EMI filter of folding chained form feedthru capacitor structure

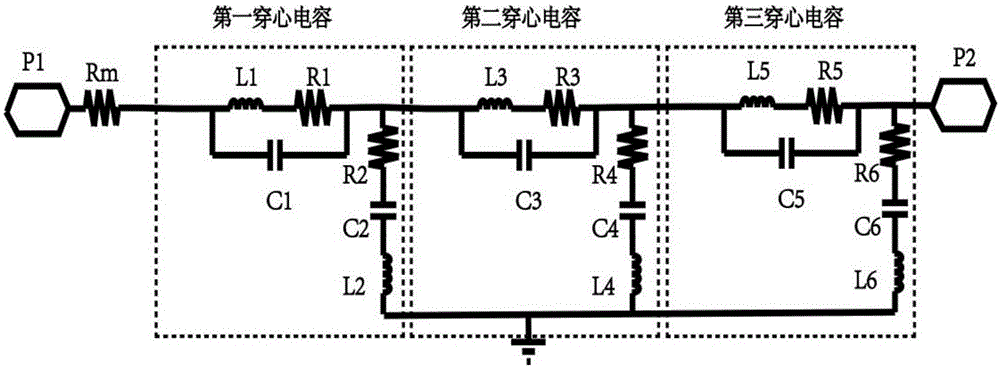

A feedthrough capacitor and filter technology, applied in the field of EMI filters, can solve problems such as limited filtering capability of a single capacitor element, affecting circuit delay characteristics, large out-of-band attenuation, etc., to improve the performance of anti-instantaneous current breakdown, reduce Small size and weight, the effect of improving device yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

