Patents

Literature

41results about How to "Low current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

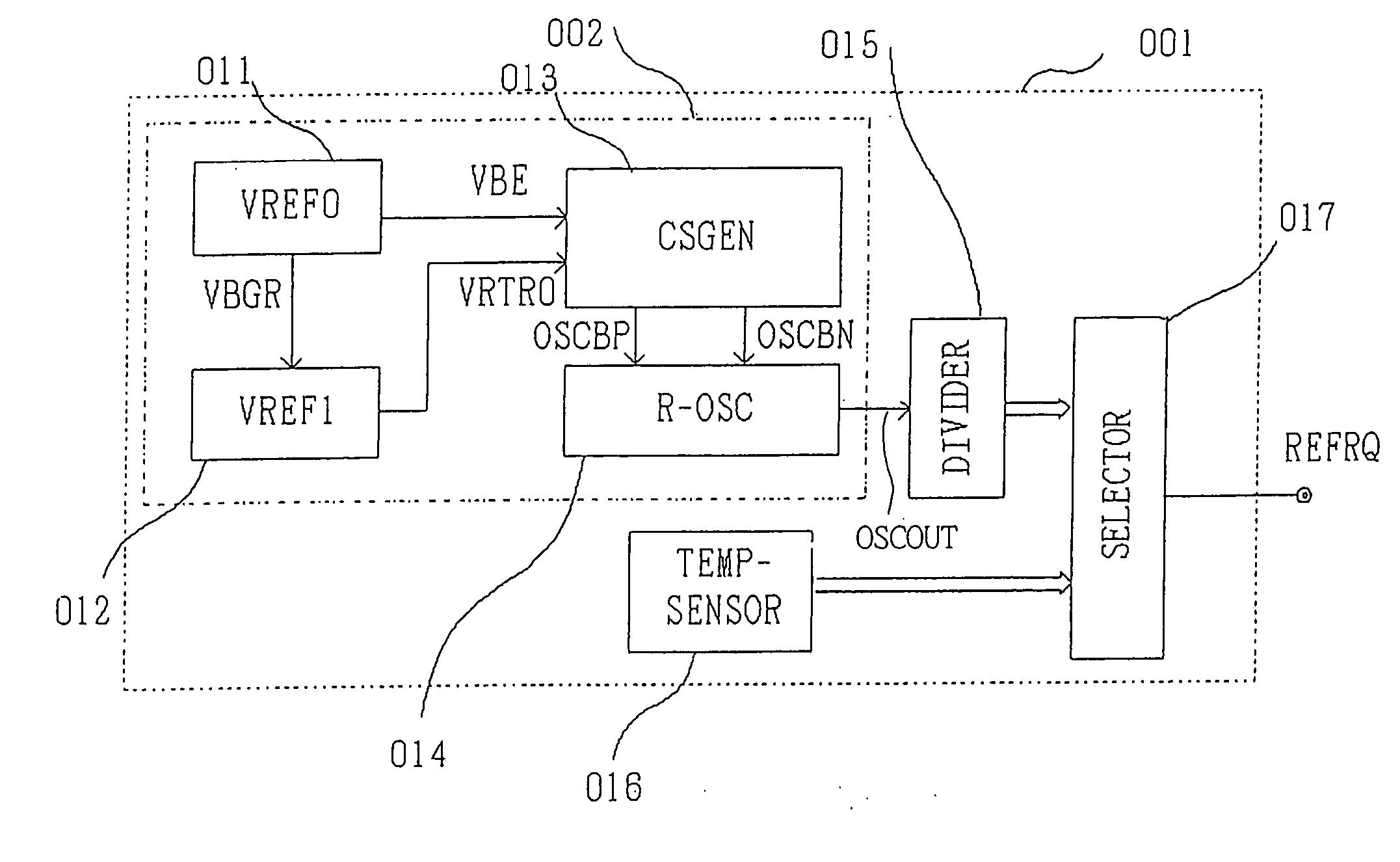

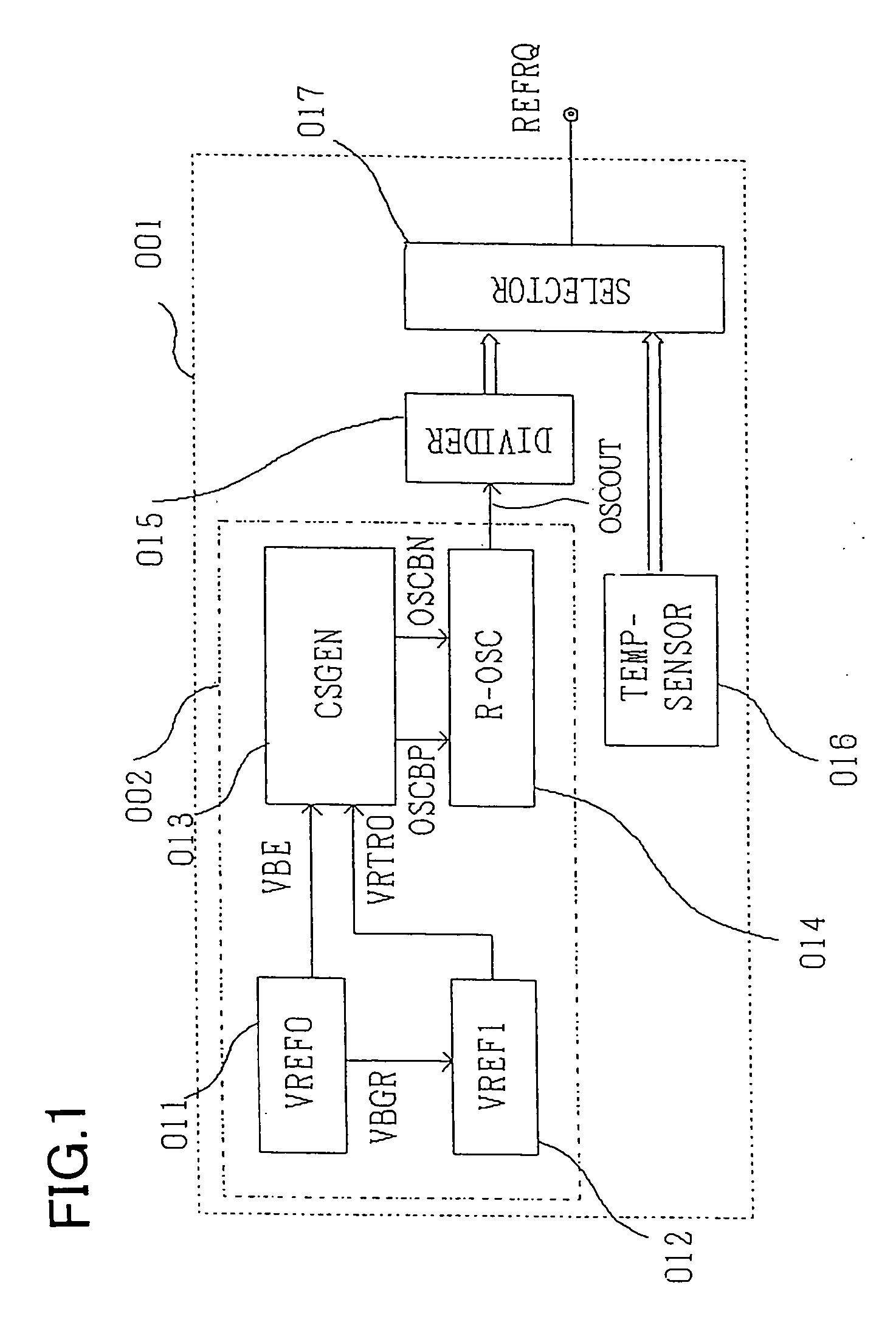

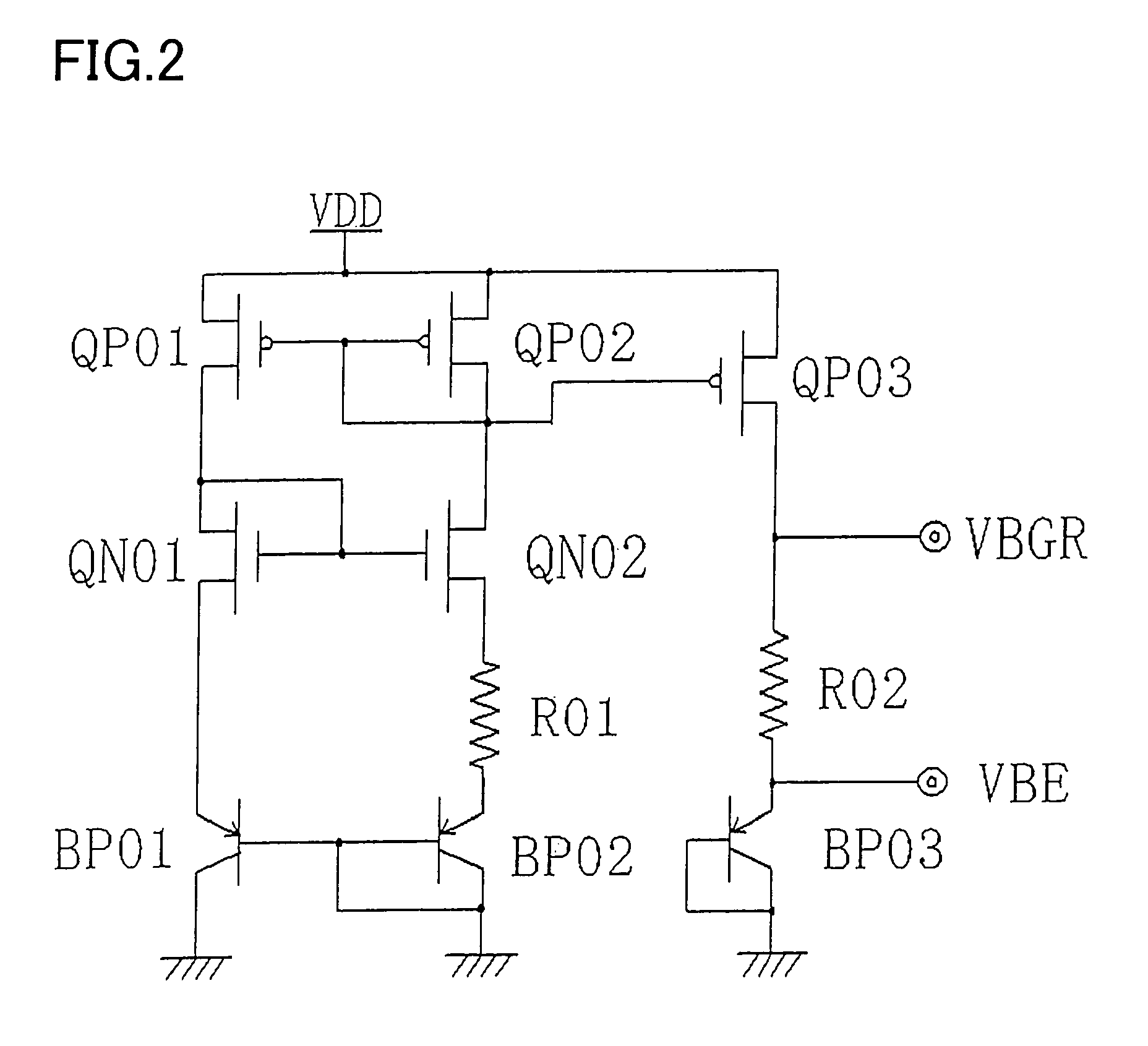

Refresh period generating circuit

A refresh period generating circuit which generates a refresh period in refreshing a DRAM cell, comprising: an oscillation circuit which oscillates at a frequency with temperature dependence on ambient temperature; a dividing circuit which divides an oscillation output of the oscillation circuit; a temperature detector which detects the ambient temperature; and a selector which switches and selects among division outputs with respective frequencies from the dividing circuit based on an output of the temperature detector, and outputs a signal as a reference of the refresh period. The temperature dependence in the oscillation circuit includes a positive temperature coefficient in a predetermined temperature range, and does not include a positive temperature coefficient out of the predetermined temperature range. The selector switches the division outputs out of the predetermined temperature range.

Owner:LONGITUDE LICENSING LTD

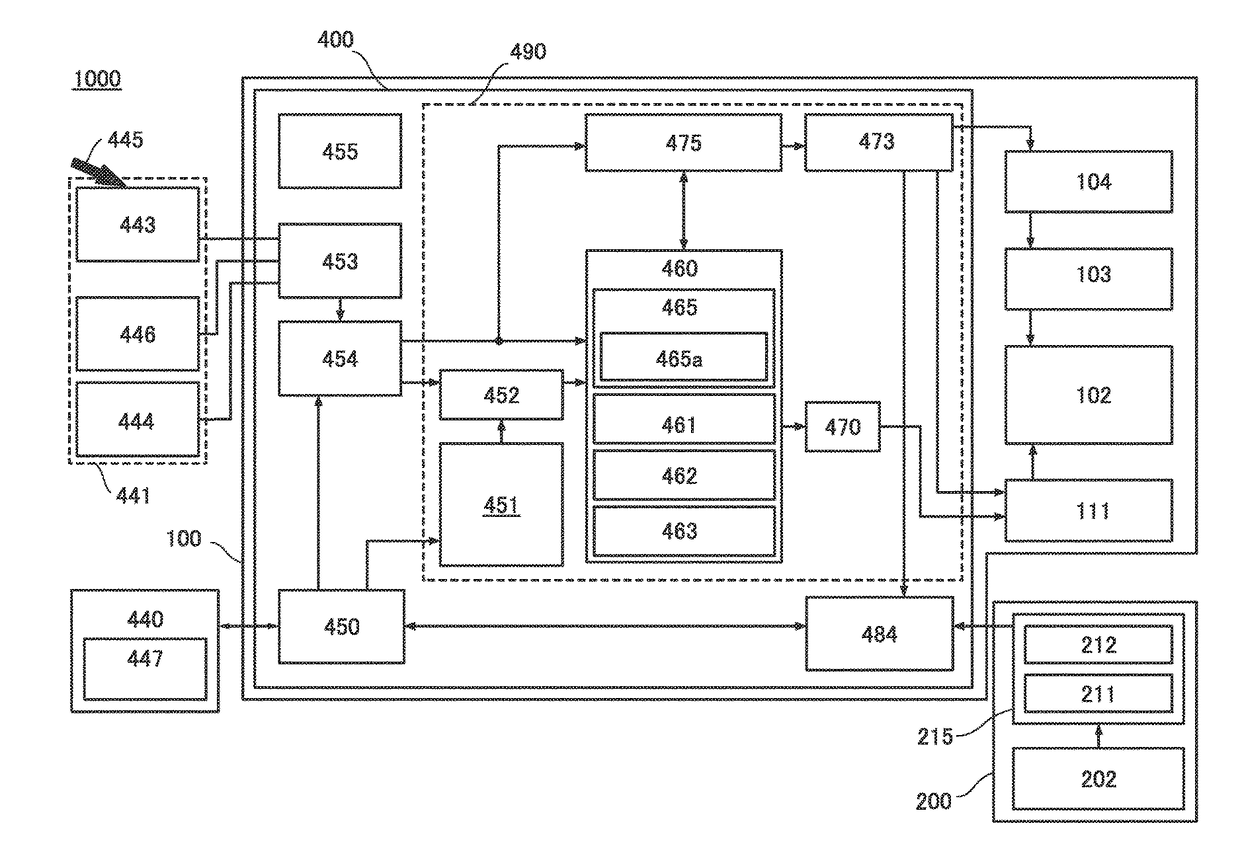

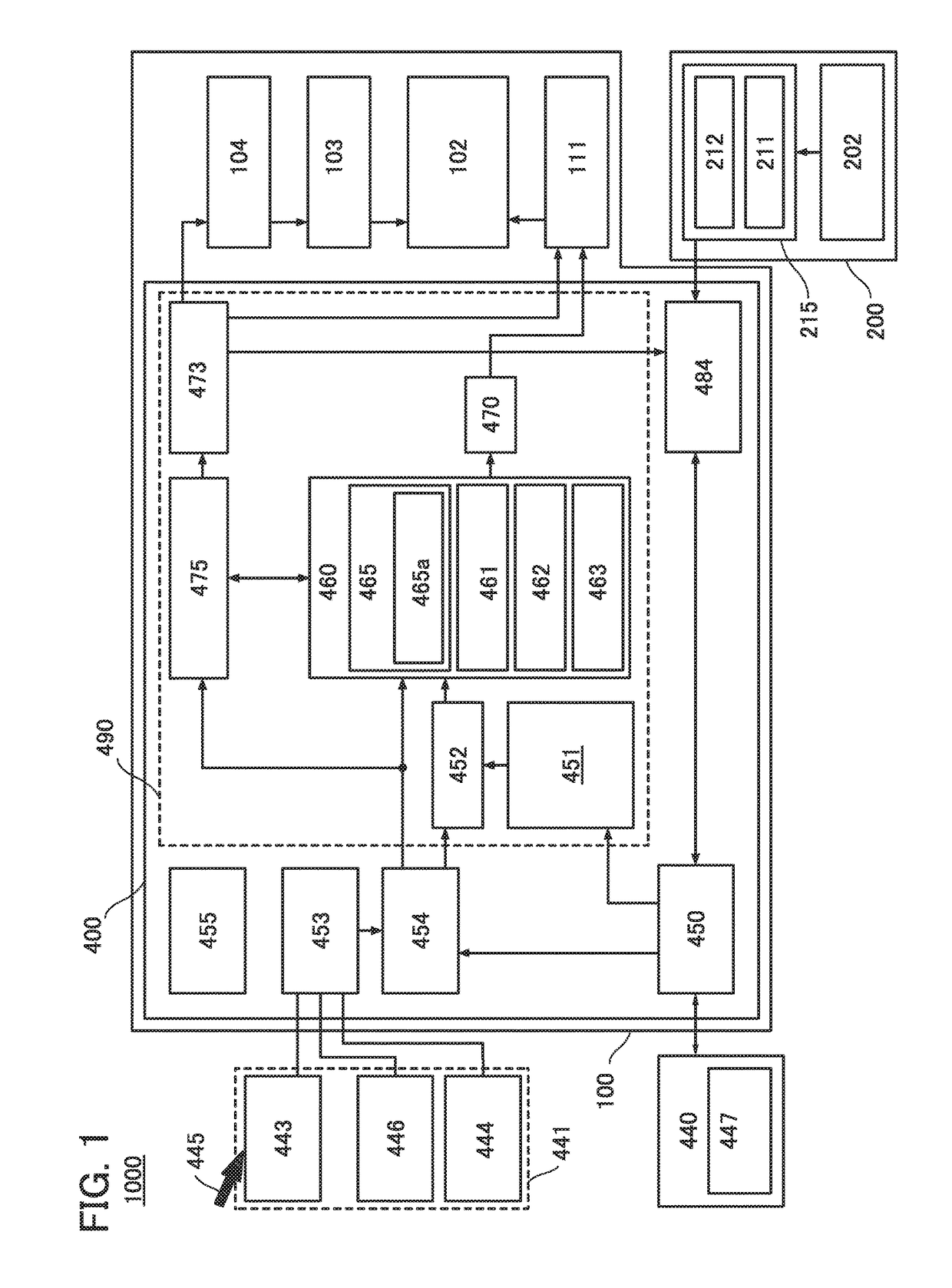

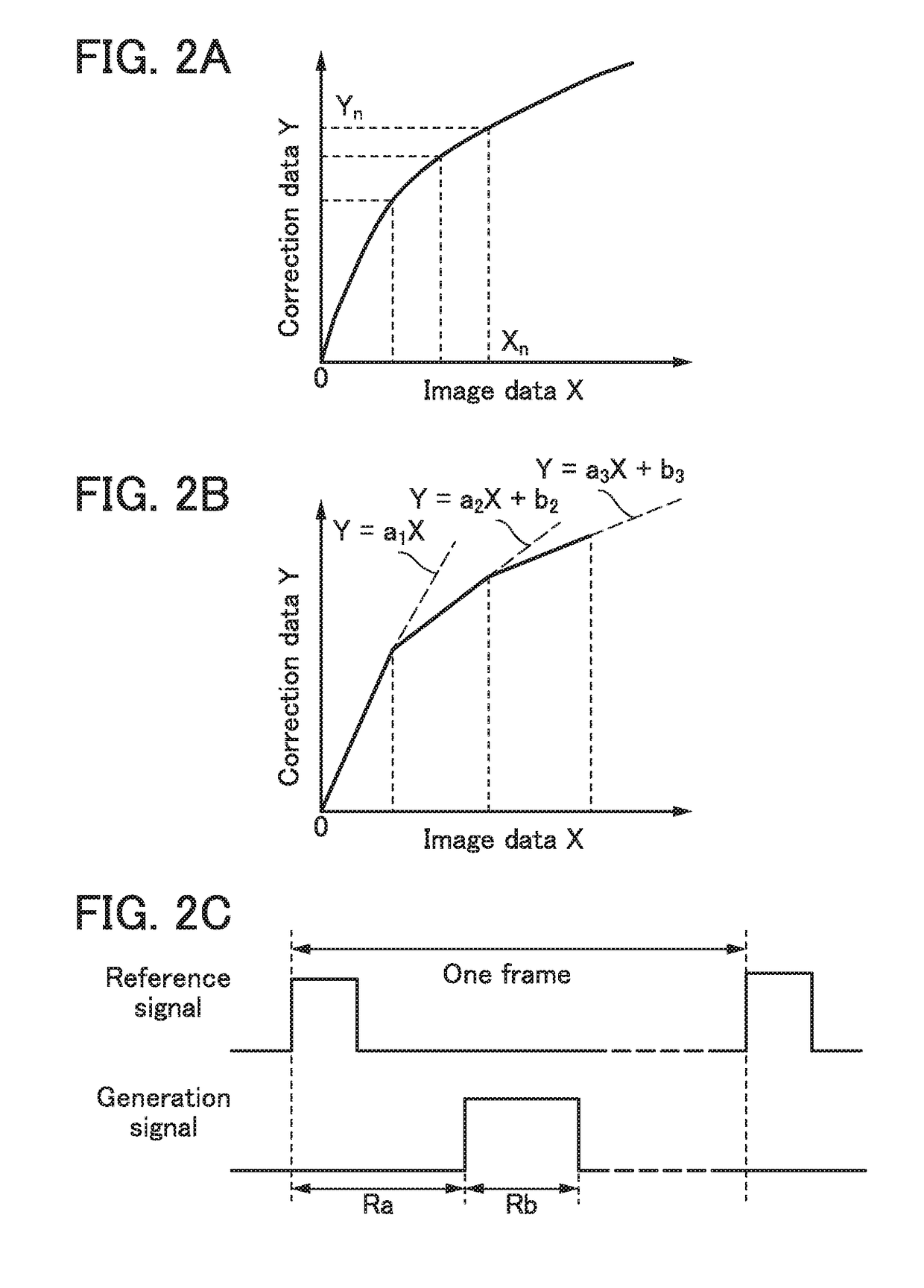

Display device and electronic device

A display device that performs image correction in accordance with external light environment is provided. The display device includes a host device and an optical sensor. In addition, the display device includes a processing circuit. The host device has a function of performing arithmetic processing using a neural network on software and a function of performing supervised learning with the neural network. The processing circuit has a function of performing arithmetic processing using a neural network on hardware. The optical sensor has a function of obtaining illuminance of external light. The obtained illuminance of external light is inputted to the host device, and a luminance and color tone preferred by users are regarded as teacher data, whereby learning is performed on the neural network of the host device. A weight coefficient obtained through the learning is used as a weight coefficient of the neural network of the processing circuit. By inputting illuminance of external light to the processing circuit, set values of luminance and color tone selected by the users are calculated in the neural network of the processing circuit.

Owner:SEMICON ENERGY LAB CO LTD

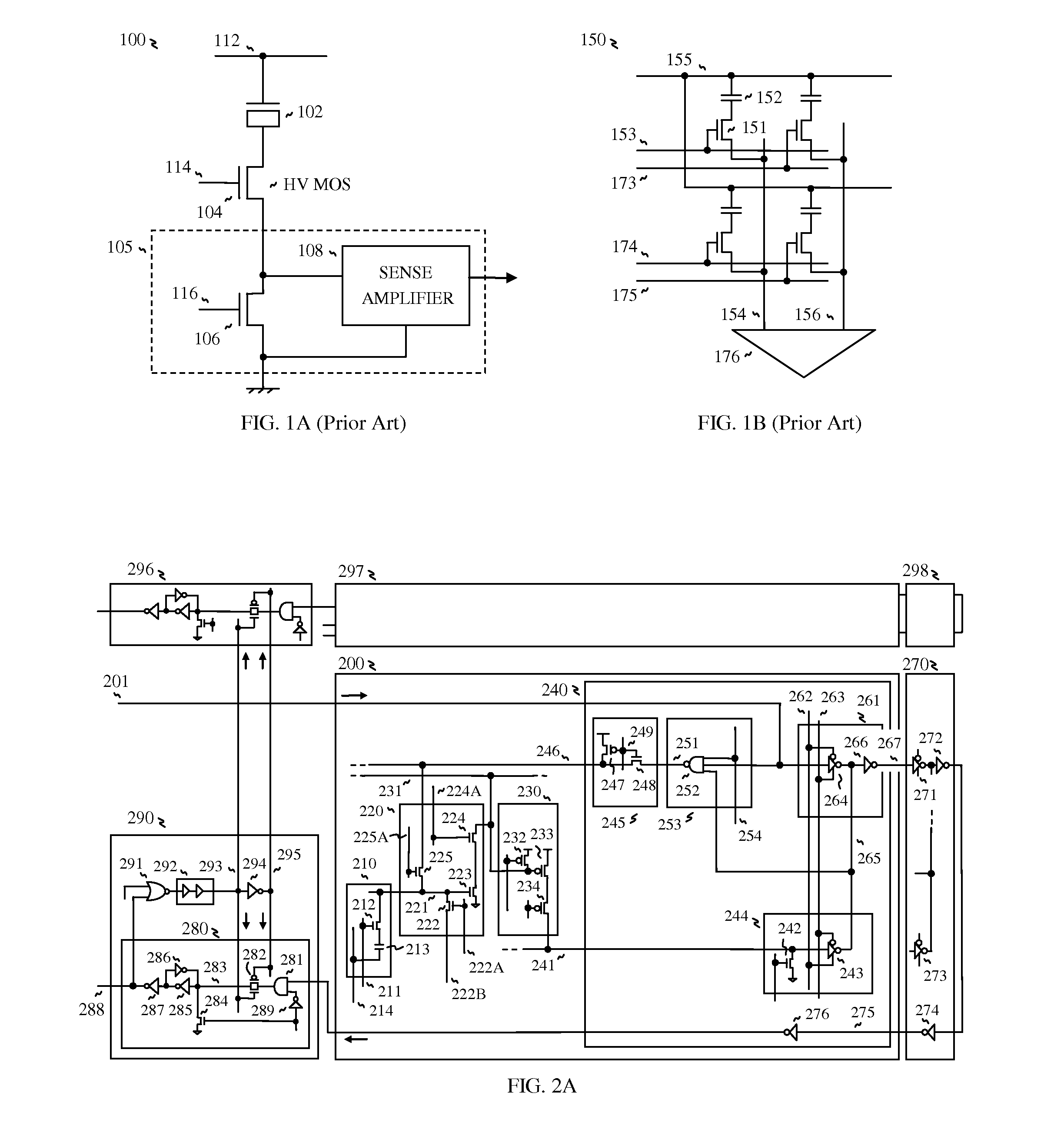

One-time programmable read only memory

InactiveUS20100061137A1Reduce sensitivityLow currentRead-only memoriesDigital storageData transmissionCapacitance

For realizing high speed one time programmable memory, bit line is multi-divided for reducing capacitance, so that the bit line is quickly charged when reading and multi-stage sense amps are used for connecting divided bit line, wherein the multi-stage sense amps are composed of a first dynamic circuit serving as a local sense amp for reading the memory cell, a second dynamic circuit serving as a segment sense amp for reading the local sense amp, and a tri-state inverter serving as an amplify circuit of a global sense amp for reading the segment sense amp. When reading data, a voltage difference in the bit line is converted to a time difference for differentiating high data (programmed) and low data (unprogrammed) by the multi-stage sense amps. And buffered data path is connected to the global sense amp for realizing fast data transfer. Additionally, alternative circuits and memory cell structures are described.

Owner:KIM JUHAN

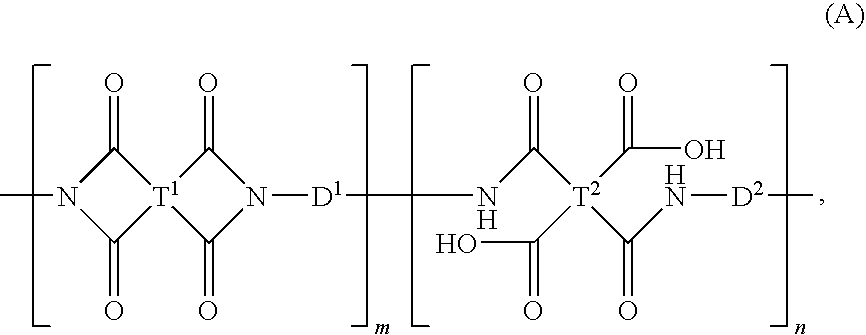

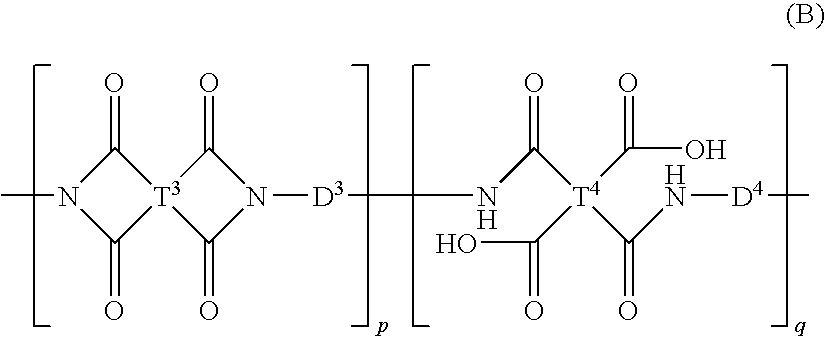

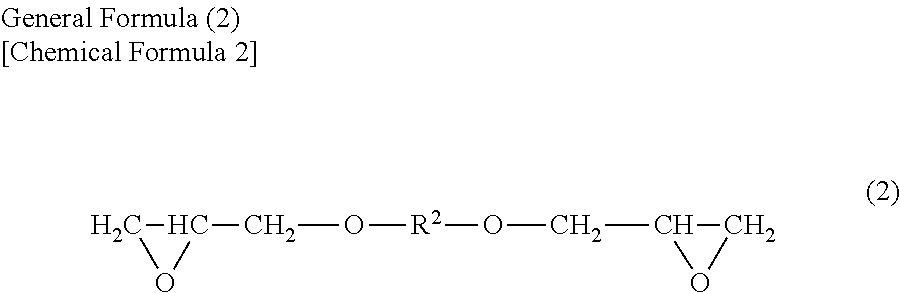

Liquid crystal alignment solution

ActiveUS20090194737A1High voltage holding ratioLow currentLiquid crystal compositionsThin material handlingDiaminePolyamide

A liquid crystal alignment solution is provided. The liquid crystal alignment solution includes a first polyimide-polyamide acid and a second polyimide-polyamide acid. The first polyimide-polyamide acid is represented by formula (A),and the second polyimide-polyamide acid is represented by formula (B),in which T1, T2, T3 and T4 are each independently a tetravalent residue of a tetracarboxylic acid dianhydride; D1, D2, D3 and D4 are each independently a divalent residue of a diamine; and m, n, p and q are each independently an positive integer,wherein m / (m+n)≦0.5 and p / (p+q)≧0.5.

