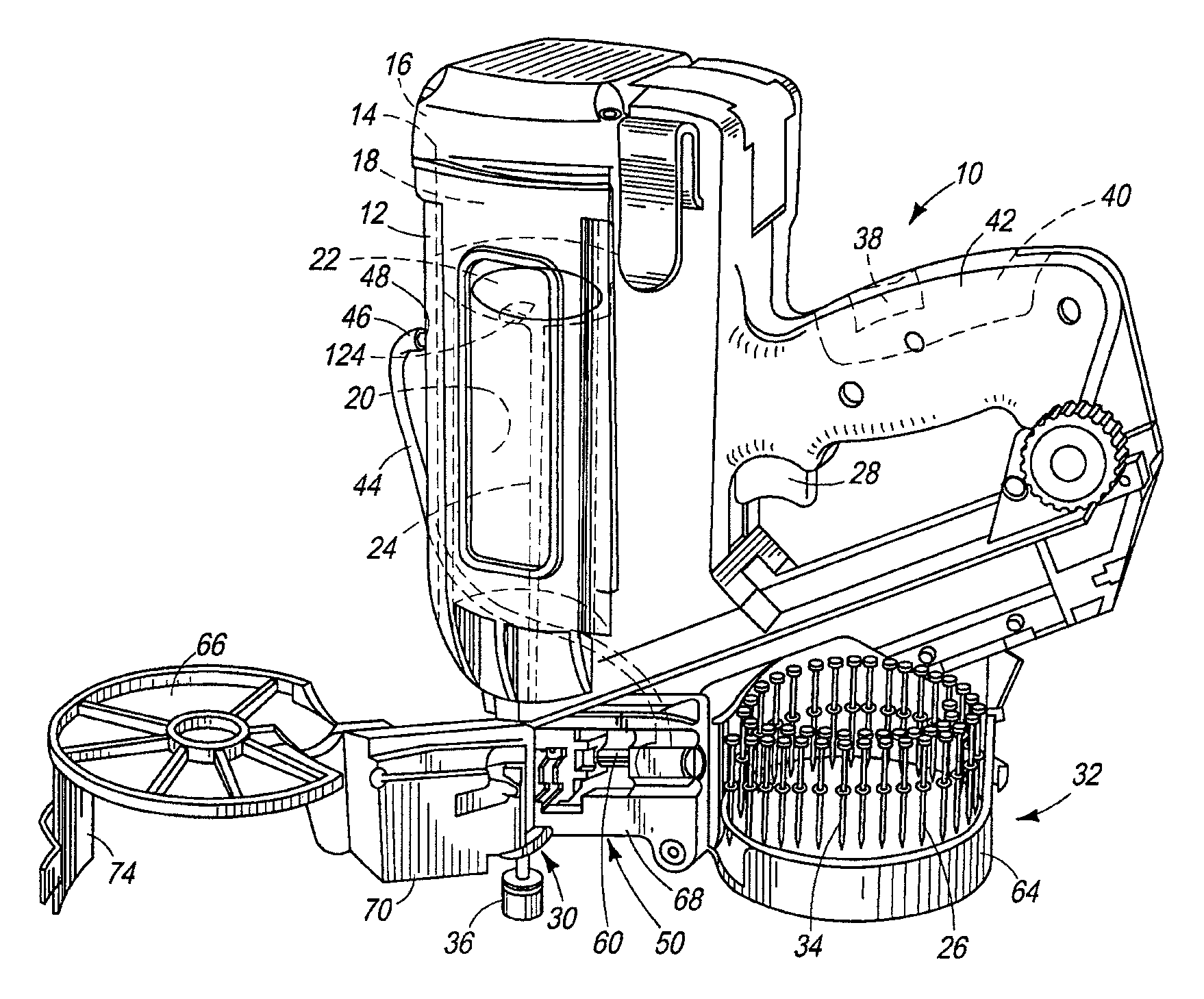

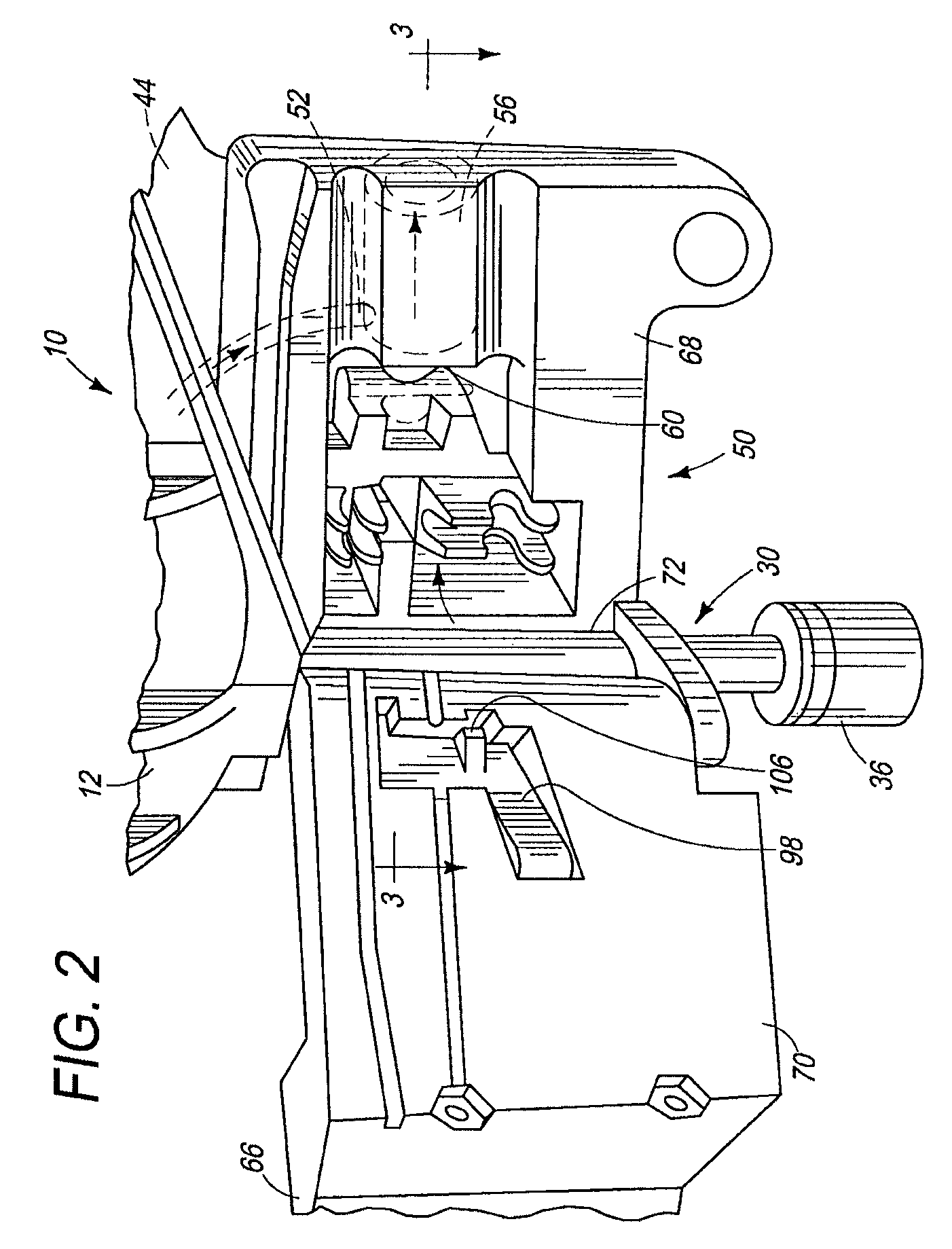

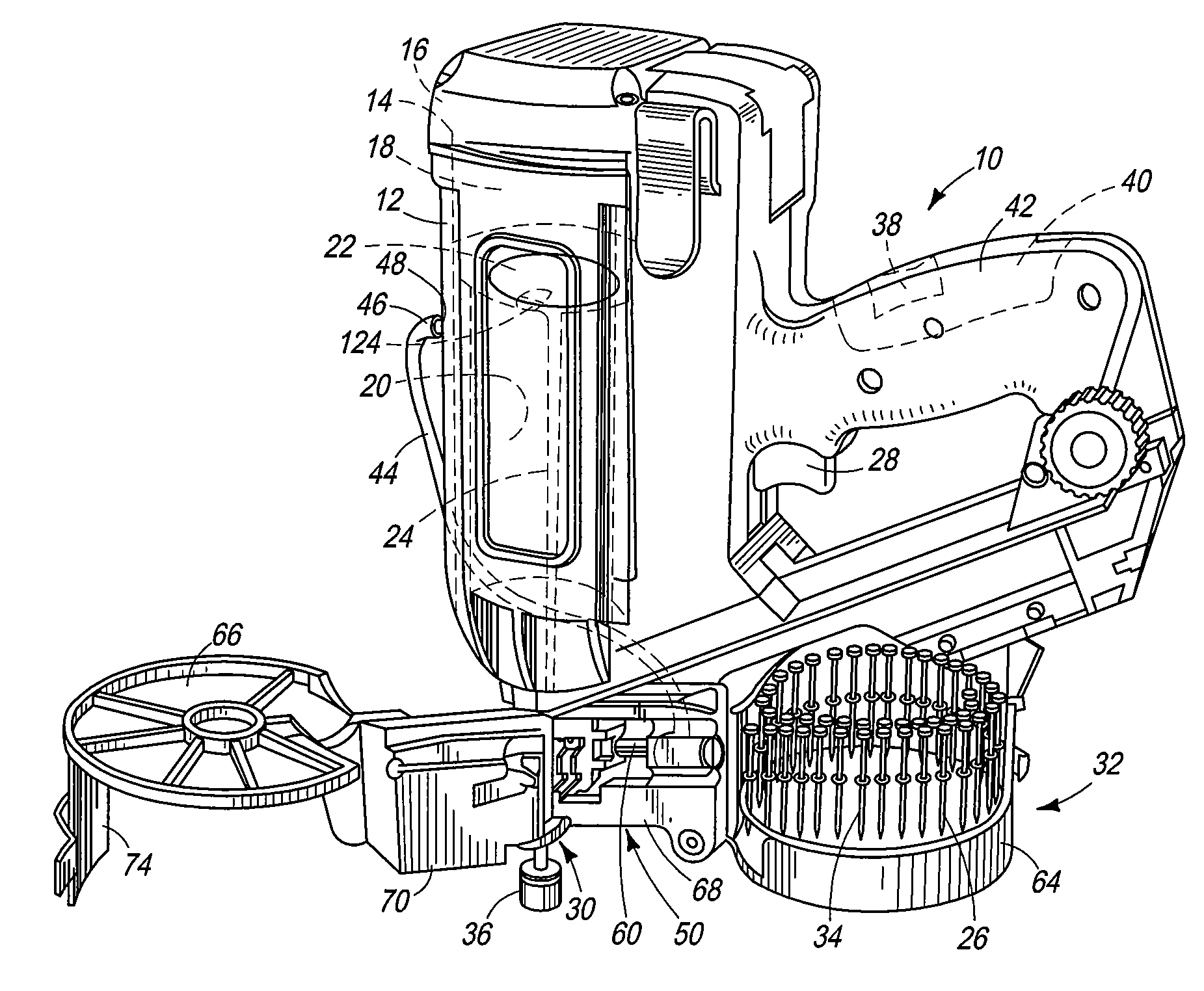

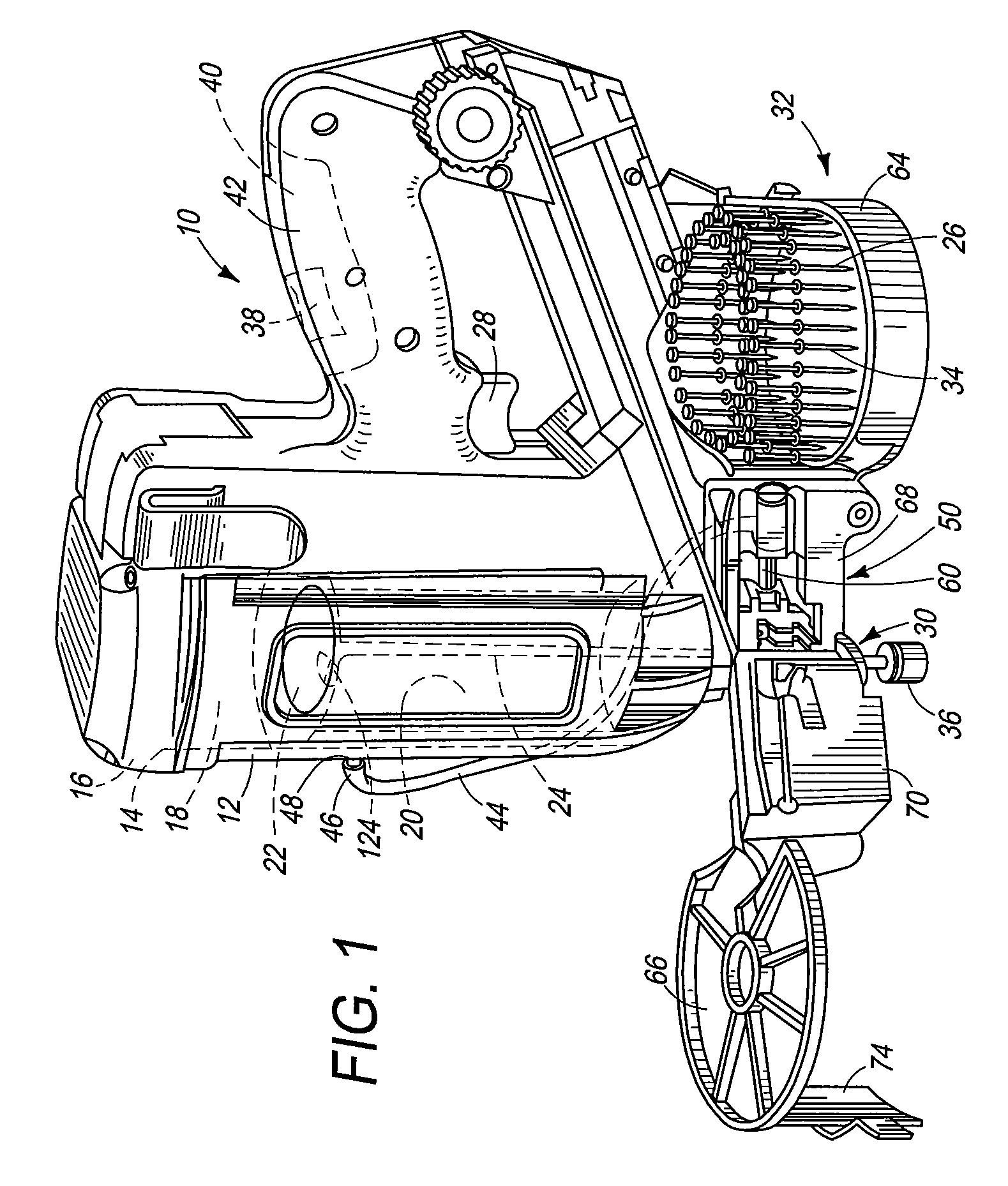

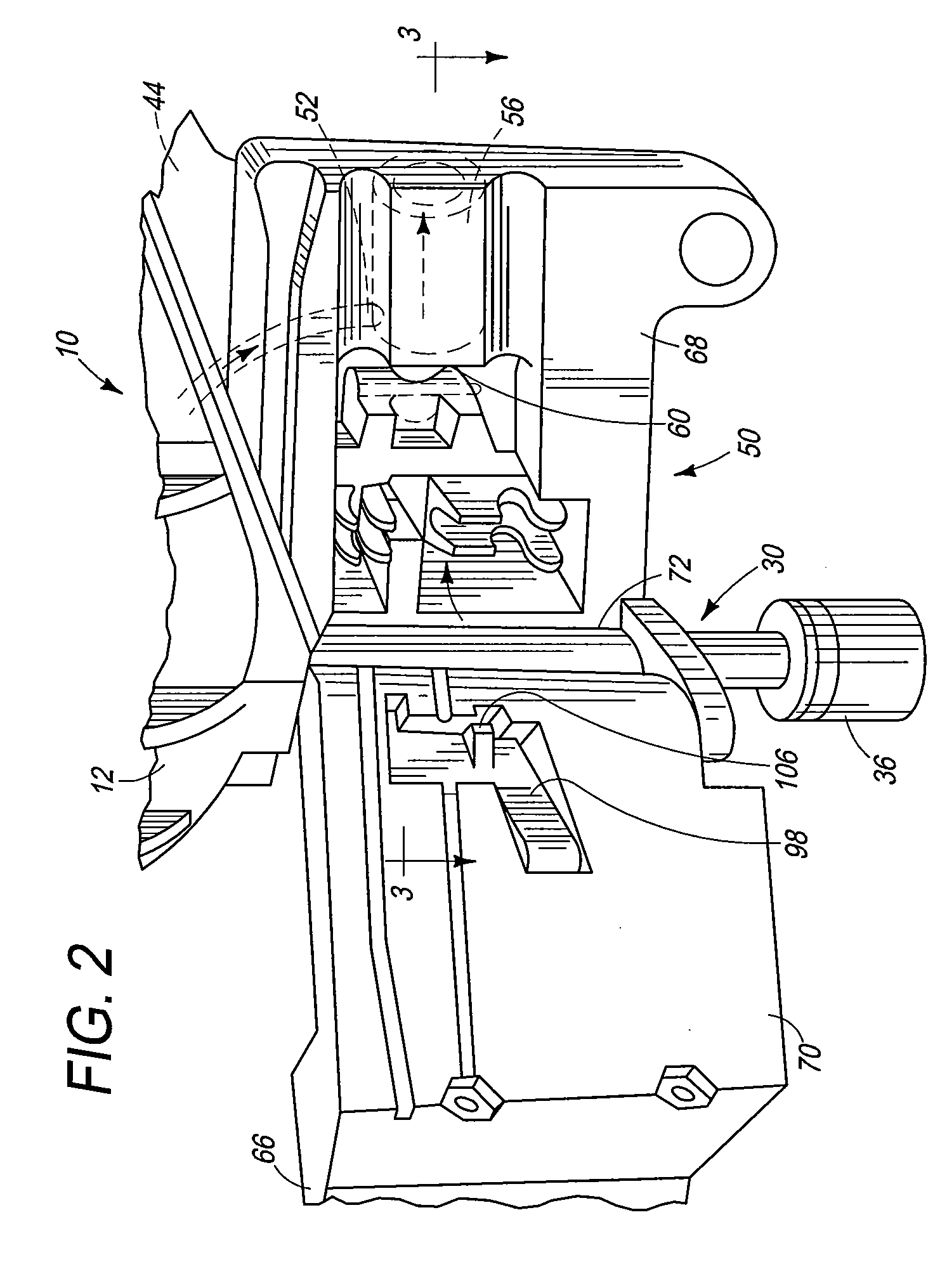

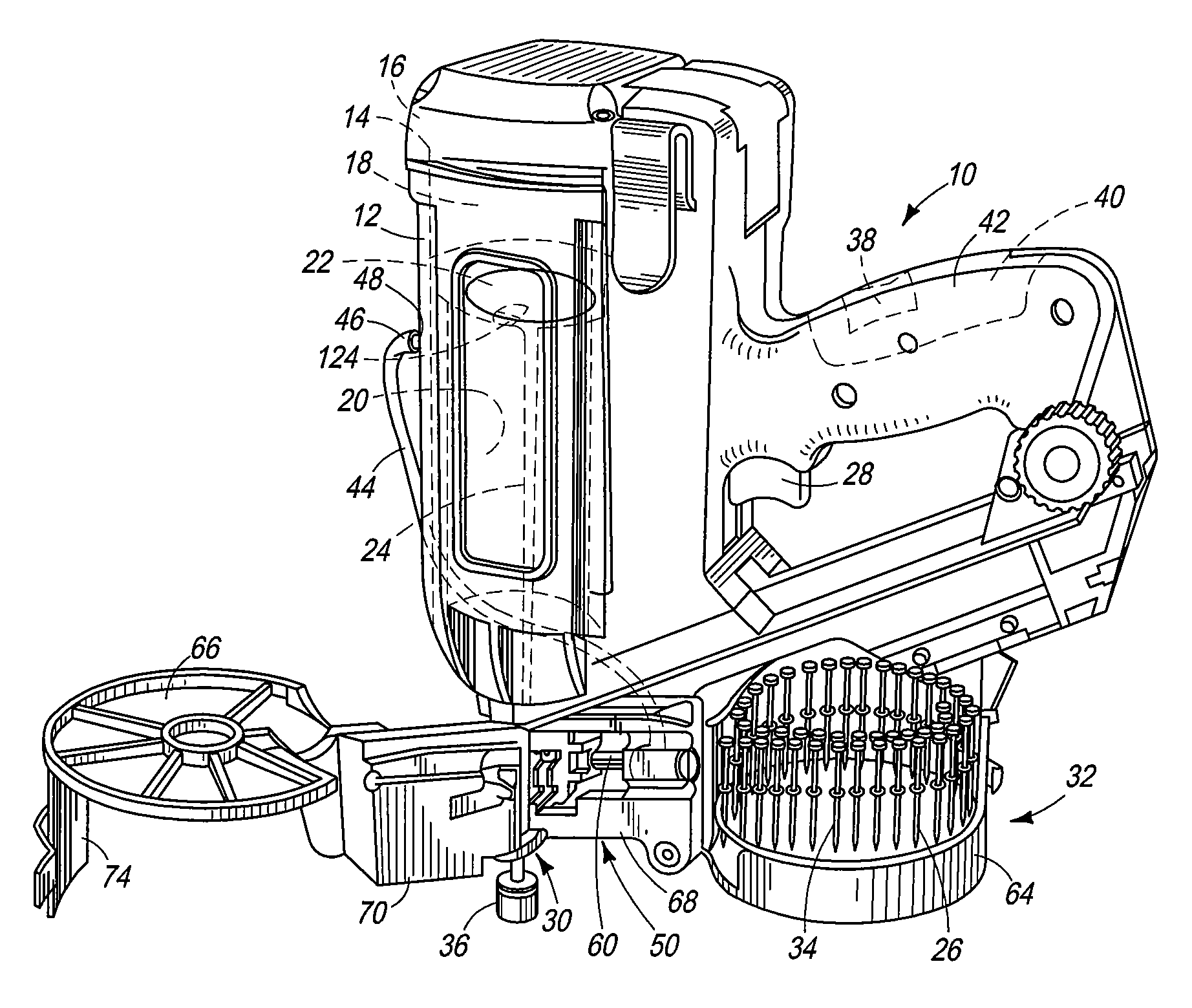

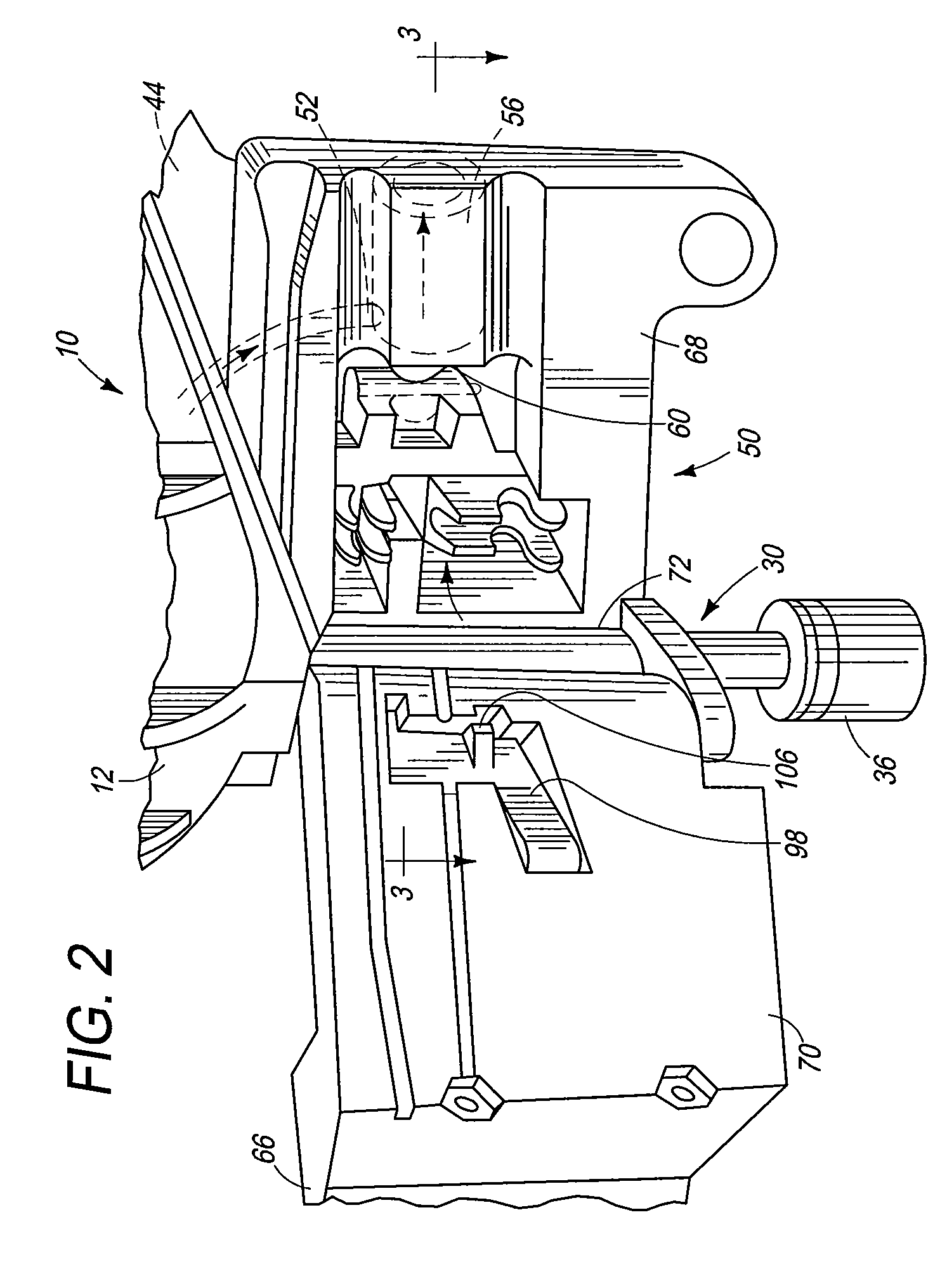

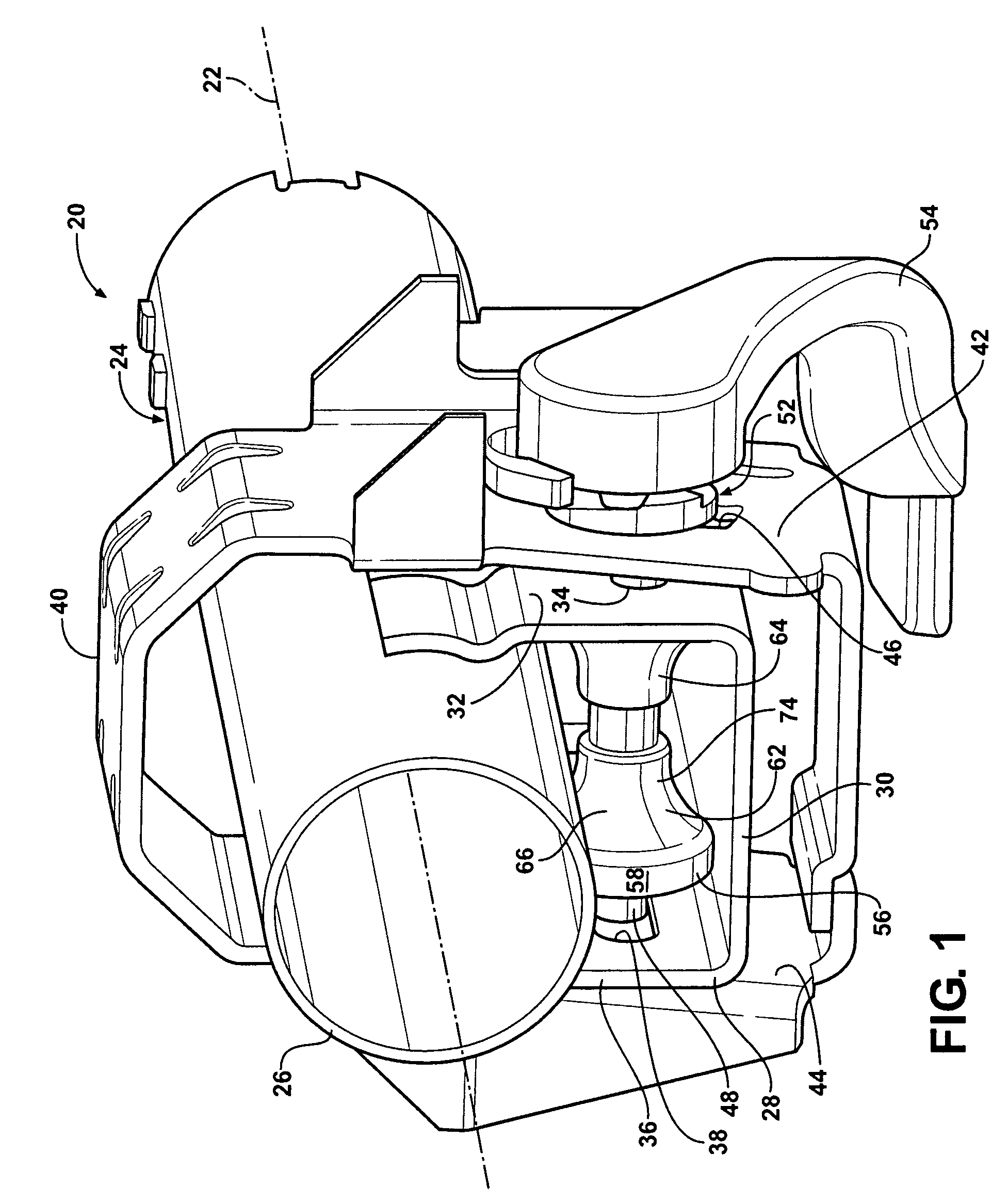

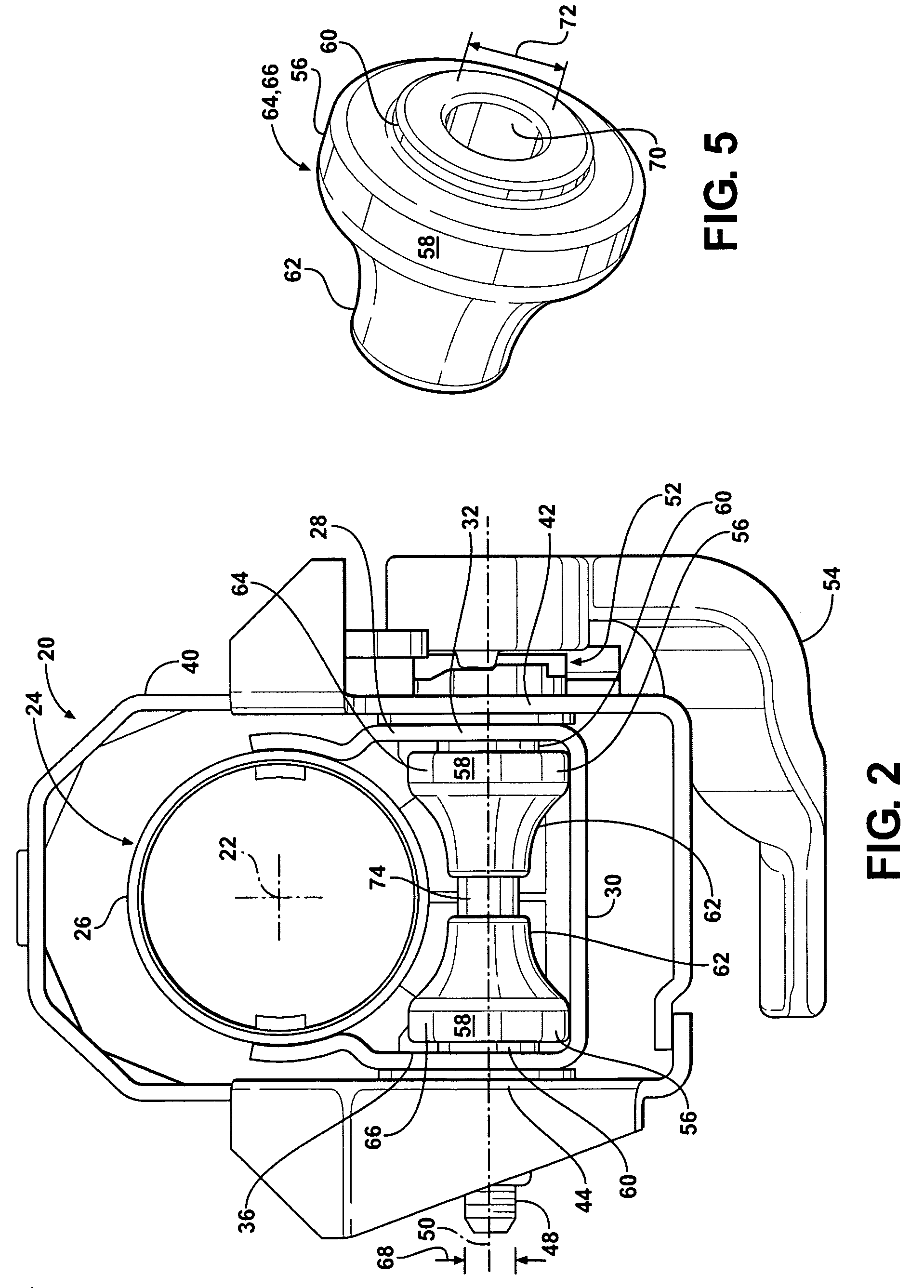

Fastener feeder delay for fastener driving tool

ActiveUS8302832B2Reduce failureExtended service lifeStapling toolsNailing toolsReciprocating motionPiston

A fastener driving tool includes a power source including a cylinder, a piston with a driver blade reciprocating in the cylinder, a tool nose associated with the power source for receiving the driver blade for driving fasteners fed into the nose, and a magazine housing a supply of the fasteners. A magazine feeder mechanism is associated with the magazine for sequentially feeding fasteners into the nose, and the feeder mechanism includes a reciprocating feed piston. A conduit is connected between a port in the cylinder and the feed mechanism for diverting combusted gas for activating the feed piston. The port is disposed in the cylinder a specified distance below a piston prefiring position, and the distance is reflective of a delay of feeding the gas to the feed piston at least until engagement between an end of the driver blade and a head of a fastener in the tool nose.

