Meat mincing and sausage filling integrated machine easy to clean

An easy-to-clean, all-in-one technology, which is applied to sausage enema machines, processed meat, and meat processing equipment, can solve problems such as difficult cleaning, low enema efficiency, and high work difficulty, and achieves reduced work difficulty, simple assembly, and improved Effect of Enema Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

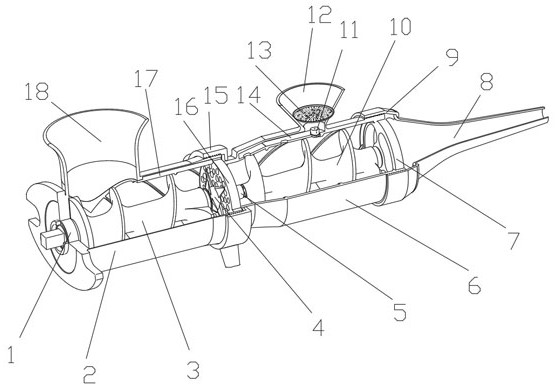

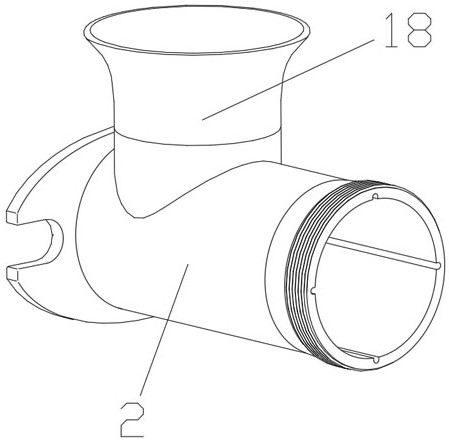

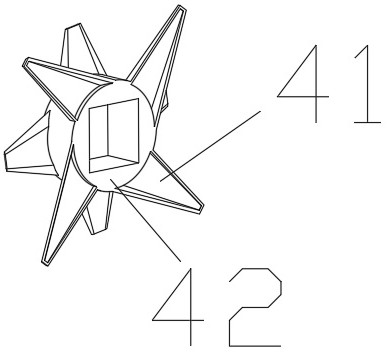

[0031] see Figure 1-11 As shown, the present invention includes a housing 2, the housing 2 is provided with a feed port 18, a screw push rod 3 is provided through the housing 2, and the screw push rod 3 is rotationally and fixedly connected with the housing 2 through a rolling bearing 1, and the On the output side of the housing 2, the end of the screw push rod 3 is axially connected to one end of the cutter shaft 5. On the output side of the blade 4 of the cutter shaft 5, the cutter shaft 5 is fitted with an orifice plate 16, and the cutter shaft 5 is connected to the orifice plate. 16 with a gap fit, on the outside of the other end of the cutter shaft 5, the housing 2 is connected to the enema nozzle 8 through the fixed end cover 15, the screw push rod 3 and the cutter shaft 5 are threadedly connected, and the cover surface of the fixed end cover 15 is in the form of a ring On the surface, the vertical wall surface of the fixed end cover 15 and the housing 2 are threaded, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com