Owner:DAXIN MATERIALS

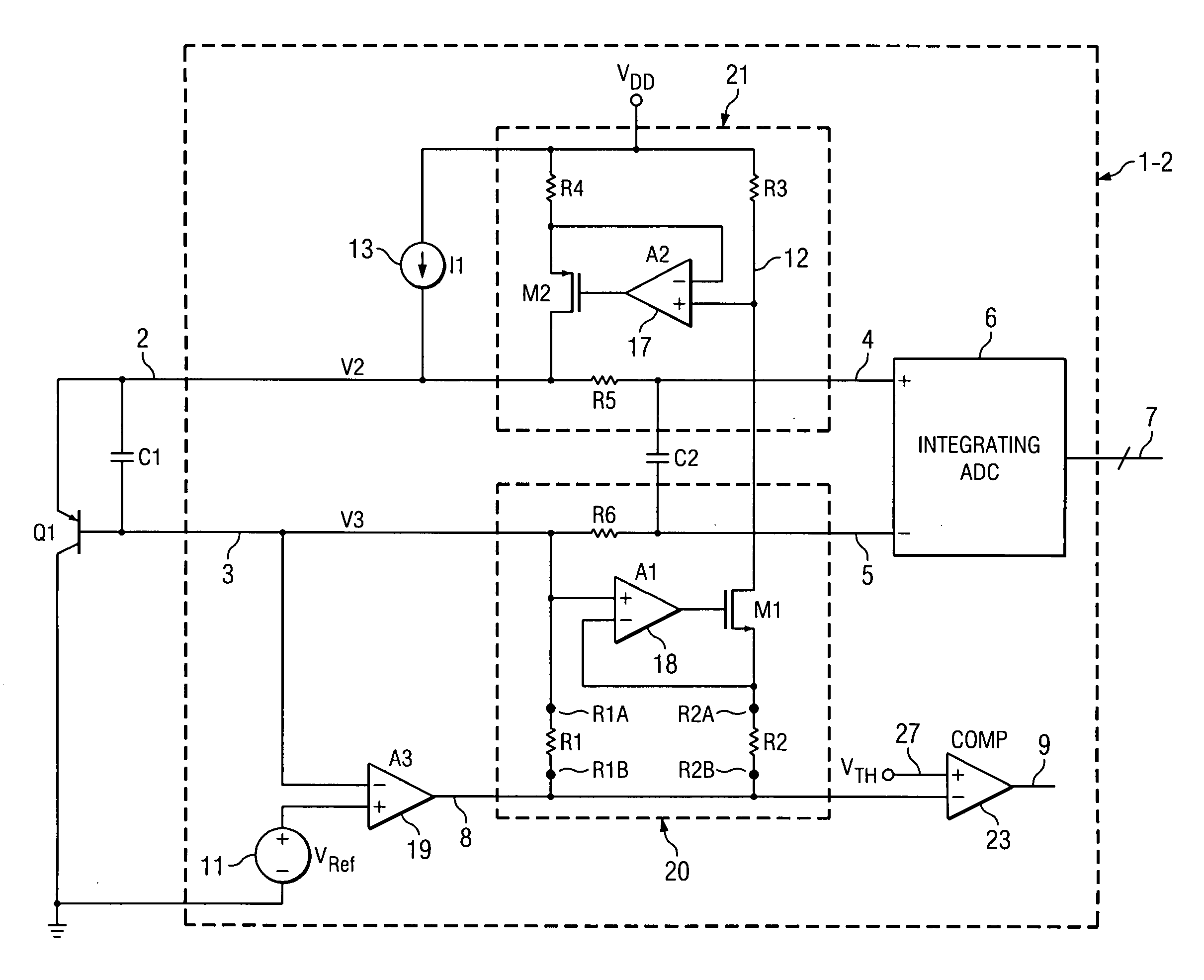

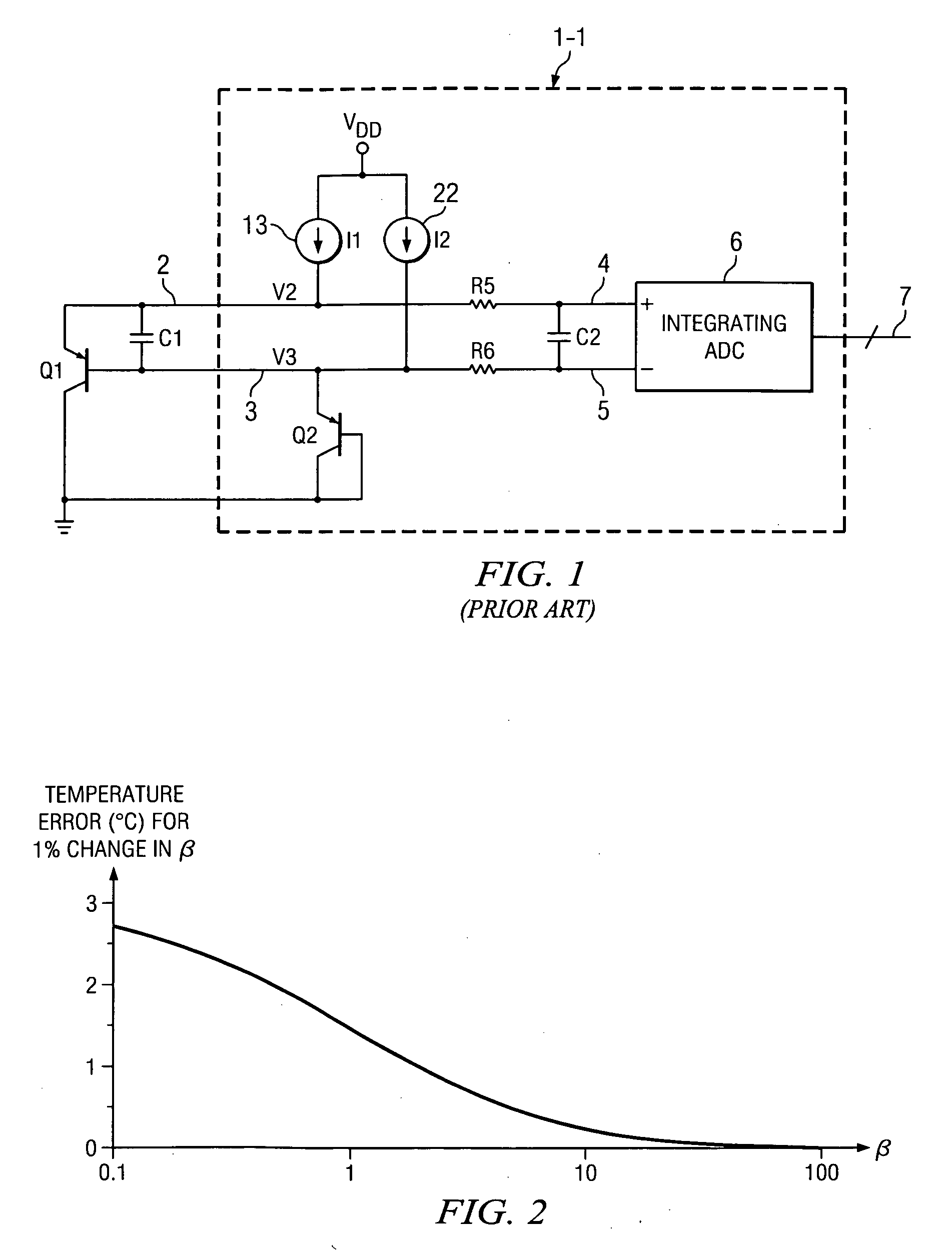

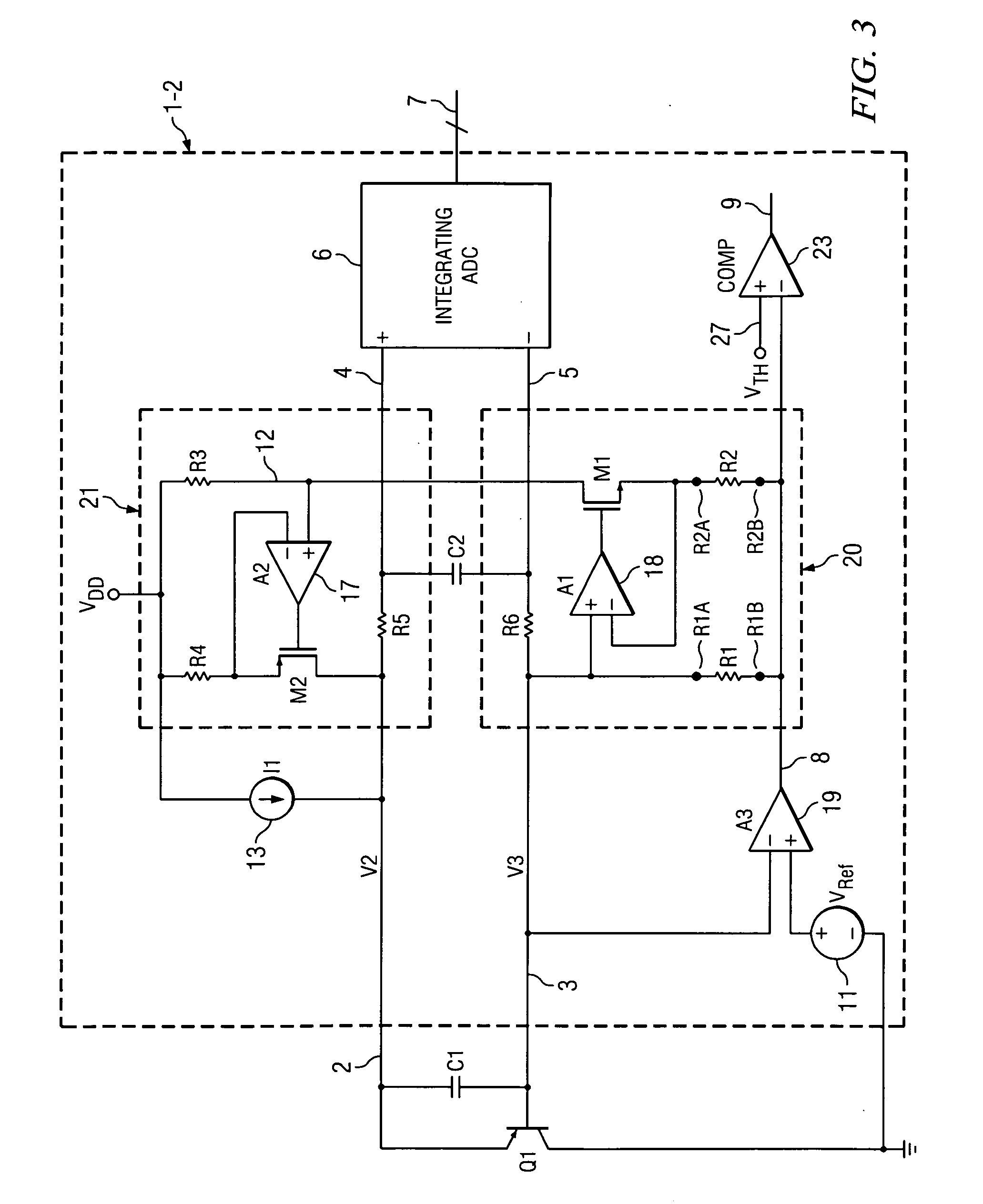

Circuit and method for beta variation compensation in single-transistor temperature sensor

ActiveUS20100329304A1Low currentAvoid measuringThermometers using electric/magnetic elementsUsing electrical meansVoltage referenceEngineering

A circuit (1-2) for compensating for variations in the current gain β of a sensing transistor (Q1) having a collector coupled to a reference voltage (GND) includes a first current mirror (20) having an input coupled to a base of the sensing transistor. A second current mirror (21) has an input coupled to an output of the first current mirror. A current source (13) is coupled to provide emitter current for the sensing transistor. An output of the second current mirror circuit (21) feeds base current of the sensing transistor back to its emitter to cause the collector current of the sensing transistor to be precisely equal to the current (I1) provided by the current source.

Owner:TEXAS INSTR INC

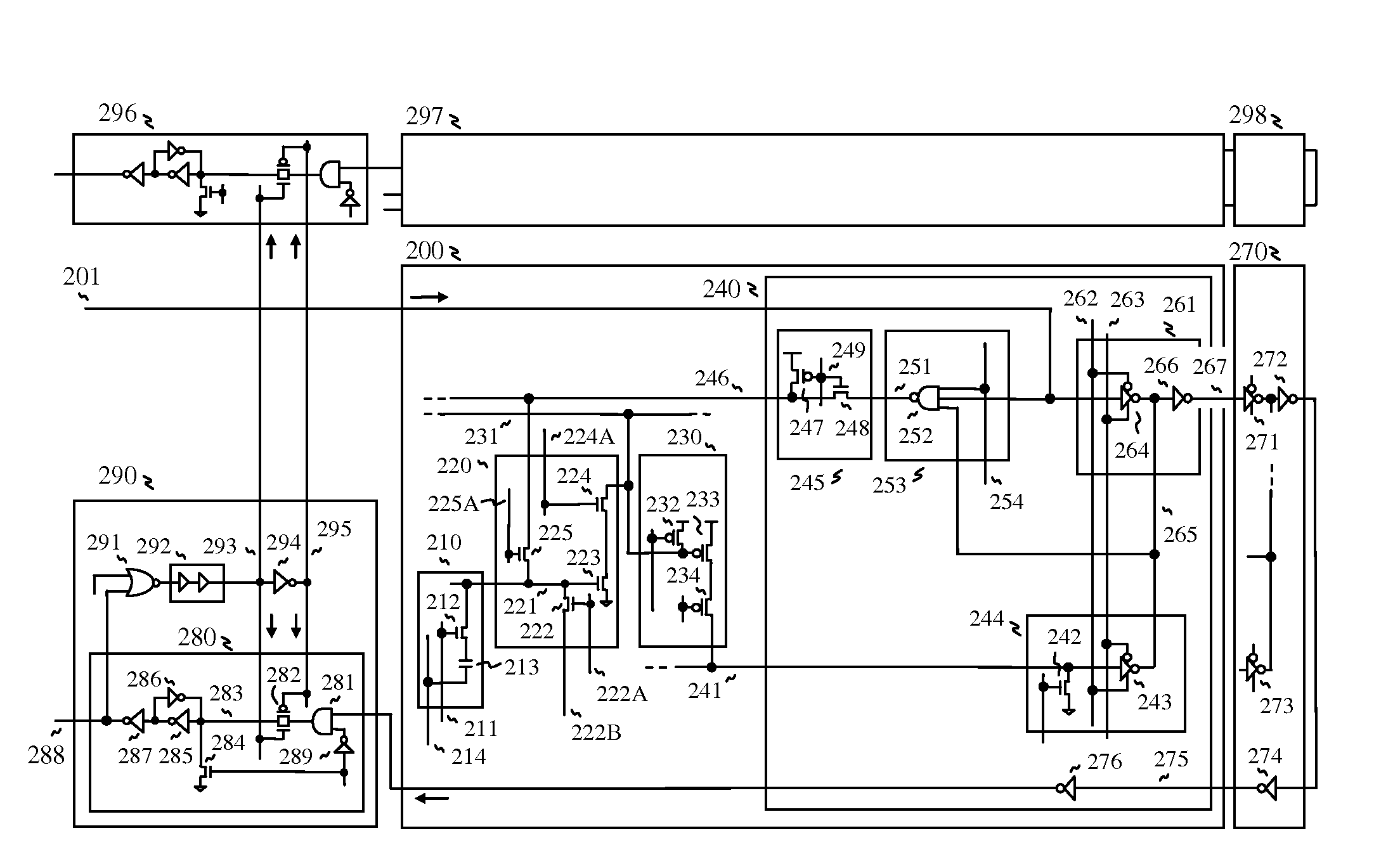

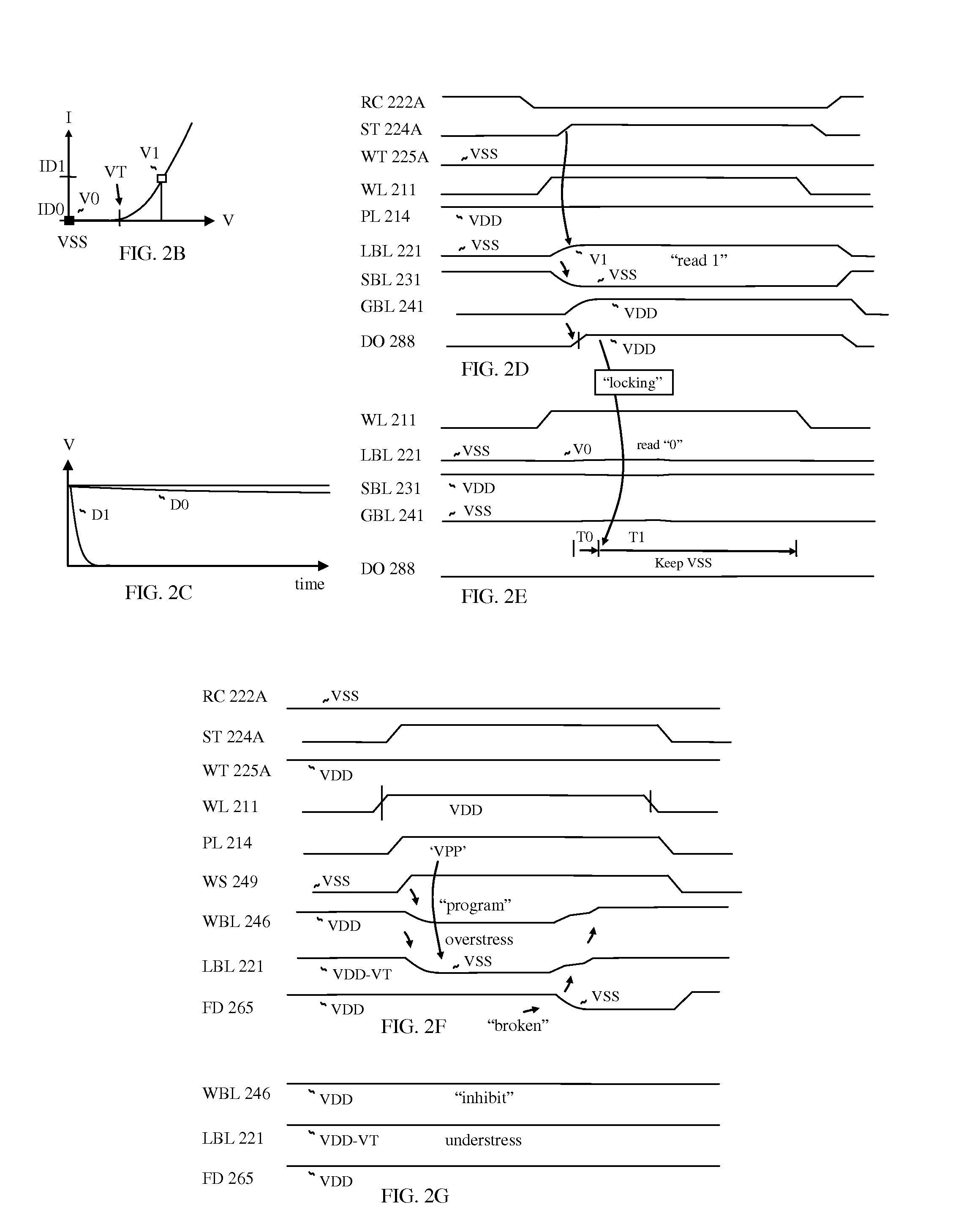

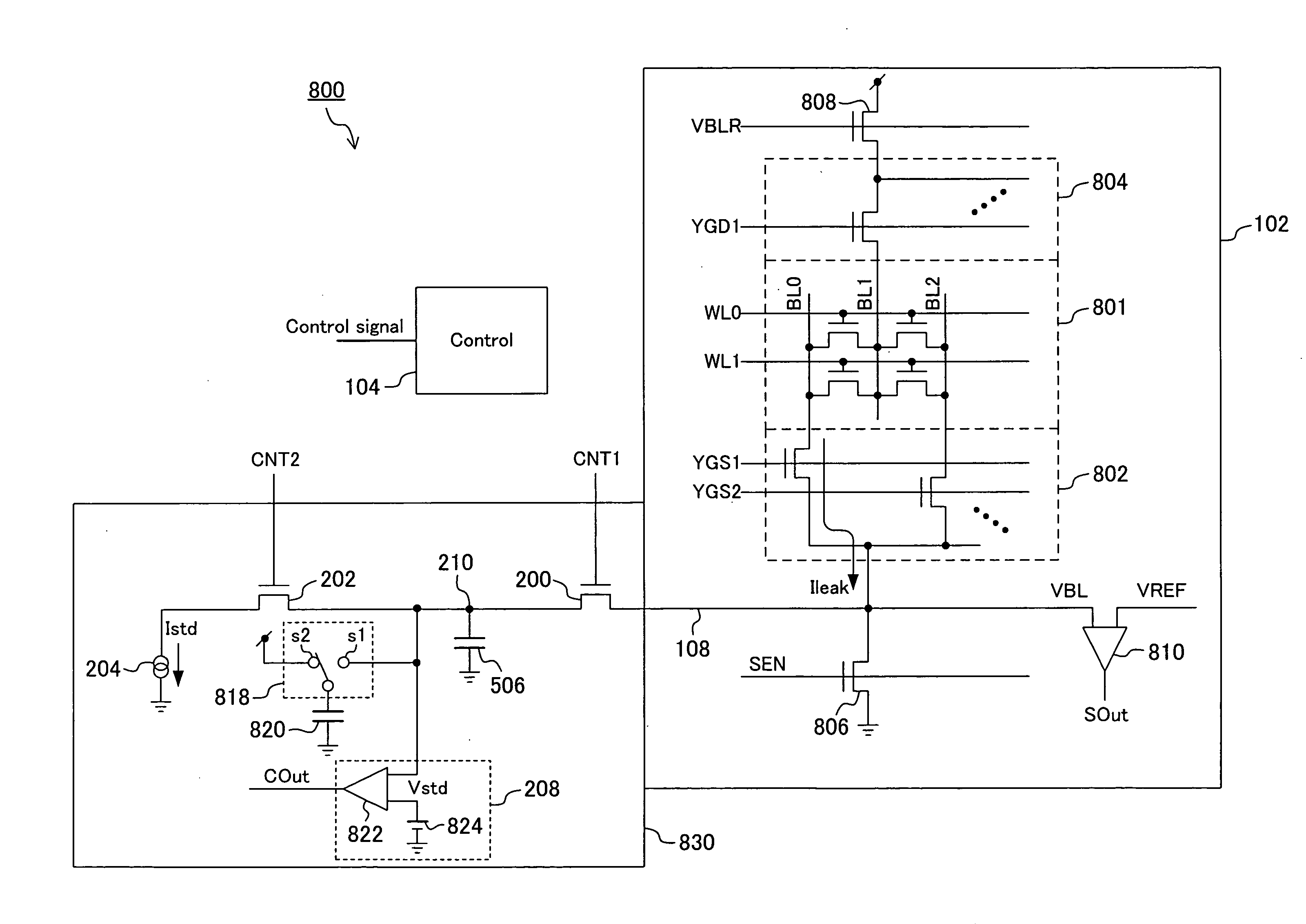

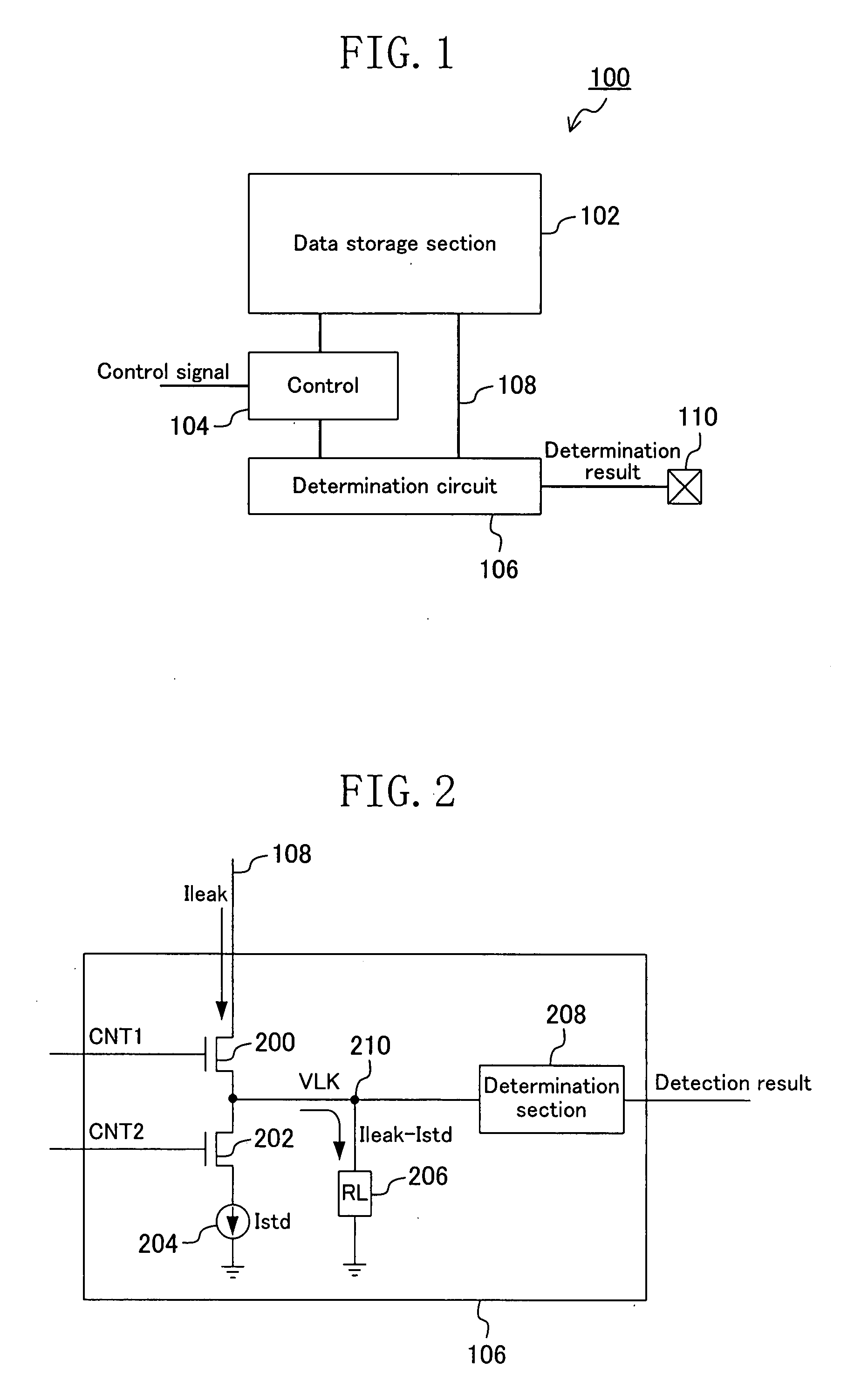

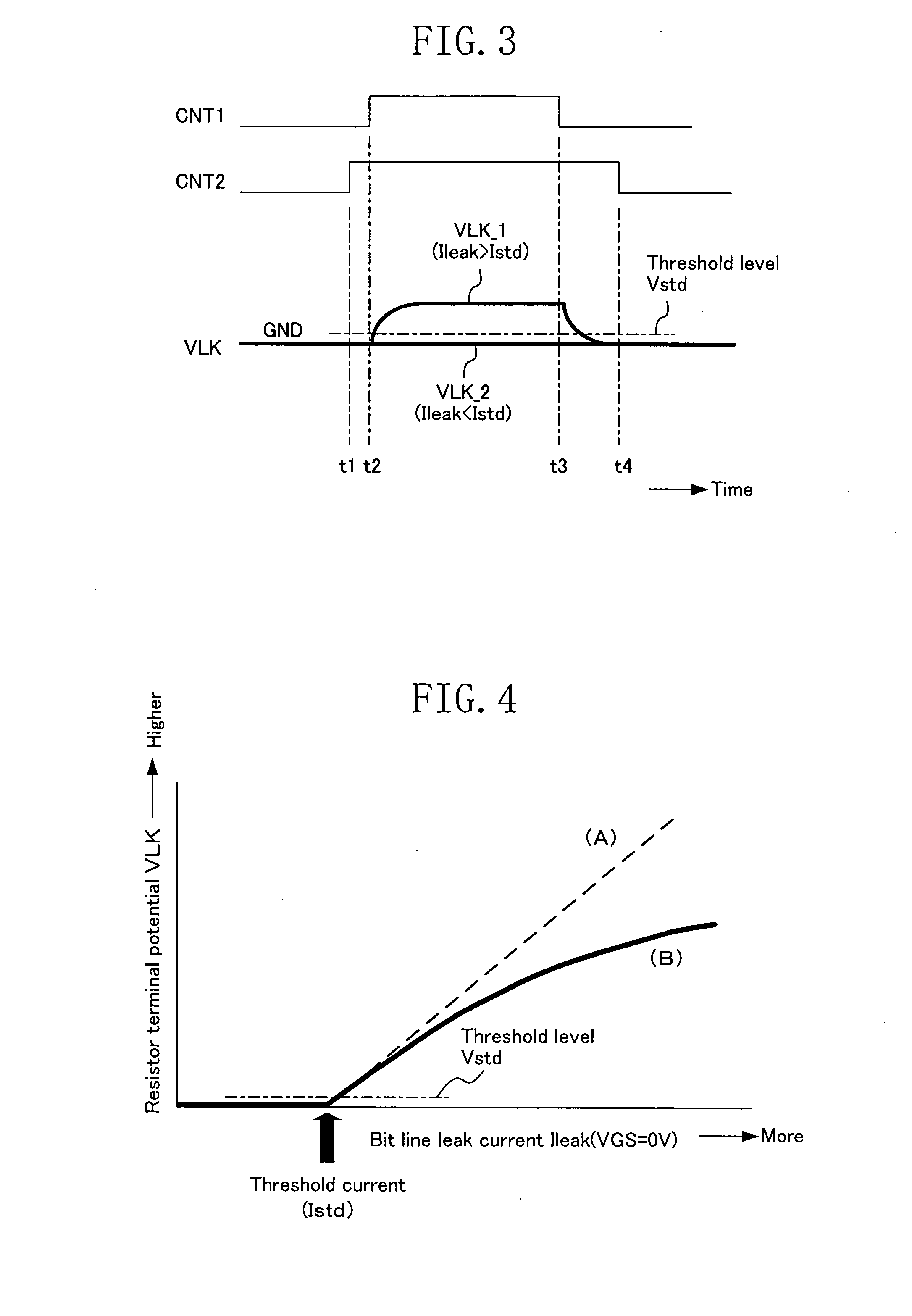

Semiconductor memory having function to determine semiconductor low current

InactiveUS20080170445A1High precisionLow currentRead-only memoriesDigital storageSense amplifierCurrent generation

A semiconductor memory, including a plurality of word lines, a plurality of bit lines, a plurality of memory cells provided at intersections between the plurality of word lines and the plurality of bit lines, and a sense amplifier for reading out what is stored in the memory cells, the semiconductor memory including: bit line selection means for selecting a bit line from among the plurality of bit lines; switch means for turning ON / OFF a current of the bit line selected by the bit line selection means; current generation means for generating a threshold current; means for extracting a differential current between the selected bit line current and the threshold current when a value of the selected bit line current is greater than that of the threshold current; voltage conversion means for converting the differential current to a voltage; and determination means for determining a magnitude relationship between the threshold current and the selected bit line current based on an output voltage from the voltage conversion means.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

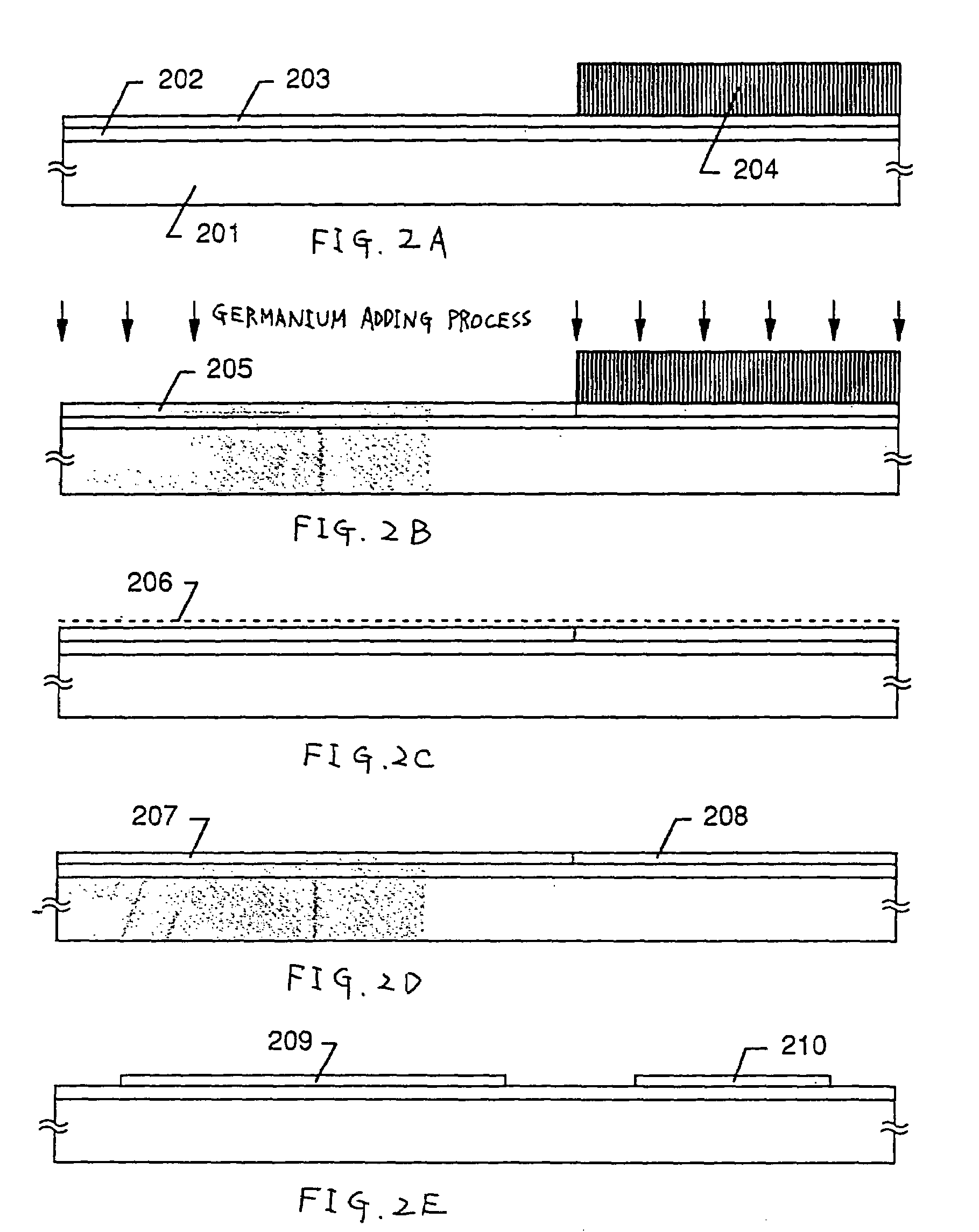

Semiconductor device and method for manufacturing same

InactiveUS7118994B2High mobilityLow currentTransistorSolid-state devicesPolycrystalline siliconSignal processing circuits

Disclosed is a semiconductor device having a driver circuit operable at high speed and a method for manufacturing same. An active matrix liquid crystal display device uses a polysilicon film for its TFT active layer constituting a pixel matrix circuit because of low off current characteristics. On the other hand, a TFT active layer constituting driver circuits and a signal processing circuit uses a poly silicon germanium film because of high speed operation characteristics.