Owner:ILLINOIS TOOL WORKS INC

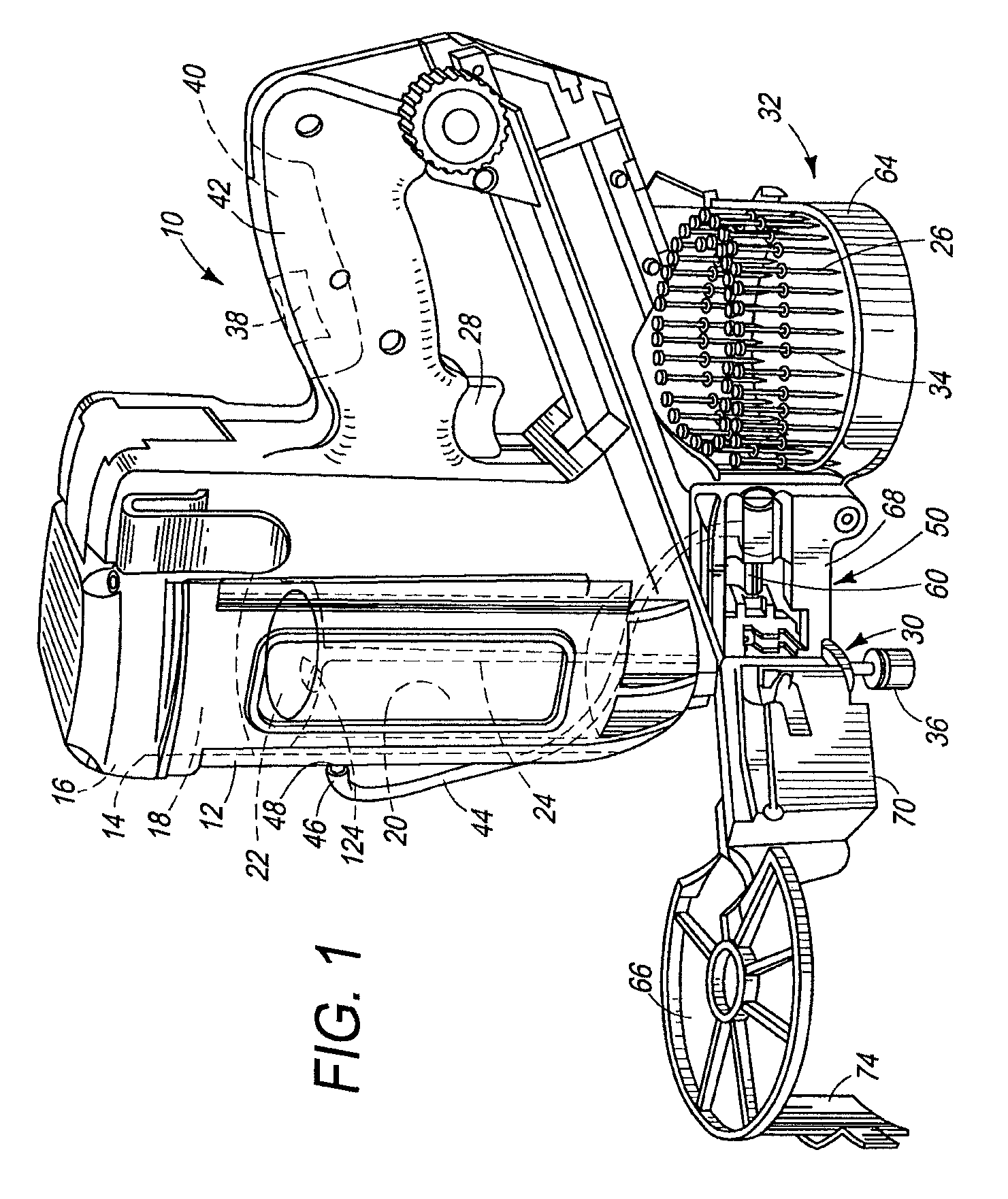

Feeder mechanism retention device for fastener driving tool

ActiveUS20080314953A1Reduce nail and collation malfunctionIncrease operational lifeStapling toolsNailing toolsFastenerEngineering

A fastener driving tool includes a power source including a reciprocating driver blade, a tool nose associated with the power source for receiving the driver blade for driving fasteners fed into the nose, a magazine constructed and arranged to house a supply of the fasteners, a magazine feeder mechanism associated with the magazine for sequentially feeding fasteners into the nose, the feeder mechanism including, operating between a retracted position and an advanced position and an electromechanical retention device that is operationally associated with the feeder mechanism and configured for retaining the mechanism in the retracted position until the driver blade is positioned to allow fastener advancement into the nose.

Owner:ILLINOIS TOOL WORKS INC

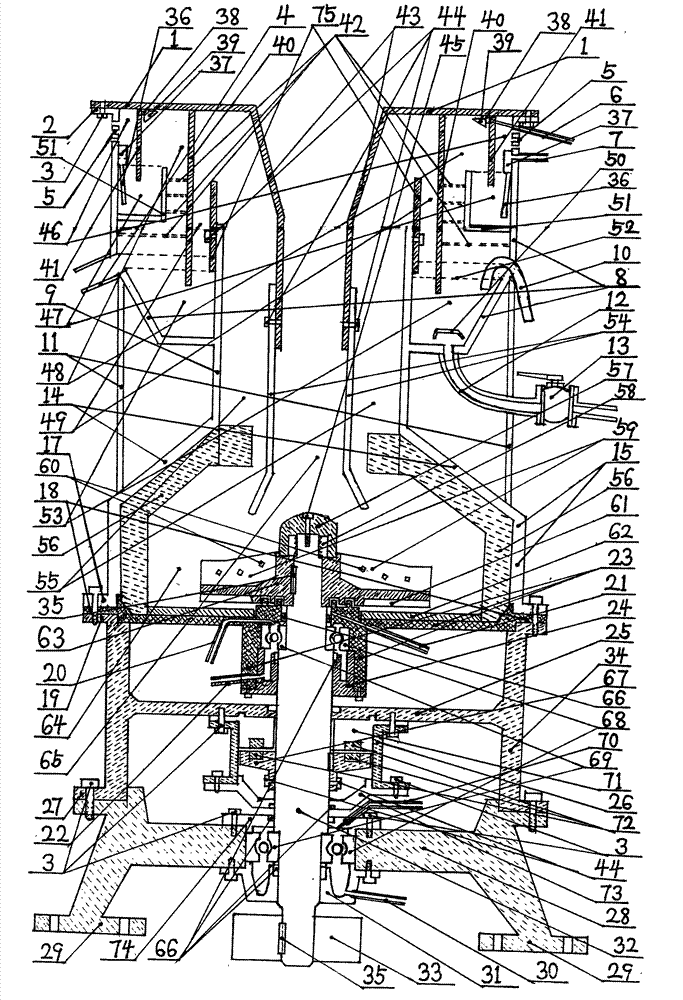

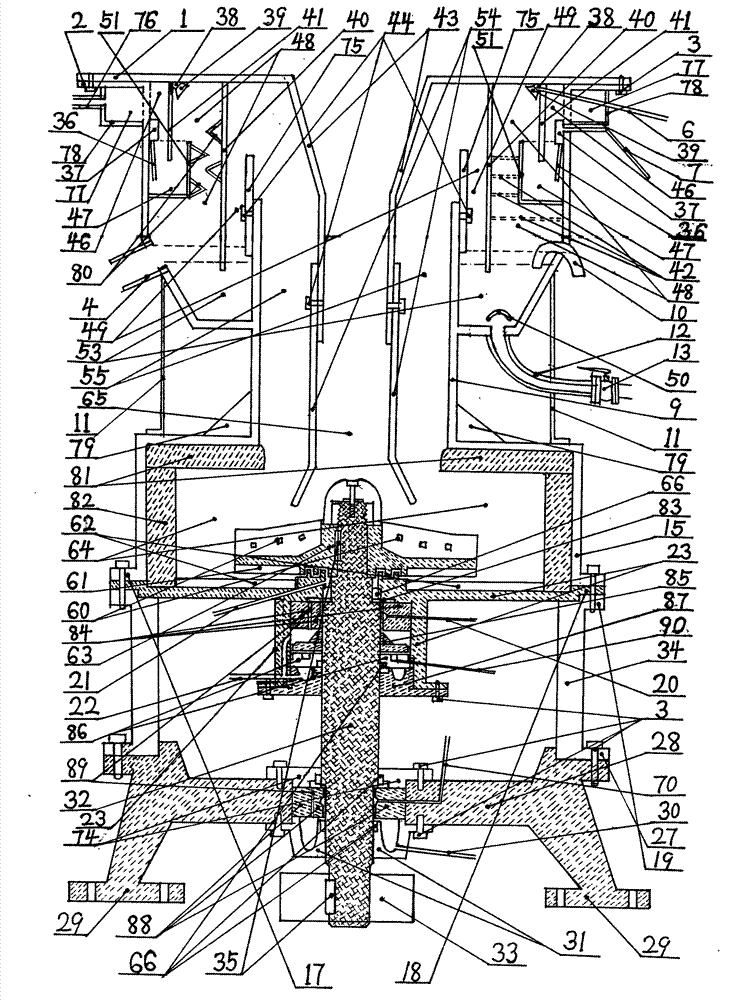

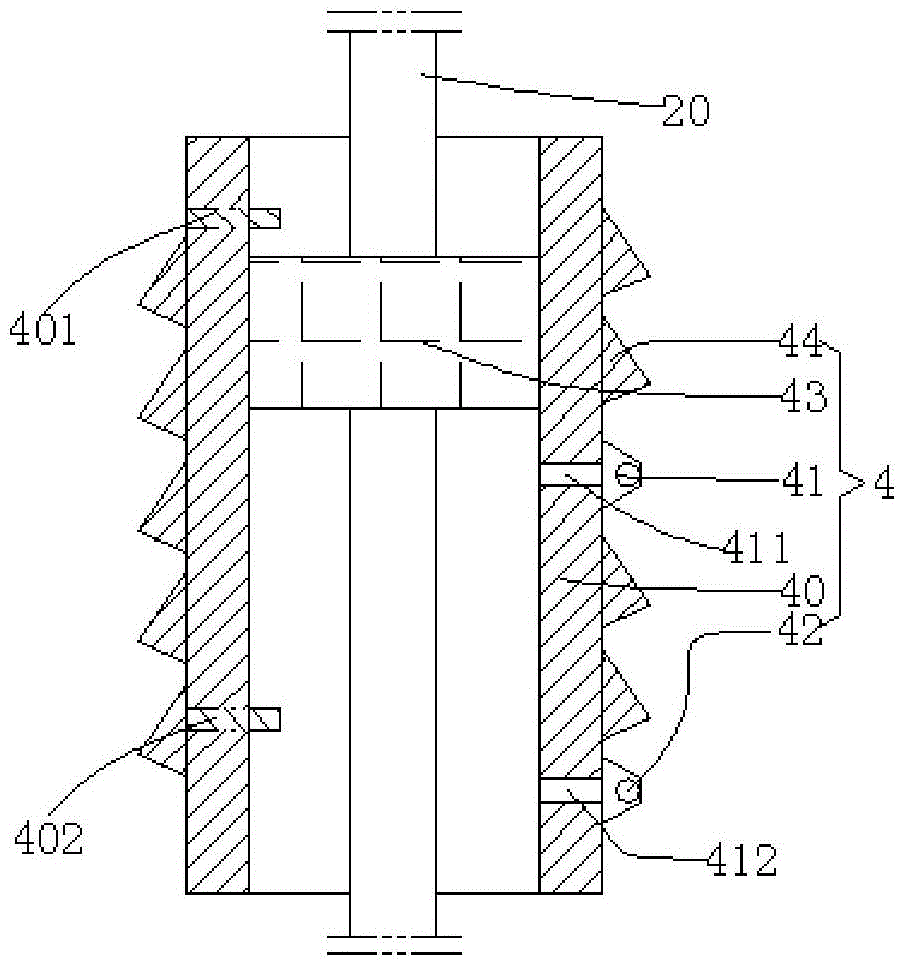

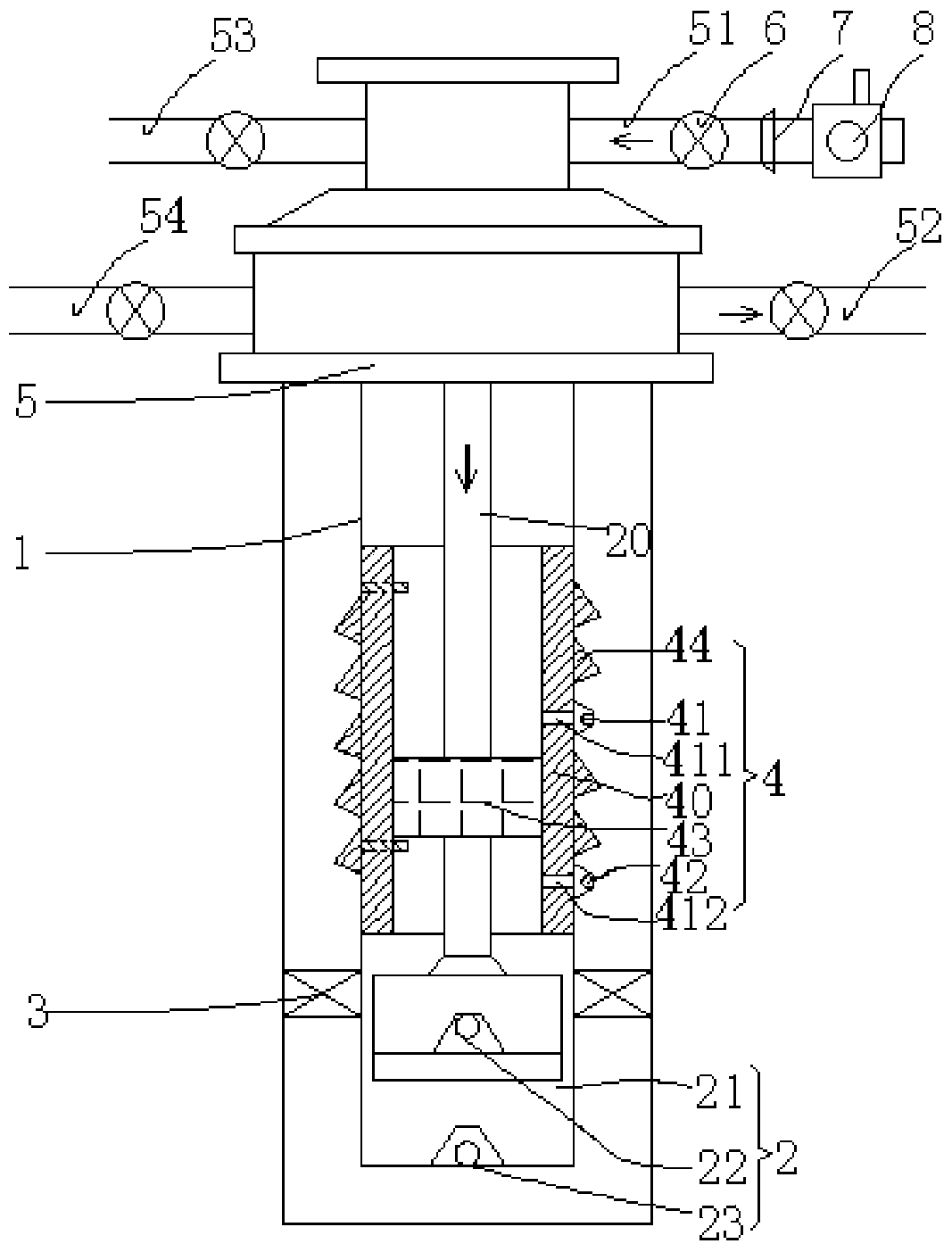

Medium-free micro pulverizer

The invention provides an ore crushing machinery without adding a crushing medium, which is a dry crushing machinery with a tower type structure; a rotating part is in the form of a longitudinal rotating shaft; one or more impeller main bodies are mounted on a shaft in series; a plurality of replaceable wear resistant blades and surface protective plates are arranged on each impeller main body, so that the impeller main body forms a rotor impeller group assembly with single-layer or multi-layer blades; a wear resistant lining layer, which comprises an upper lining plate, a material guide lining plate, an arc main lining plate, a bottom lining plate, a wear resistant fixing ring and so on, is correspondingly arranged on the periphery of each impeller; an interior cavity of each impeller forms a crushing chamber; and the crushing chambers in various stages are communicated with each other in a vertical direction. The ore crushing machinery provided by the invention has the advantages of high one-time crushing efficiency, high fine powder qualified rate, convenience in controlling, wide inlet material particle range, long service life, convenience in maintenance and no dust and noise pollution, and is very suitable for ore dressing metallurgy and architectural material industries; and standard dry powders or ore pulps can be directly produced, so that the production process is greatly simplified and production cost is reduced.

Owner:王瑞琪

Feeder mechanism retention device for fastener driving tool

A fastener driving tool including a power source having a reciprocating driver blade, a tool nose associated with the power source for receiving the driver blade for driving fasteners fed into the nose, a magazine constructed and arranged to house a supply of the fasteners and a magazine feeder mechanism associated with the magazine for sequentially feeding fasteners into the nose. The feeder mechanism operates between a retracted position and an advanced position. An electromechanical retention device is operationally associated with the feeder mechanism and is configured for retaining the feeder mechanism in the retracted position until the driver blade is positioned to allow fastener advancement into the nose.

Owner:ILLINOIS TOOL WORKS INC

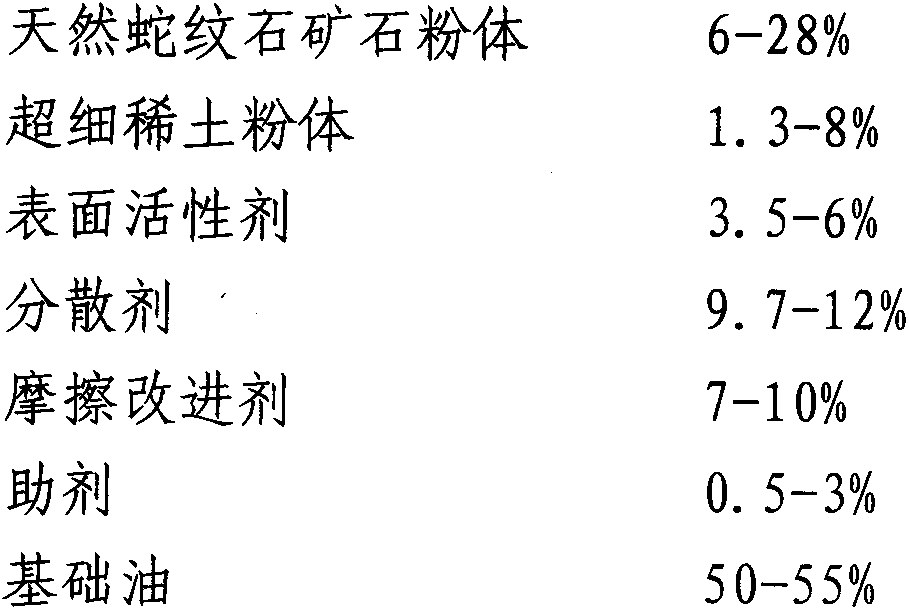

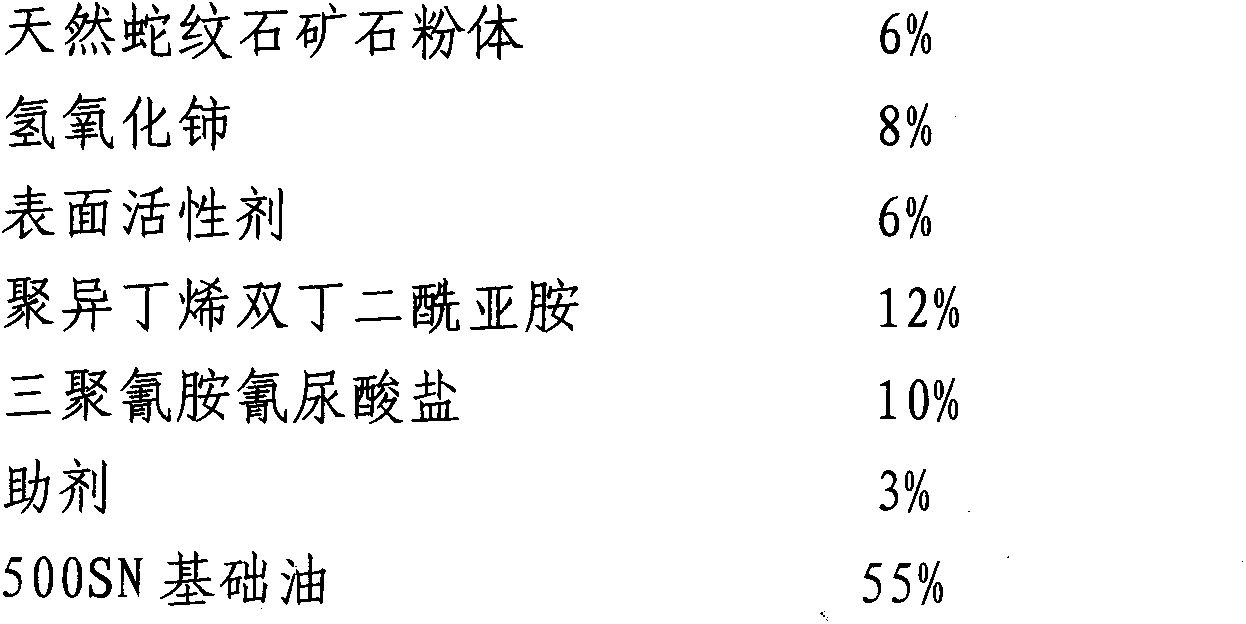

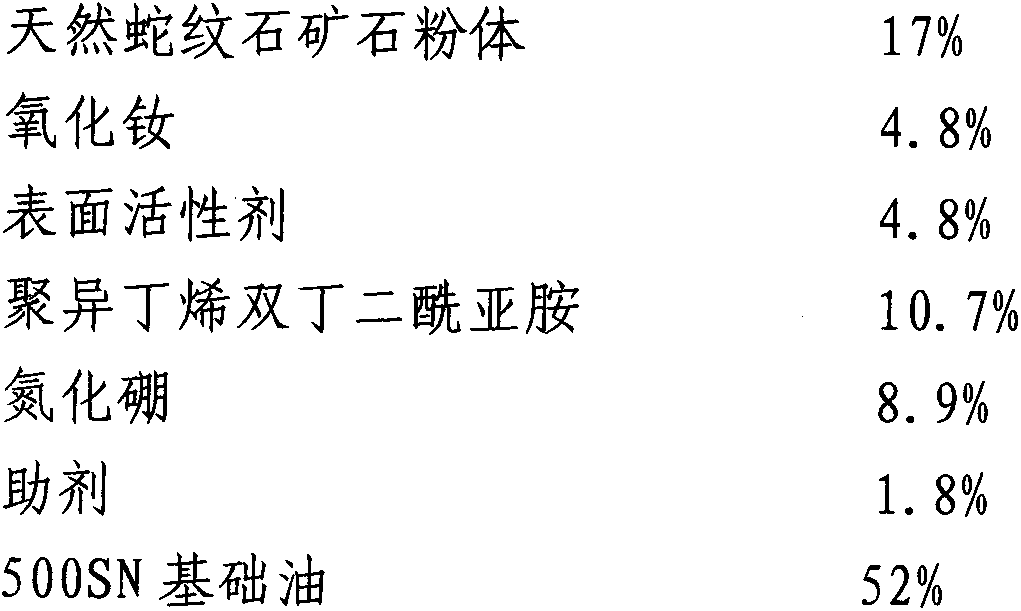

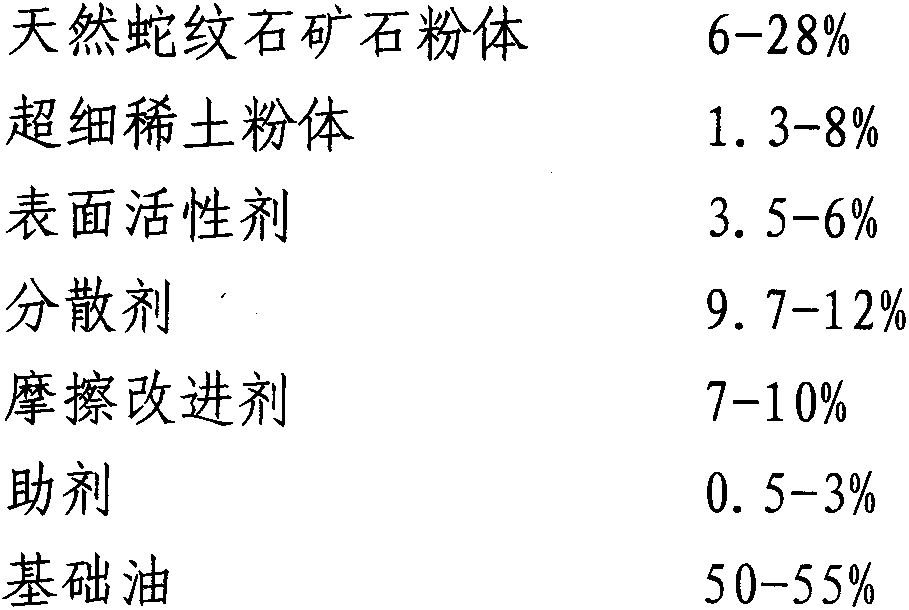

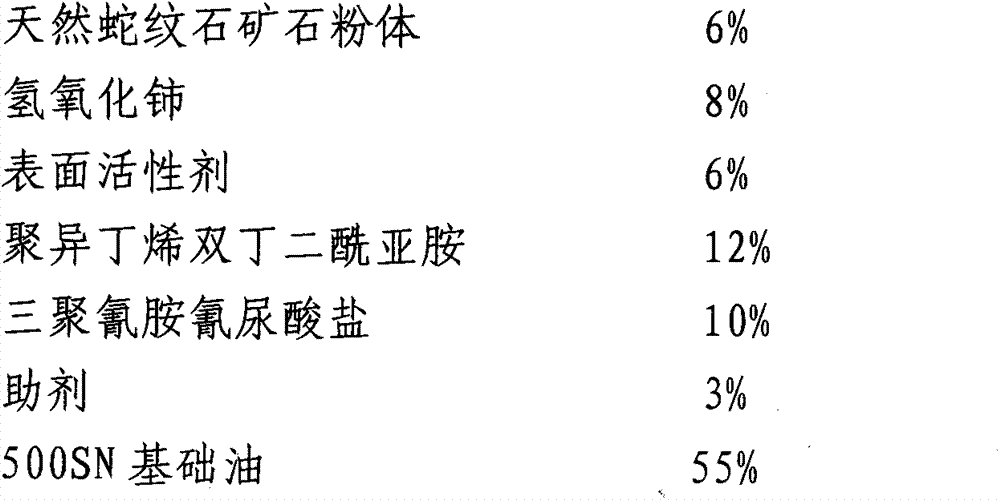

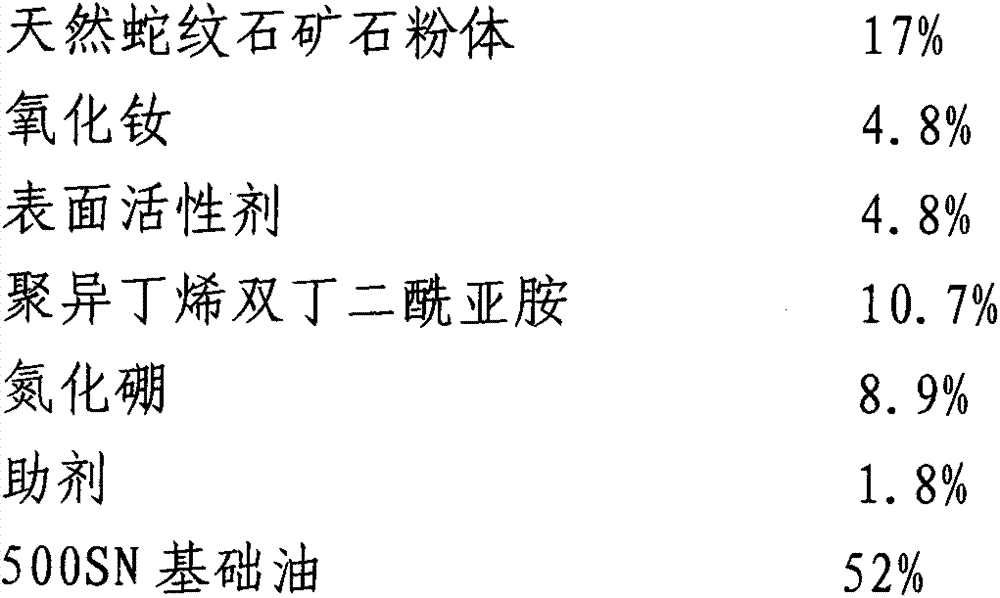

Lubricating oil additive containing ultrafine rare-earth powder

InactiveCN103642569AAvoid direct contactReduce harmful ingredientsLubricant compositionPhosphateOil additive

The invention relates to a lubricating oil additive containing ultrafine rare-earth powder. The additive consists of the following components in percentage by mass: natural serpentine mineral powder, ultrafine rare-earth powder, surfactant, a dispersing agent, a friction modifier, an auxiliary and base oil, wherein the ultrafine rare-earth powder is one of cerium hydroxide, neodymium oxide and cerium fluoride; the surfactant is borate, span-60 or oleic acid; the dispersing agent is either polyisobutene dibutyl succinimide or high molecular weight polyisobutene dibutyl succinimide; the friction modifier is one of melamine cyanurate, boron nitride and calciuym nitride; the auxiliary comprises 72% of dialkyl disulfo oxygen molybdenum phosphate sulfide, 18% of polymethyl tetradecyl acrylate and 10% of a vinyl-propylene copolymer; and the base oil is 500SN base oil. The additive has obvious corrosion resistance; and after an engine is treated technically by using the self-repairing additive, the dry friction coefficient of the machine is reduced from original 0.05 to be less than 0.005 and therefore the surface abrasion is reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

Fiber delivery apparatus and system having a creel and fiber placement head with polar axis of rotation

ActiveUS20120090788A1Improve protectionReduce any negative affects on fiber towsEngine sealsLamination ancillary operationsFiberMechanical engineering

A fiber placement system including positioner and a fiber delivery apparatus having a creel assembly and a fiber placement head is provided. The positioner moves the entire fiber delivery apparatus including the creel assembly and the fiber placement head via at least three linear degrees of freedom. The fiber delivery apparatus includes an articulating wrist for moving the fiber placement head relative to the creel assembly. The fiber placement apparatus is substantially free of linear degrees of freedom within the fiber tow paths between the spools and the fiber placement head. One or more rotational degrees of freedom may be provided along the tow path. In one embodiment, the interface between the fiber delivery apparatus and the positioner is laterally offset such that a portion of the creel axially overlaps with vertical ram of the positioner.