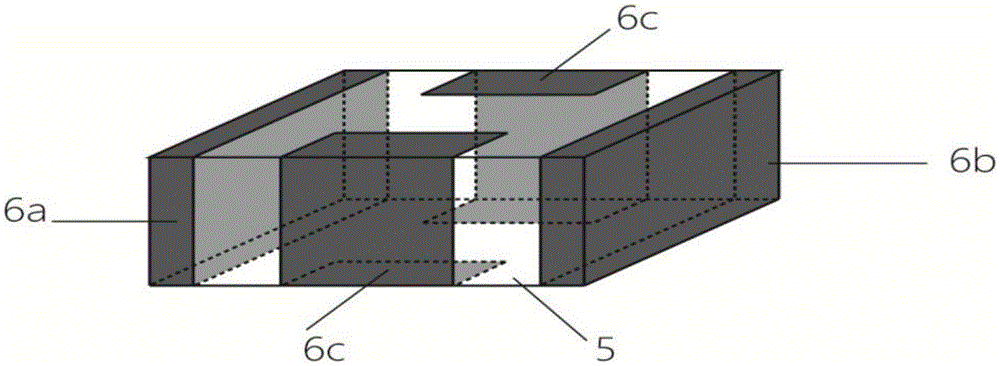

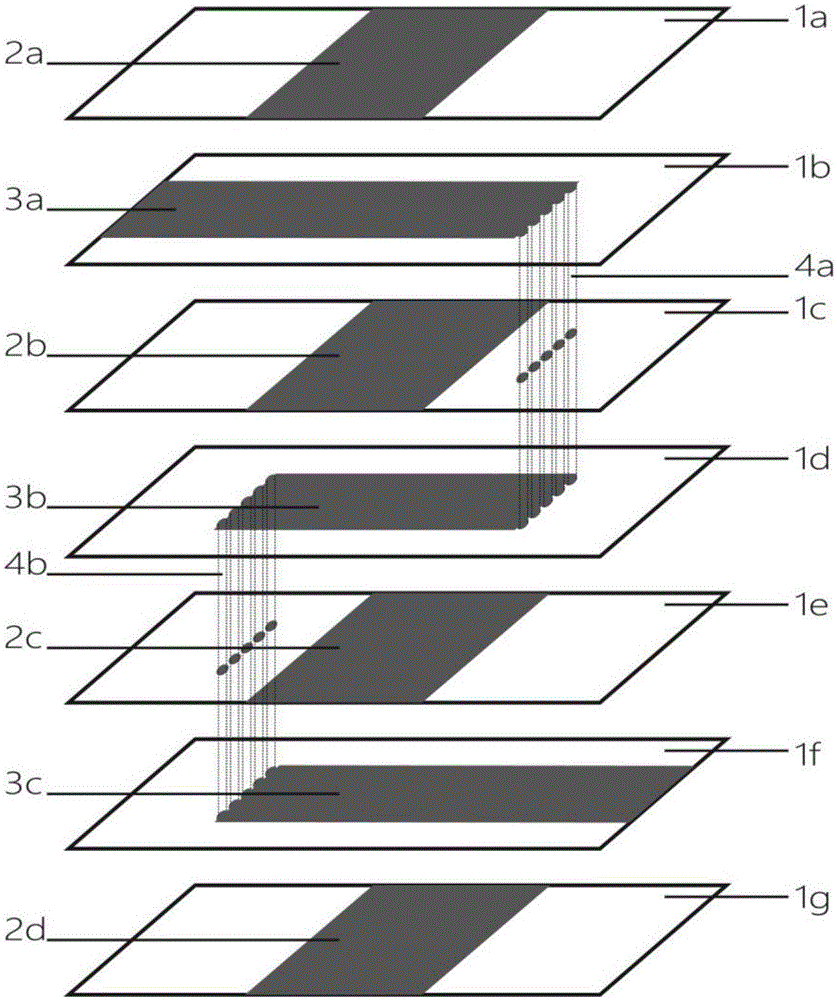

[0037] In the EMI filter with folded chain-type feedthrough capacitor structure provided in Example 1, the laminated substrate 5 is made of a ceramic material with a dielectric constant of 3000. The exploded perspective view of the laminated substrate is shown in figure 2 As shown, there are a total of seven layers of substrates printed with electrodes; the electrodes include a grounding plate and a conductive plate;

[0038] From bottom to top, the fourth grounding plate 2d is printed on the first layer of ceramic base 1g, the third conductive plate 3c is printed on the second layer of ceramic base 1f, and the third grounding plate is printed on the third layer of ceramic base 1e 2c, the second conductive electrode plate 3b is printed on the fourth layer of ceramic substrate 1d, the second ground electrode plate 2b is printed on the fifth layer of ceramic substrate 1c, and the first conductive electrode plate 3a is printed on the sixth layer of ceramic substrate 1b. The seve...

Embodiment 2

[0045] The exploded perspective view of the laminated substrate of the EMI filter with the folded chain feedthrough capacitance structure provided by Embodiment 2 is as follows Figure 4 As shown, the laminated substrate 5 is formed by laminating and co-firing electrolyte ceramic materials with a dielectric constant of 1100, as shown in Figure 4 As shown, there are a total of 15 layers of substrates printed with electrodes; the electrodes include grounding plates and conductive plates;

[0046] From top to bottom, the first layer of substrate 1a is provided with a grounding plate 2a, the third layer of base 1c is provided with a grounding plate 2b, the fifth layer of plate 1e is provided with a grounding plate 2c, and the seventh layer of substrate 1g A grounding plate 2d is provided on the top, a grounding plate 2e is provided on the ninth layer substrate 1i, a grounding electrode plate 2f is provided on the eleventh layer substrate 1k, and a grounding electrode plate 2g is ...

Embodiment 3

[0062] The exploded perspective view of the laminated substrate of the EMI filter with the folded chain feedthrough capacitance structure provided by Embodiment 3 is as follows Figure 6 , the laminated substrate 5 is formed by laminating and co-firing 23 layers of electrolyte ceramic materials with a dielectric constant of 2000;

[0063] The first layer of substrate 1a is provided with a grounding plate 2a, the third layer is basically 1c with a grounding plate 2b, the fifth layer of plate 1e is provided with a grounding plate 2c, and the seventh layer of substrate 1g is provided with a grounding electrode plate 2d, the ninth layer substrate 1i is provided with a ground electrode plate 2e, the eleventh layer substrate 1k is provided with a ground electrode plate 2f, the thirteenth layer substrate 1m is provided with a ground electrode plate 2g, and the fifteenth layer substrate 1o A grounding plate 2h is provided on the top, a grounding plate 2i is provided on the seventeenth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com