Owner:SEMICON ENERGY LAB CO LTD

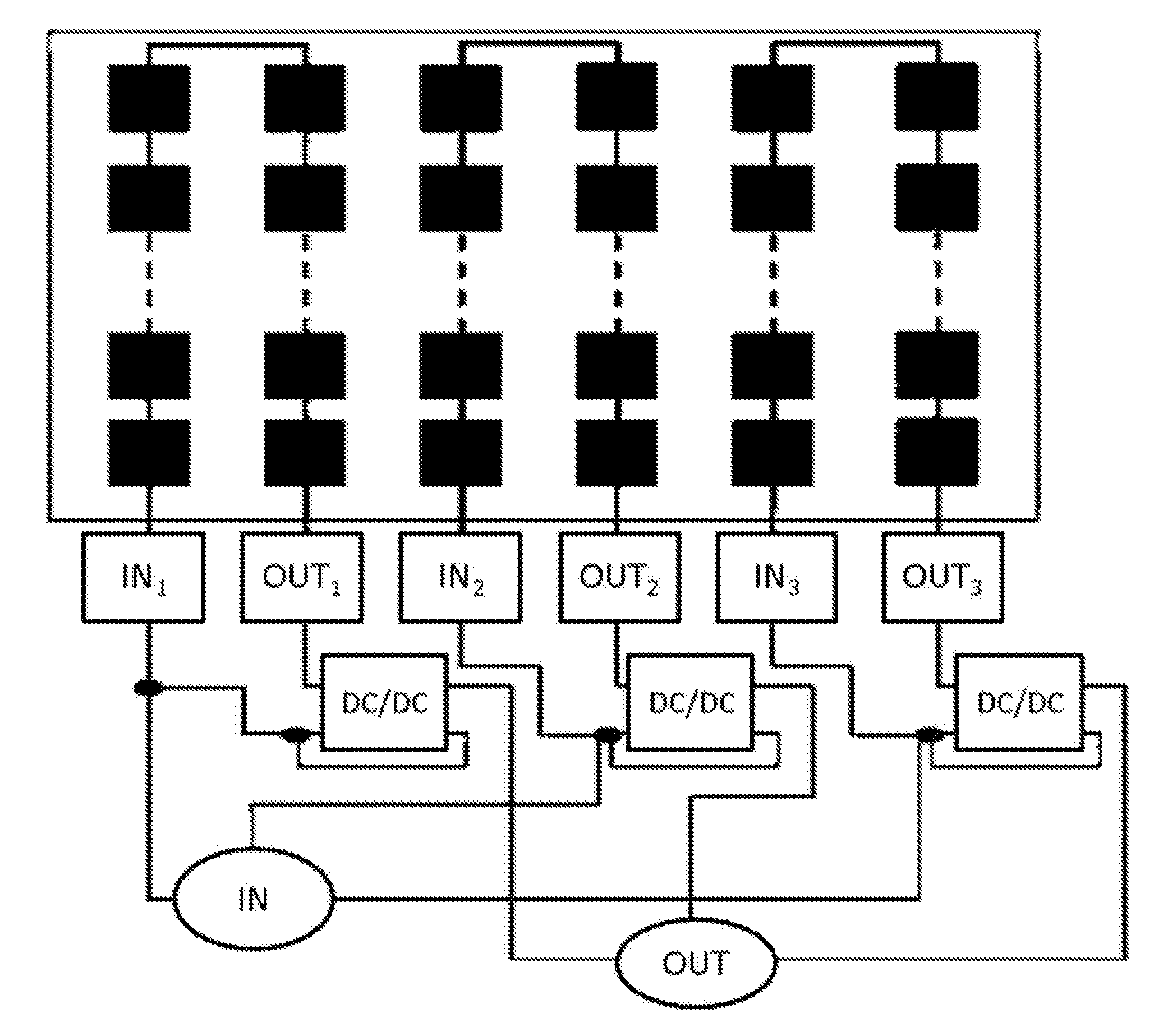

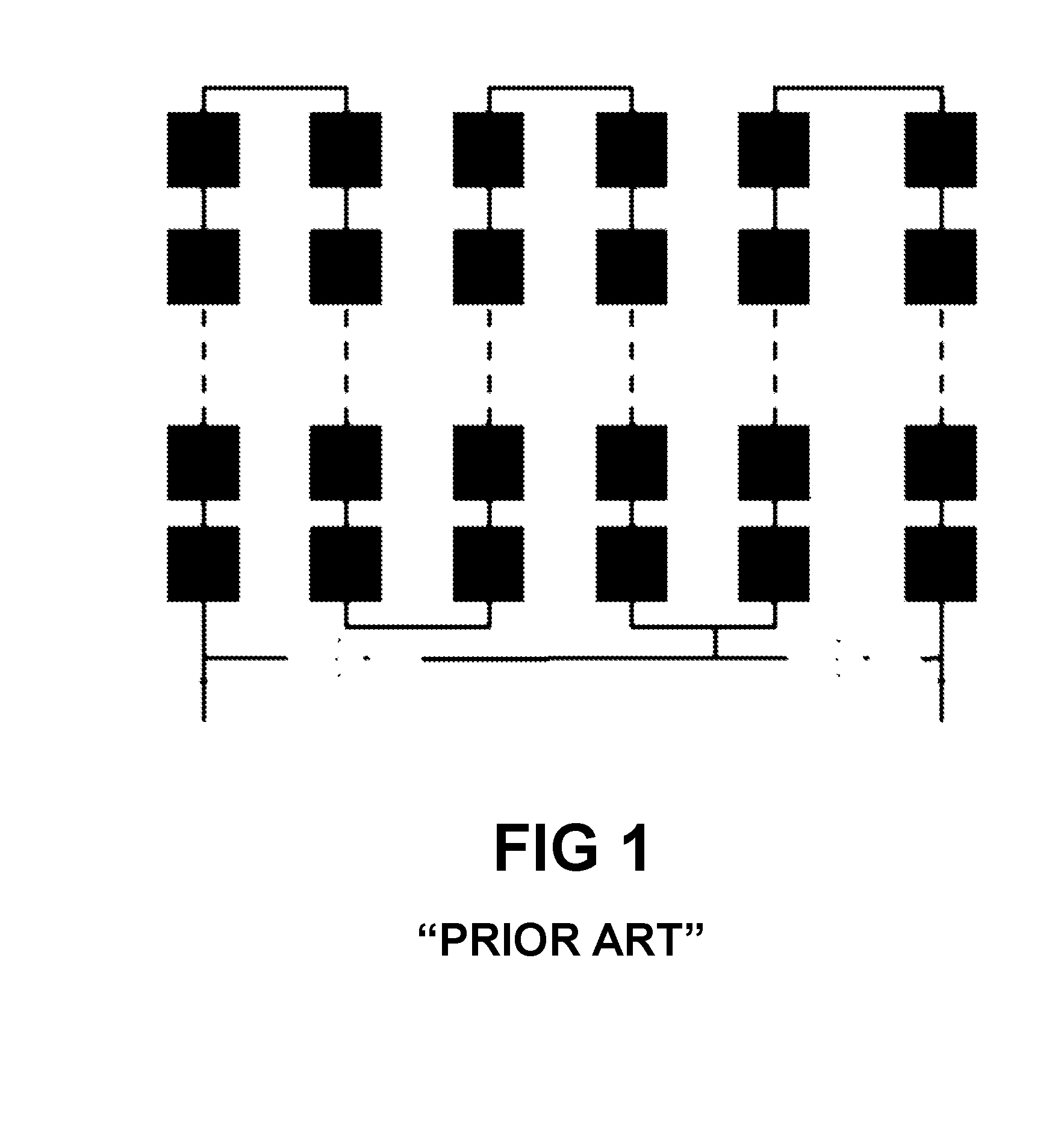

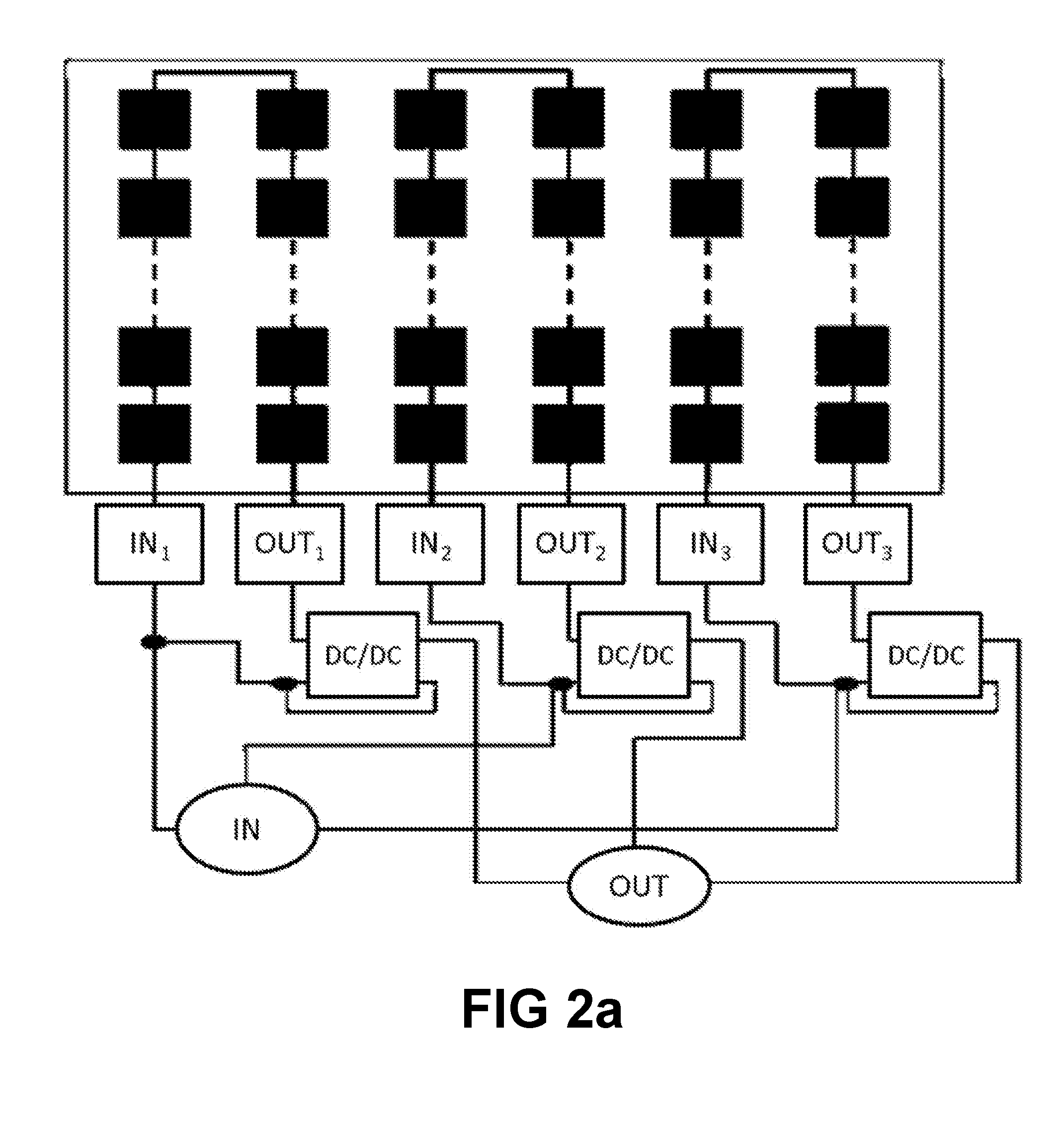

An intra-module dc-dc converter and a pv-module comprising same

ActiveUS20160268806A1High voltage gainLow currentSingle network parallel feeding arrangementsApparatus without intermediate ac conversionVoltage rangeDc dc converter

The present invention relates to an intra-module DC-DC power converter and a Photovoltaic (PV) module comprising same. The switching frequency of said intra-module DC-DC power converters may be 500 kHz. The PV module may have a controller and a plurality of switches for allowing each individual string of said PV module to be connected to one corresponding DC-DC converter, or for allowing two or more strings of said module to be connected in series and to apply the voltage of the combined string to a single DC-DC converter. The input voltage range of the DC-DC converters may be 10V to 30V, and the output voltage range may be 120V. The DC-DC converters may be connected in series or in parallel. Multiple such PV panels may be connected in a DC-grid.

Owner:KATHOLIEKE UNIV LEUVEN

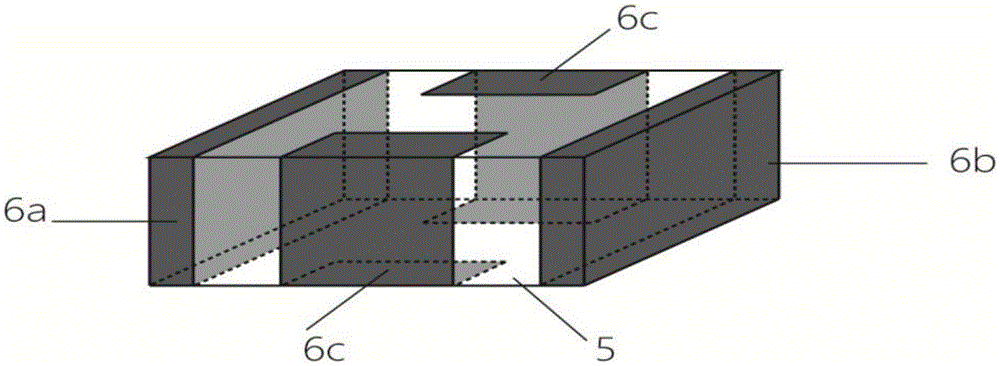

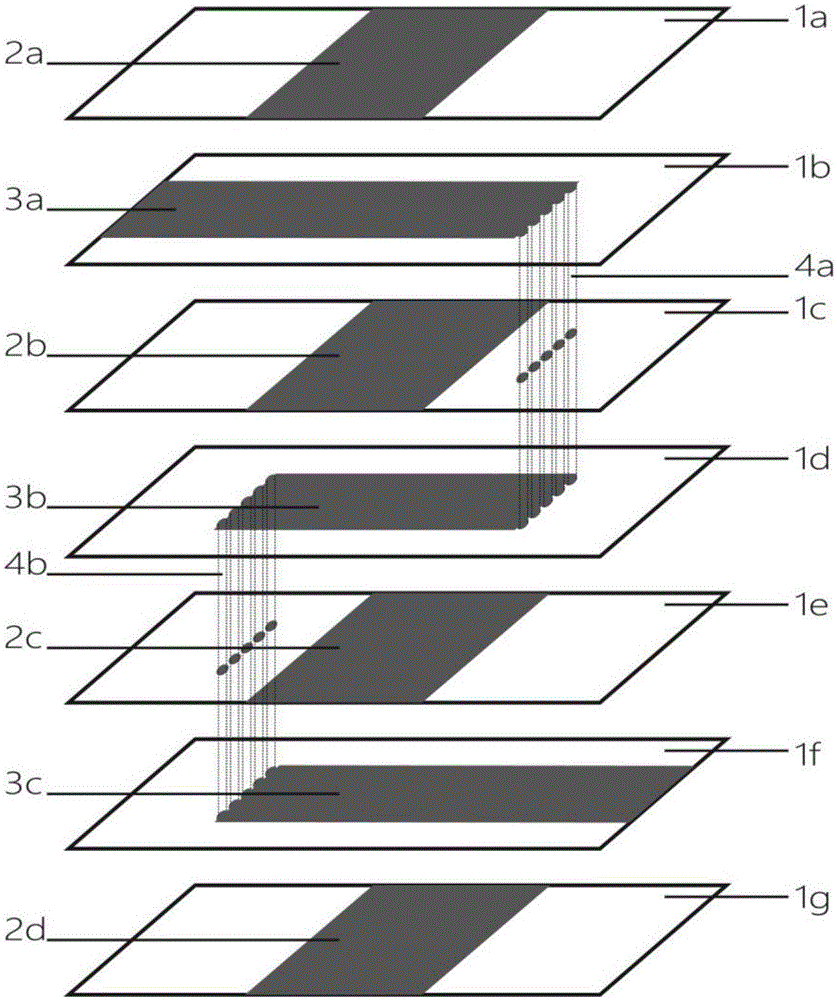

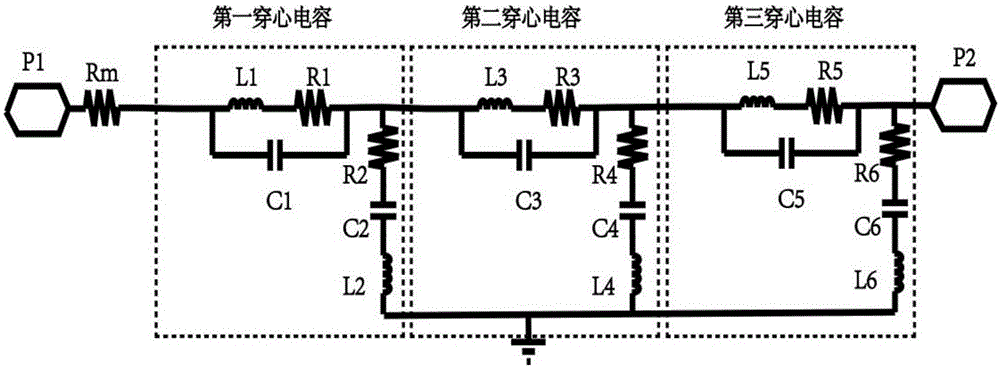

EMI filter of folding chained form feedthru capacitor structure

ActiveCN105141273AImprove latencyRealize the low-pass filter functionMultiple-port networksCapacitanceOut of band rejection

The invention discloses an EMI filter of a folding chained form feedthru capacitor structure. The EMI filter comprises a laminated substrate, an input terminal, an output terminal and two ground terminals; the laminated substrate comprises a substrate, conductive polar plates, a ground polar plate and a metal through hole, which are laminated from bottom to top in sequence; the conductive polar plate is arranged on the surface of the substrate; one end of the conductive polar plate at the first layer is connected with the input terminal, one end of the conductive polar plate on the last layer is connected with the output terminal, and the ground polar plate is arranged on the surface of the rest substrate; both ends of the ground polar plate are connected with the two ground terminals; the metal through hole is along the lamination direction of the substrate, and the conductive polar plates are connected at heads and tails through the metal through hole, so that the conductive polar plates and the ground polar plate from a spatial folding chained form feedthru capacitor structure. The chained form structure of the EMI filter provided by the invention folds and cascades a plurality of feedthru capacitors to make full use of the parasitic effect in the structure in a limited volume to achieve excellent out-of-band rejection.

Owner:HUAZHONG UNIV OF SCI & TECH

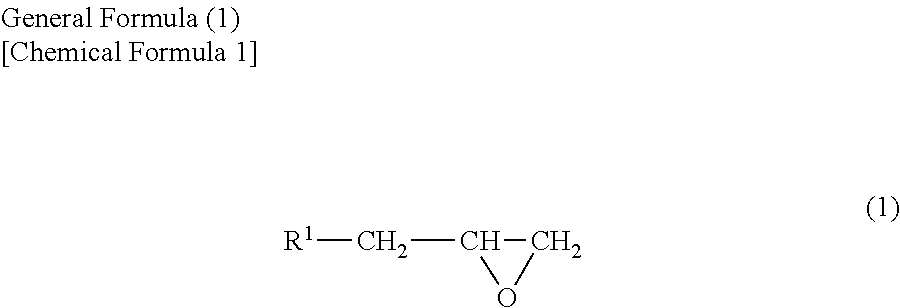

Oxidant dopant agent for conductive polymer production, and a solution thereof, and a conductive polymer prepared by using either of them, as well as an electrolyte capacitor using the conductive polymer as an electrolyte

ActiveUS20160355636A1Low leak currentLow currentSolid electrolytic capacitorsConductive materialThiophosphateOxidizing agent

There is provided an oxidant dopant agent for conductive polymer production, and a solution thereof, in which they are capable of producing a conductive polymer suitable in producing an electrolyte capacitor having a low leak current. There is also provided a conductive polymer prepared by using either of them. There is also provided an electrolyte capacitor having a low leak current. The oxidant dopant agent includes: an organic ferric sulfonate; and at least one kind selected from the group consisting of phosphoric acid, phosphate, phosphorous acid, phosphite, boric acid, borate, thiophosphoric acid, thiophosphate, dithiophosphoric acid and dithiophosphate. The solution includes the oxidant dopant agent dissolved in water, an alcohol or a mixture of water and an alcohol. A conductive polymer is prepared by means of oxidation polymerization of a monomer such as thiophene or its derivative. The conductive polymer is used as an electrolyte to provide an electrolyte capacitor.

Owner:TAYCA CORP

Diffusion technology for preparing Se battery by using etching process

InactiveCN102969403AIncrease concentrationIncreasing the thicknessFinal product manufactureSemiconductor devicesEngineeringNitrogen gas

The invention discloses a diffusion technology for preparing a Se battery by using an etching process. According to the diffusion technology, the gradient diffusion temperature, the source flow and the oxygen flow are adopted; and the diffusion technology specifically comprises the following steps of: a, putting a silicon sheet into a diffusion furnace; b, rising the temperature to 840-850 DEG C, introducing nitrogen and oxygen from a carrying source, keeping the temperature, gradually reducing the flow of a diffusion source, adding the flow of the oxygen and lasting the whole process for 10-30min; c, increasing the temperature to 860-870 DEG C, and keeping for 5-15min; and d, reducing the temperature and finishing the diffusion. By utilizing the diffusion technology for preparing the Se battery by using the etching process, high enough surface concentration and phosphorosilicate glass thickness are ensured with very good phosphorus concentration distribution curves, and a very low emitter saturation current and a very wide process window are ensured for a later etching method in etching a high sheet resistor.

Owner:泰州德通电气有限公司

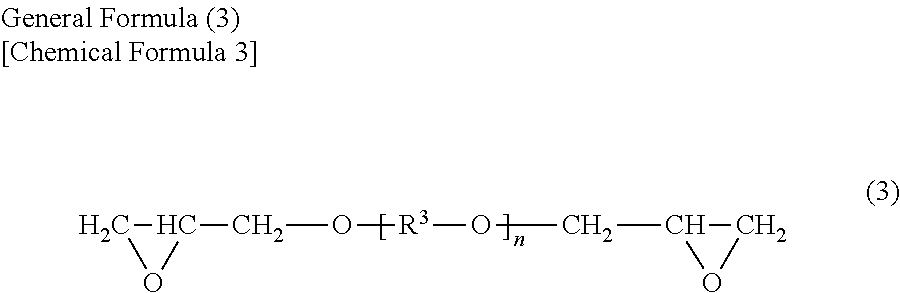

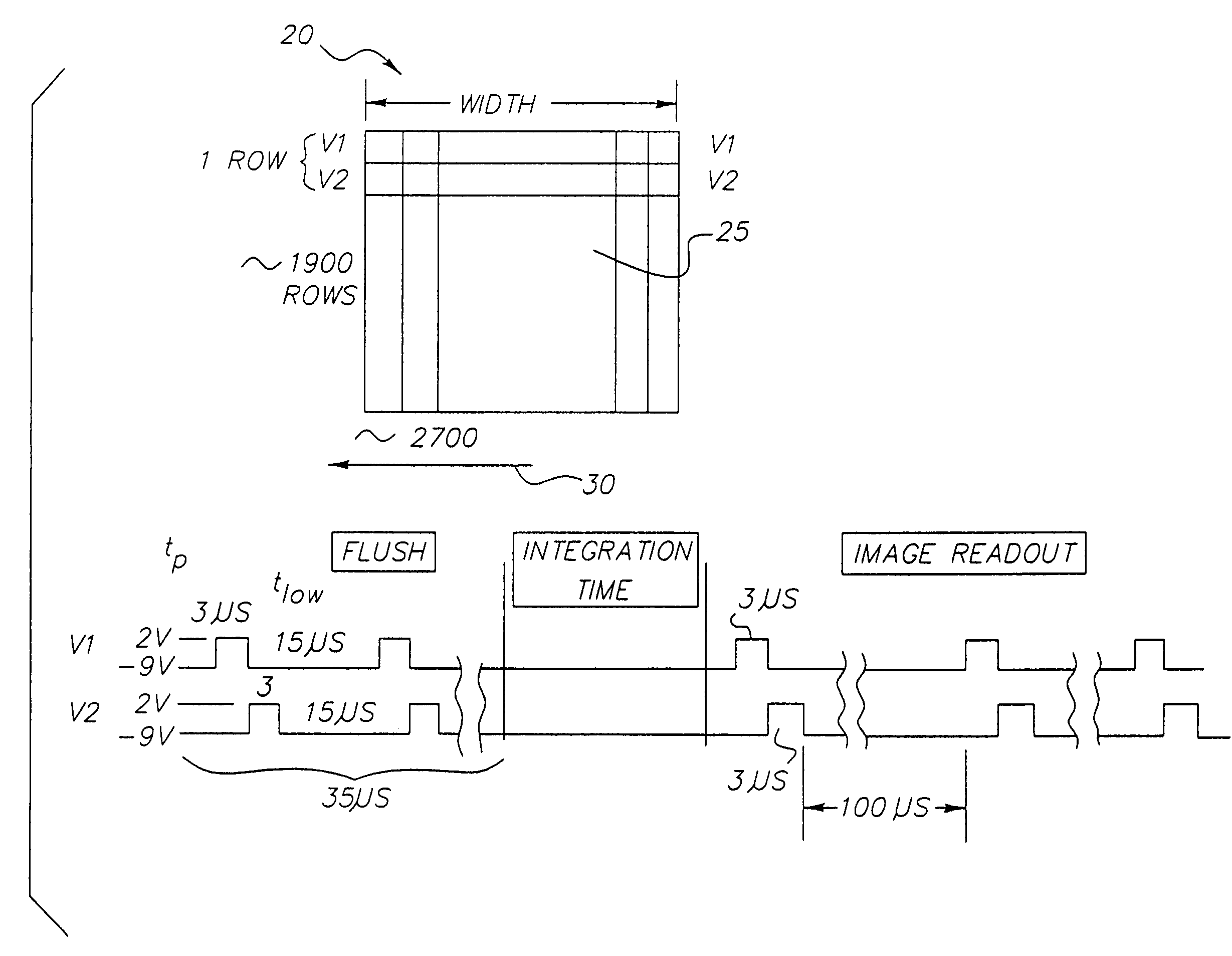

CCD having improved flushing by reducing power consumption and creating a uniform dark field while maintaining low dark current

ActiveUS7274391B2Reduce power consumptionLow currentTelevision system detailsTelevision system scanning detailsEngineeringDigital camera

A digital camera includes a CCD operating with accumulation mode clocking for capturing an electronic representation of an image; and two or more clocks operatively and respectively connected to each phase of the two or more phases for initiating flushing of excess current, wherein, to initiate flushing, a time the clocks are at a high level are substantially the same, and a time the clocks are at a low level can be selected at any duration between a minimum width at which dark current starts to substantially increase and twice its normal operating duration during image readout and for reducing power consumption while retaining minimum dark current and for having a substantially uniform dark field.

Owner:SEMICON COMPONENTS IND LLC

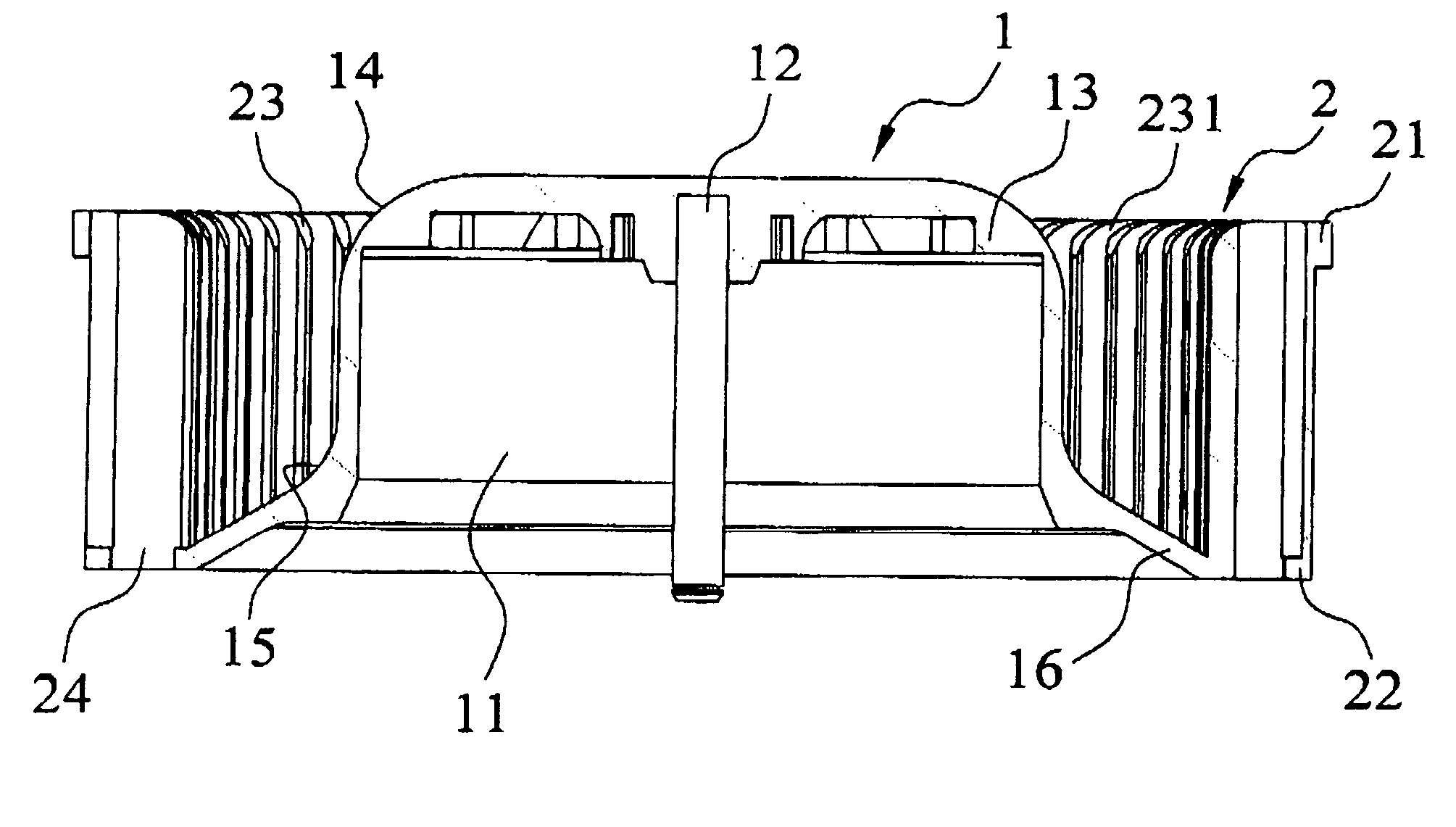

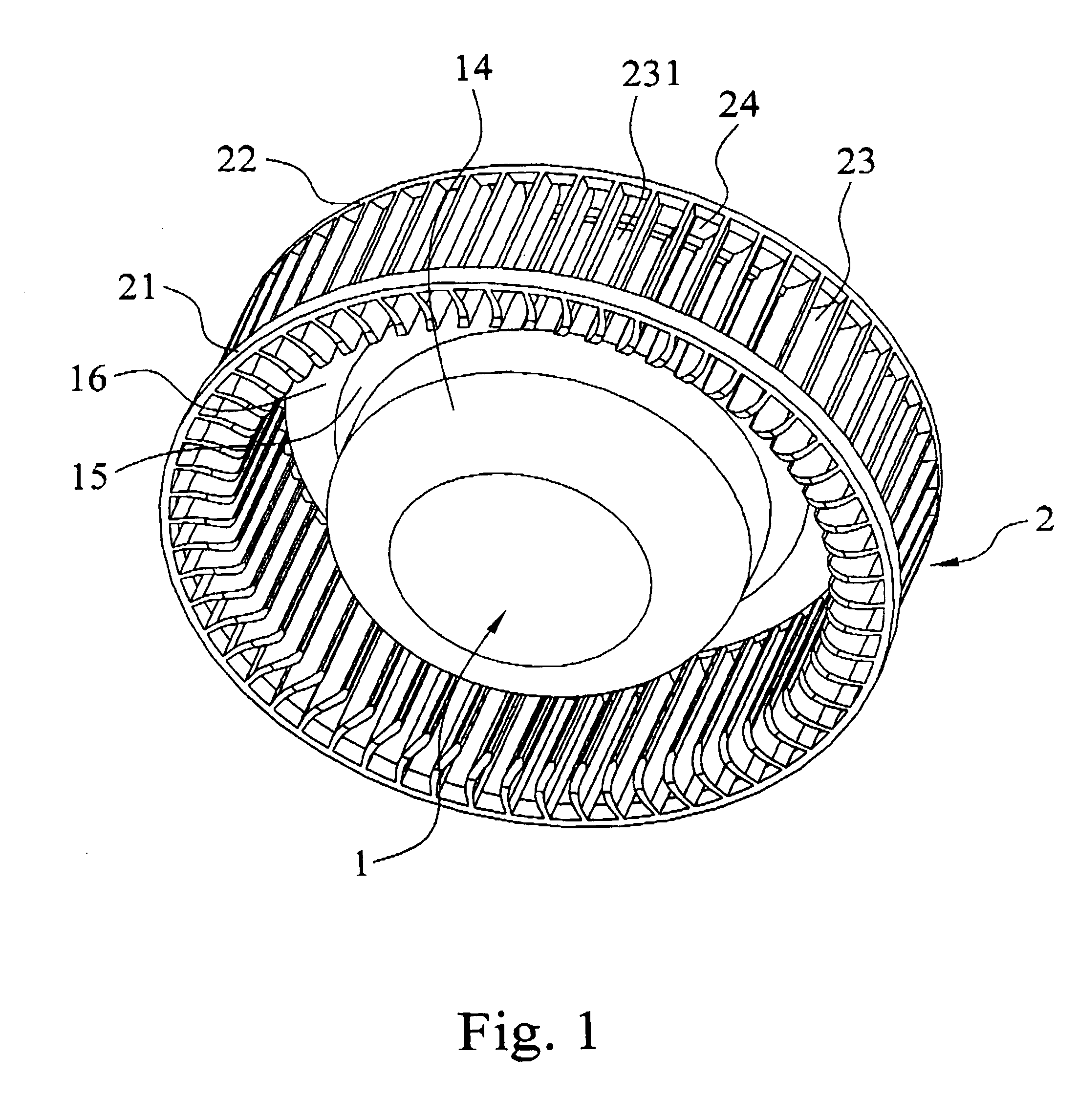

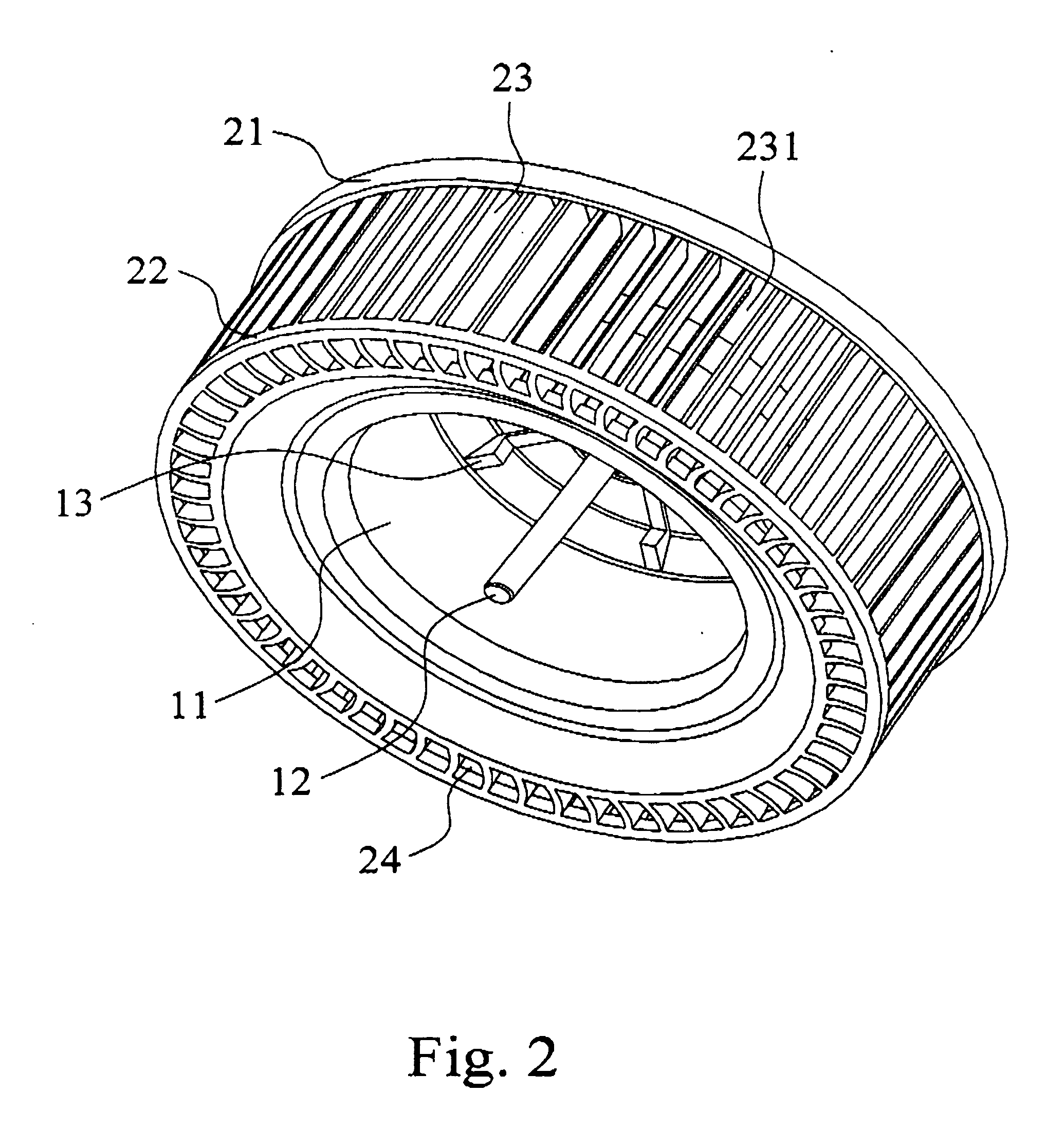

Modified centrifugal fan wheel

InactiveUS20050047916A1Low currentReduce power consumptionPropellersRotary propellersImpellerEngineering

The modified centrifugal fan wheel comprises a hollow hub and a set of blade. A hollow hub axis is disposed at the center of a hollow portion of the hollow hub. Along a top side surface of the hollow hub is a curved guiding inlet part and along a bottom side surface of the hollow hub is a curved surface with a smooth fillet extending to a closed part. A set of blades is arranged around an outer part of the hollow hub, having an up ring and a down ring. An inner part of the down ring is connected to the closed part of the hollow hub. Blades are disposed between the up ring and the down ring. Wind holes are disposed equidistantly between each of the blades and equidistant perforations are arranged on the surface of the down ring, connecting to the wind holes between each of the blades. By the closed part and the perforation of the fan wheel, low noise and low current are provided. Meanwhile, power consumption is reduced and working performance of the fan wheel is also improved.