Owner:INGERSOLL MACHINE TOOLS

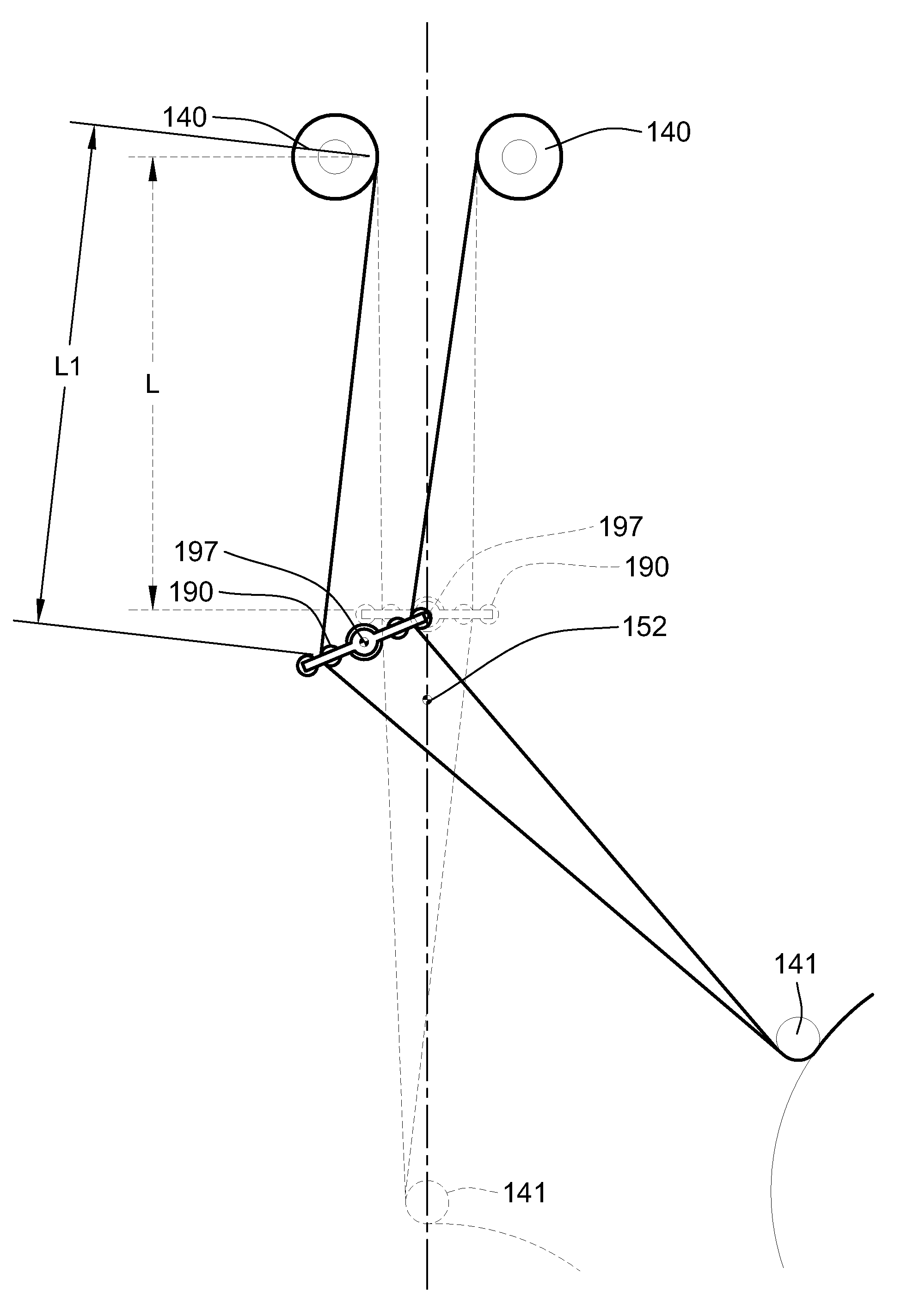

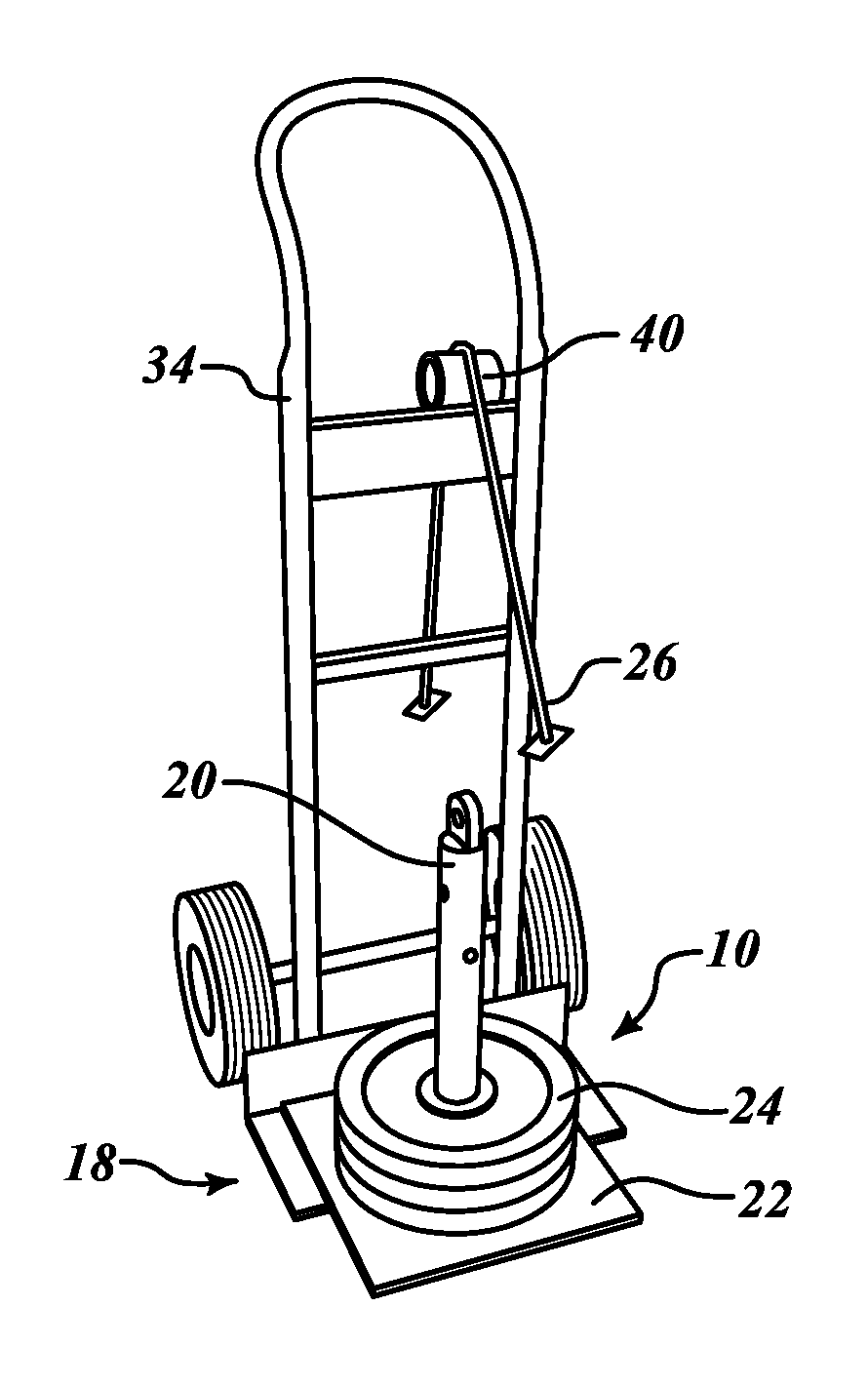

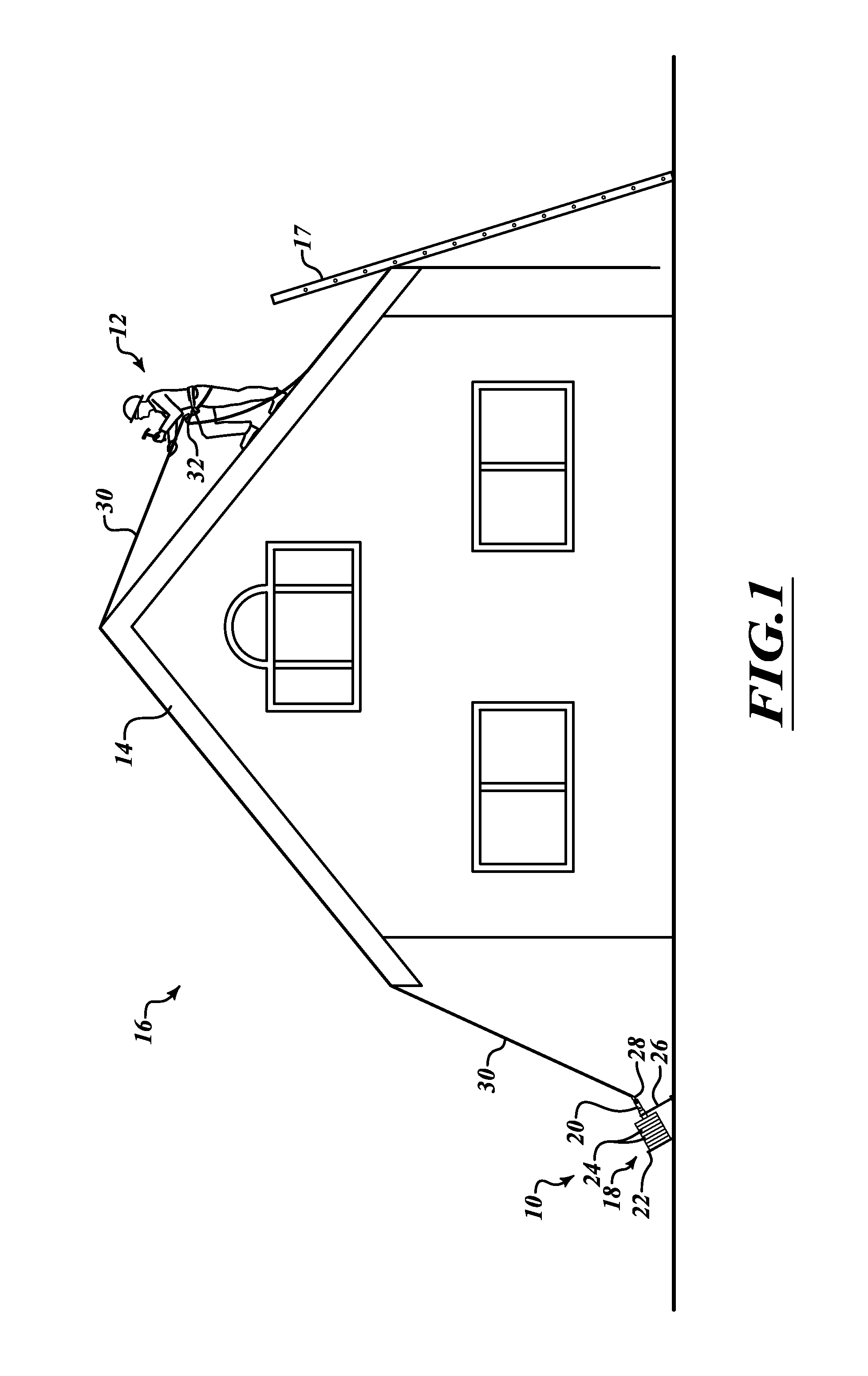

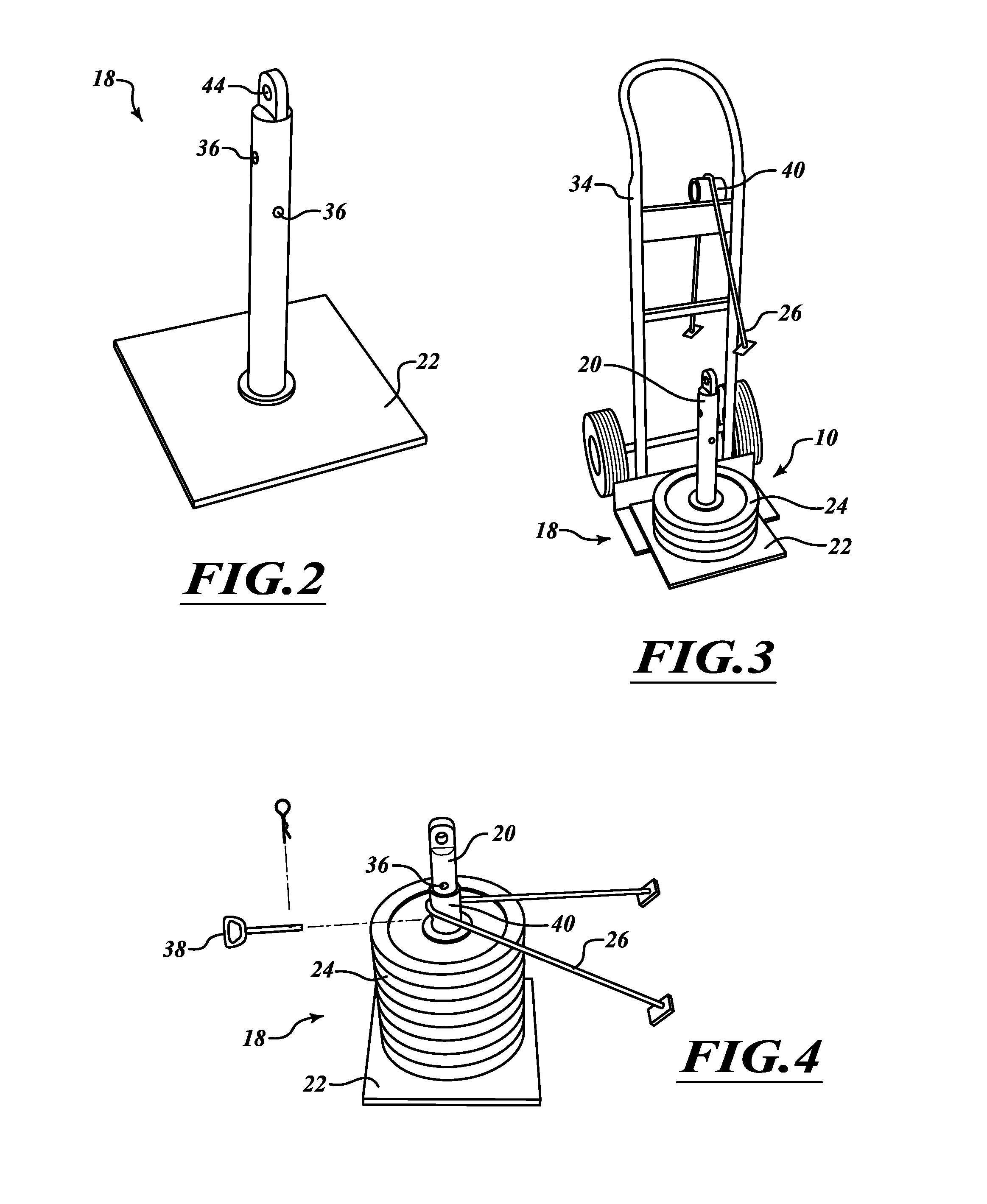

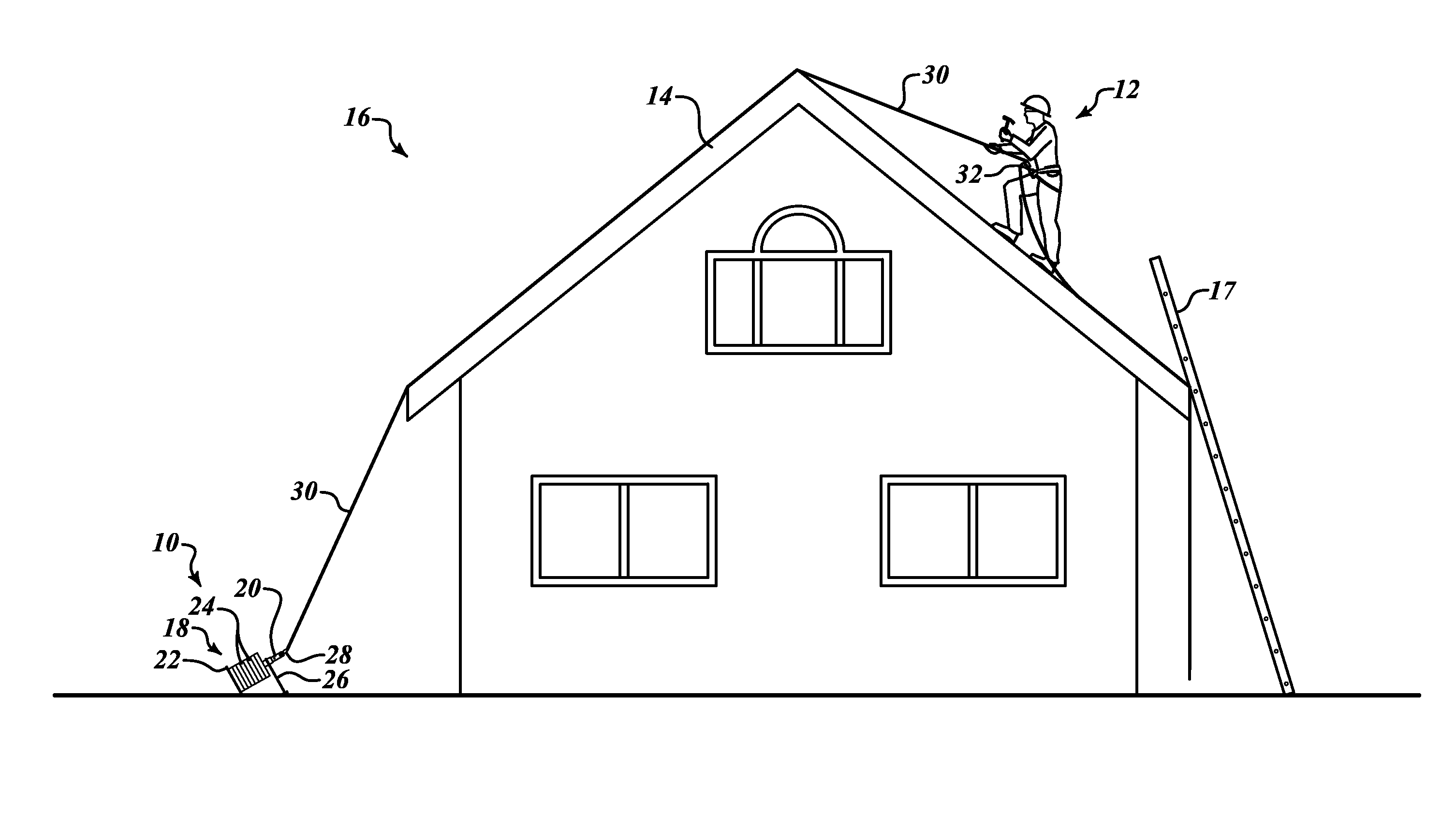

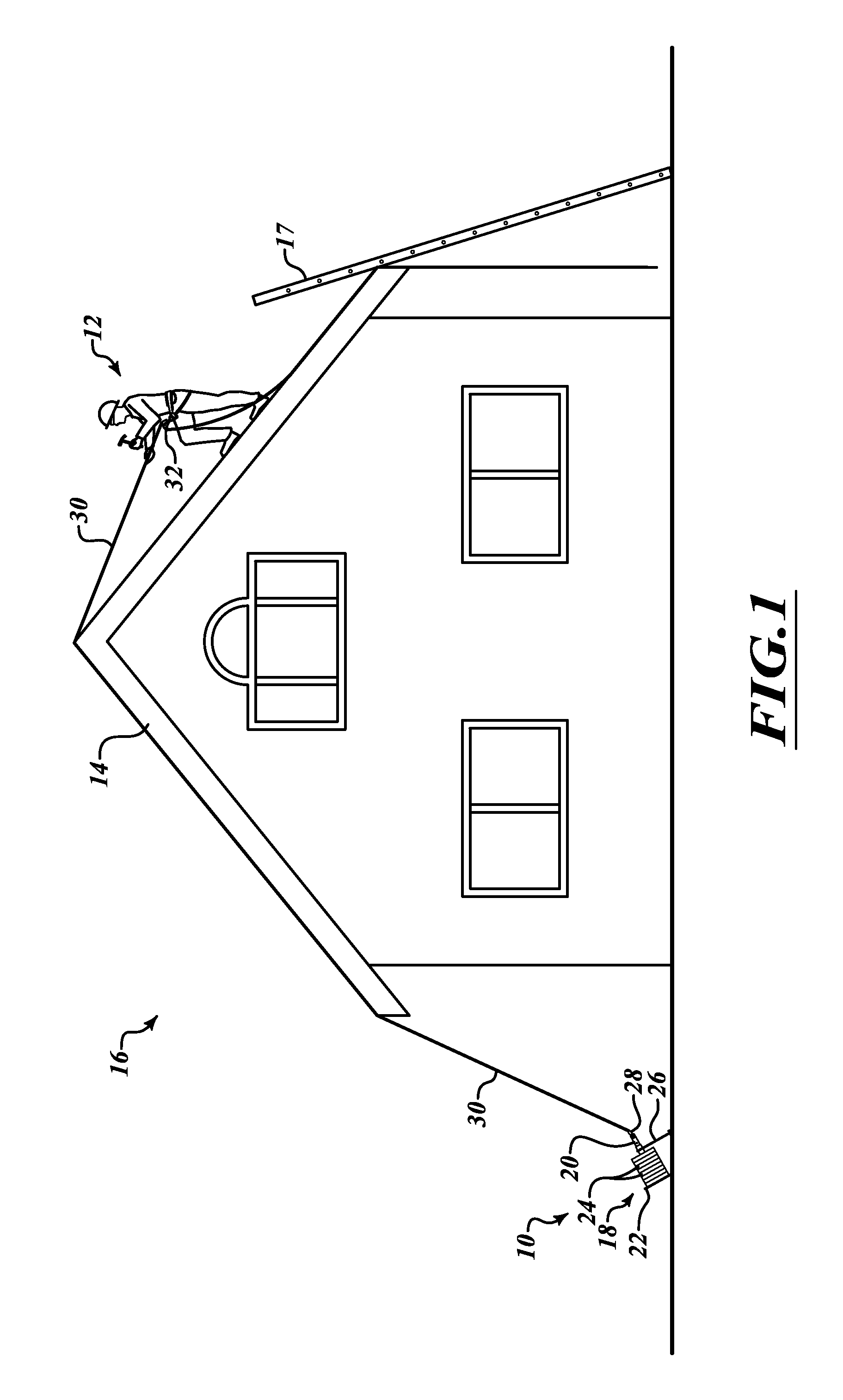

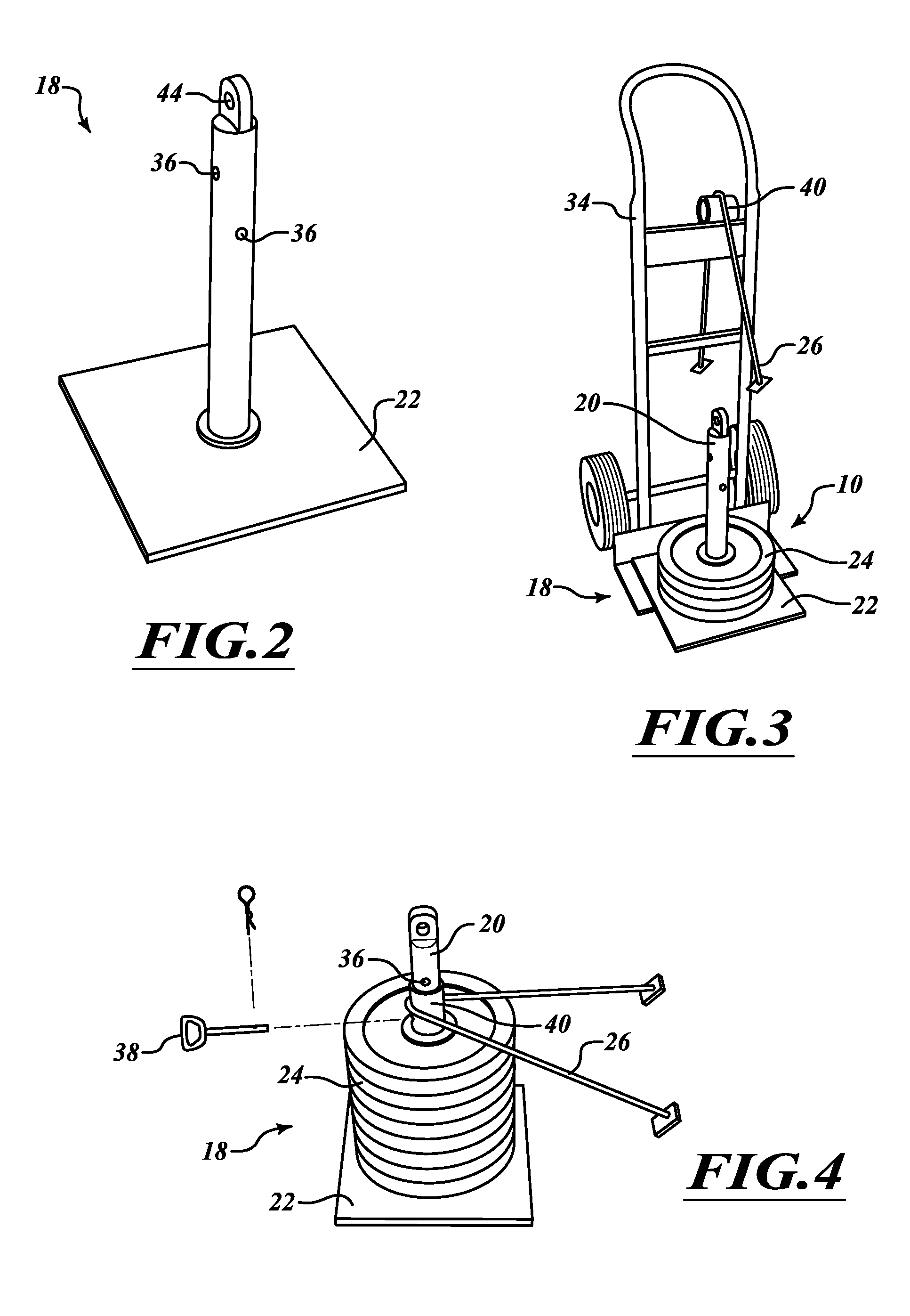

Single person portable belay anchor system and method

A portable belay anchor system is disclosed that provides a coupling location for safety rope attached to a climber, such as a roof inspector. The portable belay anchor system includes a base having a mast coupled thereto. The mast has a shaft portion and a flange portion. A plurality of removable weights are positioned on the shaft, coupled to the flange portion. The flange portion supports the weights so that the weight is carried by the shaft itself. A retaining member is coupled to the mast to hold the weights on the mast. A shackle is also coupled to the mast. A rope is coupled to the shackle to act a the belay rope which the user positions through a belay brake device.

Owner:PILOT CATASTROPHE SERVICES

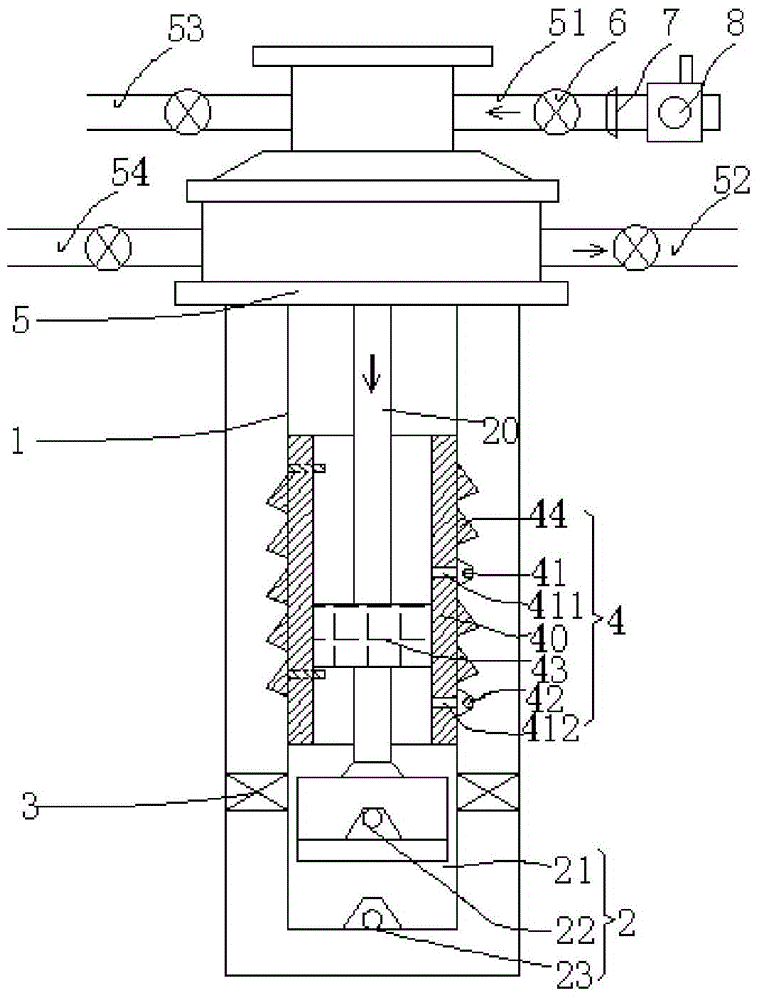

Flow distributing device, heavy oil viscosity decreasing exploitation system and extraction method thereof

The invention discloses a flow distributing device, a heavy oil viscosity decreasing exploitation system and an extraction method thereof. The flow distributing device comprises a hollow body and a sliding sealing block. The hollow part is a through hole, and the upper end and the lower end of the through hole are used for being connected with oil pipes. A first opening and a second opening are formed in the side wall of the body in the axial direction. A first check valve communicated with the first opening is arranged on the first opening, and a second check valve communicated with the second opening is arranged on the second opening. The sliding sealing block is arranged in the hollow part of the body in a sealed mode, can be fixed to a pumping rod, and can move axially along with the pumping rod. The heavy oil viscosity decreasing exploitation system with the flow distributing device and the extraction method thereof can effectively extract heavy oil.

