Five-wing fourteen-tooth anti-concretion drill bit

An anti-nodule and drill bit technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve problems such as drill bit fatigue and unusability, and achieve the effects of increasing propulsion pressure, reducing friction load, and reducing flash temperature phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

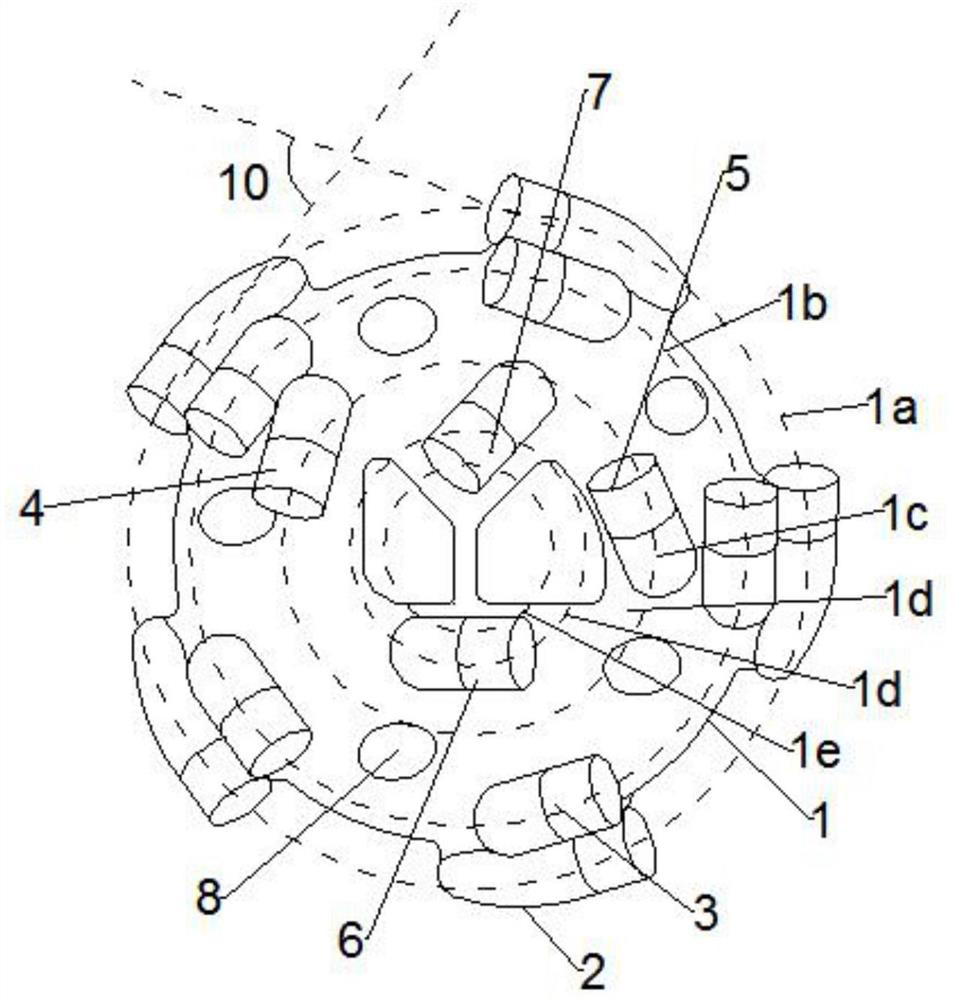

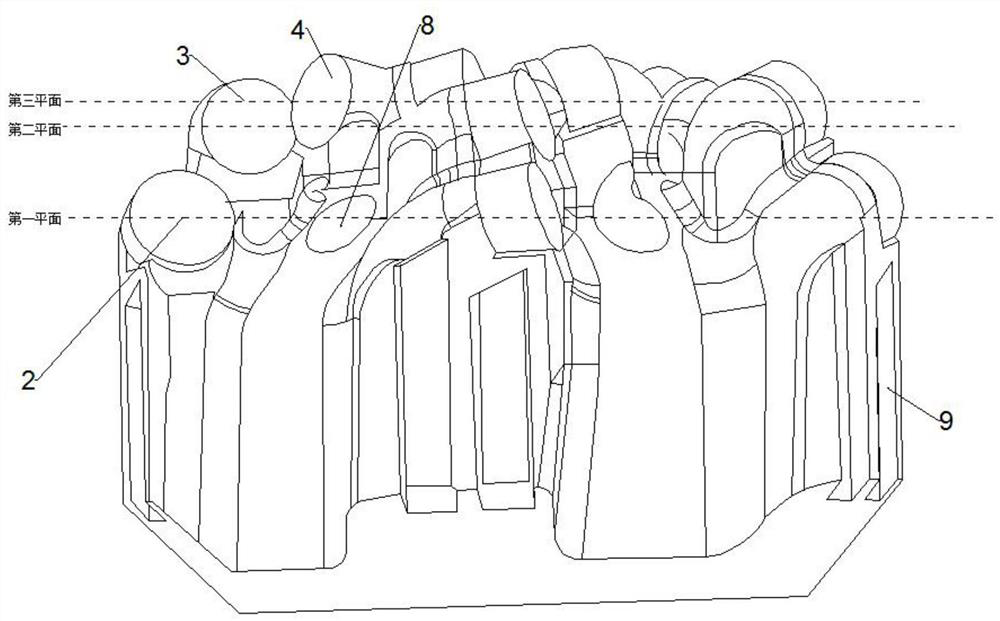

[0018] refer to Figure 1-2 As shown, the present invention provides a five-wing fourteen-tooth anti-tuberculosis drill bit, which includes a drill body 1, and takes the center of the drill body 1 as a circle to make a ring of cutting tooth lines 1a, a second ring of cutting tooth lines 1b, The three-ring cutting tooth line 1c, the fourth-ring cutting tooth line 1d, and the fifth-ring cutting tooth line 1e, these five cutting tooth lines are used as auxiliary lines when the drill bit is processed, and the first ring cutting tooth line 1a is located outside the drill body 1. The outer edge of the drill body 1 is provided with five drill teeth A2, the five drill teeth A2 are located in the first plane and the center of the tooth surface of the drill teeth A2 is located on a ring cutting tooth line 1a, between the side walls of the two adjacent drill teeth A2 A slag discharge groove is formed in between, and five drill teeth B3 are arranged near the inner side of the drill tooth ...

Embodiment 2

[0020] On the basis of the above embodiments, another embodiment of the present invention is that an included angle 10 is formed between the center extension lines of two adjacent drill teeth A2, and the angle of the included angle 10 is 72°, so that the drill teeth A2 Located in the same circle center, the distance between the drill teeth A2 is equal, the second plane is 10mm higher than the first plane, and the third plane is 1.5mm higher than the second plane, so that the whole drill bit is stepped, forming an umbrella-like dynamic during rotation , Favorable slag discharge and water rejection.

Embodiment 3

[0022] On the basis of the above embodiments, another embodiment of the present invention is that the diameter of the drill bit body (1) is 98-105mm. The distance difference between the first-ring cutting tooth line 1a and the second-ring cutting tooth line 1b is 2mm, so that during the rock crushing process, rocks not cut by this 2mm will fall by themselves under the action of external force, and the fourth-ring cutting tooth line The diameter difference between 1d and the five-ring cutting tooth line 1e is 4mm, and the side wall surface of the drill tooth A2 is provided with a gage bar 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com