Owner:DATECH TECH CO LTD

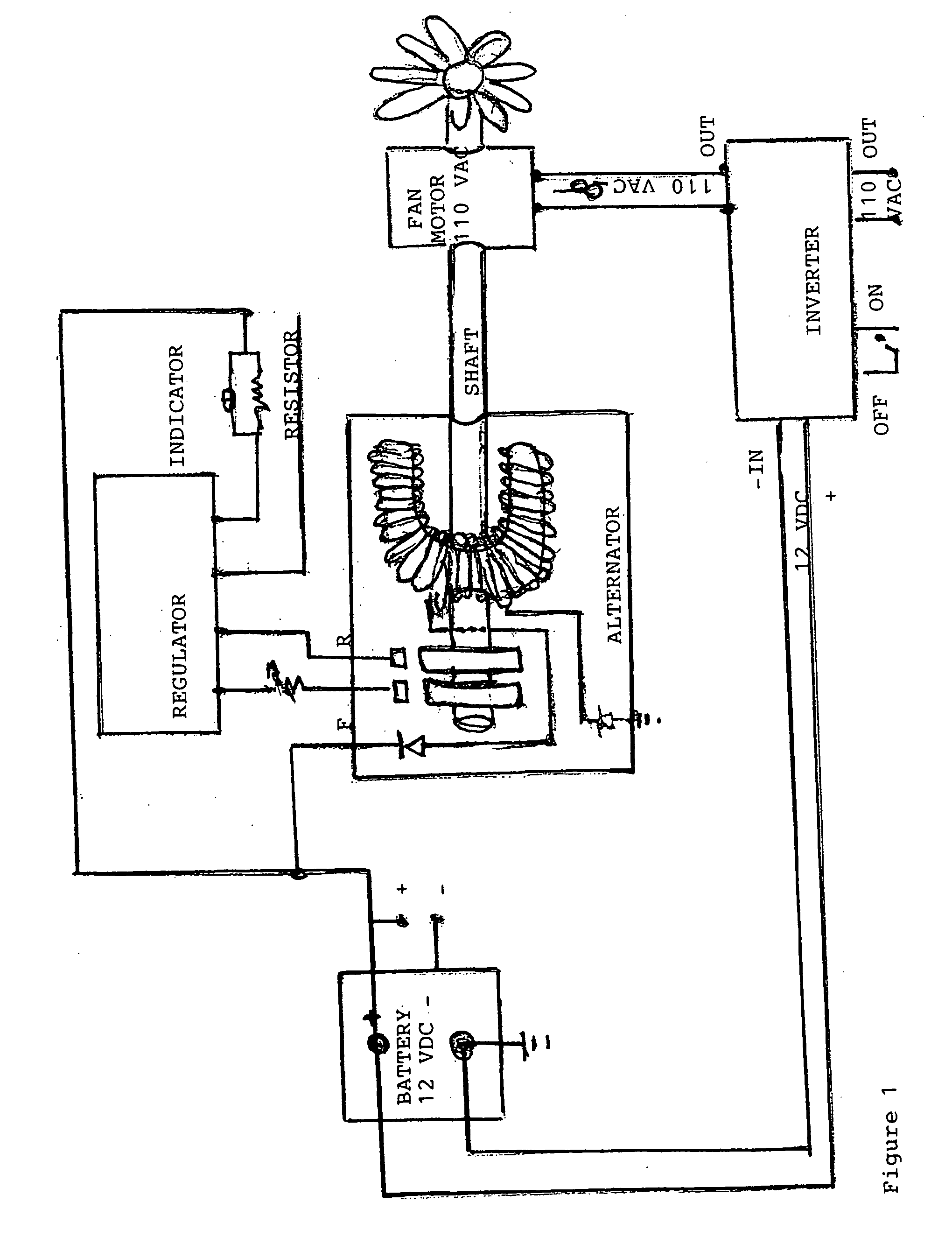

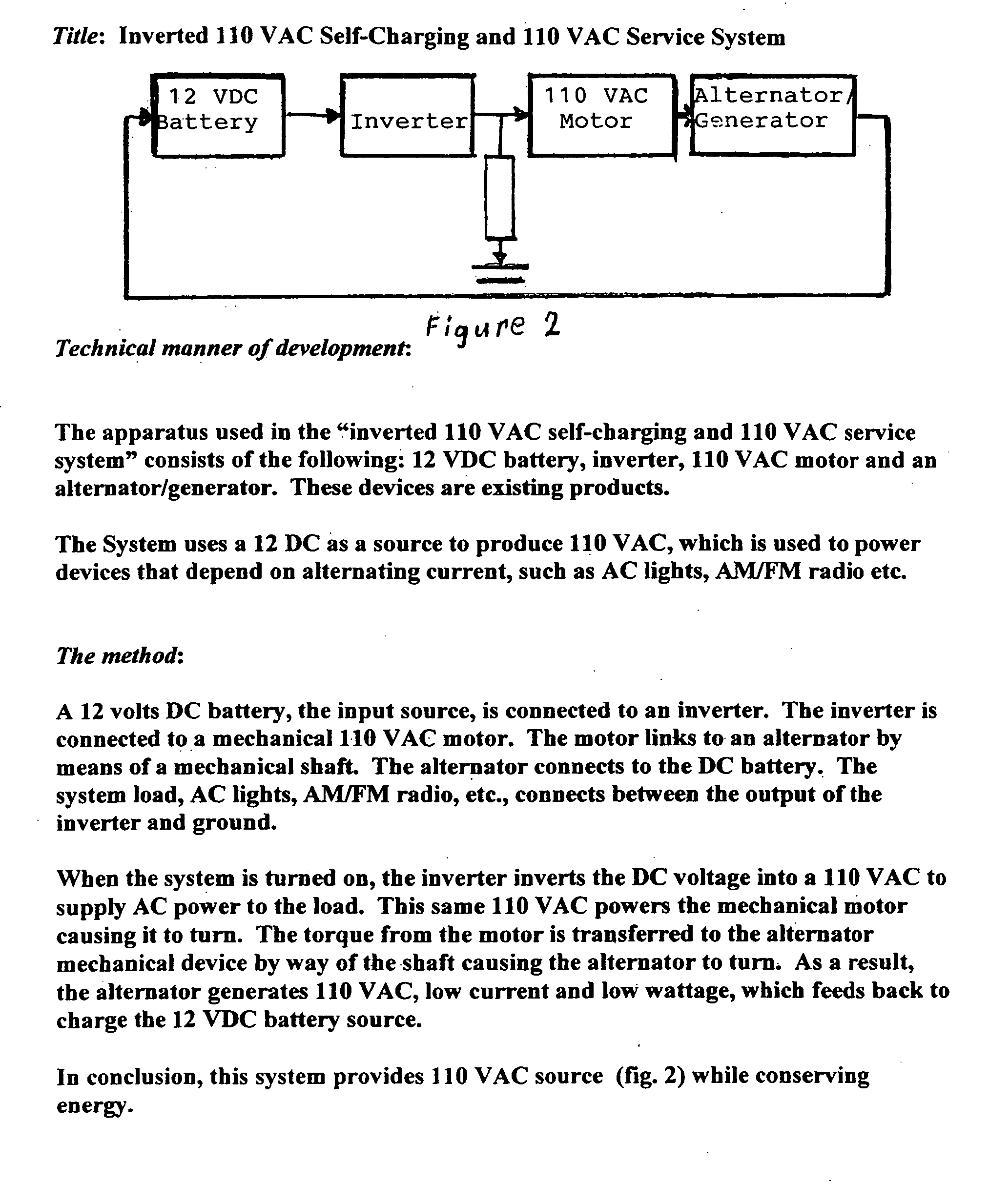

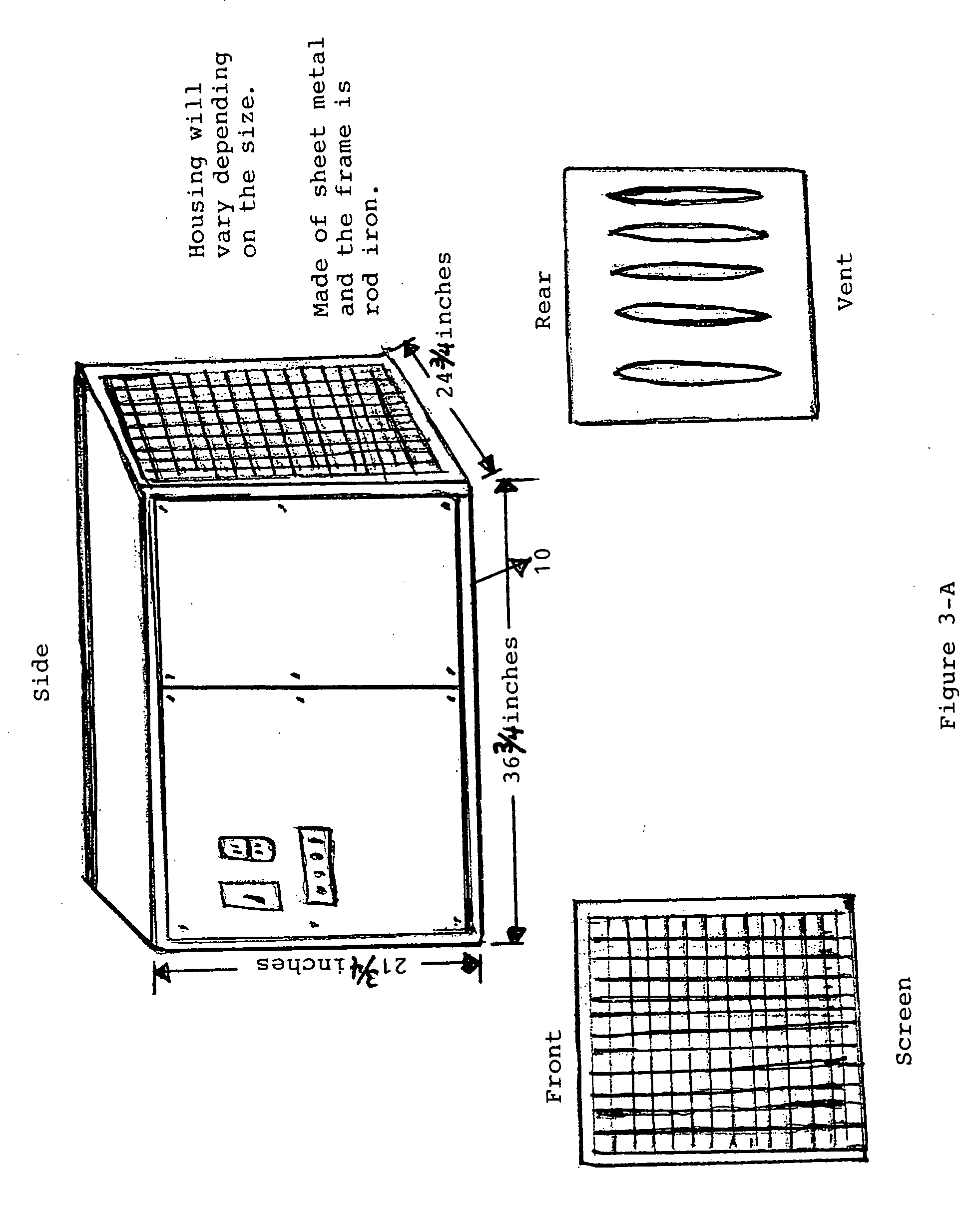

Method for recharging a battery at the same time it is being used as a power source

InactiveUS20050206344A1Low currentLow electric powerBatteries circuit arrangementsElectric powerElectricityEngineering

A method for recharging a battery, at the same time it is being used as a power source, by using a portion of the electrical output to operate an alternator to produce low current and low voltage electrical power to recharge the battery.

Owner:GRANT EARL SR

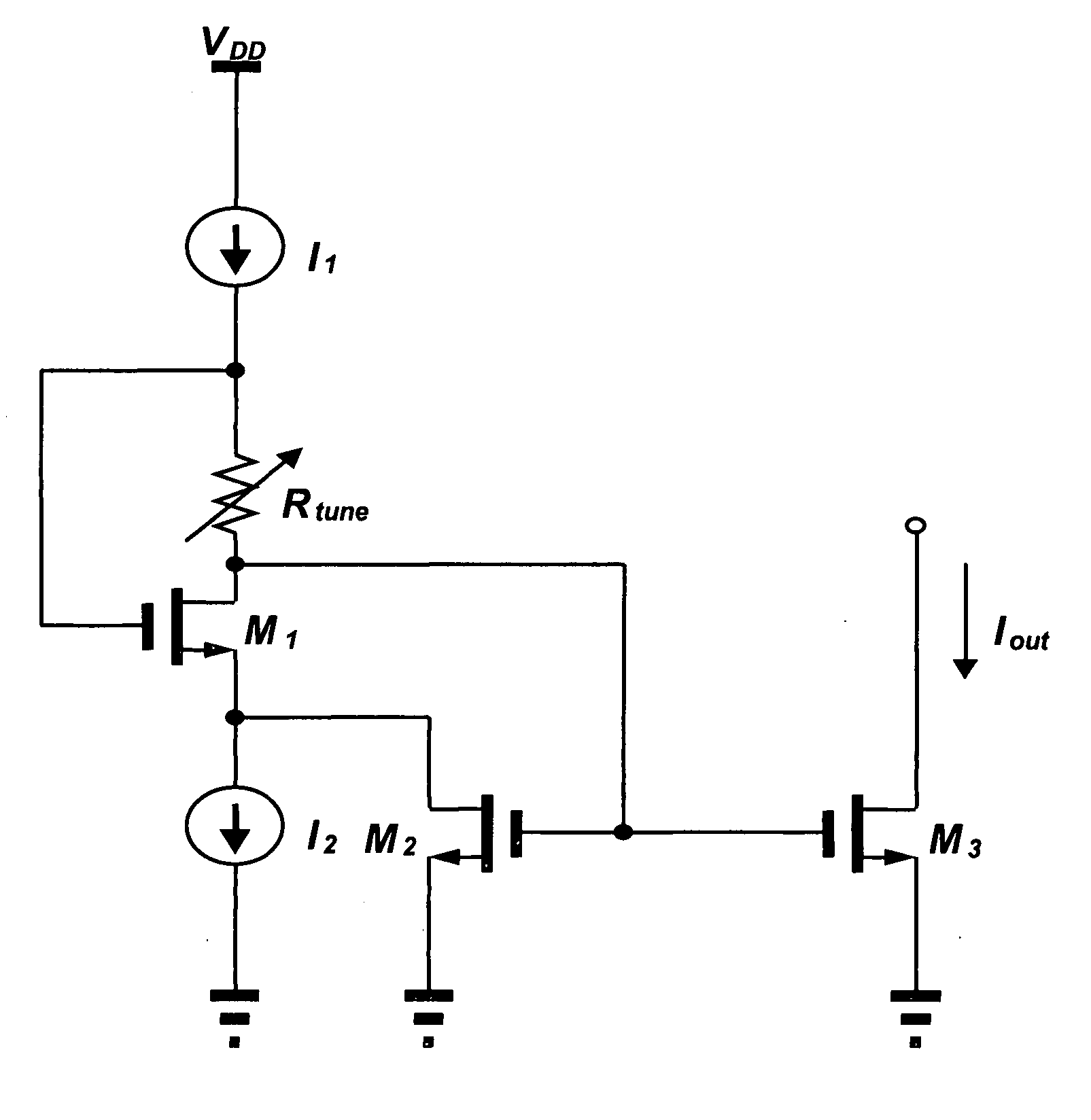

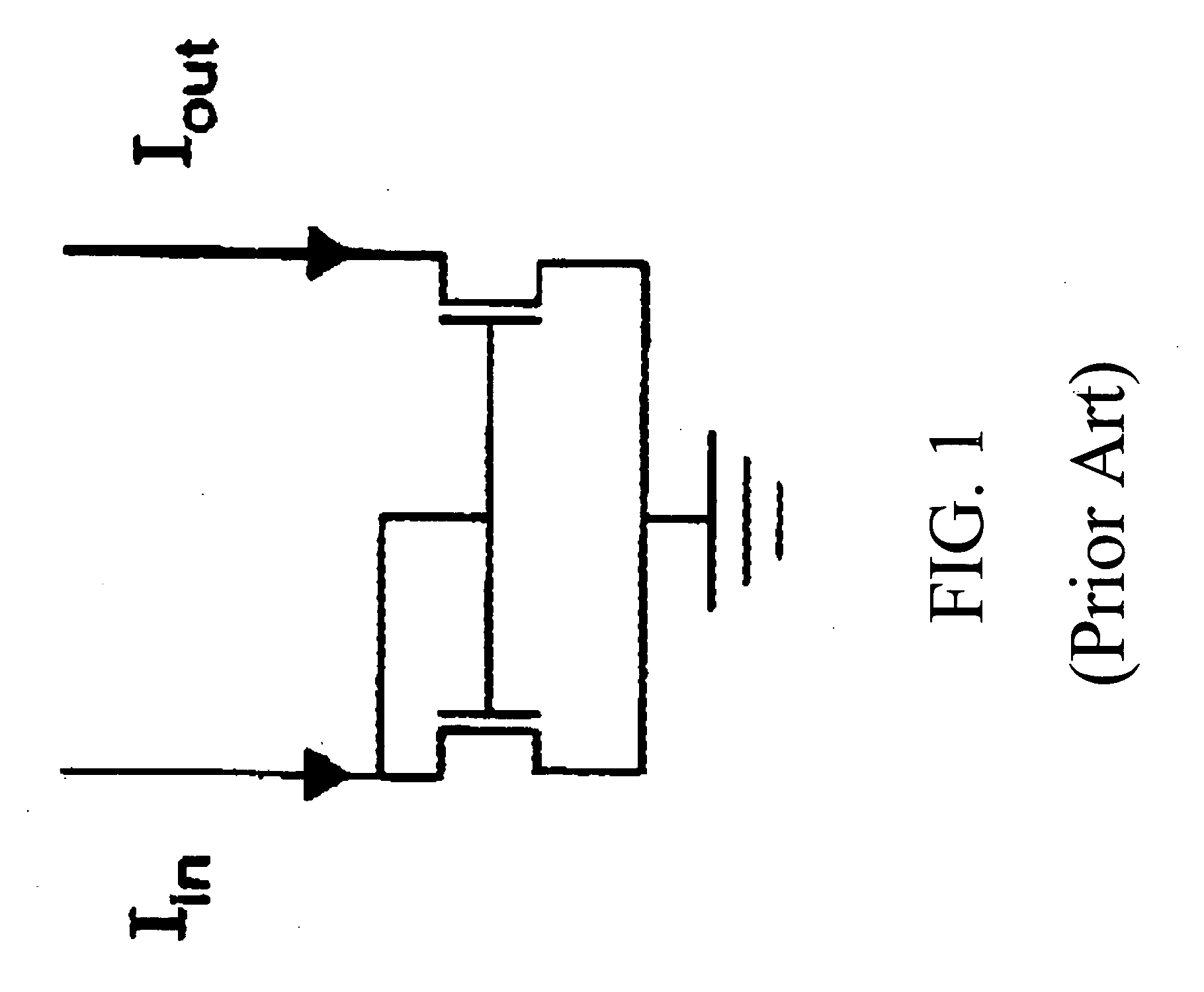

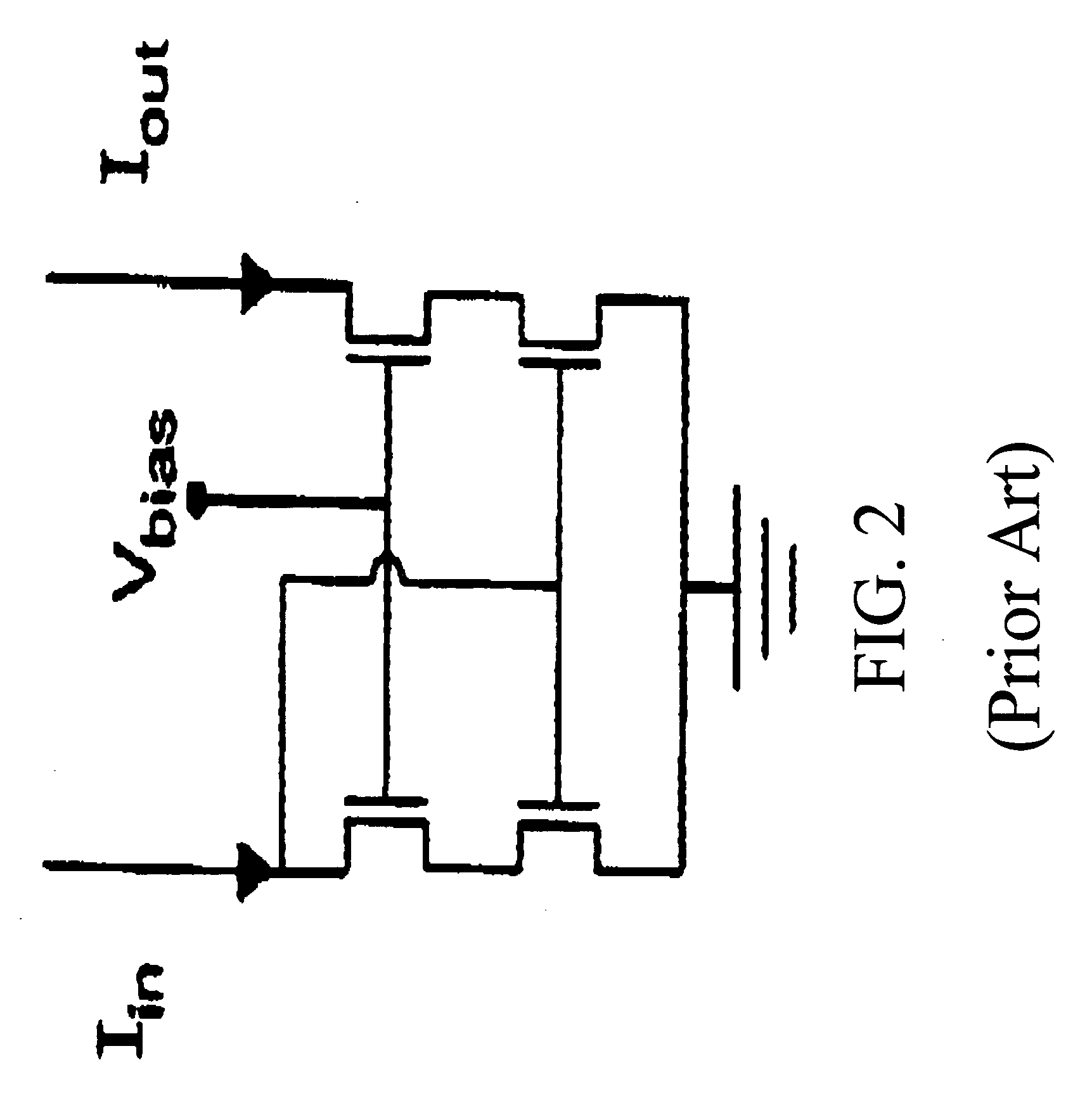

Current mirror with low static current and transconductance amplifier thereof

InactiveUS20060125566A1Low currentLow operationElectric variable regulationAmplifiers with semiconductor devices onlyTransconductanceEngineering

A current mirror with a transconductance amplifier containing the current mirror with a low static current. The current mirror includes: a load with first end and a second end, the first end coupling to a first input current and a fixed voltage difference existing between the first and second ends; a first transistor, whose drain is coupled to the second end of the load, whose gate is coupled to the first end of the load, and whose source is coupled to a second input current; and a second transistor, whose drain is coupled to a third port and an output current, whose gate is coupled to the second end of the load, and whose source is coupled to the ground. The transconductance amplifier contains: a voltage amplifier stage, a transconductance stage, and a current amplifier stage for amplifying the current and containing the current mirror.

Owner:IND TECH RES INST

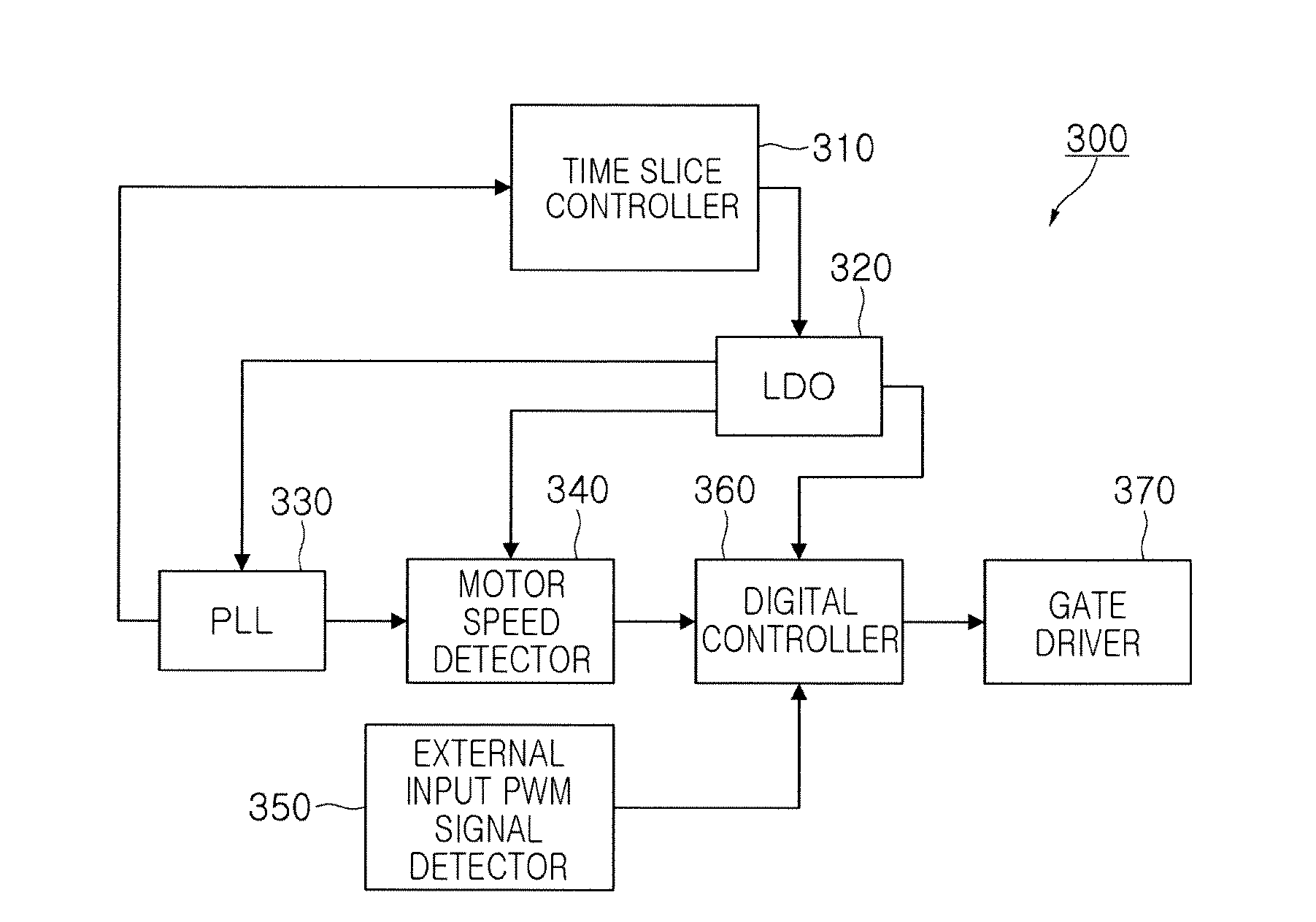

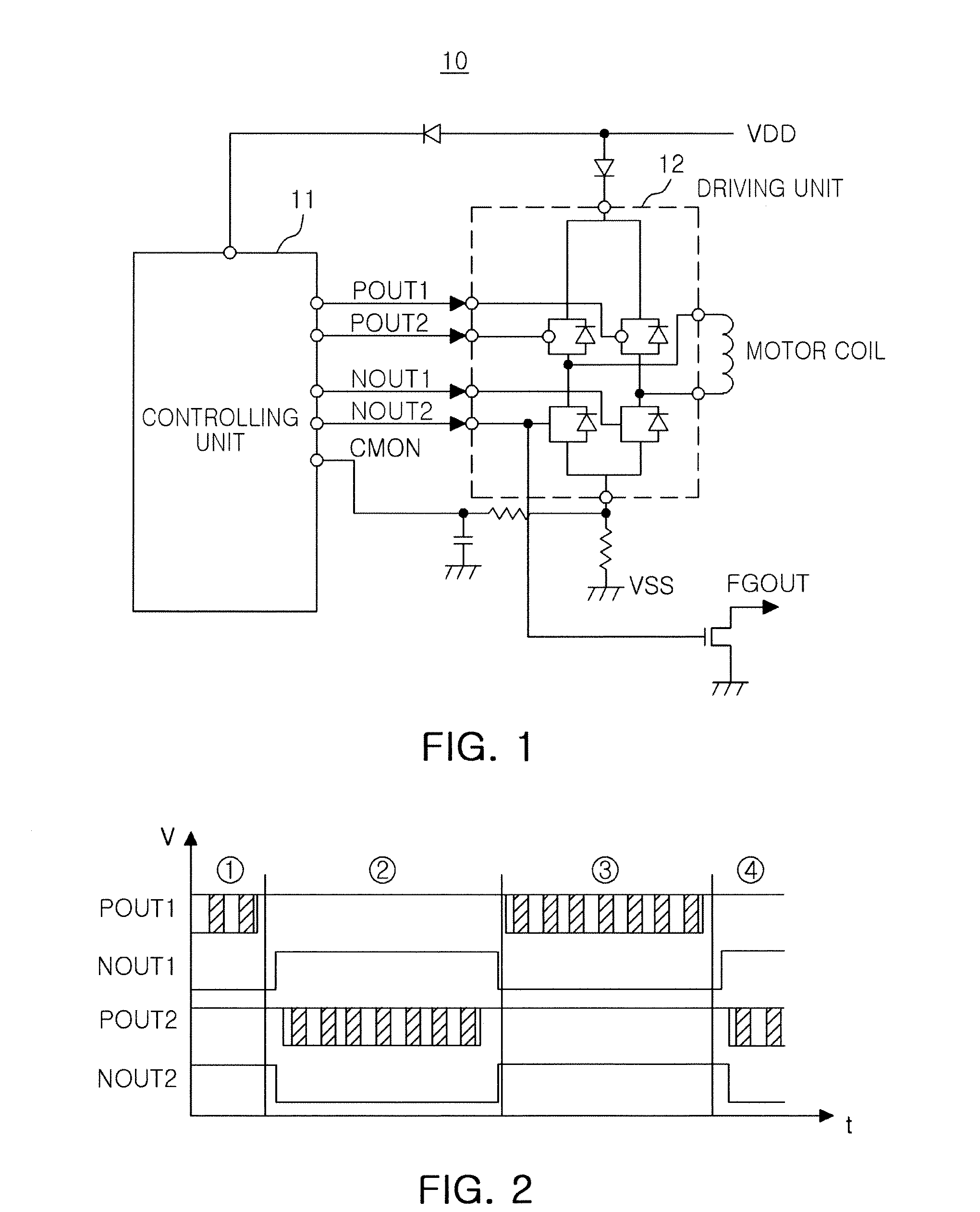

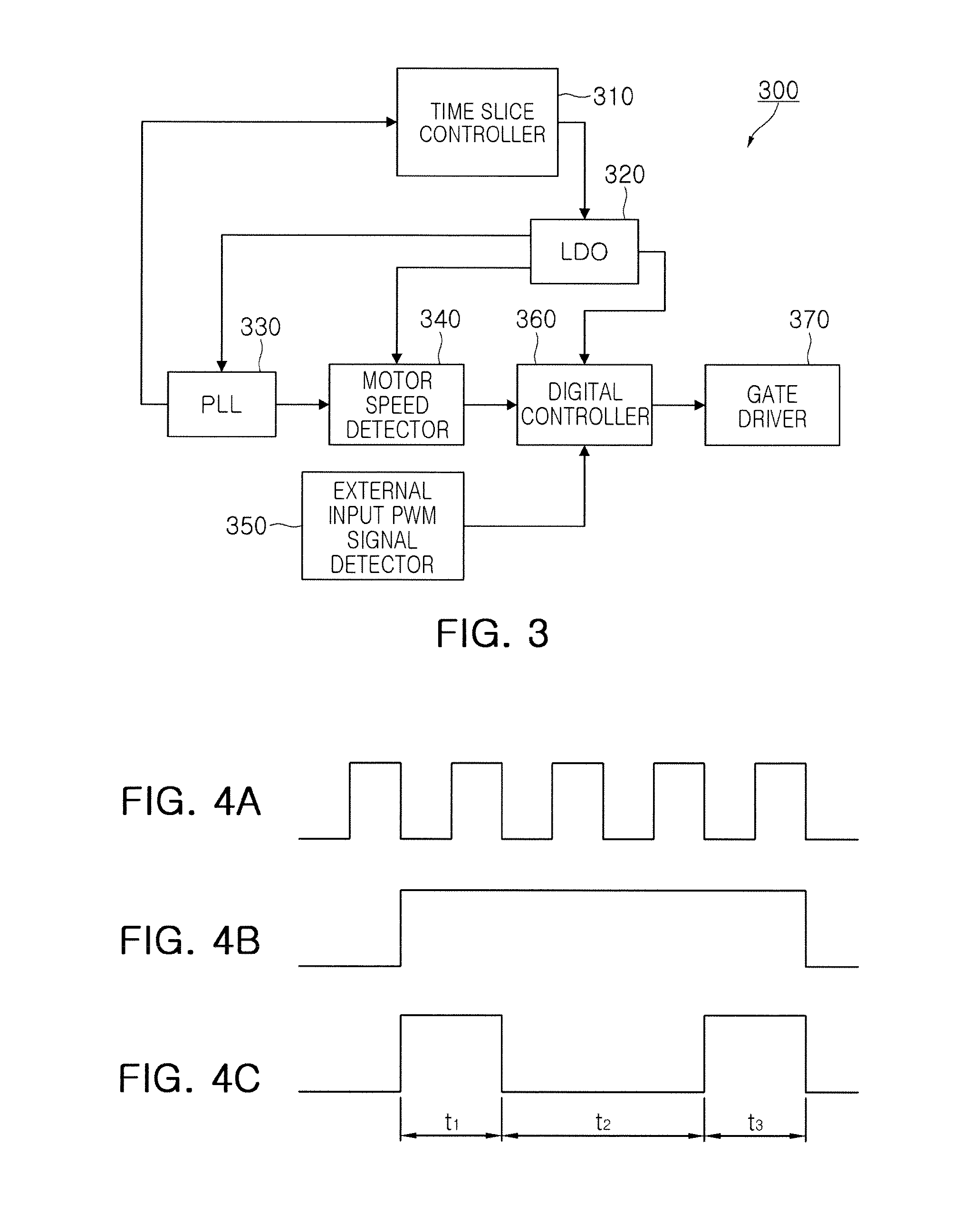

Motor driving device and method of controlling the same

InactiveUS20140062374A1Low currentMotor/generator/converter stoppersDC motor speed/torque controlMotor drivePower consumption

There are provided a motor driving device and a method of controlling the same. The motor driving device includes a controlling unit; a plurality of unit circuits provided within the controlling unit and controlling driving of a motor; and a time slice controller provided within the controlling unit and periodically generating a wake-up signal, wherein some unit circuits among the plurality of unit circuits are operated for a certain operation time upon receiving the wake-up signal, thereby allowing for effective power consumption of the motor.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Non-volatile memory low voltage and high speed erasure method

A non-volatile memory low voltage and high speed erasure method, the non-volatile memory is realized through disposing a stacked gate structure having a control gate and a floating gate on a semiconductor substrate or in an isolation well, such that adequate hot holes are generated in proceeding with low voltage and high speed erasure operation through a drain reverse bias and making changes to gate voltage. In addition, through applying positive and negative voltages on a drain, a gate, and a semiconductor substrate or well regions, adequate hot holes are generated, so as to lower the absolute voltage in achieving the objective of reducing voltage of erasing memory.

Owner:YIELD MICROELECTRONICS CORP

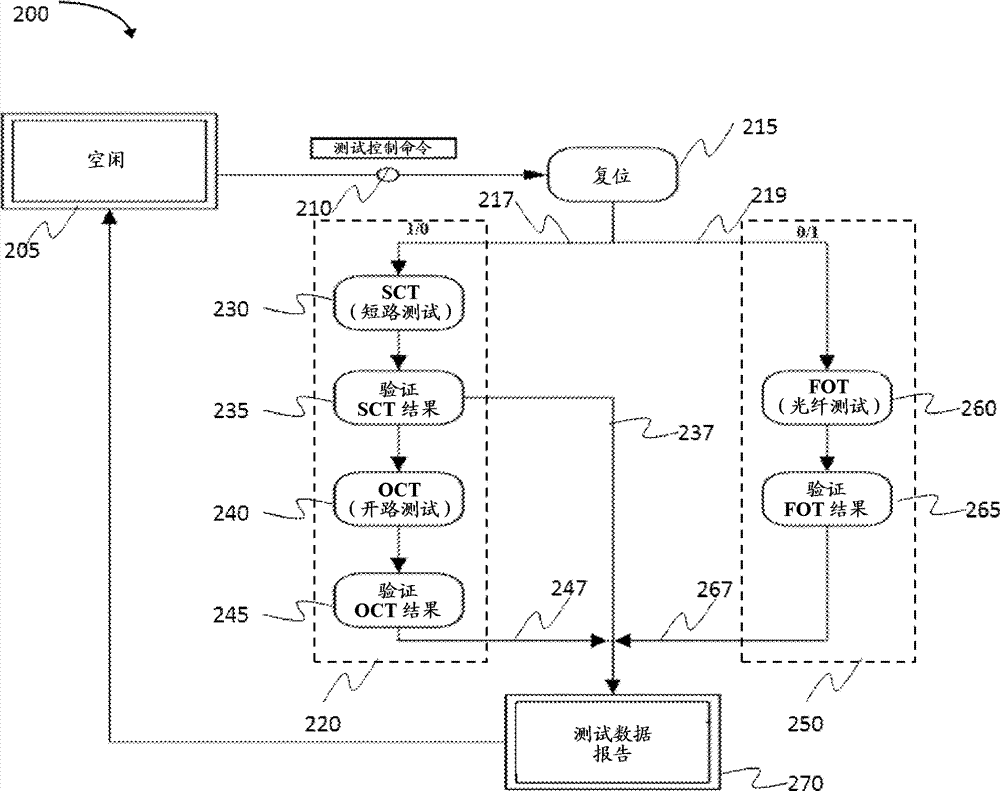

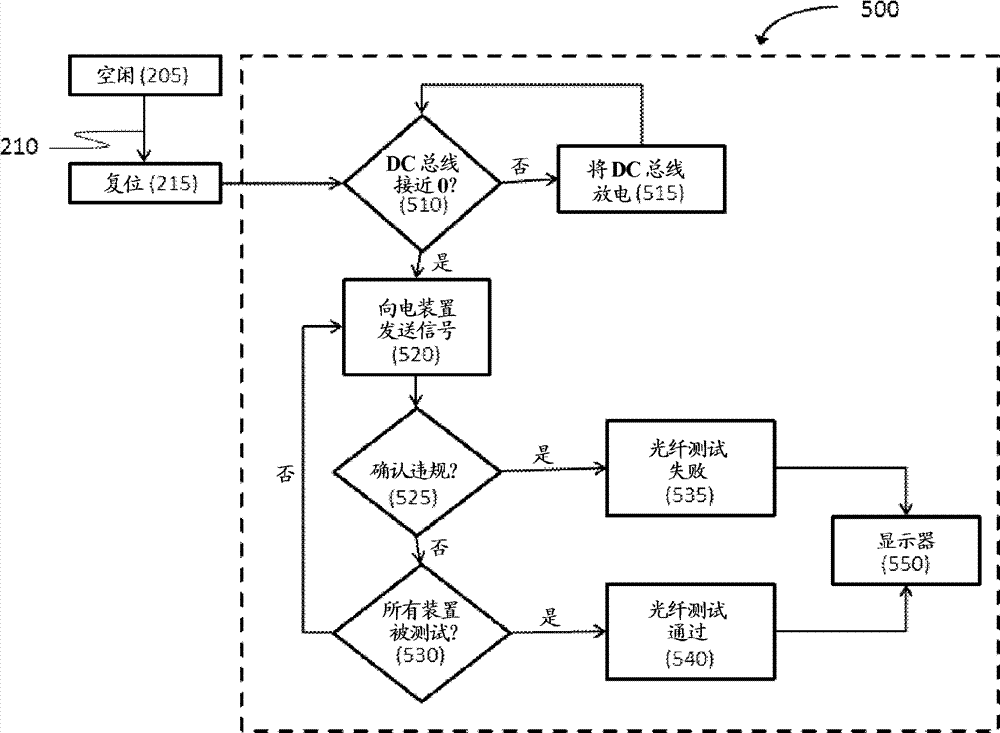

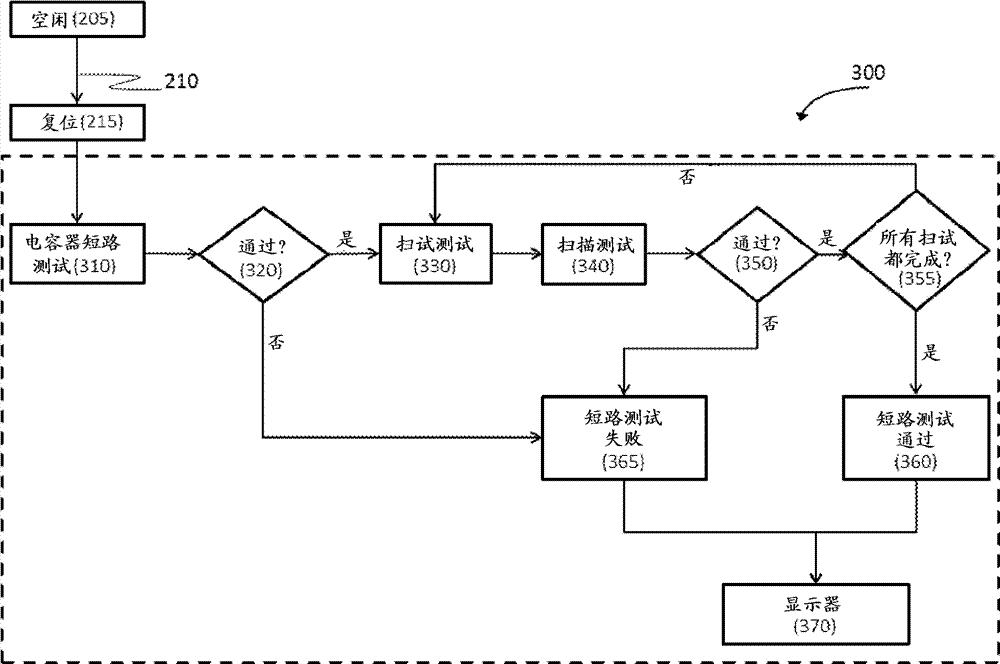

System and method for diagnosing short circuit and open circuit in power conversion system

The invention relates to a system and method for diagnosing a short circuit and an open circuit in a power conversion system. The system is used for isolating and detecting an electric fault device in a high-voltage multi-level inverter. The system comprises an input driver, a fault testing system, a receiver device and a result displayer, wherein the input driver is driven by a controller, and the receiver device receives data and diagnosis information from the fault testing system. The invention further provides the method for isolating and detecting a short circuit or an opening circuit or a fiber fault inside an electric device in the high-voltage multi-level inverter.