Owner:PETROCHINA CO LTD

Steering column assembly having rollers to reduce friction during column collapse

InactiveUS7988195B2Prevent sliding frictional engagementIncrease frictionSteering columnsSteering columnRolling resistance

A steering column assembly includes a column jacket having a jacket portion and a compression bracket attached thereto. The compression bracket includes a planar wall spaced from the column portion and a sidewall extending between the planar wall and the jacket portion. The sidewall defines a telescope slot extending along a longitudinal axis. A shaft extends through the telescope slot of the sidewall. A roller is supported on and rotatable about the shaft, and in rolling engagement with the planar wall. The roller positions the shaft within the telescope slot to prevent sliding frictional engagement between the shaft and the sidewall. The rolling coefficient of friction between the roller and the planar wall is less than the sliding coefficient of friction between the shaft and the sidewall to reduce a frictional load produced during longitudinal collapse of the steering column assembly.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

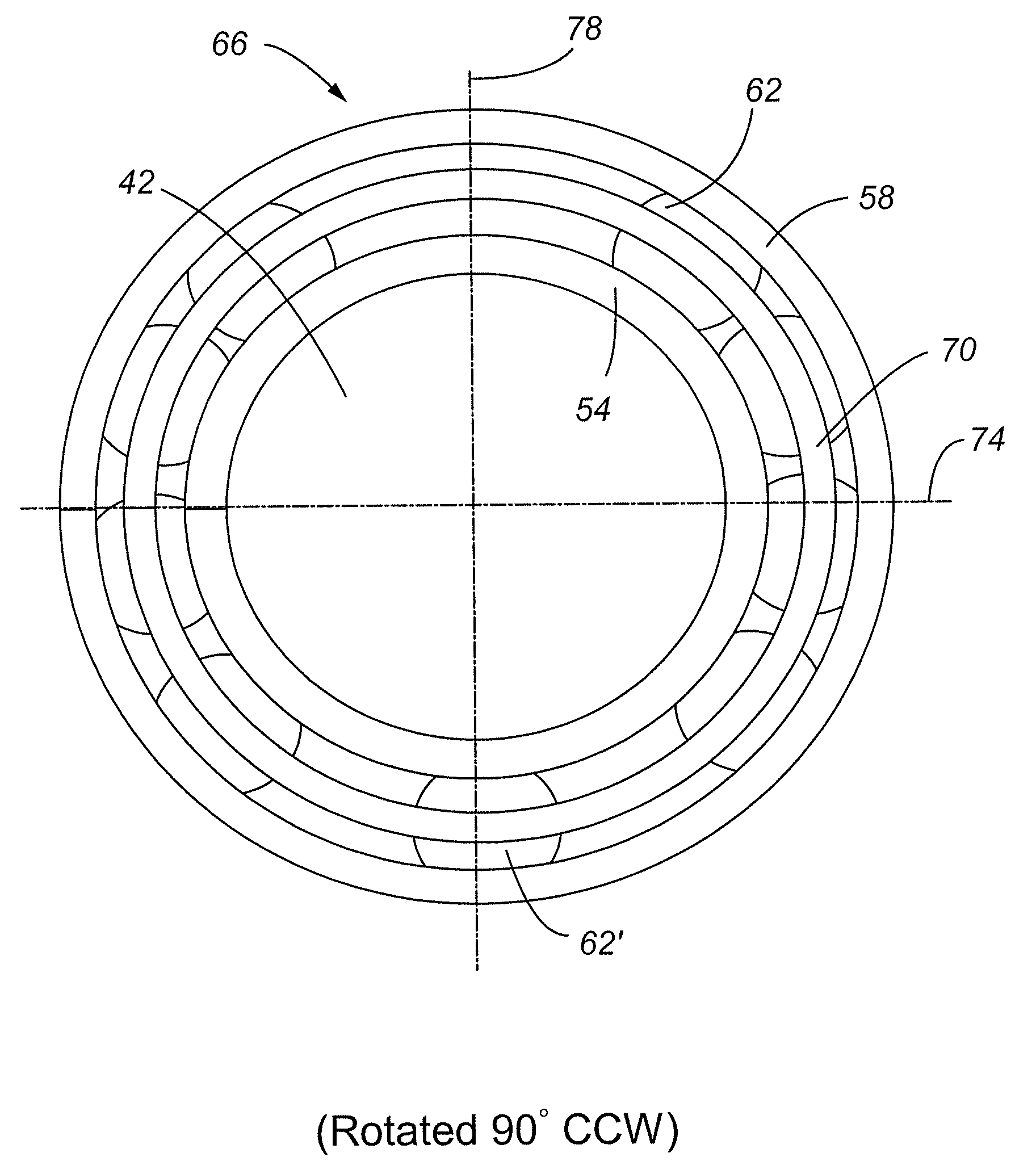

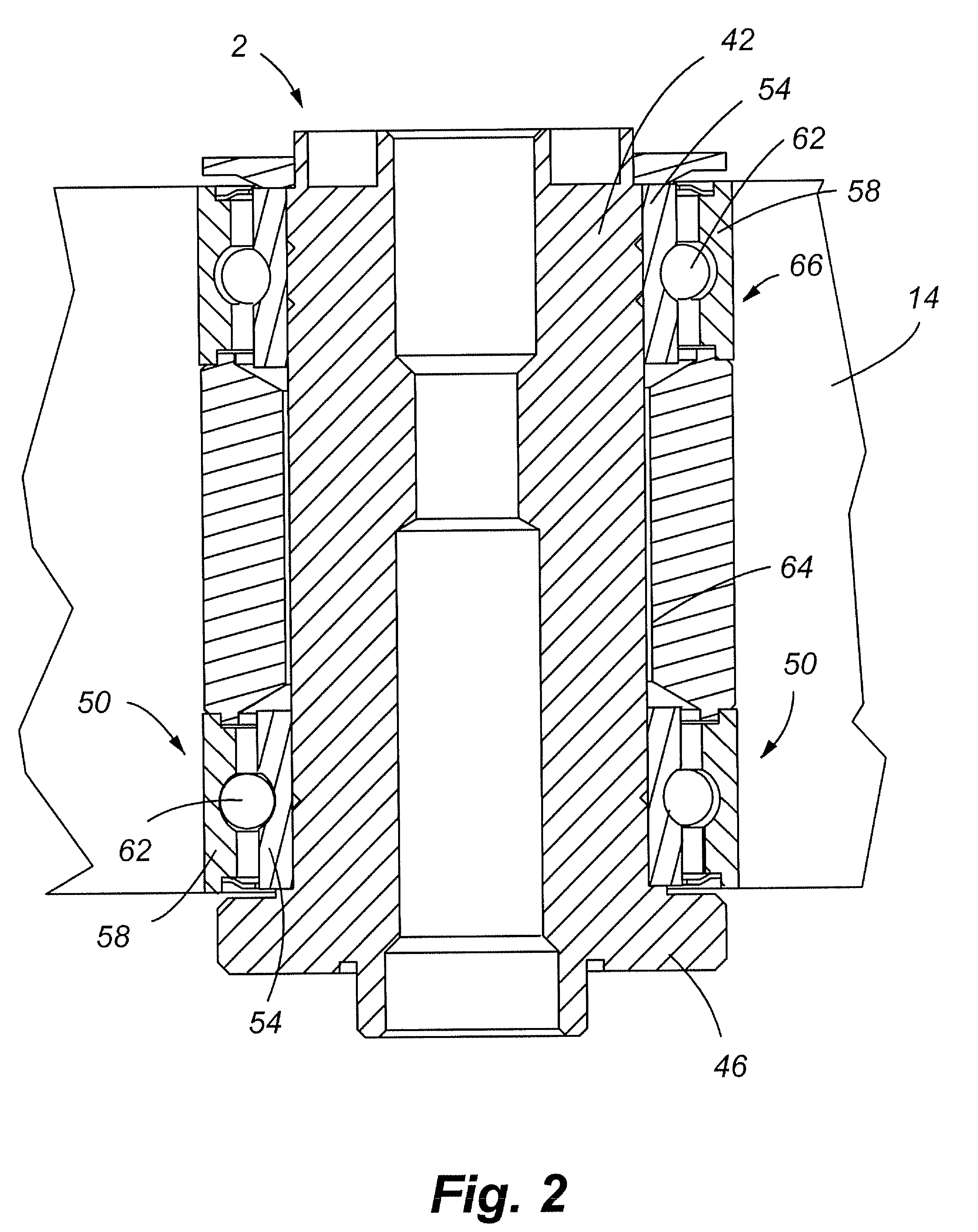

Asymmetric actuator bearing

ActiveUS20070268630A1Increase stiffnessModify ball bearing assembly stiffnessDisposition/mounting of recording headsRecord information storageBall bearingCombined use

A method is provided for maintaining the aggregate stiffness of a pivot bearing assembly generally employed along with an actuator assembly of a magnetic disk drive, while increasing the stiffness in a predetermined direction. More specifically, bearing cartridges used in conjunction with actuator assemblies of the prior art employ at least one ball bearing assembly positioned about a stationary shaft. A modification is presented herein that generally concerns repositioning and maintaining the balls of the ball bearing along a predetermined axis for efficient reaction of loads.

Owner:SEAGATE TECH LLC

Technical method of weft preparation before dyed yarn weaving

ActiveCN1710180AImproved weft yarn qualityShorten yarn-dyed processLiquid/gas/vapor yarns/filaments treatmentWater solubleYarn

The invention relates to a technique of latitude yarn preparation before color weaving. The invention features that after coloring and baking the cheese, it is directly put into production without cheese winding process. The technique requires the cheese is processed with water dissolvable waxy material while being processed with soften agent; a cheese stabling ring is needed to be installed when placing the cheese on the shelves for correcting the cheese position on the shelves, a back unrolling ring is further needed to be installed for keep the unrolling and cheese transition working freely. The invention is adaptive to various color textures production while maintaining the productivity and quality, lowering the production cost and shortening production cycle, creating social and economic profits.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

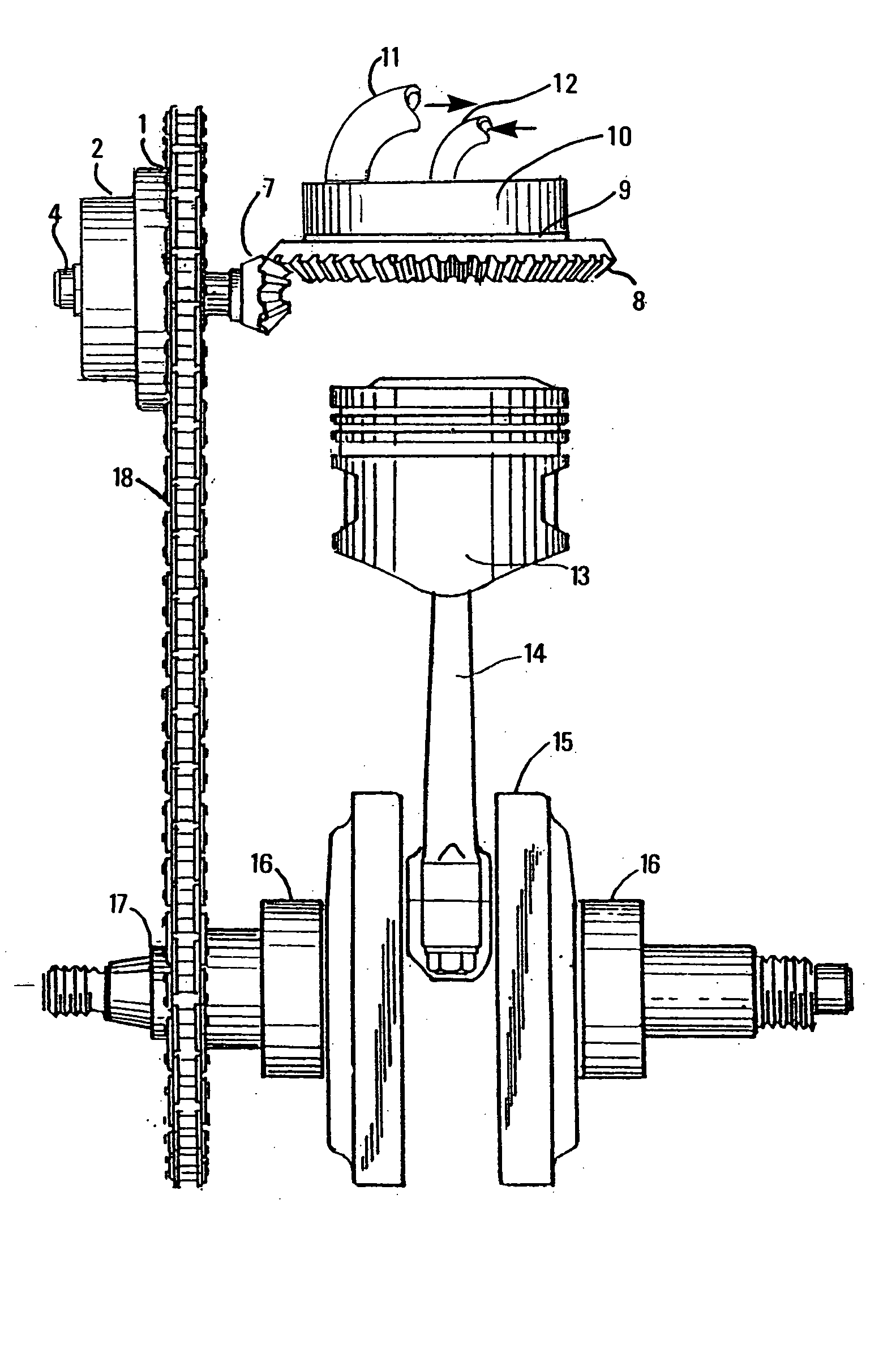

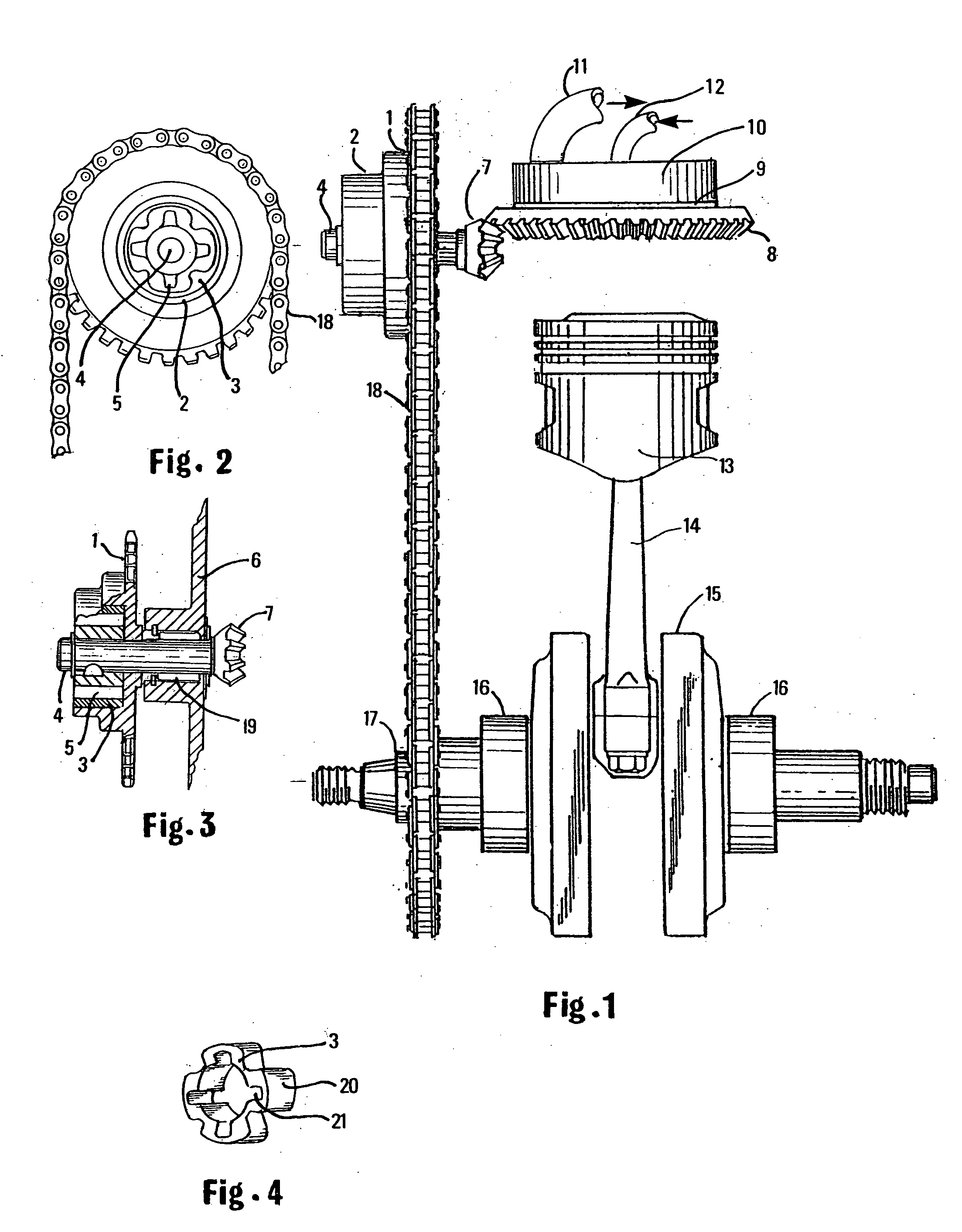

Timing gear flexible coupling

InactiveUS20050183687A1Increase torqueSliding frictionPortable liftingMachines/enginesFriction reductionPressure cycle

The invention is a timing gear flexible coupling for operation of a disc valve rotatively mounted in an internal combustion engine cylinder head. Rotation of the disc valve periodically opens and closes a plurality of exhaust and intake ports in the stationary stator of the cylinder head in a sequential manner corresponding to the alternating order of the engine of the engine thermodynamic pressure cycle. The purpose of the flexible coupling is to momentarily slow the rotational velocity of the disc valve during the highest peak pressure of the engine combustion stroke during the ignition spike which exponentially reduces the rubbing contact frictional energy between the disc and stator. The primary purpose of the timing gear flexible coupling is to reduce the shearing impact across the lubricating film at the sliding interface between the disc valve and stationary stator comprising the engine intake and exhaust ports thereby decreasing frictional surface wear and permitting faster engine acceleration.

Owner:AGAPIADES THOMAS

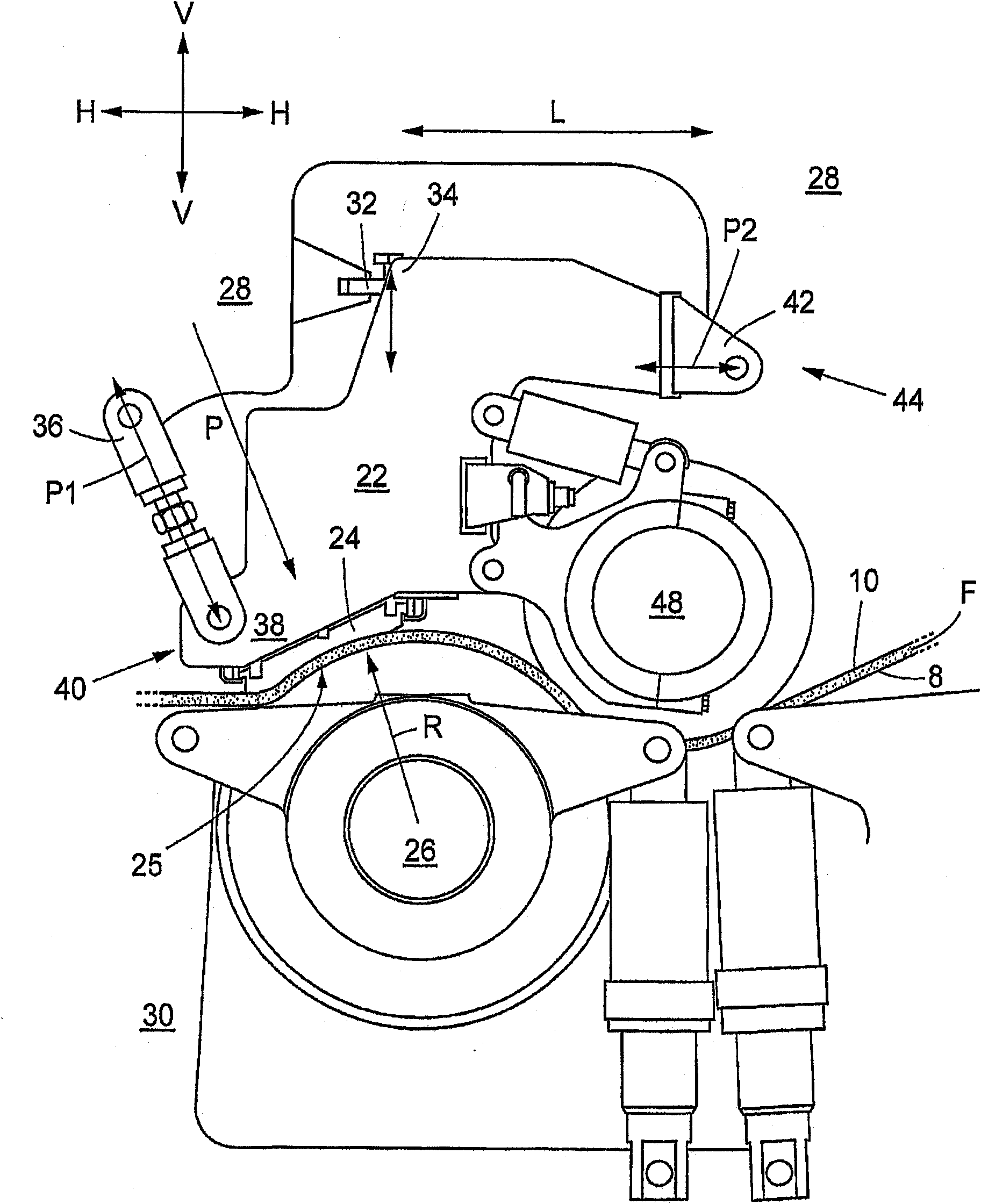

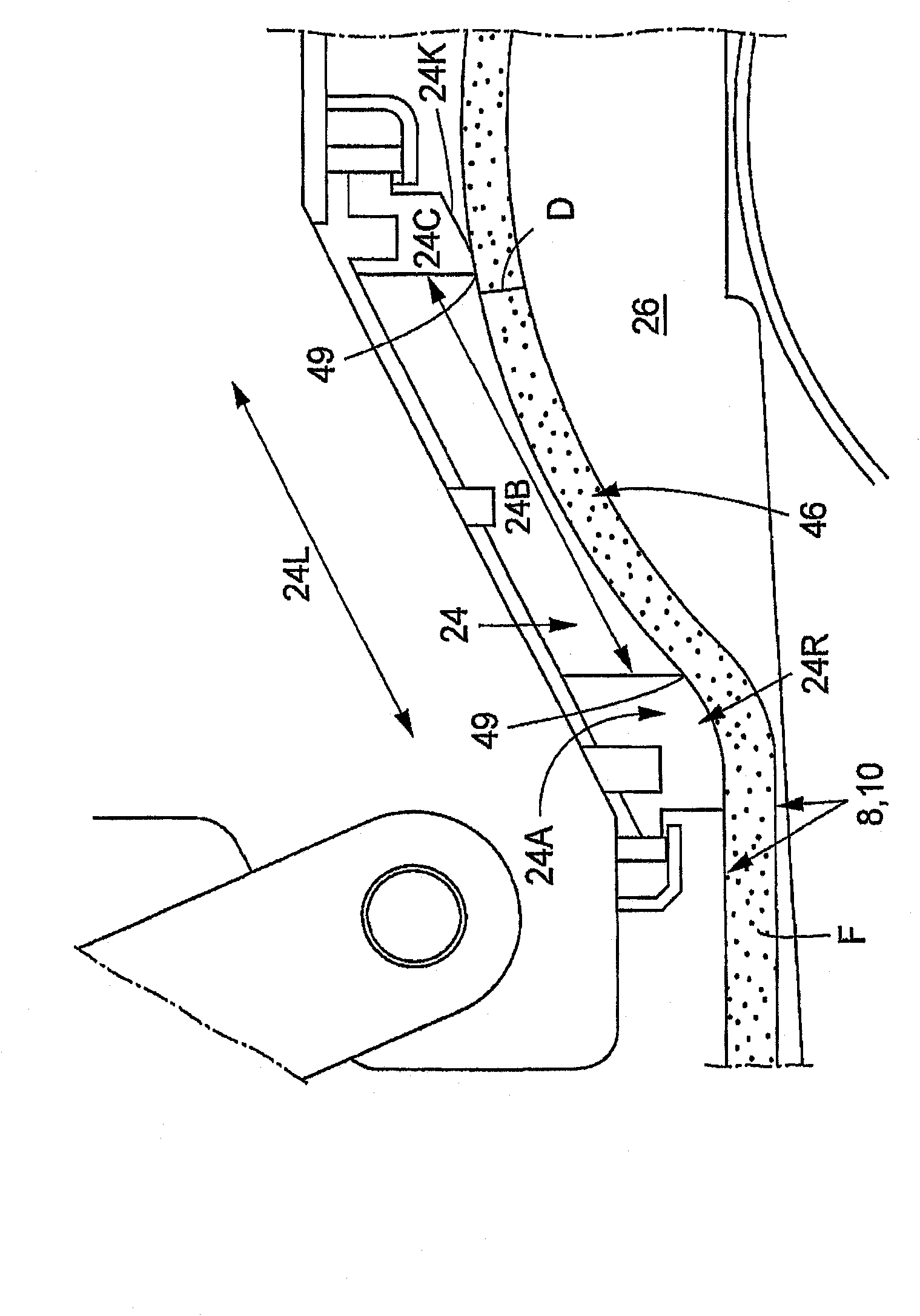

Twin wire press and method for dewatering a fibre suspension

The invention relates to a twin wire press (2) for dewatering a fibre suspension, comprising a lower wire (8) and an upper wire (10) between which a fibre web (F) is formed. An arrangement of rolls (4) comprises a first dewatering control means (22) having a dewatering element (24) forming a press nip (25) with a first roll (26) (or a second dewatering control means), where the element and the first roll, (or alternative second control means), along a section of the press nip where they bear on each other, are adapted to each other to provide a thickness profile designed to provide a dewatering profile, and where the element presses the formed web (F) against the first roll, or the alternative second control means, via the wires, whereby water pressed from the web is drained through the element. The invention also concerns a method for dewatering a fibre suspension.

