Multistage spinning roller

A spinning wheel and main spinning wheel technology, applied in the field of spinning, can solve problems such as curling, billet wrinkling, and affecting product quality, and achieve the effects of preventing vibration, wrinkling, and shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

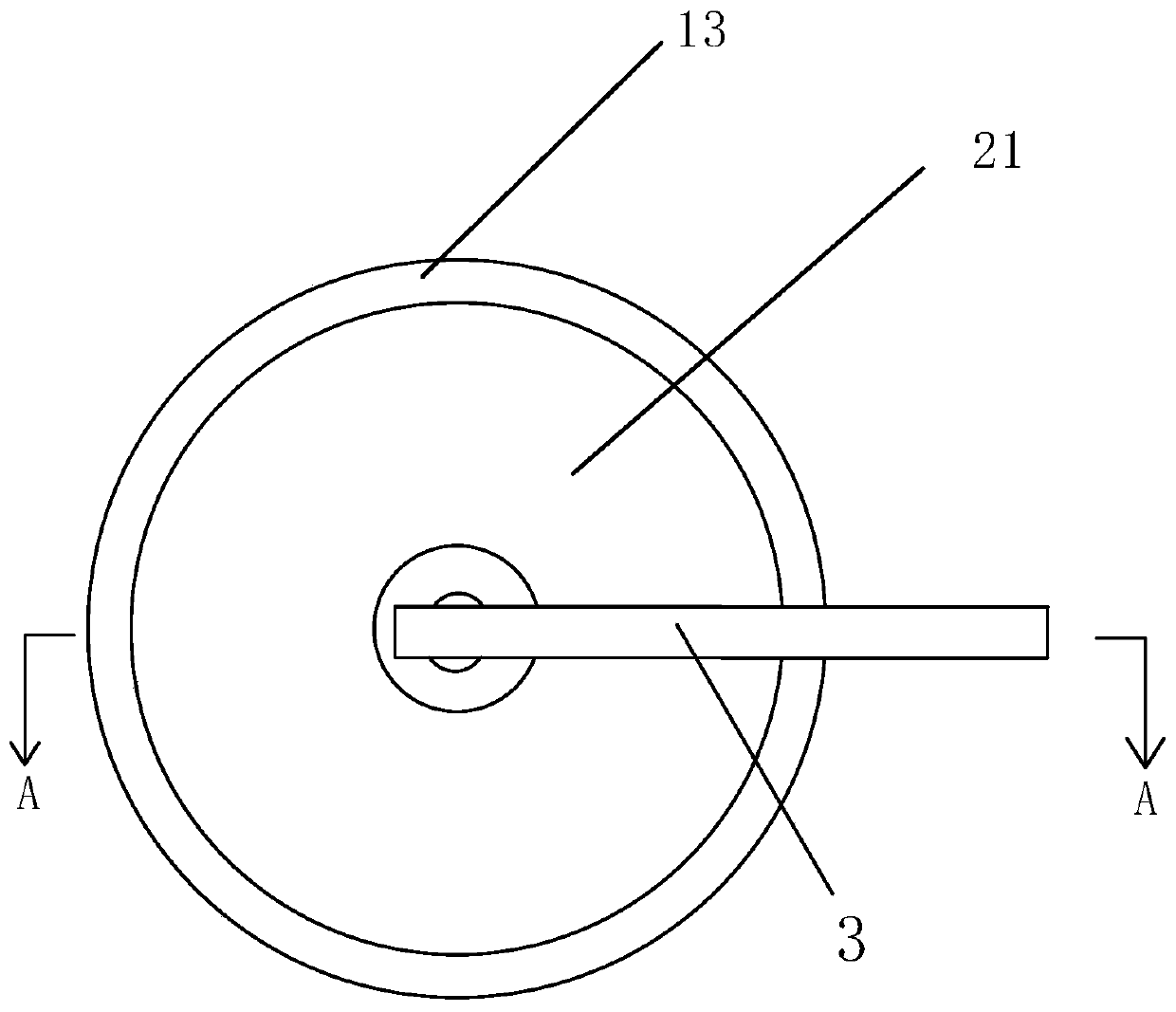

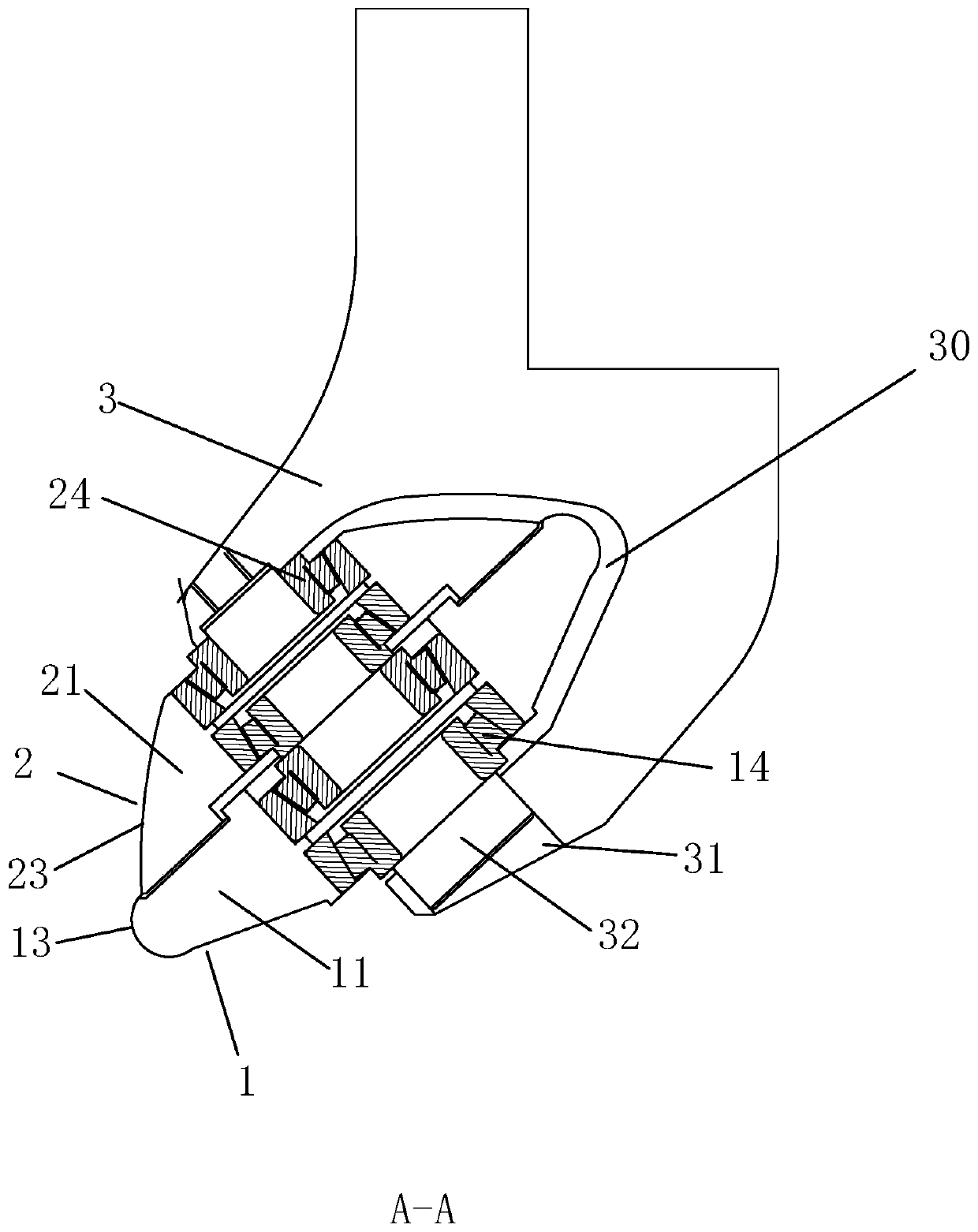

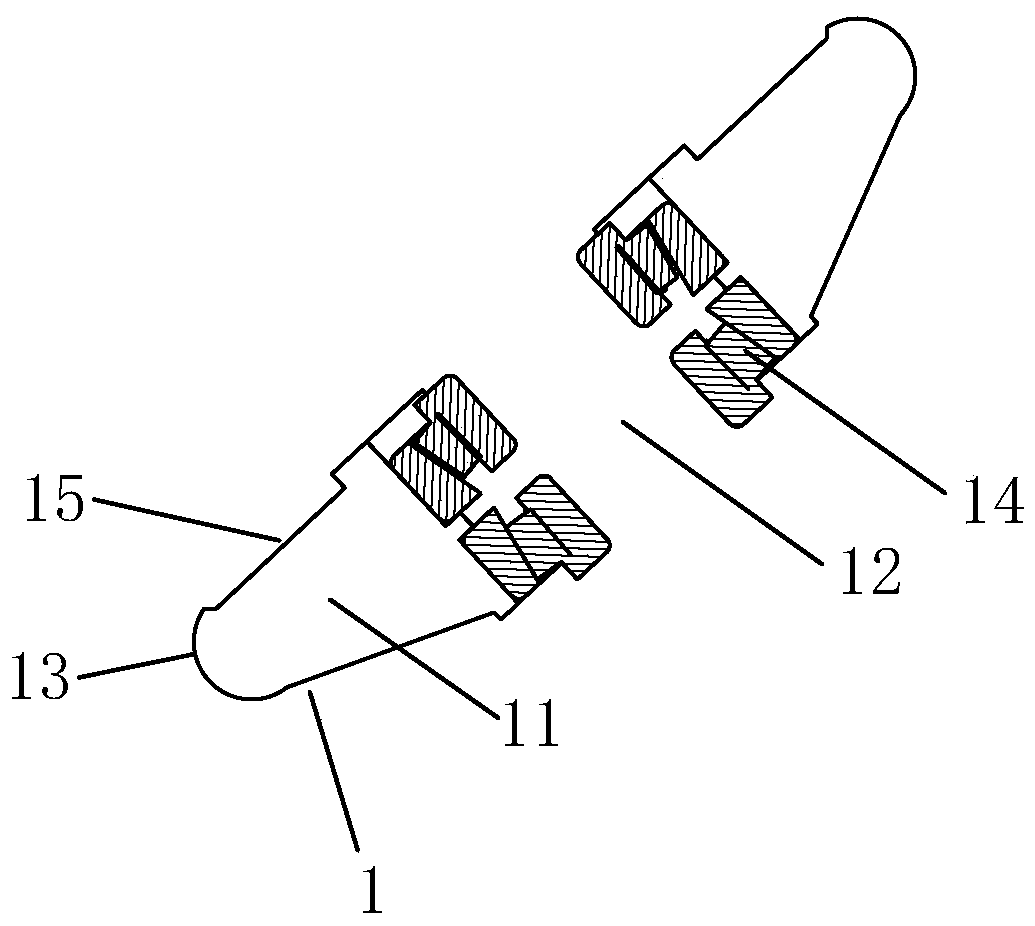

[0027] Embodiment 1: as Figure 1 to Figure 4 A multi-stage rotary wheel shown includes a main rotary wheel 1 and a rotary wheel frame 3 for installing the main rotary wheel 1, a notch 30 is set on the rotary wheel frame 3, and a notch 30 is provided at both ends of the notch 30 Fixed hole one 31, fixed shaft 32 is arranged on the fixed hole one 31, the fixed shaft 32 matches with the