Owner:GE ENERGY POWER CONVERSION TECH

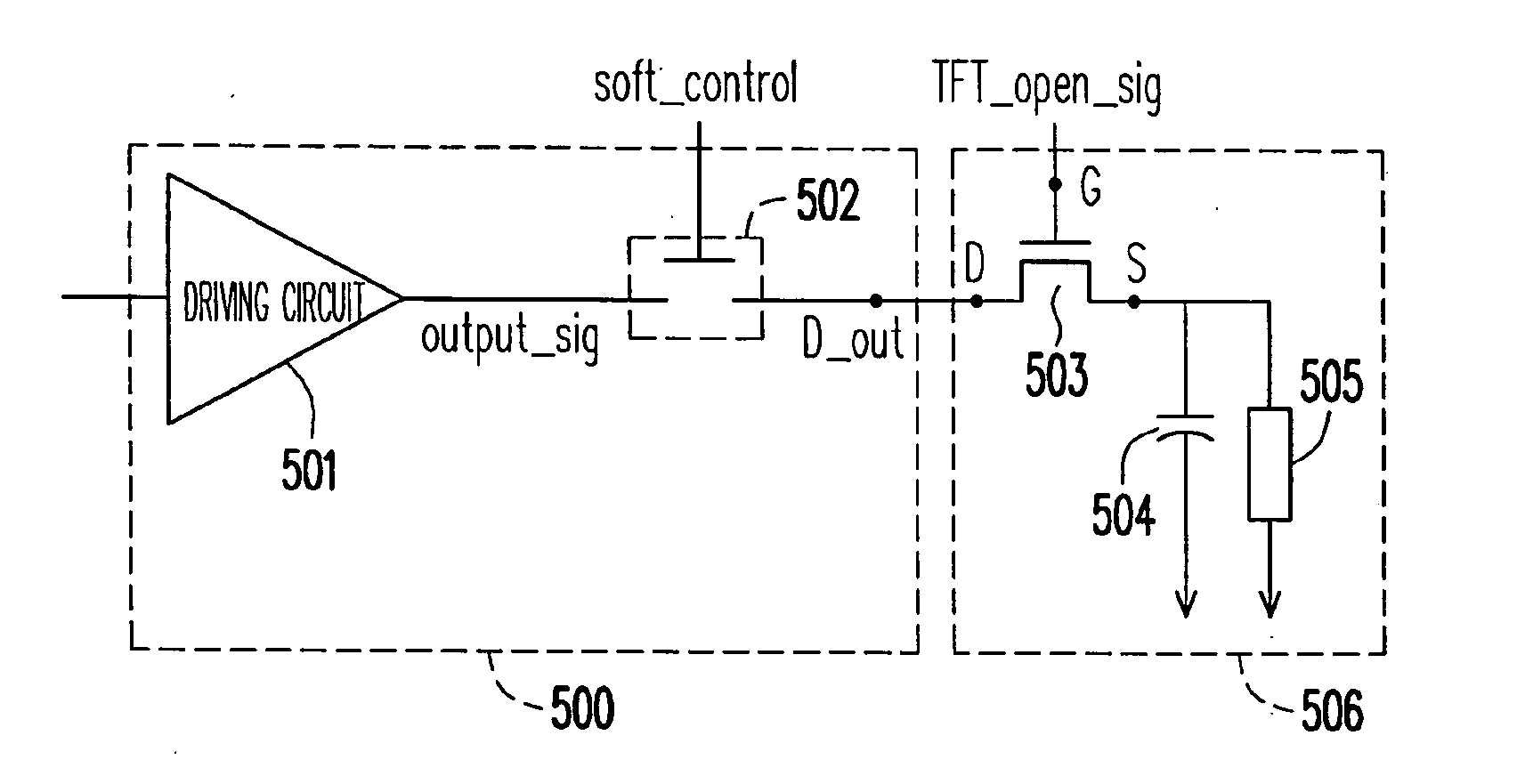

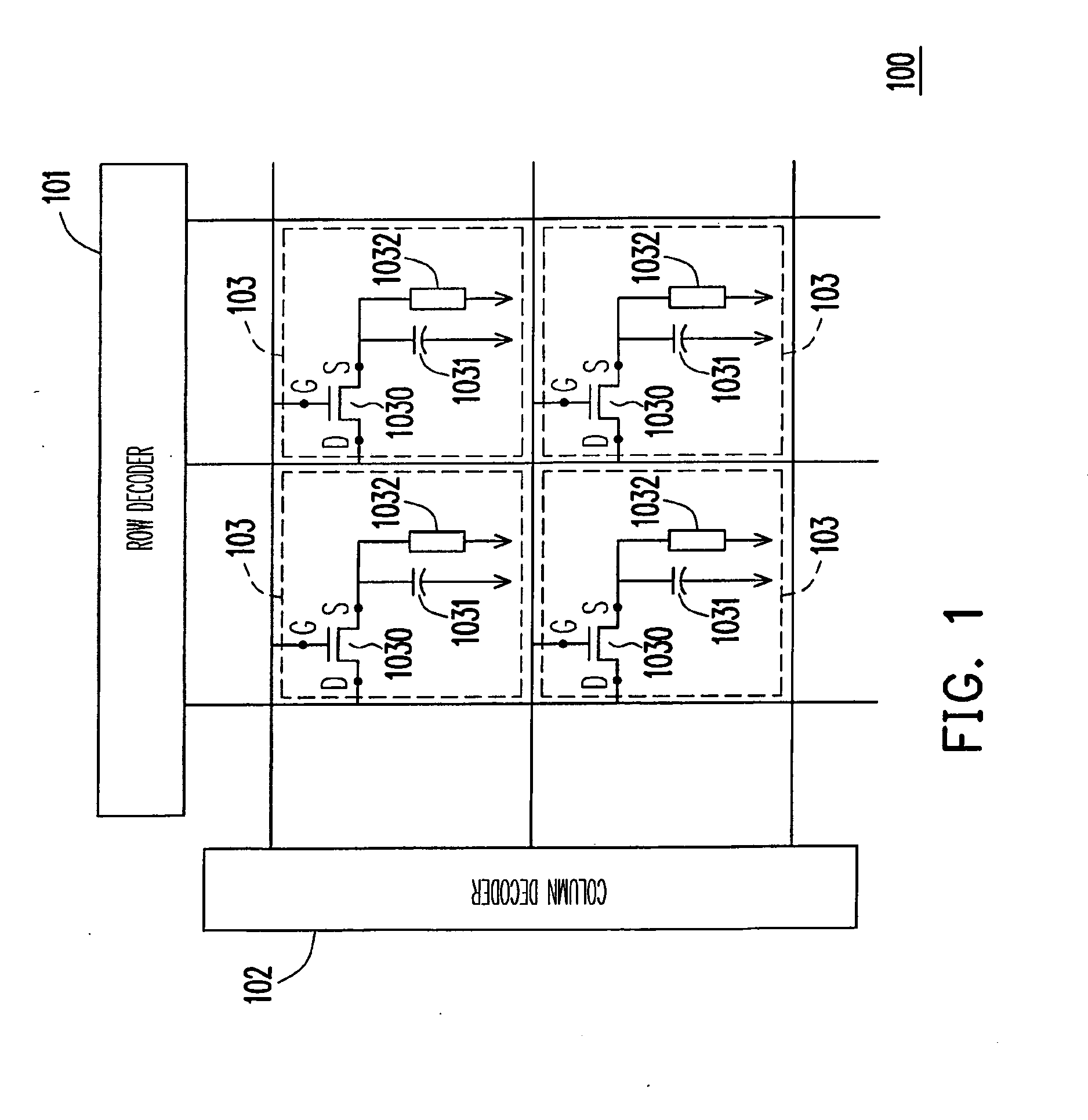

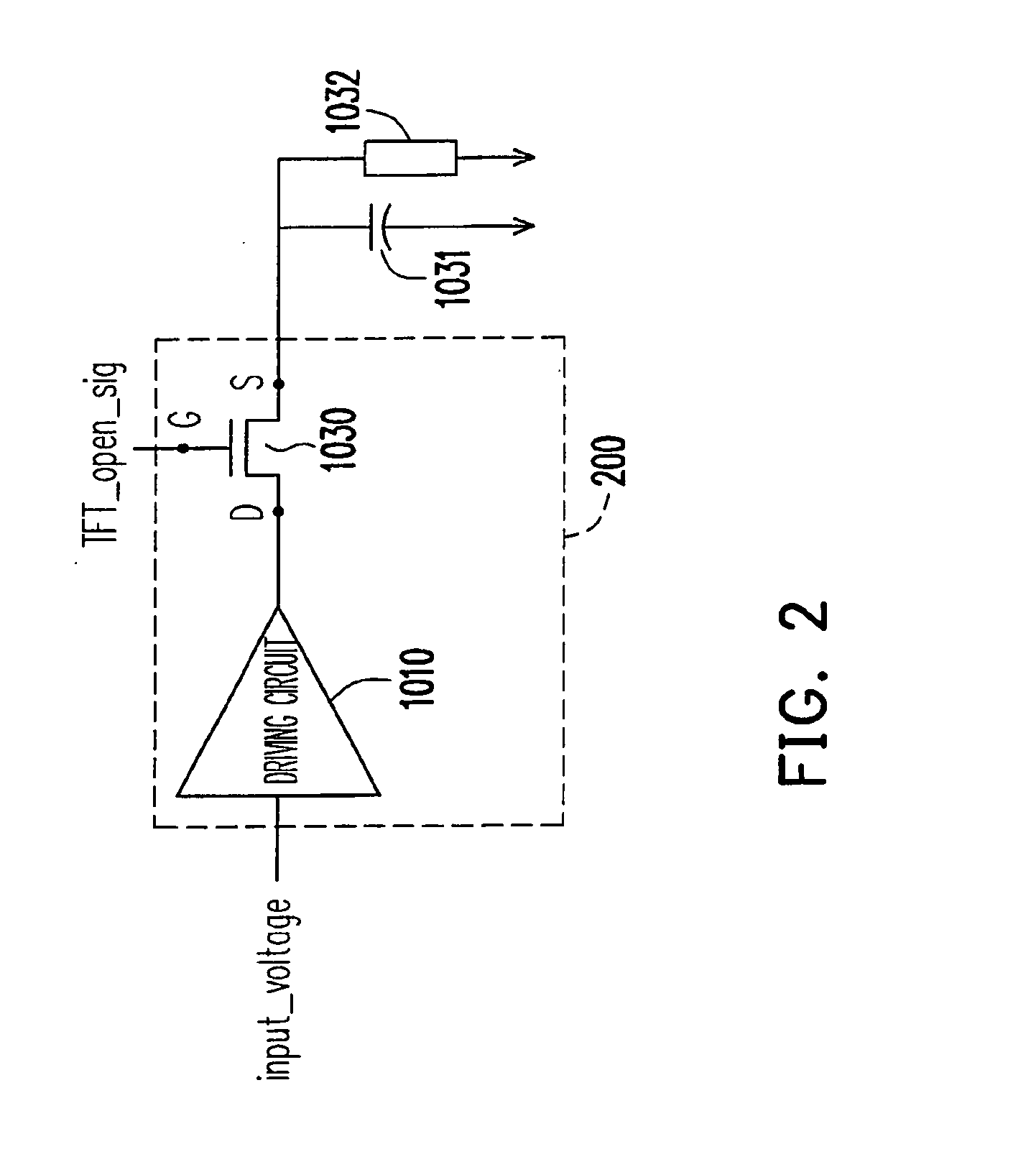

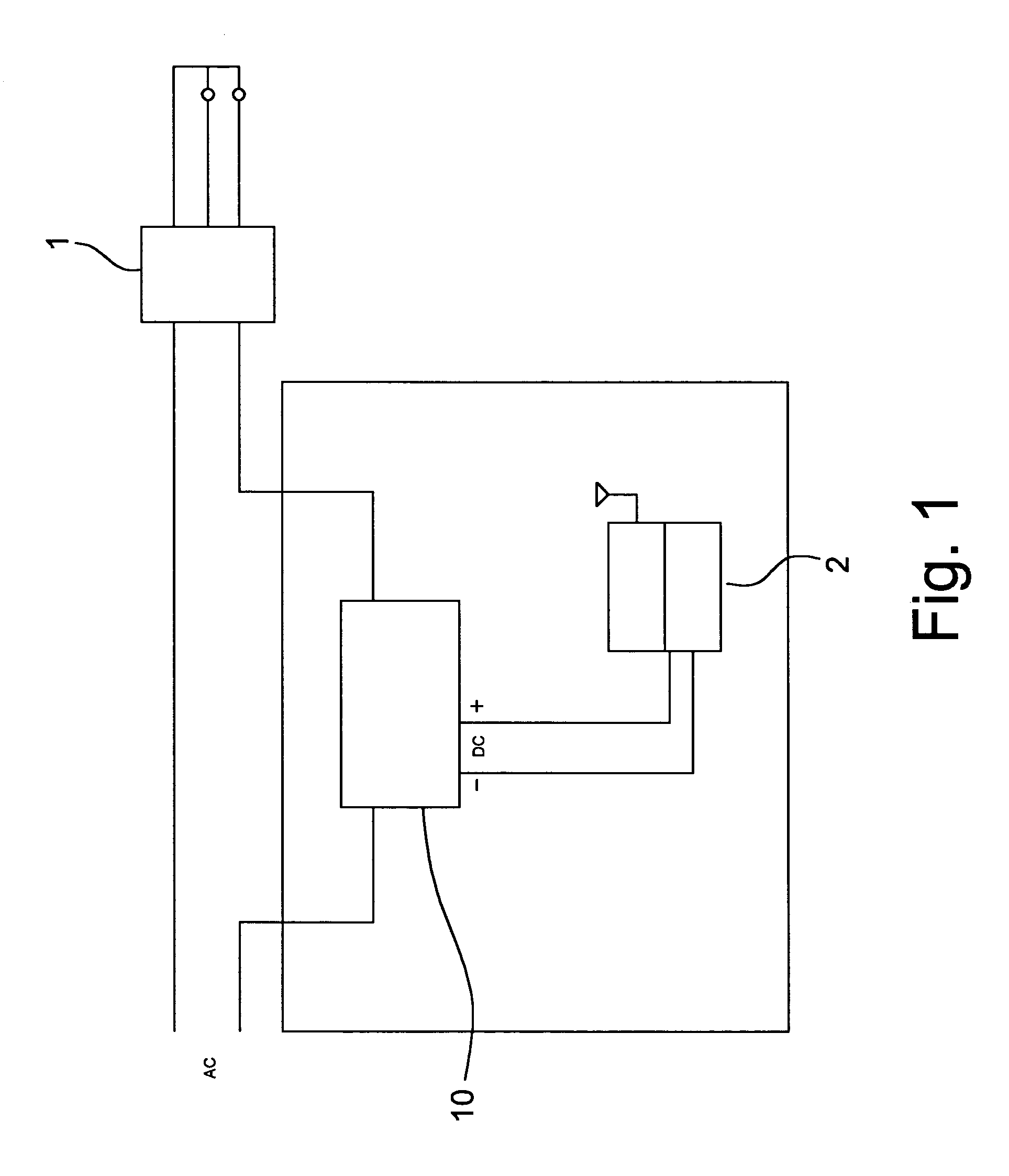

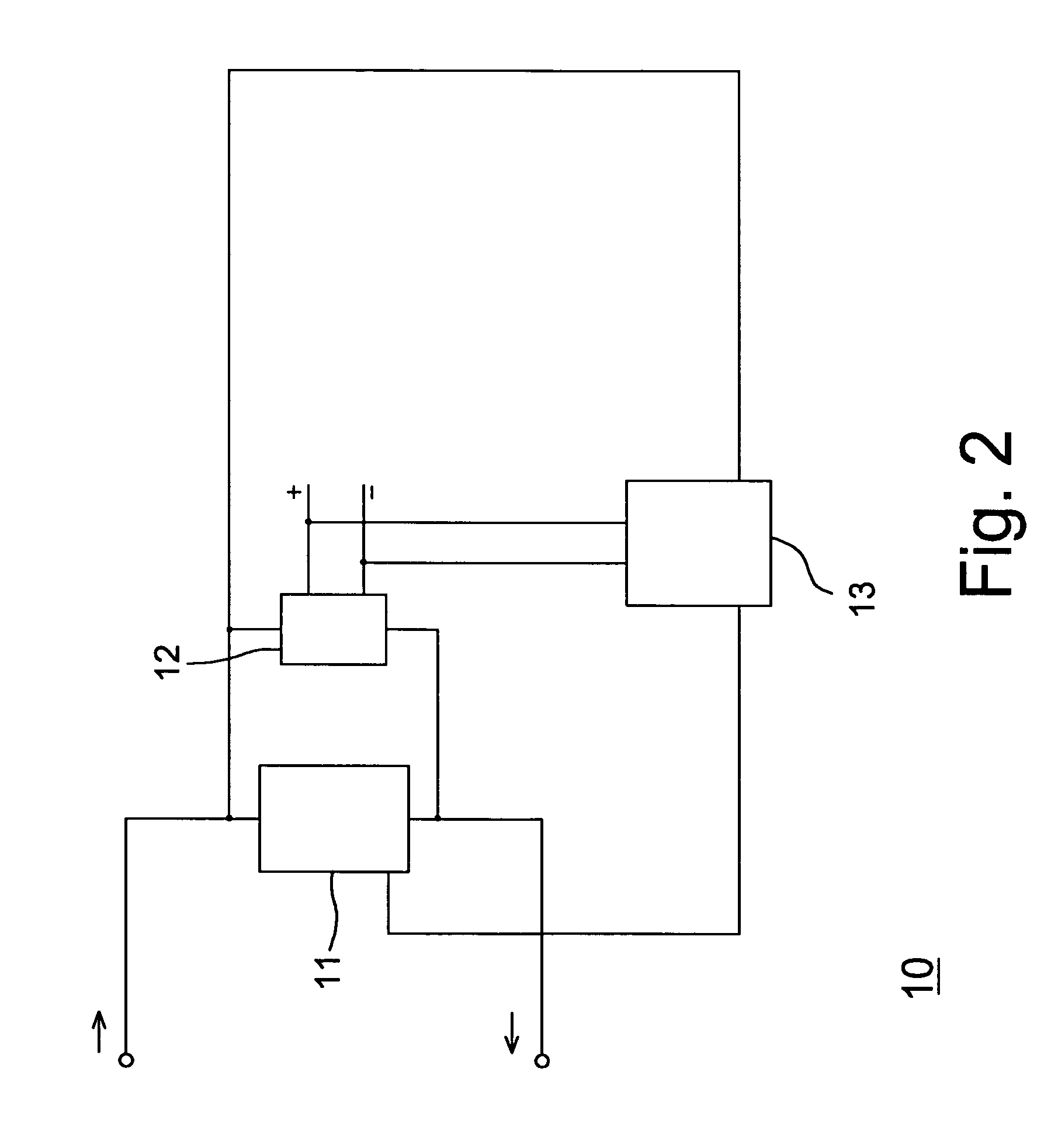

Driving apparatus, system and method thereof

ActiveUS20090085852A1Reducing spike currentLow currentAc-dc conversion without reversalConversion with intermediate conversion to dcElectricityControl switch

A driving apparatus, a system and a method thereof is provided by the present invention. The driving apparatus has at least an output terminal and includes a driving circuit and a control switch. The control switch is electrically coupled with the driving circuit. The driving circuit receives an input signal and converts the input signal into an analog driving signal. The control switch is controlled by a control signal. When the control switch is turned on, the analog driving signal is able to be sent to the output terminal of the driving apparatus. The control signal further controls the spike current generated as turning on the control switch so as to reduce the spike current. The driving apparatus can be applied to an LCD system, so that the panel and the chips of the LCD system have longer life time, lower electricity consumption and better heat dissipation performance.

Owner:NOVATEK MICROELECTRONICS CORP

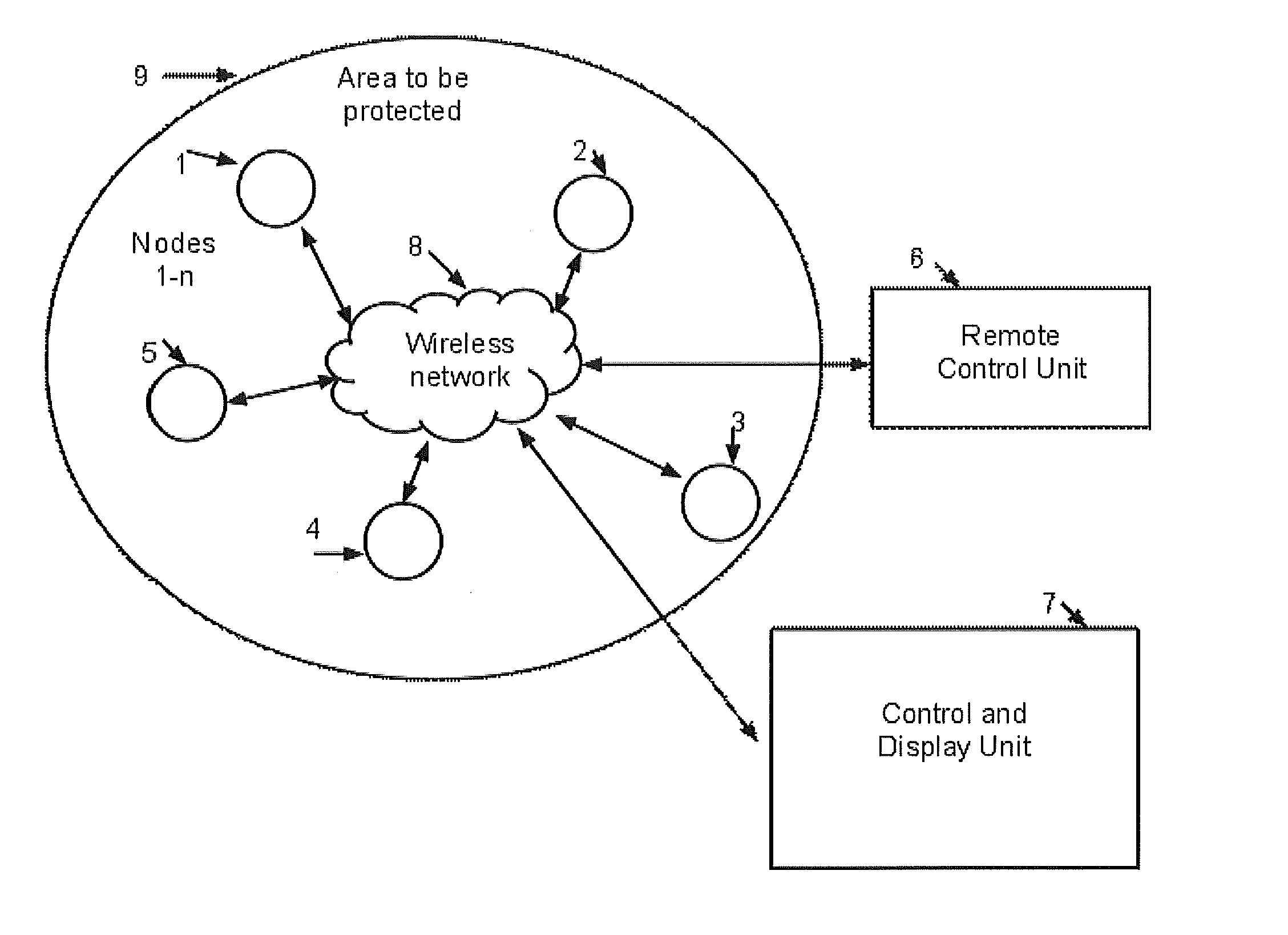

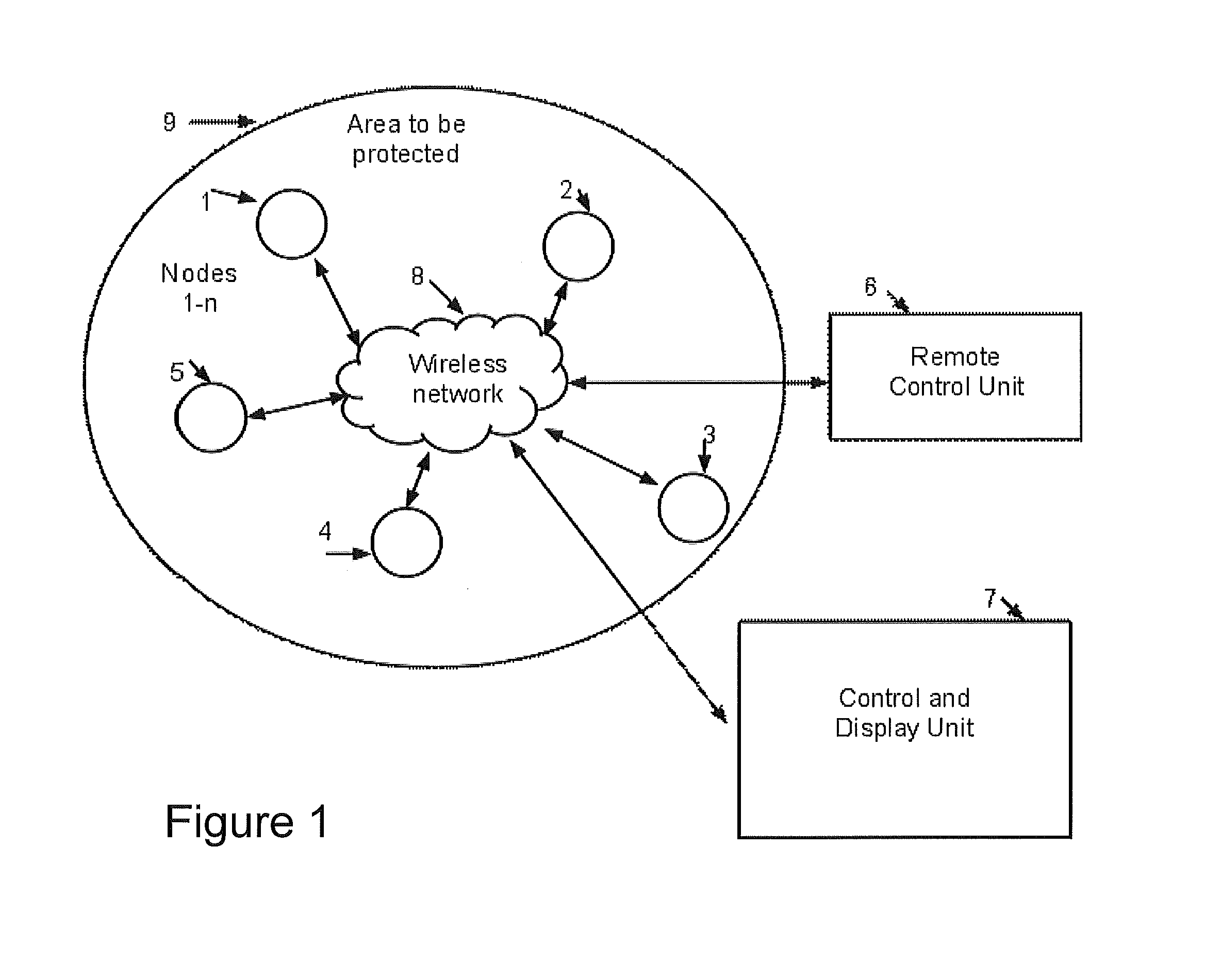

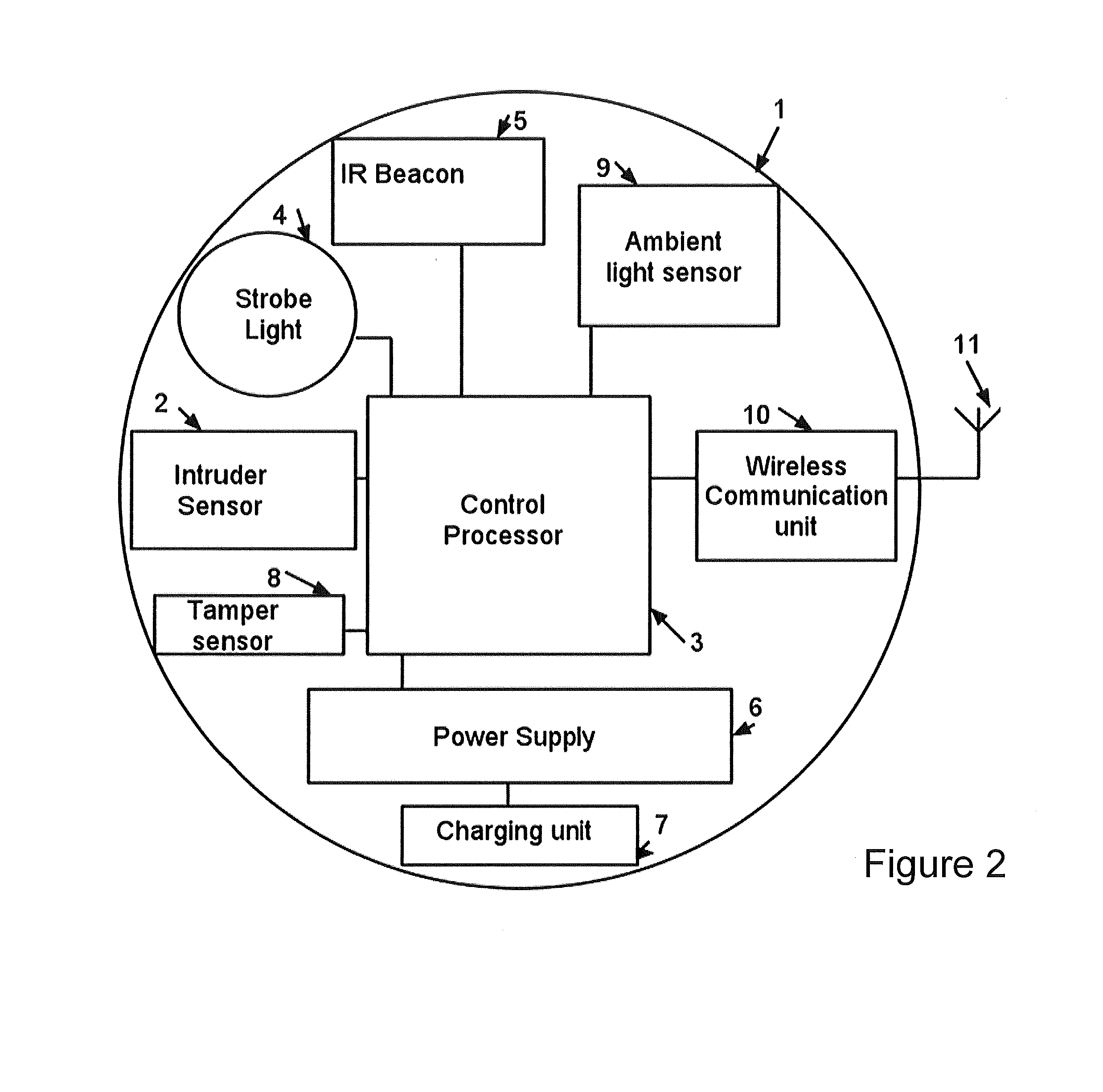

Intruder deterrent system

InactiveUS20130106605A1Enhance intruder detectionLow currentVisible signalling systemsBurglar alarmComputer scienceStrobe light

This invention relates to portable area denial systems and to related methods. We describe an intruder deterrent system, the system comprising a plurality of nodes, each said node having a strobe light, and at least one of said nodes having an intruder-detecting sensor, wherein the system is configured to flash at least one of said strobe lights on detection of an intruder by said sensor to deter said intruder.