Owner:METSO PAPER INC

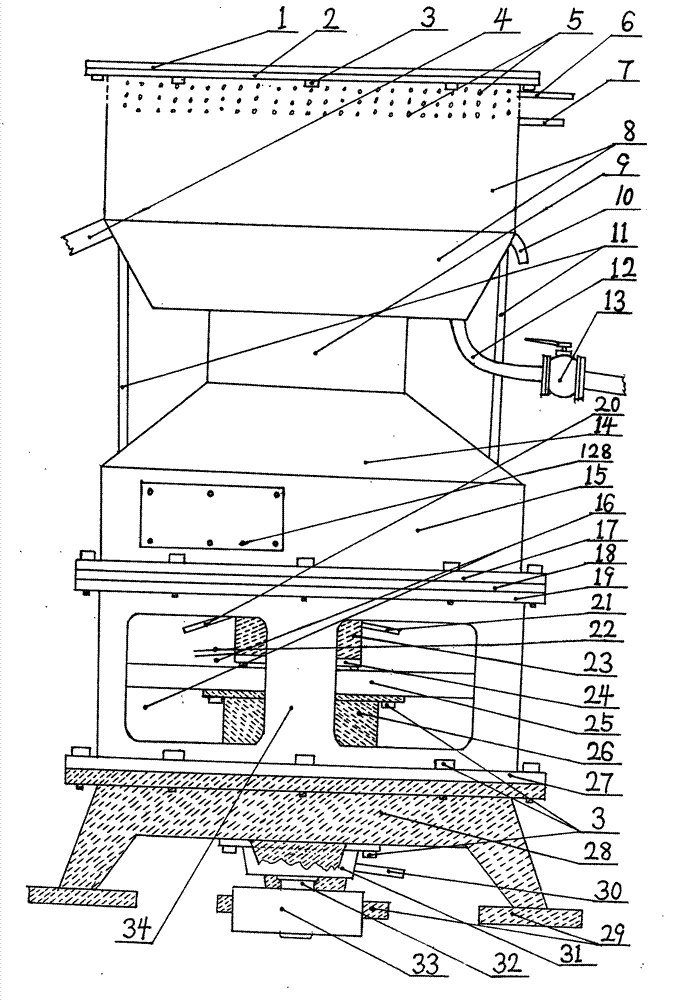

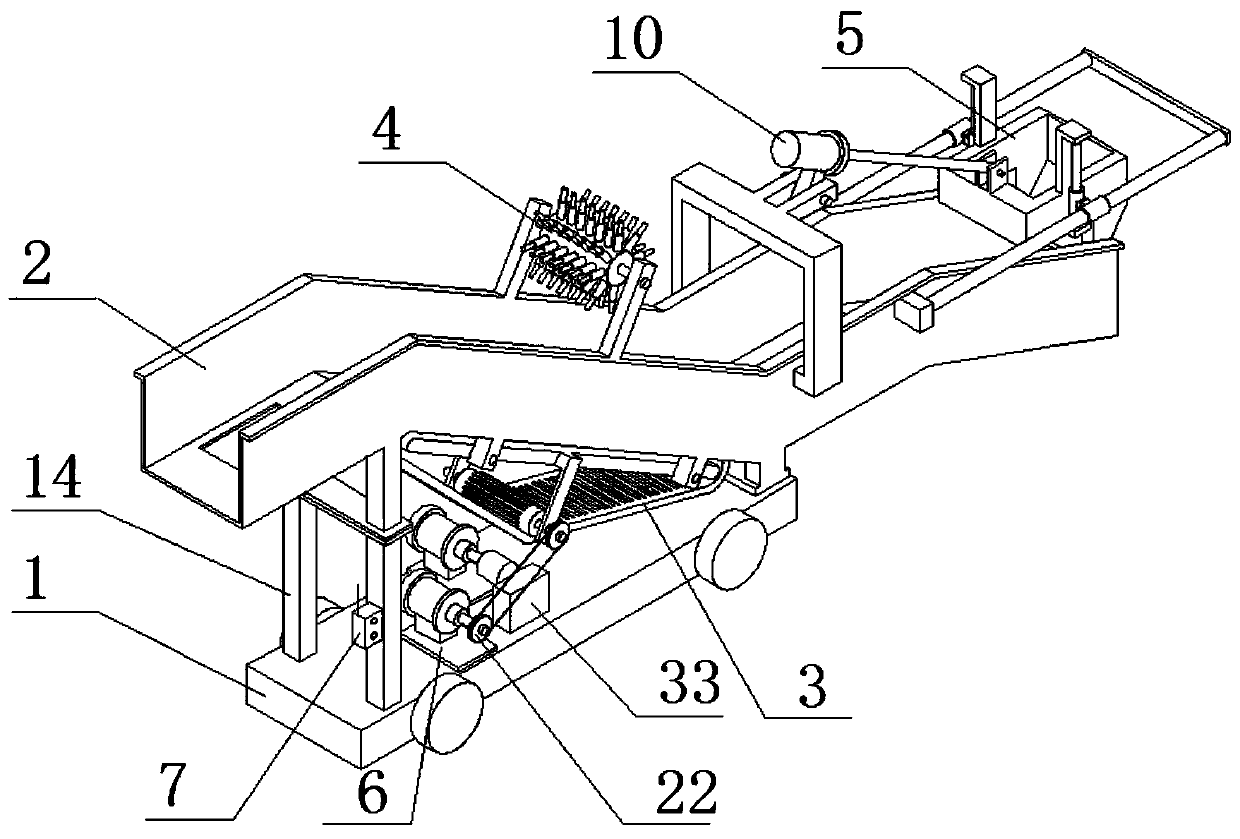

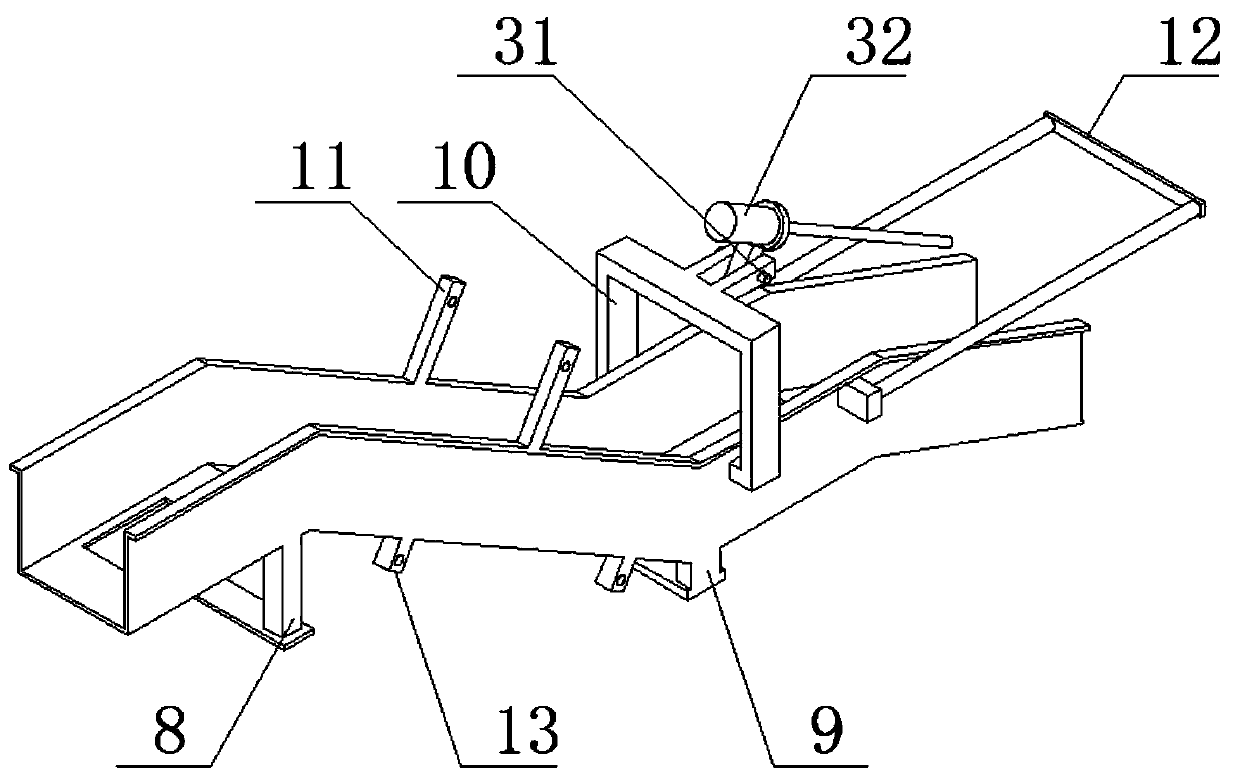

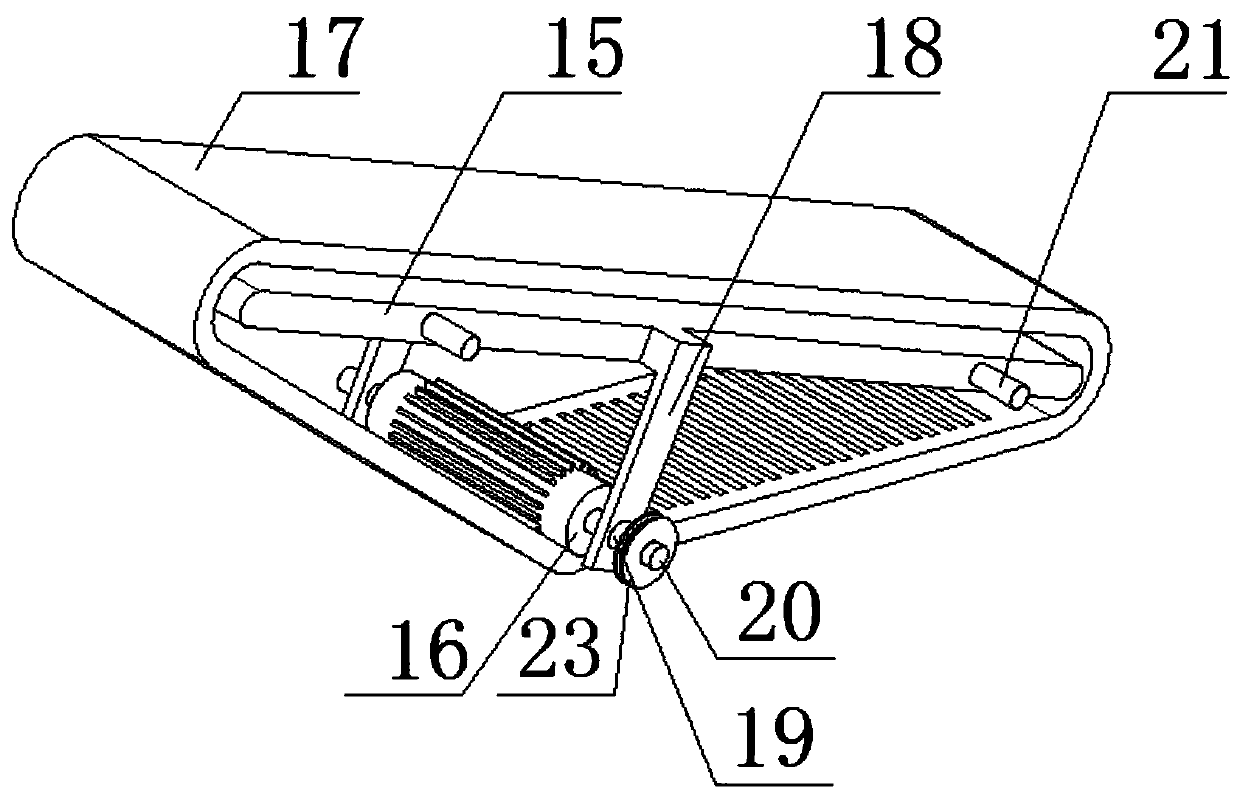

A rake bucket rock loader

ActiveCN108792648BReduce loadSolution to short lifeConveyorsGrain treatmentsFriction reductionElectric machine

The invention discloses a scraper loader which comprises a base, a conveying cover, a magnetic levitation ring sleeve combination, an automatic laser cutting device, a scraper bucket device, a drivingmotor, a control electricity box and a hydraulic system. An oil cylinder bracket, a cutting bracket and a guide column combination are arranged at the top of the conveying cover, a connecting beam, afront support and a back support are arranged at the bottom of the conveying cover, a front support beam is arranged on the base, and the conveying cover is installed on the base through matching ofthe front support and the front support beam; and the magnetic levitation ring sleeve combination comprises an electromagnetic plate, a driving roller and a permanent magnet conveying belt. Accordingto the scraper loader, the magnetic levitation ring sleeve combination is used for transferring materials, the electromagnetic plate is powered on to generate magnetism to float the permanent magnet conveying belt, and the driving motor drives the permanent magnet conveying belt to rotate to achieve long-distance transferring of rock blocks; and as the permanent magnet conveying belt is not in direct contact with the electromagnetic plate, the friction load can be reduced, the load of the driving motor is further reduced, and the service life of the driving motor is prolonged.

Owner:徐州金铎机械设备制造有限公司

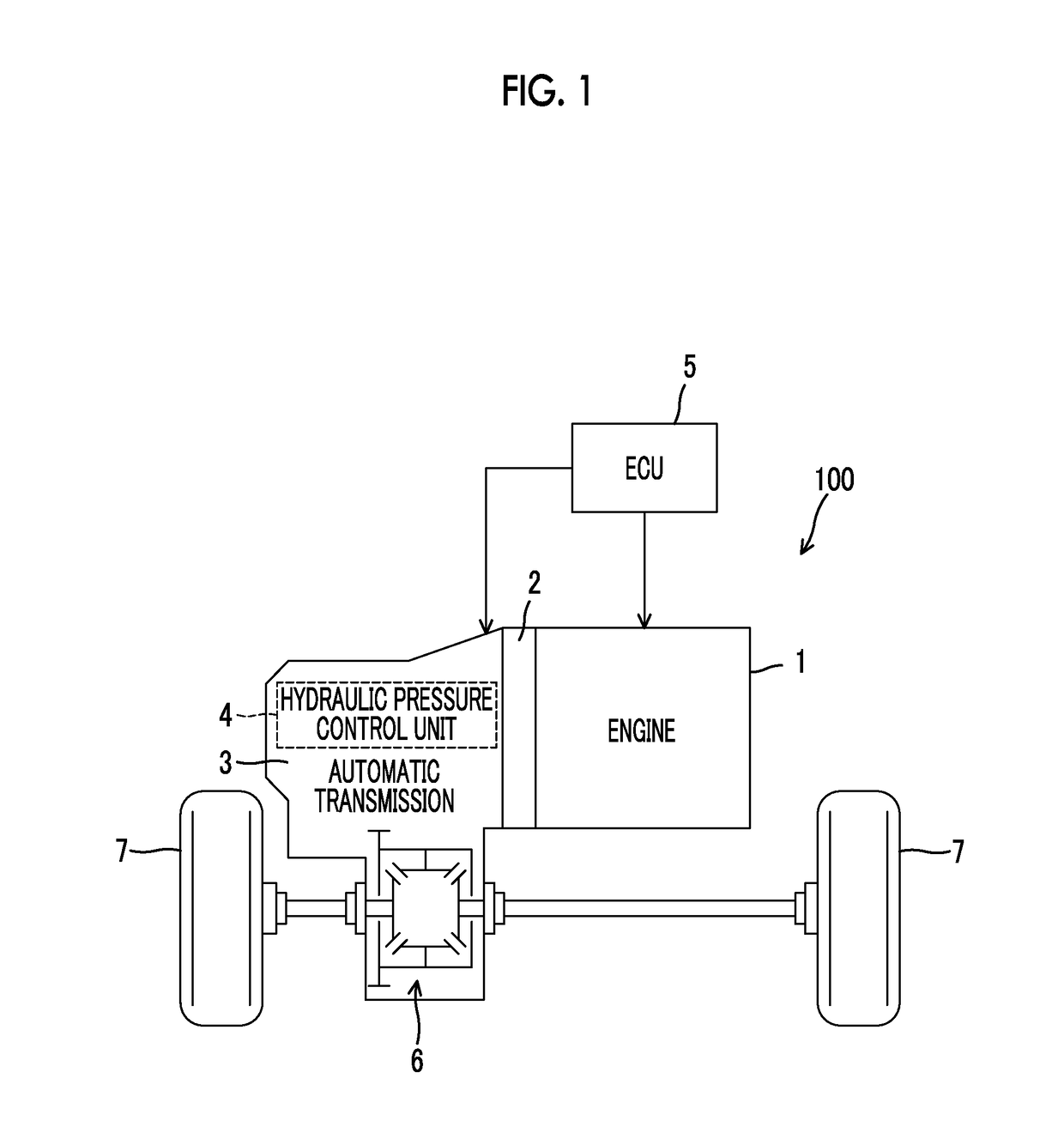

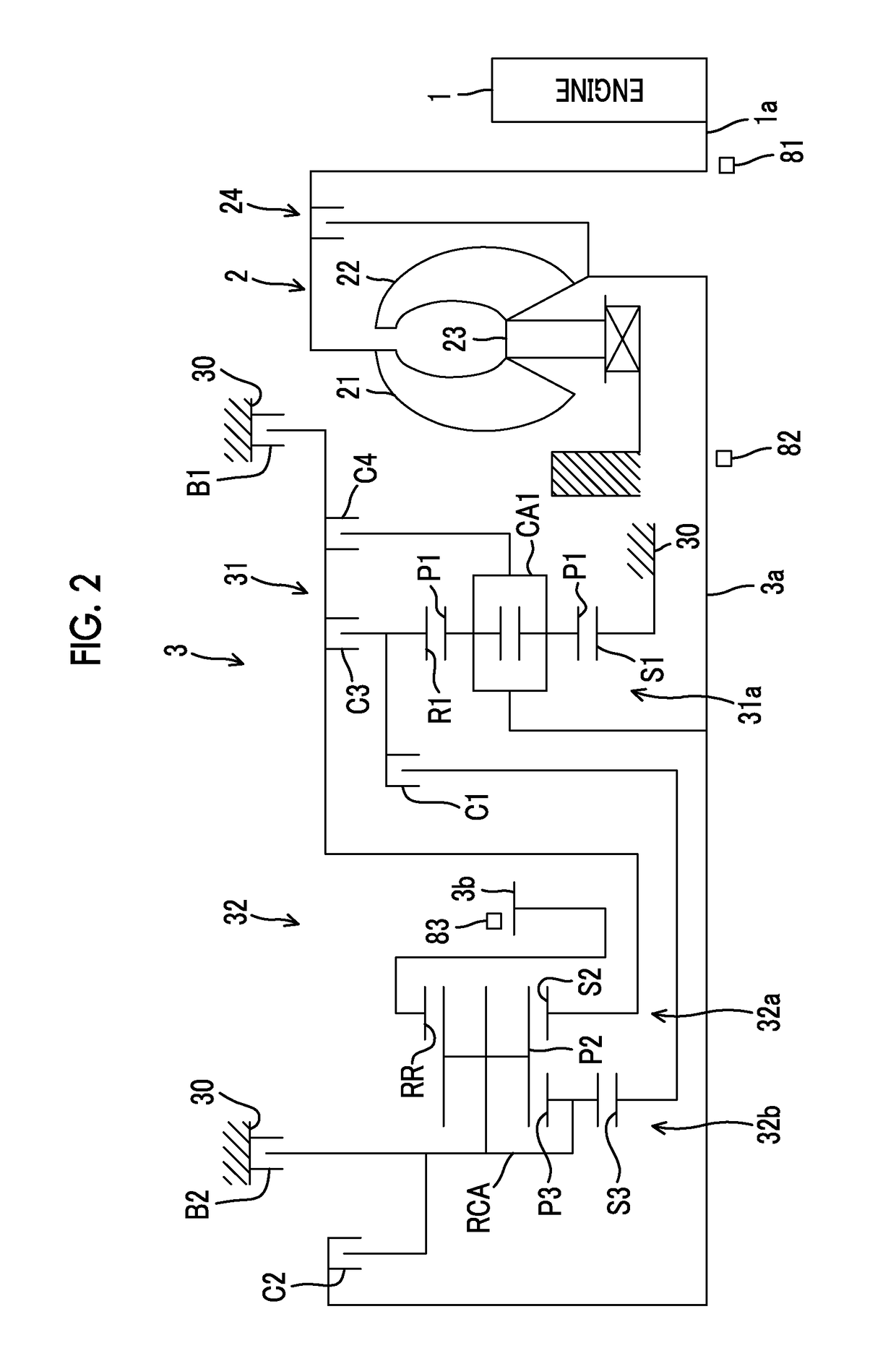

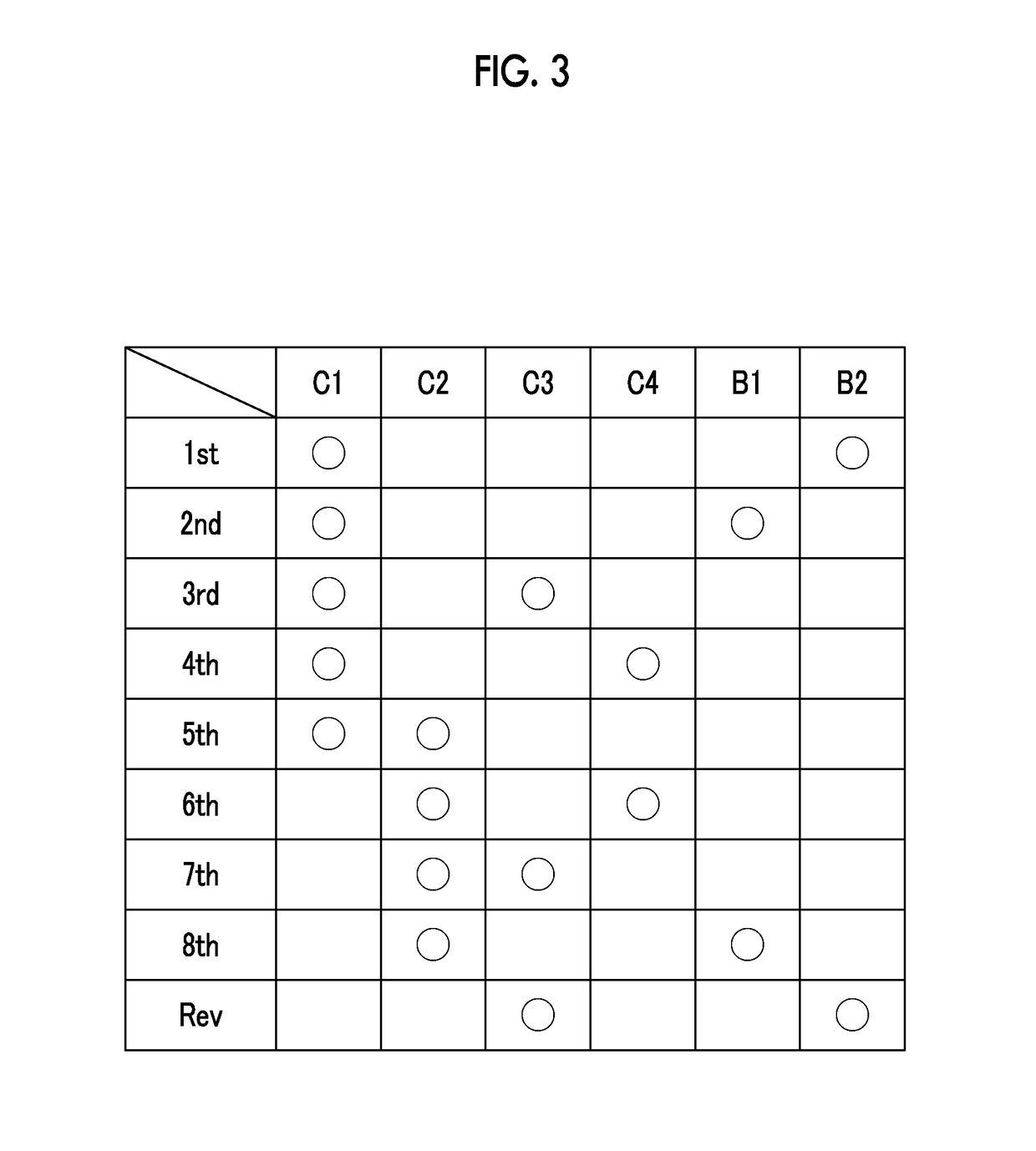

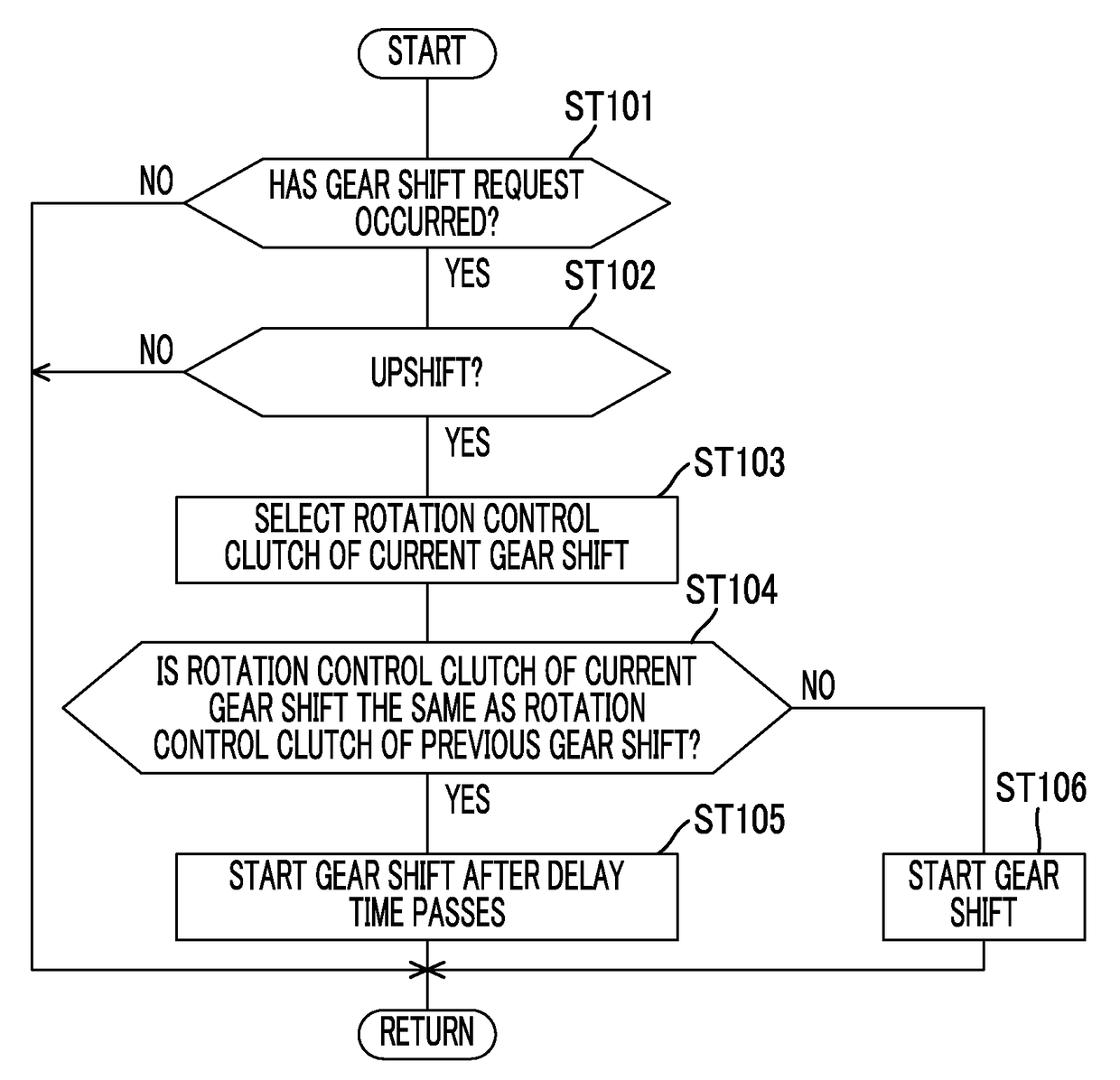

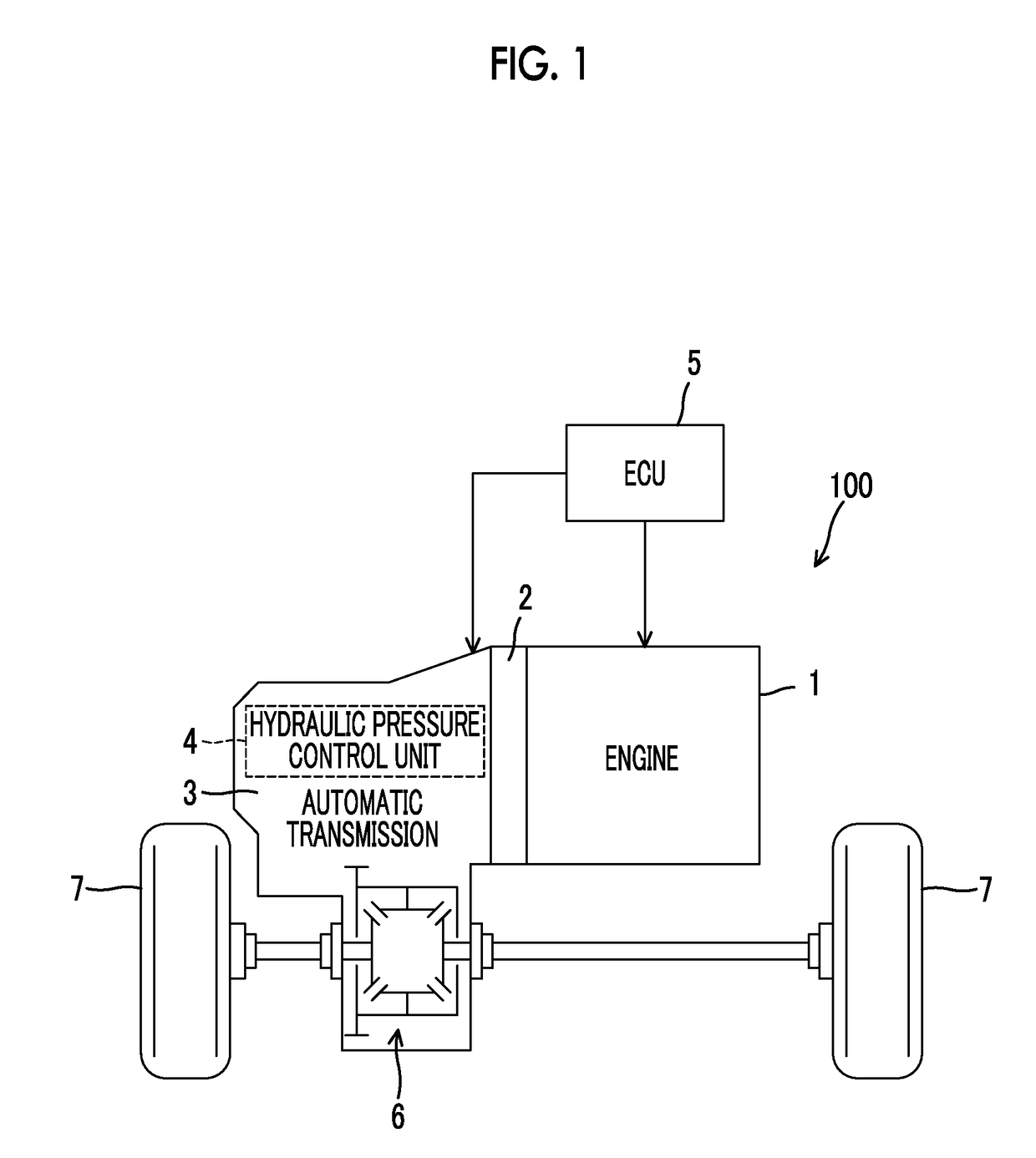

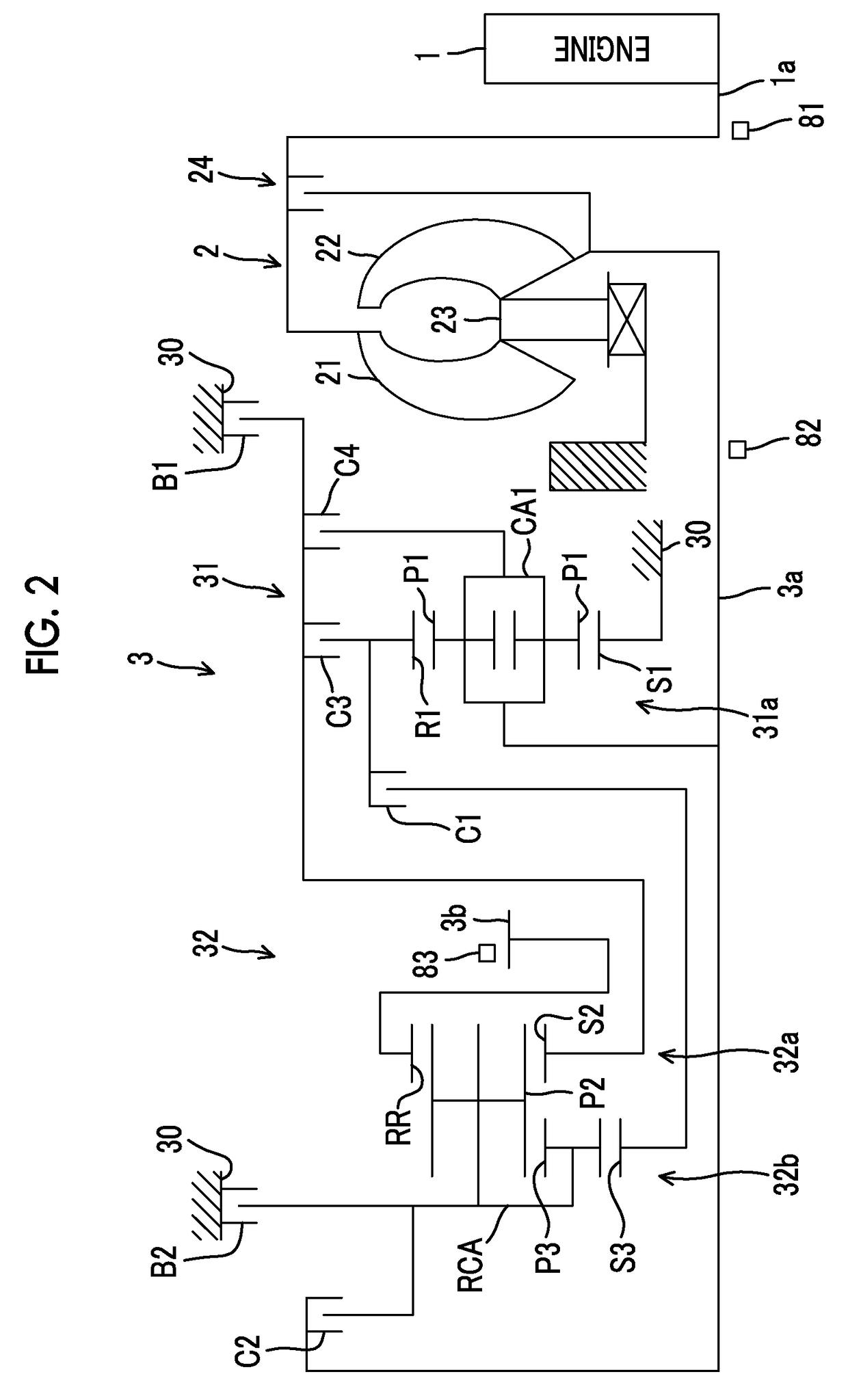

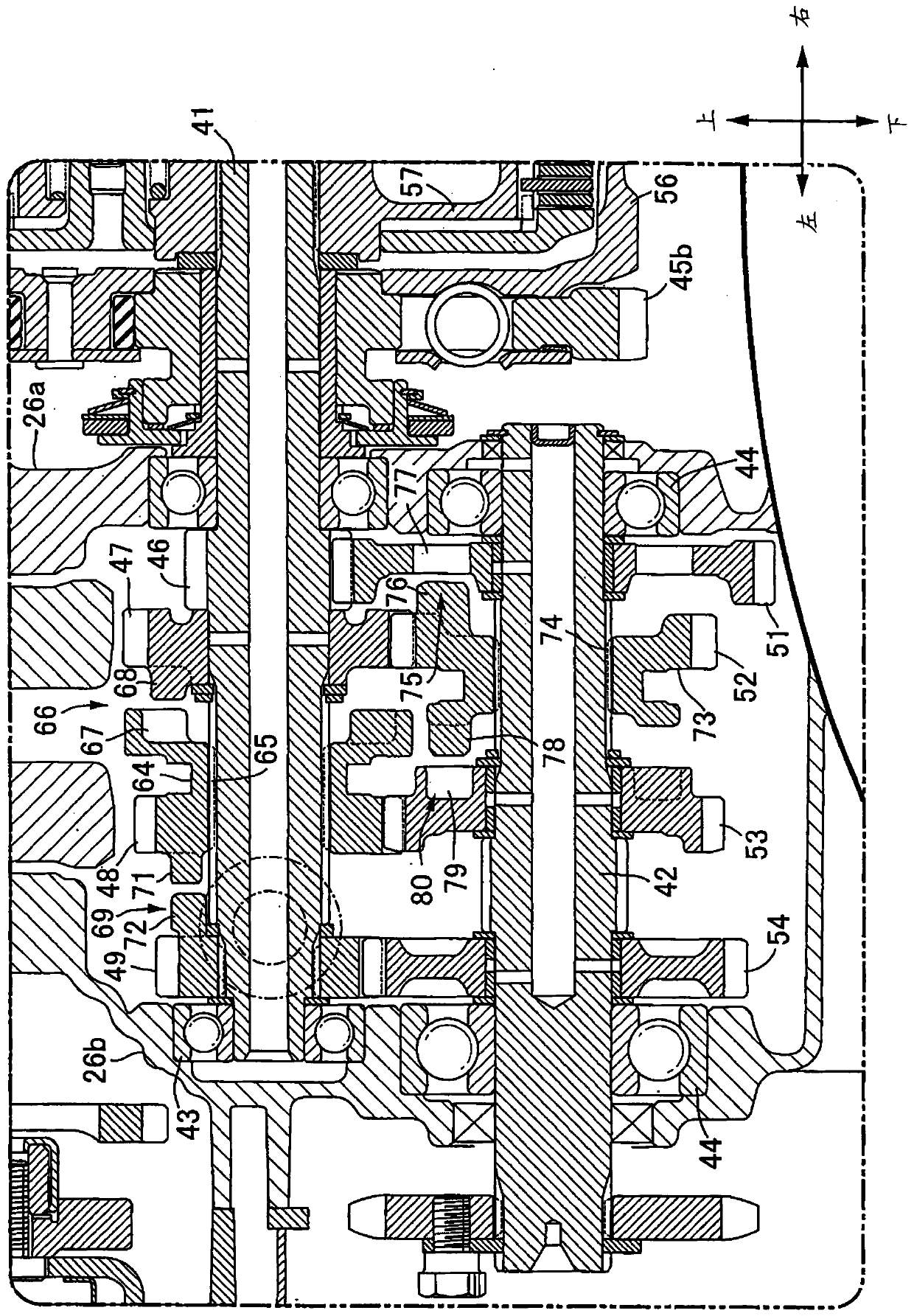

Controller for vehicle

ActiveUS10197155B2Reduce friction loadDegraded drivabilityToothed gearingsGearing controlRotation controlThermal load

When an engagement-side clutch taking charge of rotation control in an upshift is the same as a rotation control clutch of a previous gear shift, it is determined that there is a likelihood that a thermal load of a clutch friction material will increase, and the thermal load of the clutch friction material is decreased by delaying gear shift start. By setting a delay time by which the gear shift start is delayed when an accelerator depression amount is small to be shorter than when the accelerator depression amount is large depending on the accelerator depression amount, a gear shift which is an upshift can be performed without unnecessary waiting.