fixed hole one 31, the fixed shaft 32 is fixed in the fixed hole one 31, and is used for fixing the main roller 1 and the auxiliary roller 2 . The main wheel 1 includes a wheel body 11, and a flange 13 is arranged on the edge of the wheel body 11 in the circumferential direction. The material of the flange 13 is hard, which is beneficial to extruding the blank. In the middle of the wheel body one 11, a through hole one 12 through which the axial direction is penetrated is provided, and a bearing one 14 is arranged in the through hole one 12, and the bearing one 14 is fixed on the fixed shaft 32....

Embodiment 2

[0034] Example 2, such as Figure 5 , Image 6 As shown, other structures are basically the same as in Implementation 1. Due to the relatively large diameter of some billets, after spinning, due to the force of extrusion, the billet of the cylindrical body will be curled, and its curled surface exceeds the position of the auxiliary roller 2, so that the curled part of the billet will be Contact with other parts of the spinning machine will cause damage to other parts of the spinning machine, and also affect the quality of the blank. Therefore, in this embodiment, the notch 2 40 is set on the wheel frame 3, and the notch 2 40 and the The curled surface of the processed blank is opposite, and the two ends of the notch 40 are provided with a fixing hole 2 41, an auxiliary material shaft 42 is arranged on the fixing hole 2 41, an auxiliary material wheel 43 is arranged on the auxiliary material shaft 42, and an auxiliary material wheel 43 is set on the auxiliary material shaft 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com