Owner:APPLIED CONCEPTS

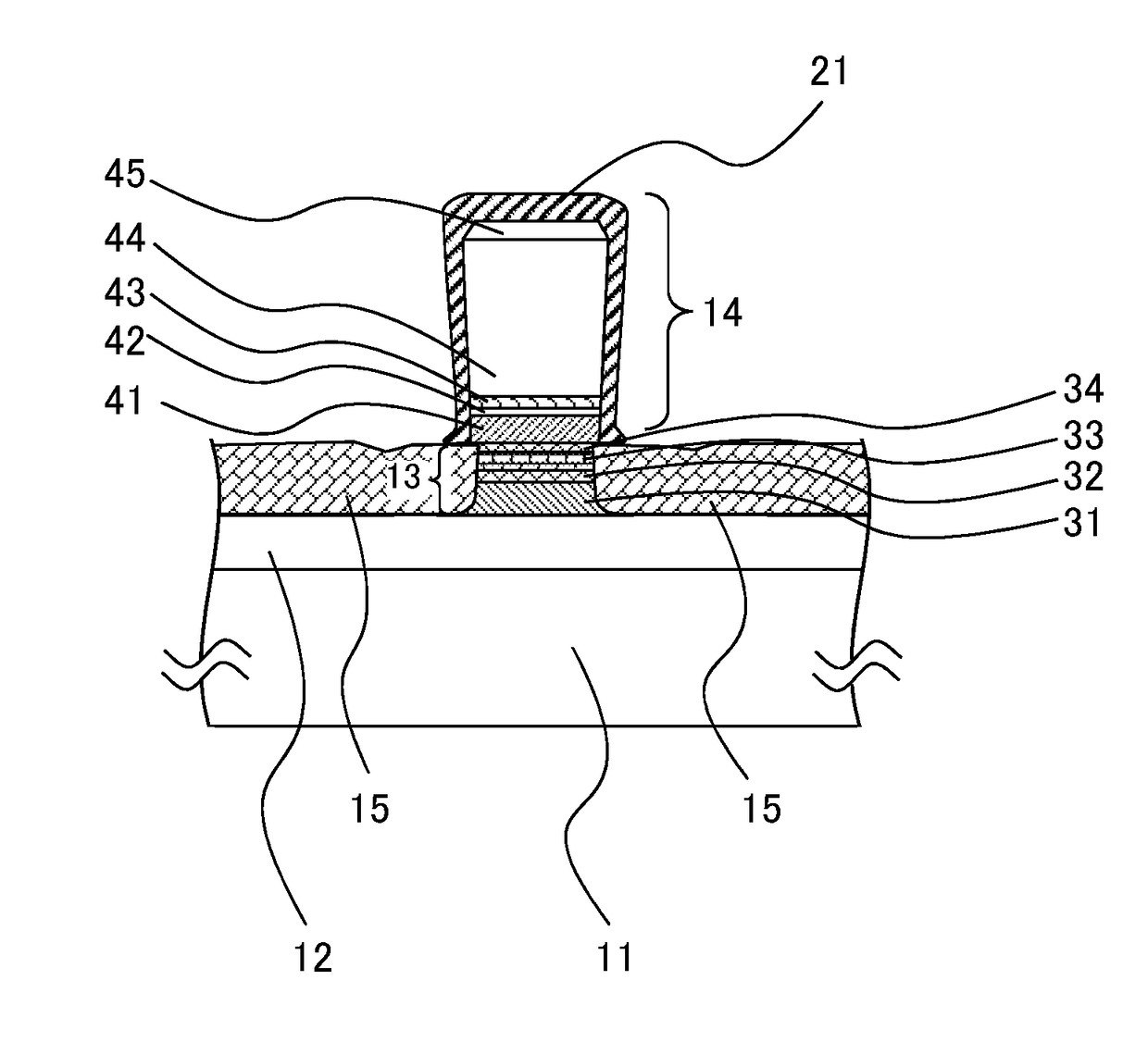

Optical semiconductor device, optical module, and method for manufacturing optical semiconductor device

ActiveUS20180090910A1Low currentHigh frequencyOptical wave guidanceLaser detailsMultiple quantumElectrical conductor

Provided is an optical semiconductor device which has long-term reliability since a threshold current is small, and a relaxation oscillation frequency is high. An optical semiconductor device includes an InP semiconductor substrate, a lower mesa structure that is disposed above the InP semiconductor substrate, and includes a multiple quantum well layer, an upper mesa structure that is disposed on the lower mesa structure, and includes a cladding layer, a buried semiconductor layer that buries both side surfaces of the lower mesa structure, and an insulating film that covers both side surfaces of the upper mesa structure by being in contact with both side surfaces of the upper mesa structure, in which the lower mesa structure includes a first semiconductor layer, above the multiple quantum well layer, and the upper mesa structure includes a second semiconductor layer which is different from the cladding layer in composition, below the cladding layer.

Owner:LUMENTUM JAPAN INC

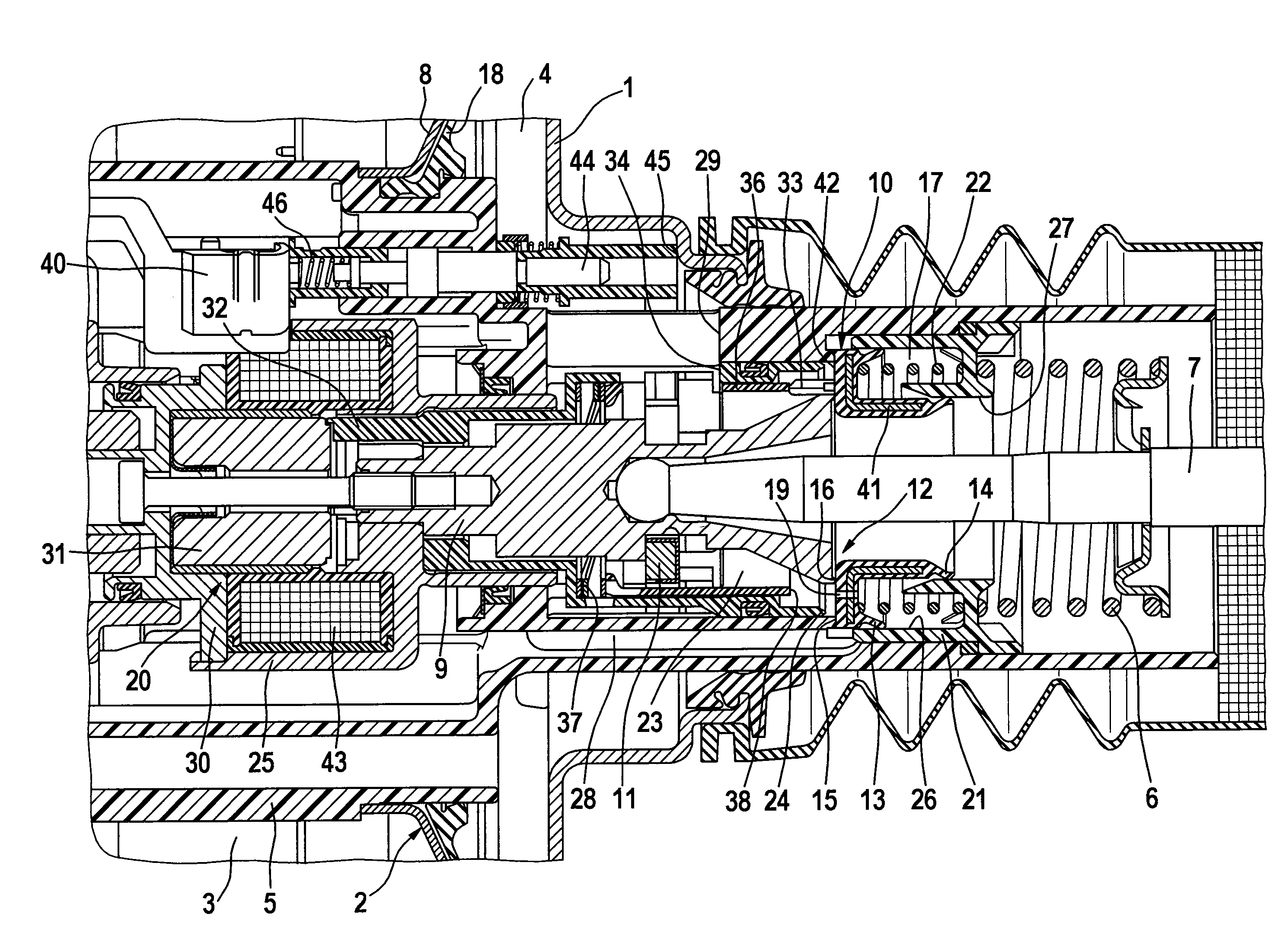

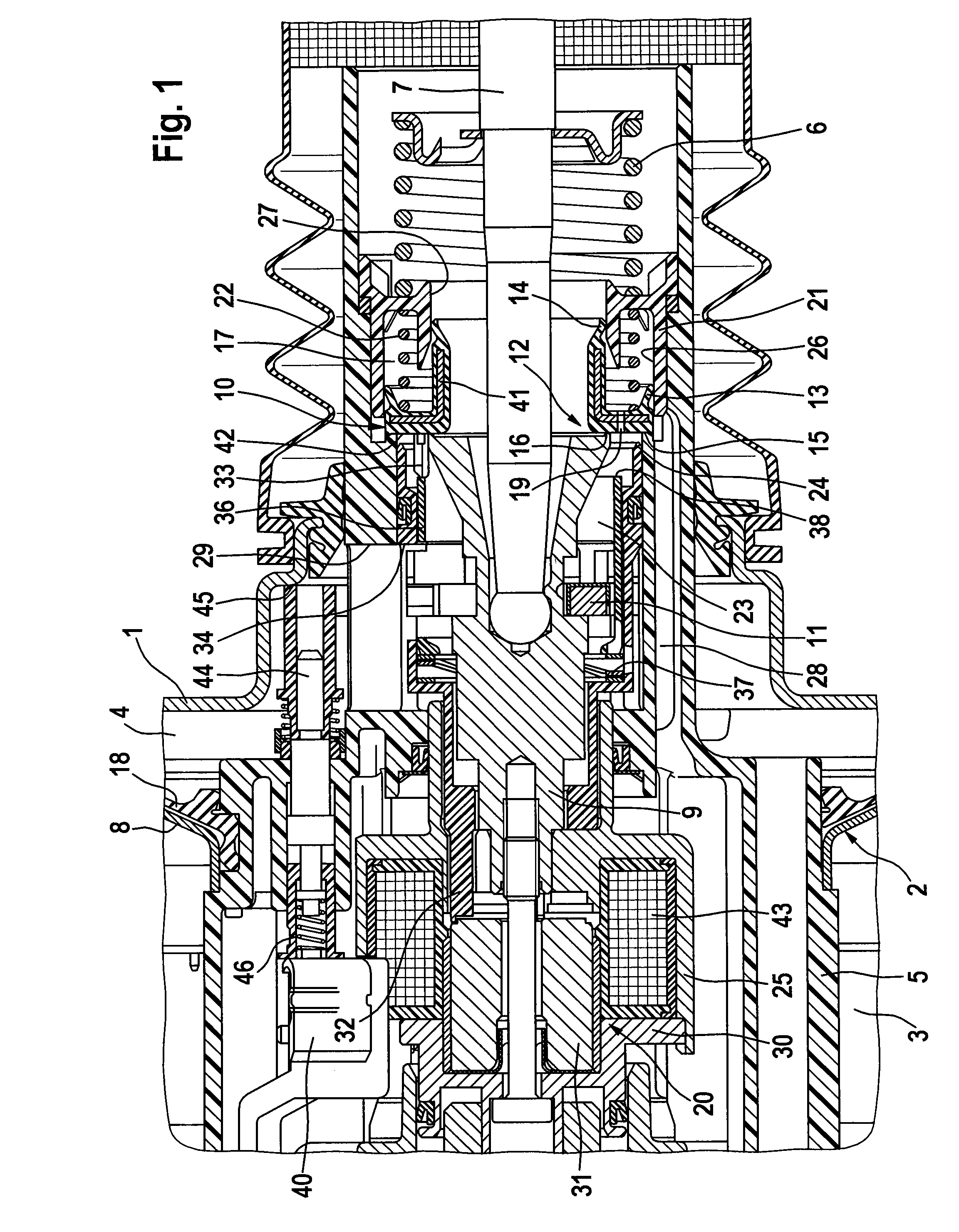

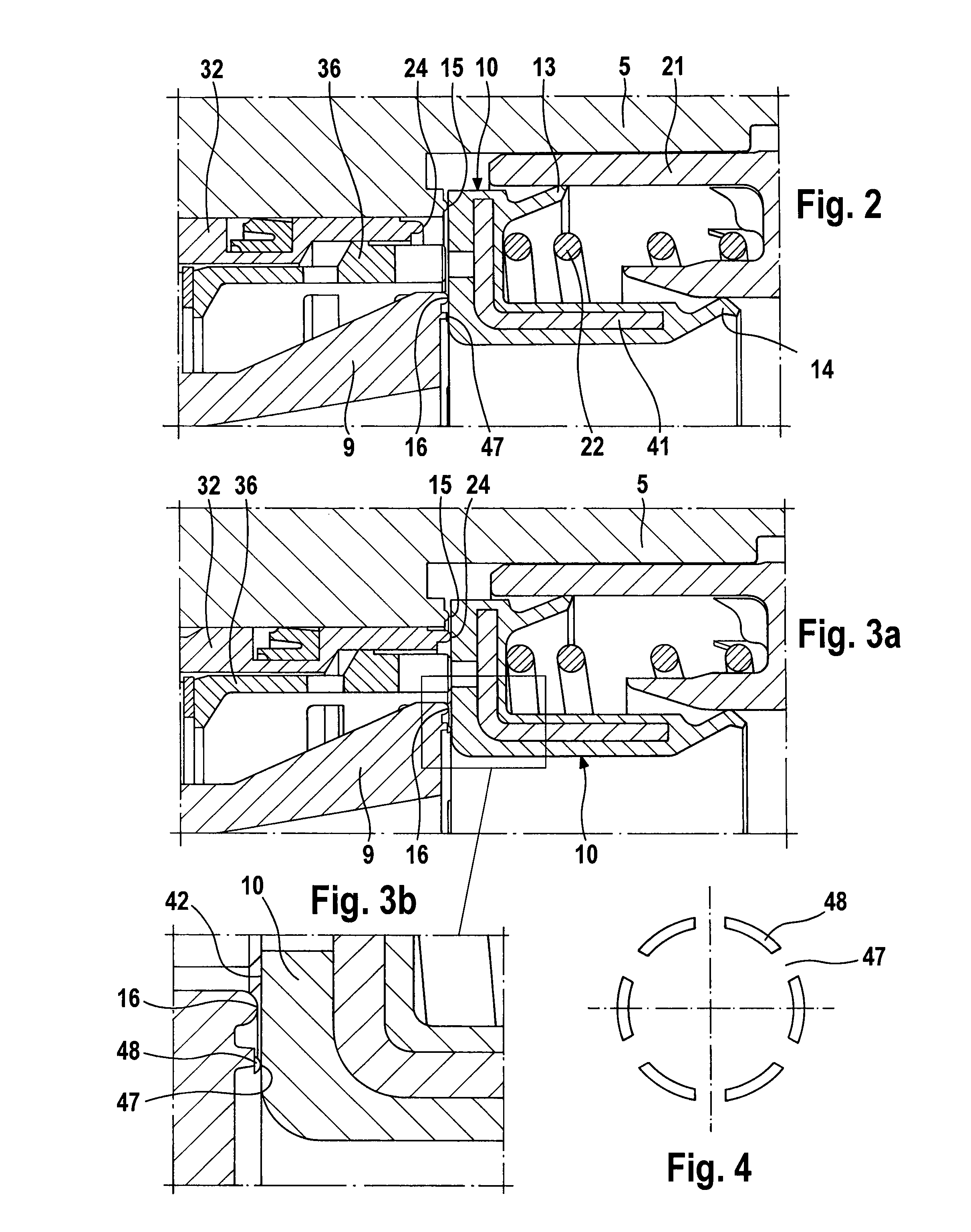

Brake servo

ActiveUS20100288119A1Low currentOverall controllabilityServomotor componentsServomotorsPistonAir volume

A brake servo whose valve piston has a concentric sealing seat which projects axially beyond a second sealing seat, with the concentric sealing seat having at least one recess for throttling the air volume flow. The controllability and also the noise characteristics of the brake servo can be improved in this way.

Owner:CONTINENTAL TEVES AG & CO OHG

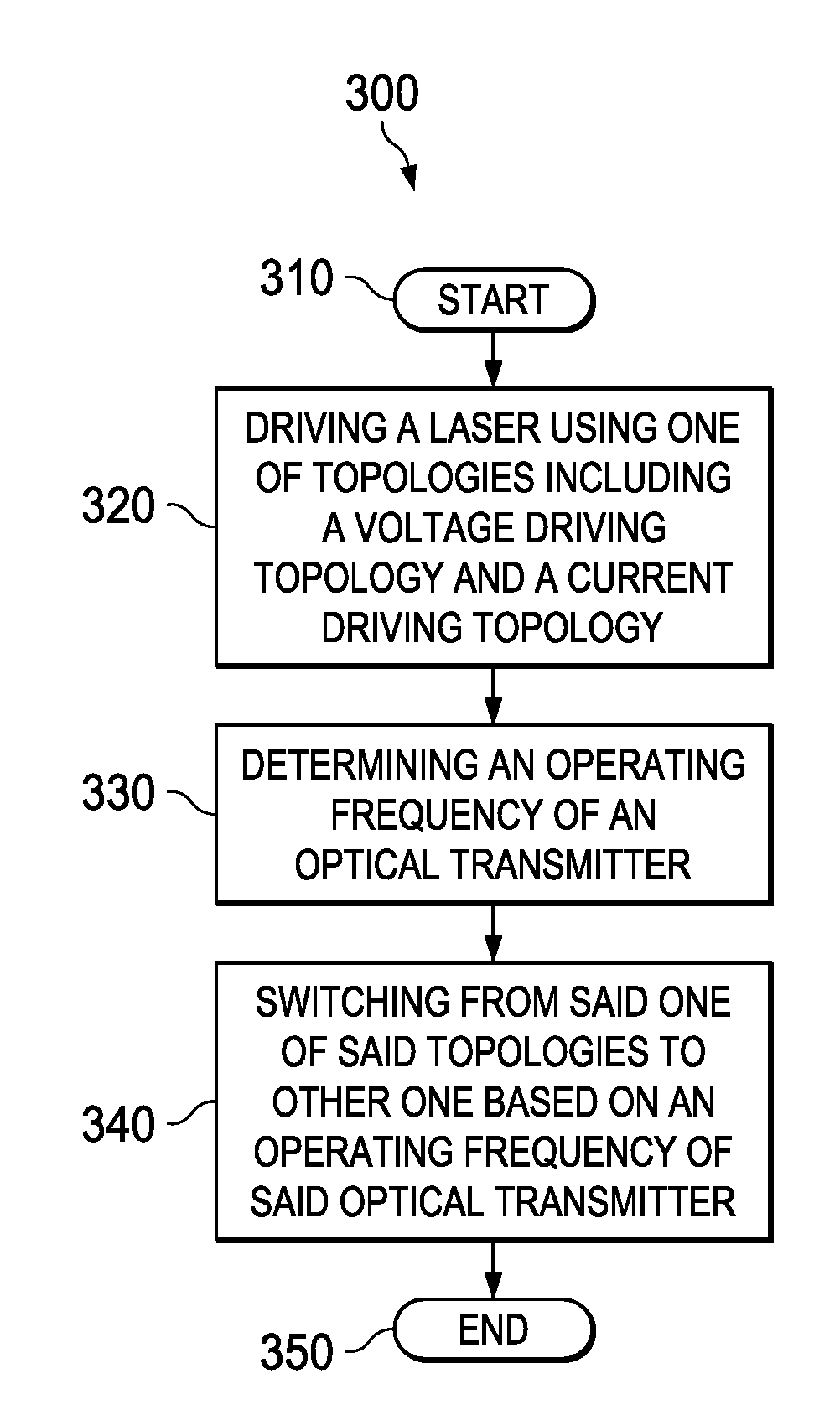

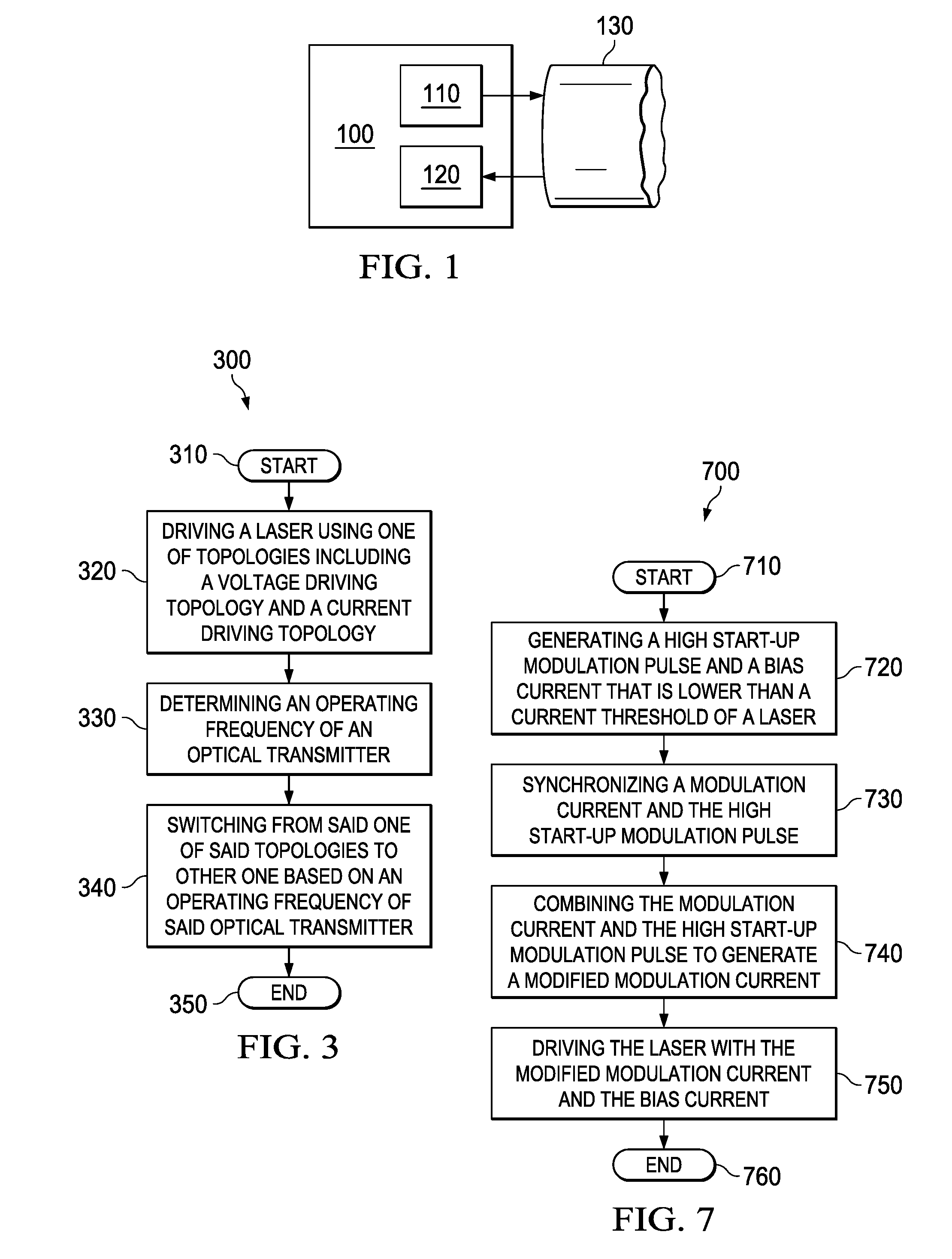

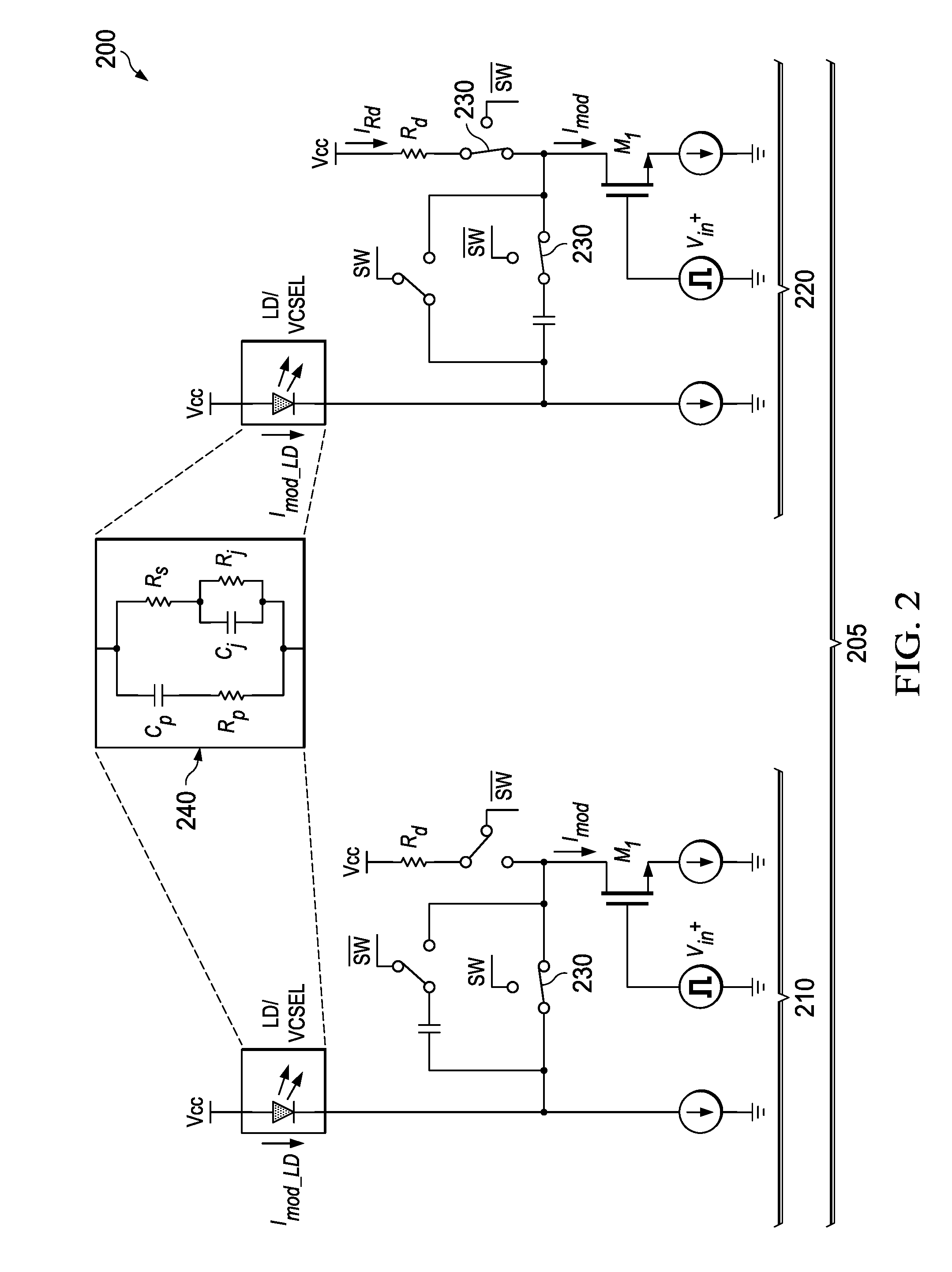

Method and circuit to reduce power consumption of optical transmitter

InactiveUS20160315713A1Low currentSynchronisation by photonic/optical meansElectromagnetic transmittersVoltageEngineering

Various embodiments of an optical transmitter and a method of operating an optical transmitter are disclosed. In one embodiment, the optical transmitter includes a laser and a laser driver configured to drive the laser using either a voltage driving topology (CDT) or a current-driving topology (VDT). The laser driver includes a switch that is configured to switch between the CDT and the CDT based on an operating frequency of the optical transmitter.