Owner:TOYOTA JIDOSHA KK

Actuator bearing having non-uniform ball spacing

ActiveUS7929253B2Increase stiffnessModify ball bearing assembly stiffnessDisposition/mounting of recording headsRecord information storageBall bearingCombined use

A method is provided for maintaining the aggregate stiffness of a pivot bearing assembly generally employed along with an actuator assembly of a magnetic disk drive, while increasing the stiffness in a predetermined direction. More specifically, bearing cartridges used in conjunction with actuator assemblies of the prior art employ at least one ball bearing assembly positioned about a stationary shaft. A modification is presented herein that generally concerns repositioning and maintaining the balls of the ball bearing along a predetermined axis for efficient reaction of loads.

Owner:SEAGATE TECH LLC

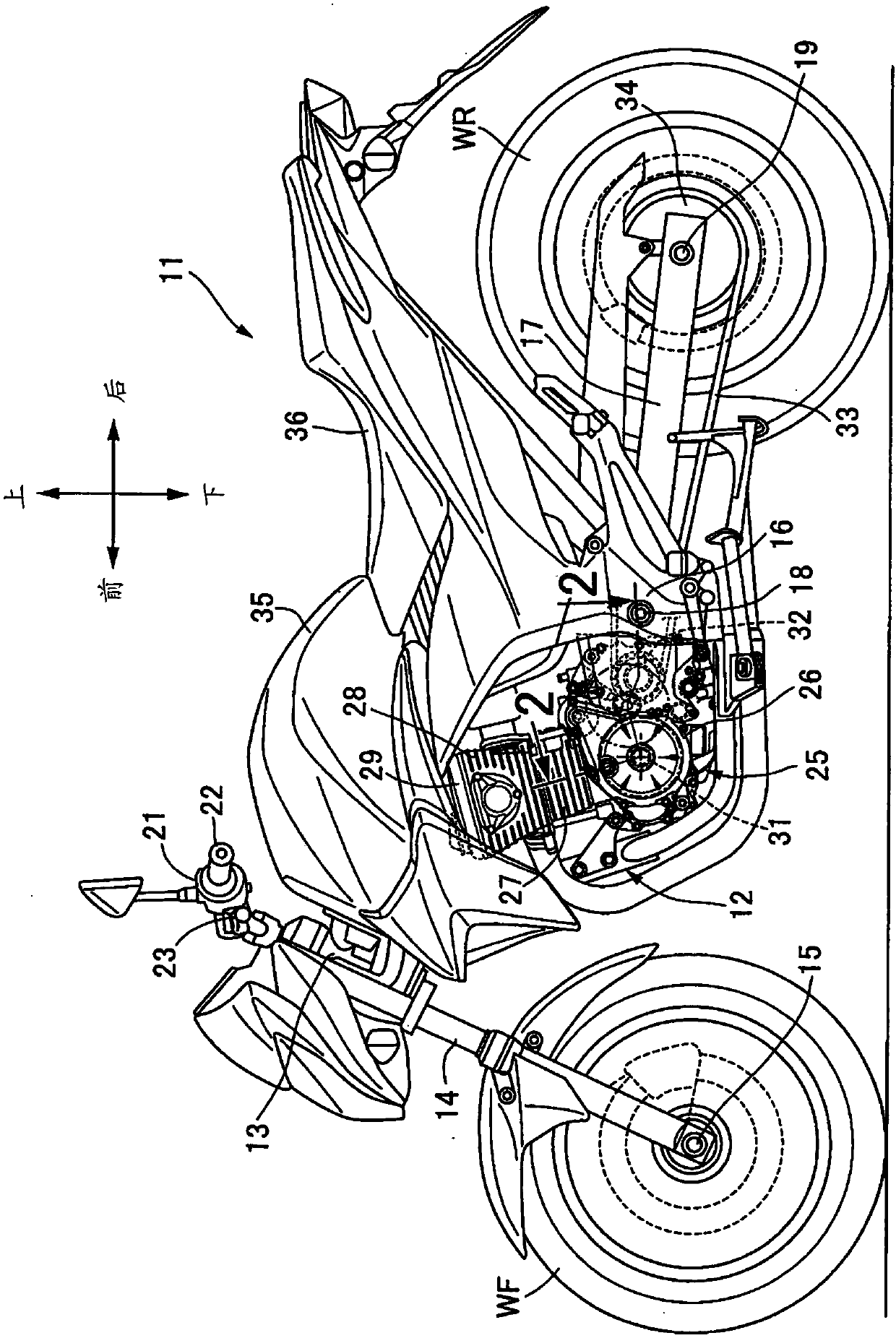

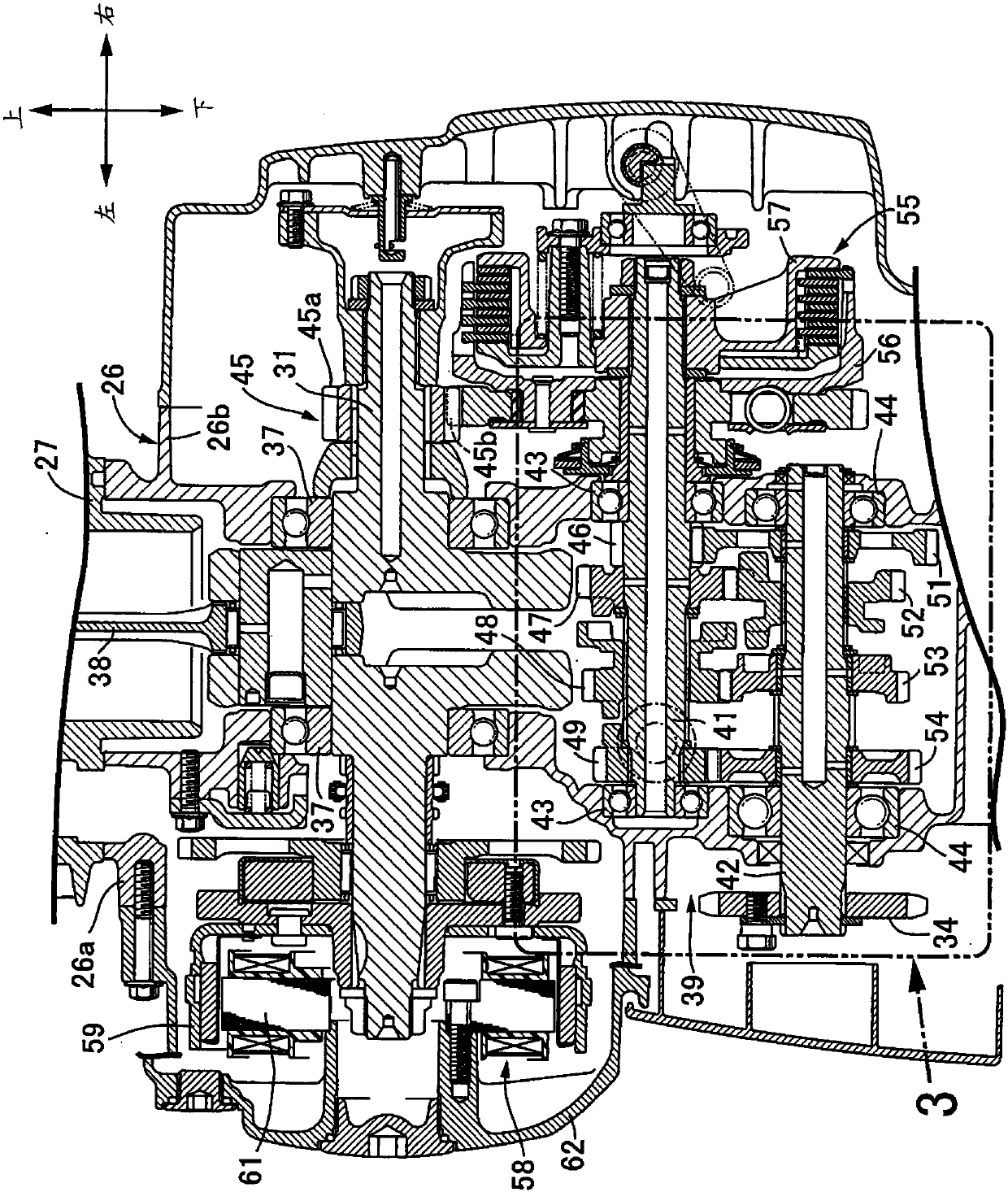

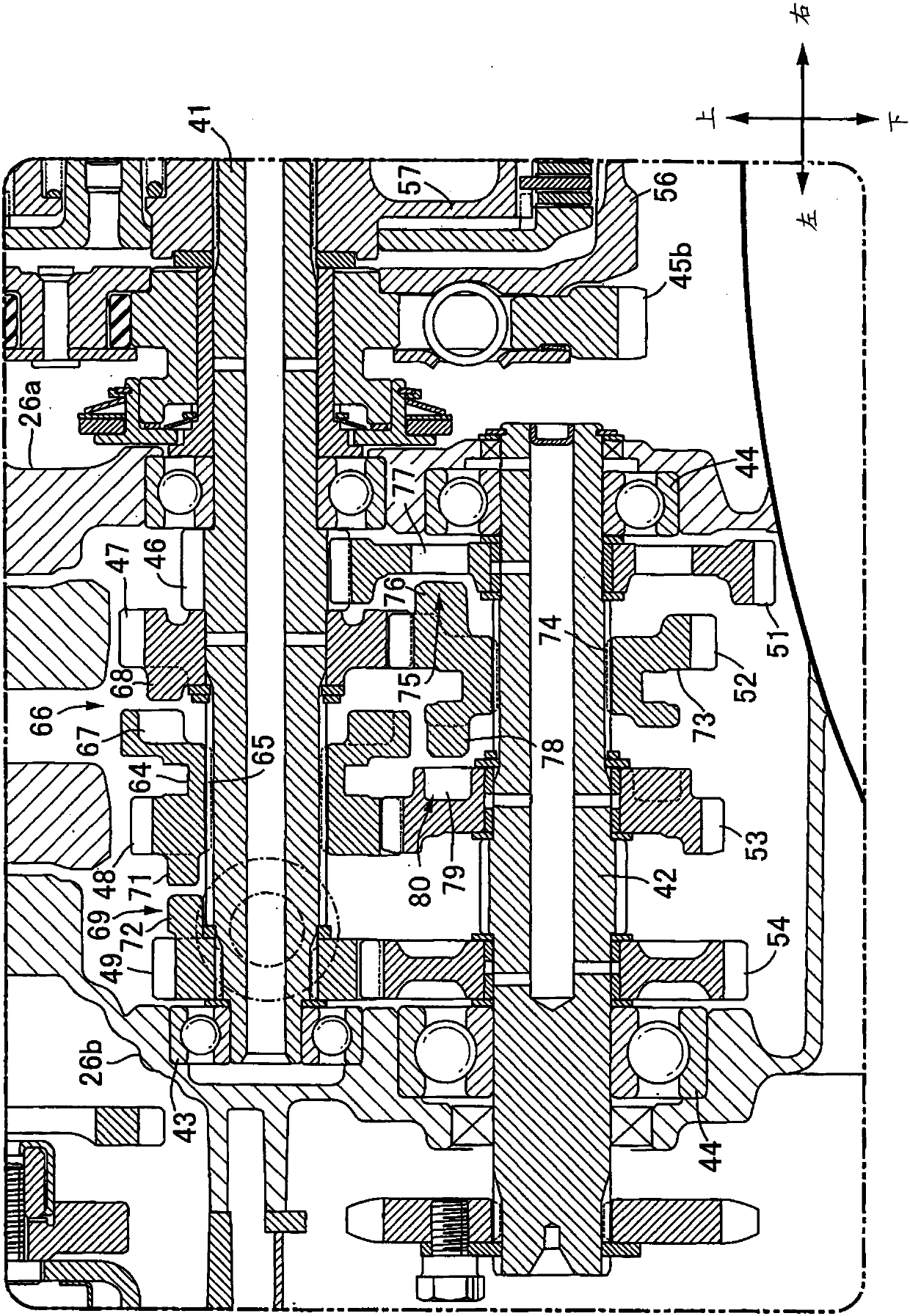

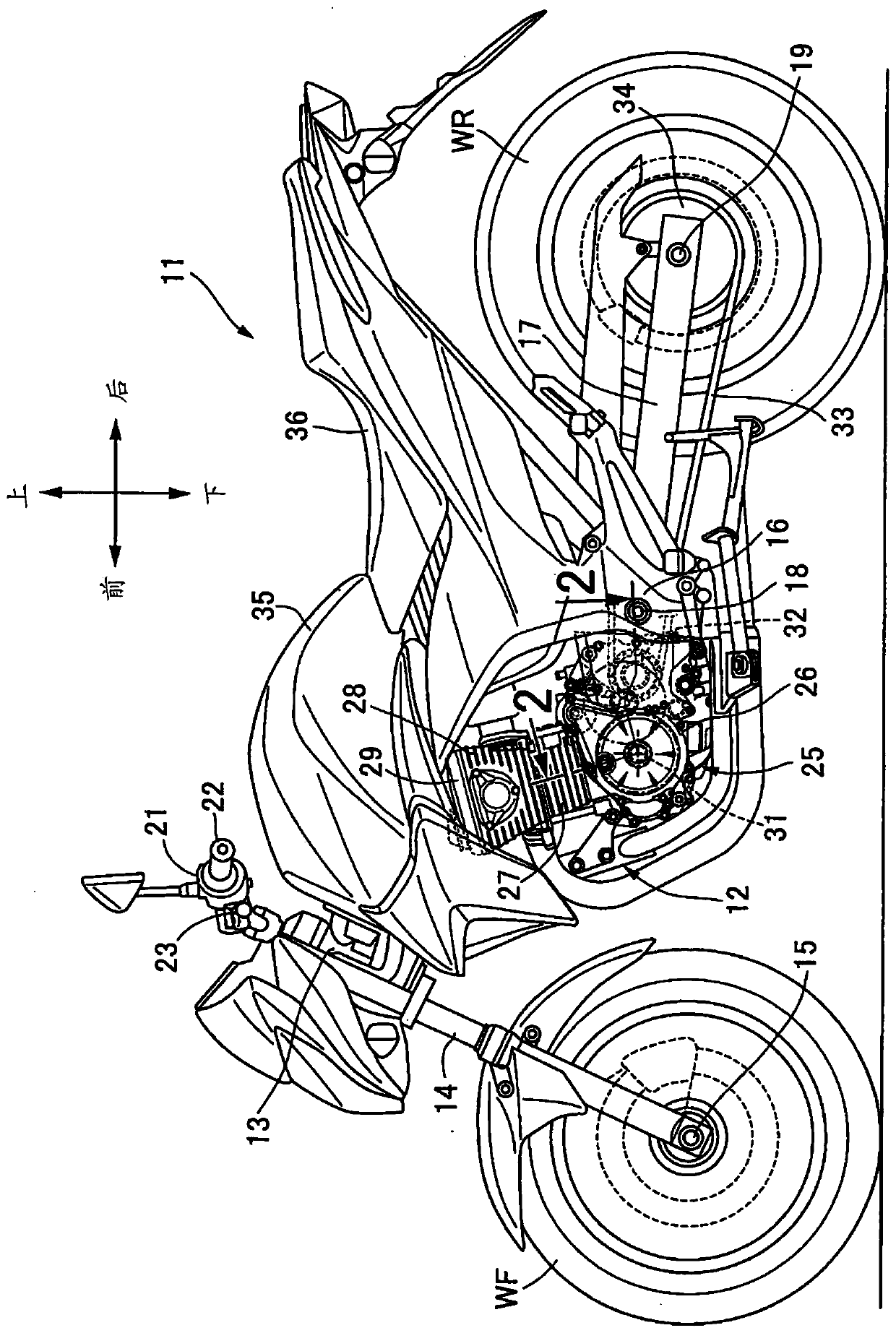

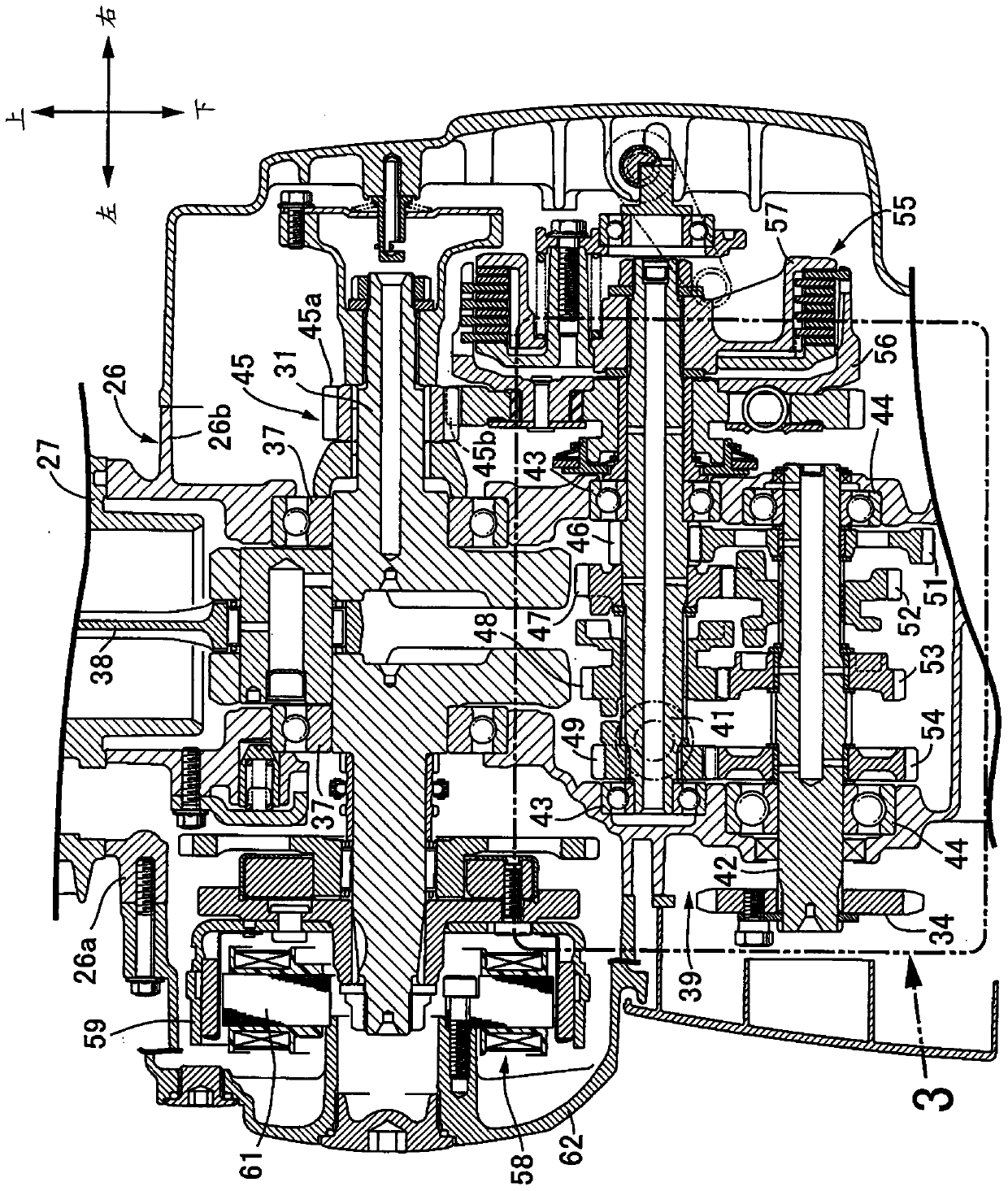

Power transmission device

ActiveCN107869580AStable supportIt is easy to produce the situation of continuous rotationGearing controlClutchCam

A power transmission device provided by the present invention can establish a combination state smoothly between a first fastening part of a driving gear and a second fastening part of a driven gear by a simple structure. In the power transmission device, a plurality of cam grooves (91,93) are formed on a variable speed drum (84), a sliding part (109) having an abutting surface (114) which abuts against a clutch shell (56) is in snap joint with a clutch hub (57), and an arm part (116) for driving the sliding part (109) is configured, is connected with the cam groove (93) and drives the slidingpart 109 along with the action of the variable speed drum (84), thereby enabling the sliding part 109 to abut against the clutch shell (56).