Owner:ALCATEL-LUCENT USA INC

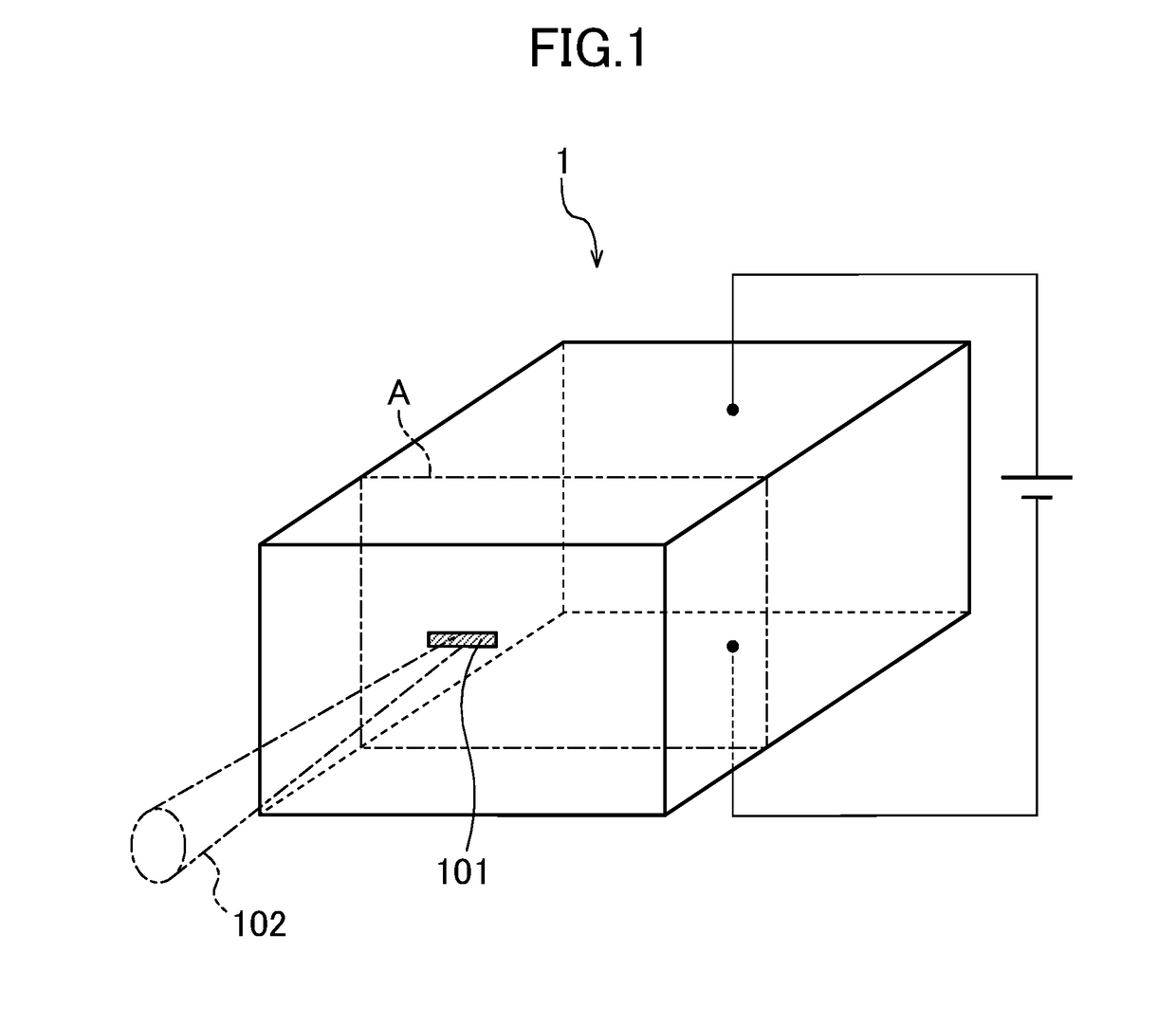

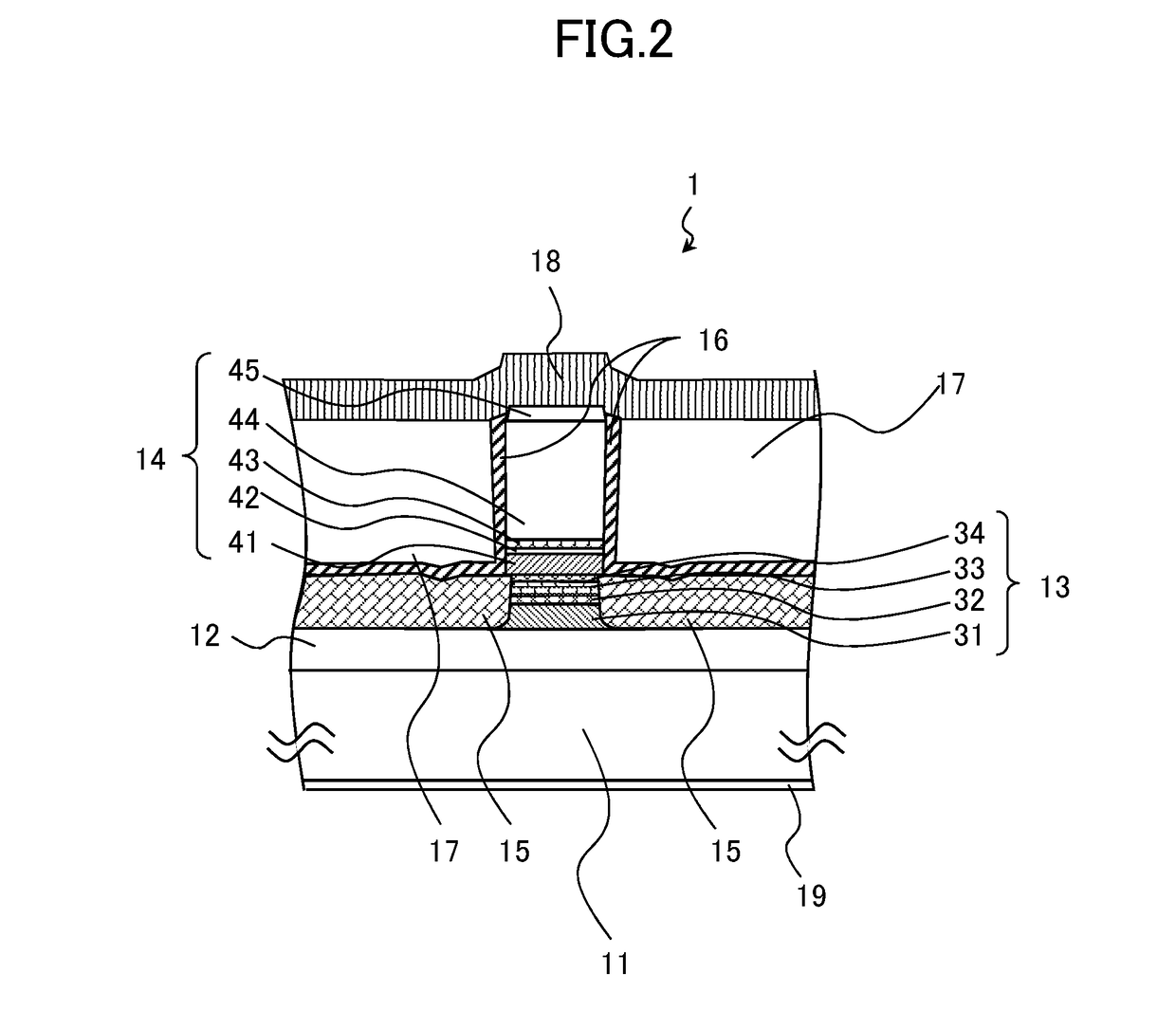

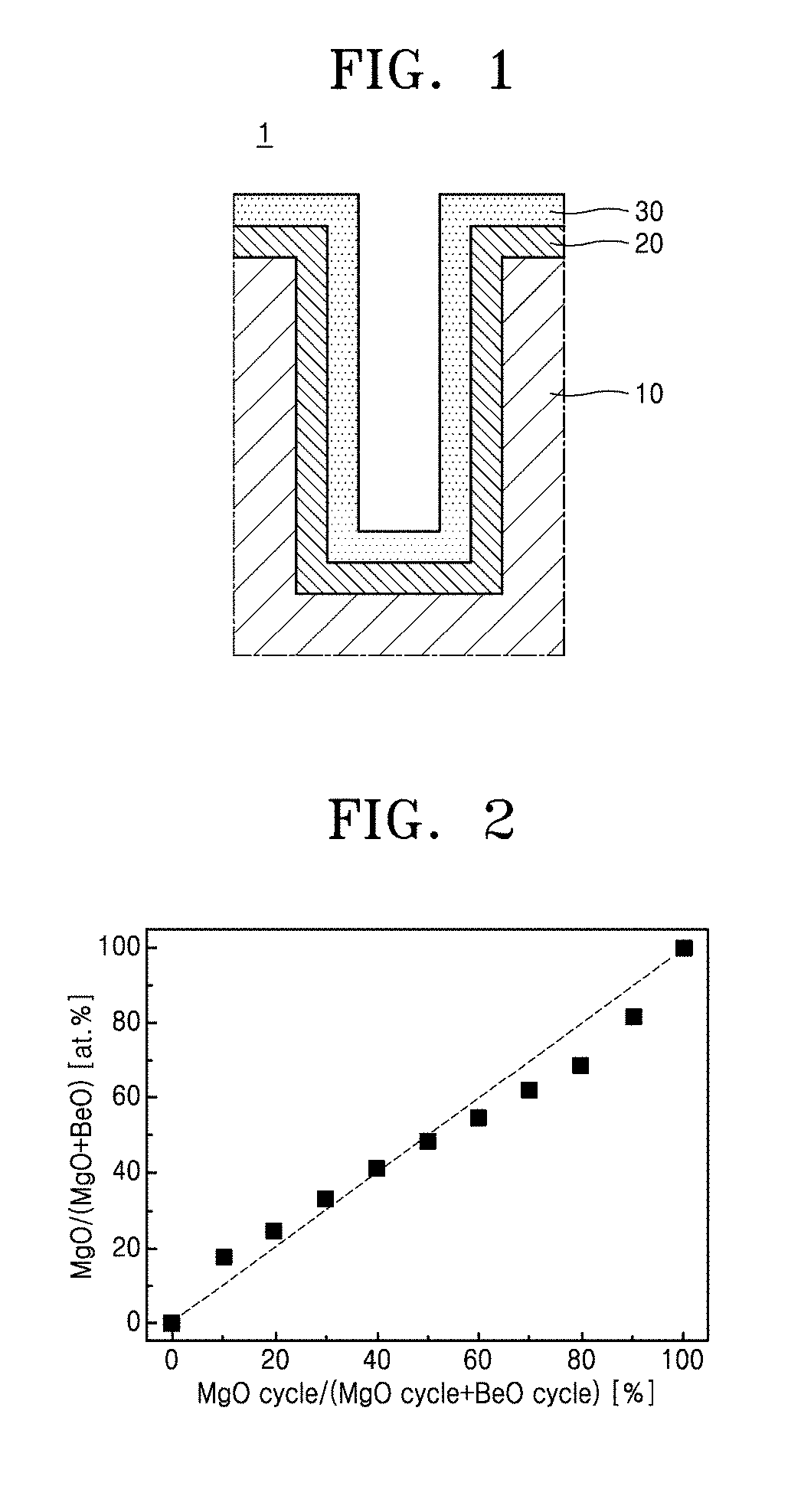

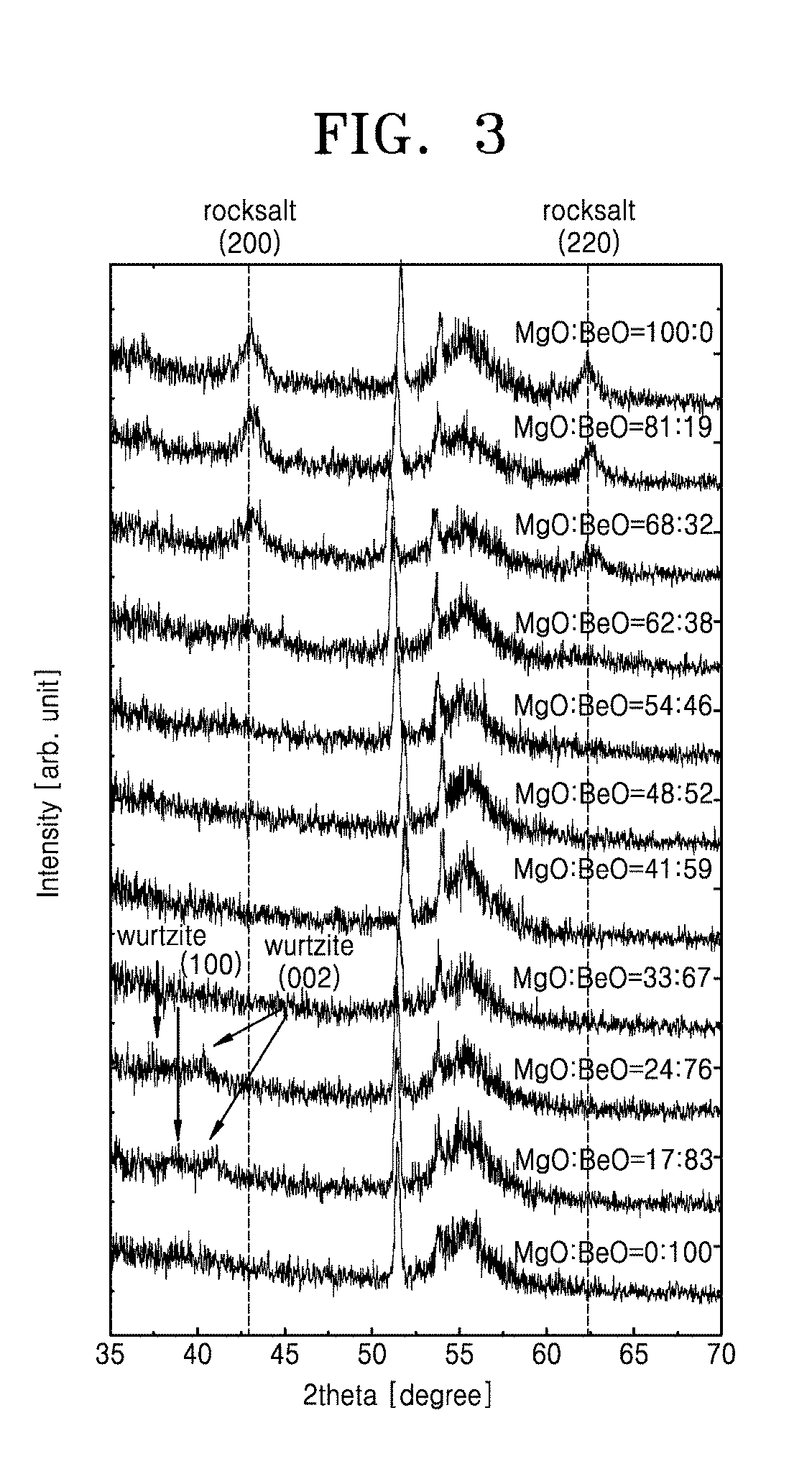

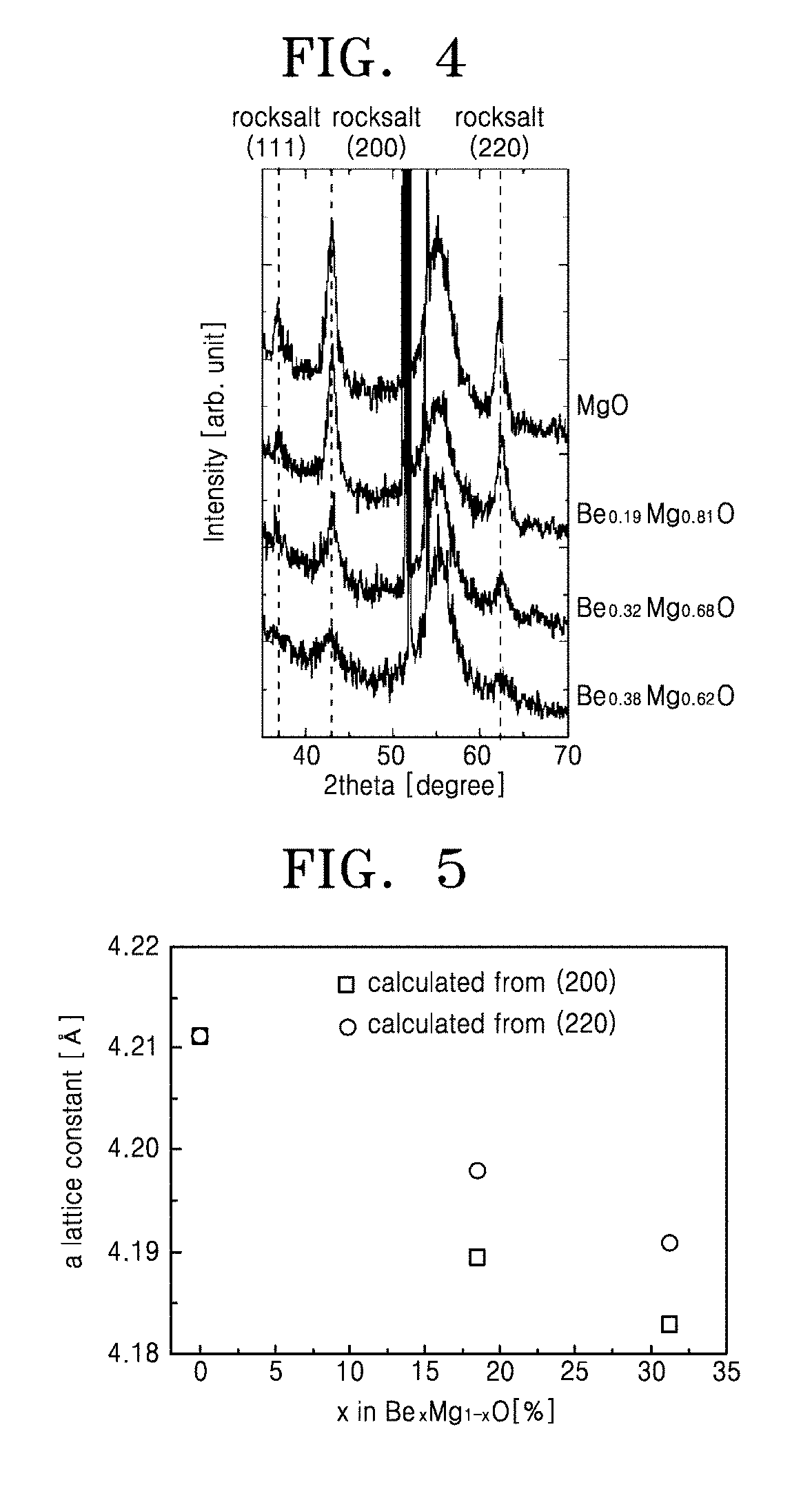

Dielectric layer, semiconductor memory device including the dielectric layer, and methods of manufacturing the dielectric layer and the semiconductor memory device

ActiveUS20190333858A1Increase dielectric constantLow currentTransistorSemiconductor/solid-state device detailsSemiconductor memorySemiconductor

Provided is a dielectric layer that has a rock salt structure in a room temperature stable phase. The dielectric layer is made of a compound having a chemical formula of BexM1-xO, where M includes one of alkaline earth metals and x has a value greater than 0 and less than 0.5.

Owner:KOREA INST OF SCI & TECH

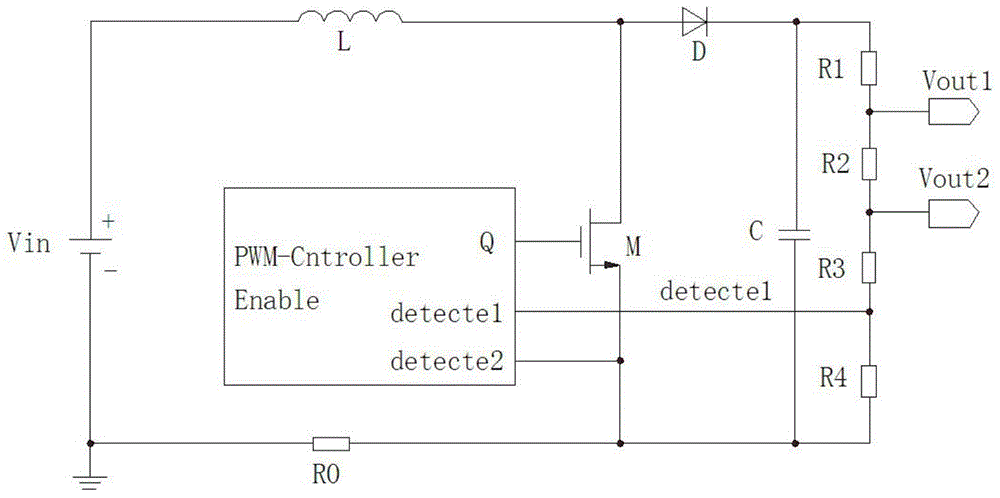

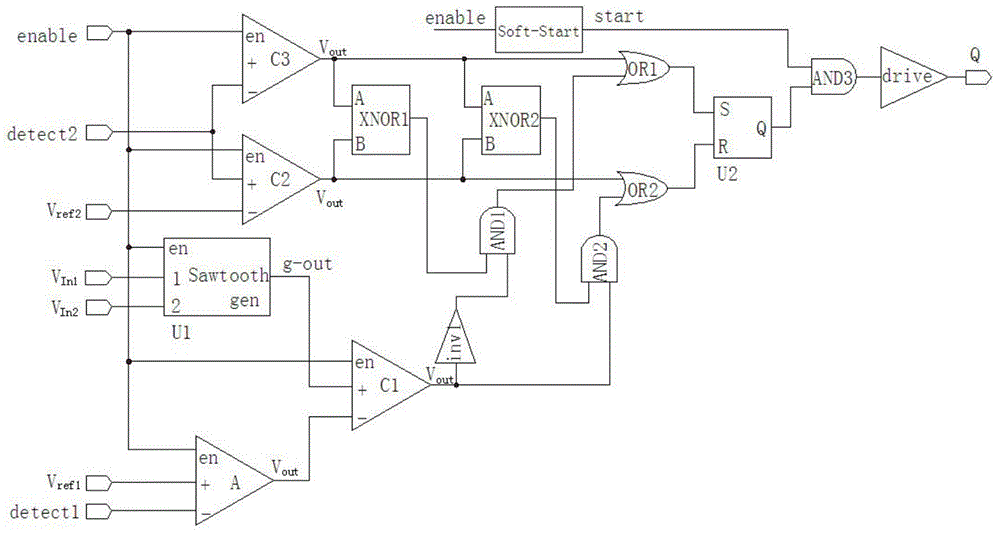

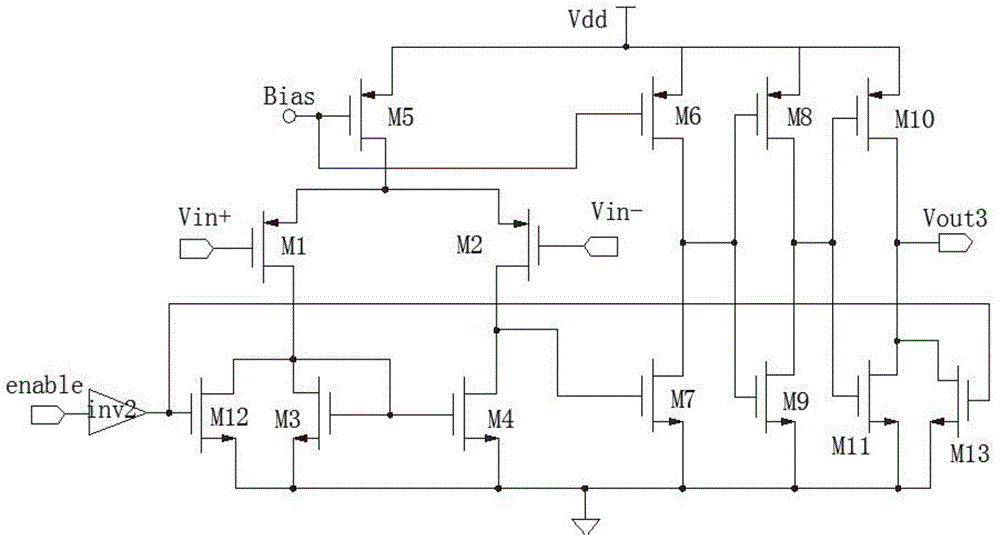

DC voltage-stabilized power supply

InactiveCN104917383AImprove conversion efficiencyLow working voltageDc-dc conversionElectric variable regulationOperating pointMode control

The invention provides a DC voltage-stabilized power supply. An inductor L, a fly-wheel diode D, a load resistor R1, a load resistor R2, a load resistor R3, a load resistor R4 and a load resistor R0 are sequentially connected in series between positive and negative electrodes of a power supply Vin, and the negative electrode of the power supply Vin is grounded; a Q end of a pulse width modulation controller is connected with a grid of a switching tube M, a detecting end detecte1 is connected with a rear end of the load resistor R3, and a detecting end detecte2 is connected with a source of the switching tube M and then connected with a rear end of the load resistor R4; and a drain of the switching tube M is connected with a rear end of the inductor L. The DC voltage-stabilized power supply has the advantages of very high conversion efficiency, low operating voltage, undercurrent and overcurrent detection, power-saving mode control and the like, provides biasing for internal operating points through a bandgap reference voltage source, greatly improves the stability of system, increases power supply voltage fluctuation resistance, and improves suppression of interference caused by temperature change and noise.

Owner:ZUNYI NORMAL COLLEGE

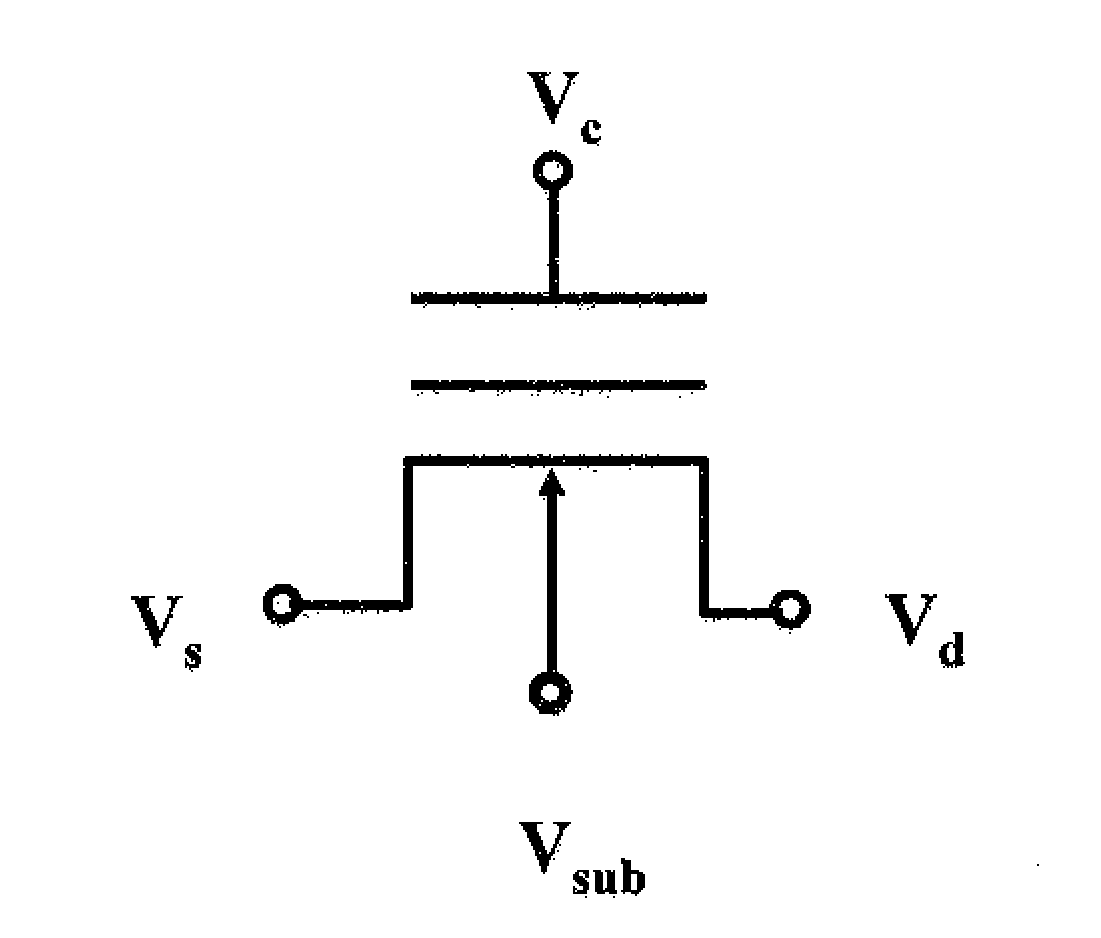

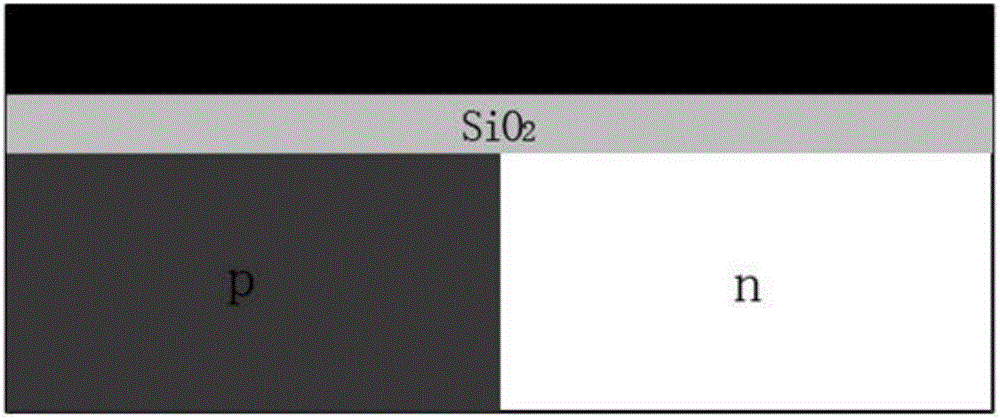

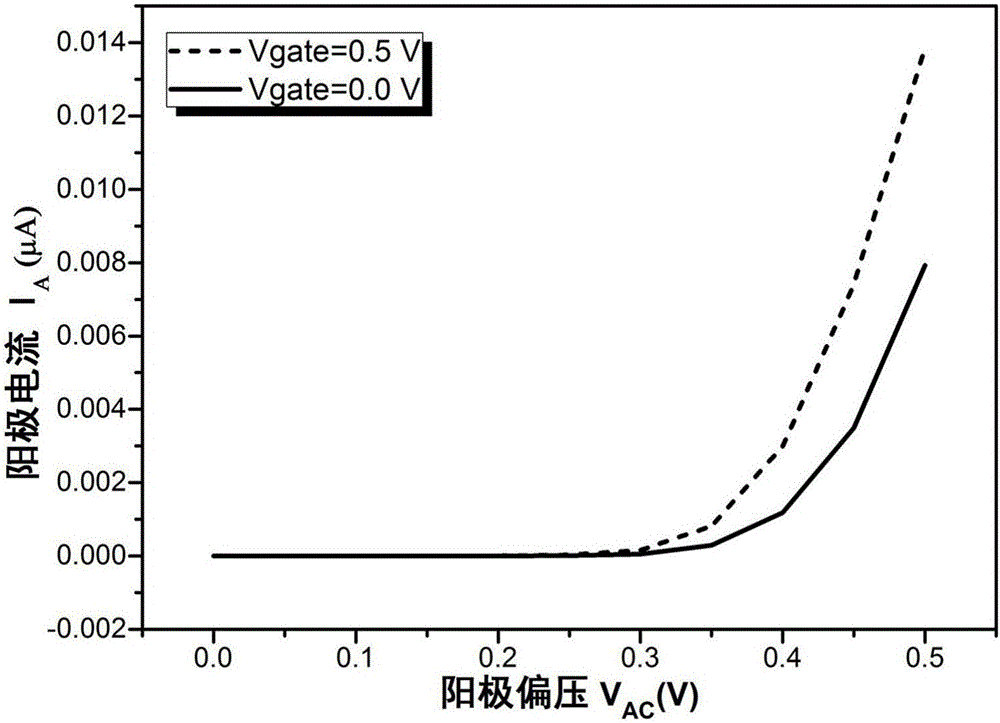

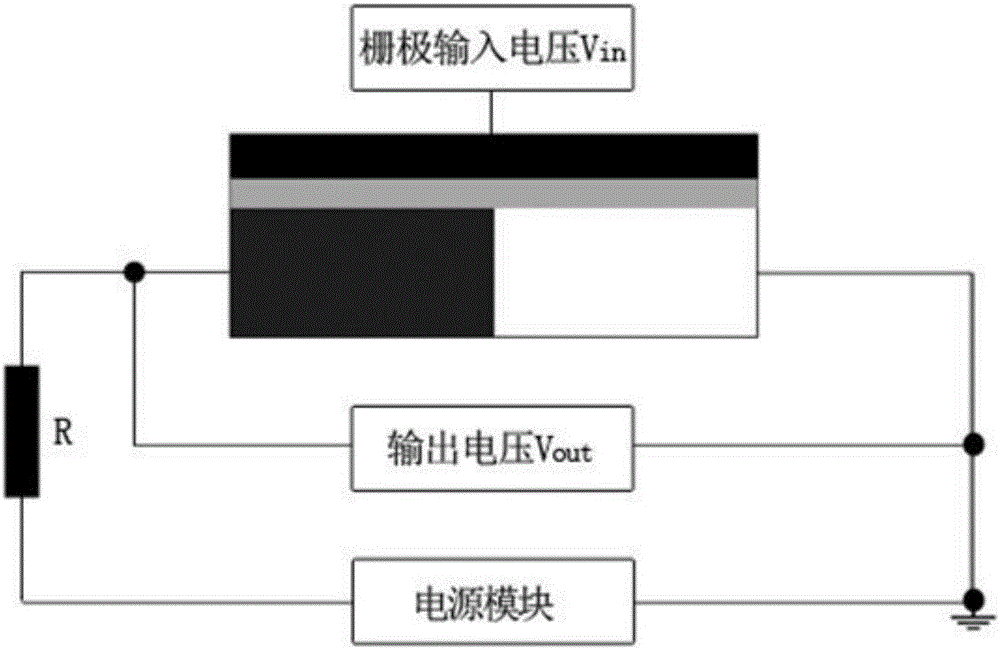

Pn junction-based logical operation device

InactiveCN106067798ASimple structureReduce volumeLogic circuits characterised by logic functionElectronic switchingMOSFETDriving current

The invention discloses a pn junction-based basic element and a device for realizing the logical circuit operation by using the above element. According to the technical scheme of the pn junction-based element for forming the logical operation device, the logical operation device comprises a pn junction and an electrode formed on an insulating layer outside the pn junction. A grid is composed of the insulating layer arranged on the pn junction and the electrode formed on the insulating layer. A p-type region and an n type region, positioned outside the pn junction, are respectively connected with signal terminals. According to the technical scheme of the invention, the above element can be used for making different logical operation devices. The element is simple in structure and is prepared based on the traditional silicon technology without any other special process. Compared with the traditional BJT and the traditional MOSFET, the device is smaller in size and higher in integration level. Moreover, the device is applicable to a logical operation circuit and can be driven by either voltage or current. Moreover, the device is low in driving voltage and driving current and wide in application prospect.

Owner:LANZHOU UNIVERSITY

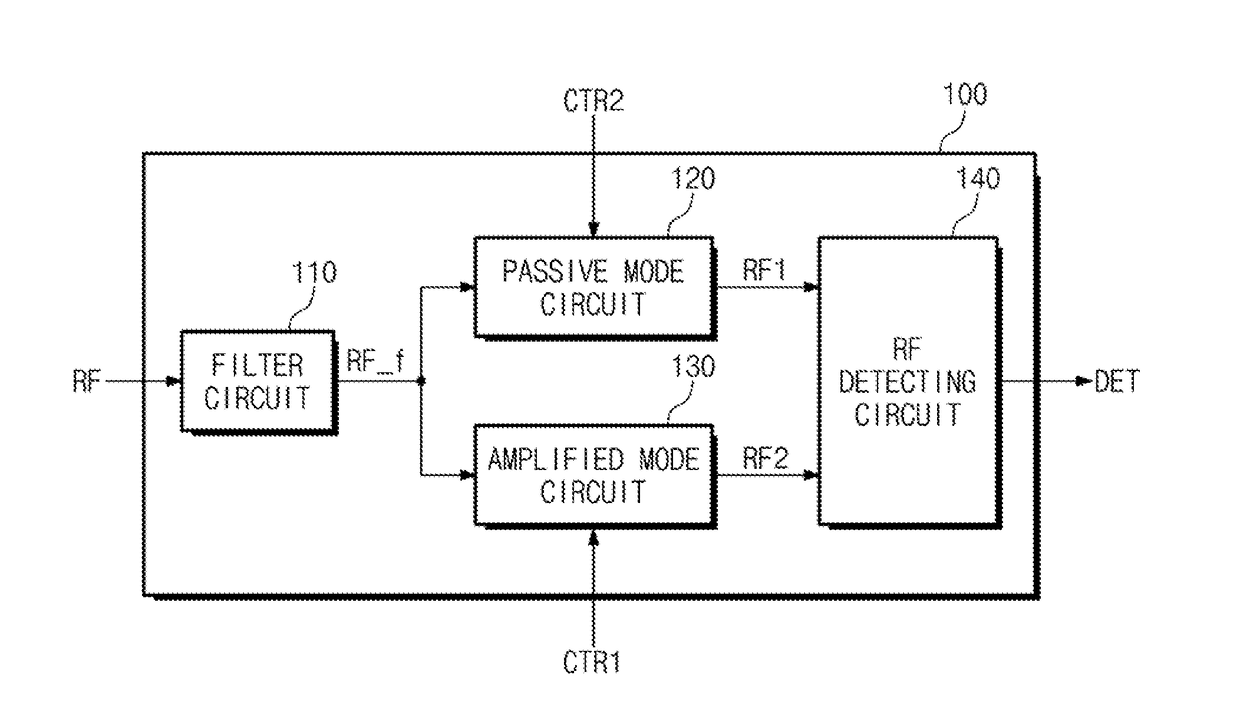

Radio-frequency communication device having a near field communication function, and method of operating the same

ActiveUS20170085298A1Low currentLow power consumptionTransmission systemsNear-field in RFIDNear field communicationCommunication device

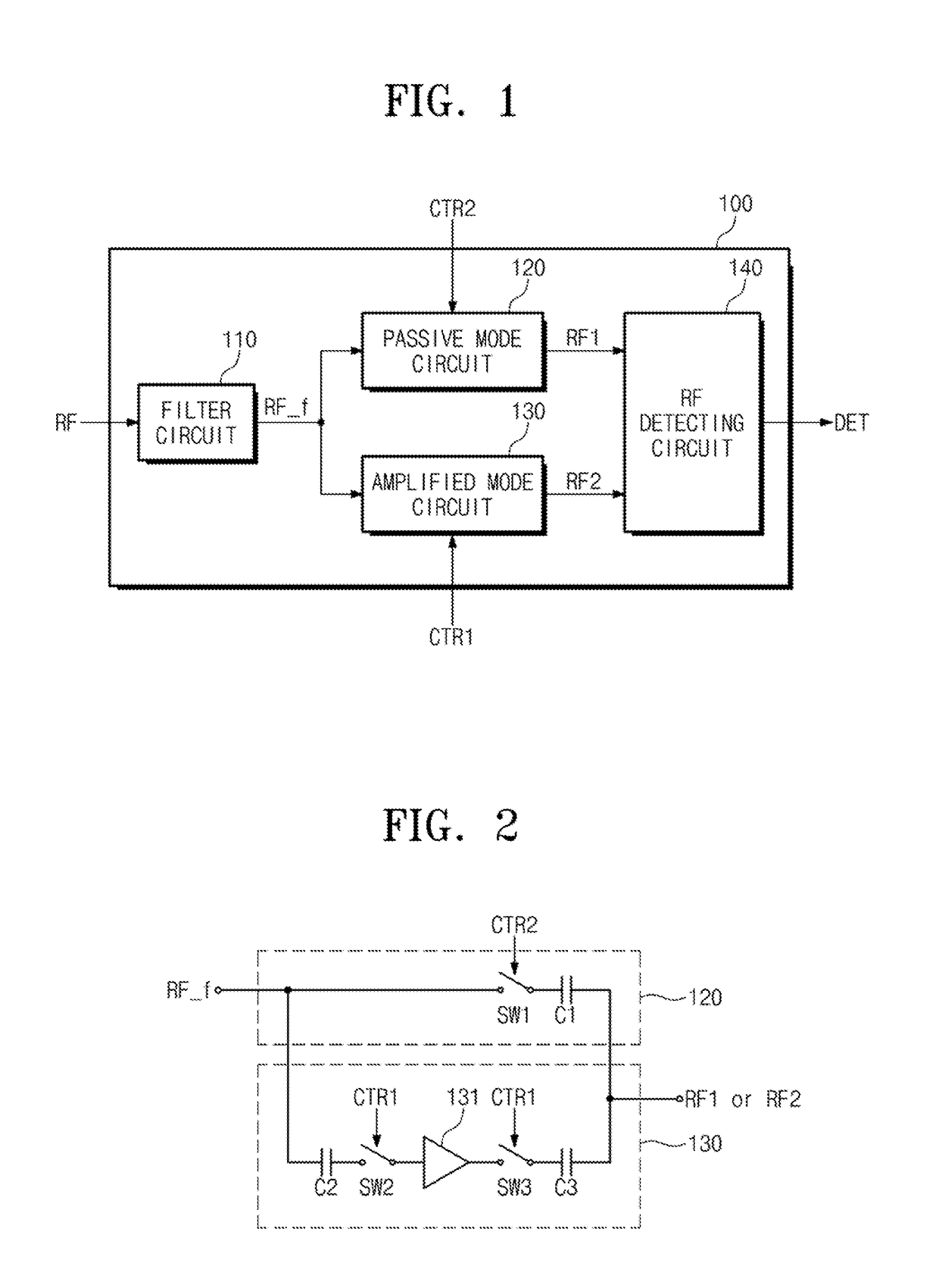

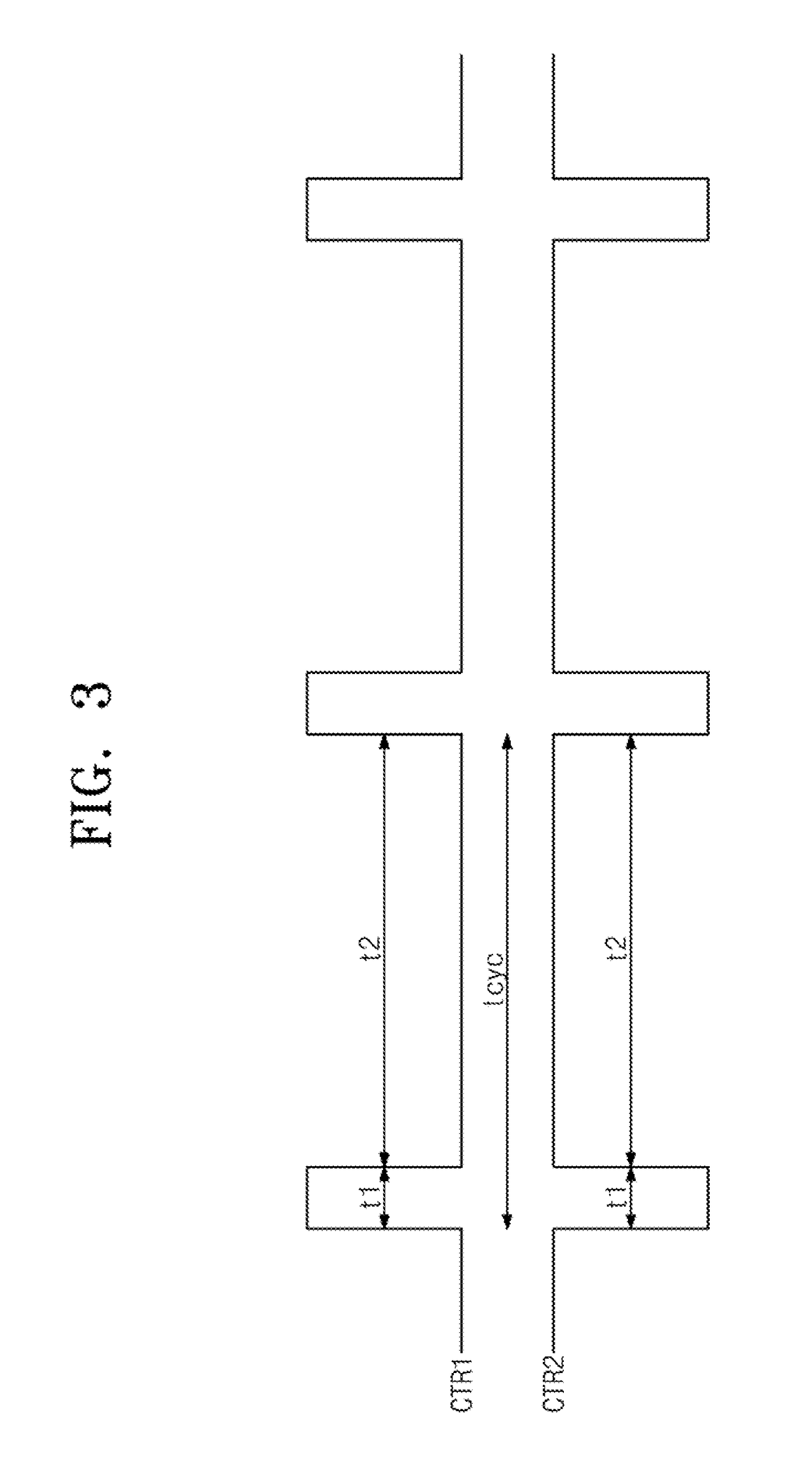

A radio-frequency (RF) communication device having a near field communication (NFC) function includes a first detection mode circuit configured to output an RF input signal received by an antenna as a first RF signal while the first detection mode circuit is enabled, and a second detection mode circuit configured to amplify the RF input signal and output the amplified RF input signal as a second RF signal while the second detection mode circuit is enabled. The first detection mode circuit is enabled during a first time period, and the second detection mode circuit is enabled during a second time period. The second time period is shorter than the first time period. The first and second detection mode circuits are enabled alternately and repeatedly.