Owner:HONDA MOTOR CO LTD

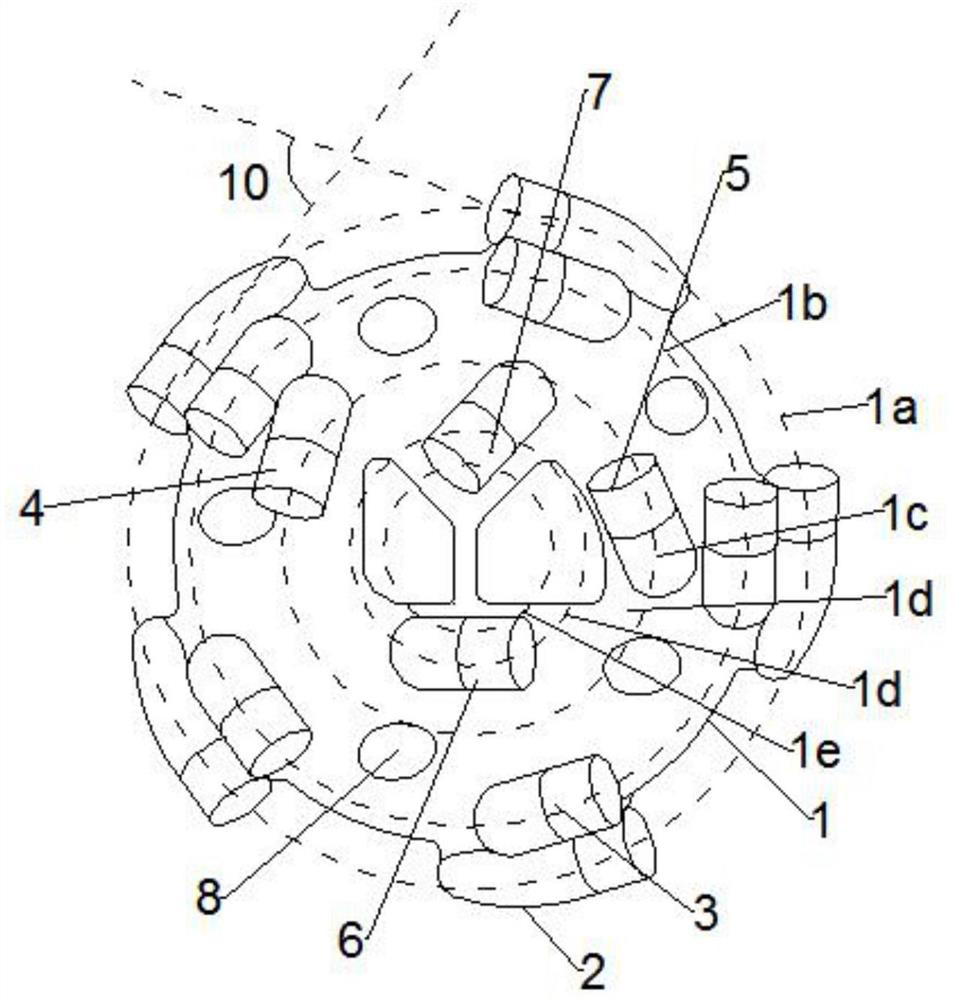

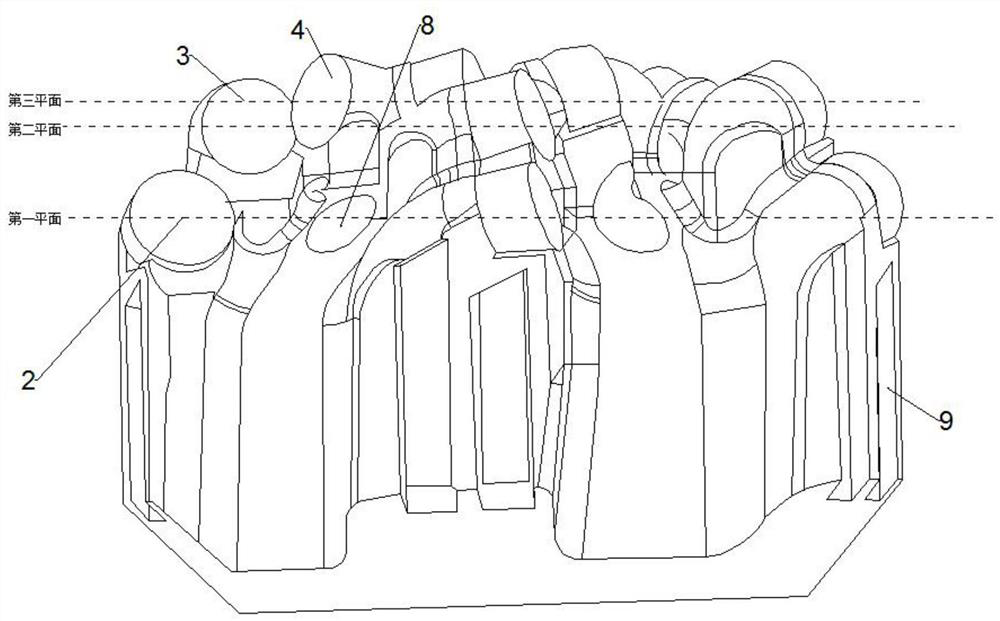

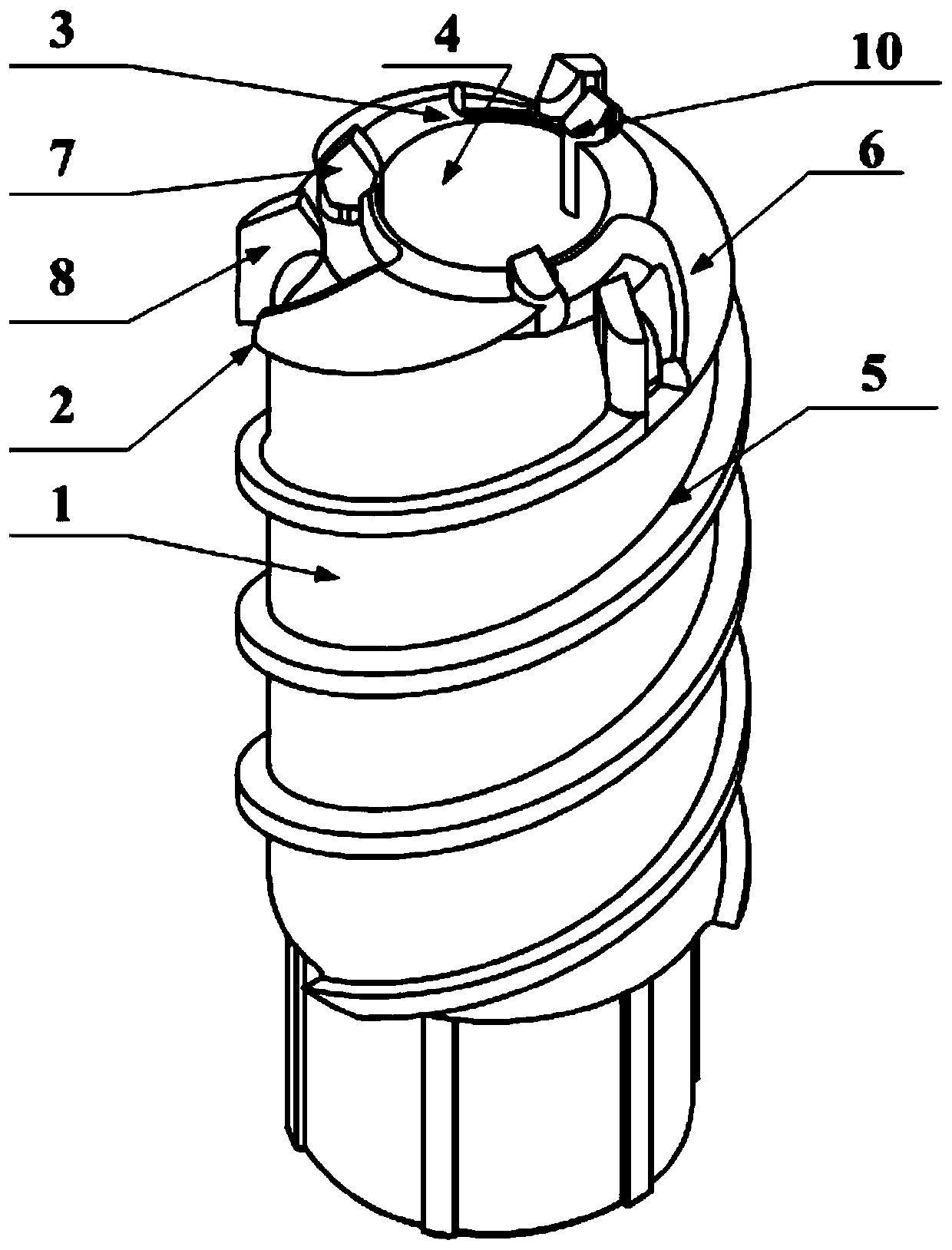

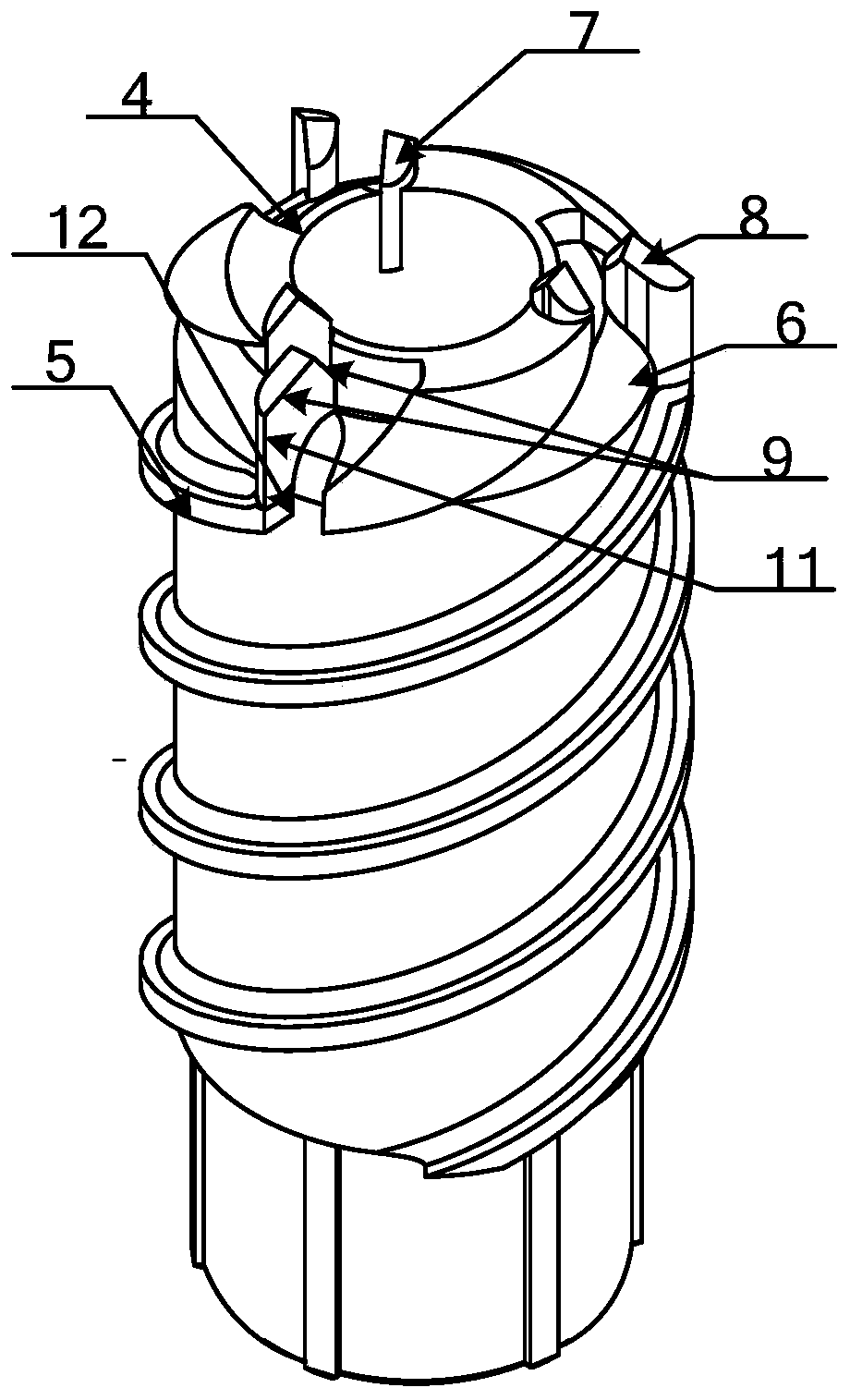

Five-wing fourteen-tooth anti-concretion drill bit

PendingCN113309471AIncrease propulsion pressureReduce friction loadDrill bitsConstructionsDrill holeEngineering

The invention discloses a five-wing fourteen-tooth anti-concretion drill bit. The five-wing fourteen-tooth anti-concretion drill bit comprises a drill bit body, wherein a first-ring cutting tooth line, a second-ring cutting tooth line, a third-ring cutting tooth line, a fourth-ring cutting tooth line and a fifth-ring cutting tooth line, of which the diameters are sequentially reduced are made by using the center of the drill bit body as a circle point, and the first-ring cutting tooth line is located outside the drill bit body. Five drill teeth A are arranged on the outer edge of the drill bit body and located in a first plane, the tooth surface centers of the drill teeth A are located on the first-ring cutting tooth line, five drill teeth B are arranged close to the inner sides of the drill teeth A, the five drill teeth B are located in a second plane, and the tooth surface centers of the drill teeth B are located on the second-ring cutting tooth line. The drill bit body is further provided with a drill tooth C, a drill tooth D, a drill tooth E and a drill tooth F. The invention aims to provide the five-wing fourteen-tooth anti-concretion drill bit, so that the friction load of the drill bit is reduced, and the drill bit can be efficiently suitable for drilling work of yellow iron concretion.

Owner:金沙县仁德钻探工具有限公司

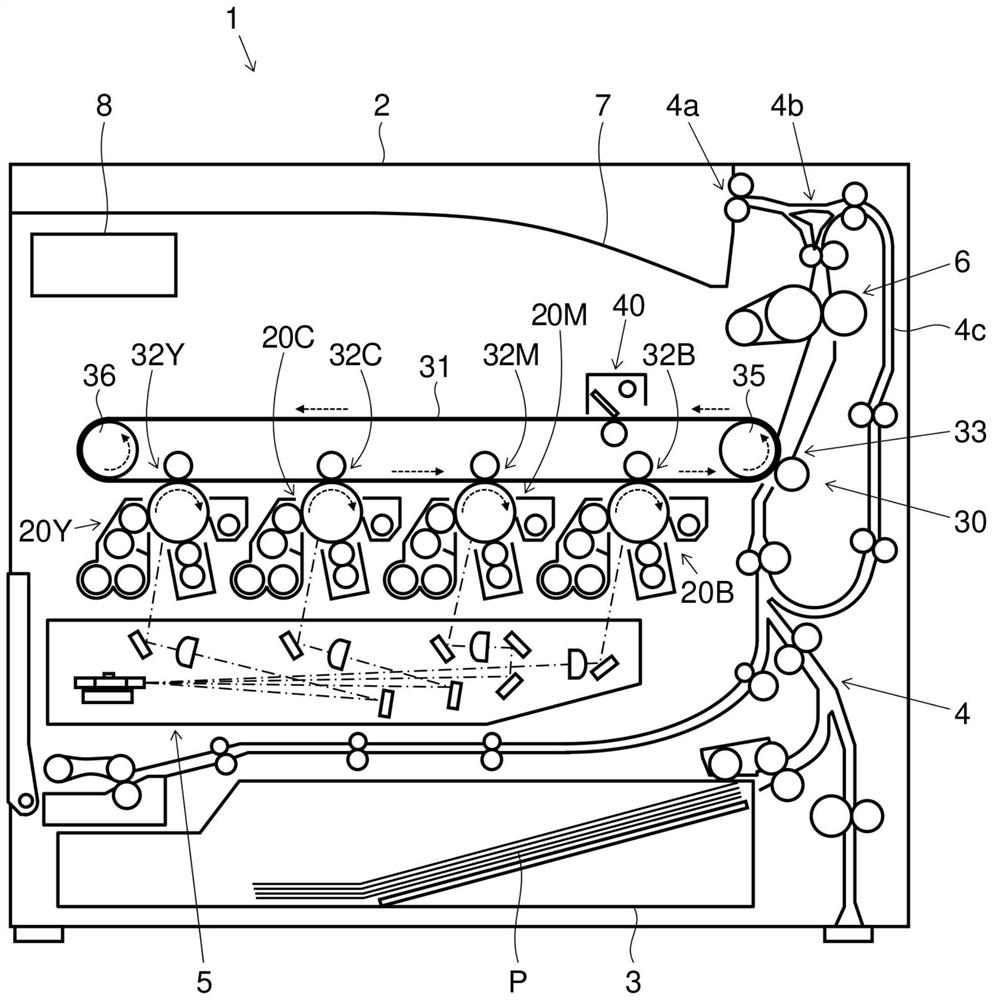

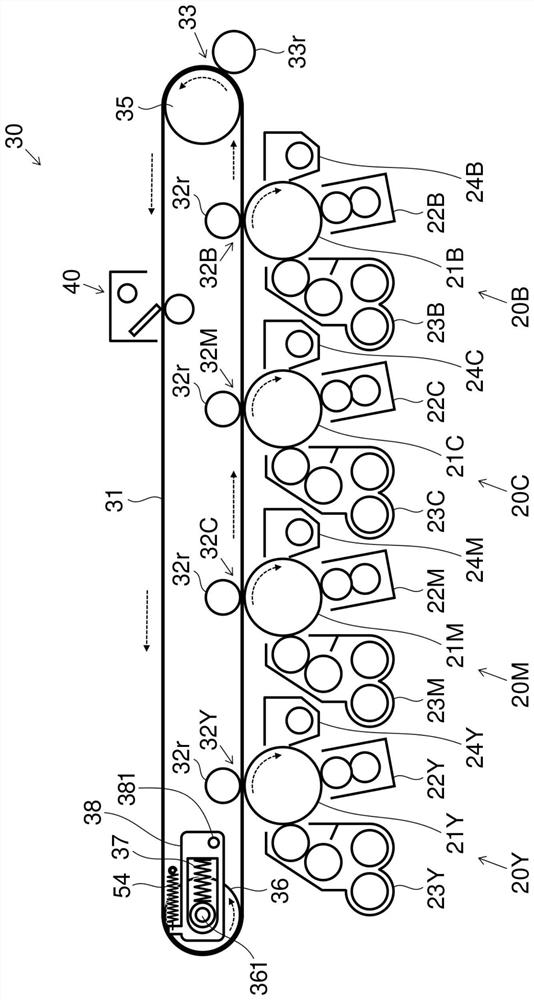

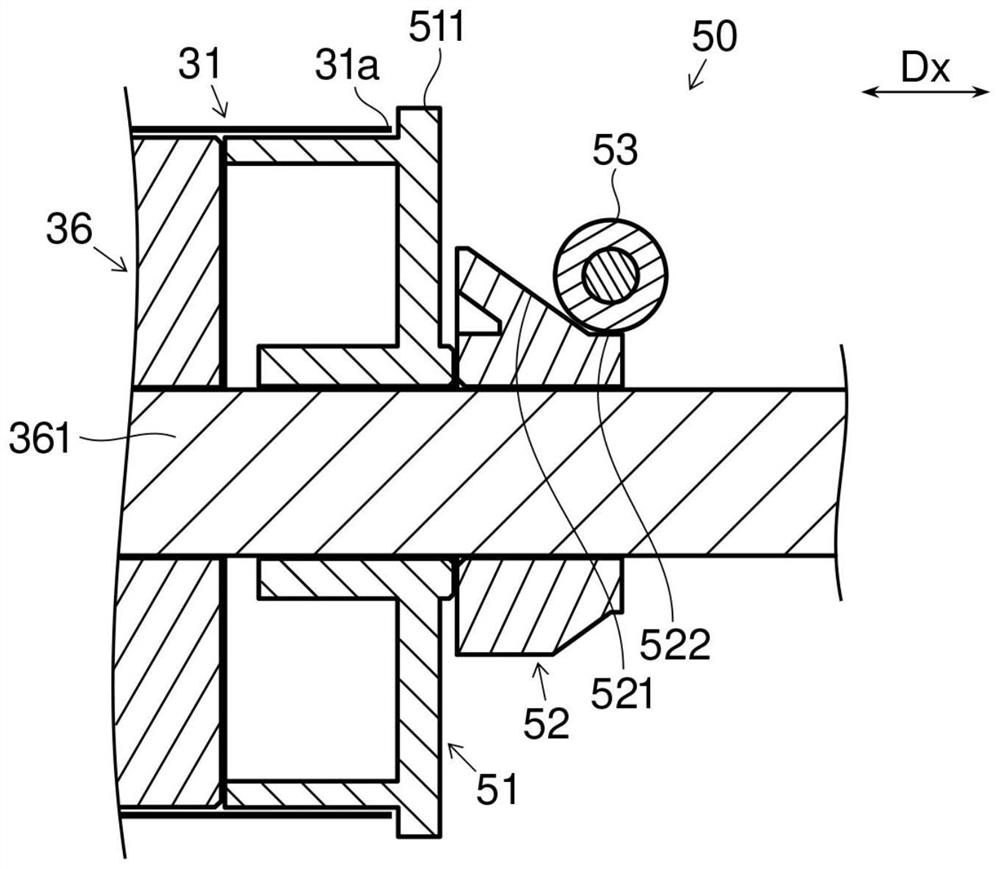

Image forming apparatus

ActiveCN113946111AInhibition lossReduce friction loadElectrographic process apparatusImage formationEngineering

Owner:KYOCERA DOCUMENT SOLUTIONS INC

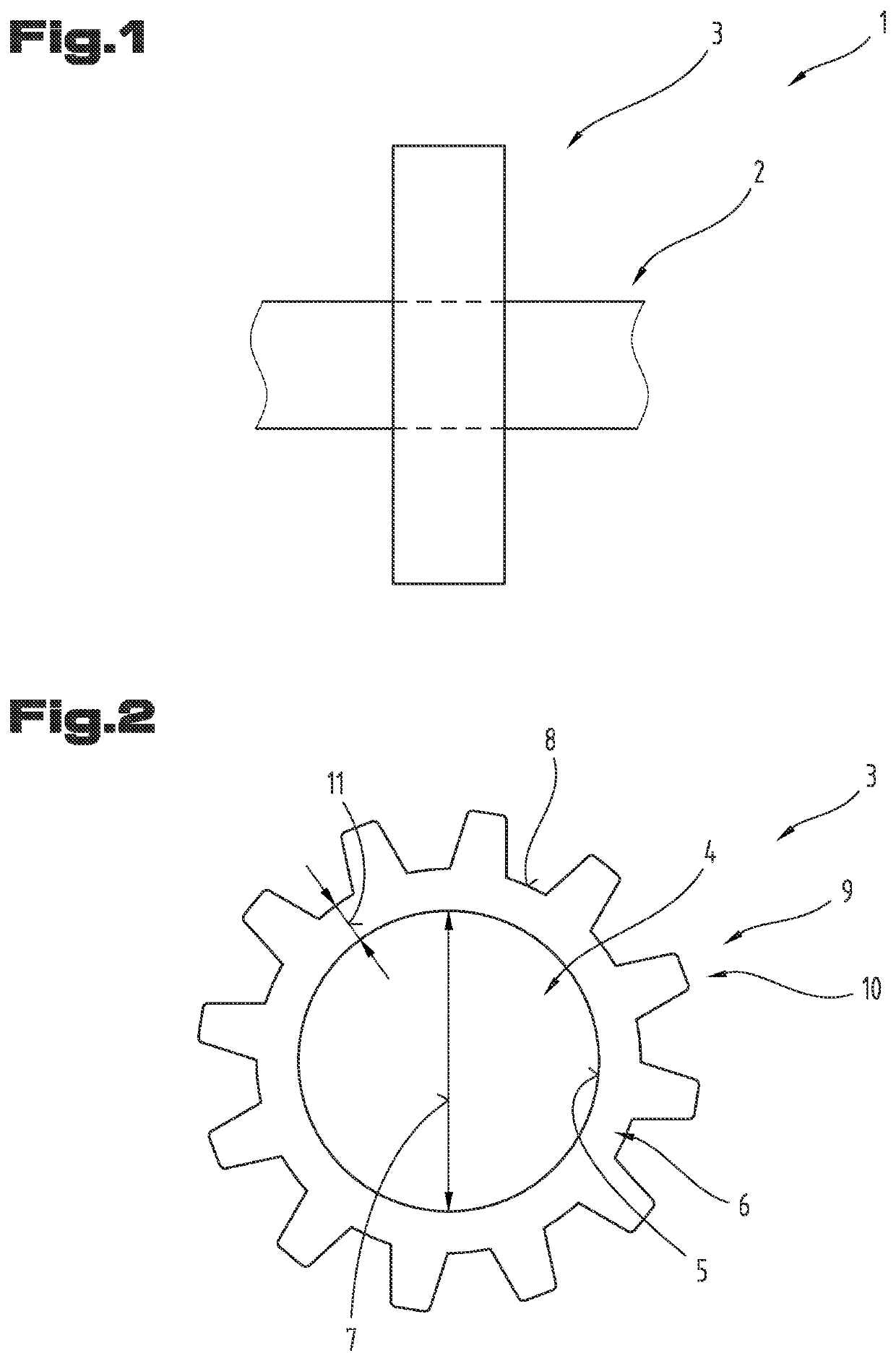

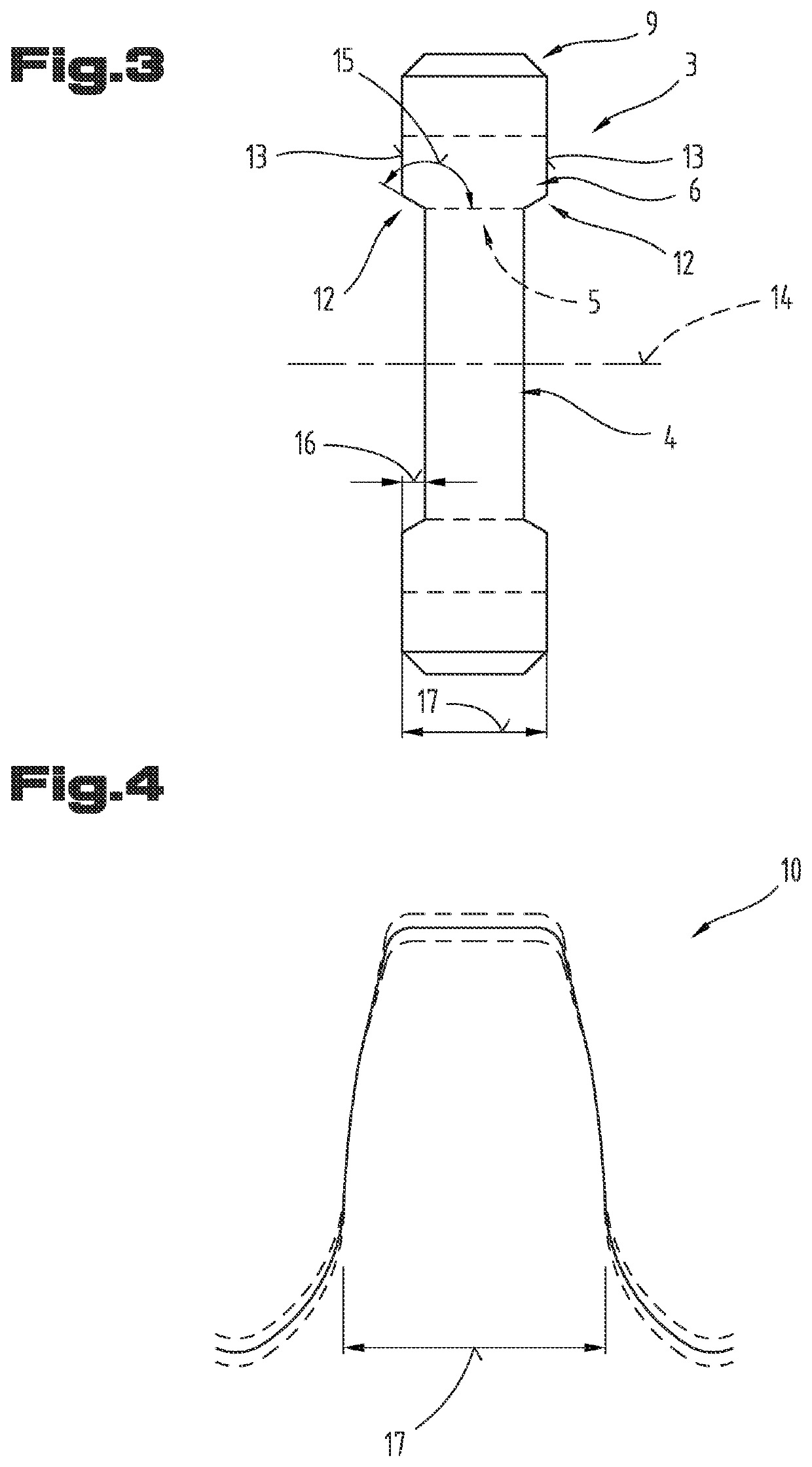

Method for connecting a first component to a second component to form an assembly

ActiveUS20220152755A1Easy to manufactureMore cost-effectivePortable liftingCouplings for rigid shaftsNet shapeNear net shape

A method for connecting a first component to a second component to form an assembly forms a press fit connection between the first component and the second component, for which purpose the second component is produced having an annular component section. A recess is formed, in which the first component is at least partially arranged. At least the annular component section of the second component is produced as a sintered component and has net shape or near net shape quality at least in the region of the recess.

Owner:MIBA SINTER AUSTRIA

Controller for Vehicle

ActiveUS20180031120A1Decrease in drivabilityDecrease thermal loadingToothed gearingsGearing controlClutchEngineering

When an engagement-side clutch taking charge of rotation control in an upshift is the same as a rotation control clutch of a previous gear shift, it is determined that there is a likelihood that a thermal load of a clutch friction material will increase, and the thermal load of the clutch friction material is decreased by delaying gear shift start. By setting a delay time by which the gear shift start is delayed when an accelerator depression amount is small to be shorter than when the accelerator depression amount is large depending on the accelerator depression amount, a gear shift which is an upshift can be performed without unnecessary waiting.

Owner:TOYOTA JIDOSHA KK

Single person portable belay anchor system and method

Owner:PILOT CATASTROPHE SERVICES

Lubricating oil additive containing ultrafine rare-earth powder

InactiveCN103642569BAvoid direct contactReduce harmful ingredientsLubricant compositionPhosphateOil additive

The invention relates to a lubricating oil additive containing ultrafine rare-earth powder. The additive consists of the following components in percentage by mass: natural serpentine mineral powder, ultrafine rare-earth powder, surfactant, a dispersing agent, a friction modifier, an auxiliary and base oil, wherein the ultrafine rare-earth powder is one of cerium hydroxide, neodymium oxide and cerium fluoride; the surfactant is borate, span-60 or oleic acid; the dispersing agent is either polyisobutene dibutyl succinimide or high molecular weight polyisobutene dibutyl succinimide; the friction modifier is one of melamine cyanurate, boron nitride and calciuym nitride; the auxiliary comprises 72% of dialkyl disulfo oxygen molybdenum phosphate sulfide, 18% of polymethyl tetradecyl acrylate and 10% of a vinyl-propylene copolymer; and the base oil is 500SN base oil. The additive has obvious corrosion resistance; and after an engine is treated technically by using the self-repairing additive, the dry friction coefficient of the machine is reduced from original 0.05 to be less than 0.005 and therefore the surface abrasion is reduced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

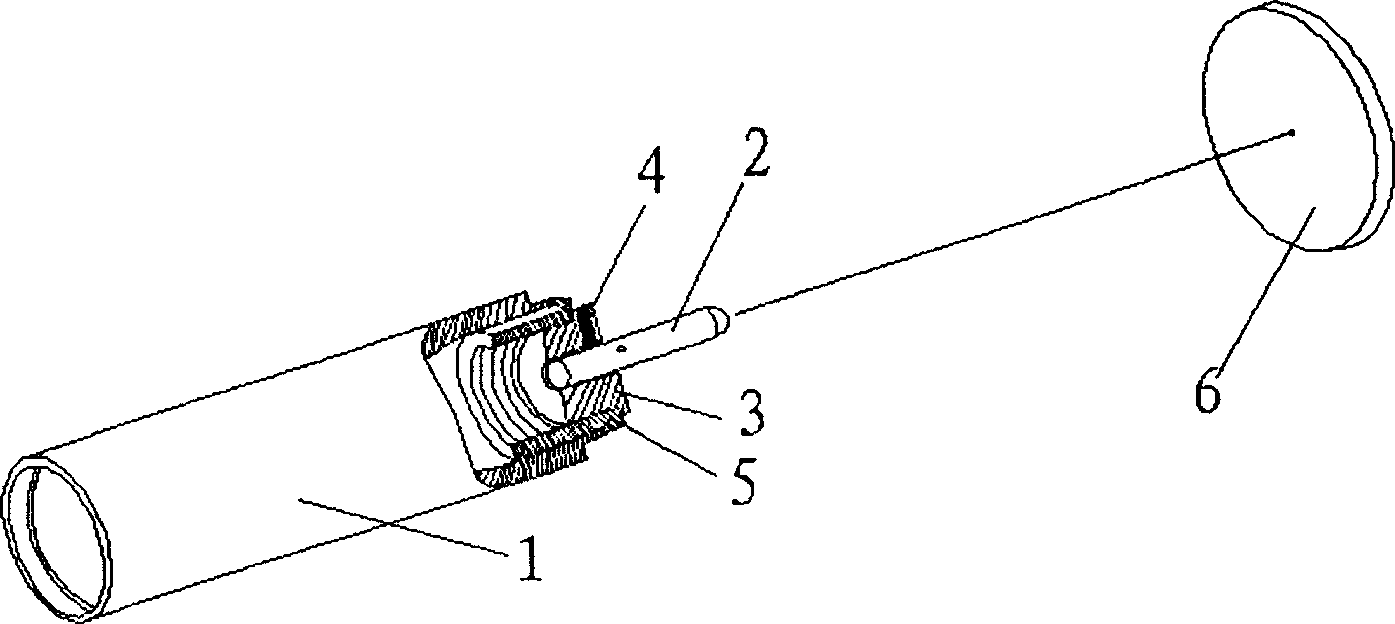

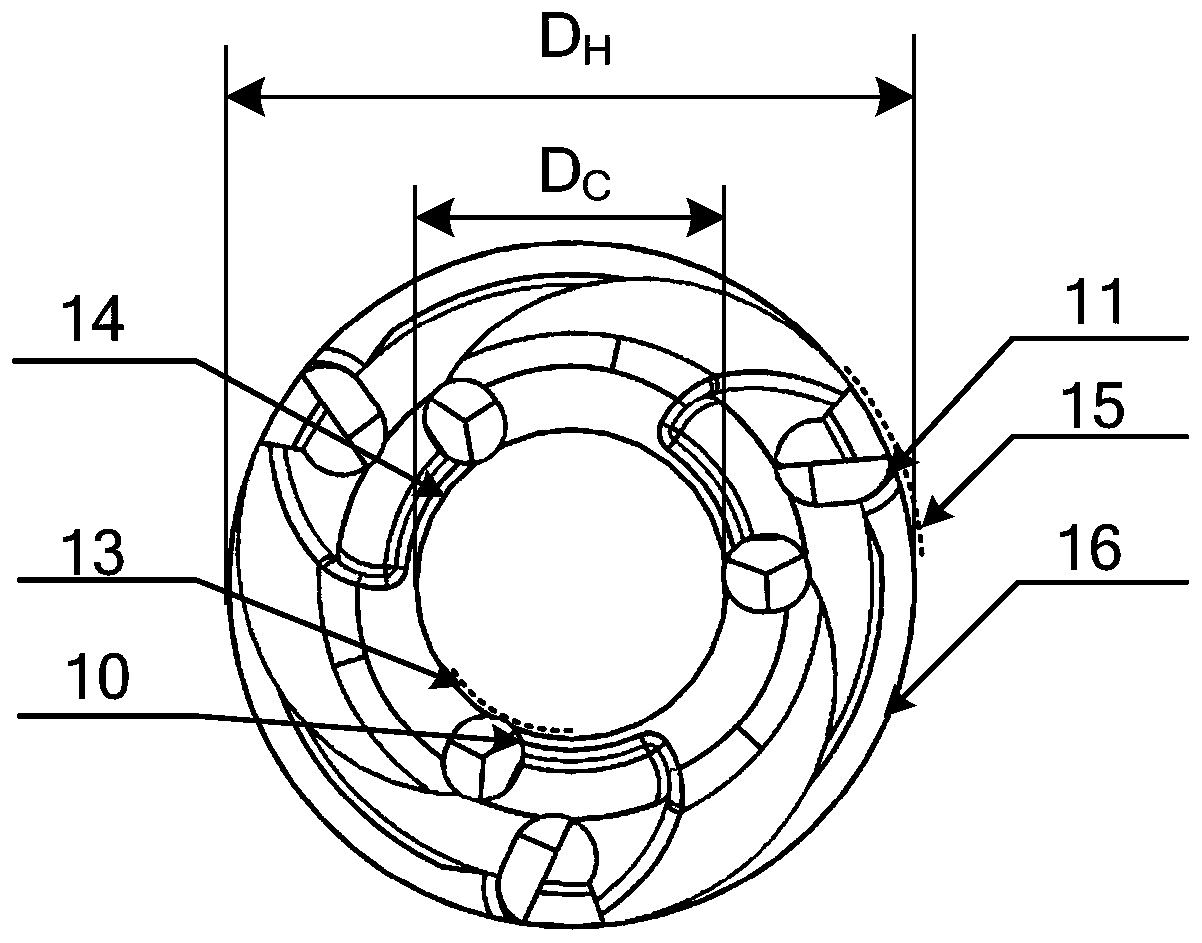

Low-force high-efficiency simulated moon rock drilling core bit

ActiveCN109083598BRapid positioningReduce friction loadDrill bitsBulkheads/pilesEngineeringHead surface

The invention provides a low-force high-efficiency simulated lunar rock drilling core bit, which comprises a hollow cylindrical drill body. The end of the drill body is provided with an ellipsoidal head. A coring channel is formed between the inner surface of the drill body and the barrier ring. The outer surface of the drill body is provided with a spiral wing. The surface of the ellipsoidal head is processed with an ellipsoidal spiral wing for chip removal. It is set on the same helical line as the helical wing, and two groups of sharp-edged cutting tools are uniformly arranged on the circumferential direction of the ellipsoidal head, which are respectively the inner sharp-angle cutting tool group and the outer sharp-angle cutting tool group. The inner sharp-angle cutting tool group includes multiple The inner sharp cutting tool and the outer sharp cutting tool group include a plurality of outer sharp cutting tools, the number of the inner sharp cutting tool is equal to the head number of the ellipsoidal spiral wing, and the number of the outer sharp cutting tool is equal to the number of heads of the screw wing. The numbers are equal. The invention can obtain better debris removal effect and higher core extraction rate in the surface drilling test of molded lunar soil.

Owner:HARBIN INST OF TECH

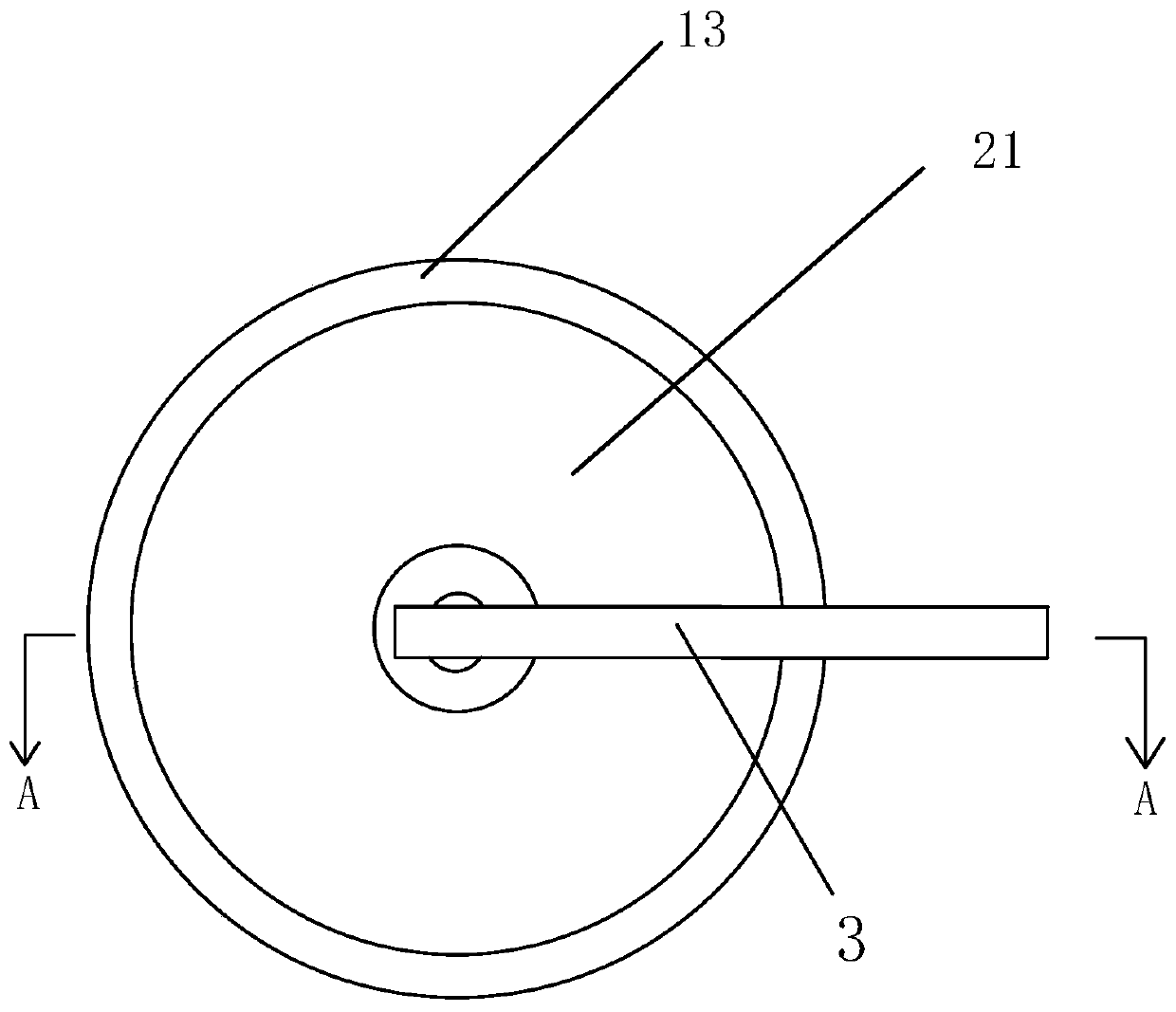

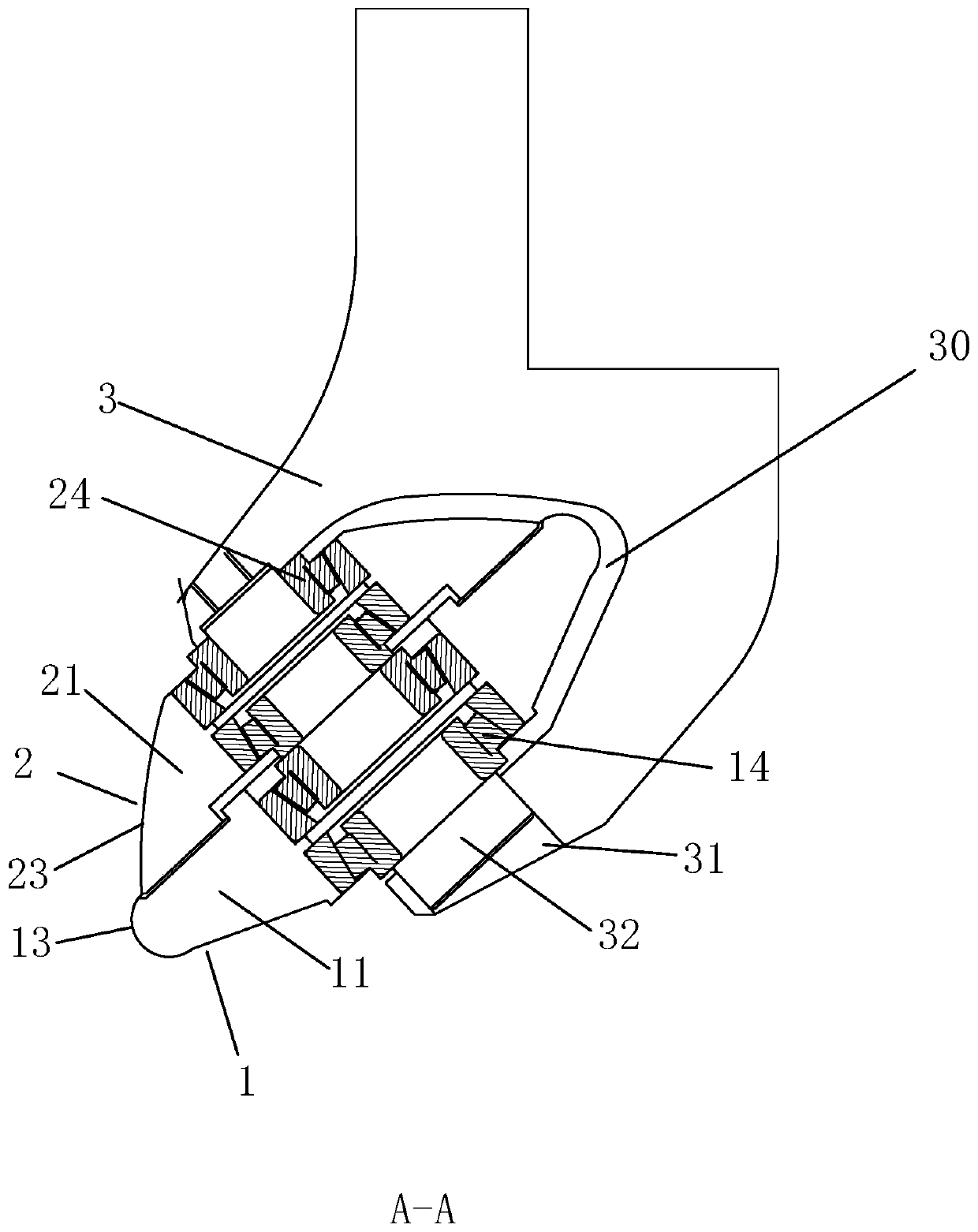

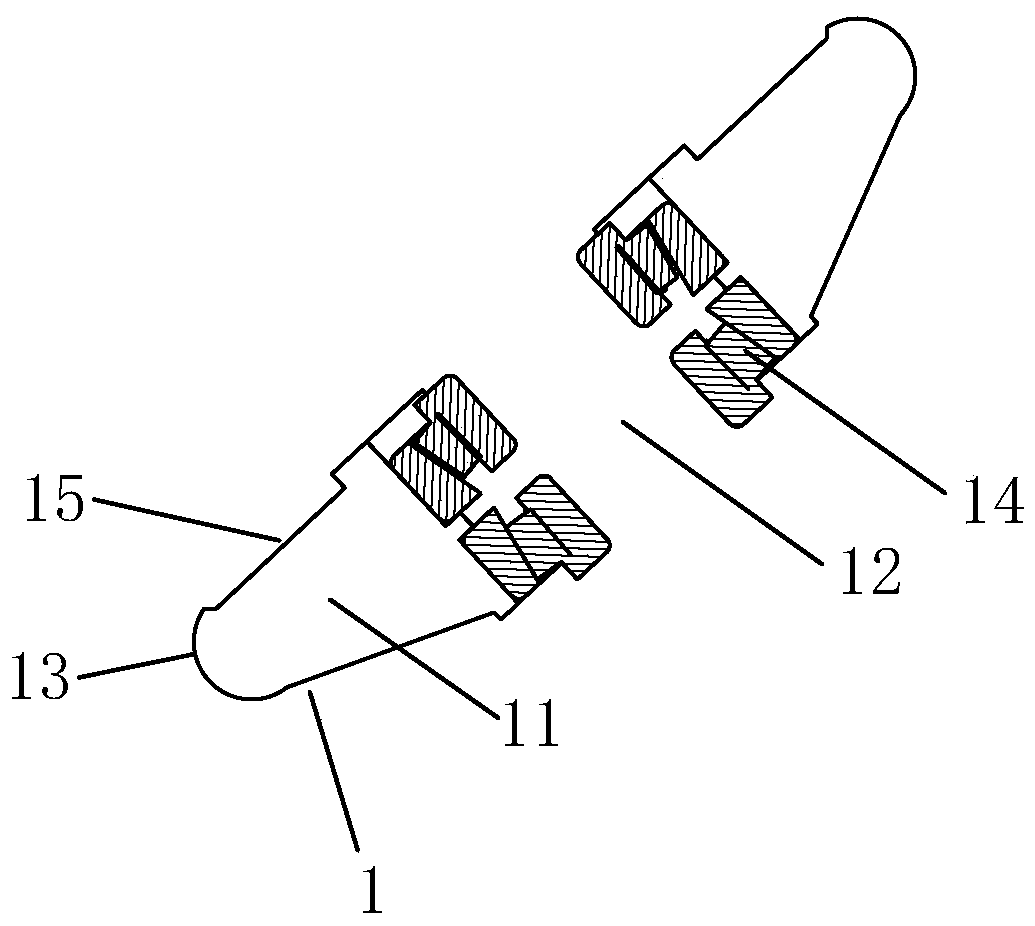

Multistage spinning roller

The invention discloses a multistage spinning roller, and belongs to the technical field of spinning. The multistage spinning roller comprises a main spinning roller (1) and a spinning wheel carrier (3). The main spinning roller (1) comprises a first roller body (11), and a first through hole (12) is formed in the middle of the first roller body (11). Auxiliary spinning rollers (2) are arranged onone side of the first roller body (11) and further comprise second roller bodies (21), and second through holes (22) are formed in the middles of the second roller bodies (21). The second through holes (22) and the first through hole (12) are located in the same axis. According to the multistage spinning roller, when the auxiliary spinning rollers (2) rotate passively, the surfaces of the auxiliary spinning rollers (2) and the surfaces of spun blanks can rotate at the same speed, friction is reduced, wrinkling and curling of the blanks are avoided, the adverse effects like blank vibrations can be prevented and product quality can be improved.

Owner:浙江博翔旋压机床有限公司

Flow diversion device, heavy oil viscosity reduction production system and production method thereof

The invention discloses a flow distributing device, a heavy oil viscosity decreasing exploitation system and an extraction method thereof. The flow distributing device comprises a hollow body and a sliding sealing block. The hollow part is a through hole, and the upper end and the lower end of the through hole are used for being connected with oil pipes. A first opening and a second opening are formed in the side wall of the body in the axial direction. A first check valve communicated with the first opening is arranged on the first opening, and a second check valve communicated with the second opening is arranged on the second opening. The sliding sealing block is arranged in the hollow part of the body in a sealed mode, can be fixed to a pumping rod, and can move axially along with the pumping rod. The heavy oil viscosity decreasing exploitation system with the flow distributing device and the extraction method thereof can effectively extract heavy oil.

Owner:PETROCHINA CO LTD

power transmission device

ActiveCN107869580BIt is easy to produce the situation of continuous rotationSmoothly combined stateGearing controlEngineeringCam

The present invention provides a power transmission device that can smoothly establish a coupling state between a first engaging portion of a driving gear and a second engaging portion of a driven gear through a simple structure. In the power transmission device, a plurality of cam grooves (91, 93) are formed in the speed change drum (84), and a sliding member (109) and a clutch hub constitute an abutment surface (114) that abuts the clutch housing (56). (57) is engaged, and is equipped with an arm member (116) that drives the sliding member (109). The arm member (116) is connected to the cam groove (93). The arm member (116) follows the movement of the speed change drum (84). The sliding member (109) is driven into contact with the clutch housing (56).

Owner:HONDA MOTOR CO LTD

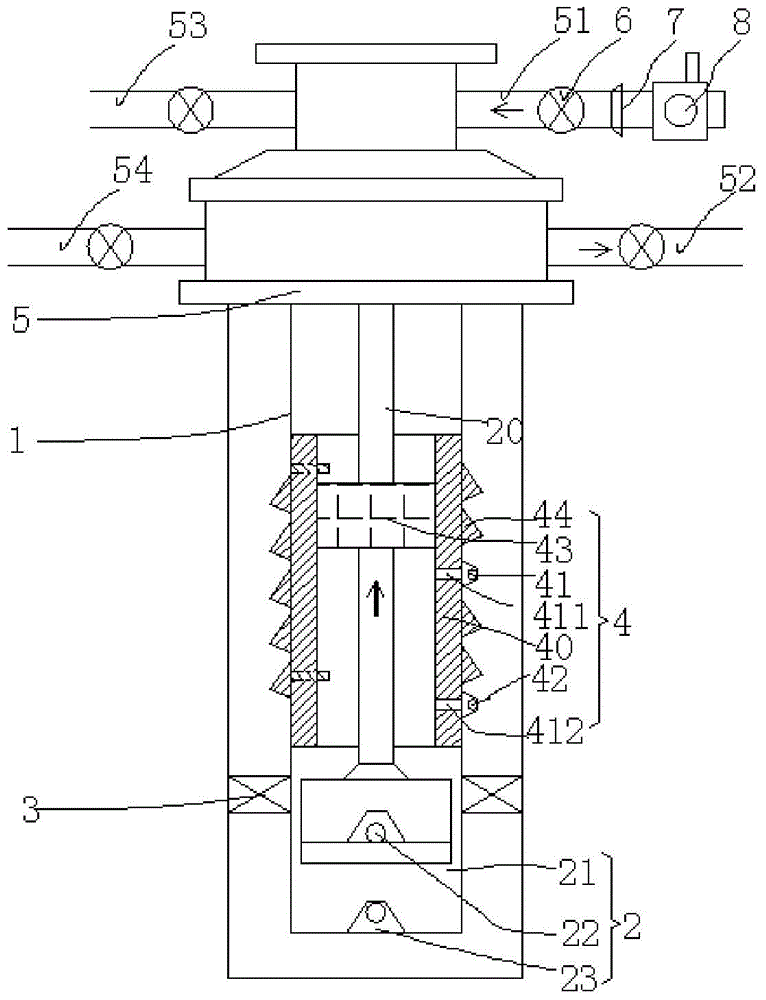

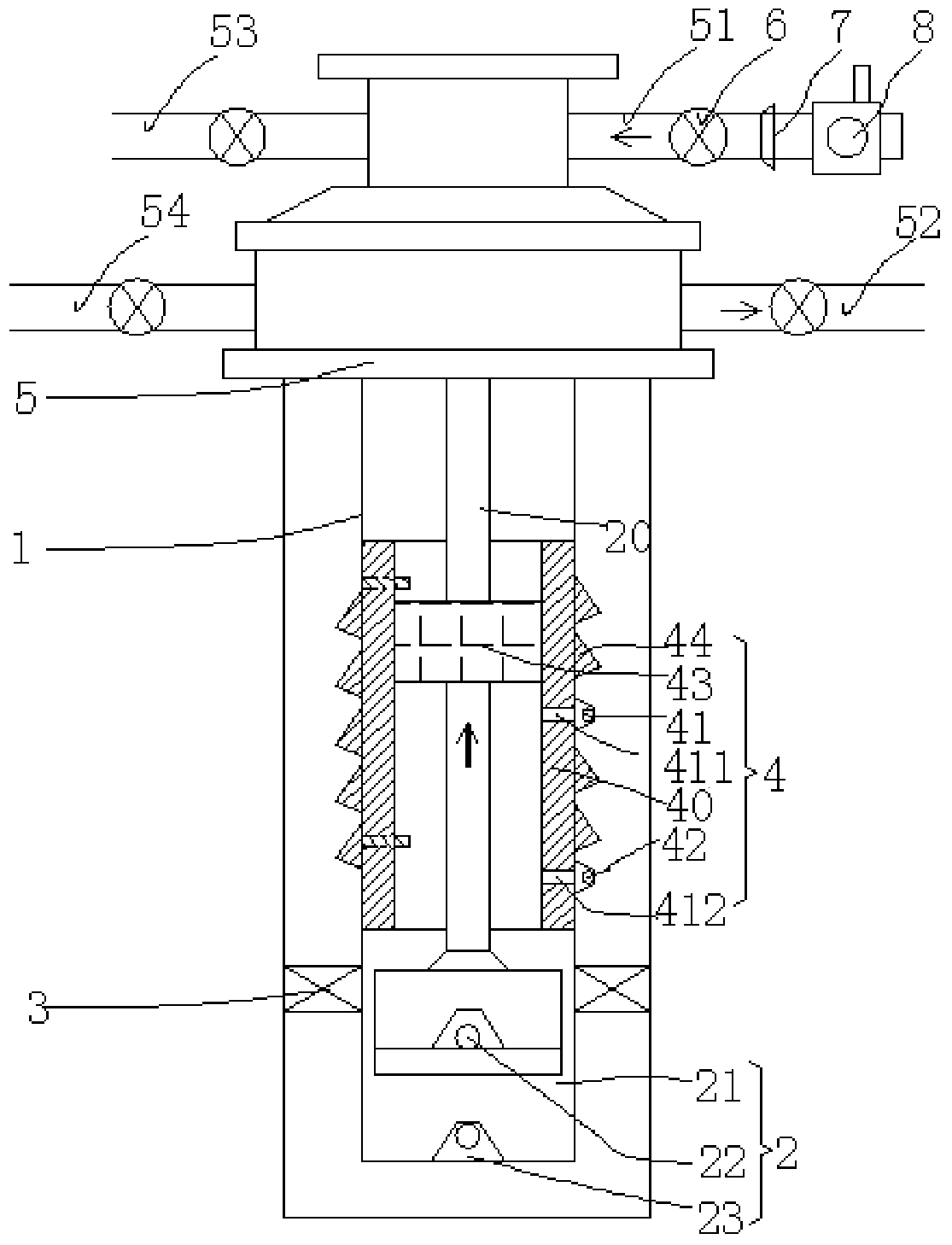

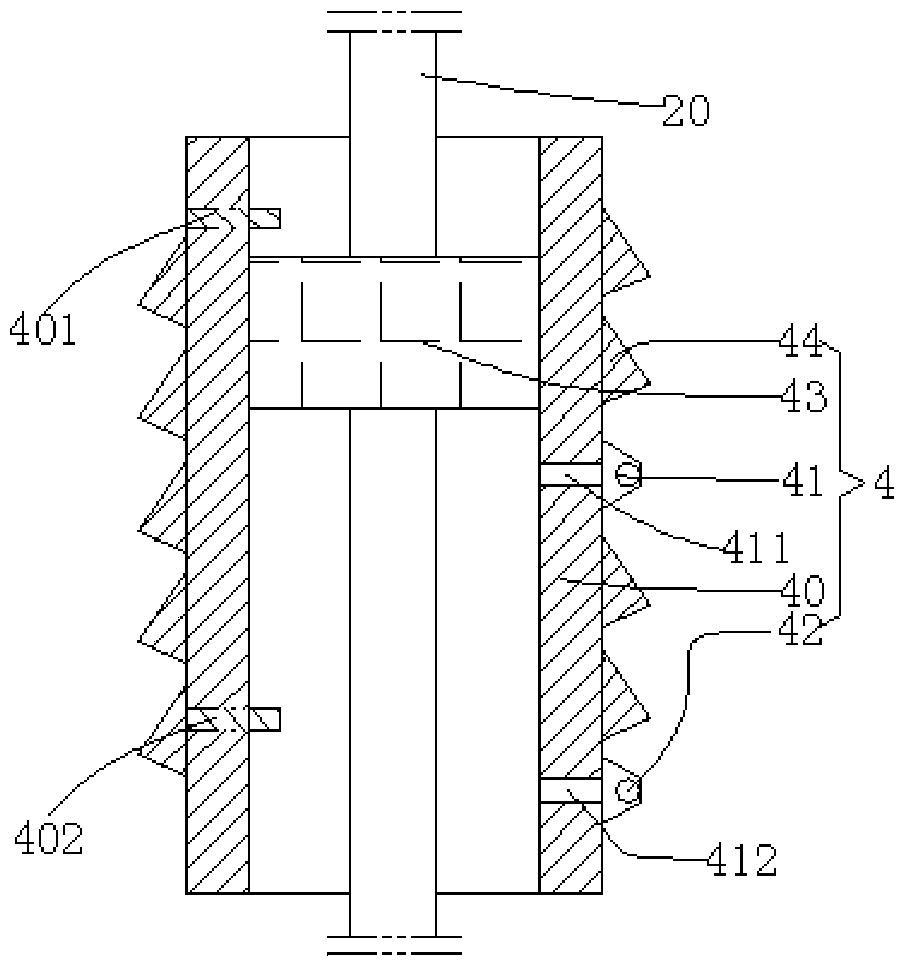

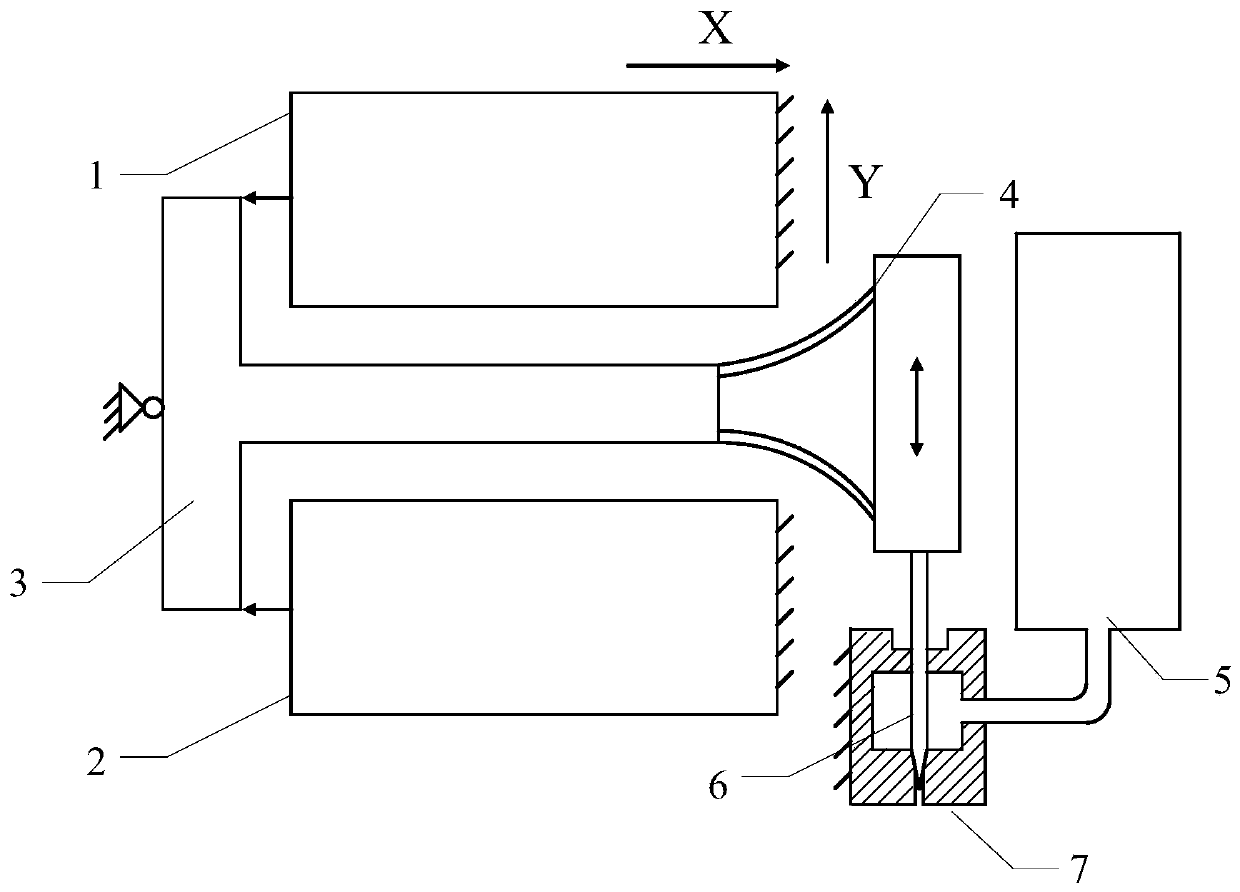

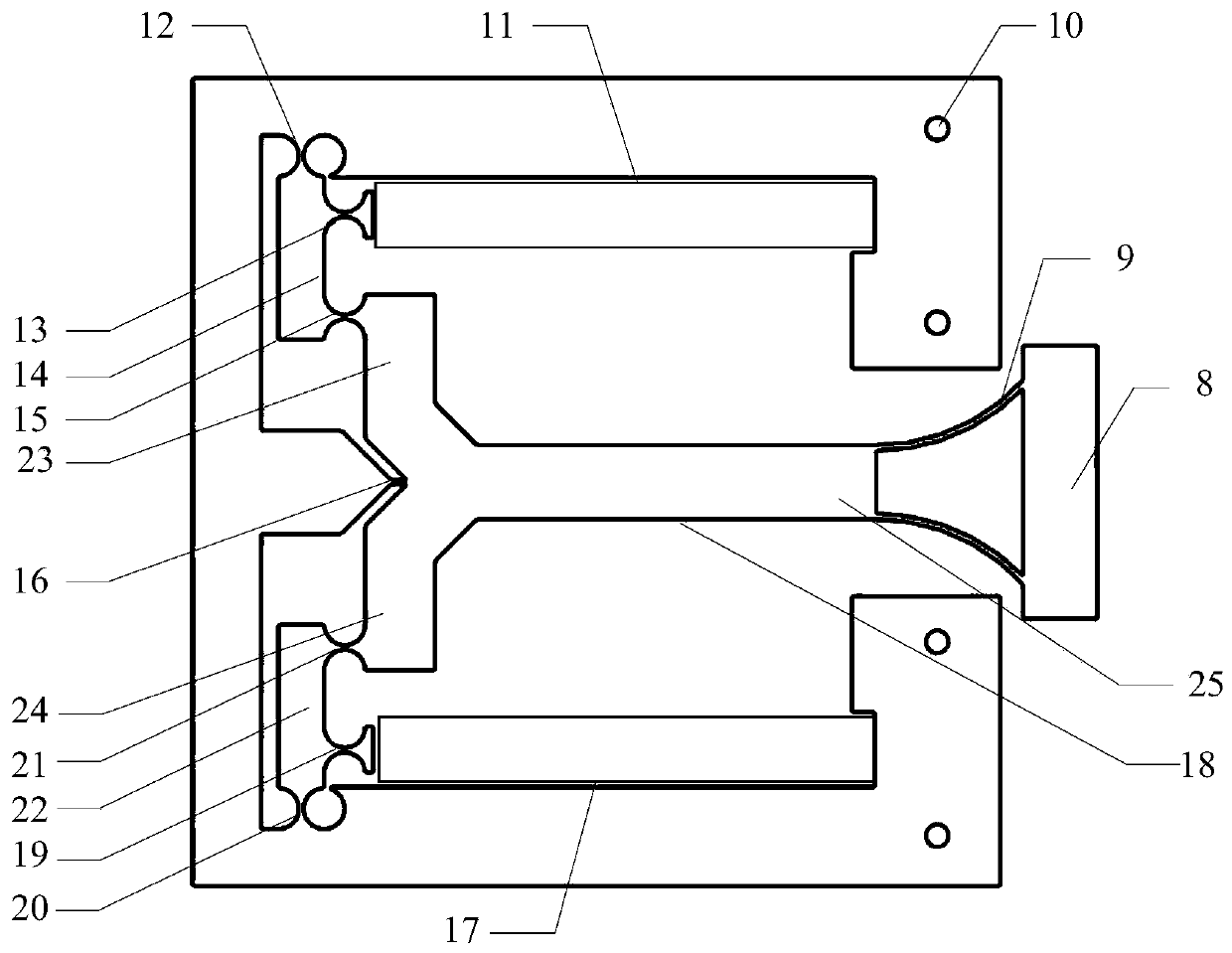

A micro-jet dispensing driving device

ActiveCN108672212BHigh displacement accuracyImprove controllabilityLiquid surface applicatorsCoatingsAdhesiveEngineering

The invention discloses a micro-jetting adhesive dispensing driving device. The device comprises an upper driving unit 1, a lower driving unit 2, a swinging unit 3 and an output unit 4; the two driving units are symmetrically arranged on two sides of the swinging unit; each driving unit adopts the flexible structure comprising a plurality of flexible hinges and rod pieces, and leftward-and-rightward micro-amplitude swinging of the rod pieces connected with the swinging unit is realized through elastic deformation of the flexible hinges; the swinging unit comprises a flexible hinge and a T-shaped rod, leftward-and-rightward swinging of the driving units is transferred to the swinging unit through elastic deformation of the flexible hinge, and up-and-down micro-amplitude swinging of the swinging unit is realized; the output unit comprises two symmetrically-arranged arc-shaped flexible beams and a striker fixing rod, up-and-down swinging of the swinging unit is transferred to the output unit through elastic deformation of the arc-shaped flexible beams, up-and-down micro-amplitude swinging of the rod pieces for mounting strikers is realized, and the micro-jetting function is realized.The designed micro-jetting adhesive dispensing driving device can be used in the fields of bioengineering, rapid manufacturing, electronic packaging and the like.

Owner:上海端怡科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com