Owner:SAMSUNG ELECTRONICS CO LTD

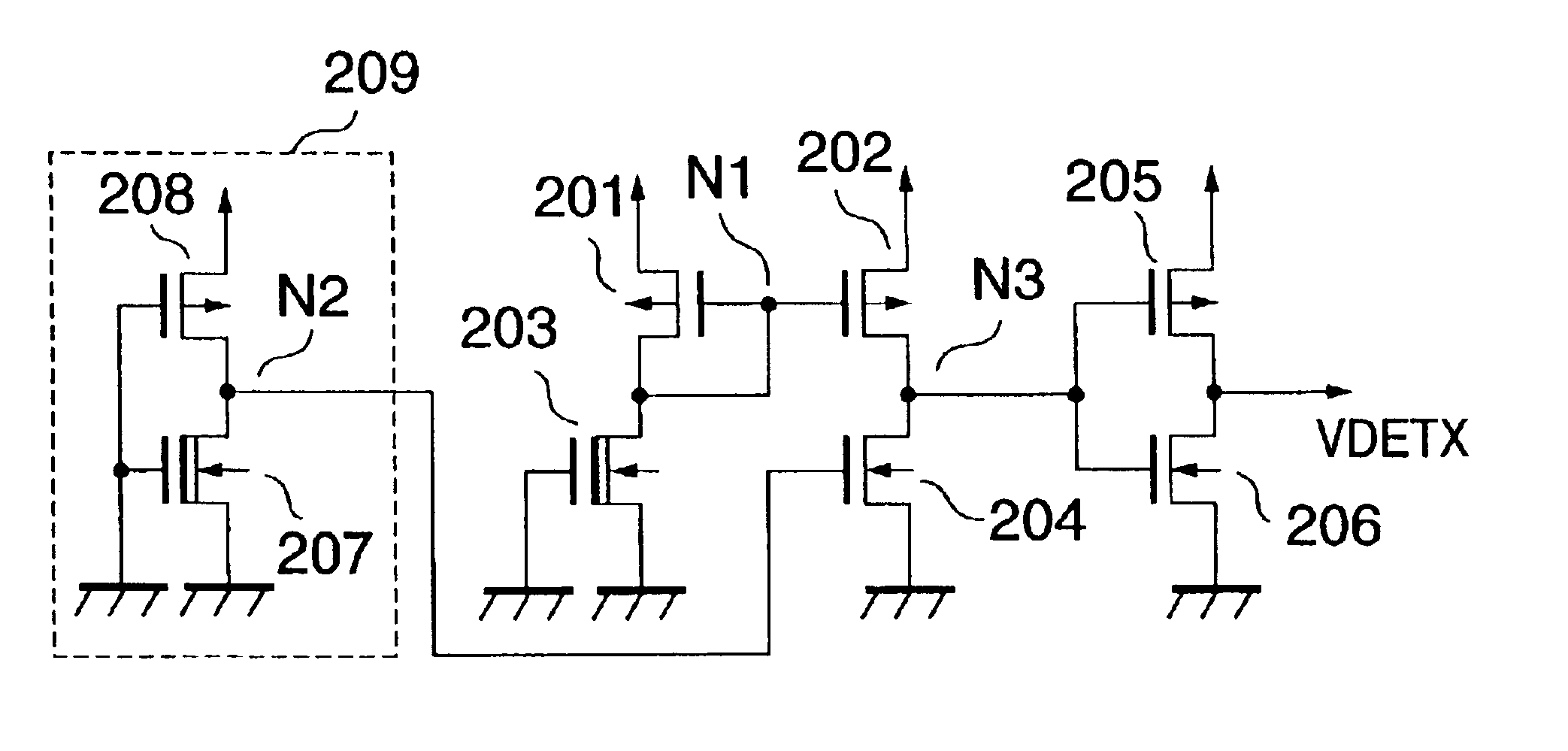

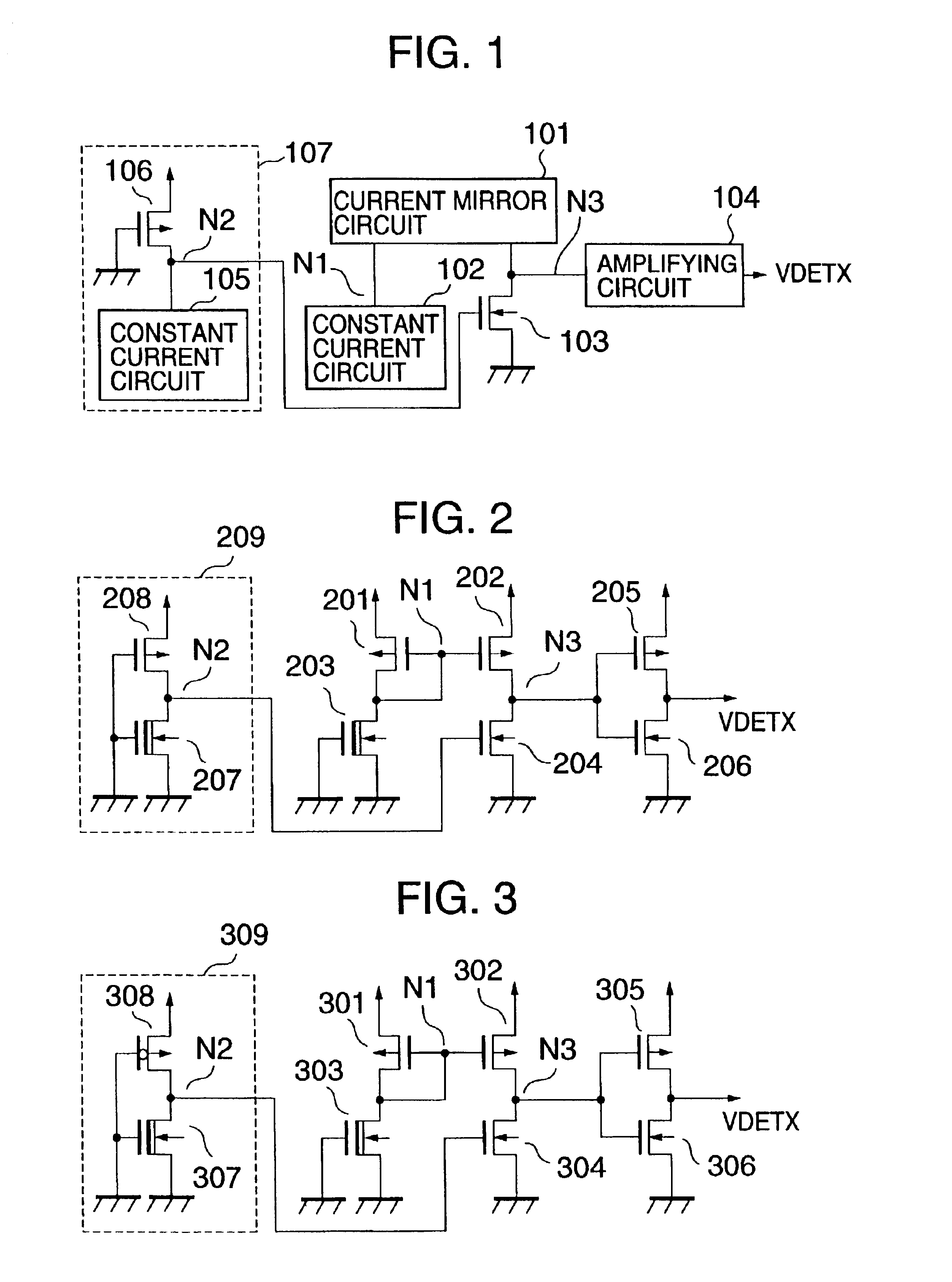

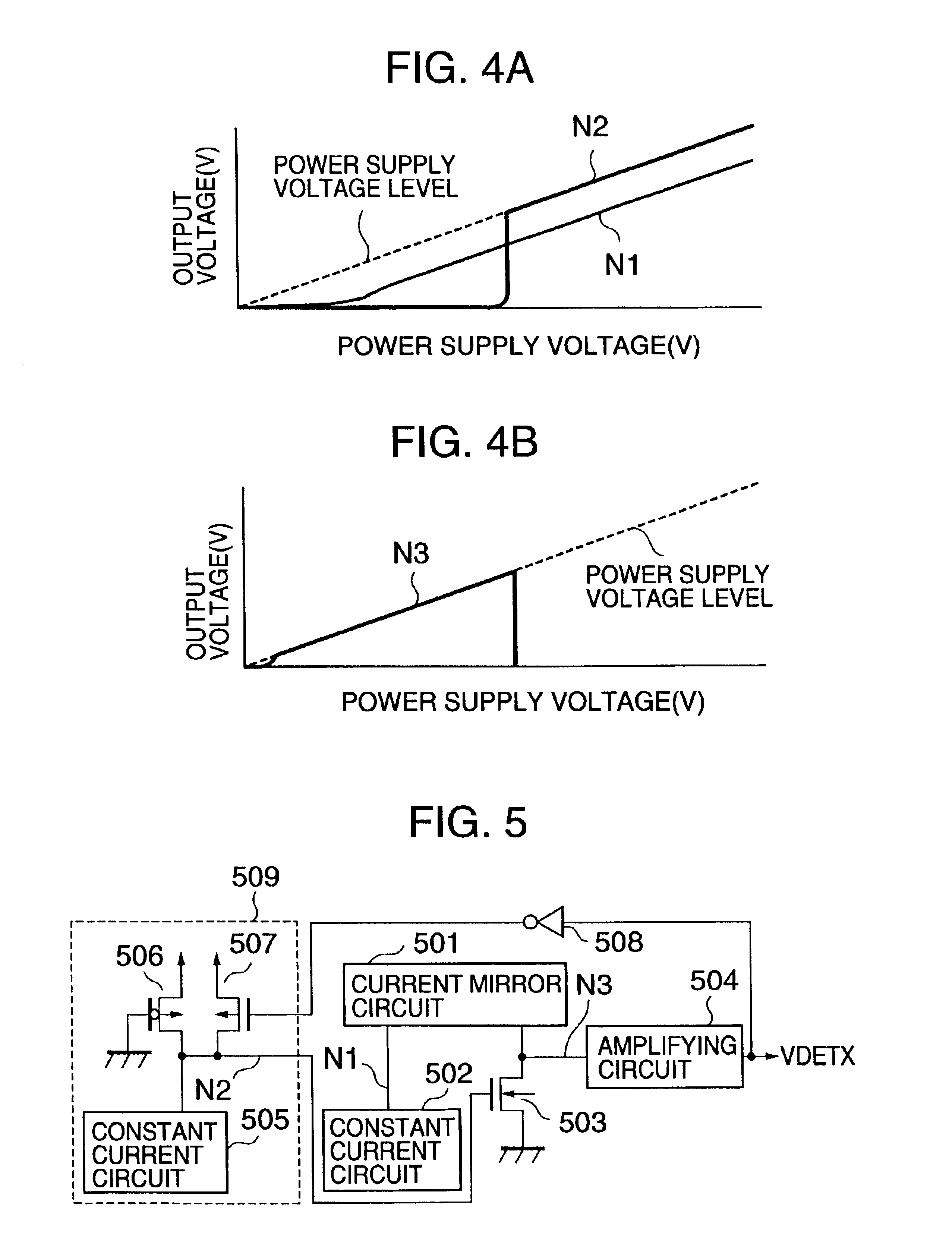

Voltage detecting circuit

InactiveUS6859040B2Reduce leakage currentLow currentDirection of current indicationVoltage polarity indicationPower inverterIntegrated circuit

There is provided a voltage detecting circuit in which a consumed electric current is small, accuracy is high, and an erroneous operation seldom occurs. In the voltage detecting circuit constituted by a bias circuit, a current mirror circuit, a load MIS transistor connected to the current mirror circuit in which current drive capability is changed by an output voltage of the bias circuit, and an amplifying inverter circuit, a potential change at an output node of the current mirror circuit at the time of detection and release of a power supply voltage is steeply changed, so that a leak current of the whole circuit can be decreased and a consumed electric current can be reduced. Besides, plural load P type MIS transistors of the bias circuit are prepared, so that a detection voltage and a release voltage can be made to have hysteresis, abnormal oscillation of a detection output VDETX in the vicinity of the detection and release voltage can be prevented, and an erroneous operation of a logic circuit to which the detection output is applied can be prevented.

Owner:ABLIC INC

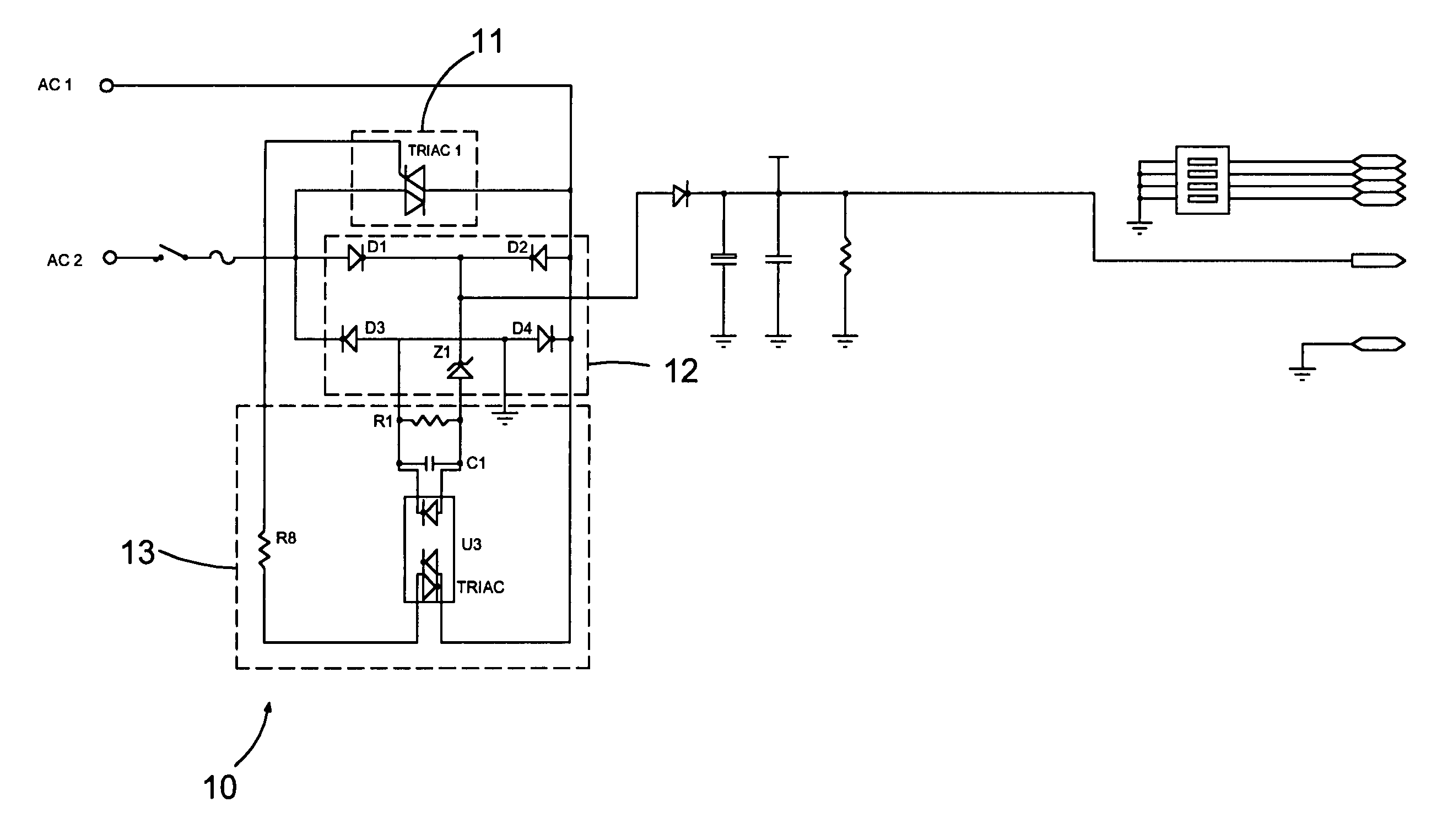

Picking and supplying circuit for discharging direct current

The present invention provides a kind of Picking and Supplying Circuit for Discharging Direct Current, which is connected with supplying line of alternating current of electrical loading in series. It contains a picking part with a control triac under a closing state, for picking the alternating current of specified volume; a commutation and voltage regulating loop, which has two pairs of diodes connected reversely in series each other, and one diode with certain voltage is connected between a pair of diodes connected in series for commutating the picked alternating current and regulating voltage and discharging the direct current; a trigger loop was designed for connecting commutation and voltage regulating loop and providing a reverse sign to make the control triac convert into an unobstructed state from the closing one and making the alternating current reply and recover the supply of the electrical loading.

Owner:HUEI LIN MIN

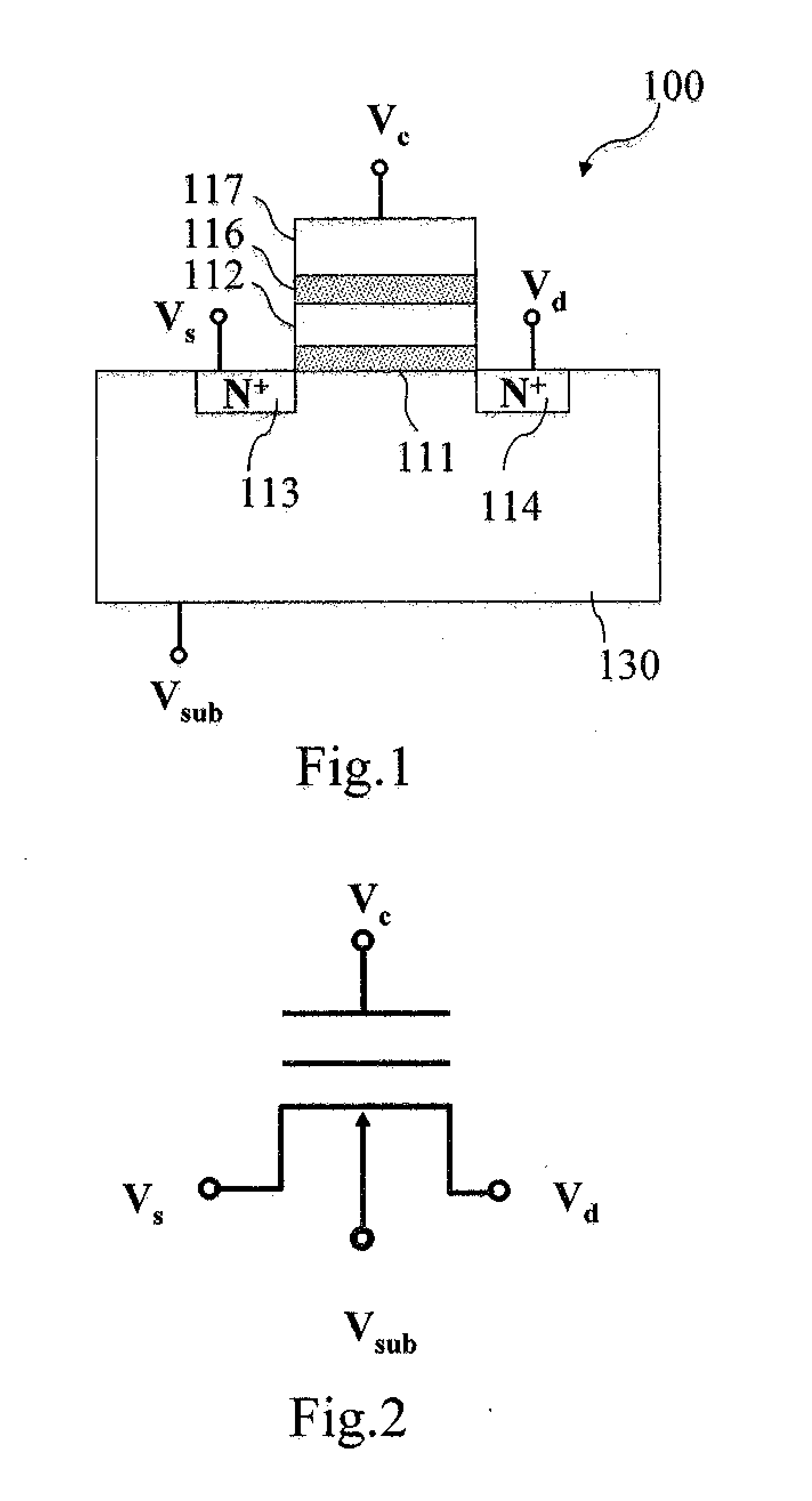

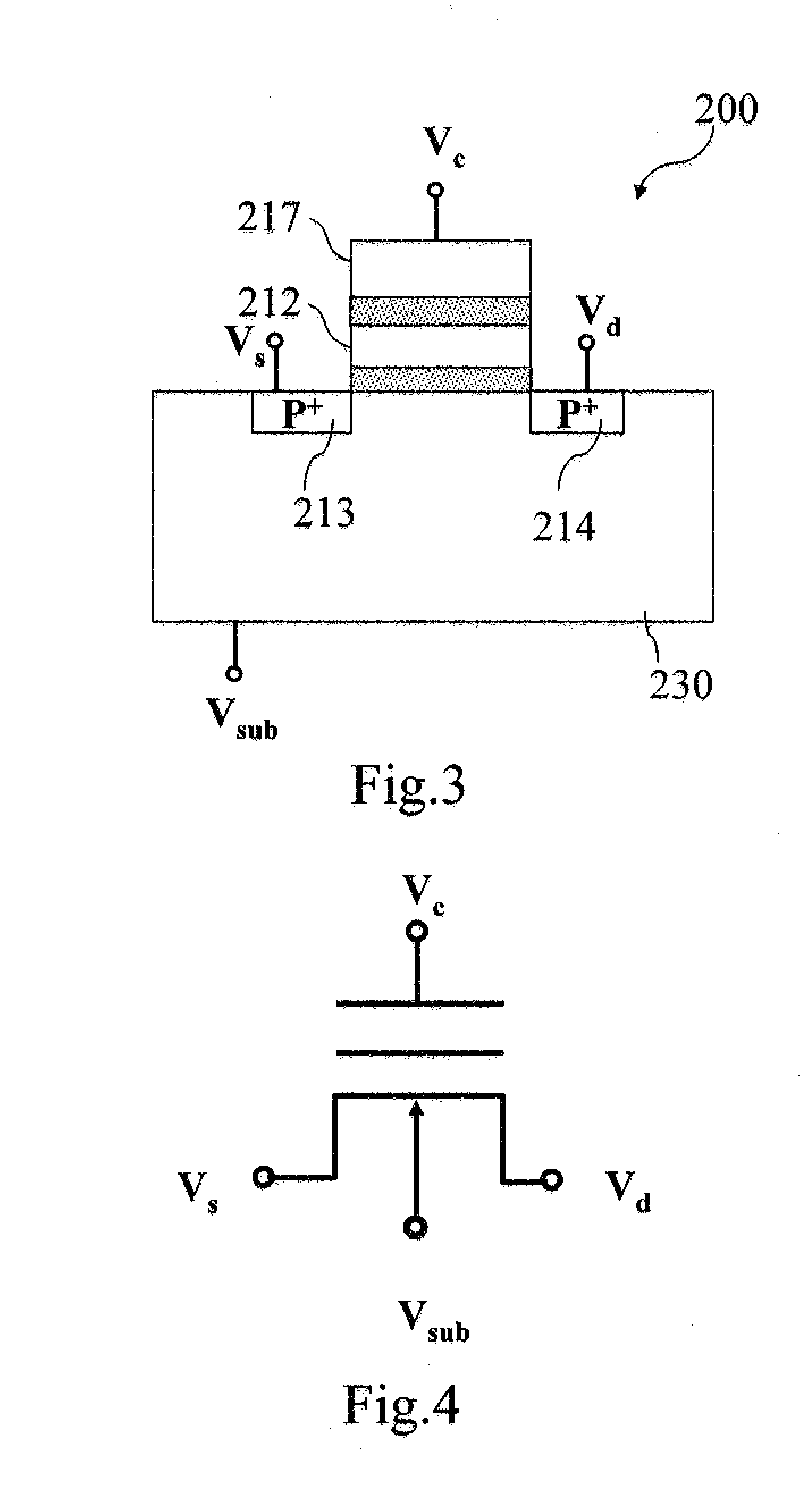

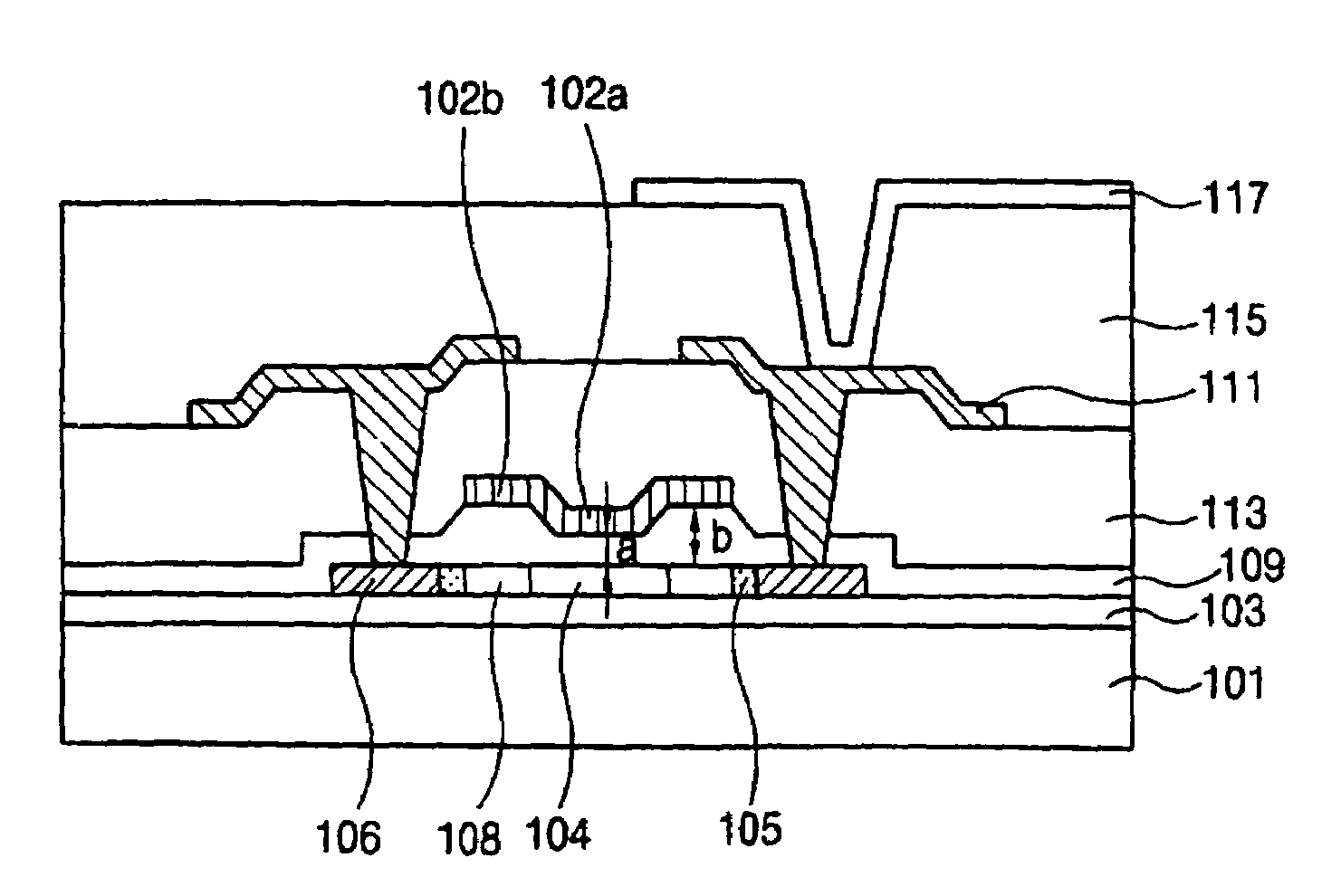

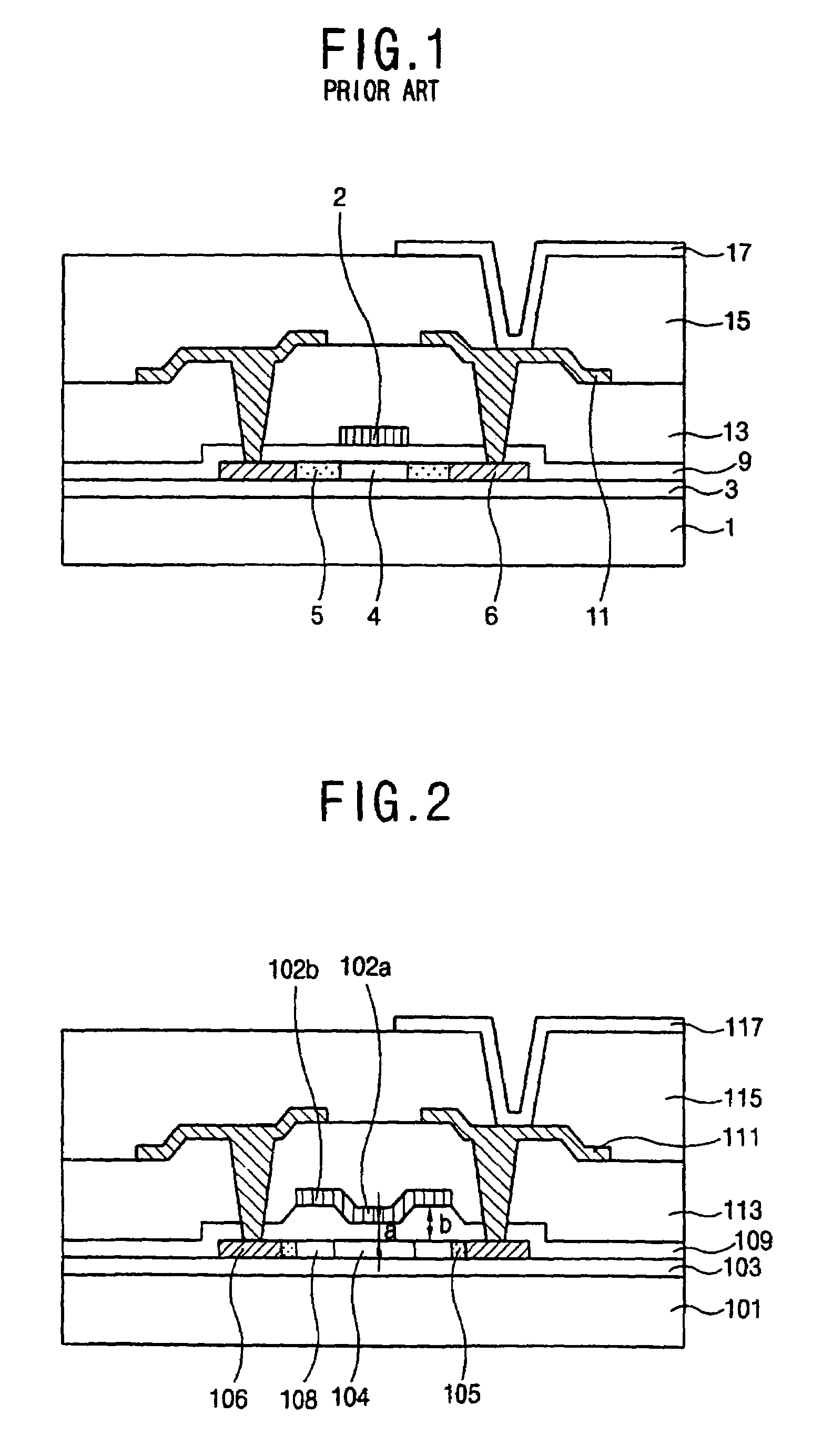

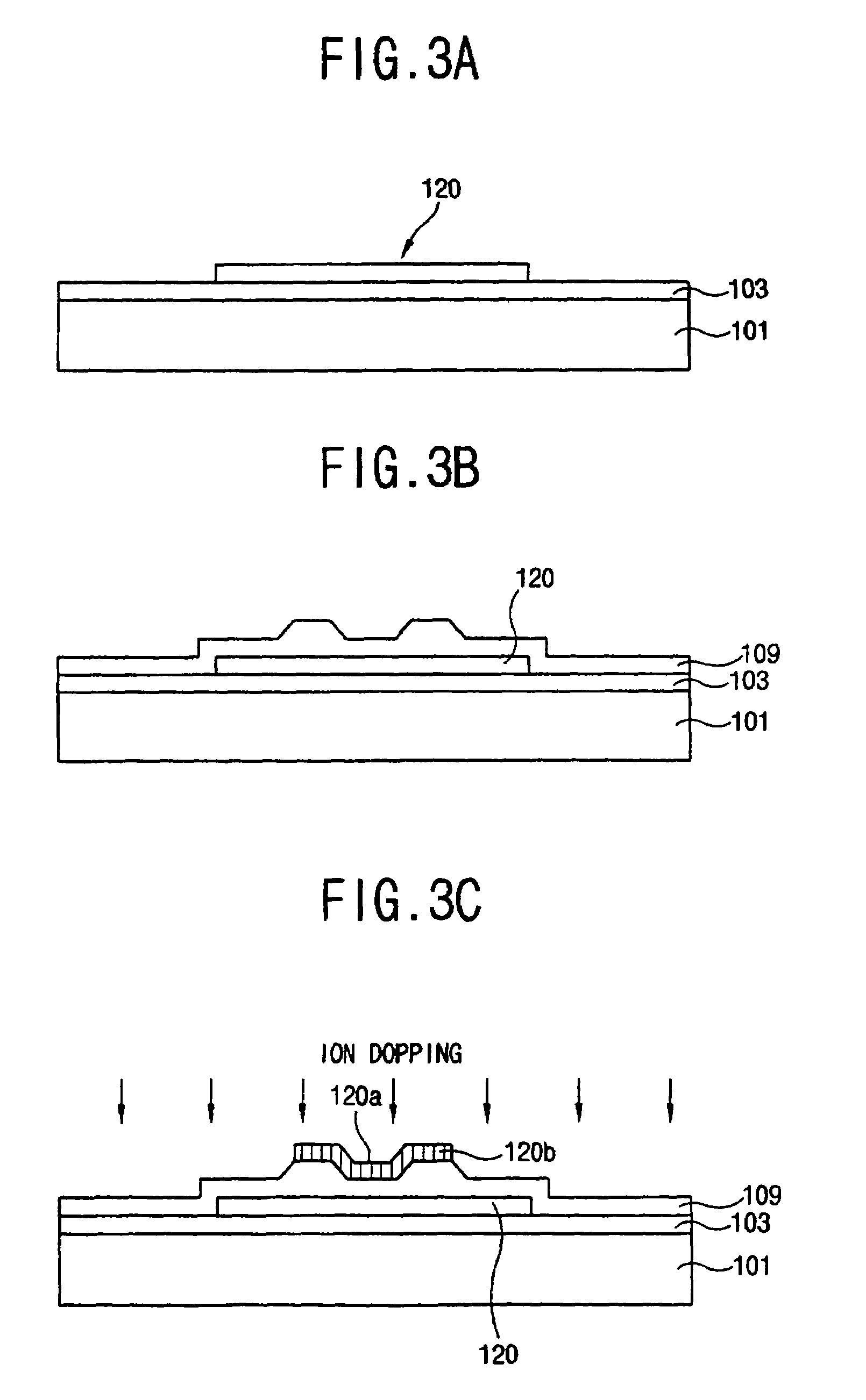

Poly-crystalline thin film transistor and fabrication method thereof

InactiveUS7008830B2Low currentReduce leakage currentTransistorSemiconductor/solid-state device manufacturingPhysicsIon doping

A thin film transistor and its fabrication method. The transistor includes a buffer layer on a substrate, and a poly-crystalline semiconductor layer on the buffer layer. The poly-crystalline semiconductor layer includes a channel layer, offset regions along sides of the channel layer, sequential doping regions along sides of the offset regions, and source and drain regions. The doping concentration is sequentially changed in the sequential doping region. A sloped gate insulation layer is on the poly-crystalline semiconductor layer. A gate electrode having a main gate electrode and auxiliary gate electrodes is on the sloped insulation layer. An interlayer is over the gate electrode and source and drain electrodes are formed in contact with the source and drain regions and on the interlayer. The poly-crystalline semiconductor layer is formed by ion doping a poly-crystalline semiconductor layer through the gate insulation layer while using the gate electrode as a mask.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com